Samsung AVXCSH023CE, AVXWNH060CE, AVXCSH032CE, AVXCSH040CE, AVXC4H052CE Service Manual

...

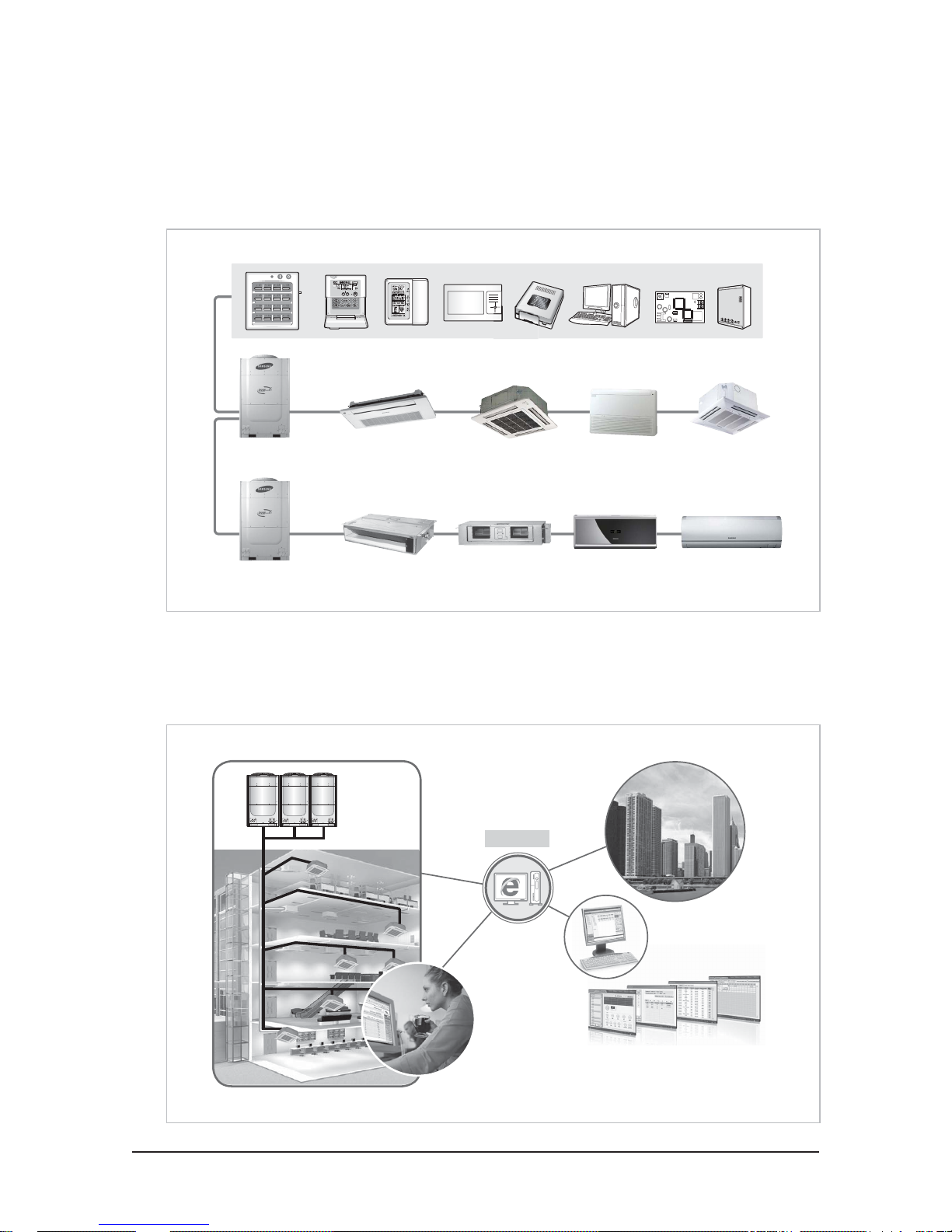

SYSTEM AIR CONDITIONER

INDOOR UNIT

AVXCSH023/032/040CE

AVXC4H052/072/100/110/145CE

AVXCMH032/040/052/060CE

AVXDSH020/032/040/052/072/100/110/145CE

AVXDUH100/110/145CE

AVXWVH020/032/040/052/060CE

AVXWNH020/032/040/052/060CE

ND023/032/0401HXCA

ND052/072/100/1454HXCA

ND032/040/052/060MHXCA

ND020/032/040/052/072/100/110/145LHXCA

ND100/110/145SHXCA

ND220/280HHXCE(CA)

ND020/032/040/052/060VHXCA

ND020/032/040/052/060NHXCA

ND052/072CHXCA

ND020/032/040/052/060QHXCA

ND052/072/100/110/1454HXCB

OUTDOOR UNIT

RVXVHT075/100/125FE

RD040/050MHXCA

RD075/100/125VHXFA

RD075/100/125VRXFA

AIR CONDITIONER CONTENTS

1. Precautions

2. Product Specifications

3. Disassembly and Reassembly

4. Troubleshooting

5. Exploded Views and Parts List

6. PCB Diagram and Parts List

7. Wiring Diagram

8. Schematic Diagram

9. Reference Sheet

Refer to the service manual in the GSPN(see the rear cover) for the more information.

Contents

1. Precautions

1-1 Precautions for the Service ························································································································· 1-1

1-2 Precautions for the Static Electricity and PL ························································································ 1-1

1-3 Precautions for the Safety ··························································································································· 1-2

1-4 Others ·································································································································································· 1-2

2. Product Specifications

2-1 The Feature of Product ································································································································· 2-1

2-1-1 Feature ··················································································································································· 2-1

2-1-2 Changes in comparison to basic model ··················································································· 2-22

2-2 Product Specifications ·································································································································· 2-24

2-2-1 Indoor Unit ··········································································································································· 2-24

2-2-2 Outdoor Unit ······································································································································· 2-47

2-3 Accessory and Option Specifications ····································································································· 2-50

2-3-1 Accessories ··········································································································································· 2-50

3. Disassembly and Reassembly

3-1 Indoor Unit ························································································································································ 3-2

3-2 Outdoor Unit ···················································································································································· 3-11

·························································································································································· 1-1

······························································································································ 2-1

············································································································ 3-1

4. Troubleshooting

4-1 Setting Option Setup Method ·················································································································· 4-1

4-1-1 PCB option code input method ·································································································· 4-1

4-1-2 Setting an indoor unit address and installation option ···················································· 4-11

4-1-3 Option Items ········································································································································ 4-17

4-2 What to check before diagnosis ··············································································································· 4-19

4-2-1 Lamp combination expression method display (cassette type indoor unit) ··········· 4-19

4-2-2

4-3 How to take measures for each symptom

(Model : RVXVHT075/100/125FE, RD075/100/125VHXFA) ···························································· 4-31

4-3-1 Outdoor unit operation flow ········································································································ 4-36

4-3-2 Indoor Unit ROOM sensor Error (Open/Short) ······································································ 4-40

4-3-3 Indoor unit EVAP IN sensor Error (Open/Short) ···································································· 4-41

4-3-4 Indoor EVAP OUT sensor Error (Open/Short) ········································································· 4-42

4-3-5 Indoor heat exchanger’s EVAP IN sensor dislocation error ·············································· 4-43

4-3-6 Indoor Heat Exchanger’s EVA OUT sensor dislocation error (Open/Short) ··············· 4-44

4-3-7

4-3-8 Operational error of indoor Unit’s Clean Fan (Open/Short) ············································· 4-46

Numeric type display(outdoor unit, Wired remote controller, wall-mount type etc.)

Simultaneous Indoor heat exchanger’s EVA IN, OUT sensor dislocation error (Open/Short)

·············································································································································· 4-1

··· 4-29

··· 4-45

Contents

4-3-9 Breakdown of EEV (2nd) ··················································································································· 4-47

nd

4-3-10 Problem with EEV closure (2

4-3-11

4-3-12 The operational error of Indoor Unit’s Fan Motor ······························································ 4-50

4-3-13 EEPROM error ···································································································································· 4-51

4-3-14 Option error of the Remote Controller for an Indoor Unit ············································ 4-52

4-3-15 Error due to confused use of Fahrenheit and Celsius ······················································ 4-53

4-3-16 Error due to incorrect Indoor Unit Power/Communication Cable Connection ···· 4-54

4-3-17 SPi Feedback Error ·························································································································· 4-55

4-3-18 Communication error between Indoor and Outdoor units during Tracking ········· 4-56

4-3-19

4-3-20 Communication error between Main and Sub Micoms of an Outdoor unit or

4-3-21 Outdoor Temperature Sensor error ························································································· 4-60

4-3-22 Outdoor Temperature dislocation error ················································································ 4-61

4-3-23 COND OUT Temperature Sensor error (Open/Short) ······················································· 4-62

4-3-24 Outdoor COND OUT Sensor dislocation error ···································································· 4-63

4-3-25 Discharge Temperature Sensor error for a digital Compressor (Open/Short) ······· 4-64

4-3-26

4-3-27 Compressor’s Discharge Temperature Sensor dislocation error ································· 4-66

4-3-28

4-3-29

4-3-30 SUMP Temperature Sensor error (Open/Short) ·································································· 4-69

4-3-31 High Pressure Temperature Sensor error (Open/Short) ·················································· 4-70

4-3-32 Low Ppressure Temperature Sensor error (Open/Short) ················································ 4-70

4-3-33 Oil Balance Valve Temp. Sensor error (Open/Short) ························································ 4-71

4-3-34 SUCTION Temperature Sensor error (Open/Short) ··························································· 4-72

4-3-35 Double pipe temperature sensor error ·················································································· 4-73

4-3-36 Main Cooling Sol Valve Open Error ·························································································· 4-74

4-3-37 EVI IN Temperature Sensor error (Open/Short) ·································································· 4-75

4-3-38 EVI OUT Temperature Sensor error (Open/Short) ······························································ 4-76

4-3-39

4-3-40

4-3-41 Protection Control by Sump Sensor Error ············································································· 4-79

4-3-42

4-3-43 3 Detection of phase negative voltage sequence, Phase fail ······································· 4-81

4-3-44

4-3-45

4-3-46 EVI EEV Open Error ························································································································· 4-84

: Detection of Floating Switch of Indoor Unit’s Drain Pump ·························· 4-49

Communication error between Indoor & Outdoor units after Completing Tracking

among Outdoor Units ··················································································································· 4-59

Discharge Temperature Sensor error for a fixed scroll Compressor (Open/Short)

:

Dislocation error of Compressor SUMP Temperature (oil temperature) Sensor

: Dislocation error of Suction Temperature Sensor ············································· 4-68

: Comp. Down due to a Protective Control of High pressure ························· 4-77

: Comp. Down due to a Protective Control of Low Pressure ·························· 4-77

: Comp. Down due to Discharge Temperature Sensor of a Compressor ··· 4-80

: Comp. Down due to compression rate control ················································· 4-82

:

Self-diagnosis of Oil valve(balance keeping valve) 1(open or closure

breakdown, sensor dislocation or defect)

) ·································································································· 4-48

··· 4-58

··· 4-65

··· 4-67

···························································· 4-83

Contents

4-3-47 , : Prohibition of the operation of Compressor due to

OoutdoorTemperature ·················································································· 4-85

4-3-48 High Pressure below the Average before Cooling (Unable to Restart) ···················· 4-86

4-3-49 Instantaneous Blackout ················································································································ 4-87

4-3-50 Error by High Temperature in an Outdoor Fan Motor ····················································· 4-87

4-3-51 RPM Error of an Outdoor Fan Motor ······················································································· 4-87

4-3-52 Over-Voltage Error of an Outdoor Fan Motor ····································································· 4-88

4-3-53 Counter-Rotation Error of an Outdoor Fan motor ···························································· 4-88

4-3-54

4-3-55

4-3-56 Liquid Compressor Protection Control ·················································································· 4-91

4-3-57 Breakdown of an EEV(1

4-3-58 Breakdown of an EEV closure(1

4-4 How to take measures for each symptom(Model : RD040/050MHXCA)

4-4-1 Indoor Unit ROOM sensor Error (Open/Short)

4-4-2 Indoor unit EVAP IN sensor Error (Open/Short)

4-4-3 Indoor EVAP OUT sensor Error (Open/Short)

4-4-4 Indoor Heat Exchanger’s EVAP IN sensor dislocation error

4-4-5 Indoor Heat Exchanger’s EVA OUT sensor dislocation error (Open/Short)

4-4-6

4-4-7

4-4-8

4-4-9

4-4-10

4-4-11

4-4-12 EEPROM error

4-4-13 Option error of the Remote Controller for an Indoor Unit

4-4-14 Error due to confused use of Fahrenheit and Celsius

4-4-15 Error due to incorrect Indoor Unit Power/Communication Cable Connection

4-4-16 Communication error between Indoor and Outdoor units during Tracking

4-4-17

4-4-18 Communication error between main PCB and inverter PCB during Tracking

4-4-19 Outdoor Temperature Sensor error

4-4-20 COND OUT Temperature Sensor error (Open/Short)

4-4-21

4-4-22 Discharge Temperature Sensor error (Open/Short)

4-4-23

4-4-24 High Pressure Temperature Sensor error (Open/Short)

4-4-25 Double pipe temperature sensor error(Open/Short)

4-4-26 OLP sensor error (Open/Short)

: Over-voltage error of Compressor ·········································································· 4-89

: Low-amperage error of Compressor ······································································ 4-90

st

) ············································································································· 4-92

st

) ····························································································· 4-93

································

·····································································

···································································

········································································

·············································

···············

:

Simultaneous Indoor Heat Exchanger’s EVA IN, OUT sensor dislocation error (Open/Short)

: Breakdown of EEV (2nd)

: Problem with EEV closure (2nd)

: Detection of Floating Switch of Indoor Unit’s Drain Pump

: The operational error of Indoor Unit’s Fan Motor

: Mixed operation Error

··································································································································

································································································

··················································································

····························

············································

·································································································

············································

·····················································

········

Communication error between Indoor & Outdoor units after Completing Tracking

························································································

······················································

: Outdoor COND OUT Sensor dislocation error

: Compressor’s Discharge Temperature Sensor dislocation error

································································································

···················································

·························································

················

·················································

······················································

······

····

····

···

4-94

4-97

4-98

4-99

4-100

4-101

4-102

4-103

4-104

4-105

4-106

4-107

4-108

4-109

4-109

4-109

4-110

4-111

4-112

4-113

4-114

4-115

4-116

4-117

4-118

4-119

4-120

Contents

4-4-27 : Freezing control causes comp. down

4-4-28

4-4-29

4-4-30

4-4-31

4-4-32

4-4-33

4-4-34

4-4-35

4-4-36

5. Exploded Views and Parts List

: High voltage protection compressor stopped

: Compressor down by low pressure sensor protection control

: Dischase temperature sensor error

, , :

Abnormal outside temperature halts operation of the compressor

: Current protection control causes comp. down

: OLP protection control caused comp. down

, : Electrical malfunctions of the outdoor machine

: EEV Off-malfunctions (1st)

: EEV Off inefficiently (1st)

·························································································

·····························································································

·········································································································· 5-1

···································································

··················································

··················

·······································································

···

···············································

·····················································

······························

4-121

4-122

4-123

4-124

4-125

4-125

4-126

4-127

4-128

4-128

5-1 Indoor Unit ························································································································································ 5-1

5-1-1 Slim 1 way cassette type ················································································································· 5-1

5-1-2 Mini 4 way cassette type ················································································································ 5-7

5-1-3 4 way cassette type ··························································································································· 5-11

5-1-4 Globel 4 way cassette type ············································································································ 5-17

5-1-5 Duct type(Slim I) ································································································································· 5-23

5-1-6 Duct type(Slim II) ······························································································································· 5-25

5-1-7 Duct type(Slim III) ······························································································································ 5-27

5-1-8 Duct type(MSP) ··································································································································· 5-29

5-1-9 Duct type(BIG) ····································································································································· 5-33

5-1-10 Wall-mounted type(Vivace) ········································································································ 5-35

5-1-11 Wall-mounted type(Neo Forte without EEV) ······································································· 5-39

5-1-12 Wall-mounted type(Neo Forte with EEV) ·············································································· 5-43

5-1-13 Ceiling type ········································································································································· 5-47

5-2 Outdoor Unit ···················································································································································· 5-51

5-2-1 RVXVHT075/100FE, RD075/100VHXFA ····················································································· 5-51

5-2-2 RVXVHT125FE, RD125VHXFA ········································································································ 5-55

5-2-3 RD075/100VRXFA ······························································································································· 5-59

5-2-4 RD125VRXFA ········································································································································ 5-63

5-2-5 RD040/050MHXCA ···························································································································· 5-67

6. PCB Diagram

6-1 Indoor Unit ························································································································································ 6-1

6-1-1 Slim 1 way cassette type ················································································································· 6-1

6-1-2 4 way cassette type ··························································································································· 6-3

6-1-3 Mini 4 way cassette type ················································································································ 6-4

6-1-4 Duct type(Slim) ··································································································································· 6-5

······················································································································································· 6-1

Contents

6-1-5 Duct type(MSP) ··································································································································· 6-9

6-1-6 Duct type(BIG) ····································································································································· 6-11

6-1-7 Wall-mounted type(Neo Forte without EEV) ········································································· 6-15

6-1-8 Wall-mounted type(Neo Forte with EEV) ················································································ 6-19

6-1-9 Wall-mounted type(Vivace) ··········································································································· 6-23

6-1-10 Ceiling type ········································································································································· 6-26

6-2 Outdoor Unit ···················································································································································· 6-27

6-2-1 RVXVHT075/100/125FE, RD075/100/125VHXFA ·································································· 6-27

6-2-2 RD040/050MHXCA ···························································································································· 6-33

7. Wiring Diagram

7-1 Indoor unit ························································································································································· 7-1

7-1-1 Slim 1 way cassette type ················································································································· 7-1

7-1-2 4 way cassette type ··························································································································· 7-2

7-1-3 Mini 4way cassette type ·················································································································· 7-3

7-1-4 Duct type(Slim I, II) ···························································································································· 7-4

7-1-5 Duct type(Slim III) ······························································································································ 7-5

7-1-6 Duct type(MSP) ··································································································································· 7-6

7-1-7 Duct type(BIG) ····································································································································· 7-7

7-1-8 Wall Mounted type(Vivace) ··········································································································· 7-8

7-1-9 Wall Mounted type(Neo Forte with EEV) ················································································· 7-9

7-1-10 Wall Mounted type(Neo Forte without EEV) ······································································· 7-10

7-1-11 Distributor kit ···································································································································· 7-11

7-1-12 Ceiling type ········································································································································· 7-12

7-2 Outdoor Unit ···················································································································································· 7-13

8. Schematic Diagram

8-1 Indoor Unit ························································································································································ 8-1

8-1-1 Slim 1 way cassette type ················································································································· 8-1

8-1-2 4 way cassette type ··························································································································· 8-2

8-1-3 Mini 4 way cassette type ················································································································ 8-3

8-1-4 Duct type ··············································································································································· 8-4

8-1-5 Duct type(BIG) ····································································································································· 8-5

8-1-6 Wall-mounted type(Neo Forte/Vivace) ····················································································· 8-7

8-1-7 Wall-mounted type(Neo Forte with EEV) ················································································ 8-8

8-1-8 Ceiling type ··········································································································································· 8-9

8-2 Outdoor Unit ···················································································································································· 8-10

8-2-1 RVXVHT075/100/125FE, RD075/100/125VHXFA ·································································· 8-10

8-2-2 RD040/050MHXCA ···························································································································· 8-15

················································································································································ 7-1

······································································································································ 8-1

Contents

9. Reference Sheet

9-1 Index for Model Name ·································································································································· 9-1

9-1-1 Indoor Unit ··········································································································································· 9-1

9-1-2 Outdoor Unit ······································································································································· 9-3

9-2 Refrigerant Circuit Diagram ························································································································ 9-5

9-2-1 Cycle Operation Mode ····················································································································· 9-5

··············································································································································· 9-1

1. Precautions

1-1 Precautions for the Service

OUse the standard parts when replacing the electric parts.

– Confirm the model name, rated voltage, rated current of the electric parts.

ORepair the disconnection of HARNESS securely when repairing the break down.

– If there is any connection error, it causes an abnormal noise and incorrect operation.

OIn case that you assemble or disassemble the products with laying it on the side, do work on the work cloth.

– If not, the exterior of products can be scratched.

ORemove dust and foreign materials from harness, connection part, and inspection part thoroughly when repairing the

break down.

– It protects the danger of fire such as tracking and short.

OTighten tightly the service valve of outdoor unit and the cap of charging valve with a monkey spanner.

OCheck the assembly status of parts after repairing the break down.

– It should be same as the status before repairing.

1-2 Precautions for the Static Electricity and PL

OAs the PCB power terminal has a weakness for the static electricity, pay attention to it during the repair and measurement.

– Work with insulation gloves during the repair and measurement of PCB.

OCheck the distance between the product and the other electronic appliances such as TV, video, and audio.

It should be over 6.6ft.

– If not, it causes a bad picture quality or a noise.

ORepairing the products by consumer should be strictly prohibited.

– There is a danger of electric shock or fire due to incorrect disassembly.

Samsung Electronics 1-1

1-3 Precautions for the Safety

ODo not pull any electric wires and do not touch an auxiliary power switch with a wet hand.

– There is a danger of electric shock or fire.

OIn case any wire or power plug has been damaged, replace it to eliminate any possible danger.

ODo not bend the power cord by force and do not put any heavy object on the power cord.

– There is a danger of electric shock or fire.

ODo not use multi socket.

– There is a danger of electric shock or fire.

OGround the product if necessary.

– Be sure to ground the product if there is any danger of electric leakage due to water or moisture.

OBe sure to turn off the auxiliary power switch or pull out the power plug during replacement or repair of electric parts.

– There is a danger of electric shock.

OIn case the product will not be in use for a long time, the battery of remote control should be kept separately.

– Leakage of inside fluid can cause break down of remote control.

The installation must be done by the manufacturer or its service agent or a similar qualified person in order to avoid a hazard.

O

– Installation by an unqualified person may cause a water leakage, electric shock or fire and so on.

O

The electric work must be done by service agent or similarly qualified persons according to national wiring regulations and use

only rated cable.

– If the capacity of the power cable is insufficient or electric work is not properly completed, electric shock or fire may occur.

O

Use only rated parts and tools.

– If you don’t use the rated parts and tools, it can cause trouble with the air conditioner and bring about injury.

O

If any gas or impurities except R410A refrigerant come into the refrigerant pipe, serious problem may occur and it may cause

injury.

O

Leak test must be done using only Nitrogen(NO2)gas.

O

R410A refrigerant is used for DVM PLUS ,,,, SUPER FJM air conditioner.

– When using R410A, moisture or foreign substances may affect to the capacity and reliability of the product.Safety precautions

must be taken when installing the refrigerant pipe.

– The design pressure of the unit is 4.1MPa. Select appropriate material and thickness according to the regulations.

– R410A is a quasi-azeotrope of two refrigerants.

Make sure to charge liquid one when adding refrigerant.

If you charge gaseous refrigerant, it may affect the capacity and reliability of the product as a result of change formation of the

refrigerant.

O

Connect only the indoor units fit on R410A refrigerant. Check whether the indoor units can be connected with the product’s

catalogue. (When incorrect indoor units are connected, they cannot operate normally.)

1-4 Others

OWhen installing, make sure there is no leakage. When recovering the refrigerant, ground the compressor first before removing the

connection pipe. If the refrigerant pipe is not properly connected and the compressor works with the service valve open, the pipe

inhales the air and it makes the pressure inside of the refrigerant cycle abnormally high. It may cause explosion and injury.

1-2 Samsung Electronics

2. Product Specifications

2-1 The Feature of Product

2-1-1 Feature

2-1-1-1 RVXVHT075/100/125FE, RD075/100/125VHXFA, RD075/100/125VRXFA

1. Introduction

DVM PLUS III is a module multi-system air conditioner that has the world’s largest capacity(7.5~37.5HP) with the application of a

DVI (Digital Vapor Injection) compressor, and can connect up to a maximum of 49 indoor units.

• The highest COP levels in the industry

• The smallest installation space requirement in the world

• The highest heating capacity and COP in low temperature condition (14°F/-10°C)

• Possible to connect up to 49 indoor units

• Digital unit module

2.

New technology of DVM PLUS III

Q Digital hybrid system

DHS (Digital Hybrid System) is a brand new concept system

composed of DVI (Digital Vapor Injection) compressor, vapor

injection technology and turbo intercooler. These 3 factors

together provide highly efficient performance.

1) DVI compressor

Efficient and reliable DVI (Digital Vapor Injection) compressor

coupled with vapor injection technology has been applied to

improve cooling and heating performance and energy efficiency.

Compressor

Vapor

injection

port

DVI

PWM valve

Vapor

Injection

Discharge port

Suction port

Oil port

Turbo

Intercooler

Gas inlet

Samsung Electronics 2-1

Product Specifications

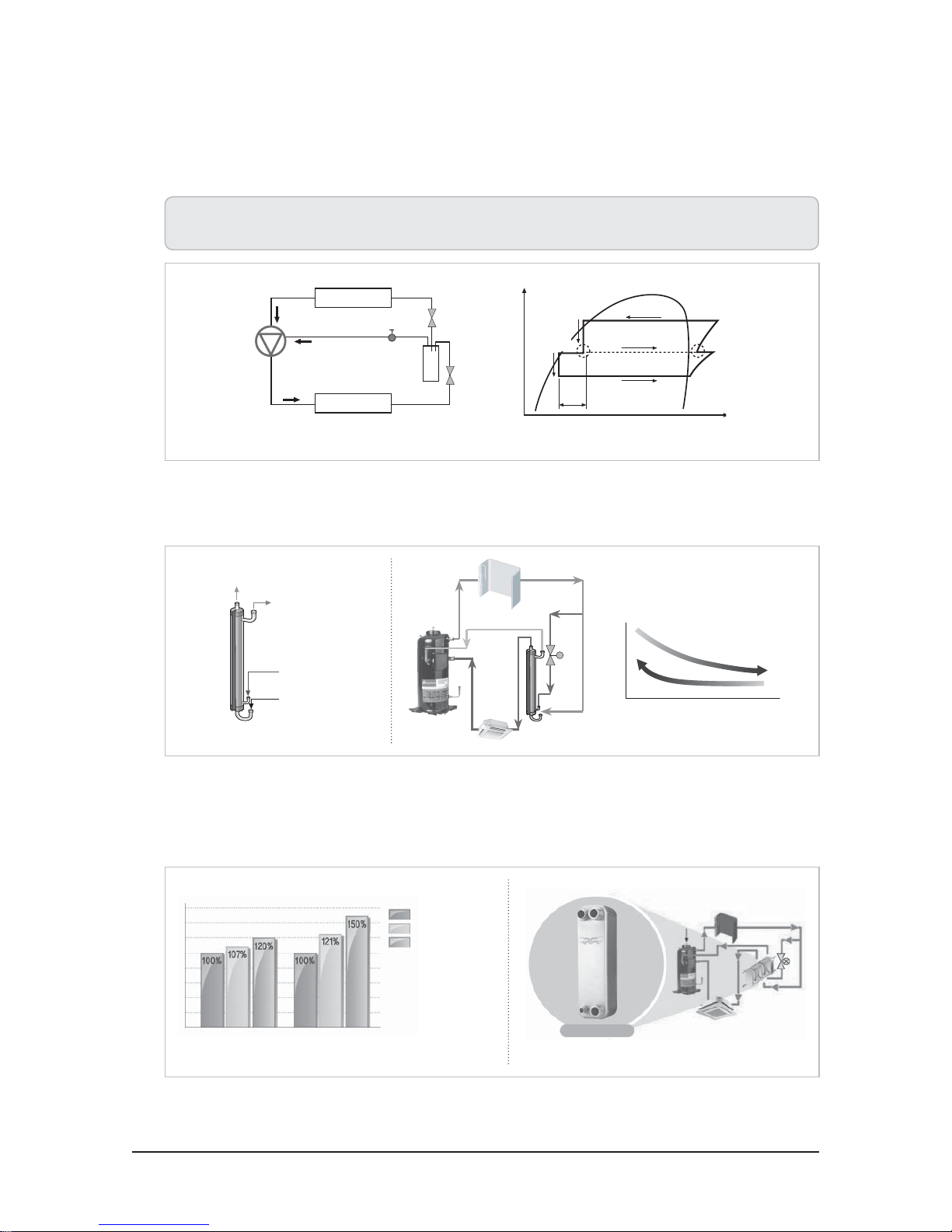

2) Vapor injection technology

Improved cooling and heating performance and COP by a new technology of two stage compression. As injecting optimized

mid-range pressure refrigerant, this technology achieved the high heating performance and COP under the lowest temperature,

which leads the industry.

• Increase refrigerant flow rates with a new vapor injection technology.

• Improved sub-cooling necessary for long piping installation while increasing cooling and heating performance and COP.

More mass flow passing Indoor unit

Evaporator (ID)

DVI compressor

Vapor injection

Condenser (OD)

Mo

Mi

Mo + Mi

Solenoid Valve

2nd

EEV

Flash tank

1st

EEV

1st Expansion

2nd

Expansion

Vapor injection reduces the liquid enthalpy in flash tank,

facilitating heat exchanger to absorb heat more.

increases heating capacity.

Mo + Mi

Mi

Vapor injection

Mo

Enthalpy (kJ/kg)

Injection

point

3) Turbo intercooler (RVXVH075/100/125FE, RD075/100/125VHXFA Only)

Turbo intercooler (Shell & tube type) improves cooling and heating COP and secures reliable operation of installation with long

piping [200m(656ft)].

Subcooling liquid refrigerant

Low temperature gas

refrigerant

Low temp. liquid

refrigerant

Saturated liquid

refrigerant

Temperature

High

Low

4) Plate type intercooler (RD075/100/125VRXFA Only)

The plate type intercooler is the new concept intercooler technology which is more advanced than the existing double layered

pipe type and Shell & Tube type heat exchanger. The plate type intercooler increases heat exchange efficiency by 30% and

provides stable performance with long piping and vertical piping.

Double layered pipe

Shell & Tube

Plate type

Turbo

Inter-

Cooler

DVI

Compressor

EER Heat transfer efficiency

Efficiency Rate

Plate type

Structure Diagram

2-2 Samsung Electronics

Product Specifications

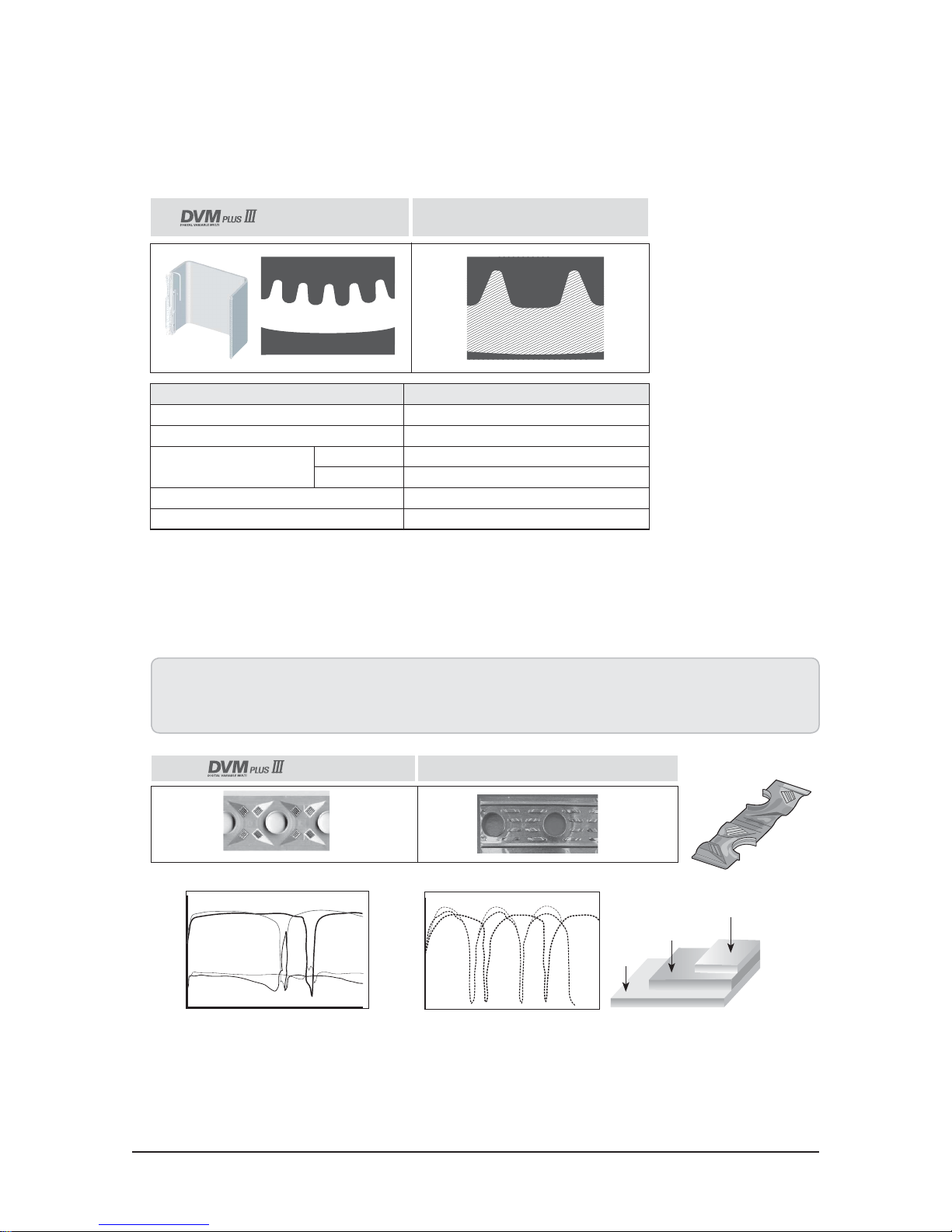

Q High efficiency Ø0.32 heat exchanger

Efficient Ø0.32 grooved tube reduced pressure loss while increasing heat exchange rates to improve COP. Grooved shape is designed

to be high and slim to increase heat transfer performance inside the tube.

New grooved shape

(High and slim)

Company A

Item Improved heat exchanger

Diameter(inch)

Heat transfer surface area

Pressure loss in heat

exchanger

Evaporation

Condensation

Inside heat transfer performance

Ø0.28

14.1%

10.3%

30.8%

o

19%

Ø0.32

n

p

p

n

Pressure resistance same

Q New G-fin

Highly efficient new G-fin increased heat transfer performance, reinforced corrosion resistance, and increased operating duration in

frost condition.

• Heat transfer performance improved by 13% compared to the conventional fin, even with the equivalent pressure loss.

• Epoxy acrylic coating reinforced corrosion resistance.

• 1.4 times longer heating operation in frost condition thanks to new G-fin.

(New G-fin)

60

50

40

30

20

10

0

-10

-20

Eva. Cond., temperature (°C)

-30

030

Time (min.)

5000

4000

3000

2000

1000

Capacity, Power output (W)

60

Conventional model (Louver fin)

0

030

60 90 120

Time (min.)

Anti corrosive layer

Epoxy acrylic

Raw aluminum

material

92μm

Hydrophilic layer

Acrylic resin + surfactant

1.0μm

2.0μm

Samsung Electronics 2-3

Product Specifications

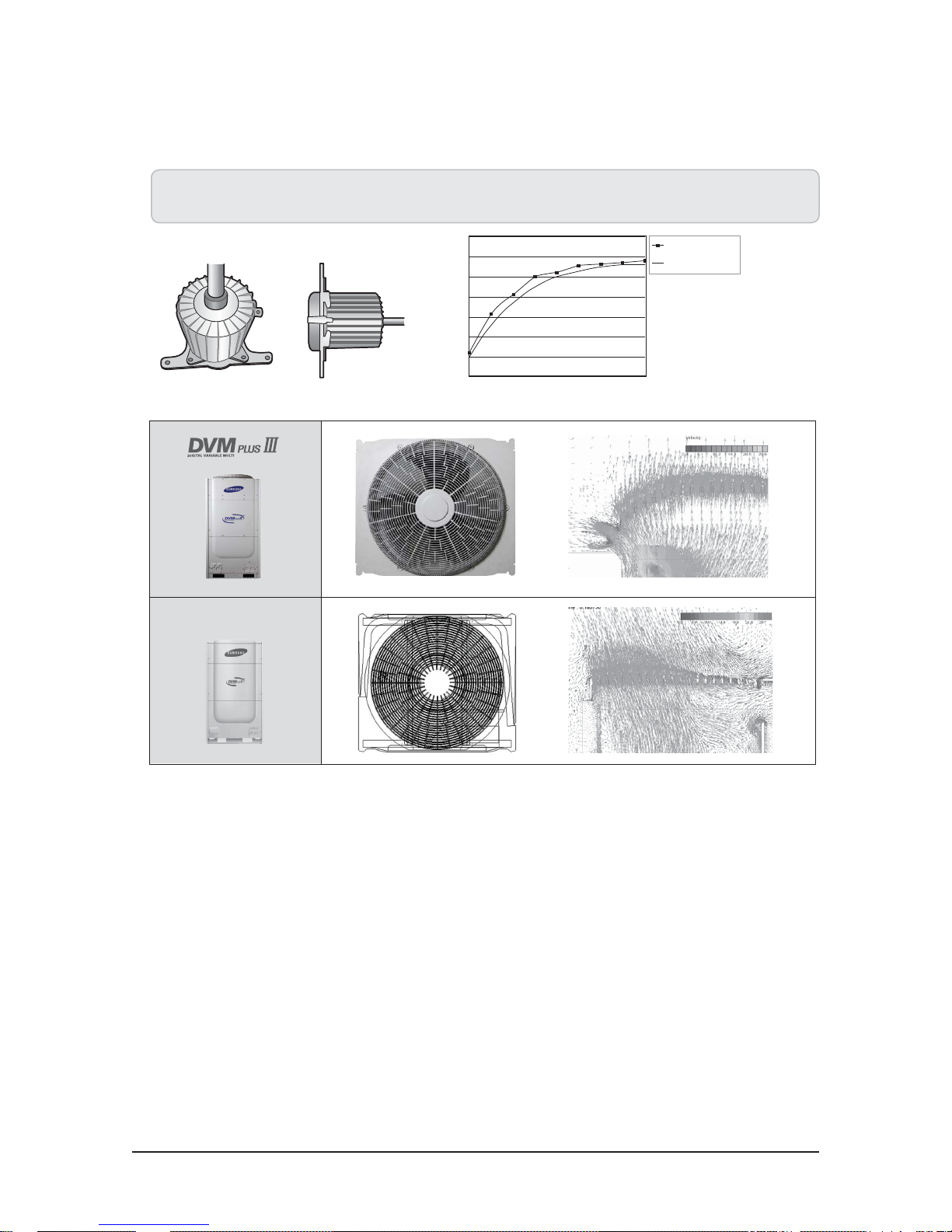

Q Newly designed fan guard

Fan guard has been optimized to improve air volume and reduce noise and vibration.

• BLDC motor, which is 2.7% more efficient than the competitors has been applied.

• High static pressure propeller fan and the optimum Bell mouth figuration for high external static pressure. (8mmAq)

Conventional model

100

90

80

70

60

Efficiency

50

40

30

200 300 400 500 600 700 800 900

RPM

DVM PLUS III

Company A

1000

2-4 Samsung Electronics

Product Specifications

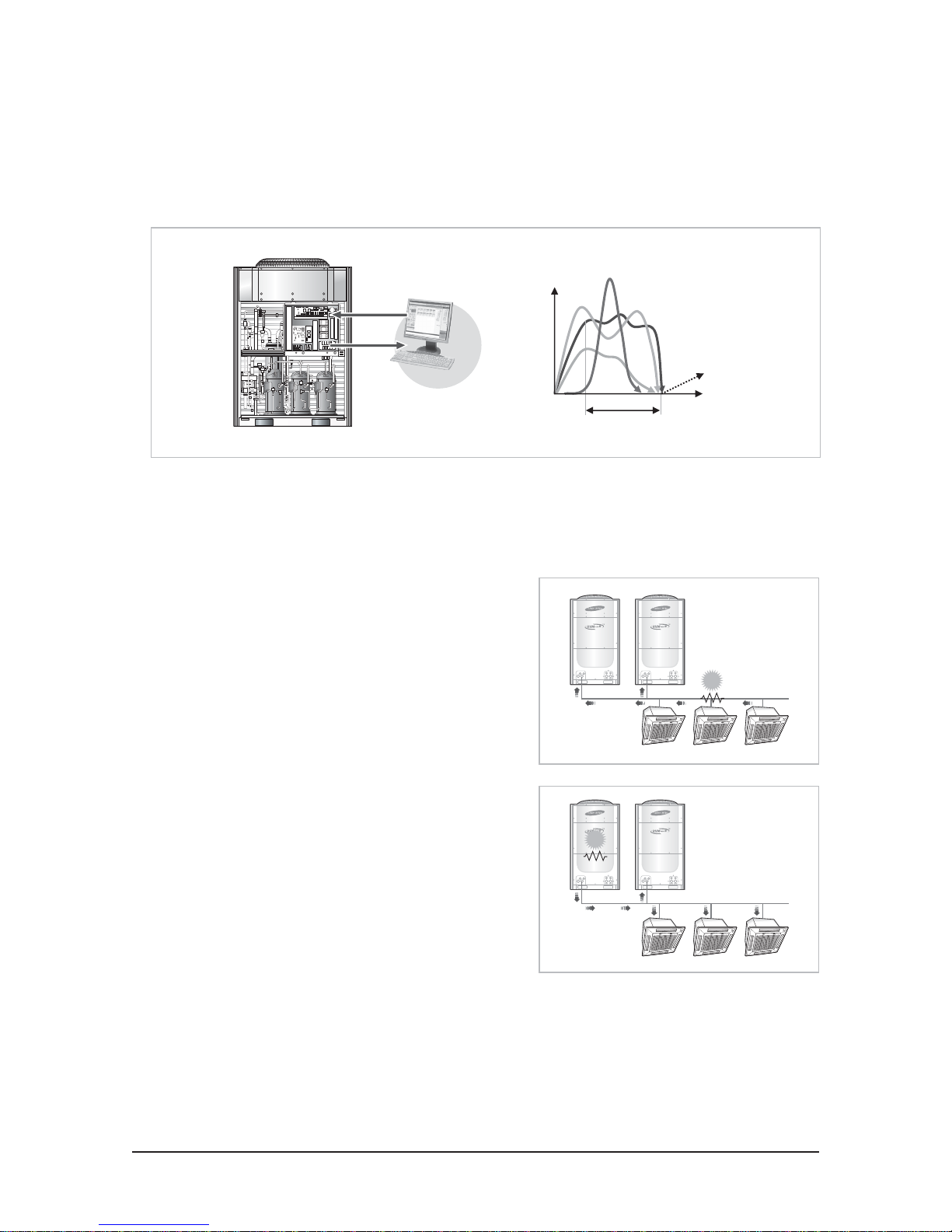

Q Upgraded control solutions

1) Easy management system

A wide range of control system is provided to support various needs and applications such as individual or central control and

automated building management.

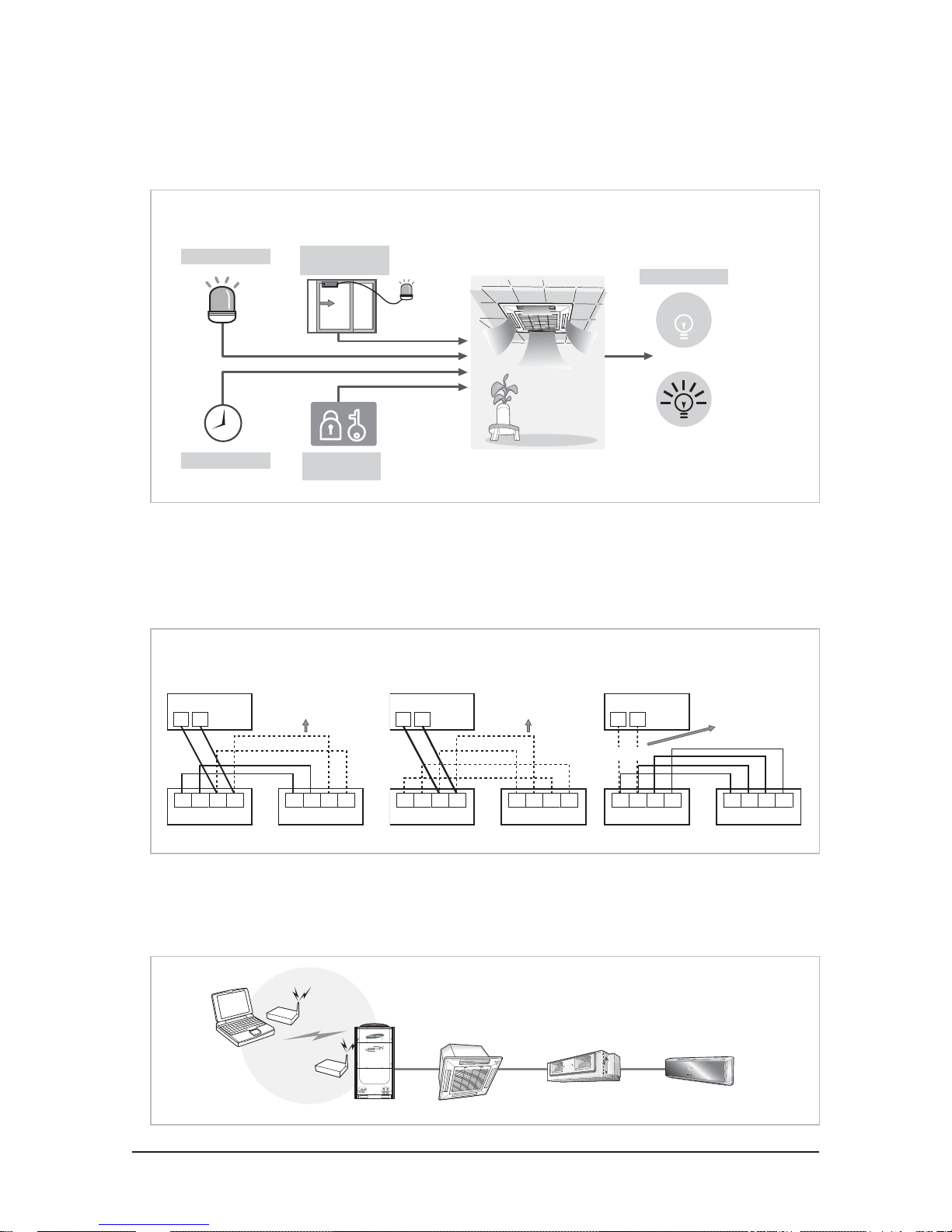

2) Enhanced remote analysis

System managers, installers or service engineers can monitor the whole air-conditioning system through the internet, analyzing

the operation and providing service promptly.

Internet

Samsung Electronics 2-5

Product Specifications

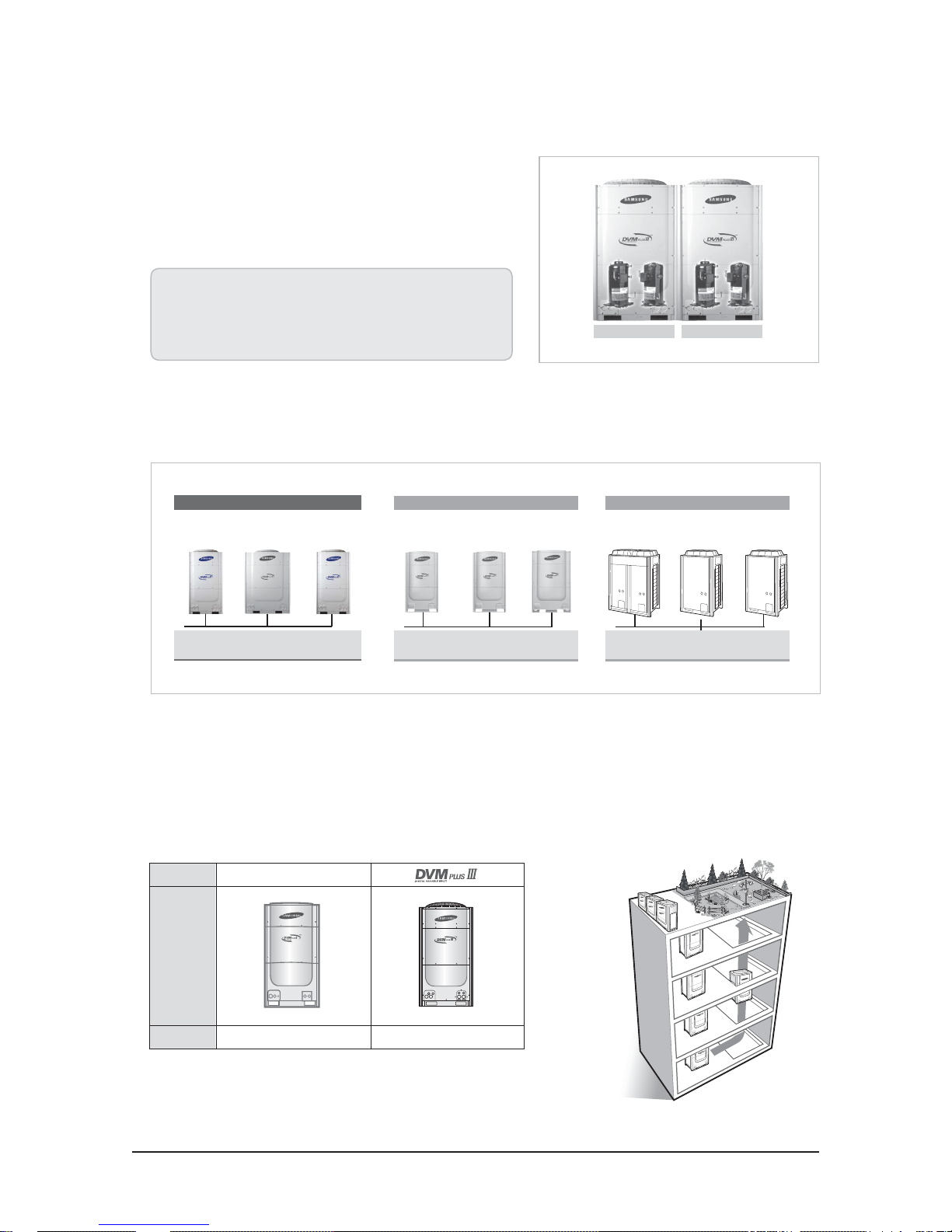

3) Simple contact control

Contact interface makes it possible to connect mechanical contacts to indoor units directly, allowing individual and group control

as well as malfunction monitoring of the indoor units.

Z

Direct ON/OFF indoor unit control

Emergent control

Schedule control

Window

synchronization

Key holder

synchronization

Operation state

Normal

Faulty

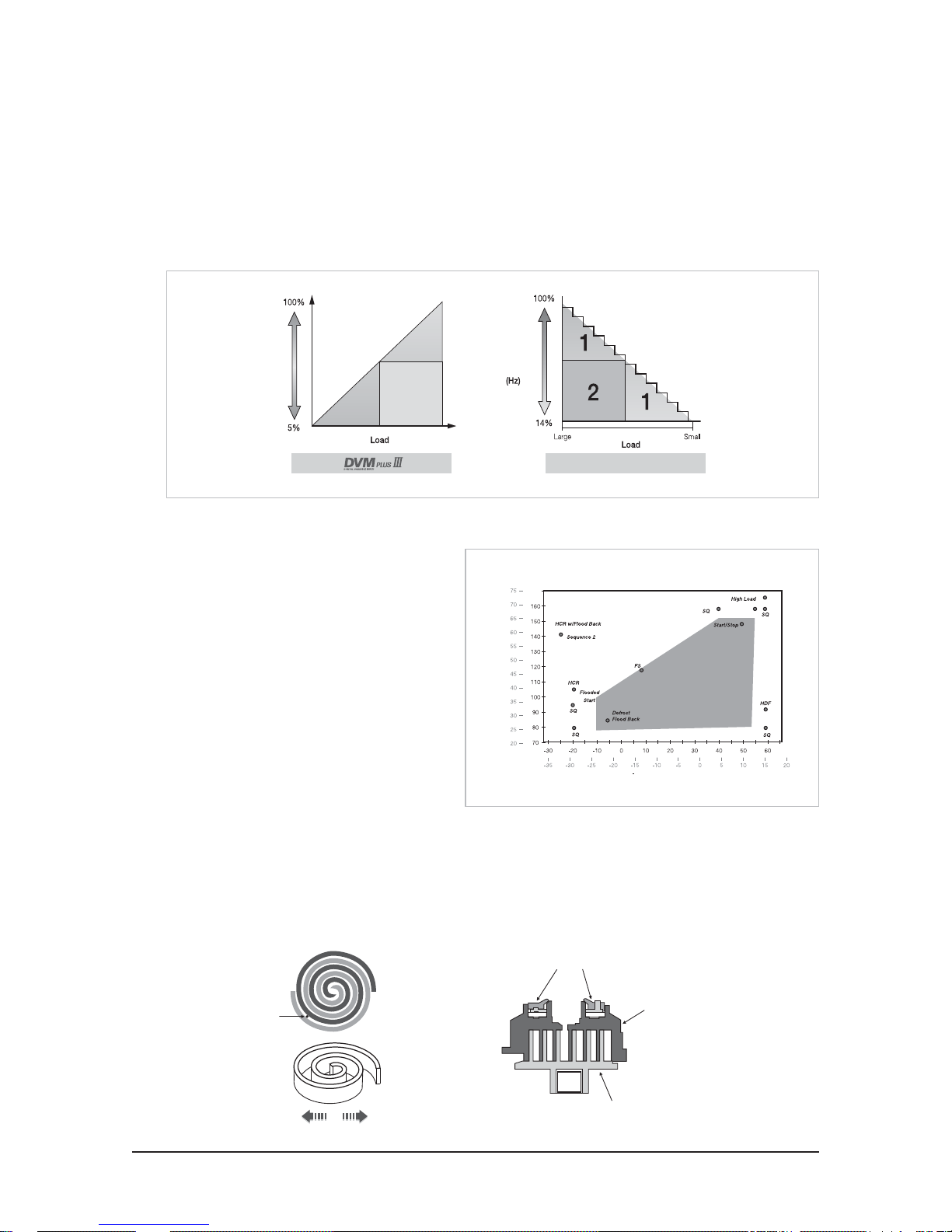

4) Wrong wiring protection

Non-polarity communication ensures Normal Operation of air-conditioning system even in case of wrong communication wiring.

Furthermore, power protection mechanism protects indoor units from blowing out under a crossed connection between power and

communication wires, resulting in enhancing system safety and robustness.

Z

Z

Automatic recovery for incorrect

Protection against wrong power line connection

communication wiring

Outdoor unit

F1 F2

L N F1 F2

Indoor unit 1

Non-Polarility

Wrong wiring

Wrong wiring

L N F1 F2

Indoor unit 1

Outdoor unit

F1 F2

L N F1 F2

Indoor unit 1

Wrong wiring

Wrong wiring

Wrong wiring

Wrong wiring

Protection

L N F1 F2

Indoor unit 1

Outdoor unit

F1 F2

Wrong wiring

L N F1 F2

Indoor unit 1

Protection

L N F1 F2

Indoor unit 1

5) Wireless test run tool

Zigbee wireless test run tool provides installers with easy and convenient control and monitoring of the outdoor unit and 49 indoor

units without bothersome wiring.

2-6 Samsung Electronics

Product Specifications

3. Main features of DVM PLUS III, DVM PLUS III HR

T High Performance and Efficiency

Q High COP

High efficiency DVM PLUS III has improved average cooling and heating COP compared to conventional products and achieved the

world’s top class energy efficiency.

• DHS(Digital Hybrid System) technology increased refrigerant flow rate and evaporation enthalpy difference.

• Wide Ø0.32 Grooved tube and new G-fin increased heat exchange efficiency.

• The best BLDC motor in the industry and optimum fan guard design increased efficiency.

17.5HP7.5HP

&RQYHQWLRQDO&RQYHQWLRQDO

&RPSDQ\$&RPSDQ\$

Q Improved heating performance

Vapor injection technology has improved heating performance

by 20% at a low ambient temperature of (14ºF/-10ºC).

&RQYHQWLRQDO&RQYHQWLRQDO

&RPSDQ\$&RPSDQ\$

10HP

Company ACompany A

ConventionalConventional

21kW

21kW

25kW

Samsung Electronics 2-7

Product Specifications

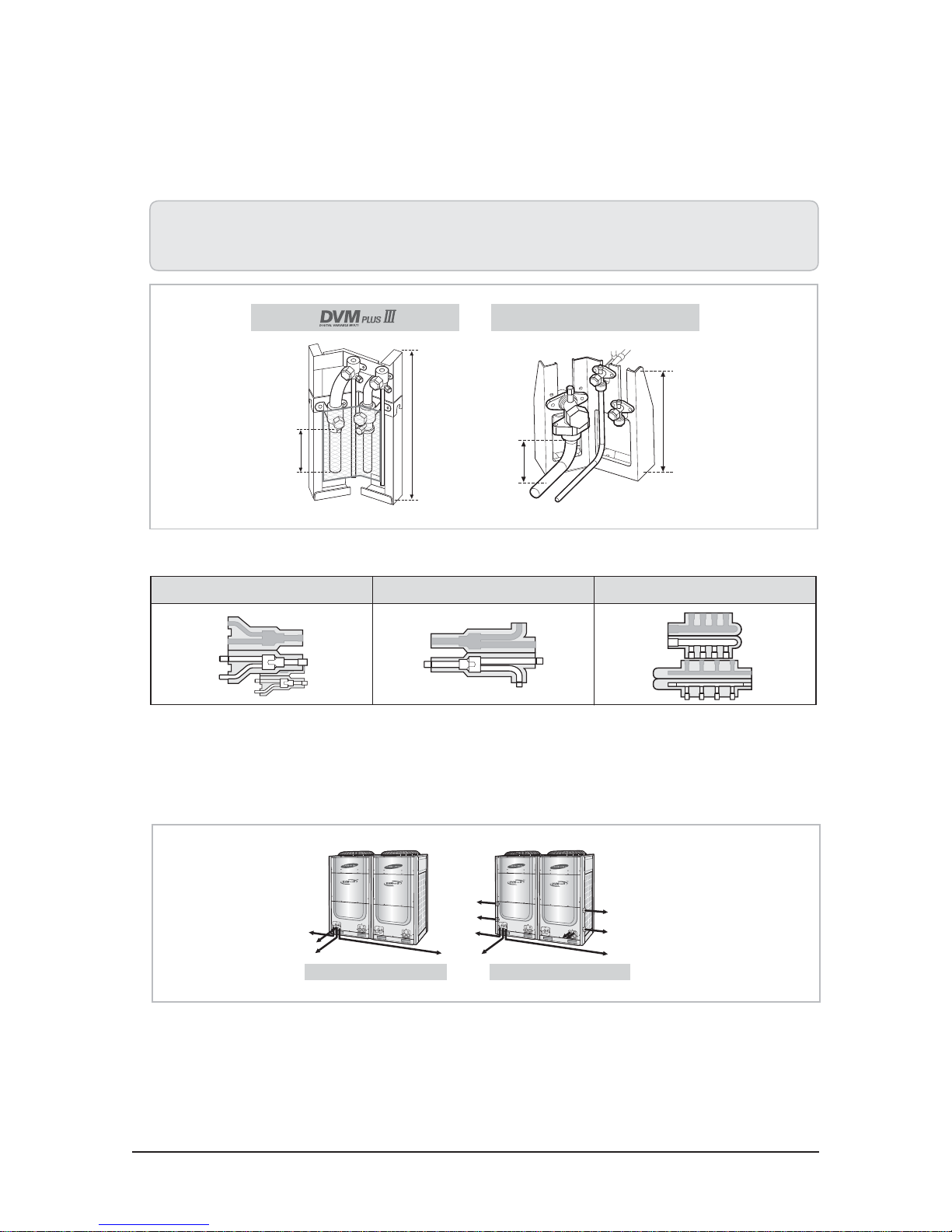

T Simple and Easy Installation

Q Digital unit module

Digital unit module combination enables the system to alternate

compressor operation to prolong each compressor’s life cycle and

improves COP with part loads.

DVI

FVI

Scroll

Scroll

• Control the compressor capacity precisely.

• Ensure long life cycle by alternating operation of the DVI compressors.

• Improve COP using multiple heat exchangers of outdoor units at part

loads.

A unit B unit

Q Free installation

DVM PLUS III provides the degree of freedom from priority of capacity when installing outdoor units in module.

DVI

Scroll

Scroll

FVI

7.5HP

(Digital unit)

DVM PLUS III

12.5HP

(Digital unit)

Any priority is OK.

10HP

(Digital unit)

Conventional model

7.5HP

(Fixed unit)

A digital outdoor unit with the largest

10HP

(Fixed unit)

capacity should come last.

(Digital unit)

12.5HP

An outdoor unit with the largest capacity

Company A

14HP 10HP

>

should come first.

8HP

>

Q Small size and light weight

To facilitate the convenience and mobility of module installation, DVM PLUS III is the best compact air conditioner in the world

with its small size and weight. It reduces the burden of weight and minimizes the required installation space (it can be installed in

the rooftop), ensuring a more spacious place for relaxation, parking lots, or additional offices, for instance.

Z

Rooftop space (Garden)

Item

Conventional model

Design

Weight

250kg(551lbs) (100%) 240kg(529lbs) (96%)

2-8 Samsung Electronics

Product Specifications

Q Rapid installation

DVM PLUS III supports more convenient and rapid installation work through the improvement of service valve structure and the

provision of branch joints.

• Improved the location of service valve and welding points for aiding piping connection work

• Modified the plate into open structure type for keeping interference out during welding work

• The application of OTS (One Touch Solution) valve that makes it easy to connect pipes and to open or shut valves.

DVM PLUS Ⅱ

423mm(16.65inch)

120mm(4.72inch)

50mm(1.97inch)

260mm(10.24inch)

Ô Y, Header, Outdoor joints allow easy piping expansion and reduction with insulations to facilitate the installation.

Y-joint Outdoor joint Header joint

Q Free piping & wiring directions

DVM PLUS III is easy to install as its piping can be connected from front, right, left and bottom side.

Wiring hole (Conduits) adds convenience as it allows power and communication lines to be connected in various ways and directions.

Samsung Electronics 2-9

Free piping connection Free wiring connection

Product Specifications

Q The world’s longest piping length

DVM PLUS III has an actual piping length of 656ft, with the maximum

piping length of 147.6ft from the first branch joint to the farthest

indoor unit, thereby providing convenience and flexibility for installation for commercial buildings.

Level differences

between indoor &

outdoor unit : 164ft

• The longest piping length : 721.8ft (Equivalent)

• Total piping length: 3280.8ft

• From the first branch joint to the farthest indoor unit : 295.3ft

- Upsize all pipes between branch joints. (liquid&gas)

Level difference between

indoor units : 49.2ft

Q Automatic piping length recognition

With automatic piping length recognition, installation can be carried out without extra PCB setup.

P

The longest pipe length

: 721.8ft (Equivalent)

The first branch

joint to the farthest

indoor unit : 147.6ft

(1 size up : 295.3ft)

∆P

pressure according to

pressure drop of piping

(

∆P

Q High external static pressure

To respond to a range of various installation environments, DVM PLUS

III is designed to be used even in external static pressure of 8 mmAq.

∆P{

Corrected target

compensation)

h

Indoor’s low pressure

(Eva. inlet temperature

of indoor units)

Outdoor unit’s

low pressure

2-10 Samsung Electronics

Product Specifications

T Easy Maintenance

Q Auto data backup in PCB

In case of problems in product, operation information of last 20 mins is stored before system shut down. Therefore, DVM PLUS III can

be diagnosed rapidly and serviced.

High pressure

Data

SNET 1+

Data storing

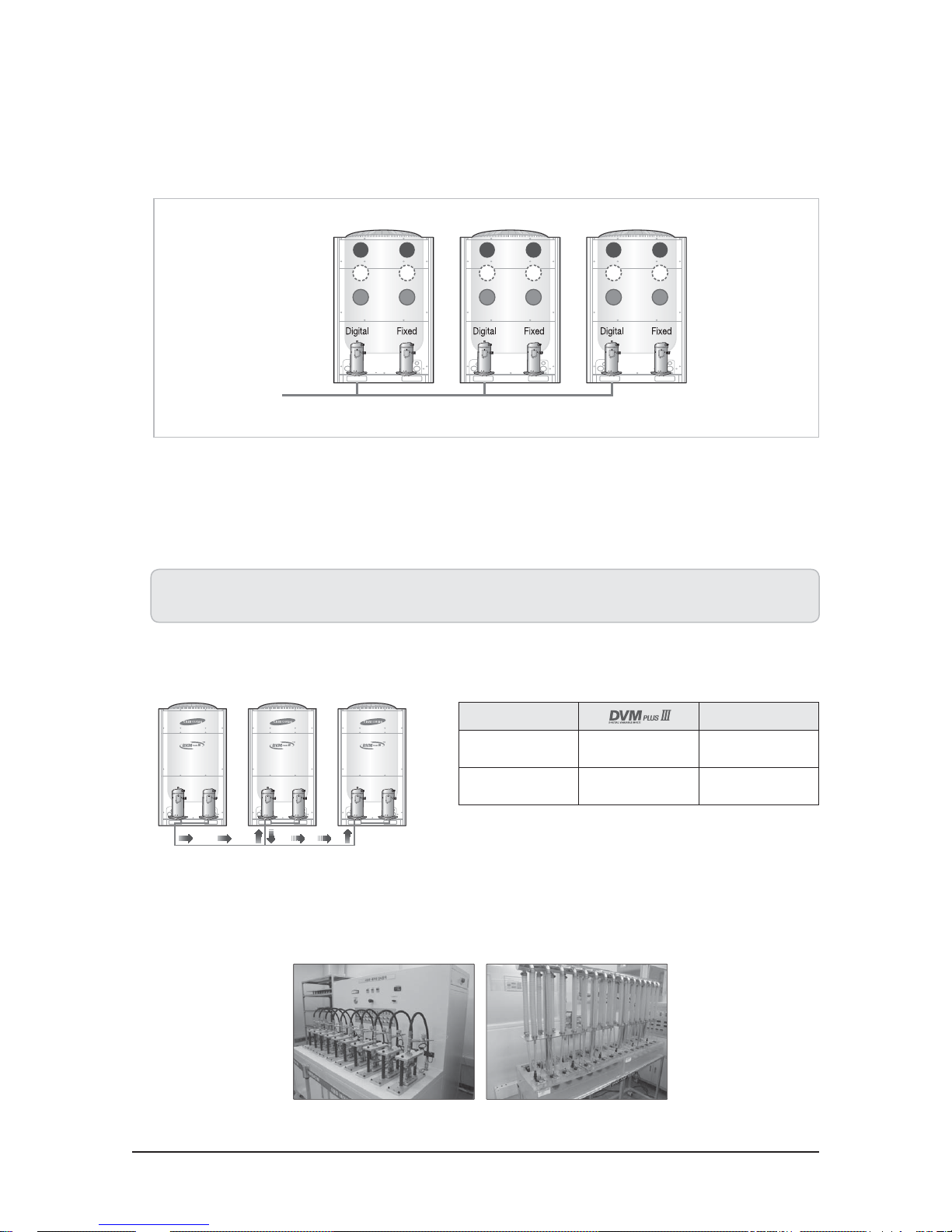

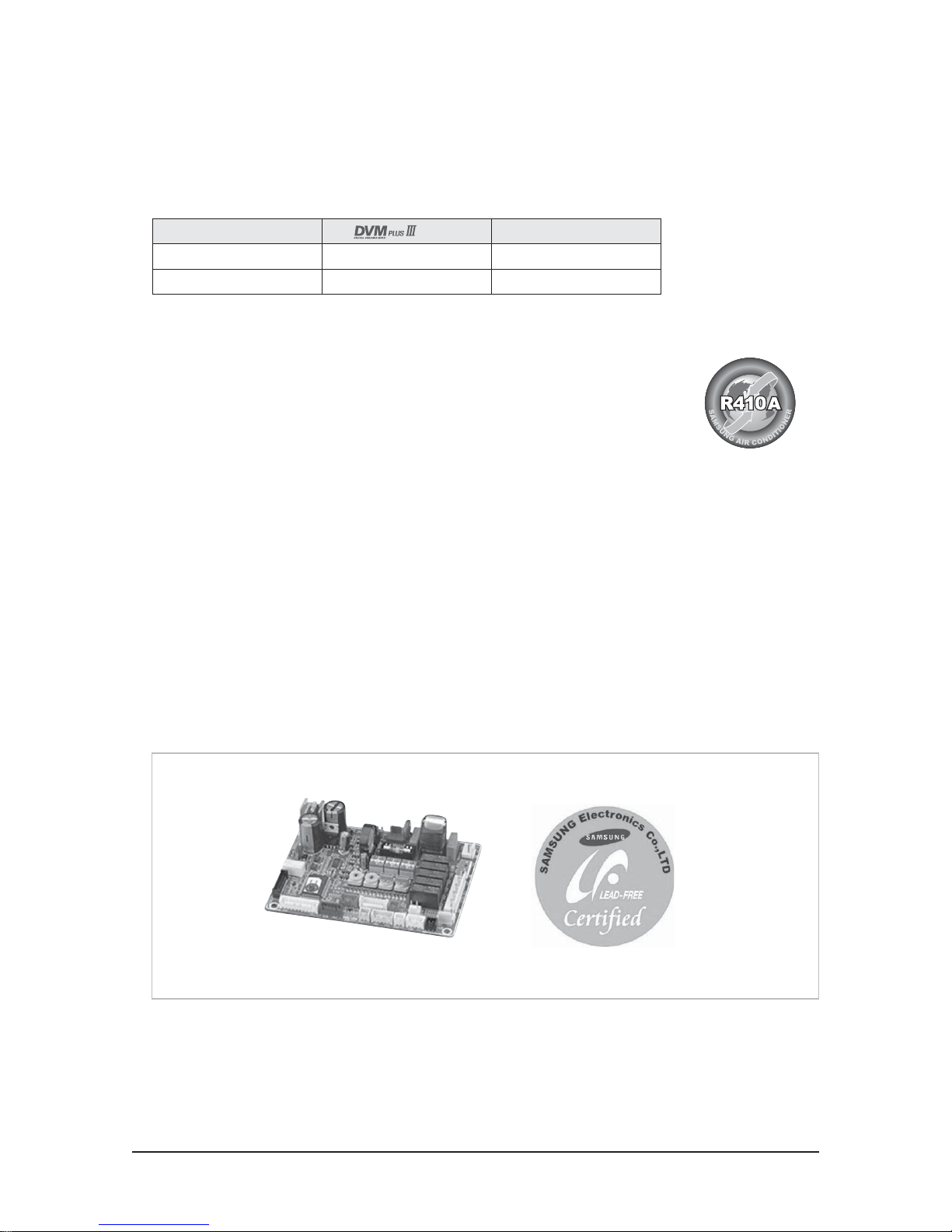

Q Refrigerant pump-down and pump-out

DVM PLUS III provides several functions to facilitate the replacements of product, additional installation and maintenance without

much effort.

Fan motor RPM

Current

System

stop

Time

Z

Refrigerant pump-down function

In case of moving outdoor units, maintenance of pipes between

indoor units, between outdoor units and indoor units, it is possible

that recover refrigerant into outdoor units.

Z

Refrigerant pump-out function

In case of maintenance of outdoor units, it is possible that recover

refrigerant into indoor or pipes.

Breakdown

Breakdown

Samsung Electronics 2-11

Product Specifications

T High Reliability

Q Optimum control and high reliability of DVI scroll compressor

1) DVI scroll compressor

As DVM PLUS III employs a DVI scroll compressor, it can adjust not only the compressor capacity linearly in accordance with

indoor loads, but at minimum load. Therefore it is superior to Inverter system in creating a pleasant indoor environment and

energy saving.

DVI

DVI

compressor

DVI

compressor

compressor

FVI

compressor

Inverter

compressor

Company A

2) Dual compliances

Through rigorous tests such as High load and liquid

flood back, DVI compressor is evaluated as reliable as it

can operate under any conditions.

°F

°C

170

Condensing temperature

°F

°C

Evaporating temperature

As DVI compressor is mechanically simple in structure, it has strong durability, and flexibility in radial and axial directions while being

strong against debris, liquid flood back, leakage of refrigerant inside the scroll, and internal overheating. In particular, it is very strong

against partial abrasion and compressor burn out by internal overheating compared with inverter compressor that employs tip seal

techniques.

Z

Radial compliance

Z

Axial compliance

Floating seal

Debris

2-12 Samsung Electronics

Lower scroll

(Orbiting)

Upper scroll

(Fixed)

Product Specifications

Q Compressor operating pattern

Digital unit’s module installation secures reliability of long life cycle with sequential activation of compressors and improves part load

efficiency as it is possible to use bigger outdoor units to take care of part load.

Q Oil balancing and recovery technology

In terms of oil recovery that is the most important operation in module system air conditioner’s reliability,

DVM PLUS III :

• Achieves continuous cooling or heating during oil recovery operation.

• Allows level difference between outdoor unit module.

Ô DVM PLUS III’s oil recovery has much higher reliability as internal and external oil balancing take place simultaneously.

Z

Oil balancing

Z

Oil recovery

Company A

Oil recovery during

cooling operation

Oil recovery during

heating operation

Cooling operation Cooling operation

Heating operation Cooling operation

Q Acceleration life cycle test

All parts fitted to DVM PLUS III ensure reliability for life cycle through ALT (Acceleration Life cycle Test ).

Samsung Electronics 2-13

Product Specifications

Q Robust design

DVM PLUS III ensures product reliability through robust design against all

potential defects that can occur in the process of production, distribution

and customers’ usage environment.

Robust design through CAE

T Sound Quality

Q Sound quality

DVM PLUS III improves the problem of noise not only at the low sound level, but also at the actual sound quality level by:

• Developing a sound insulation material for compressor

• Improving fan guard air flow

• Adopting Ø0.32 heat exchanger

Ô In particular, it enhances sound quality as it improves compressor noise by 4dB(A) by employing new material with better

acoustic absorptivity.

1.200

1.000

0.800

0.600

0.400

Acoustic absorptivity

0.200

0.000

250 500 1000 2000 4000

Frequency (Hz)

Conventional

material

New material

2-14 Samsung Electronics

T Environment Friendly

Q Small refrigerant charge amount

With consideration of environment, DVM PLUS III is less charged compared to competitor’s products.

of (10HP) Company A (10HP)

Refrigerant volume 7.5kg(16.5lbs) 8.4kg(18.5lbs)

% 89 100

Q Refrigerant leakage prevention

To prevent refrigerant leakage, we provide how to diagnose any refrigerant leakage in operation. Also,

changing service valves from flange type to brazed type further prevents refrigerant leakage.

Product Specifications

Q RoHS compliance

RoHS restriction only applies to small or large household appliances, IT equipment, lightings, power train, toys, leisure or sports

equipment, and vending machines.

Samsung expands the RoHS restriction into its entire range of products based on its own environmental policies.

Q Lead-free

DVM PLUS III is an environment friendly product that prevents pollution problems caused by the use of lead, by applying lead-free

indoor and outdoor PCBs.

Samsung Electronics 2-15

Product Specifications

4. DVM PLUS III HR

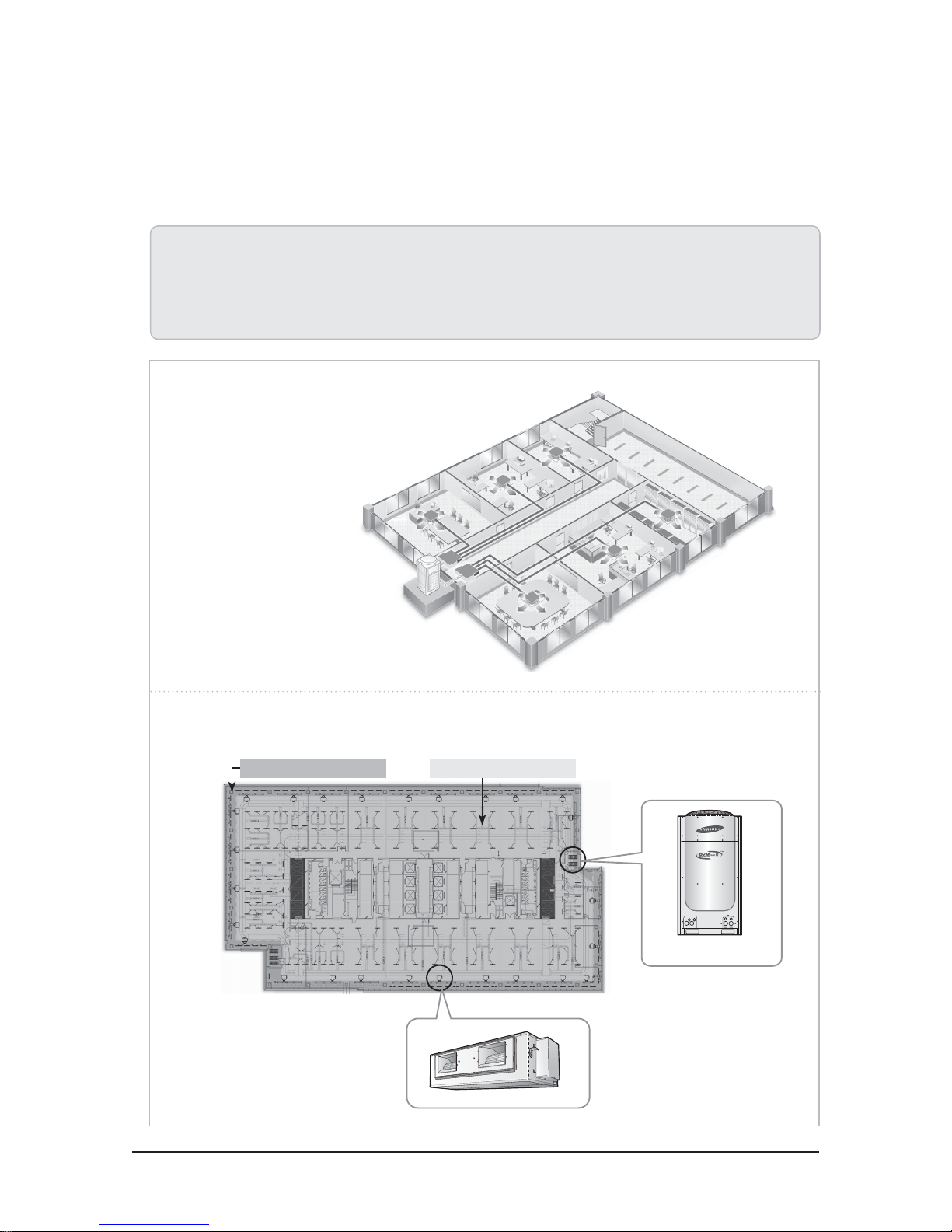

1) Versatile application

As DVM PLUS III HR allows a simultaneous cooling and heating operation with one system, the product makes it possible for a wide

range of applications.

• Great for places where simultaneous cooling and heating operation is required such as hotels, nursing homes, conference rooms,

etc.

• For seasonal air-conditioning which may need a simultaneous cooling and heating operation.

• In case of medium or large office, DVM PLUS III HR satisfies cooling and heating operation simultaneously for the requirements of

interior and perimeter zone.

Z

Simultaneously cooling and heating for individual rooms

Heating

Cooling

Heating

Z

Simultaneously cooling and heating for each zone

Perimeter Zone : Heating Interior Zone : Cooling

MCU (Mode Change Unit)

Cooling

Cooling

Heating

2-16 Samsung Electronics

DVM PLUS III HR

2) High COP

P

As DVM PLUS III HR utilizes the retrieved energy from indoor

cooling operation for heating, which has a high energy

efficiency and is further enhanced by our Vapor Injection

technology.

3) Wide operation range

DVM PLUS III HR can carry out a simultaneous cooling and

heating operation within a wide range of temperatures.

h

3

Indoor

temp.

30 C

Simultaneous

operation

zone

18 C

16 C

Heating

-20 C -10 C 24 C 30 C 43 C

Product Specifications

Q3

Q2

Q1

h2h

1

h

Cooling

Outdoor

temp.

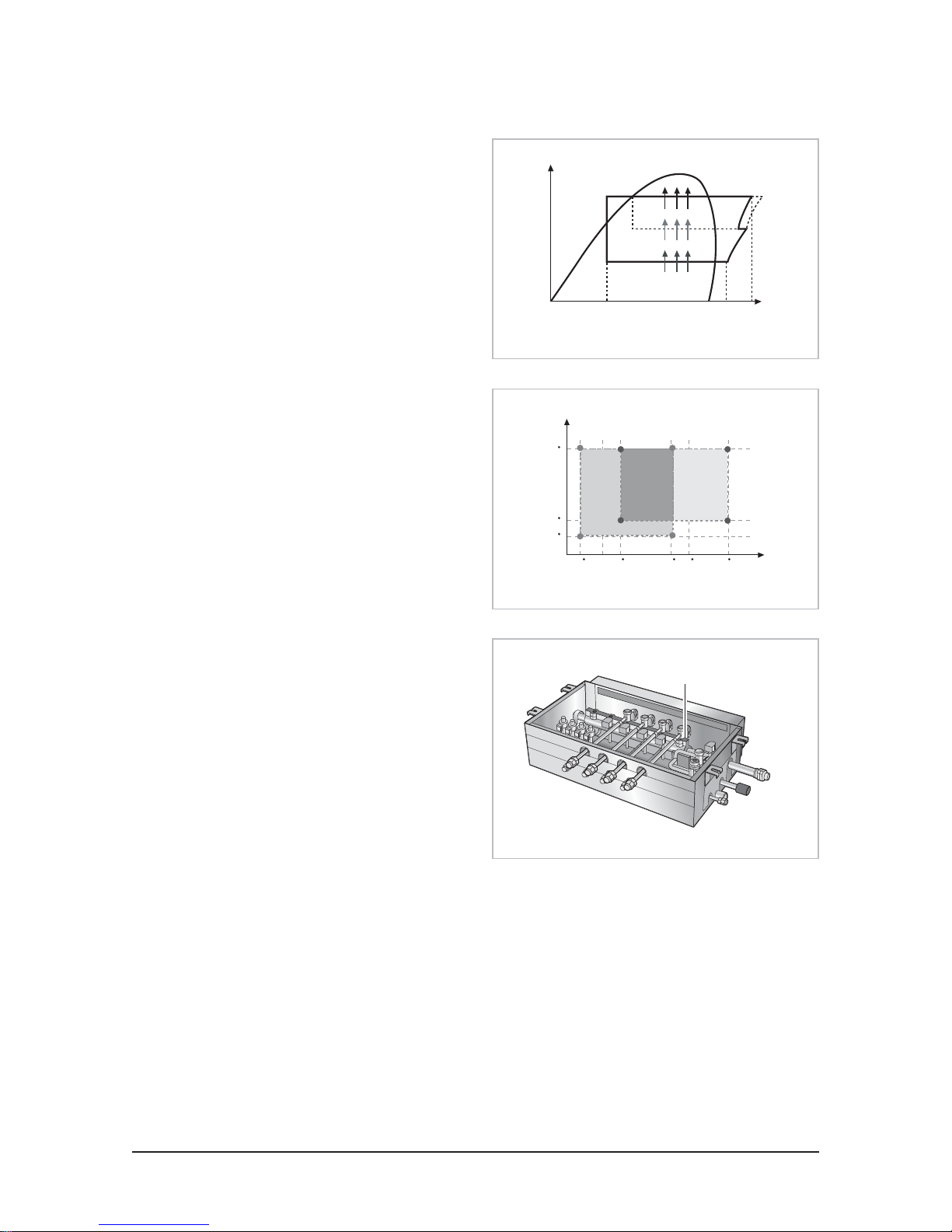

4) New MCU

The MCU for DVM PLUS III HR has a double-tube heat

exchanger for securing high subcooling effect by the MCU

itself, thus improving the reliability of the long piping and

cooling and heating performance.

MCU subcooling heat exchanger

Samsung Electronics 2-17

Product Specifications

Feature(Cont.)

2-1-1-2 RD040/050MHXCA

Summarize

Overview

POWER SAVING

Samsung patented compressor

Samsung has been researching and developing compressors since the 70's.

It has developed power saving compressors for more than thirty years.

The SUPER FJM compressor adopts a double-rotor BLDC compressor with permanent magnets made by Samsung. Electricity for the

compressor rotor is obtained from a neodium-iron-boron permanent magnetic material (boron magnet can attract iron material weighing

1000 times its own weight.) It strengthens the rotary moment of the compressor to maximize the entire efficiency of the compressor.

SUPER FJM is an all-in-one type product integrating the control R&D and Samsung patented compressor.

The air conditioning system uses the latest single tube in parallel connection and both the indoor and

outdoor machines use independent electronic expansion valves to control the amount of coolant.

You can connect a maximum of nine indoor machines to one outdoor machine.

SUPER FJM considers the trend in air conditioner use. It optimizes the energy efficiency

of loads ranging from partial to full. It achieves an excellent energy effect for the users

of the air conditioner.

BLDC electricity

“Permanent magnet,” strong magnetic rotor

Double rotor compression cylinder

Nd-Fe-B Neodium-Iron-Boron magnet

SAMSUNG's double-rotor compressor has the upper and lower rotors designed symmetrically.

The double rotor in symmetry can remove vibrations caused by the eccentric design of the cylinder.

2 rotors balancing the rotary moment

Permanent magnet rotor

Eccentric design

Nd-Fe-B Neodium-Iron-Boron magnet

Centered symmetry

Upper cylinder

Lower rotor

Upper rotor

Lower cylinder

High efficiency heat exchanger

SUPER FJM uses new multiple-teeth screw pipes with a diameter of 8 mm to improve the heat exchangeability of the pipe by 30.8%.

The water-friendly aluminum foil in the heat exchanger uses the G-fin patent design to improve the efficiency of heat exchange by 13%.

Multiple-teeth screw pipes

General screw pipes

DC fan electricity

The SUPER FJM outdoor machine uses DC fan electricity. The rotational speed of electricity is 100 RPM to 1050 RPM with step-free control.

The electrical efficiency is improved by about

33% compared to AC electricity.

2-18 Samsung Electronics

Efficiency

Speed (RPM)

Product Specifications

Excellent energy efficiency

All the SUPER FJM series is superior to class 1 energy efficiency, the power saving standard for multiple connection (heat pump) machines.

Its IPLV(C), the comprehensive energy efficiency is 4.94.

Lower energy consumption

Middle

Higher energy consumption

FRESHNESS AND HEALTH

Environment friendliness

SUPER FJM uses the environment-friendly coolant, R410A and all of its parts are in strict compliance with the EU environment guidelines (RoHS).

It controls toxic materials and prevents damage to the atmosphere. It does not spread any toxic materials indoors.

Strong heater

SUPER FJM adopts Samsung's high performance double-rotor compressor. Compared to other products, its heating effect at -10°C is about 20% higher.

à SUPER FJM's excellent energy efficiency

World's number one class

Energy efficiency

SUPER FJM

Comprehensive energy efficiency

SUPER FJM optimizes the aspects of environment friendliness, air control, toxic

material control, low temperature heaters and noise. It guarantees a refreshing

and healthy environment for the user.

Cadmium

Lead

Brominated flame retardant

Poly brom penyl

With smart

control

Hexa chromium

mercury

Heating performance (kW)

Heating performance

improved 20%

External temperature(°C)

SUPER FJM measurement

Other product measurement

Other product measurement

Outside temperature rises about 7°C

Inside temperature rises about 3°C

The air conditioning capacity increases about 0.8HP

Deep level anti-bacteria

All of the SUPER FJM indoor heat exchanger aluminum foil is processed with special anti-bacteria paint to prevent the growth of bacteria

in the humid inner area of the air conditioner and maintain clean indoor air.

Basic materials for the aluminum foil

Anti-corrosion layer

(resin, anti-corrosion materials)

Water friendly layer

(Silicon+water-friendly material

+anti-corrosions)

Indoor machine heat exchanger

Aluminum foil pin

Ticks in the blankets

Sofa ticks

Carpet ticks

Pet's ticks

Threatens the indoor air environment.

Samsung Electronics 2-19

Product Specifications

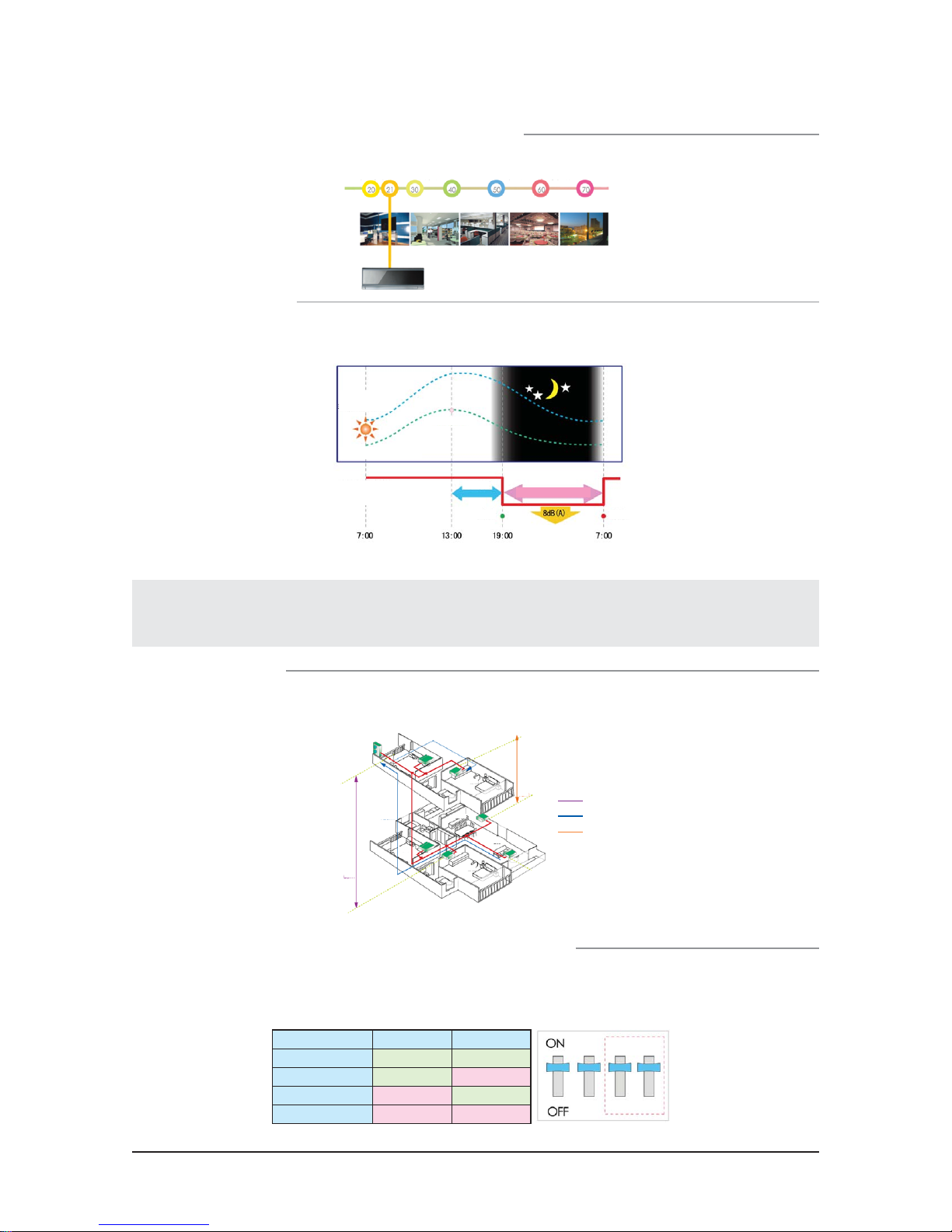

Quiet operation of the indoor machine

SUPER FJM's indoor machine has a minimum noise level of 21 decibels. Even in the late, quiet night, you can hardly hear any noise.

Quiet night

SUPER FJM's outdoor machine can be set to quiet nighttime operation mode. The outdoor machine executes quiet operation (sleeping mode)

after six hours. After 12 hours, it returns to the previous mode automatically.

Hearing test room Library room Office room Convention hall Crowded streets

Environment load

change curves

Max temperature

Temperature change curve

Decibels

Noise change curve

(sleeping mode)

SIMPLE DESIGN AND INSTALLATION

Long pipe

The SUPER FJM indoor/outdoor machine's pipe length is a max. of 70 meters. The max. drop height between the indoor and the outdoor

machines is 30 meters. (If the outdoor machine is located below the indoor machine, it is 25 meters). The max. pipe length after installation of the

first branch pipe is 40 meters.

After 6 hours

1 hour of quiet operation

Start Stop

The SUPER FJM design supports simple installation. The outdoor and indoor

machines use a copper pipe and a branch pipe string in parallel connection.

They are provided with electricity independently.

Bedroom

Bedroom

Max outdoor/indoor drop heights 30m

Max actual pipe length 70m

Max drop heights between the indoor machines 15m

(Caution: The max. pipe length for the 3HP model is 45 meters.

The max. indoor/outdoor drop height is 15 meters and the max. drop heights

between the indoor machines is 7.5 meters.

The max. pipe length after installation of the first branch pipe is 30 meters.)

Bedroom

Kitchen

Livingroom

Bedroom

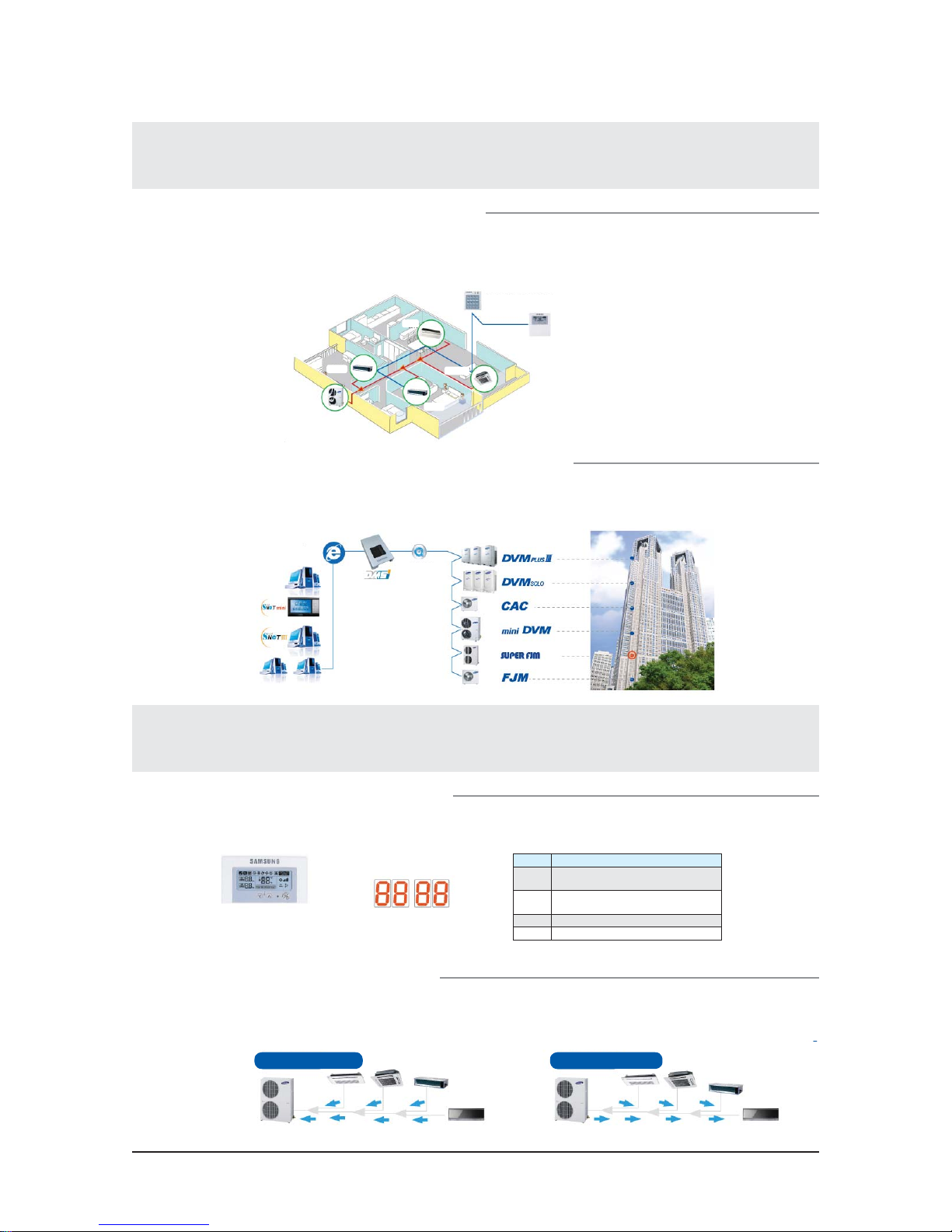

Limitations of the operational current classes

SUPER FJM's indoor/outdoor machine control circuit board uses four types of current limits mode. It can be efficiently installed in an area with

a shortage of electrical stability. If it is to be remodeled for an old building that does not meet the electricity capacity standard, first install an air

conditioner for testing. Then set the current after expanding the electricity capacity.

Current limit mode DIP button DIP button

Mode 1 ON ON

Mode 2 ON OFF

Mode 3 OFF ON

Mode 4 OFF OFF

2-20 Samsung Electronics

Product Specifications

PROHIBITION

Independent smart central control

Independent controllers are installed in each indoor machine of SUPER FJM. Using the central controller, it can control all the indoor machines at

home. When leaving home, use the central controller installed in the living room to turn off all the air conditioners. You can prevent unnecessary

power consumption caused by the air conditioner running with no one at home.

Smart group control for multiple households

SUPER FJM supports group controls in conjunction with Samsung's other commercial air conditioners. It achieves a wide range of smart control

including individual metering for each household, computer monitoring and network monitoring.

Ethernet

SUPER FJM with smart control uses the smart network control method for management and

support simple controls.

ON/OFF central controller

Bedroom

Kitchen

Livingroom

Bedroom

Connection

Functional central controller

SPEEDY TROUBLESHOOTING

that support speedy troubleshooting.

Self diagnosis of malfunctions

SUPER FJM is designed to perform perfect smart self diagnosis functions

The SUPER FJM indoor/outdoor machines has an LED monitor where you can quickly diagnose the operational variables and repair them

Control parts Malfunction codes

LED display of the control panel

of the outdoor machine

Codes Causes for malfunction

Communication failures between the indoor

E101

machine and the outdoor machine

Bad power connection between the indoor and

E460

the outdoor machines

E467 Bad operation of the compressor

E466 Inadequate voltage supply

Auto recovery of the coolant

SUPER FJM is designed to support the saving function that recovers the coolant automatically for the user. Depending on which outdoor or

indoor machine is being repaired, it decides which machine to recover the coolant from. This way, the amount of coolant can be saved.

Repaired indoor machine Repaired outdoor machine

Samsung Electronics 2-21

Loading...

Loading...