Samsung RC***MHXGA, RC***MHXEA Installation Manual

RCMHXGA

RCMHXEA

Air to Water Heat Pump

Mono Outdoor Unit

installation manual

imagine the possibilities

Thank you for purchasing this Samsung product.

To receive more complete service, please

register your product at

www.samsung.com/register

DB98-00000A(1)

IFSE P G RD

2

Contents

Safety precautions

Warning

Carefully read the content of this manual before installing the air to water heat pump and store the manual in a safe place in order

to be able to use it as reference after installation.

For maximum safety, installers should always carefully read the following warnings.

Store the operation and installation manual in a safe location and remember to hand it over to the new owner if the air conditioner

is sold or transferred.

Store the user and installation manual in a safe location and remember to hand it over to the new owner if the air to water heat

pump is sold or transferred.

This manual explains how to install Air-Water Heat Pump. The use of other types of units with different control systems may

damage the units and invalidate the warranty. The manufacturer shall not be responsible for damages arising from the use of non

compliant units.

The air conditioner is compliant with the requirements of the Low Voltage Directive (72/23/EEC), the EMC Directive (89/336/EEC)

and the Directive on pressurized equipment (97/23/EEC).

The manufacturer shall not be responsible for damage originating from unauthorized changes or the improper connection of

electric and hydraulic lines. Failure to comply with these instructions or to comply with the requirements set forth in the “Operating

limits” table, included in the manual, shall immediately invalidate the warranty.

Do not use the units if you see some damages on the units and recognize something bad such as loud noisy, smell of burning.

In order to prevent electric shocks, fires or injuries, always stop the unit, disable the protection switch and contact SAMSUNG’s

technical support if the unit produces smoke, if the power cable is hot or damaged or if the unit is very noisy.

Always remember to inspect the unit, electric connections, refrigerant tubes and protections regularly. These operations shall be

performed by qualified personnel only.

The unit contains moving parts and electrical parts, which should always be kept out of the reach of children.

Carefully follow the precautions listed below because they are essential to guarantee the safety of the equipment.

• Always disconnect a power supply of Air-Water Heat Pump before servicing it or accessing

components inside the unit.

• Verify that installation and testing operations shall be performed by qualified personnel.

• To prevent serious damage on the system and injuries to users, precautions and other notices

shall be observed.

WARNING

Safety Precautions ...................................................................................................................................................................................................................2

Product Specifications ..........................................................................................................................................................................................................4

Application Examples ......................................................................................................................................................................................................... 7

Main Components ................................................................................................................................................................................................................. 9

Functional Diagram ............................................................................................................................................................................................................ 13

Installing the Unit ............................................................................................................................................................................................................... 15

Piping Work ............................................................................................................................................................................................................................. 22

Wiring ...................................................................................................................................................................................................................................... 29

Testing operations ............................................................................................................................................................................................................. 35

Trouble shooting ................................................................................................................................................................................................................ 37

Maintenance ......................................................................................................................................................................................................................... 38

ENGLISH

3

Do not attempt to repair, move, alter or reinstall the unit by unauthorized personnel, these operations may cause

product damage, electric shocks and fires.

Do not place containers with liquids or other objects on the unit.

All the materials used for the manufacture and packaging of the air to water heat pump are recyclable.

The packing material and exhaust batteries of the remote controller(optional) must be disposed of in accordance with local

regulations.

The air to water heat pump containing a refrigerant must be disposed in authorized center or returned to retailer as special wastes.

Wear protective gloves to unpack, move, install, and service the unit to avoid your hands being injured by the edge of the parts.

Do not touch the internal parts (water pipes, refrigerant pipes, heat exchangers, etc) while running the units.

And if you need to adjust and touch the units, have enough time for the unit can be cooled and be sure to wear protective

gloves.

In case of refrigerant leakage, try to avoid getting in contact with the refrigerant because this could result in severe wounds.

When you install the Air to water heat pump in a small room, you must consider a proper ventilation to prevent a leakage level

within the maximum permissible limit.

- In that case, you may die from suffocation by some possibility.

Make sure to safely dispose of packing materials. Packing materials, such as nails and other metal or wooden pallets may cause

children get injured.

Inspect the product shipped and check if damaged during transport. If the product has some damages,

DO NOT INSTALL and immediately discuss about the damages with the carrier or retailer (if the installer or the authorized

technician has collected the material from the retailer.)

Our units shall be installed in compliance with the spaces described in the installation manual, to ensure accessibility from both

sides and allow repairs or maintenance operations to be carried out.

If the units installed without complying with procedures described in manual, additional expenses can be asked because special

harnesses, ladders, scaffolding or any other elevation system for repair service will NOT be considered part of the warranty and will

be charged to the end customer.

Always make sure that the power supply is compliant with local safety standards.

Verify that the voltage and frequency of the power supply comply with the specifications and input power is sufficient to ensure

the operation of any other domestic appliance connected to the same electric lines.

Always verify that the cut-off and protection switches are suitably selected.

Always verify that electric connections (cable entry, section of leads, protections…) are compliant with the electric specifications

and with the instructions provided in the wiring scheme. Always verify that all connections comply with the standards applicable

to the installation of air to water heat pumps.

Devices disconnected from the power supply should be completely disconnected in the condition of overvoltage category.

Do not connect the earth wire to the gas pipe or water pipe, lighting rod, surge absorber, or telephone earth wire.

If earthing is not complete, it may cause an electric shock or fire.

Be sure to install both an earth leakage detector and circuit breaker with specified capacity in accordance with relevant local

and national regulations.

- If it is not installed properly, it may cause electric shocks and fire.

Make sure that the condensed water runs well out of the unit at low ambient temperature. Drain pipe and cond heater can frost/

ice can not grow. If drain work is not effective for releasing condensed water, it can make the units get damaged by massive ice and

system can be stop , covered by ice.

Install the power cable and communication cable of the indoor and outdoor unit at least 1m away from the electric appliance.

Protect the unit from rats or small animals. If an animal makes a contact with the electric parts, it can cause malfunctions,

smoke or fire. Please instruct the customer to keep the area around the unit clean.

4

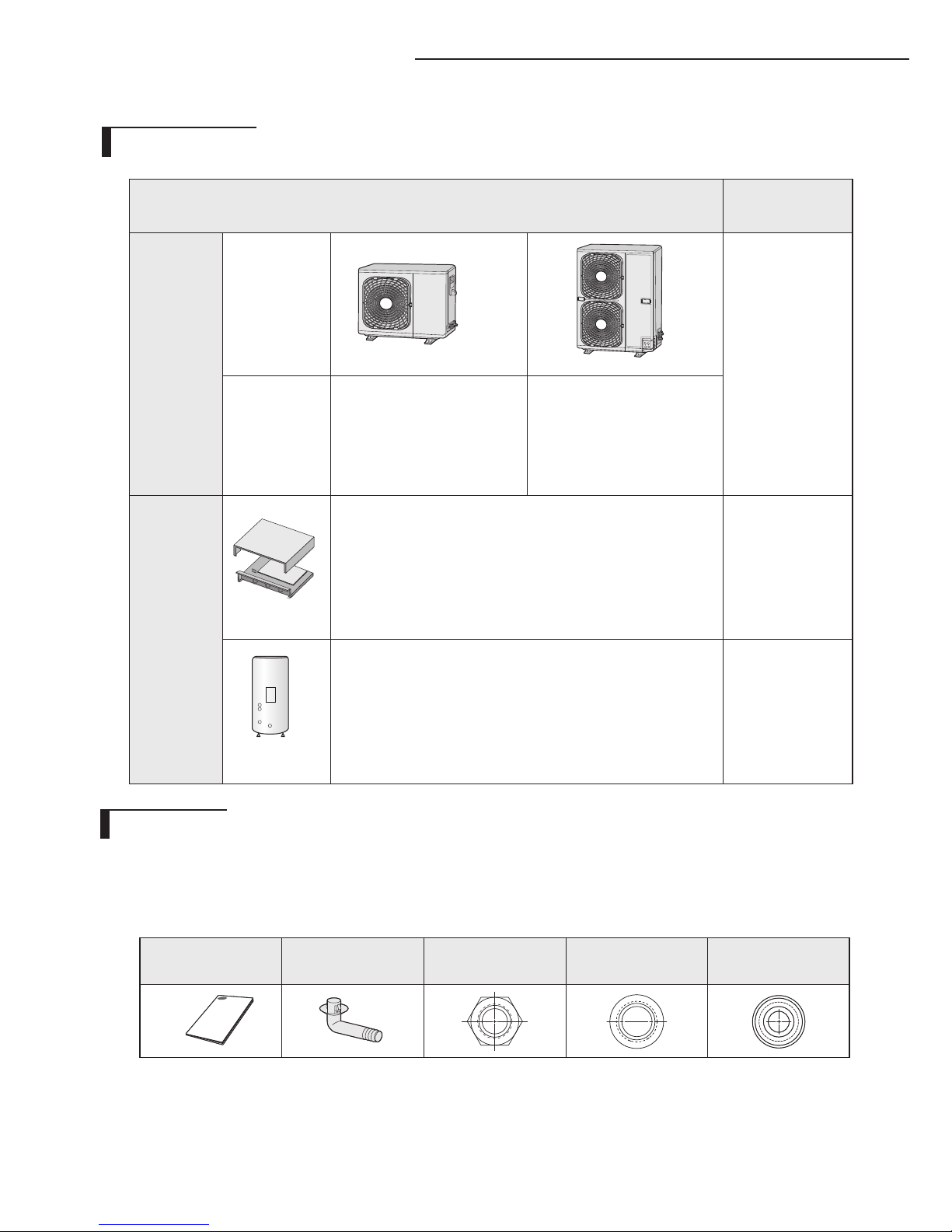

Product Specifications

Line-up Remark

Heat

Pump Units

Chassis

-

Model Name RC090MHXEA

RC120MHXEA

RC120MHXGA

RC140MHXEA

RC140MHXGA

RC160MHXEA

RC160MHXGA

Auxiliary

Parts

MIM-E03A Requisite

Standard models:

NH200CHXEA

NH300CHXEA

Solar connected

NH200CHXES

NH300CHXES

Option

Product Line-up

Accessories

Keep supplied accessories until the installation is finished.

Hand the installation manual over to the customer after finishing installation.

The quantities are indicated in parentheses.

Installation manual (1) Drain plug (1) Fastener-nut(1) Rubber-cover wire(2) Drain cap (1)

Control Kit

Domestic Hot

Water tank

ENGLISH

5

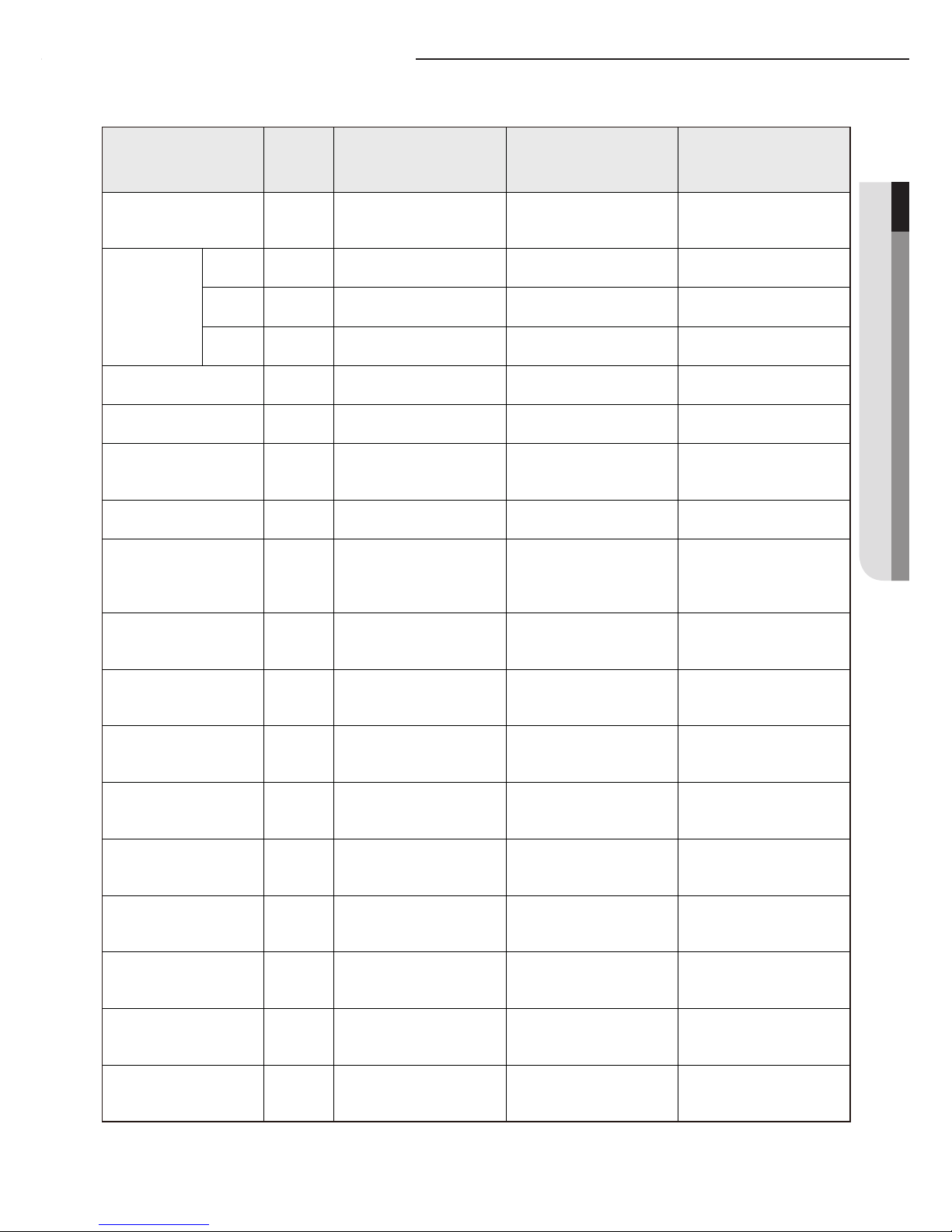

Product Specifications

Type Unit

RC120MHXEA

RC120MHXGA

RC140MHXEA

RC140MHXGA

RC160MHXEA

RC160MHXGA

Power Source -

1P, 220~240VAC 50Hz

3P, 380-415VAC 50Hz

1P, 220~240VAC 50Hz

3P, 380-415VAC 50Hz

1P, 220~240VAC 50Hz

3P, 380-415VAC 50Hz

Nominal

Capacity

7°C kW 12.0 14.0 16.0

2°C

kW 10.0

13.0

15.0

-15°C kW 12.5 12.5 12.5

COP (A7-W35) - 4.70 4.50 4.30

Compressor - Rotary Inverter Rotary Inverter Rotary Inverter

Condenser -

Brazing type

72 plates

Brazing type

72 plates

Brazing type

72 plates

Evaporator - Φ7, FP 1.7, L950 Φ7, FP 1.7, L950 Φ7, FP 1.7, L950

Fan & Motor -

Propeller, Φ520,

3-blade

BLDC Inverter

Propeller, Φ520,

3-blade

BLDC Inverter

Propeller, Φ520,

3-blade

BLDC Inverter

Flow Switch LPM

16 ± 1.5

Magnetic (decreasing)

16 ± 1.5

Magnetic (decreasing)

16 ± 1.5

Magnetic (decreasing)

Base Heater W 150 150 150

Refrigerant g 2,200 (R410A) 2,200 (R410A) 2,200 (R410A)

Noise

(Heat/Cool, Pressure)

dB 64/62 64 / 62 64 / 62

Water Connection

(In/Out)

Inch 1.0 / 1.0 1.0 / 1.0 1.0 / 1.0

Leaving Water

Temperature

°C

Cooling : 5 ~ 25

Heating : 25 ~ 55

Cooling : 5 ~ 25

Heating : 25 ~ 55

Cooling : 5 ~ 25

Heating : 25 ~ 55

Operating range

(Heat/Cool)

°C -20~35 / 10~46 -20~35 / 10~46 -20~35 / 10~46

Weight (net) Kg 112 112 112

Size (WxHxD, net) mm 940 x 1,420 x 330 940 x 1,420 x 330 940 x 1,420 x 330

6

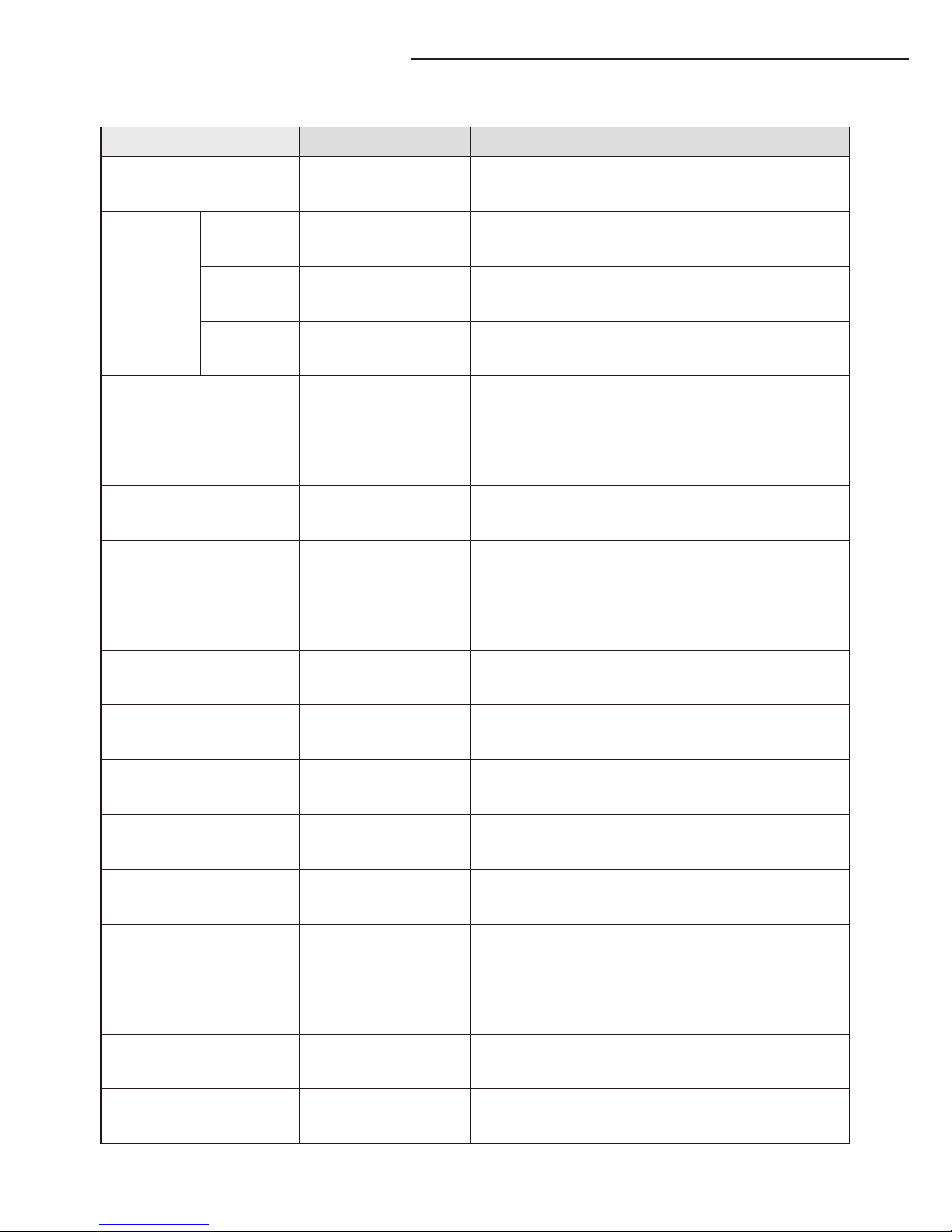

Product Specifications

Type

Unit RC090MHXEA

Power Source - 1P, 220~240VAC 50Hz

Nominal

Capacity

7°C kW 9

2°C kW 9

-15°C kW 7

COP (A7-W35) - 4.1

Compressor - Rotary Inverter

Condenser -

Brazing type

48 plates

Evaporator - Φ7, FP 1.6, L850

Fan & Motor -

Propeller, Φ520, 3-blade

BLDC Inverter

Flow Switch LPM

16 ± 1.5

Magnetic (decreasing)

Base Heater W 150

Refrigerant g 1,850 (R410A)

Noise

(Heat/Cool, Pressure)

dB 63/ 60

Water Connection

(In/Out)

Inch 1.0 / 1.0

Leaving Water Temperature °C

Cooling : 5 ~ 25

Heating : 25 ~ 55

Operating range

(Heat/Cool)

°C -20~35 / 10~46

Weight (net) Kg 83

Size (WxHxD, net) mm 940 x 998 x 330

ENGLISH

7

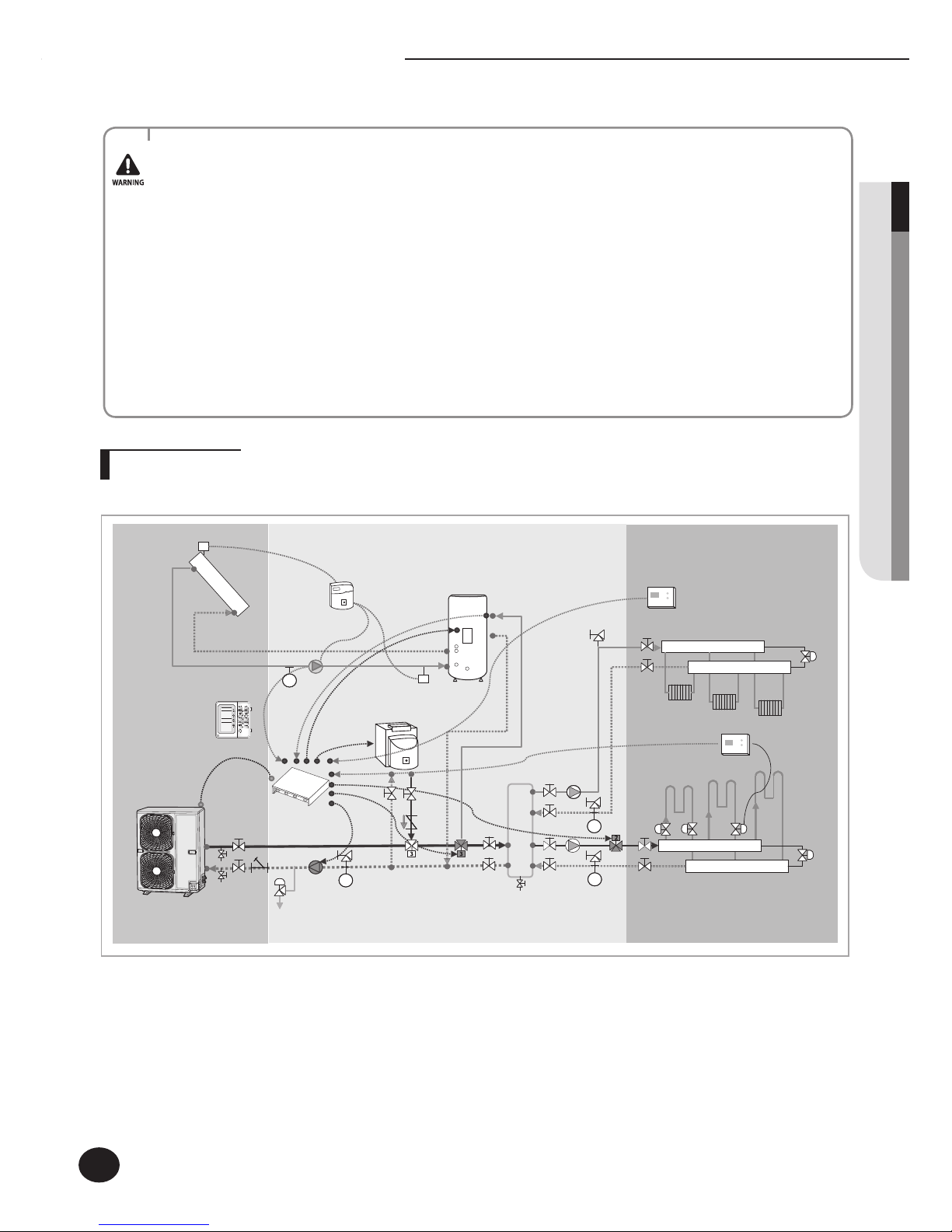

T

T

Solar Collector

1) Solar Signal Input

T

T

E

E

E

Return Header

Under-Floor Heating Coils

T

Supply Header

T

B

4) Zone Controller #1 (Radiators)

3-way Diverting valve

Supply Header

Radiators or Convectors

Return Header

Mixing Tank

Indoor

Secondary

Secondary

Pump #1

E

E

3) Back up Boiler

Operation Output

[Application #2]

Thermostatic

& Balancing Valves

[Application #3]

Differential Pressure

bypass valve

[Application #1]

Zone Thermostat

& 2-way Valve

45℃

40℃

50~55℃

Mechanical RoomOutdoor

2) DHW Sensor Input

& Booster Heater Output

Solar Pump

Control Kit

Outdoor unit

Primary

Pump

E

E

Air-vent

Drain

YRY

R

R

Pressure

Relief valve

3.0 bar

Expansion

Tank

Shut-Off &

Drain valve

Strainer

DHW tank

Air-vent

Air-vent

Air-ventAir-vent

5) Zone Controller #2 (UFHs)

6) 2way operation

7) 3way operation

8) Circulator for heat pump

Operation

Wired Controller

Pump #2

E

Booster Heater

Application Examples

E-7

•

The application examples given below are for illustration purposes only.

•

When the SAMSUNG Air-to-Water Heat Pump system is used in series with another heat source (e.g. gas boiler),

ensure that the return water temperature not exceed 55°C.

•

The unit is only to be used in a closed water system. Application in an open water circuit can lead to excessive

corrosion of the water piping.

•

SAMSUNG can not be put responsible for incorrect or unsafe situations in the water system. Make sure that the

boiler, radiators, convectors, solar collectors, UFHs, FCUs, additional pumps, pipings, and controls in the water

system are in accordance with relevant local laws and regulations under the installer's responsibility.

•

By-pass valve shall be installed for space heating loops. When one of loops or all loops are closed , water flow rate

could be low condition. To keep flow rate approximately and prevent flow stop, the by-pass valve shall be installed

between supply collector and return collector.

•

SAMSUNG shall not be held liable for any damage resulting from not observing this rule.

Application #1

Mono Outdoor + Control Kit

8

Application Examples

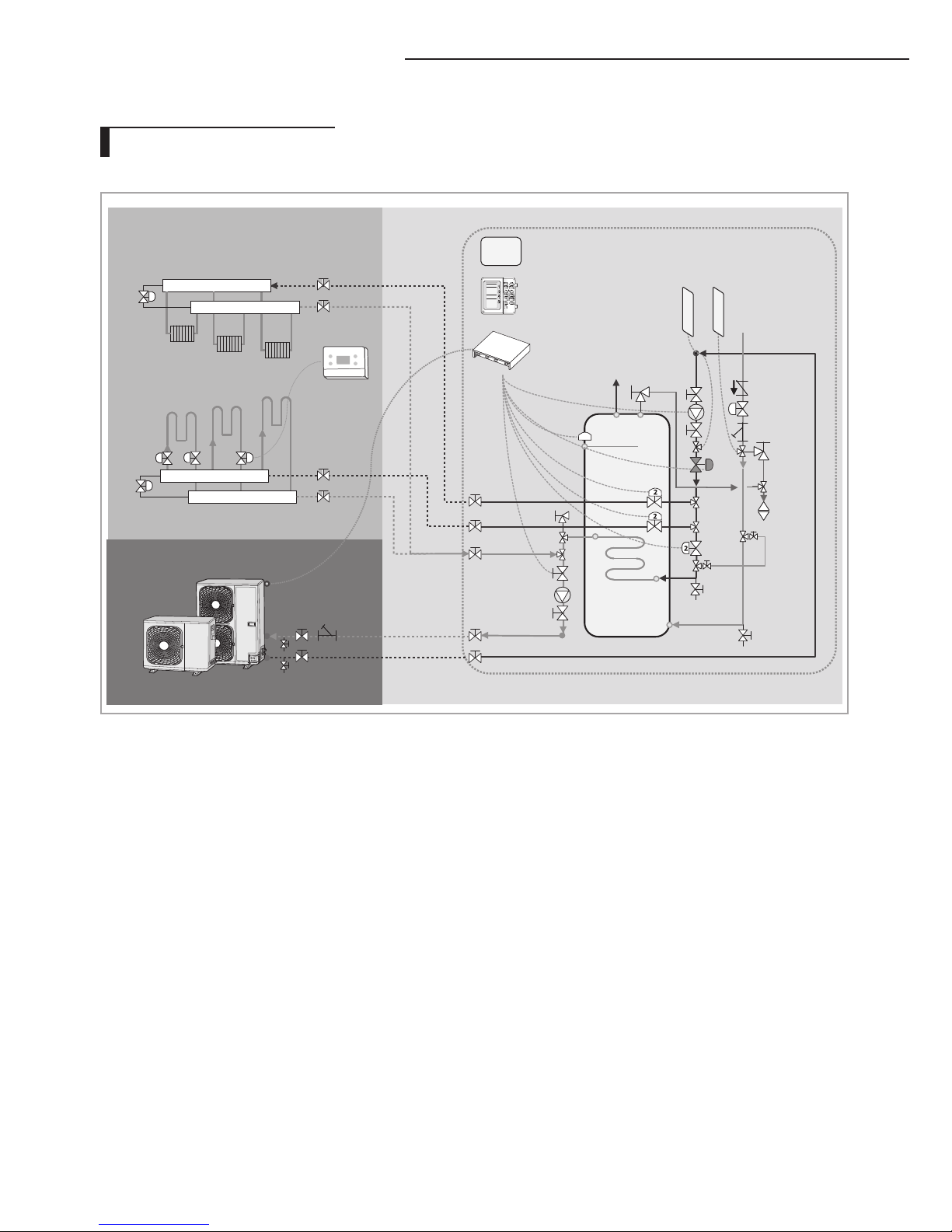

Application #2

Mono Outdoor + Cylinder Unit

Indoor

Outdoor

Return Header

Under-Floor Heating Coils

T

Supply Header

T

B

Supply Header

Radiators or Convectors

Return Header

Cylinder Unit

Outdoor unit

Room Thermostat

(Wireless)

Control Kit

(provided by SAMSUNG)

Wired Controller

RF Receiver

Hot water Supply

From City Water

Expansion Vessel

PP

FF

T

ENGLISH

9

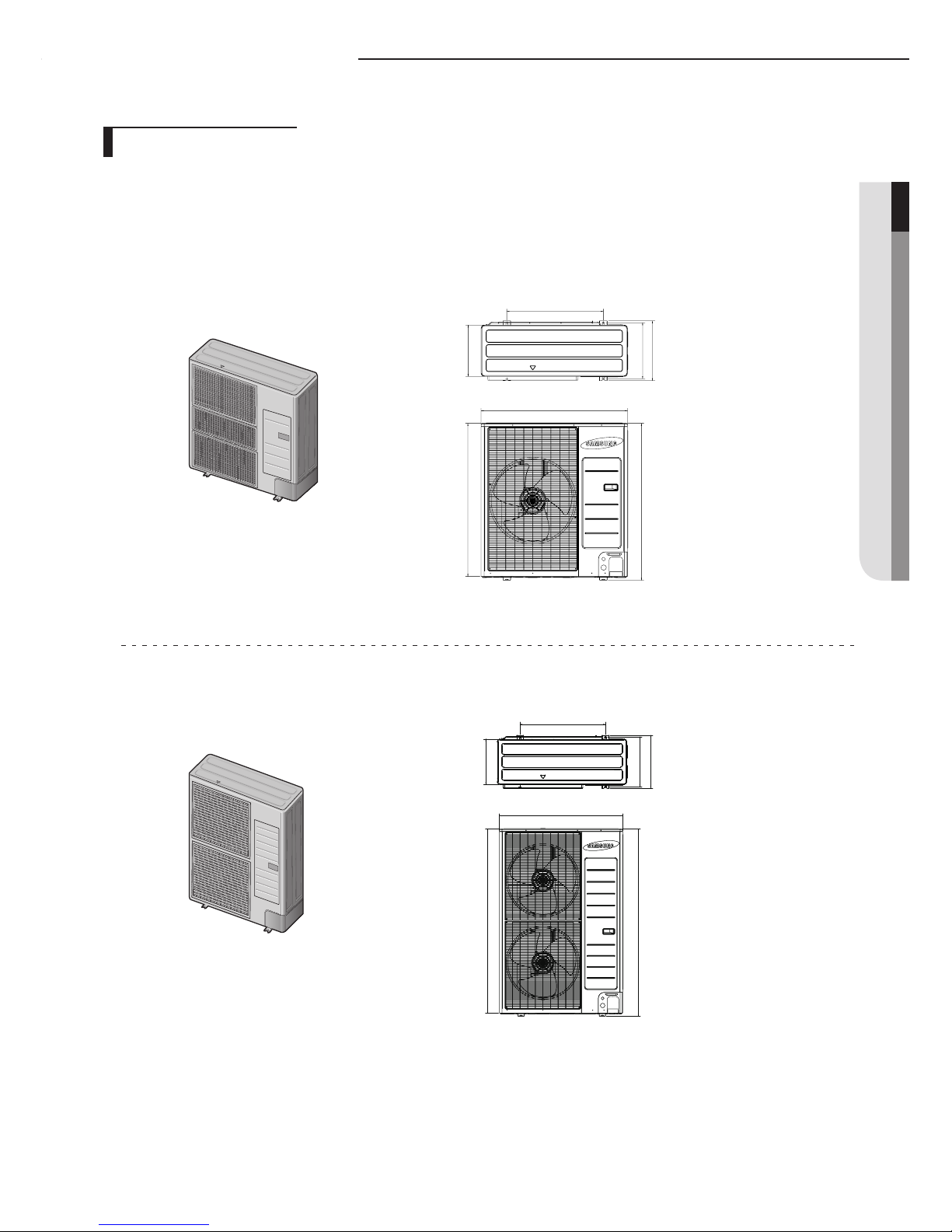

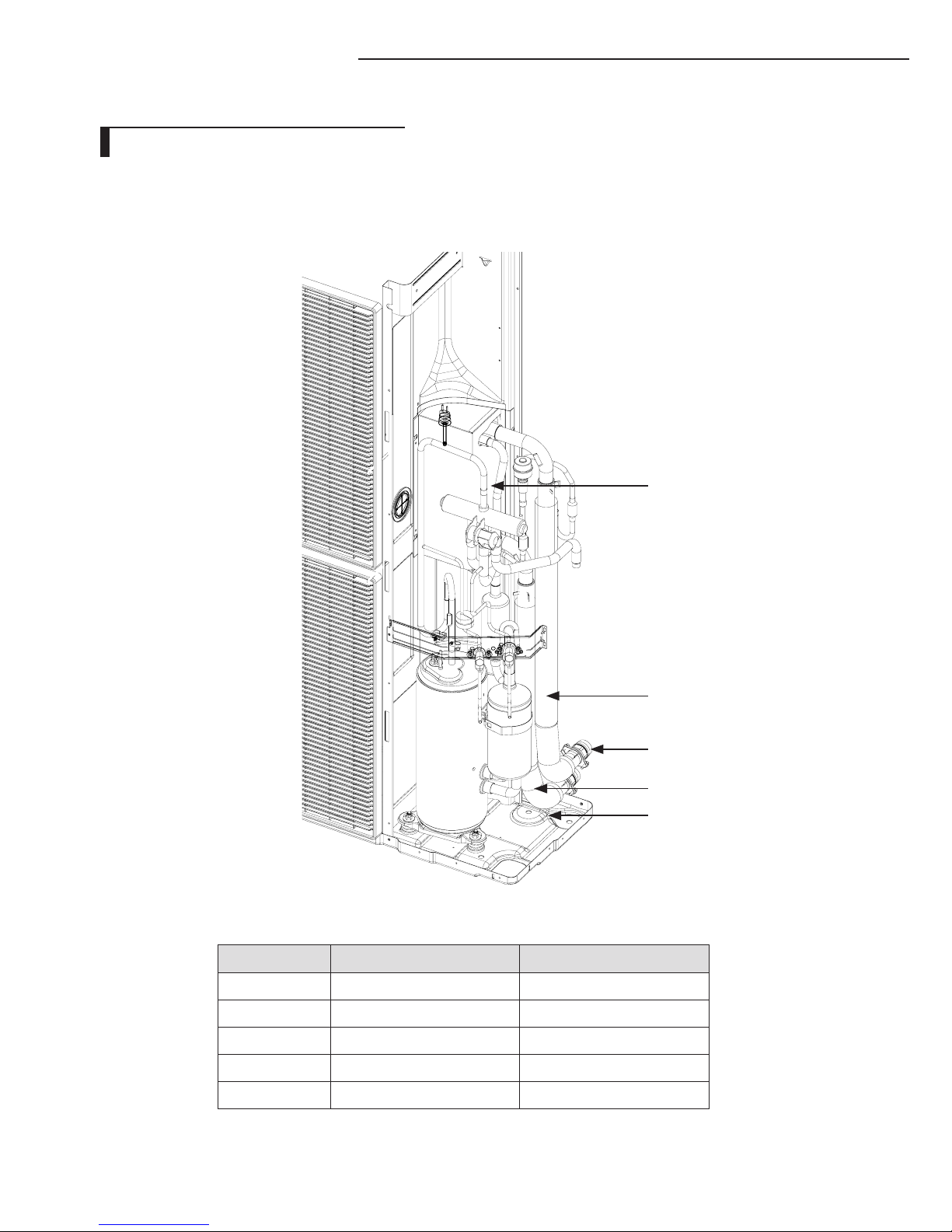

Main Components

Heat Pump for R410A.

1-Fan Chassis:

RC090MHX

2-Fan Chassis:

RC120MHX/RC140MHX/RC160MHX

620

940

330973

998

528

537

675

360

384

Dimensions(Overall)

620

330

360

384

940

1395

1420

10

Main Components

Dimensions (Water pipe)

513.4

151.5

83.5

244.4

(Unit : mm)(Unit : mm)

RC090MHX

RC120MHX/RC140MHX/RC160MHX

ENGLISH

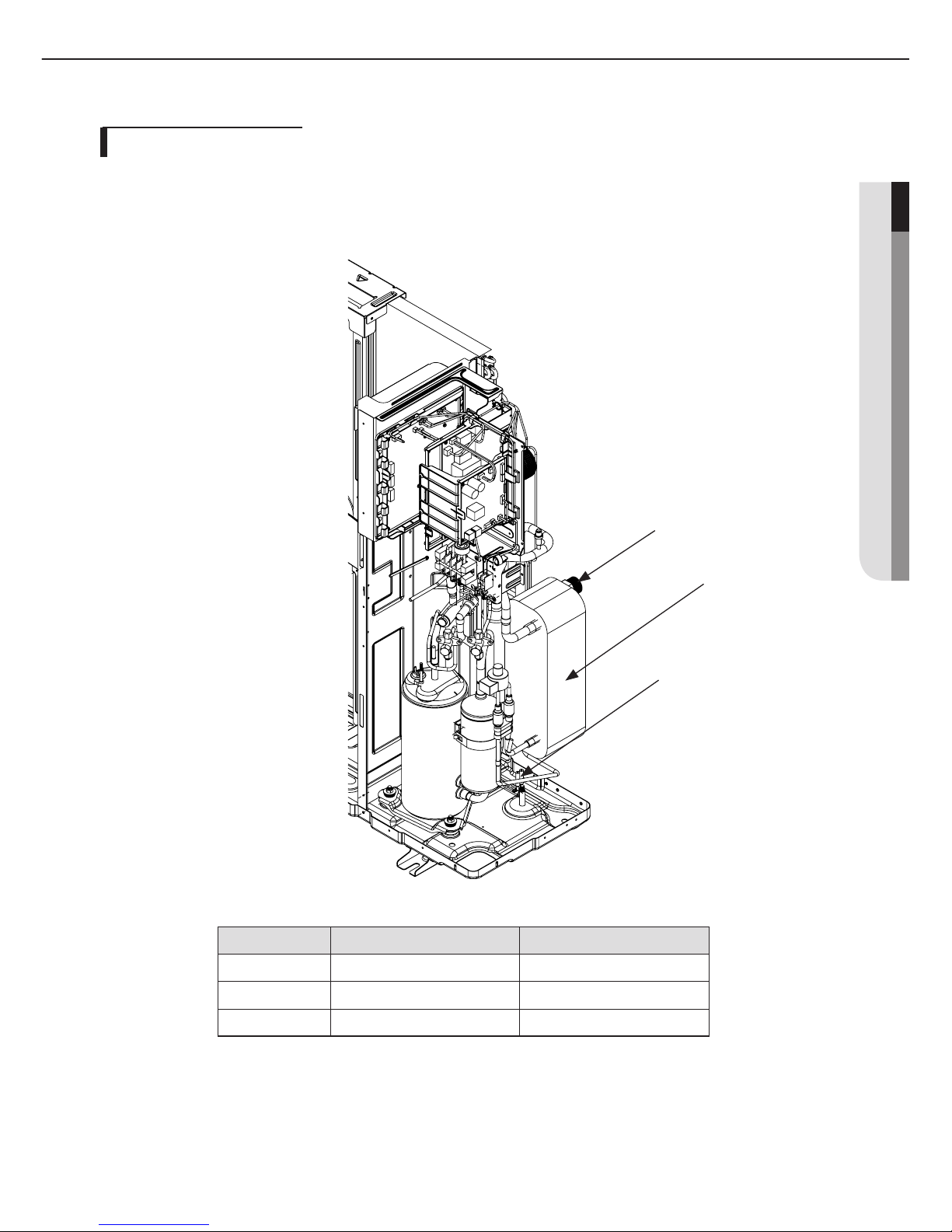

11

NO. Name Note.

1 PHE 48P

2 Base Heater SUS316L, 150W

3 Water fitting BSPP 1" Male

③

①

②

Components(RC090)

12

Main Components

NO. Name Note.

1 PHE 72P

2 Base Heater SUS316L, 150W

3 Water Hose In Rubber Hose

4 Water Hose Out Rubber Hose

5 Water fitting BSPP 1" Male

①

④

③

⑤

②

Components(RC120/140/160)

ENGLISH

13

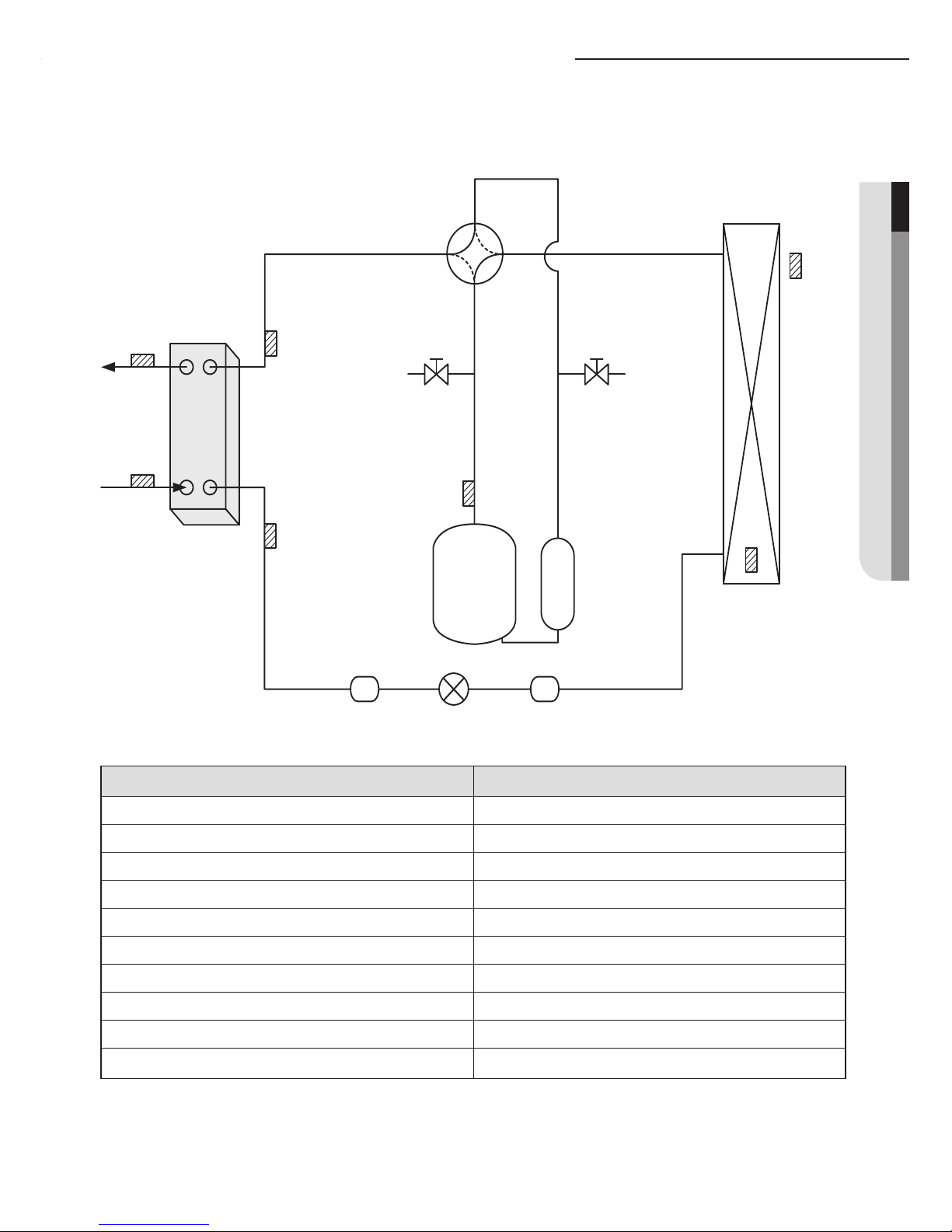

Functional Diagram (RC090MHX)

Part Description

PHE

Plate heat exchanger

T/S #1 For water outlet temp sensor

T/S #2 For water inlet temp sensor

T/S #3 For PHE In temp

T/S #4 For PHE Out temp

T/S #5 For discharge temp

T/S #6

For Cond temp

T/S #7 For Ambient temp sensor

S/V Service valve ¼ inch

Accum ACCUMULATOR

PHE

T/S #3

T/S #4

S/V S/V

4WAY

v/v

T/S #5

Comp

Filter

Filter

Exp. v/v

Accum

T/S #6

T/S #7

T/S #1

T/S #2

14

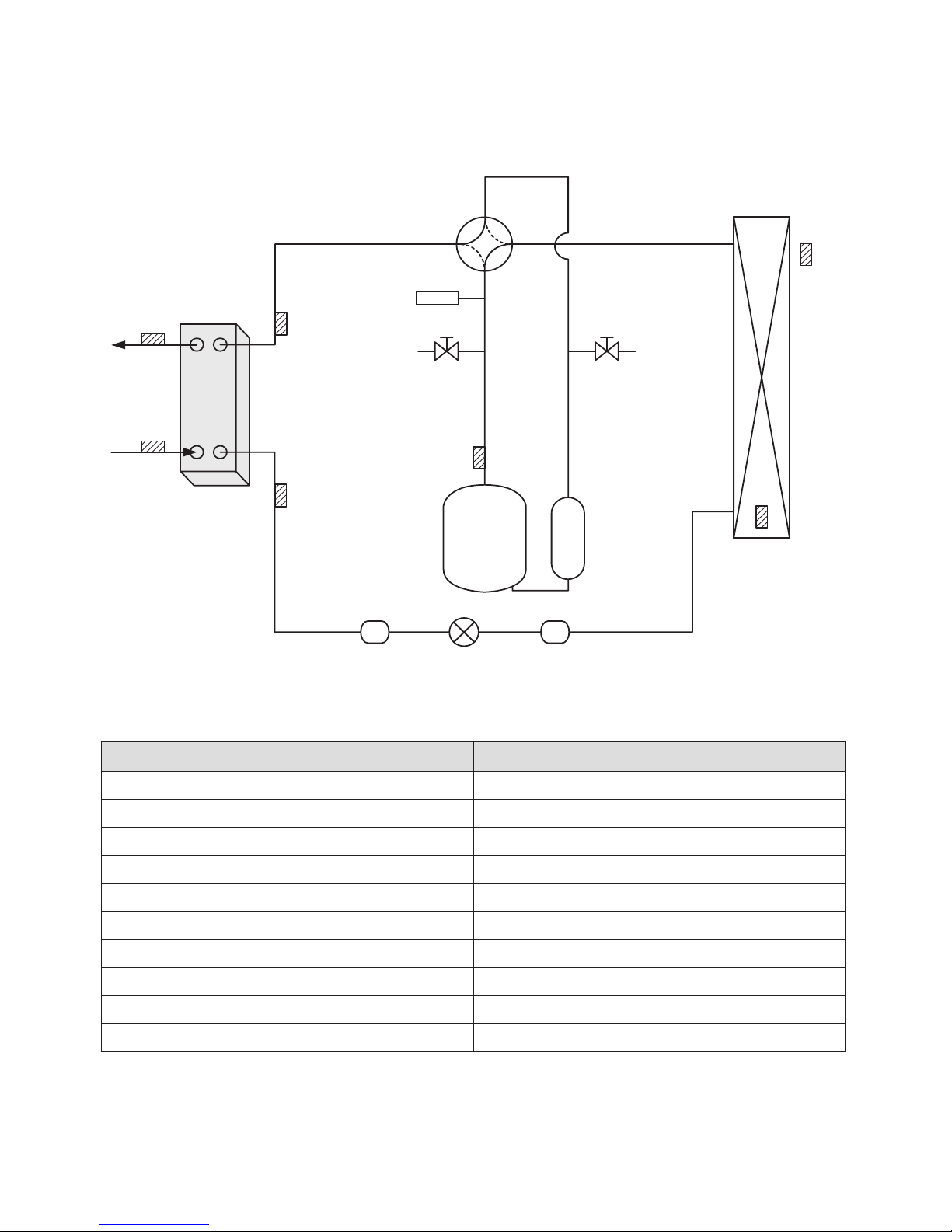

Functional Diagram (RC120MHX/RC140MHX/RC160MHX)

Part Description

PHE Plate heat exchanger

T/S #1 For water outlet temp sensor

T/S #2 For water inlet temp sensor

T/S #3 For PHE In temp

T/S #4

For PHE Out temp

T/S #5 For discharge temp

T/S #6 For Cond temp

T/S #7 For Ambient temp sensor

S/V Service valve ¼ inch

Accum ACCUMULATOR

PHE

T/S #3

T/S #4

S/V S/V

4WAY

v/v

T/S #5

Comp

Filter

HP s/w

Filter

Exp. v/v

Accum

T/S #6

T/S #7

T/S #1

T/S #2

Loading...

Loading...