Samsung RB1955SWRB1955SH, RB1955SW, RB1955SH, RB1955VQ, RB2155SW Service Manual

...

RB1955SW

RB1955SH

RB1955VQ

RB2155SW

RB2155SH

RB2155BB

Model:

Bottom-Mounted Freezer

SAMSUNG Home Appliance Service

2

IMPORTANT SAFETY NOTICE

The service guide is for service men with adequate backgrounds of

electrical, electronic, and mechanical experience. Any attempt to repair a

major appliance may result in personal injury and property damage. The

manufacturer or dealer cannot be responsible for the interpretation of this

informatio

n.

SAMSUNG ELECTRONICS AMERICA, INC.

Technical Service Guide

Copyright ⓒ2004

All rights reserved. This service guide may not be reproduced in whole or in

part in any form without written per mission from the SAMSUNG ELECTRONICS

Company.

WARNING

3

Contents

1. Installation

······································

4

2. Nomenclature

····································

4

3. Product Specifications

·······························

5

4. Electrical part specifications & standard

·····················

5

5. Warranty information

································

7

6. Interior Views and Dimensions

···························

8

7. Refrigeration Cycle and Cool Air Circulation Route

···············

10

8. Mechanical Disassembly

······························

12

9. Operation Function

·································

19

10.

Circuit Descriptions

································

26

11. Diagnostics

·····································

34

12. Illustrated Parts Catalog

·····························

48

13. Safety instruction on services

··························

56

●

Appendix ⅠⅠ(Reference for circuit diagnostics)

·················

57

●

Appendix ⅡⅡ(Circuit diagram)

···························

61

4

1. INSTALLATION

2. NOMENCLATURE

1) T o pr otect refrigerator in movement

Use padded hand truck from side only.

2) Remove all protective tape and pad fr om the refrigerators.

Connect power cord. Adjust the clearance between the doors.

3) Temperature contr ols ar d preset in the factory for

recommended settings.

The refrigerator should runs smoothly and lower the

temperature gradually.

4) Once the refrigerator temperature is sufficiently low

It is recommended to store foods in the refrigerator .

It takes a fe w hours to reach the preset temperatures .

2004 Models

R

B

19

55

SW

/

XAA

Product ; R - REFRIGERATOR

Capacity ; CU. FT

B - BOTTOM MOUNTED FREEZER (BMF)

OPTION ; 55-NO DISPENSER 77-DISPENSER

COLOR ; SW-SNOW WHITE SH-STAINLESS PLATINUM

VQ-BISQUE GLOSSY BB-BLACK

Buyer code

Label Location

5

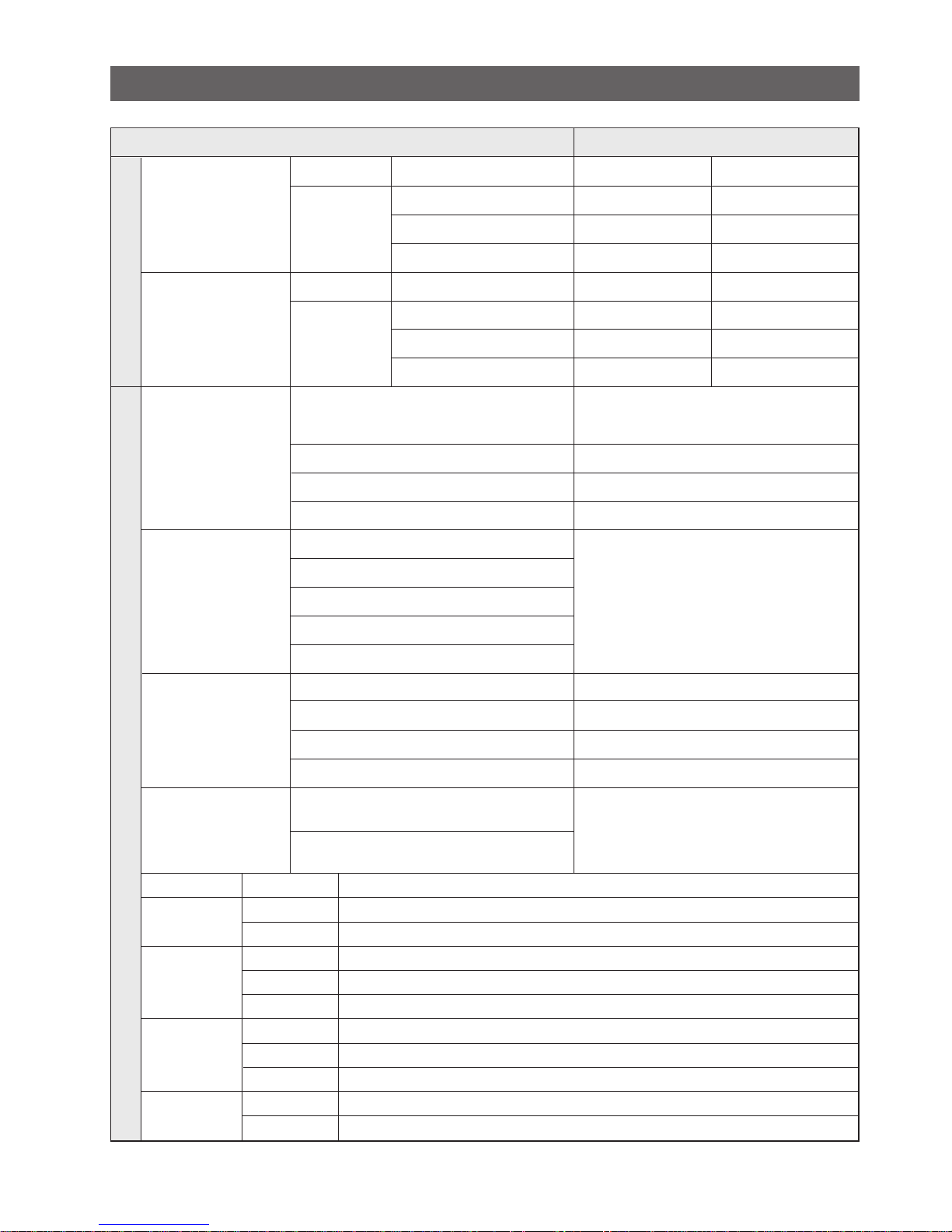

3. PRODUCT SPECIFICATIONS

4. ELECTRICAL PART SPECIFICATIONS & STANDARD

MK172C-L2U

115V

60HZ

RSCR

R134a

Freol α-10c(Ester), 265cc

Split Fin & Tube Type

Split Fin & Tube Type

Forced & Natural Convection Type

Molecular Sieve XH-9

ID0.82

X

L3000

BSBN(Brass screw)

AC125V 1.4A(SSD-6D)

Condenser

Dryer

Capillary tube

Earth screw

Door switch

Model

Starting type

Refrigerant

Oil Charge

Freezer

Refrigerator

Evaporator

Compressor

RB1955SW/SH/VQ RB2155SW/SH/BB

BMF 2 Door

Electronic control

CYCLO-PENTANE

CYCLO-PENTANE

A.B.S

A.B.S

227

241

32.3X28.3X69.9 32.3X30.3X69.9

Model

Type

Temperature control

Total

Freezer

Refrigerator

Net Capacity

(ft

3

)

Cabinet insulation

Door insulation

Cabinet

Door

Liner

Foam

Net weight(Ib)

Net dimension

(W

XDX

H)

18.7

5.9

12.8

20.4

6.5

13.9

STANDARD

ITEM

Model

Rated Voltage

Frequency

RB1955SW/SH/VQ RB2155SW/SH/BB

ELECTRICAL PART SPECIFICATIONS & STANDARD

6

RSCR 250VAC, 12㎌

4TM437RHBYY-53

130±5

69±9

J531Q33E100M200-2

10±20%

IS3210-SNP6D

IS3208-SNP6H

IS3208-SCH6A

ITEM STANDARD

Min. 12hrs, Max. 22Hrs

Min. 6hrs, Max. 11Hrs

10±2min

4hr

±

10min

THERMISTOR (502AT), SPEC:5.0K

Ω

AT 77

℉

Freezer

Type

F-Sensor

Type

R-Sensor

ON(℉)

–12.0℉

0℉

10℉

ON(℉)

36℉

42℉

48℉

Temperature Selection

–14℉

–2℉

8℉

Temperature Selection

34℉

40℉

46℉

OFF(℉)

–16.0℉

–4℉

6℉

OFF(℉)

32℉

38℉

44℉

Refrigerator

Defrosting

Sensor

Heater

Fuse

First Defrost Cycle

(Concurrent Defrost of F and R)

Defrost Cycle(FRE)

Defrost Cycle(REF)

Pause Time

Freezer-Sensor

Refrigerator-Sensor

FRE Evap-Sensor

REF Evap-Sensor

Ambient TEMP-Sensor

Defrost Heater(FRE)

Drain Heater(FRE)

Defrost Heater(REF)

Drain Heater(REF)

TemperatureElectrical parts

242W

52W

120W

38W

AC250V 10A 77±5˚C

Thermal-Fuse for preventing

overheating of Freezer Defrost-Heater

Thermal-Fuse for preventing

overheating of Freezer Defrost-Heater

110V-130V/15W

110V-130/30W

Capacitor

Over-Load

Protector

STARTING-

RELA Y

MOT OR-F AN

LAMP

RUNNING

MODEL

TEMP. ON

TEMP. OFF

MODEL

OPERATION

FRE.

REF.

CIRCUIT

FRE

(INCANDESCENT)

REF

(INCANDESCENT)

5. WARRANTY INFORMATION

7

8

• Deli drawer

Pull it out to disassemble.

•

Door Bin

Push it up and slide it out

to disassemble.

• Glass Shelf

Pull it out until its stop

Tilt down and slide it out.

• Ice trays

• Vegetable Drawer

• Gallon Bin

Light

• Freezer Drawer

•

•

•

•

•

•

•

6. Interior Views and Dimensions

6-1) Shelves and Bins

9

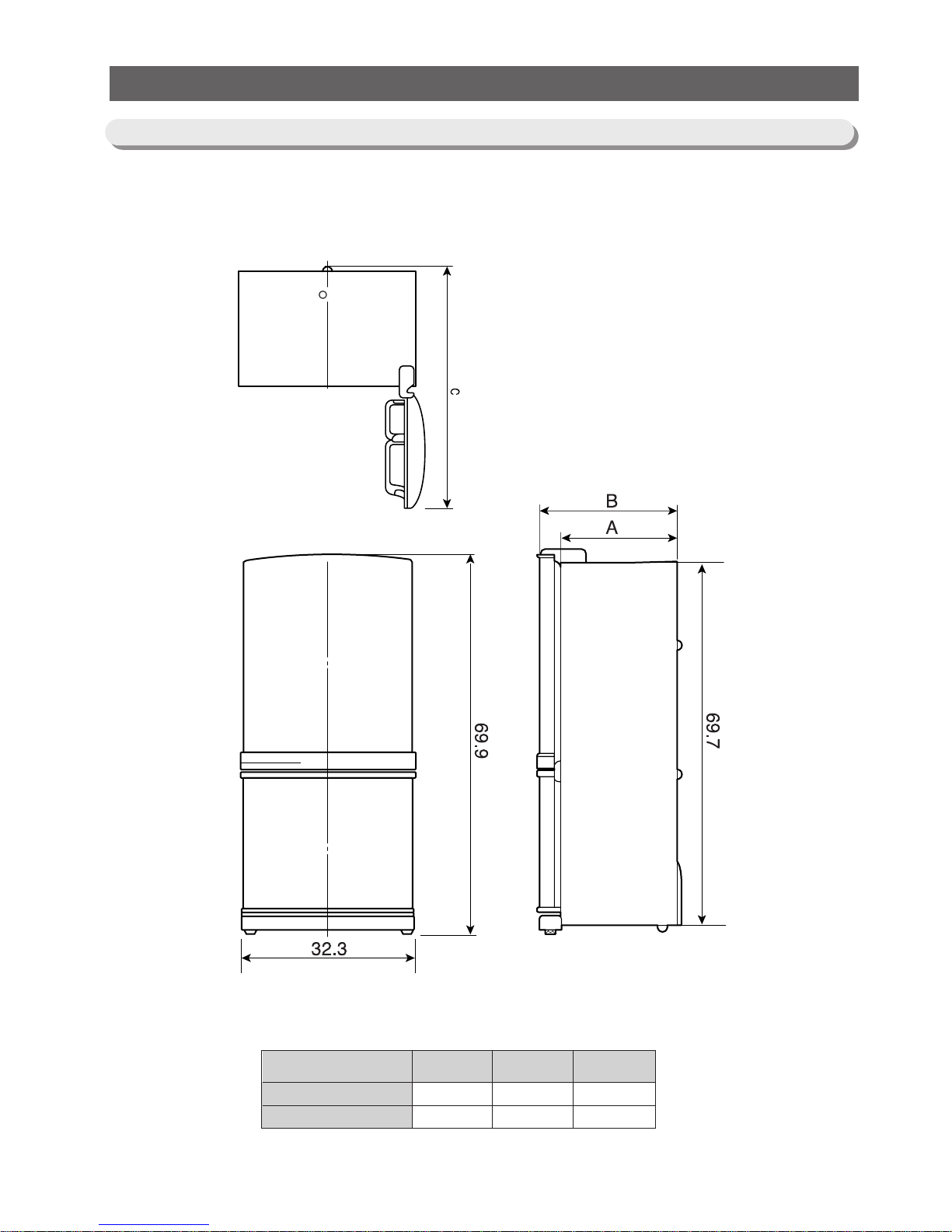

Interior Views and Dimensions

MODEL

RB1955

RB2155

A

24.3

26.3

B

28.3

30.3

C

57.8

59.8

6-2) Dimensions of Refrigerator (Inches)

10

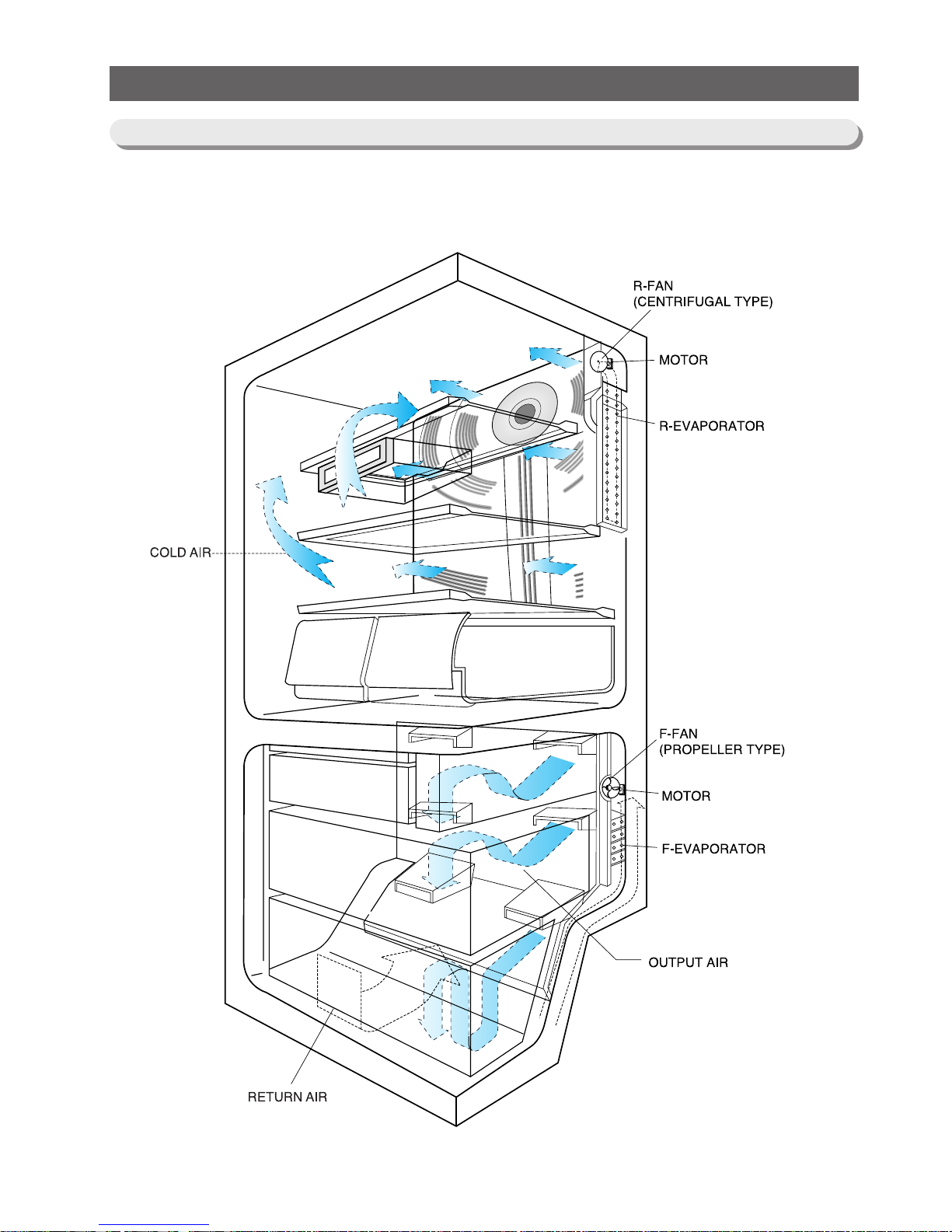

7. Refrigeration Cycle and Cool Air Circulation Route

Compressor → Sub condenser → Cluster pipe → Hot pipe → Dryer → Capillary tube

→ R-Evaporator → F-Evaporator → Accumulator → Suction pipe → Compressor

7-1) Refrigerant Route in Refrigeration cycle

11

Refrigeration Cycle and Cool Air Circulation Route

7-2) Cool Air Circulation

12

8.

Mechanical Disassembly

Refrigerator Disassembly

Control Panel ········································ 13

Refrigerator Light

······································ 14

Freezer Light

········································ 14

Evaporator Cover in the Refrigerator

·························· 15

Evaporator Cover in the Freezer

····························· 16

Evaporator in the Freezer

································· 17

Evaporator in the Refrigerator

······························ 17

Machine Compartment & Electric Box

··························18

13

Mechanical Disassembly

1. Remove the screws.

2. Pull out the control panel.

3. Disconnect the wire connector.

Control Panel

14

Mechanical Disassembly

1. Remove the screw.

2. Remove the lamp cover by unlocking the tabs

and pulling the cover down.

3. Replace the lightbulb by turning it counterclockwise.

4. After replacing the bulb, reattach the cover

and the screw it again.

5. Plug the power cord in and check the lamp by

pressing the R-door switch.

Always unplug the power cord before replacing the refrigerator lamp.

There is the danger of electric shock.

1. Remove the cover by pressing the bottom tab.

2. Replace the lightbulb by turning it counter-clock

wise.

3. Reattach the cover and check the lamp by

pressing door switch.

Warning

Refrigerator Light

Freezer Light

15

Mechanical Disassembly

1. Remove all shelves and drawers from the

refrigerator.

2. Pull out the screw caps with a small flat-blade

screwdriver.

3. Remove 6 Phillps screws from the cover.

4. Unlock the 2 tabs with a flat-blade screwdriver

on each side of the bottom cover.

5. Remove the evaporator cover by pulling out

from the bottom of the evaporator cover.

Evaporator Cover in the Refrigerator

6. Disconnect the wire connector.

■Ductwork of the evaporator fan assembly.

16

6. Remove 2 screws from the rear cover of the

freezer evaporator and unlock the tabs to

remove it.

Mechanical Disassembly

1.

Remove all drawers from the freezer.

2. Remove screws (2) from the support rail.

3. Pull down the holder of the support rail and

disconnect the wire connector to remove it.

4. Unlock the tabs around the evaporator cover

from the buttom.

5. Disconnect wire connector from the top-left

corner.

2 screws

①

①

②

③

②

Evaporator Cover in Freezer

Mechanical Disassembly

17

Evaporator in Freezer

Accumulator

Thermistor

Thermal

Fuse

Evaporator is located in the bottom of freezer to

produce cold air driven across the evaporator coils.

1. Take off the ductwork in Freezer.

2. Disconnect the wire connector (Heater,

Bimental, and Thermistor).

3. Desolder the inlet and outlet tubes.

4. Remove the evaporator.

5. Take the same steps to seal the system as

mentioned earlier.

Evaporator is located in the bottom of refrigerator.

1. Take off the ductwork in refrigerator.

2. Disconnect the wire connector.(Heater and

Thermistor)

3. Desolder the capillary tube and the suction line

from the evaporator.

4. Remove the evaporator.

5. With a file, score the capillary tube just

upstream of the soldered point. Break off the

soldered section to help prevent solder from

plugging the tube during soldering.

6. Place a new evaporator and braze the suction

and capillary tube to evaporator using silver

solder.

7. Install a replacement dryer.

8. Evacuate and recharge the system using

reasonable procedures.

Evaporator in Refrigerator

Thermal

Fuse

Thermistor

18

1. Unplug the power cord.

5. Electric box assembly

Make sure the power cord is

unplugged before replacing any

electric components.

Mechanical Disassembly

2. Remove the screws of the compartment cover.

Slide it up and take out from the refrigerator.

3. Mechine compartment assembly

Machine Compartment &&Electric Box

Warning

4. Disassemble the electric box cover after

removing the screws with a Phillips screwdriver.

9. Operation Function

19

9-1) Digital Panel ···································20

9-2) Temperature Control Function

·························20

9-3) Power Freeze and Power cool Functions

··················· 20

9-4) Sound Function

································· 21

9-5) Defrost Function

································· 21

9-6) Forced Operation Function

··························· 22

9-7) Power failure compensating Function

····················· 23

9-8) Exhibition Function

······························· 23

9-9) Self - Diagnostics Function

··························· 23

9-10) Component Load Operation Function.

···················· 24

9-11) C-Fan Motor Delay function

·························· 25

Loading...

Loading...