Page 1

PLASMA DISPLAY TV CONTENTS

1. Precaution

2. Product Specification

3. Disassembly & Reassembly

4. Troubleshooting

5. Exploded View & Part List

6. Wiring Diagram

7. Schematic Diagram

SERVICE

Manual

PN42A450P1D

PLASMA DISPLAY TV

Chassis : F45A(N_HD)_Pyrope

Model : PN42A450P1DXZC

Refer to the service manual in the GSPN (see the rear cover) for the more information.

Page 2

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© Samsung Electronics Co., Ltd. Mar. 2008

Printed in Korea

AA82-05103A

Area Web Site

North America service.samsungportal.com

Latin America latin.samsungportal.com

CIS cis.samsungportal.com

Europe europe.samsungportal.com

China china.samsungportal.com

Asia asia.samsungportal.com

Mideast & Africa mea.samsungportal.com

GSPN (Global Service Partner Network)

Page 3

Table of Contents

Chapter 1 Precaution

■ 1-1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

■ 1-2 Servicing Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

■ 1-3 Static Electricity Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

■ 1-4 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2 Product Specification

■ 2-1 Product Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

■ 2-2 Specifications Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

■ 2-3 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3 Disassembly & Reassembly

■ 3-1 Overall Disassembly & Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Chapter 4 Troubleshooting

■ 4-1 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

■ 4-2 Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

■ 4-3 Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-32

Chapter 5 Exploded View & Part List

■ 5-1 PN42A450P1DXZC Exploded View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

■ 5-2 PN42A450P1DXZC Service Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Chapter 6 Wiring Diagram

■ 6-1 Overall Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Chapter 7 Schematic Diagram

■ 7-1 Circuit Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

■ 7-2 Schematic Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Page 4

1. Make sure all protective devices are properly installed

including non-metallic handles and compartment covers

when installing or re-installing the chassis or chassis

assemblies.

2. Make sure that no gaps exist between the cabinets for

children to insert their fingers in to prevent children from

receiving electric shocks. Gaps mentioned above include

ventilation holes between the PDP module and the cabinet mask, and the improper installation of the rear cabinet.

Errors may occur when the resistance is below 1.0 ㏁ or

over 5.2 ㏁.

In these cases, make sure that the device is repaired

before sending it back to the customer.

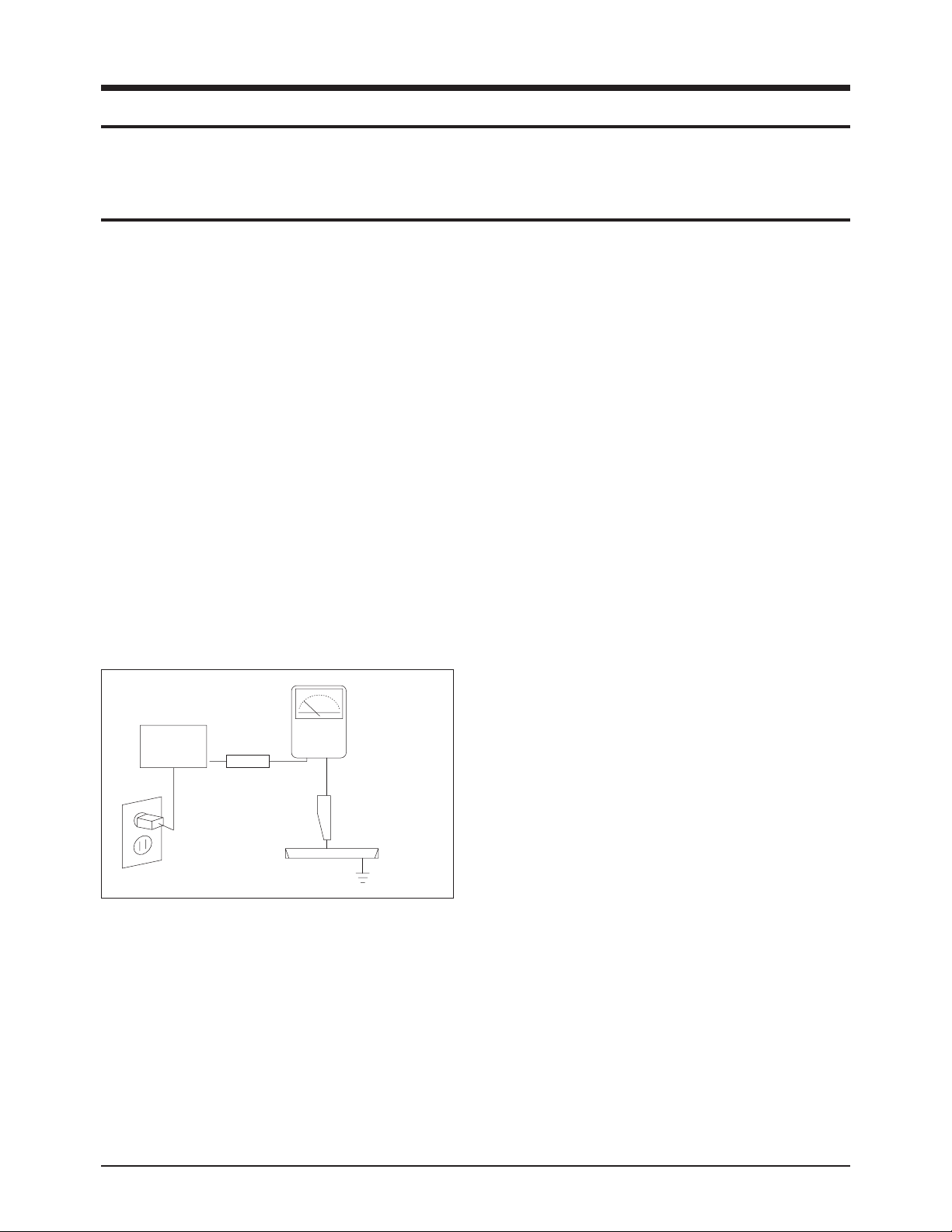

3. Check for Electricity Leakage (Figure 1-1)

Warning: Do not use an insulated transformer for checking the leakage. Use only those current leakage testers

or mirroring systems that comply with ANSIC 101.1 and

the Underwriter Laboratory's specifications (UL1410,

59.7).

Fig. 1-1 AC Leakage Test

4. Ahigh voltage is maintained within the specified limits

using safety parts, calibration and tolerances. When

voltage exceeds the specified limits, check each special

part.

5. Warning for Engineering Changes:

Never make any changes or additions to the circuit

design or the internal part for this product.

Ex: Do not add any audio or video accessory

connectors. This might cause physical damage.

Furthermore, any changes or additions to the original

design/engineering will invalidate the warranty.

6. Warning - Hot Chassis:

Some TV chassis are directly connected to one end of

the AC power cord for electrical reasons.

Without insulated transformers, the product can only be

repaired safely when the chassis is connected to the

earth end of the AC power source.

To make sure the AC power cord is properly connected,

follow the instructions below. Use the voltmeter to

measure the voltage between the chassis and the

earth ground. If the measurement is over 1.0V, unplug

the AC power cord and change the polarity before reinserting it. Measure the voltage between the chassis

and the ground again.

7. Some TV chassis are shipped with an additional secondary grounding system. The secondary system is

adjacent to the AC power line. These two grounding

systems are separated in the circuit using an unbreakable/unchangeable insulation material.

8. When any parts, material or wiring appear overheated or

damaged, replace them with new immediately. When

any damage or overheating is detected, correct this

immediately and make a regular check of possible

errors.

9. Check for the original shape of the lead, especially that

of the antenna wiring, any sharp edges, the AC power

and the high voltage power. Carefully check if the wiring

is too tight, incorrectly placed or loose. Never change the

space between the part and the printed circuit board.

Check the AC power cord for possible damages. Keep

the part or the lead away from any heat-emitting

materials.

Precaution

Samsung Electronics 1-1

To avoid possible damage, electric shocks or exposure to radiation, follow the instructions below with regard to safety, installation, service and ESD.

1. Precaution

1-1 Safety Precautions

(READING SHOULD

DEVICE

UNDER

TEST

EXPOSED METAL

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

SURFACES

LEAKAGE

CURRENT

TESTER

NOT BE ABOVE

0.5mA)

EARTH

GROUND

Page 5

10. Safety Indication:

Some electrical circuits or device related materials

require special attention to their safety features, which

cannot be viewed by the naked eye. If an original part is

replaced with another irregular one, the safety or

protective features will be lost even if the new one has a

higher voltage or more watts.

Critical safety parts should be bracketed with ( ).

Use only regular parts for replacements (in particular,

flame resistance and dielectric strength specifications).

Irregular parts or materials may cause electric shock or

fire.

Precaution

1-2 Samsung Electronics

!

Page 6

1. The service instructions are printed on the cabinet, and

should be followed by any service personnel.

2. Make sure to unplug the AC power cord from the power

source before starting any repairs.

(a) Remove or re-install parts or assemblies.

(b) Disconnect the electric plug or connector, if any.

(c) Connect the test part in parallel with the electrolytic

capacitor.

3. Some parts are placed at a higher position than the

printed board. Insulated tubes or tapes are used for this

purpose. The internal wiring is clamped using buckles to

avoid contact with heat emitting parts. These parts are

installed back to their original position.

4. After the repair, make sure to check if the screws, parts

or cables are properly installed. Make sure no damage is

caused to the repaired part and its surroundings.

5. Check for insulation between the blade of the AC plug

and that of any conductive materials (i.e. the metal

panel, input terminal, earphone jack, etc).

6. Insulation Check Process: Unplug the power cord from

the AC source and turn the switch on. Connect the insulating resistance meter (500v) to the AC plug blade.

The insulating resistance between the blade of the AC

plug and that of the conductive material should be more

than 1 ㏁.

7. Any B+ interlock should not be damaged.

If the metal heat sink is not properly installed, no

connection to the AC power should be made.

8. Make sure the grounding lead of the tester is connected

to the chassis ground before connecting to the positive

lead. The ground lead of the tester should be removed

last.

9. Beware of risks of any current leakage coming into

contact with the high-capacity capacitor.

10. The sharp edges of the metal material may cause

physical damage, so protect yourself by wearing gloves

during the repair.

11. Due to the nature of plasma display panels, partial afterimages may appear if a still picture is displayed on the

screen for a long period of time.

This is caused by brightness deterioration due to the

storage effect of the panel, and to prevent this from

happening, we recommend that the brightness and contrast are reduced.

(e.g.) Contrast: 25, Brightness: 50

Precaution

Samsung Electronics 1-3

Warning 1: First carefully read the "Safety Instruction" in this service manual.

When there is a conflict between the service and the safety instructions, follow the safety instruction at all times.

Warning 2: Any electrolytic capacitor with the wrong polarity will explode.

1-2 Servicing Precautions

Page 7

1-3 Static Electricity Precautions

1. Some semi-conductive ("solid state") devices are

vulnerable to static electricity. These devices are known

as ESD. ESD includes the integrated circuit and the field

effect transistor. To avoid any materials damage from

electrostatic shock, follow the instructions described

below.

2. Remove any static electricity from your body by

connecting the earth ground before handling any

semi-conductive parts or assemblies. Alternatively,

wear a dischargeable wrist-belt.

(Make sure to remove any static electricity before

connecting the power source - this is a safety instruction

for avoiding electric shock)

3. Remove the ESD assembly and place it on a conductive

surface such as aluminum foil to prevent accumulating

static electricity.

4. Do not use any Freon-based chemicals.

Such chemicals will generate static electricity that

causes damage to the ESD.

5. Use only grounded-tip irons for soldering purposes.

6. Use only anti-static solder removal devices.

Most solder removal devices do not support an

anti-static feature. Asolder removal device without an

anti-static feature can store enough static electricity to

cause damage to the ESD.

7. Do not remove the ESD from the protective box until the

replacement is ready. Most ESD replacements are

covered with lead, which will cause a short to the entire

unit due to the conductive foam, aluminum foil or other

conductive materials.

8. Remove the protective material from the ESD

replacement lead immediately after connecting it to the

chassis or circuit assembly.

9. Take extreme caution in handling any uncovered ESD

replacements. Actions such as brushing clothes or lifting

your leg from the carpet floor can generate enough static

electricity to damage the ESD.

Precaution

1-4 Samsung Electronics

CAUTION

These servicing instructions are for use by

qualified service personnel only.

To reduce the risk of electric shock do not

perform any servicing other than that contained in the

operating instructions unless you are qualified to do so.

Page 8

Precaution

Samsung Electronics 1-5

1-4 Installation Precautions

1. For safety reasons, more than two people are required

for carrying the product.

2. Keep the power cord away from any heat emitting

devices, as a melted covering may cause fire or electric

shock.

3. Do not place the product in areas with poor ventilation

such as a bookshelf or closet. The increased internal

temperature may cause fire.

4. Bend the external antenna cable when connecting it to

the product. This is a measure to protect it from being

exposed to moisture. Otherwise, it may cause a fire or

electric shock.

5. Make sure to turn the power off and unplug the power

cord from the outlet before repositioning the product.

Also check the antenna cable or the external connectors

if they are fully unplugged. Damage to the cord may

cause fire or electric shock.

6. Keep the antenna far away from any high-voltage cables

and install it firmly. Contact with the high-voltage cable or

the antenna falling over may cause fire or electric shock.

7. When connecting the RF antenna, check for a DTV

receiving system and install a separate DTV reception

antenna for areas with no DTV signal.

8. When installing the product, leave enough space (4")

between the product and the wall for ventilation

purposes.

Arise in temperature within the product may cause fire.

9. When moving a PDP with removable speakers, detach

the speakers first before moving the main body.

Moving the PDP main body without separating the

speakers may cause the speakers to detach, possibly

causing damage or injury.

Page 9

1-6 Samsung Electronics

MEMO

Page 10

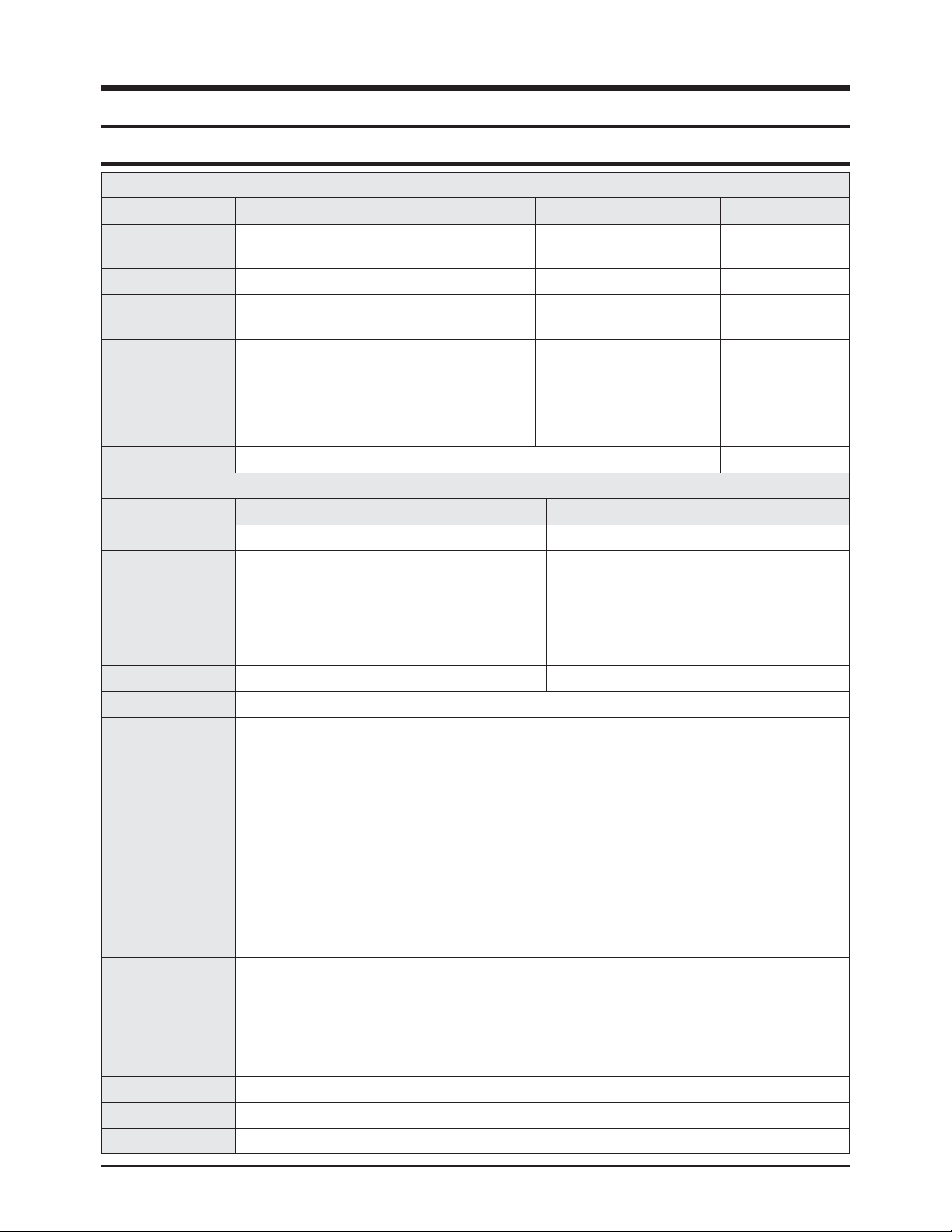

Product Specification

Samsung Electronics 2-1

2. Product Specification

2-1 Product Specification

Features

Block Specification Major IC Remark

RF Digital/Analog (DTV Built In)

NTSC/VSB/QAM Tuner

KS1411

PDP Module Samsung SDI W3 Module 42"HD/50"HD New Module

Power

Samsung/Dong-yang electro

mechanics SMPS

Video

NTSC 3.58, ATSC

HDMI

DNIe(FBE3)

Component, PC

MSD2248

Sound SRS TruSuround XT, Dolby Digital MSD2248, STA335W Optical Output

Cabinet P450 Design

Specification

Model PN42A450P1D PN50A450P1D

Screen Size 42 Inches (16:9) 50 Inches (16:9)

Dimensions (WxHxD)

41.5 x 26.3 x 3.7 inches (without stand)

41.5 x 28.5 x 12.4 inches (with stand)

48.4 x 29.8 x 3.7 inches (without stand)

48.4 x 32.0 x 12.4 inches (with stand)

Weight

59.31 lbs (without stand)

67.24 lbs (with stand)

75.41 lbs without stand

81.57 lbs with stand

PC Resolution 1024 x 768 @ 75Hz 1360 x 768 @ 60Hz

Power consumption 330W 470W

Voltage AC 100~240V, 60Hz

ANTENNAinput

ANTAIR IN or CABLE IN

※75Ω

unbalanced

VIDEO input

AV1, AV2

S-VIDEO1

COMPONENT1 - 480i/480p/720p/1080i/1080p

COMPONENT2 - 480i/480p/720p/1080i/1080p

PC

HDMI1 : 480p/720p/1080i/1080p

HDMI2(DVI Compatible) - 480p/720p/1080i/1080p

HDMI3(SIDE AV) - 480p/720p/1080i/1080p

480i is not contained in HDMI EDID data.

However, it can be displayed.

AUDIO input

AV1, AV2

S-VIDEO

COMPONENT1 - 480i/480p/720p/1080i/1080p

COMPONENT2 - 480i/480p/720p/1080i/1080p

PC

DVI

Audio Output AUDIO (L/R)

Speaker Output 10W + 10W

New Features Anynet+

Page 11

Product Specification

2-2 Samsung Electronics

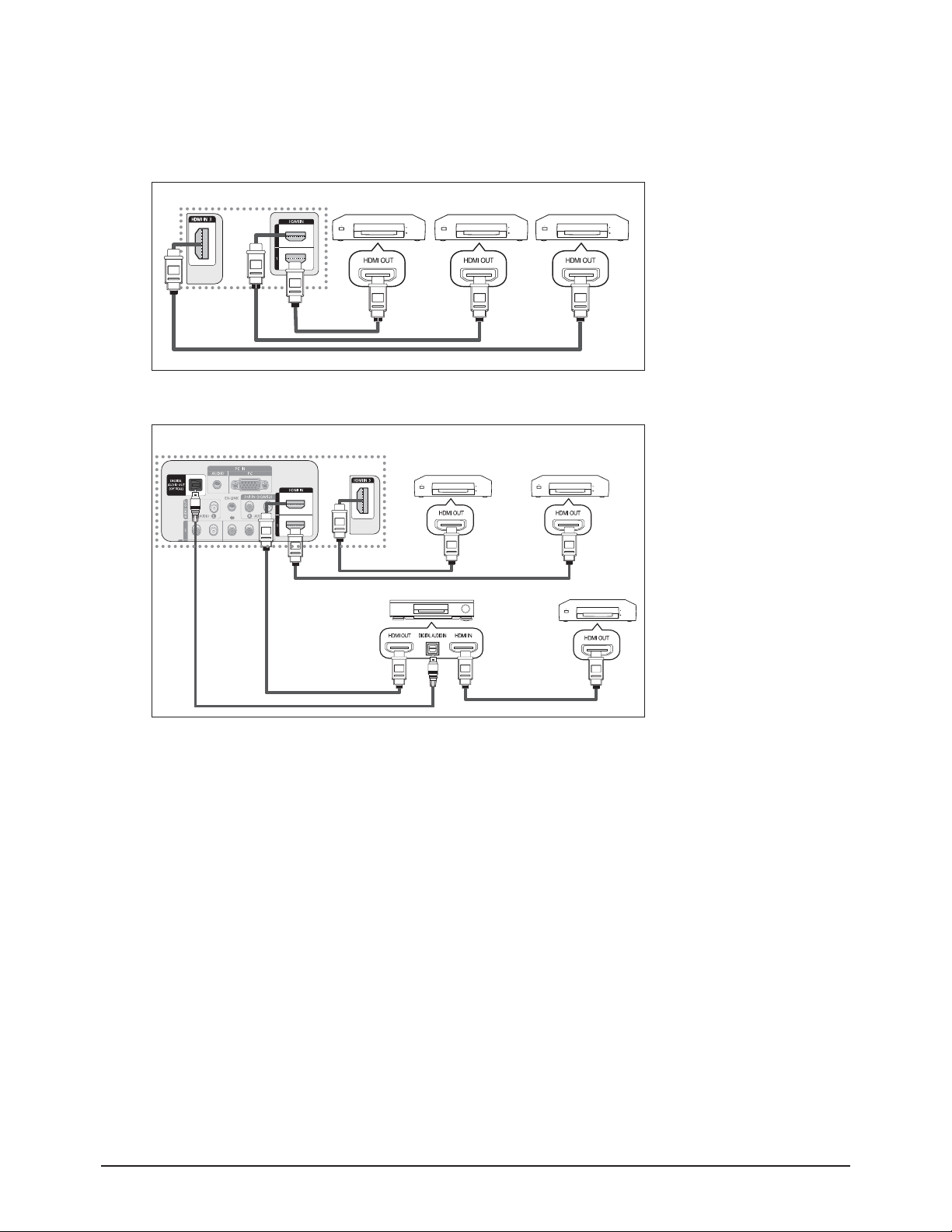

■■

New Features explanation

- Anynet+ : Anynet+ is an AV network system that enables you to control all connected Samsung AV devices with your

Samsung TV's remote.

To directly connect to TV

TV

Anynet+ Device 1 Anynet+ Device 2 Anynet+ Device 3

Connect the [HDMI 1], [HDMI 2]

or [HDMI 3] jack on the TV

and the HDMI OUT jack of the

corresponding Anynet+ device

using the HDMI cable.

HDMI Cable

HDMI Cable

To connect to Home Theater

TV

HDMI Cable

Optical Cable

Connect the Optical cable between [Digital Audio Out (Optical)] on your TV and Digital Audio Input on the Home

˧

Theater.

Connect only one Home Theater.

˧

You can listen to 5.1 channel sound through the home theater’s speakers. Otherwise, you can only listen to 2 channel

˧

stereo sound in other cases. Make sure to connect the Digital Audio IN (Optical) of the home theater and the TV

correctly to listen to TV sound through the home theater. However, you cannot listen to sound from the BD recorder

that is sent to the home theater via the TV in 5.1 channel sound because the TV outputs only 2 channel stereo sound.

Please see the manual for the home theater.

You can connect an Anynet+ device using the HDMI cable. Some HDMI cables may not support Anynet+ functions.

˧

Anynet+ works when the AV device supporting Anynet+ is in the Standby or On status.

˧

Anynet+ supports up to 12 AV devices in total. Note that you can connect up to 3 devices of the same type.

˧

HDMI Cable

HDMI Cable

Anynet+ Device 1 Anynet+ Device 2

HDMI Cable

Home Theater

HDMI Cable

Anynet+ Device 3

1. Connect the [HDMI 1],

[HDMI 2] or [HDMI 3]

jack on the TV and the

HDMI OUT jack of the

corresponding Anynet

device using the HDMI

cable.

2. Connect the HDMI IN jack

of the home theater and

the HDMI OUT jack of the

corresponding Anynet

device using the HDMI

cable.

+

+

Page 12

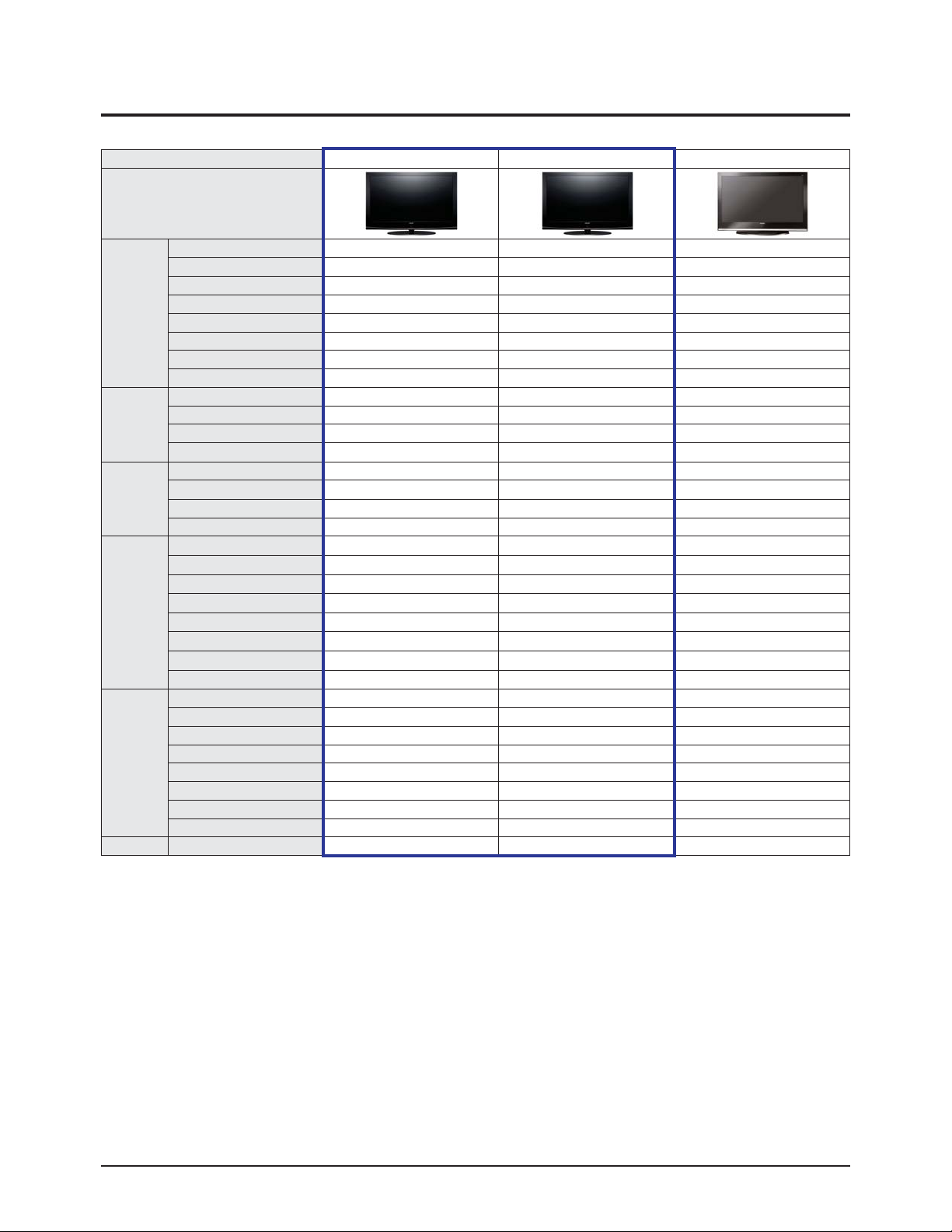

Product Specification

Samsung Electronics 2-3

2-2 Specifications Analysis

Model PN42A450P1DXZA PN50A450P1DXZA HP-T4254 (Lily-42HD)

Design

Basic

Display Type PDP TV PDP TV PDP TV

Built-In Tuner

○ ○ ○

Resolution 1024 x 768 1365 x 768 1024 x 768

PDP Module W3 W3 W2A

Screen Size 42" 50" 42"

Picture ratio 16 : 9 16 : 9 16 : 9

Dimensions (WxHxD) 41.5 x 28.5 x 12.4 inches 48.4 x 32.0 x 12.4 inches 41.5 x 29.9 x 12.4 inches

Weight 67.24 lbs / 30.5 kg 81.57 lbs / 37 kg 73.2 lbs / 33.2kg

Picture

Brightness 1,500 Cd/m2 1,300 Cd/m2 1,500 Cd/m2

Contrast Ratio 10000:1 10000:1 10000:1

Picture Enhacer FBE3 FBE3 FBE2

Comb Filter

○ ○ ○

Audio

Equalizer 5 Band 5 Band 5 Band

Auto Volume Control

○ ○ ○

Surround Sound SRS TruSurround XT SRS TruSurround XT SRS TruSurround XT

Speaker Output 10W + 10W 10W + 10W 10W + 10W

Features

PIP X X

○

Double Window X X

○

Caption

○ ○ ○

Still Image X X

○

EPG

○ ○ ○

My Color Control

○ ○ ○

Energy Saving

○ ○ ○

Anynet

○ ○ ○

Connections

Antenna 1(Cable or Air) 1(Cable or Air) 2 (Cable/Air)

AV Input 2 2 2

S-Video 1 1 2

Component 2 2 2

PC(D-SUB) 1 1 1

DVI X X X

HDMI 3 3 3

Optical 1 1 1

ETC Speaker/Stand Built-in Speaker Built-in Speaker Built-in Speaker

※○: application, X: non-application

Page 13

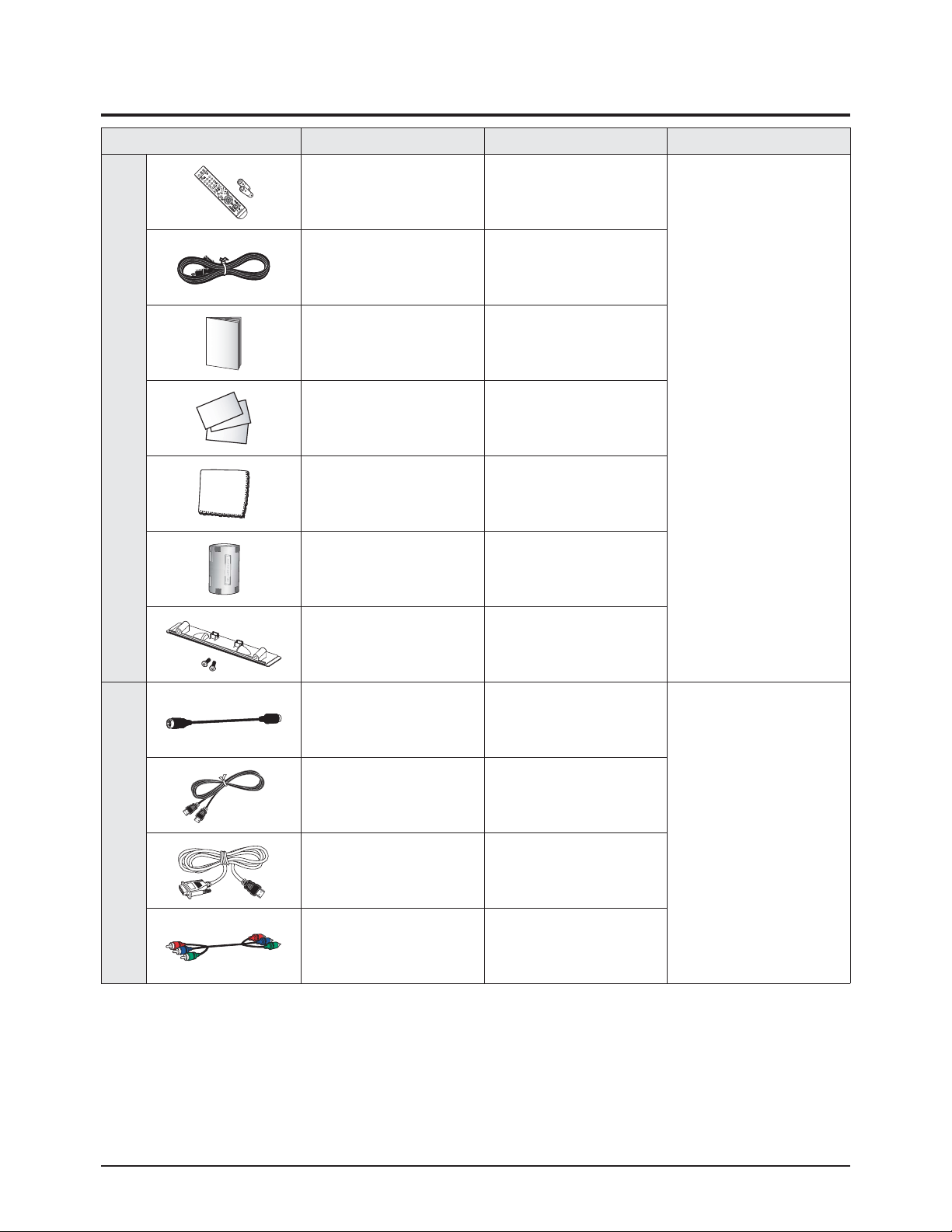

Product Specification

2-4 Samsung Electronics

2-3 Accessories

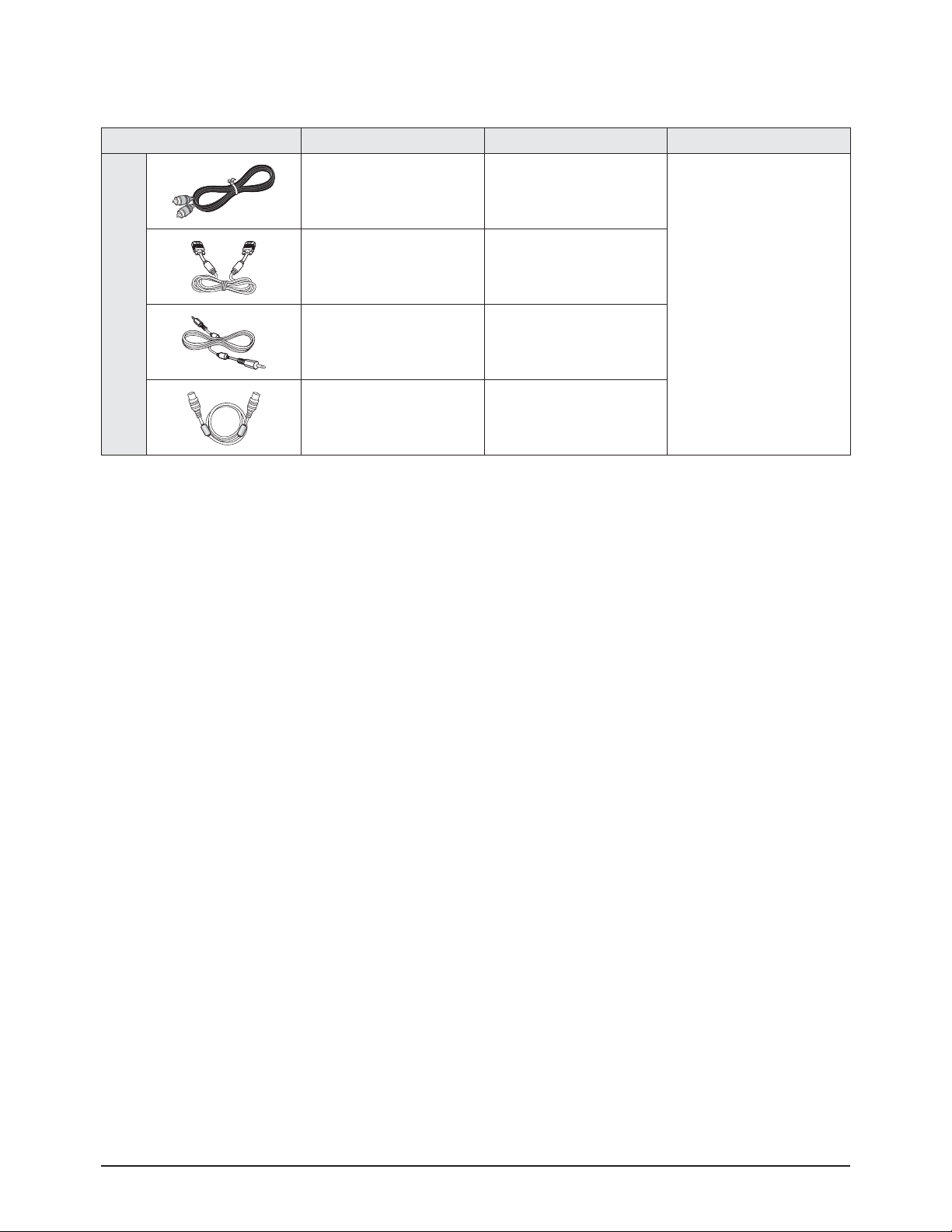

Accessories Item Item code Remark

SuppliedAccessories

Remote Control

Batteries

BN59-00687A

4301-000103

Samsung Service center

Power Cord 3903-000144

Owner's Instructions BN68-01399B

Warranty Card

Registration Card

Safety Guide Manual

-

-

AA68-03242L

Cloth-Clean BN63-01798A

Ferrite Core for

Power Cord

3301-001305

Cover-Bottom

Screws (2ea)

BN63-03055A

6003-001621

Accessories that canbe purchased

additionally

S-VIDEO Cable

47.244 inches

BN39-00149A

Electronics Store/

Internal shopping mall

HDMI Cable

118.11 inches

BN39-00641A

HDMI/DVI cable

118.11 inches

BN39-00643A

Component Cables (RCA)

59.055 inches

BN39-00279A

Page 14

Product Specification

Samsung Electronics 2-5

Accessories Item Item code Remark

Accessories that canbe purchased

additionally

Optical Cable None

Electronics Store/

Internal shopping mall

PC Cable

72.047 inches

BN39-00115A

PC Audio Cable

78.740 inches

BN39-00061B

Antenna Cable

118.11 inches

BN39-00333A

Page 15

2-6 Samsung Electronics

MEMO

Page 16

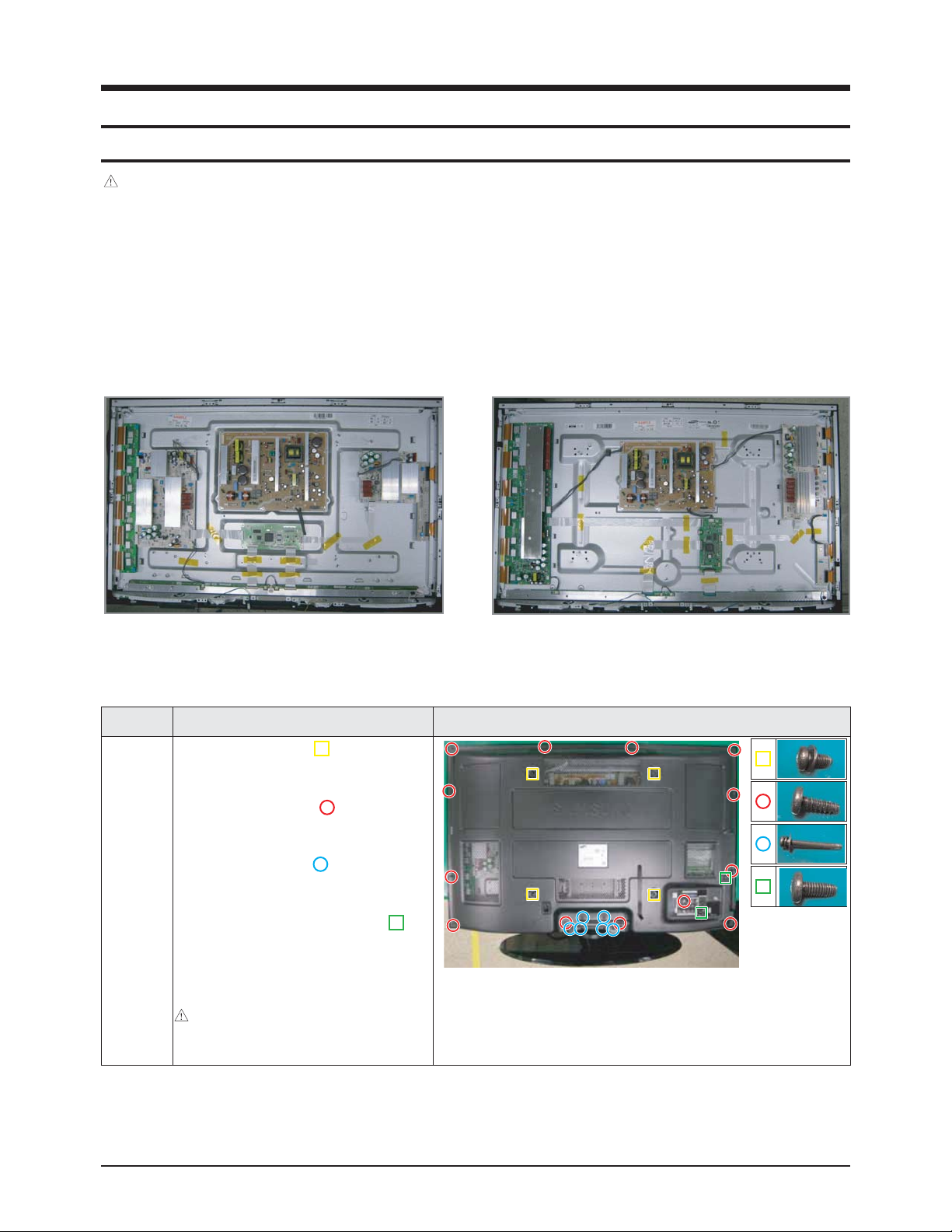

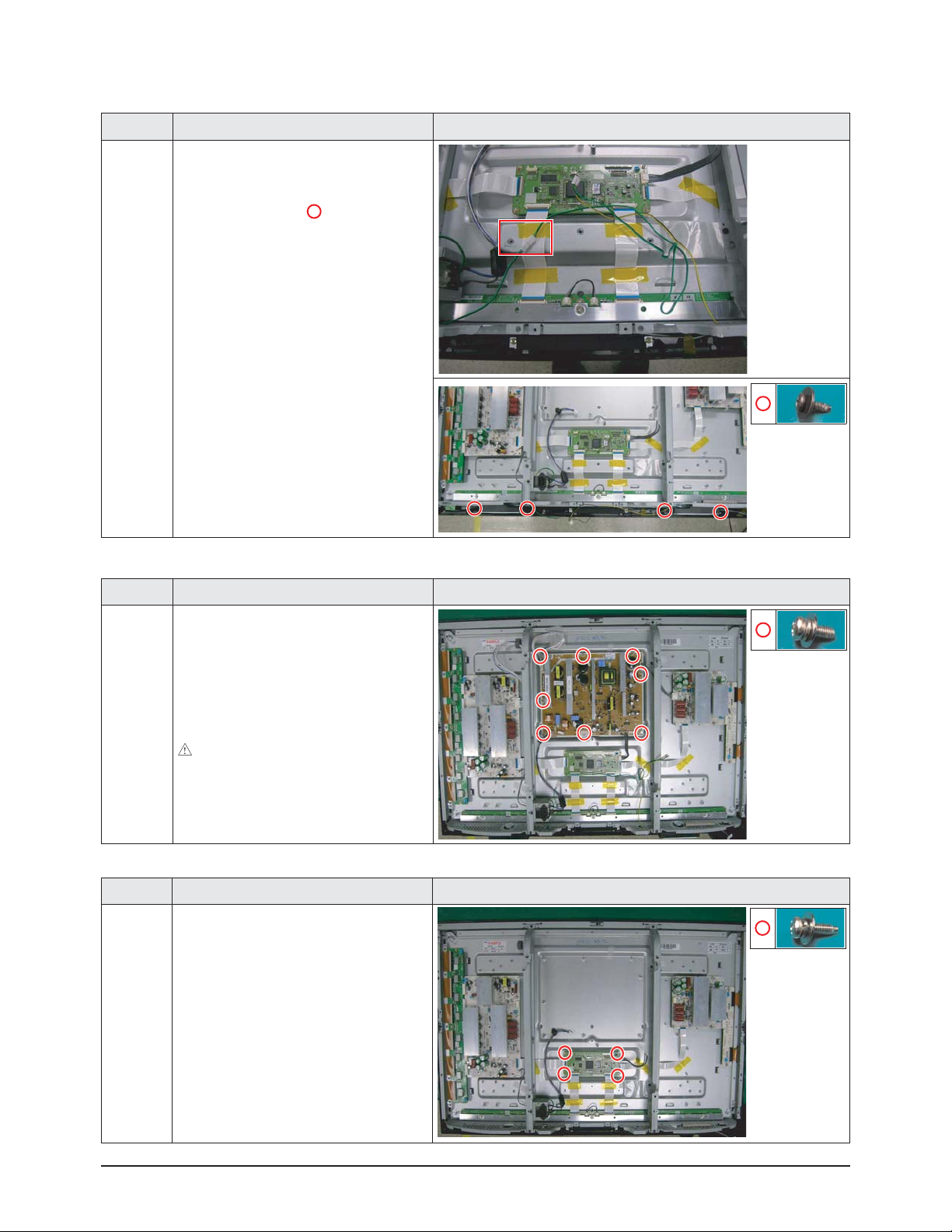

Part Name Description Description Photo

Cover

Rear

① Remove 4 screws. ( )

: M8,L16,ZPC(BLK),SWRCH18A,WP

② Remove 13 screws. ( )

: BH,+,B,M4,L3,ZPC(BLK)

③ Remove 6 screws. ( )

: PH,+,WSP,S,M4,L35,ZPC(BLK)

④ Remove the 2 machine screws. ( )

: BH,+,S,M4,L10,ZPC(BLK)

⑤ Remove the rear cover.

: Please lay the PDP unit face down on a

soft surface when removing the stand.

Disassembly & Reassembly

Samsung Electronics 3-1

3. Disassembly & Reassembly

3-1 Overall Disassembly & Reassembly

3-1-1 Separation of ASSY COVER P-REAR

Notice

- Be sure to separate the power cord before disassembling the unit.

- Discharge the capacitors first when separating PCB's with high capacity capacitors such as SMPS, X Main Board, YMain

Board, etc. (Aspark may be generated by the electric charge, and there is danger of electronic shock.)

- Check that the cables are properly connected referring to the circuit diagram when disassembling or assembling the unit

taking care not to damage the cables.

- Take care not to scratch the Glass Filter in the front.

- Assemble the boards in the reverse order of the disassembly.

- The plasma must be layed down on a flat padded surface for disassembly and reassembly.

<42">

<50">

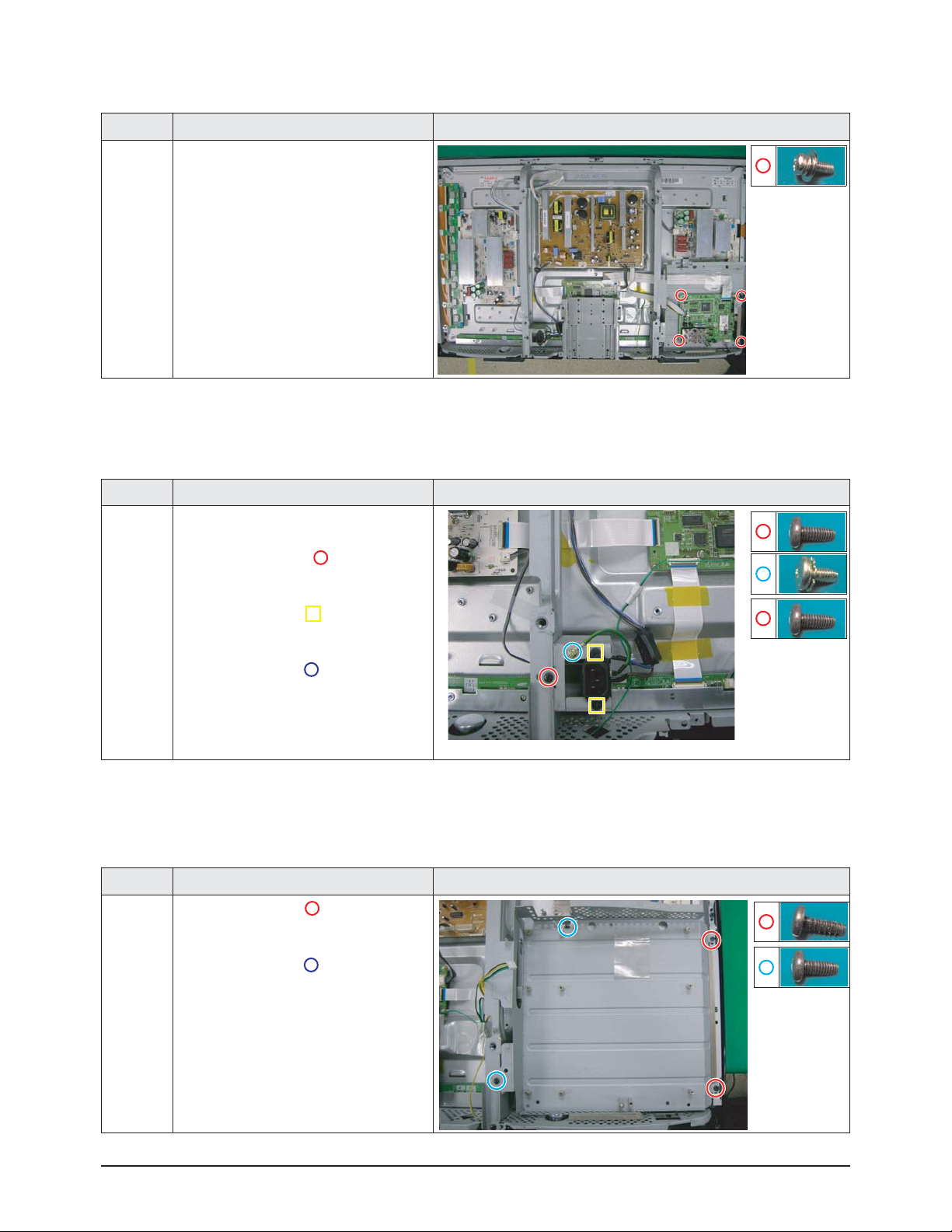

Page 17

Disassembly & Reassembly

3-2 Samsung Electronics

3-1-3 Separation of FILTER-EMI AC LINE

Part Name Description Description Photo

FILTER-

EMI

AC LINE

① Detach connector from SMPS.

② Remove 1 screws. ( )

: BH,+,S,M4,L10,ZPC(BLK)

③ Remove 2 screw. ( )

: PH,+,WWP,M3,L8,NI PLT

④ Remove 1 screws.( )

: BH,+,S,M4,L10,ZPC(BLK)

⑤ Separate FILTER-EMI AC LINE from

bracket.

3-1-4 Separation of BRACKET-PCB

Part Name Description Description Photo

Bracket

PCB

① Remove 2 screw.( )

: BH,+,B,M4,L3,ZPC(BLK)

② Remove 2 screw.( )

: BH,+,S,M4,L10,ZPC(BLK)

③ Remove the BRACKET-PCB.

3-1-2 Separation of ASSY PCB MISC-MAIN

Part Name Description Description Photo

Main

Board

① Detach all connectors from the Main

Board.

② Remove 4 screws.

: PH,+,WWP,M3,L8,NI PLT

③ Remove the Main Board.

▶The photo is for 42".

50" is very similiar with 42".

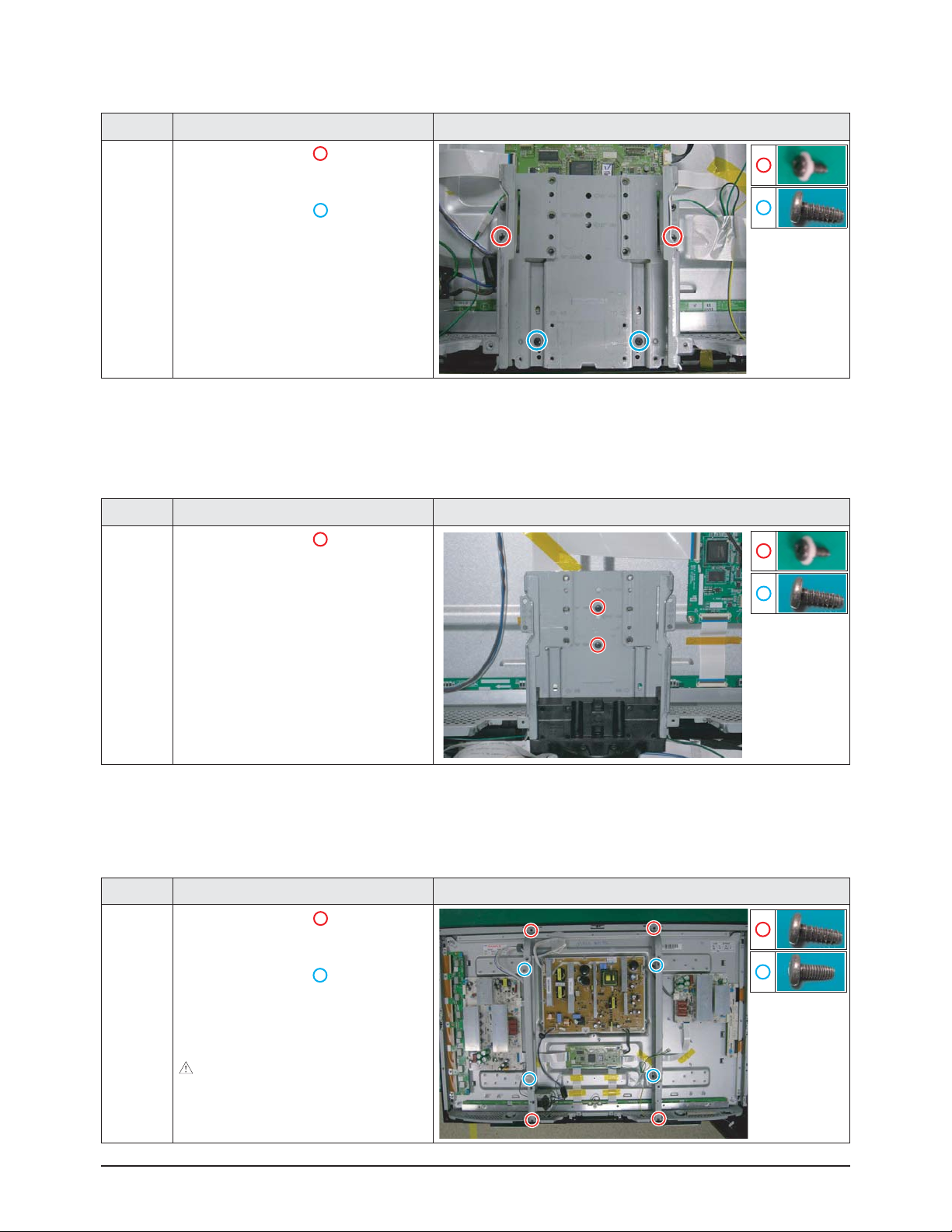

Page 18

Disassembly & Reassembly

Samsung Electronics 3-3

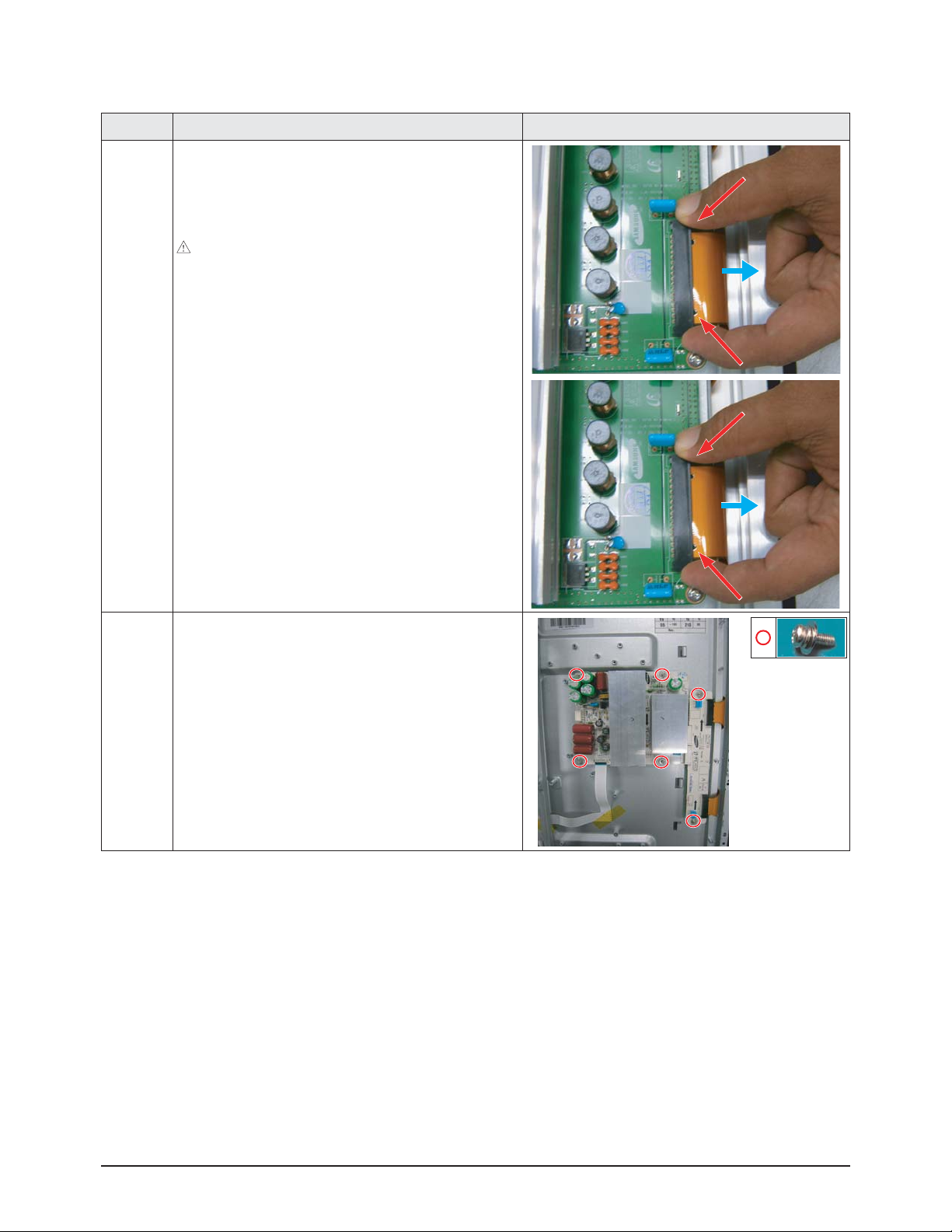

3-1-7 Separation of ASSY BRACKET P-WALL

Part Name Description Description Photo

42"

Wall

Bracket

① Remove 4 screws. ( )

: BH,+,B,M4,L3,ZPC(BLK)

② Remove 4 screws. ( )

: BH,+,S,M4,L10,ZPC(BLK)

③ Remove Wall Bracket.

: Please lay the PDP panel face down

on a soft surface when separating front

cover.

3-1-5 Separation of ASSY BRACKET 42"

Part Name Description Description Photo

Bracket

① Remove 2 screws. ( )

: BH,+,PT,S Tite,M4,L10,ZPC(BLK)

② Remove 2 screws. ( )

: BH,+,B,M4,L3,ZPC(BLK)

③ Remove Bracket.

3-1-6 Separation of ASSY BRACKET 50"

Part Name Description Description Photo

Bracket

① Remove 2 screws. ( )

: BH,+,PT,S Tite,M4,L10,ZPC(BLK)

② Remove Bracket.

Page 19

Disassembly & Reassembly

3-4 Samsung Electronics

3-1-10 Separation of ASSY PDP MODULE P-LOGIC MAIN BOARD

Part Name Description Description Photo

Logic

Board

① Detach all connectors from the Logic

Main Board.

② Remove 4 screws.

: WSP,PH,+,M3,L8,NI PLT

③ Remove the Logic Main Board.

3-1-9 Separation of SMPS-PDP TV

Part Name Description Description Photo

SMPS

① Detach all connectors from the SMPS.

② Remove 8 screws.

: PH,+,WWP,M3,L8,NI PLT

③ Remove the SMPS.

: Wear gloves when handling the power

board as there may be some remaining

electrical charge in the capacitor.

Specifically, avoid touching any part of

the capacitor.

3-1-8 Separation of ASSY SPEAKER P

Part Name Description Description Photo

Speaker

① Disconnect left speaker cable from right

speaker cable.

② Remove 4 screws.( )

: BH,+,WP,B,M4.0,L3,ZPC(BLK),

SWRCH18A

③ Remove the Speaker.

▶The photo is for 42".

50" is very similiar with 42".

Page 20

Disassembly & Reassembly

Samsung Electronics 3-5

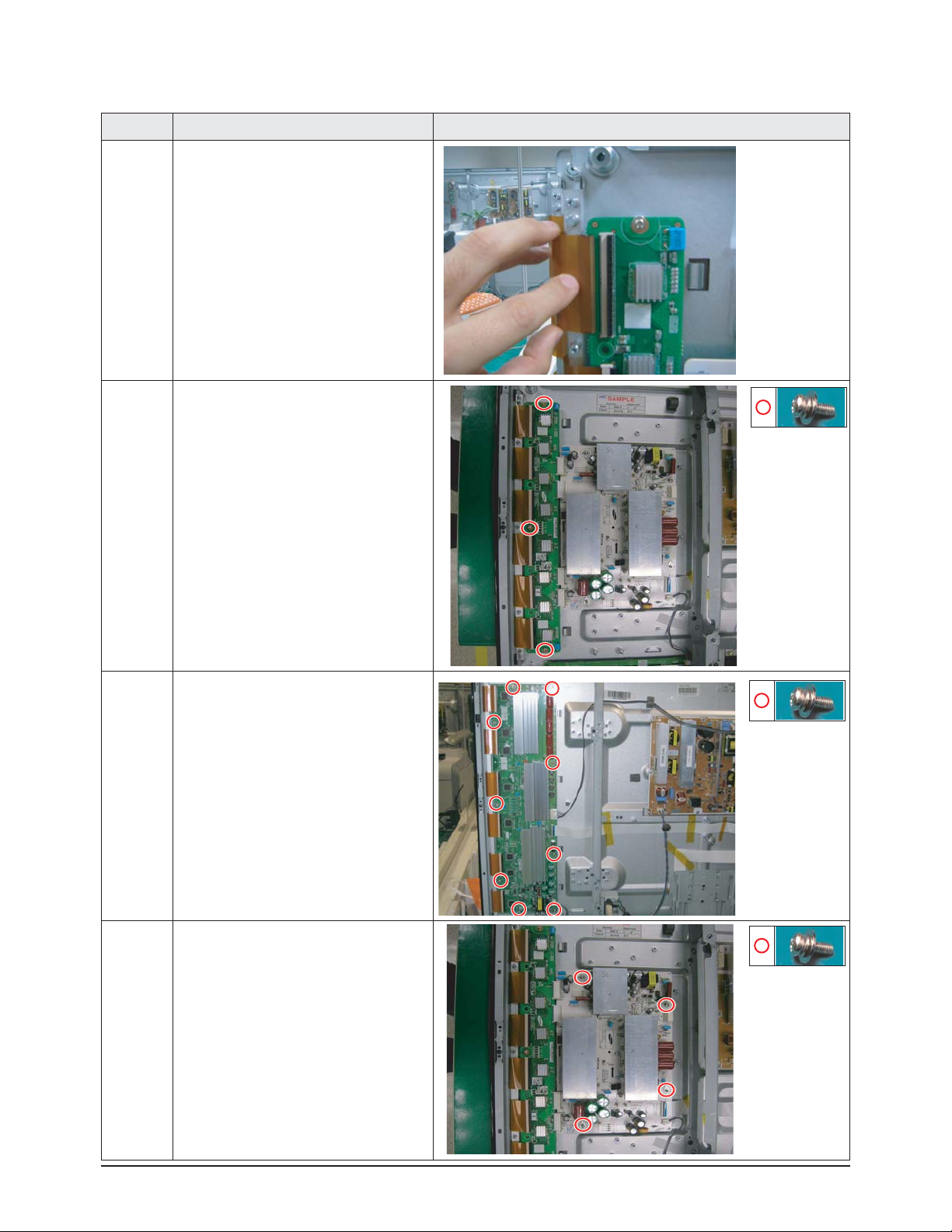

3-1-11 Separation of ASSY PDPMODULE P-X MAIN BOARD

Part Name Description Description Photo

Flat Cable

① Detach all Connectors from the X Main Board.

※ To separate the Flat Cable of the X-Board, press the

upper and the lower sides of the connector.

: Pinch the sides, but then push down in the ribbon, it

should slide out after that.

X-Main

Board

① Remove 6 screws.

: PH,+,WWP,M3,L8,NI PLT

② Remove the X-Main Board.

Page 21

Disassembly & Reassembly

3-6 Samsung Electronics

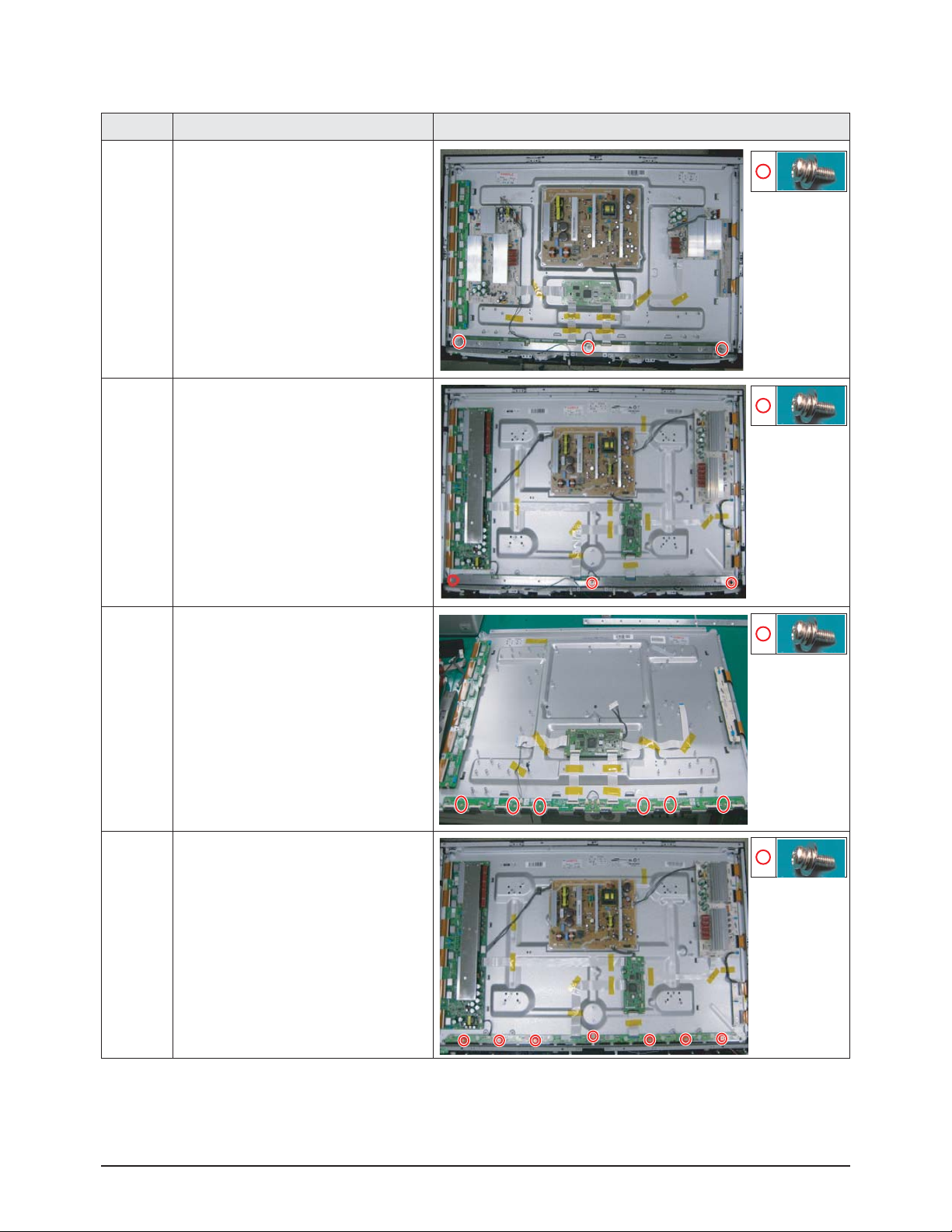

3-1-12 Separation of ASSY PDP MODULE P-Y MAIN BOARD

Part Name Description Description Photo

Flat Cable

① Detach the 6 scan board connectors

from the panel .

42"

Y-Scan

Board

① Remove 3 screws.

: PH,+,WWP,M3,L8,NI PLT

50"

Y-Scan

Board

① Remove 9 screws.

: PH,+,WWP,M3,L8,NI PLT

Y-Scan

Board

① Remove 4 screws.

: PH,+,WWP,M3,L8,NI PLT

② Detach all connectors from the Y-Main

Board.

▶This is only for 42".

Page 22

Disassembly & Reassembly

Samsung Electronics 3-7

3-1-13 Separation of ASSY PDP MODULE P-ADDRESS BUFFER BOARD

Part Name Description Description Photo

42"

Still Bar

① Remove 3 screws.

: PH,+,WWP,M3,L8,NI PLT

② Remove the still bar.

▶Before removing the still bar, you should

lift up the panel a little.

50"

Still Bar

① Remove 3 screws.

: PH,+,WWP,M3,L8,NI PLT

② Remove the still bar.

▶Before removing the still bar, you should

lift up the panel a little.

42"

Buffer

Board

① Detach the all connectors from the

buffer board.

② Remove 6 screws.

: PH,+,WWP,M3,L8,NI PLT

③ Remove the E-Board and F-Board.

50"

Buffer

Board

① Detach the all connectors from the

buffer board.

② Remove 7 screws.

: PH,+,WWP,M3,L8,NI PLT

③ Remove the E-Board and F-Board.

Page 23

Disassembly & Reassembly

3-8 Samsung Electronics

3-1-15 Separation of ASSY PCB FUNCTION & DECO LED

Part Name Description Description Photo

Function

Board

① Remove 3 screws.

: BH,+,B,M4,L3,ZPC(BLK)

3-1-14 Separation of ASSY PANEL BRACKETS

Part Name Description Description Photo

Panel

Brackets

① Remove 7 screws. ( )

: BH,+,B,M4,L3,ZPC(BLK)

② Remove the Side Panel Brackets.

Page 24

Troubleshooting

Samsung Electronics 4-1

4-1-1 First Checklist for Troubleshooting

1. Check the various cable connections first.

- Check to see if there is a burnt or damaged cable.

- Check to see if there is a disconnected or loose cable connection.

- Check to see if the cables are connected according to the connection diagram.

2. Check the power input to the Main Board.

3. Check the voltage in and out between the SMPS ↔ Main Board, between the SMPS ↔ X, YMain Board, and between the

Logic Boards.

4. Troubleshooting

4-1 Troubleshooting

Page 25

Troubleshooting

4-2 Samsung Electronics

4-1-2 Checkpoints by Error Mode

■

■

No Power

Symptom

- The LEDs on the front panel do not work when connecting the power cord.

- The SMPS relay does not work when connecting the power cord.

- The units appears to be dead.

Major Checklist

The SMPS relay or the LEDs on the front panel does not work when connecting the power cord if the cables

are improperly connected or the Main Board or SMPS is not functioning. In this case, check the following:

- Check the internal cable connection status inside the unit.

- Check the fuses of each part.

- Check the output voltage of SMPS.

- Replace the Main Board.

Troubleshooting

Procedures

Is the AC IN socket connector and

the SMPS CN800S connected?

Insert the AC in connector and the

SMPS CN800S connector

Is the Fuse (F801S) of the SMPS

Power Input Part blown?

Replace Fuse (F801S)

Replace the SMPS

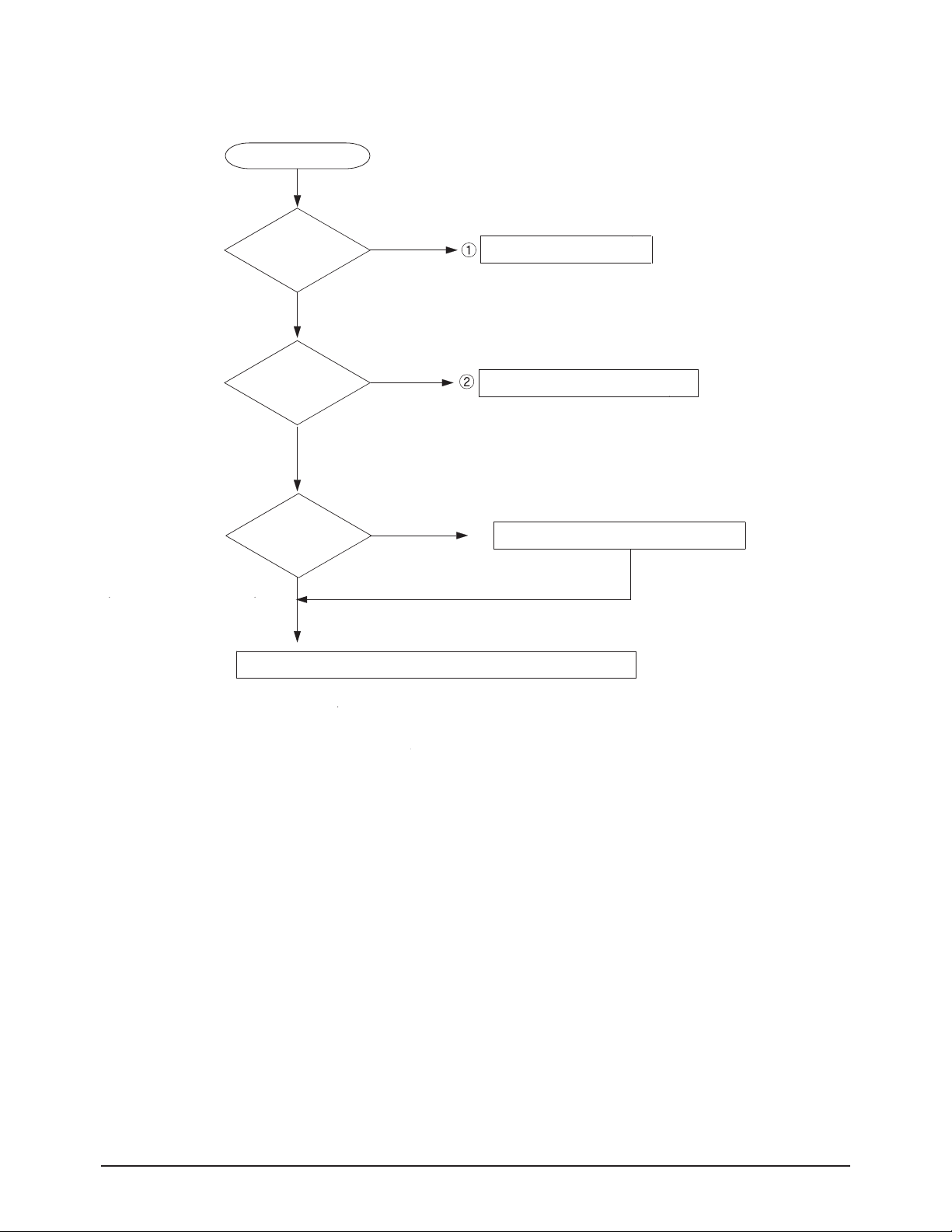

SMPS CN801

Pin 3 : STB 5V

Pin 2 PS-ON : Check to see if it is 0V

Replace the Main Board

①

①

②

Yes

No

Yes

No

No

Yes

<42" (50" is almost same with 42")>

Page 26

Troubleshooting

Samsung Electronics 4-3

■

■

When the unit is repeatedly turned on and off

Symptom - The SMPS relay is repeatedly turned on and off.

Major Checklist

In general, the SMPS relay repeatedly turns on and off by the protection function due to a defect on a board

connected to the SMPS.

- Disconnect all cables from the SMPS, operate the SMPS alone and check if the SMPS works properly and if

each voltage output is correct.

- If the symptom continues even when SMPS is operated alone, replace the SMPS.

- If the symptom is not observed when operating the SMPS alone, find any defective assemblies by connecting

the cables one by one.

Troubleshooting

Procedures

Caution

When separating and connecting the cables such as CN810, CN809, CN808, CN807 of the Main SMPS, CN4701

of the X Main Board, and CN5707 of the Y Main Board, a spark may be generated by the electric charge of the

high capacity capacitor. Therefore, wait some time after disconnecting the power cord from the unit.

Does the symptom continue when

connecting the power after removing

CN810 from the SMPS?

Replace the Y Main Board

Does the symptom continue when

connecting the power after removing

CN809 from the SMPS?

Replace the X Main Board

Replace the Logic Board

Does the symptom continue when

connecting the power after removing

CN807 from the SMPS?

Replace the SMPS

①

②

③

Yes

No

No

No

Yes

Yes

<42" (50" is almost same with 42")>

Page 27

Troubleshooting

4-4 Samsung Electronics

■

■

No Picture (When audio is normal)

Symptom - Audio is normal but no picture is displayed on the screen.

Major Checklist

- This may happen when the Main Board is functioning but the X, YMain Board, Logic Board, or Y Buffer

Boards are not.

- The output voltage of the Main SMPS.

- This may happen when the LVDS cable connecting the Main Board and the Logic Board is disconnected.

Troubleshooting

Procedures

Caution

When separating and connecting the cables such as CN810, CN809, CN807 of the Main SMPS, CN4701 of the

X Main Board, and CN5707 of the Y Main Board, a spark may be generated by the electric charge of the high

capacity capacitor. Therefore, wait some time after disconnecting the power cord from the unit.

CN810

CN809

CN807

Are the Vs and Va voltages normal after

removing all cables from the SMPS?

(CN810, CN809, CN807)

Replace the SMPS

Yes

No

Did problem improve?

Did problem improve?

Did problem improve?

Did problem improve?

Replace the Y Main Board

Replace the X Main Board

Replace the Logic Board

Replace the Y Scan Board

No

No

No

No

Yes

Yes

Yes

<42" (50" is almost same with 42")>

Page 28

Troubleshooting

Samsung Electronics 4-5

■■

No Sound

Symptom - Video is normal but there is no sound.

Major Checklist

- When the speaker connectors are disconnected or damaged.

- When the sound processing part of the Main Board is not functioning.

- Speaker defect.

Troubleshooting

Procedures

Is the cable connection between the

Main Board and the speaker

properly connected?

Connect the cable properly or

replace the cable, if necessary.

Is the output voltage of SMPS normal?

(CN801 #13)

Replace the SMPS

Replace the Main Board

Is the speaker output terminal

of the Main Board normal?

Replace the Speaker

①

②

③

Yes

No

No

No

Yes

Yes

<42" (50" is almost same with 42")>

Page 29

Troubleshooting

4-6 Samsung Electronics

■

■

No Video

Symptom - Anormal/cable network analog broadcast screen is blank or abnormal but OSD is OK.

Major Checklist

- Check the antenna connection settings (Air: NTSC / ATSC, Cable: NTSC)

- Check the CVBS cable connection.

- Check the power input of the Main board.

Troubleshooting

Procedures

Is the antenna connection setting

properly configured?

Configure properly

Replace the SMPS

Check CN1001 pin2 for +5V

Replace the Main Board

①

No

No

Yes

Yes

Page 30

Troubleshooting

Samsung Electronics 4-7

■

SMPS Troubleshooting

Power ON

STBY

Abnormal

Check the UB801, DX807

Normal

Abnormal

Multi

Check the UB801, DX806, DX809

Normal

Abnormal

ྛ

VS/VA

Check the U804, DS823, DS824, DS825

Check the Other board (Image Board or Driver Board) or Cable.

Page 31

Troubleshooting

4-8 Samsung Electronics

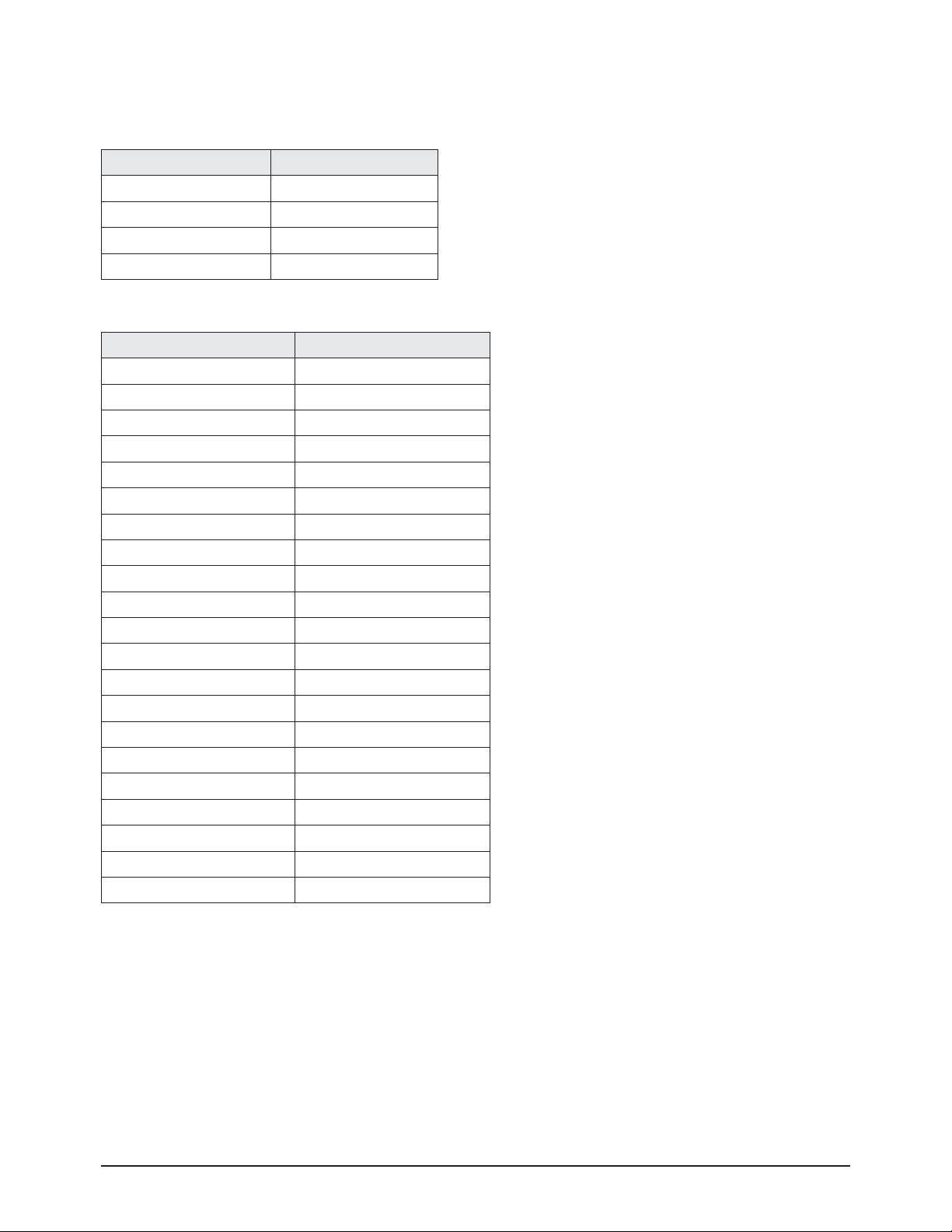

Condition Name Description Related Board

No Voltage Output Operating Voltage don't exist PSU

No Display Operating Voltage exist, but an Image doesn't exist on screen Y-MAIN, X-MAIN, Logic Main, Cable

Abnormal Display Abnormal Image (not open or short) is no screen Y-MAIN, X-MAIN, Logic Main

Sustain Open Some horizontal lines don't exist on screen Scan Buffer, FPC of X/Y

Sustain Short Some horizontal lines appear to be linked on screen Scan Buffer, FPC of X/Y

Address Open Some vertical lines don't exist on screen Logic Main, Logic Buffer, TCP

Address Short Some vertical lines appear to be linked on screen Logic Main, Logic Buffer, TCP

■

■

Drive Board Troubleshooting

1) Troubleshooting Summary

Page 32

Troubleshooting

Samsung Electronics 4-9

2) Troubleshooting Procedure in Abnormal Conditions

① No Display

▶ No Display is related with Y-MAIN, X-MAIN, Logic Main and so on.

This page shows you how to check the boards, and the following pages show you how to find the defective board.

No Display

[ Logic Main ]

LED Blinks

Check the LED

YES NO

Check if internal is

Check if any address

data output is detected

Default Black

[ Y-MAIN ]

Check necessary points

[ Logic Main ]

Check if power is supplied

YES NO

operation

MICOM operation

Check the ASIC

Control Signal output

Check if the data

and control signals

between DDR & ASIC

( 5V, 3.3V )

Check the

are normal

[ X-MAIN ]

Check necessary points

Check the

power connectivity

Check the FUSE

Check the

input voltage

If the input voltage is

abnormal, replace the

PSU and check it

again as this indicates

a PSU output error

[ X-MAIN ]

Check several points

FUSE

OK

FET/

DIODE

OK

X-MAIN

Normal State

OPEN

Replace the Board

SHORT

Replace the Board

F5000 for VDD

F5801 for Vs

F5800 for VCC

Q5500, Q5200,

Q5201, Q5202,

Q5203, Q5400,

Q5401, Q5402,

Q5300, D5105

D5104, D5103,

Q5101, D5101,

Q5100

[ Y-MAIN ]

Check several points

FUSE

OK

FET/

DIODE

OK

Y-MAIN

Normal State

OPEN

SHORT

Replace the Board

Replace the Board

F4001 for VCC

F4003 for Vs

F4005 for VDD

F4004 for Ve

Q4002, Q4202,

Q4004, D4014,

D4013, Q4003

Q4101, Q4001,

D4018, Q4007,

Q4006, Q4005

D4011, D4004

Page 33

Troubleshooting

4-10 Samsung Electronics

② Abnormal Display(Abnormal Image is on Screen.(except abnormality in Sustain or Address))

▶ Abnormal Display is related with Y-MAIN, X-MAIN, Logic Main and so on.

This page shows you how to check the boards, and the following pages show you how to find the defective board.

Abnormal

Display

F5000 for VDD

F5801 for Vs

F5800 for VCC

[ Logic Main ]

LED Blinks

( action of Vsync )

YES

Replace the Board

[ Y-MAIN ]

Check several points

FUSE

OK

[ Logic Main ]

Observation of

abnormal display

Regular

abnormal

pattern

OPEN

Check necessary points

NO

Replace the Board

[ Y-MAIN ]

Logic Main

Normal State

Replace Panel

F4001 for VCC

F4003 for Vs

F4005 for VDD

F4004 for Ve

[ X-MAIN ]

Check necessary points

[ X-MAIN ]

Check several points

FUSE

OK

OPEN

Replace the Board

Q5500, Q5200,

Q5201, Q5202,

Q5203, Q5400,

Q5401, Q5402,

Q5300, Q5101,

Q5100

FET

OK

Y-MAIN

Normal State

SHORT

Replace the Board

Q4002, Q4202,

Q4004, Q4003

Q4101, Q4001,

Q4007, Q4006,

Q4005

FET

OK

X-MAIN

Normal State

SHORT

Replace the Board

Page 34

Troubleshooting

Samsung Electronics 4-11

③ Sustain Open (some horizontal lines don't exist on screen)

④ Sustain Short (some horizontal lines appear to be linked on Video)

[ Y-FPC ]

Sustain Open

After Changing Y-buffer,

recheck the status

OK

Done

(Defect is from Y-buffer)

NG

Replace the Panel

There is a defect on the FPC

[ Y-FPC ]

(Discharging in unwanted Scan line)

Sustain Short

After Changing Y-buffer,

recheck the status

OK

Done

(Defect is from Y-buffer)

NG

Replace the Panel

There is a defect on the FPC

Page 35

Troubleshooting

4-12 Samsung Electronics

⑤ Address Open, Short

▶ Address Open and Short is related with Logic Main, Logic Buffer, FFC, TCP film and so on.

This page shows you how to check the boards, and the following pages show you how to find the defective board.

[ Logic Main ]

Address Open/Short

Check the LED operation

LED2011 : blink

LED2010 : on

Check if the internal mode

screen is normal

OK

Reload the data onto the

MICOM and recheck it

Check the detailed waveform

and control the signal waveform

DONE

NG

Check if a specific TCP Block

screen is displayed abnormally

OK

Check the

Video Board

Check if there is an open or

short circuit on the Buffer Board

and the Logic Main address

data output section.

Check the FFC connection status

OK

OK

NG

NG

Replace Logic Main /

Address Buffer (E or F) /

check the voltage of

C2901, C2902, C2903 is 1.25V

OK

FFC

Replace the Panel

NG

check the voltage of

U2650 pin1 is 3.3V

NG

NG

Page 36

Troubleshooting

Samsung Electronics 4-13

4-1-3 Troubleshooting

Symptom Related Image Causes and Countermeasures

Ablank vertical cell (block)

appears on the screen.

Address buffer defect

- Replace the corresponding upper/lower

buffers (E, F)

COF defect (burnt)

- Replace the module

Agreen screen appears when

the TV is turned on.

The Scale is not reseting

- Replace the Main board

The OSD box appears but there

is no text.

Incorrect program version

- Check the version of each program

- Replace the Main board

Ablank upper (or lower) block

appears on the screen.

Upper/Lower Y Buffer defect

- Replace the corresponding upper/lower

buffers (E, F)

Page 37

Troubleshooting

4-14 Samsung Electronics

Symptom Related Image Causes and Countermeasures

Either the main or sub picture

does not appear.

Replace the Main board

Avertical green line appears on

the screen.

The SMPS voltage is incorrect

- Adjust the SMPS voltage according to

the voltage printed on the module label

Dim screen (blurred in red) X-Main board defect

- Replace the X-Main board

Ablank screen appears - Replace the Y-Main board

Page 38

Troubleshooting

Samsung Electronics 4-15

4-1-4 Troubleshooting Procedures by assembly

No Assembly Major Symptoms

1 SMPS-PDP TV No power, Blank screen, the Relay repeats On and Off.

2 ASSY PDP MODULE P-X-MAIN Blank screen

3 ASSY PDP MODULE P-Y-MAIN Blank screen

4 ASSY PDP MODULE P-LOGIC MAIN Blank screen, Screen noise

5 ASSY PDP MODULE P-Y-MAIN SCAN BUFFER Row Bar screen is blank (42" Only)

6 ASSY PDP MODULE P-ADDRESS E BUFFER Corresponding Buffer Board block screen is blank.

7 ASSY PDP MODULE P-ADDRESS F BUFFER Corresponding Buffer Board block screen is blank.

8 ASSY PCB MISC-MAIN No Power, Abnormal screen for each input source, PIP screen trouble, Sound trouble

9 ASSY BOARD P-FUNCTION The side function key does not work properly

<PDP 42”>

<PDP 50”>

Page 39

Troubleshooting

4-16 Samsung Electronics

4-2 Adjustment

4-2-1 Service Instruction

■ Before Performing After Sales Services

1. Check if the measurement and test equipment is working properly.

2. Secure sufficient work space for disassembling the product.

3. Prepare a soft pad for disassembling the product.

■ Service adjustment item after replacement of Board

<If adjustment equipment is available>

① PDP Option of Factory Mode → set the Factory Data Type item as the suitable value of relevant model.

② Adjust Calibration of Factory Mode for each mode.

③ Adjust White Balance of Factory Mode.

<If adjustment equipment is not available>

① Write down the value of HDMI White Balance of Factory Mode before replacing Board.

② PDP Option of Factory Mode → set the Factory Data Type item as the suitable value of relevant model.

③ Set the value of HDMI White Balance with the value written down before.

Page 40

Troubleshooting

Samsung Electronics 4-17

4-2-2 How to Access Service Mode

1. General Remote

To Enter: → →→→→

(Interval between key strokes: less than 3 sec)

To Exit: →

2. Factory Remote

To Enter: →→→(Interval between key strokes: less than 3 sec)

To Exit: →

Press the Factory key twice with a key stroke interval of more than 1 second (Pressing once enters Aging Mode)

3. Settings when entering Factory mode

- Sharp Screen (Dynamic), Color Tone (Cool1), Factory (Dynamic CE Off), DNIe(Off)

4. Adjustment Procedures

- Channel ▲▼Key: Select an item.

- Volume ◀▶ Key : Adjust the value up or down.

- MENU Key : Save the changes to the EEPROM and return to the higher-level mode.

- Using the Numeric (0~9) keys, you can select a channel.

- Using the SOURCE key, you can switch AV modes.

5. Initial SERVICE MODE DISPLAY State

※ The version of the firmware displayed at the bottom of the screen may differ and the firmware is subject to change for the

improvement of product functions.

※ If you have adjusted the settings in Service Mode, you have to reset the product.

※ If you exit Service Mode without reset, DNIe vlaue keeps Off regardless of setting up the user.

POWER OFF MUTE POWER ON

POWER OFF POWER ON

POWER OFF POWER ON

1 8 2

POWER ON INFO FACTORY Key

1. ADC

2. ADC Target

3. ADC Result

4. Option Byte

5. Adjust

6. White Balance

7. W/B Movie

8. EPAstandard

9. FBE3

10. VDEC

11. Scaler

12. Sharpness

13. PE

14. Sound

15. Dynamic Contrast

16. PDP Option

17. Expert Settings

18. Expert D-Settings

19. Expert Gray Scale

20. Expert C-Space

21. Expert Others

22. CHECKSUM 0x0000

23. Reset

T-CRLAUSC-00xx

Dec 29 2007

PN42A450

EDID FAIL

Option :

Page 41

Troubleshooting

4-18 Samsung Electronics

4-2-3 Factory Data

★★

The underlined are items applied during the service adjustment. None of the others should be adjusted.

1. ADC

Item Data

AV Calibration Comp Calibration PC Calibration HDMI Calibration -

2. ADC Target

Item Default data

1st_AV_Low 18

1st_AV_High 220

1st_AV_Delta 1

1st_COMP_Low 16

1st_COMP_High 235

1st_COMP_Delta 1

1st_PC_Low 1

1st_PC_High 235

1st_PC_Delta 1

2nd_AV_Low 1

2nd_AV_High 235

2nd_AV_Delta 1

2nd_COMP_Low 1

2nd_COMP_High 235

2nd_COMP_Delta 1

2nd_PC_Low 1

2nd_PC_High 235

2nd_PC_Delta 1

2nd_HDMI_Low 1

2nd_HDMI_High 235

2nd_HDMI_Delta 1

Page 42

Troubleshooting

Samsung Electronics 4-19

3. ADC Value

4. Option Byte

Item Default data TV/AV/S_Video Component PC DTV/HDMI Remark

LUMA_OFFSET 128 140 - - -

LUMA_GAIN 128 118 - - -

RED_CUTOFF 128 - 128 130 -

GREEN_CUTOFF 128 - 127 132 -

BLUE_OFFSET 128 - 128 128 -

RED_GAIN 128 - 105 78 -

GREEN_GAIN 128 - 105 79 -

BLUE_GAIN 128 - 105 78 2nd_R offset 128 106 110 110 112

2nd_G offset 128 108 113 110 112

2nd_B offset 128 106 111 110 112

2nd_R gain 128 128 118 128 118

2nd_G gain 128 128 117 128 118

2nd_B gain 128 1150 118 128 118

Item Default data

LCD/PDP LCD

Model Select L450

Inch 32 Inch

Panel Option 32AM

Dimming INT

Mirror OFF

AV Number 2

COMP. Number 2

HDMI Number 3

Light Effect ON

HeadPhone ON

Anynet+(HDMI-CEC) ON

Carrier Mute OFF

Volume Curve Large

RS 232C Auto wall

Gamma 0.9

Mute Time[RF] 400ms

CH Memory Samex

PC Mode Ident Auto

HDMI Mode Ident Auto

HPD Control 1200ms

Page 43

Troubleshooting

4-20 Samsung Electronics

5. Adjust

6. White Balance

Item Default data

Watchdog Enable ON

Watchdog Count 10sec

Spread Spectrum OFF

Shop Mode OFF

DEBUG MODE DEBUG OFF

MSTAR Out Format Vesa

FBE In Format Vesa

FBE Out Format Vesa

Hotel Option

EDID

HDCP Key Download

Item Default data TV/AV/S_Video Component PC DTV/HDMI Remark

Sub Brightness 128 128 128 128 128

R-Offset 128 128 128 128 128

G-Offset 128 128 128 128 128

B-Offset 128 128 128 128 128

Sub Contrast 128 128 128 128 128

R-Gain 128 128 128 128 128

G-Gain 128 128 128 128 128

B-Gain 128 128 128 128 128

Page 44

Troubleshooting

Samsung Electronics 4-21

7. W/B Movie

Item Default data

W/B MOVIE Off

MODE -

Color Tone -

MSub Brightness -

MSub Contrast -

W2_Rgain -

W2_Bgain W2_Roffset W2_Boffset -

W1_Rgain -

W1_Bgain W1_Roffset W1_Boffset -

NOR_Rgain -

NOR_Bgain -

NOR_Roffset NOR_Boffset -

C2_Rgain -

C2_Bgain C2_Roffset C2_Boffset -

Movie Contrast -

Movie Bright -

Movie Color -

Movie Sharpness -

Movie Tint -

Movie Backlight -

Movie Gamma -

8. EPAStandard

Item Default data

Standard Contrast 80

Standard Brightness 45

Standard Sharpness 50

Standard Color 50

Standard Tint 0

Standard Backlight 7

Page 45

Troubleshooting

4-22 Samsung Electronics

9. FBE3

Item Default data RF

AV / SVIDEO

COMP480i/

480p

COMP720p/1

080i/1080p

HDMI DTV

HDMI PC/

Aanalog PC

Patt-Sel 0 0 0 0 0 0 0 0

B-Slope gain 60 60 60 60 60 60 60 60

B-Tilt min 30 30 30 30 30 30 30 30

B-Tilt max 110 110 110 110 110 110 110 110

Lfunc-Basis 75 75 75 75 75 75 75 75

Hfunc-Basis 80 80 80 80 80 80 80 80

Mean-Offset1 30 30 30 30 30 30 30 30

Mean-Offset2 235 235 235 235 235 235 235 235

Mean-Slope 112 112 112 112 112 112 112 112

ACR-Offset 10 10 10 10 10 10 10 10

ACR-Th1 10 10 10 10 10 10 10 10

ACR-Th2 110 110 110 110 110 110 110 110

Skin-Enable ON ON ON ON ON ON ON ON

Skin-UV 128 128 128 128 128 128 128 128

Sub color 128 128 128 128 128 128 128 128

M-Skin-UV 128 128 128 128 128 128 128 128

M-Sub color 128 128 128 128 128 128 128 128

10. VDEC

Item Default data RF AV S-VHS

Saturation 0x80 80 80 80

CTI_MD 0x02 2 2 2

CBCRLP_MD 0x01 0 0 0

11. Scaler

Item Default data

DNR_off 0

DNR_low 2

DNR_mid 3

DNR_high 4

Y_DELAY_EN 1

YC_STEP 1

Page 46

Troubleshooting

Samsung Electronics 4-23

12. Sharpness

14. Sound

Item Range

Carrier Mute 1

High DEV 0

CM_TH_HIGH 2990

CM_TH_LOW 20B0

ST_PILOT_TH_HIGH D00

ST_PILOT_TH_LOW 600

ST_VAR_TH_HIGH 1800

ST_VAR_TH_LOW 1000

SAP_AMP_TH_HIGH 1

SAP_AMP_TH_LOW 4

SAP_NSR_TH_HIGH 4500

SAP_NSR_TH_LOW 3000

"AMP_Volume" 29

Limiter Attack 9

Limiter Release F

Post Scale 7F

Speaker EQ 0

AV Sync. 3C

Item Default data RF AV/S-VHS

component HDMI DTV

PC /

HDMI pc timing

480i/p 720p1080i / p 480i/p 720p1080i / p SD HD

H1 Gain 0x10 0x10 0x10 0x10 0x10 0x10 0x10 0x10 0x10 0x10

H2 Gain 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08

H3 Gain 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08

H4 Gain 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08

V1 Gain 0x28 0x28 0x28 0x28 0x28 0x28 0x28 0x28 0x28 0x28

V2 Gain 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08 0x08

H overshoot 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF

V overshoot 0x60 0x60 0x60 0x60 0x60 0x60 0x60 0x60 0x60 0x60

H undershoot 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF 0xFF

V undershoot 0x60 0x60 0x60 0x60 0x60 0x60 0x60 0x60 0x60 0x60

Coring TH2 0x01 0x01 0x01 0x01 0x01 0x01 0x01 0x01 0x01 0x01

Coring TH1 0x01 0x01 0x01 0x01 0x01 0x01 0x01 0x01 0x01 0x01

Mid_color_level 0xAC

13. PE

Item Default data control register 480i 480p 720p 1080i

Page 47

Troubleshooting

4-24 Samsung Electronics

15. Dynamic Contrast

Item Default data

Dynamic Contrast On

Dynamic Dimming Off

Y_MEAN 0

16. PDP Option

Item Default data control register Range Remark

Pixel Shift Test Off ON/OFF

Panel Pattern Select 0

Panel Resolution -

Panel Inch -

Panel Version -

Panel Temperature -

Logic SW Version -

Model Select P450

Factory Data Type 42SP5

Checksum -

MB SW Off

MB Offset 0xC0

Ve Signal Control 0xBFFF

FRC Mode 100Hz

FRC DBG MarkOn 0

17. Checksum

18. Reset

Page 48

Troubleshooting

Samsung Electronics 4-25

4-2-4 Service Adjustment - You must perform Calibration in the Lattice Pattern before adjusting the White Balance.

■■

Color Calibration

Adjust spec.

1. Source : HDMI

2. Setting Mode : 1280*720@60Hz

3. Pattern : Pattern #24 (Chess Pattern)

4. Use Equipment : CA210 & Master MSPG925 Generator

※ Use other equipment only after comparing the result with that of the Master equipment.

( Chess Pattern )

Input mode Calibration Pattern

CVBS IN (Model_#1) Perform in NTSC B&W Pattern #24 Lattice

Component IN (Model_#6) Perform in 720p B&W Pattern #24 Lattice

PC Analog IN (Model_#21)

Perform in VESAXGA(1024x768)

B&W Pattern #24

Lattice

HDMI IN Perform in 720p B&W Pattern #24 Lattice

<Table 1>

Page 49

Troubleshooting

4-26 Samsung Electronics

■ Method of Color Calibration (AV)

1) Apply the NTSC Lattice (N0. 3) pattern signal to the AV IN 1 port

2) Press the Source key to switch to "AV1" mode

3) Enter Service mode

4) Select the "Calibration" menu

5) Select the "AV Calibration" menu.

6) In "AV Calibration Off" status, press the "▶" key to perform Calibration.

7) When Calibration is complete, it returns to the high-level menu.

8) You can see the change of the "AV Calibration" status from Failure to Success.

■ Method of Color Calibration (Component)

1) Apply the 720p Lattice (N0. 6) pattern signal to the Component IN 1 port

2) Press the Source key to switch to "Component1" mode

3) Enter Service mode

4) Select the "Calibration" menu

5) Select the "Comp Calibration" menu.

6) In "Comp Calibration Off" status, press the "▶" key to perform Calibration.

7) When Calibration is complete, it returns to the high-level menu.

8) You can see the change of the "Comp Calibration" status from Failure to Success.

■ Method of Color Calibration (PC)

1) Apply the VESAXGA Lattice (N0. 21) pattern signal to the PC IN port

2) Press the Source key to switch to "PC" mode

3) Enter Service mode

4) Select the "Calibration" menu

5) Select the "PC Calibration" menu.

6) In "PC Calibration Off" status, press the "▶" key to perform Calibration.

7) When Calibration is complete, it returns to the high-level menu.

8) You can see the change of the "PC Calibration" status from Failure to Success.

■ Method of Color Calibration (HDMI)

1) Apply the 720p Lattice (N0. 6) pattern signal to the HDMI1/DVI IN port

2) Press the Source key to switch to "HDMI1" mode

3) Enter Service mode

4) Select the "Calibration" menu

5) Select the "HDMI Calibration" menu.

6) In "HDMI Calibration Off" status, press the "▶" key to perform Calibration.

7) When Calibration is complete, it returns to the high-level menu.

8) You can see the change of the "HDMI Calibration" status from Failure to Success.

Page 50

Troubleshooting

Samsung Electronics 4-27

■

■

White Balance

Adjust spec.

1. Source : HDMI

2. Setting Mode : 1280*720@60Hz

3. Pattern : Pattern #92

4. Use Equipment : MIK-7256 (MSPG925L)

5. Work order

① Connect HDMI (DVI) output terminal of MIK-7256 (MSPG925L) to the HDMI input in main set

② Set the input to HDMI mode

③ Enter the White Balance menu of service mode

④ Contact CA-210 sensor to glass filter

⑤ Adjust the low light

- Adjust Sub-Bright (LBE) to set the 'Y' value

- Adjust R-Offset ('x') and B-Offset ('y') to the color coordinates.

* Do not adjust G-Offset data

⑥ Adjust the high light.

- Adjust Sub-Contrast (LBE) to set the 'Y' value

- Adjust R-Gain ('x') and B-Gain ('y') to the color coordinates.

* Do not adjust the G-gain data

( SAMSUNG WHITE BALANCE Adjustment PATTERN with FPD )

( Fixed Position of CA210 Probe )

Page 51

Troubleshooting

4-28 Samsung Electronics

Input mode

(CA-210)

x Y(L) T(K), MPCD

CVBS

(NTSC)

H/L 278

FIX

10,500 (± 0)

(Sub_CT:128)

L/L 278

10.5 cd/㎡

11,000 (-3)

(3.0 Ft)

COMP

(720P)

H/L 278

FIX

10,500 (± 0)

(Sub_CT:128)

L/L 278

10.3 cd/㎡

11,000 (-6)

(3.0 Ft)

HDMI

(720P)

H/L 278

FIX

10,500 (± 0)

(Sub_CT:128)

L/L 278

10.3 cd/㎡

10,500 (± 0)

(3.0 Ft)

Page 52

Troubleshooting

Samsung Electronics 4-29

Replaced assembly items Check Items

ASSY PCB MISC-MAIN

1) Auto Program

2) White Balance Adjust

SMPS-PDP TV Vs, Va voltage check and adjust

ASSY PDP MODULE P-LOGIC MAIN

Not to be adjusted

ASSY PDP MODULE P-X-MAIN

ASSY PDP MODULE P-Y-MAIN

ASSY PDP MODULE P-Y-MAIN SCAN BUFFER

ASSY PDP MODULE P-ADDRESS E BUFFER

ASSY PDP MODULE P-ADDRESS F BUFFER

ASSY BOARD P-SIDE HDMI A/V

* PDP 50" Check items listed after changing each

Replaced assembly items Check Items

ASSY PCB MISC-MAIN

1) Auto Program

2) White Balance Adjust

SMPS-PDP TV Vs, Va voltage check and adjust

ASSY PDP MODULE P-LOGIC MAIN

Not to be adjusted

ASSY PDP MODULE P-X-MAIN

ASSY PDP MODULE P-Y-MAIN

ASSY PDP MODULE P-Y-MAIN SCAN BUFFER

ASSY PDP MODULE P-Y-MAIN SCAN BUFFER

ASSY PDP MODULE P-ADDRESS E BUFFER

ASSY PDP MODULE P-ADDRESS F BUFFER

ASSY BOARD P-SIDE HDMI A/V

※ When replacing the SMPS or PDP panel, you have to check the voltage printed on the panel sticker and adjust it.

4-2-5 Replacements & Calibration

* PDP 42" Check items listed after changing each

Page 53

Troubleshooting

4-30 Samsung Electronics

2. Apoint of adjusting SMPS-MAIN voltage.

Value Board Adjustment

Vs 210

SMPS

Va 55

Vset -

Ve 95

Vscan -190

■

Voltage Adjustment

1. After replacing the SMPS or PDPpanel, you must adjust the voltage referring to the voltage label printed on the panel.

(If you do not adjust the voltage, an abnormal discharge symptom may appear.)

SMPS

Voltage Label

Vs

Va

Page 54

Troubleshooting

Samsung Electronics 4-31

■

■

Y-RR and Y-FR controls

Set the main reset (rising : 60usec, falling : 80usec) by change the value of variable resistor.

<42">

<50">

▶The picture is only for 50".

42" has only Falling ramp variable resistor.

Test Point

60usec

Rising ramp

variable resistor

Falling ramp

80usec

variable resistor

Test Point

Page 55

Troubleshooting

4-32 Samsung Electronics

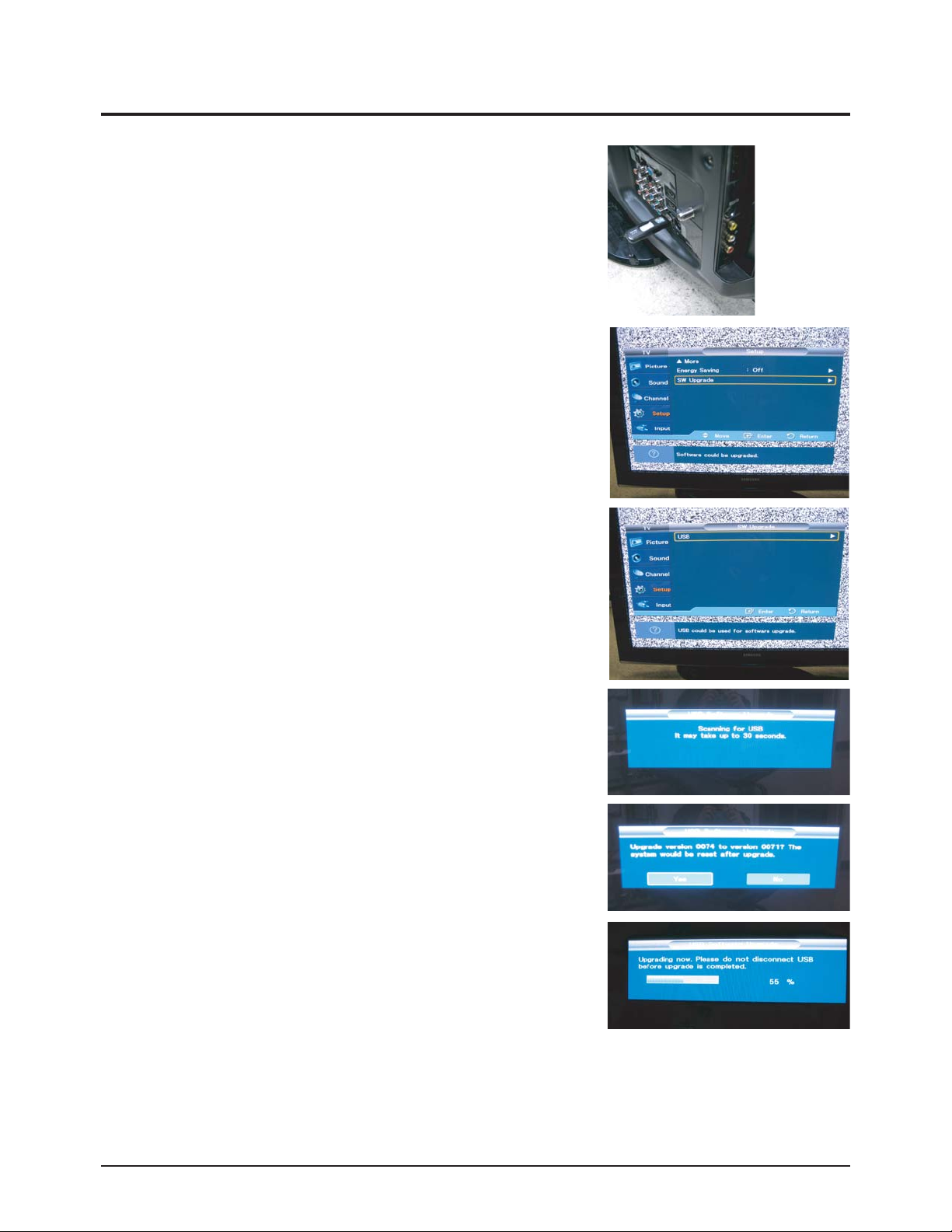

4-3 Upgrade

4-3-1 USB Download Method

1. Copy the Upgrade Files into the path "T-CRLAUSC" in USB flash driver.

2. USB Download

① Insert the USB Memory Stick to the SERVICE port in Stand-by mode.

② Turn the power on.

③ Press "MENU" and find "SW Upgrade" in Menu "SETUP".

④ Select the "SW Upgrade" from the menu.

⑤ Select "USB" from the menu.

⑥ The banner OSD "Scaning for USB..." is displayed.

⑦ The banner OSD "Upgrade version **** to version ****" is displayed.

Select "Yes".

⑧ The banner OSD "Upgrade version **** to version ****" is displayed.

It takes about 30 sec.

(Warning: Don't remove USB flash driver during upgrade.)

⑨ The banner OSD "Upgrade is completed" is displayed when the upgrade is

completed.

⑩ Remove the USB flash driver from PDP TV and check the program version.

Page 56

Troubleshooting

Samsung Electronics 4-33

4-3-2 How to Check the Version of the Program

1. Procedures for checking in the User Menu

① Select the "Setup" menu in the Menu screen

② Place the cursor over the "SW Upgrade" of "Setup" and press the "info" key on the remote control.

③ The version of the program is displayed at the bottom of the Menu screen

2. How to check Program Version on factory mode.

PROGRAM VERSION

PROGRAM VERSION

Page 57

Samsung Electronics5-1

Exploded View & Part List

5. Exploded View & Part List

5-1 PN42A450P1DXZC Exploded View

M0013

M0125

T0079

M0523

M0523

M0027

M0412

T0165

T0044

M0149

M0150

M0146

T0175

M0145

T0456

T0603

T0175

T0003

M0112

M0150

M0102

T0056

Page 58

5-2Samsung Electronics

Exploded View & Part List

Loc. No. Code No. Description Specification Q'ty SA/SNA Remark

M0013 BN96-06771A ASSY COVER P-REAR P450 42Inch,PCM,0.5,BK 1 S.A

M0027 BN96-05835A ASSY STAND P-BASE -,42Q9/42C9,-,ABS,SF-0 1 S.A

M0102 BN96-04802A ASSY BLU P Bordeaux Plus,BACK LIGHT UNIT 1 S.A

M0112 BN63-04217A COVER-FRONT 450 , 42",PMMA+ABS,HB,BK27,B 1 S.N.A

M0125 BN96-07190A ASSY INLET P Pyrope,350mm,IG-N06BES1,250 1 S.A

M0145 BN96-07248B ASSY BOARD P-FUNCTION&IR PYROPE,CT5000-5 1 S.A

M0146 BN96-06750B ASSY BRACKET P-FILTER SIDE P410 42Inch,S 2 S.N.A

M0149 BN96-06749A ASSY BRACKET P-FILTER TOP P450 42Inch,SA 1 S.N.A

M0150 BN96-06751A ASSY BRACKET P-FILTER BOTTOM P450 42Inch 1 S.N.A

M0150 BN96-06748A ASSY BRACKET P-SUPPORT FILTER P410 42Inc 1 S.N.A

M0412 BN96-06697D ASSY BRACKET P-PCB 42P450,SEA,SECC,T0.5 1 S.N.A

M0523 BN96-06753A ASSY BRACKET P-SUPPORT STAND P410 42Inch 1 S.N.A

M0523 BN96-06756A ASSY BRACKET P-WALL P410 42Inch,SECC T1. 2 S.A

T0003 BN96-06769A ASSY COVER P-FRONT P450 42Inch,,ABS+PMMA 1 S.A

T0044 BN96-07188A ASSY PDP MODULE P S42AX-YB04,42HD W3,PL4 1 S.A

T0056 BN63-04212A COVER-DECORATION 450 , 42",ABS,HB,GRAY(G 1 S.N.A

T0079 BN94-01461A ASSY PCB MISC-MAIN PN42A450P1DXZA,F45A,B 1 S.A

T0165 BN96-06696A ASSY COVER P-AV Spinel 50,58" 1 S.A

T0175 BN96-07086A ASSY SPEAKER P 8ohm,CORAL,PDP,10W,350/45 1 S.A

T0175 BN96-07086B ASSY SPEAKER P 8ohm,CORAL,PDP,10W,200mm, 1 S.A

T0456 BN67-00176A GLASS-FILTER EMI 42"C9,Sputter,T=46%,984 1 S.A

T0603 BN64-00628A WINDOW-RMC 50P9,PC,VIOLET 1 S.N.A

Page 59

Samsung Electronics5-3

Exploded View & Part List

5-2 PN42A450P1DXZC Service Item

Loc. No. Code No. Description Specification Q'ty Remark

M0013 BN96-06771A ASSY COVER P-REAR P450 42Inch,PCM,0.5,BK 1

M0027 BN96-05835A ASSY STAND P-BASE -,42Q9/42C9,-,ABS,SF-0 1

M0154 BN96-06760A ASSY PDP P-Y-MAIN BUFFER PL42AX030A,42HD 1

M0523 BN96-06756A ASSY BRACKET P-WALL P410 42Inch,SECC T1. 2

M2893 BN39-00827A LEAD CONNECTOR LILLY 42"/50",UL1007#26,U 1

T0003 BN96-06769A ASSY COVER P-FRONT P450 42Inch,,ABS+PMMA 1

T0037 BN96-06761A ASSY PDP P-LOGIC MAIN PL42AX030A,42HD W3 1

T0038 BN96-06762A ASSY PDP P-ADDRESS E-BUFFER PL42AX030A,4 1

T0039 BN96-06763A ASSY PDP P-ADDRESS F-BUFFER PL42AX030A,4 1

T0044 BN96-07188A ASSY PDP MODULE P S42AX-YB04,42HD W3,PL4 1

T0045 BN96-06757A ASSY PDP P-X-MAIN BOARD PL42AX030A,42HD 1

T0045 BN96-06758A ASSY PDP P-X-MAIN BUFFER PL42AX030A,42HD 1

T0074 BN59-00687A REMOCON TM-96B,49,AMERICA 1

T0079 BN94-01461A ASSY PCB MISC-MAIN PN42A450P1DXZA,F45A,B 1

T0175 BN96-07086A ASSY SPEAKER P 8ohm,CORAL,PDP,10W,350/45 1

T0175 BN96-07086B ASSY SPEAKER P 8ohm,CORAL,PDP,10W,200mm, 1

T0262 BN96-06759A ASSY PDP P-Y-MAIN BOARD PL42AX030A,42HD 1

T0764 BN44-00206A SMPS-PDP TV W3 PDP SMPS,SEM,AC/DC,406.6W 1

※ This is the list which is available to repair the real material at the time of service.

Page 60

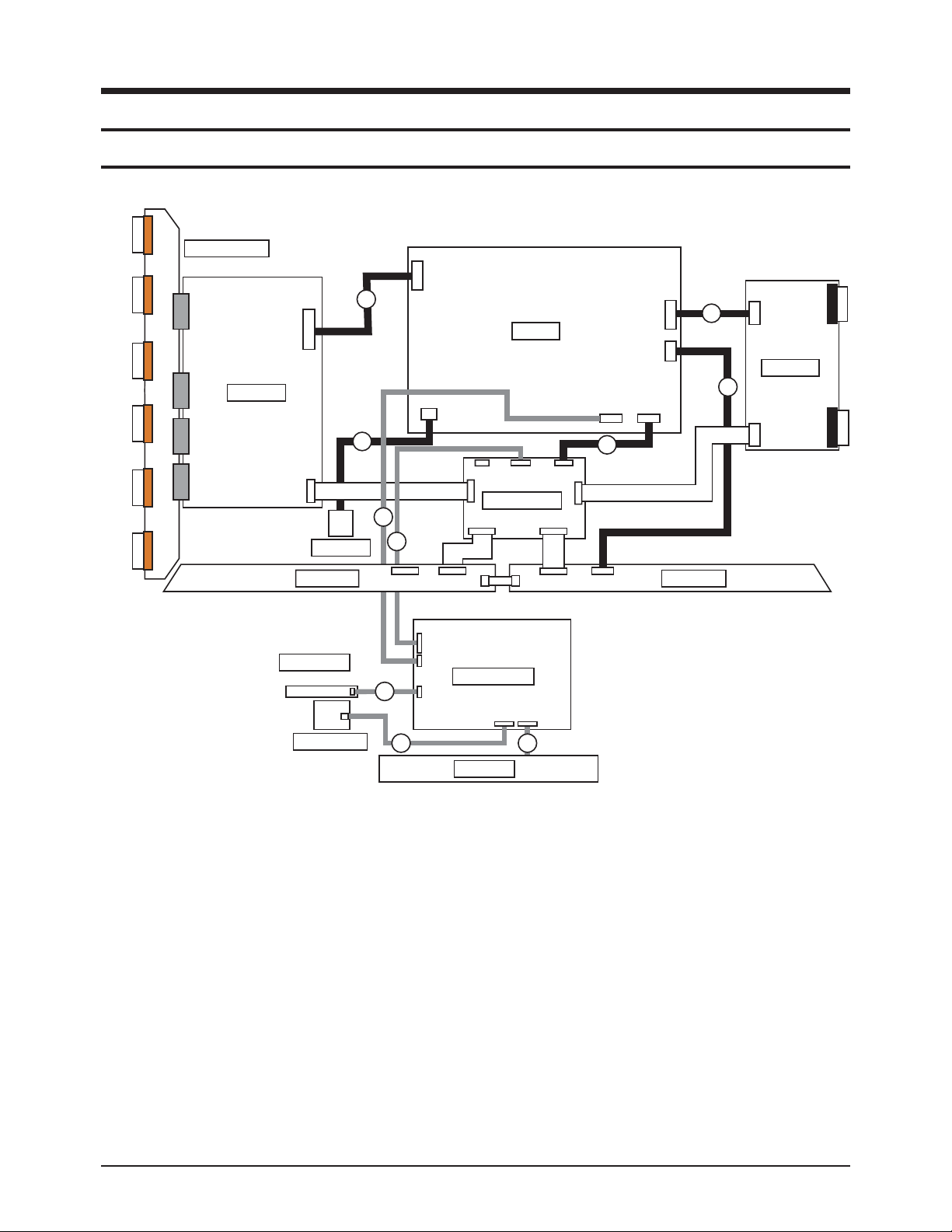

Wiring Diagram

Samsung Electronics 6-1

6. Wiring Diagram

6-1 Overall Wiring

<42" Overall Wiring>

CN5401

CN5402

CN5403

CN5501

CN5502

CN5503

Y-MAIN SCAN

CN5407

CN5408

Y-DRIVE

CN5409

CN5412

CN5707

CN5701

E-BUFFER

FUNCTION

AC-INLET

CN1

CN3

CN810

4

CN809

5

CN4701

CN4002

SMPS

CN808

X-DRIVE

6

CN800

11

CN2000CN2001CN2006

CN2002

2

LOGIC BOARD

CN2028

CN2004

CN801

CN2003

?

CN807

CN4001

7

CN4004

1

F-BUFFER

CN902

CN101

CN2500CN2509

CN2510

CN2600

CN2610

CN2609

MAIN BOARD

10

CN202P

CN201

CN401

POWER SW

8 9

SPEAKER

Page 61

<50" Overall Wiring>

※ The code number of cable(Lead-connector) can be changed, see "5. Exploded View & Part List."

Wiring Diagram

6-2 Samsung Electronics

Use

① LVDS ⑧ POWER CABLE ⑪ AC INLET

Code

42" - BN96-07158K

50" - BN96-07158F

BN39-00827A BN96-07190A

Photo

CN5401

CN5402

CN5403

CN5501

CN5502

CN5503

Y-MAIN SCAN(HIGH)

CN5407

CN5507

Y-MAIN SCAN(LOW)

4

AC-INLET

E-BUFFER

FUNCTION

CN3

CN810

5

CN809

CN4701

CN4002

SMPS

CN2609

X-DRIVE

CN4004

CN4001

CN4000

CN808

CN800

11

CN2000CN2001

CN2004

CN2500CN2509

CN2510

MAIN BOARD

CN201

CN2003

CN2005

CN2600

CN2610

CN401

CN1

CN2002

2

CN2006

LOGIC BOARD

1

CN902

CN101

10

CN202P

CN801

CN807

7

6

F-BUFFER

POWER SW

8

9

SPEAKER

Page 62

Wiring Diagram

Samsung Electronics 6-3

①

CN902(MAIN B'D) ↔ CN2001(LOGIC B'D)

Pin No. Signal Pin No. Signal

1 RxIN0- 16 NC

2 RxIN0+ 17 GND

3 RxIN1- 18 WP

4 RxIN1+ 19 SCL

5 RxIN2- 20 SDA

6 RxIN2+ 21 LVDS Opt

7 RxINCLK- 22 DCC Opt

8 RxINCLK+ 23 GND

9 RxIN3- 24 GND

10 RxIN3+ 25 GND

11 NC 26 Vdd

12 NC 27 Vdd

13 NC 28 Vdd

14 NC 29 Vdd

15 NC 30 Vdd

②

CN101(MAIN B'D) ↔ CN801(MAIN SMPS)

CN101(MAIN B'D) CN801(MAIN SMPS)

Pin No. Signal Pin No. Signal Pin No. Signal Pin No. Signal

1 NC 13 5V 1 PS_ON 13 5V

2 SW_POWER 14 5V 2 NC(Auto_V) 14 5V

3 GND 15 5V 3 STBY 15 5V

4 STD_VCC 16 5V 4 GND_STBY 16 5V

5 GND 17 GND 5 GND_18V AMP 17 GND_12V

6 GND 18 GND 6 GND_18V AMP 18 GND_12V

7 18V 19 GND 7 18V AMP 19 12V

8 18V 20 13V 8 18V AMP 20 GND_12V

9 GND 21 13V 9 GND_5V 21 12V

10 GND 22 13V 10 GND_5V 22 12V

11 GND 23 NC 11 GND_5V 23 NC(FAN_ON)

12 GND 24 NC 12 GND_5V 24 NC(FAN_DET)

6-1-1 Pin Connection

Page 63

Wiring Diagram

6-4 Samsung Electronics

③

CN703S(MAIN B'D) ↔ CN101(SIDE AV)

Pin No. Signal Pin No. Signal Pin No. Signal Pin No. Signal

1 GND 12 TXC- 23 NC 34 VIDEO_SR_IN

2 TX2+ 13 GND 24 NC 35 VIDEO_SL_IN

3 TX2- 14 MICOM_CEC 25 GND 36 HP_IDENT

4 GND 15 GND 26 SVHS_IDENT 37 HP_OUT_R

5 TX1+ 16 TSCL 27 SVHS_Y 38 HP_OUT_L

6 TX1- 17 TSDA 28 GND 39 USB_VCC

7 GND 18 LSCL 29 SVHS_C 40 B1.8V

8 TX0+ 19 HDMI3_5V 30 GND 41 B3.3V

9 TX0- 20 HPD_SIL9185 31 VIDEO_IDENT

10 GND 21 DDC_WP 32 VIDEO_CVBS

11 TXC+ 22 GND 33 GND

④

CN810(SMPS)

↔

CN5707_42"(Y B'D)

CN5407_50"(Y B'D)

Pin No. Signal

1 Vg

2 GND

3 GND

4 GND

5 Vs

6 Vs

⑤

CN809(SMPS)

↔

CN4701(X B'D)

Pin No. Signal

1 Vg

2 GND

3 GND

4 Vs

5 Vs

⑥

CN808(SMPS)

↔

CN2609(E-BUFFER)

Pin No. Signal

1 Va

2 GND

3 5.3V

⑨

CN401(MAIN B'D)

↔

SPEAKER

Pin No. Signal

1 R+_OUT

2 R-_OUT

3 L+_OUT

4 L-_OUT

⑩

CN202P(MAIN B'D)

↔

FUNCTION

Pin No. Signal

1 KEY_INPUT1

2 KEY_INPUT2

3 GND

⑪

CN800(SMPS)

↔

AC INLET

Pin No. Signal

1 AC Neutral

2 N/C

3 AC Live

⑦

CN807(SMPS)

↔

CN2000(LOGIC B'D)

Pin No. Signal

1 STBY

2 VS_ON

3 N/C

4 PS_ON

5 RTN

6 5.3V

7 RTN

8 RTN

9 5.3V

10 5.3V

⑧

CN201(MAIN B'D)

↔

POWER&IR

Pin No. Signal

1 IR

2 GND

3 A5V_1

4 LED_STB

5 BUZZER

6 KEY_INPUT1

7 KEY_INPUT2

8 GND

9 B5V

10 LED_CTRL

Page 64

Wiring Diagram

Samsung Electronics 6-5

42" Loc. No. 50" Loc. No. Description

CN5401 CN5401 Horizontal Y-scan line(1~128) of Module and Y-Main Scan Connect

CN5402 CN5402 Horizontal Y-scan line(129~256) of Module and Y-Main Scan Connect

CN5403 CN5403 Horizontal Y-scan line(256~384) of Module and Y-Main Scan Connect

- CN5512 Y-Main Scan(High) and Y-Main Scan(Low) Connect

CN5501 CN5501 Horizontal Y-scan line(384~512) of Module and Y-Main Scan Connect

CN5502 CN5502 Horizontal Y-scan line(512~640) of Module and Y-Main Scan Connect

CN5503 CN5503 Horizontal Y-scan line(640~768) of Module and Y-Main Scan Connect

CN5407 CN5407 Upper Y-Drive and Y-Main Scan Connect

CN5507 CN5507 Lower Y-Drive and Y-Main Scan Connect

CN5707 CN5507 Vs(205V),Vg(15v) Power input connect(6Pin) of Y-Drive

CN5701 CN5701 Y-Drive control signal from Logic Board

CN810 CN810 Vs(205V),Vg(15v) Power input connect(6Pin) of SMPS for Y-Drive

CN809 CN809 Vs(205V),Vg(15v) Power input connect(6Pin) of SMPS for X-Drive

CN808 CN808 Va(63V) ,5.3V Power input connect(3Pin) of SMPS for F-Buffer

CN807 CN807 Power input connect(10pin) for Logic Board

CN801 CN801 Image signal(LVDS) connect(41pin) from Main Board

CN800 CN800 AC Power input connect from AC-inlet

CN4002 CN4002 Horizontal X-scan line of Module and X-scan Connect(first Block)

CN4001 CN4001 Horizontal X-scan line of Module and X-scan Connect(second Block)

- CN4000 Horizontal X-scan line of Module and X-scan Connect(third Block)

CN2000 CN2000 Power input connect(10pin) of Logic Board from SMPS

CN2001 CN2001 Image signal(LVDS) connect(41pin) of Logic board from Main Board

CN2002 CN2002 Y-Drive control signal of Logic Board

CN2004 CN2005 Address Data(684th~1366th) connect for F-Buffer board

CN2028 CN2004 Address Data(1st~683th) connect for E-Buffer board

CN2500 CN2500 Address Data(1st~683th) connect from Logic Board

CN2510 CN2510 Power input connect from F-Buffer Board

CN2610 CN2610 Power input connect to E-Buffer Board

CN2600 CN2600 Address Data(684th~1366th) connect from Logic board

CN2609 CN2609 Va(63V) ,5.3V Power input connect(3Pin) from SMPS

CN1101 CN1101 Power input connect(24Pin) from SMPS

CN2202 CN2202 Image signal(LVDS) connect(41pin) for Logic board

CN1605 CN1605 Function input(source,ch up/down...) connect on Main board

CN1404 CN1404 Video signal input connect form Side AV ass'y

CN1606 CN1606 Power SW input connect on Main Board

CN1203 CN1203 Speak out connect on Main Board

CN101 CN101 Video signal input connect on Side AV ass'y

CN1 CN1 Function input(source,ch up/down...) connect to Main board

CN3 CN3 Power SW input connect to Main Board

6-1-2 Connector role

Page 65

6-6 Samsung Electronics

MEMO

Page 66

Schematic Diagram

Samsung Electronics 7-1

7. Schematic Diagram

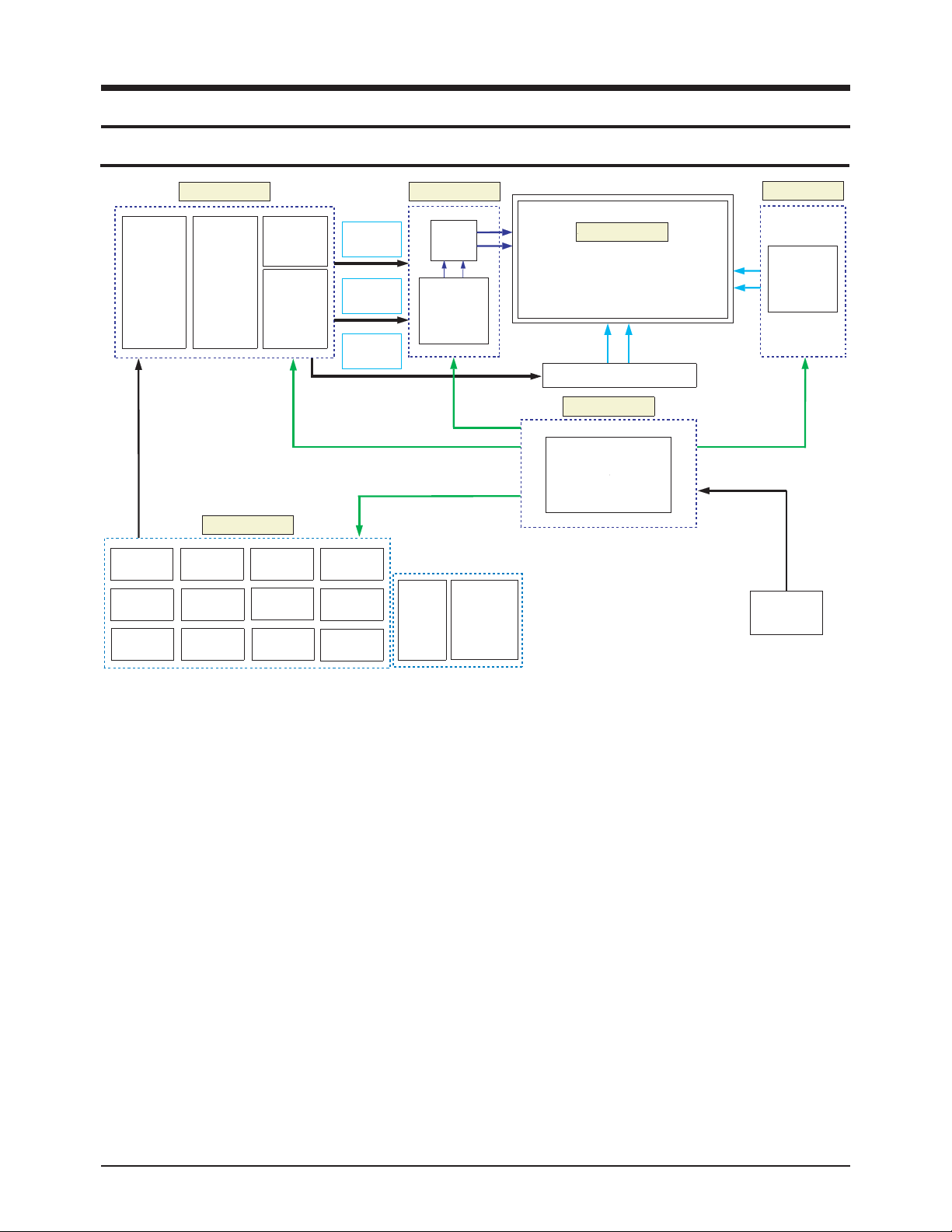

7-1 Circuit Description

■ SMPS Board

The SMPS used for the PDP has been designed to be efficient, compact and lightweight. For VS and VAoutputs, a LLC converter

has been used. For the other outputs, a Flyback converter has been used.

■ LOGIC Board

The logic circuit consists of a Logic Main Board and an Address Buffer Board. The Logic Main Board decodes the video signal

encoded by the Video Board, outputs the ADDRESS data signal for each pattern and generates X and Y drive signals. The

Address Buffer Board buffers and transfers the ADDRESS data output signal using TCP IC.

- LVDS with built-in video signal processing (W/L, error diffusion, APC, FCR, etc.) applied and 1 ASIC chip.

- Outputs the address Drive IC control and data signals to the Buffer Board.

- Outputs the control signal for the X and Y Drive Boards.

- Monitors major drive voltages (Micom Circuit Block); detects if a surge voltage has been applied and protects the Drive Circuit.

- Temperature Adaptive Operating Mode (Low Temperature/Room Temperature/High Temperature); Discharge optimization for

each temperature level.

■ X-MAIN Board

Connects to the X terminal block, 1) provides maintaining voltage waveform (including ERC), and 2) maintains the Ve bias in the

Scan section.

■ Y-MAIN Board

Connects to the Y terminal block, 1) provides maintaining voltage waveform (including ERC), 2) provides Y Rising, Falling Ramp

waveforms, and 3) maintains the Vscan bias.

■ Address Buffer Board

It delivers the data signal and control signal to the TCP.

LVDS

Recever

Input

Data

Processor

LVDS

Trans

Image

Scaler

TMDS

Logic Board

Data

Controller

Main Board

Image

Enhancer

CPU

Decoder

A/D

Converter

DRAM

Driver

Timing

Controller

Deinterlacer

Video

Decoder

Video

S/W

Display

Data

Display

Timing

Scan

Timing

Audio

Processor

Speaker

Out

Micom

Y Main Board

Driver

Y-Pulse

Generator

Tune r

Row

RF

Splitter

PDP Panel

42” - 1024x768 Pixels

1024x768x3 Cells (R,G,B)

50” - 1365x768 Pixels

1365x768x3 Cells (R,G,B)

Address Buffer

SMPS Board

Main SMPS

X Main Board

X-Pulse

Generator

AC Power

Source

Page 67

7-2 Samsung Electronics

MEMO

Page 68

Samsung Electronics

Schematic Diagram

7-3

E

B

C

VDD

GND

E

B

C

VIN VOUT

ADJ

OUT

GND

OUTIN

VIN VOUT

ADJ

VIN VOUT

ADJ

E

B

C

GND

OUTIN

GND

OUTIN

D

DSGD

D

/RESET,RESE

VDD

GND

OUT

GND

OUTIN

OUT

GND

OUTIN

This Document can not be used without Samsung’s authorization.

7-2 Schematic Diagram

7-2-1 MAIN POWER BLOCK

Power

A5V

TP1004

CN1001

C1084

10uF

10V

SMW200-24C

CN_N_024

B13V

FGND

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

TP1001

IC1008

BA178M09FP

FGND

FGND

Invert_HSYNC

TP1017

TP1002

B8V

FGND

TP1003

C1072

10uF

D1011

LL4148

75V

10V

TP1005

IC1009

KIA7805AF

FGND

TP1007

TP1006

B13V_S

B5V_TUNER

TP1018

C1066

10uF 10NF

10V

FGND

B5V - A5 _1 OPTION

A5V_1

ADD

DELETE

A5V_1

PIHC_DAEB

D911DB

32

C1050

100nF

16V

FGND