Page 1

4-1-1 Before Making Adjustments

4-1-1 (a) ORIENTATION

When servicing, always face the monitor to the

east.

4-1-1 (b) MAGNETIC FIELDS

Whenever possible, use magnetic field isolation

equipment such as a Helmholtz field to surround

the monitor. If a Helmholtz field is not available,

frequently degauss the unit under test.

Caution: Other electrical equipment may cause

external magnetic fields which may

interfere with monitor performance.

Use an external degaussing coil to limit magnetic

build up on the monitor. If an external degaussing

coil is not available, use the internal degaussing

circuit. However, do not use the internal

degaussing circuit more than once per 30 minutes.

4-1-1 (c) WARM-UP TIME

The monitor must be on for 30 minutes before

starting alignment. Warm-up time is especially

critical in color temperature and white balance

adjustments.

4-1-1 (d) SIGNAL

Analog, 0.7 Vp-p positive at 75 ohm, internal

termination

Sync: TTL level, negative/positive

4-1-1 (e) SCANNING FREQUENCY

Horizontal: 30 kHz ~ 85 kHz (Automatic)

Vertical: 50 Hz ~ 160 Hz (Automatic)

Unless otherwise specified, adjust at the

1024 x 768 mode (68 kHz/85 Hz) signal.

4-1-2 Required Equipment

The following equipment may be necessary for

adjustment procedures:

4-1-2 (a) DISPLAY CONTROL ADJUSTMENT

1. Non-metallic (–) screwdriver:

1.5, 2.5, 3 mm

2. Non-metallic (+) screwdriver:

1.5, 2.5, 3 mm

3. Digital Multimeter (DMM), or

Digital Voltmeter

4. Signal generator, or

DM200 software

5. Software: Softjig or DM200

6. Interface Board Ver. 2.0 Code No.

BH81-90001K

7. Parallel communications cable (25-pin to

25-pin); Code No. BH81-90001H

8. Signal cable (15-pin to 15-pin cable with

additional 3-pin connector); Code No.

BH81-90001J

9. 5 V DC adapter, not supplied

10. Personal computer

Note: Softjig Ass’y (includes items 6, 7 and 9)

Code No. BH81-90001L

4-1-2 (b) COLOR ADJUSTMENTS

1. All equipment listed in 4-1-2 (a), above

2. Color analyzer, or any luminance

measurement equipment

PN17MT/MO 4-1

4 Alignment and Adjustments

This section of the service manual explains how to make permanent adjustments to the monitor. Directions

are given for adjustments using the monitor Interface Board Ver. 2.0 and software (Softjig).

4-1 Adjustment Conditions

Caution: Changes made without the Softjig are saved only to the user mode settings. As such, the

settings are not permanently stored and may be inadvertently deleted by the user.

Page 2

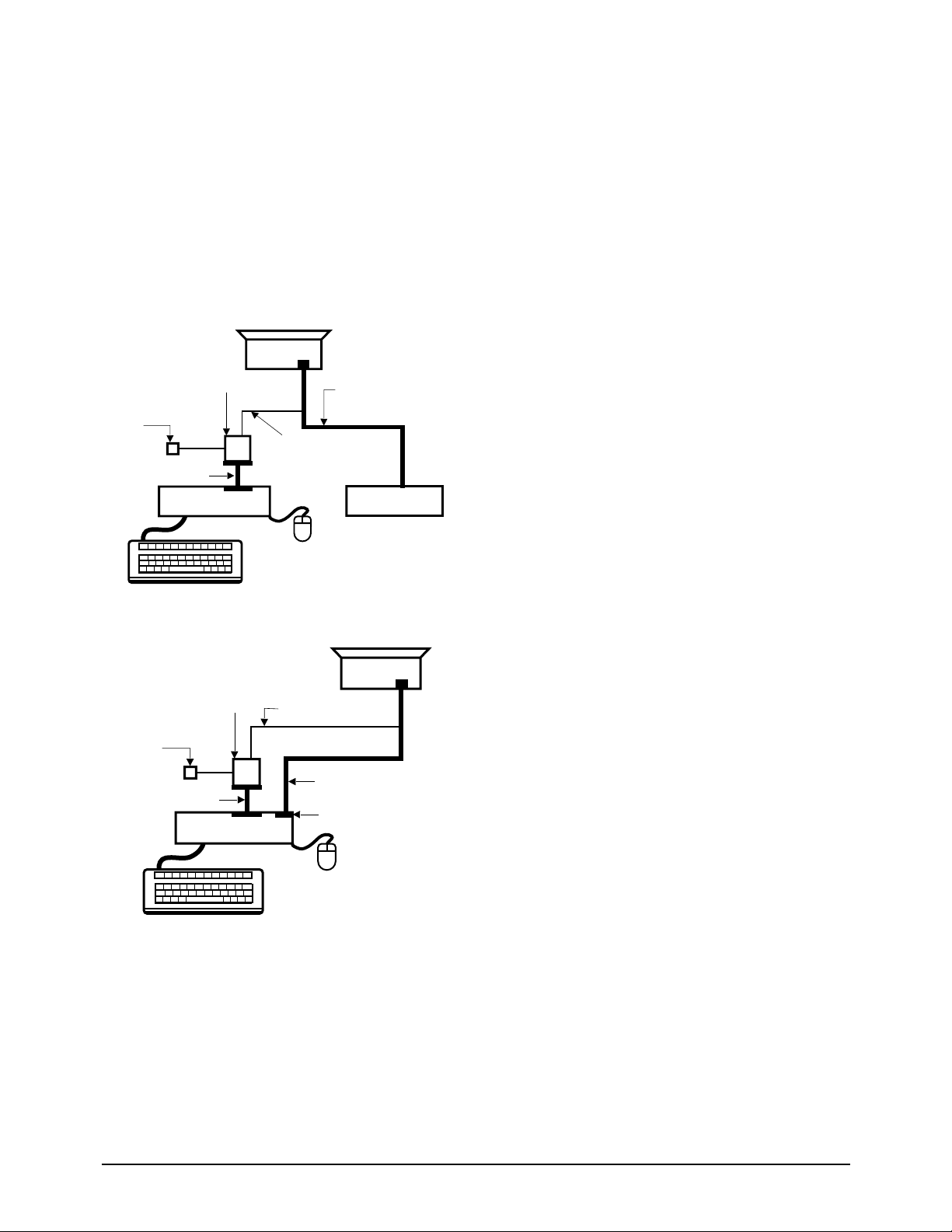

4-1-3 Connecting the SoftJig

Connect the monitor to the signal generator and/

or PC as illustrated in Figures 4-1 and 4-2.

Note: The signal cable connector which includes

the 3-wire cable must connect to the

monitor. If you use Setup 2 (PC only, no

signal generator) you can only make

adjustments to the signal timing available

on that computer system. To make

corrections to all factory timings requires

the use of an additional signal generator.

4 Alignment and Adjustments

4-2 PN17MT/MO

MONITOR

INTERFACE

BOARD VER. 2.0

PC

SIGNAL

GENERATOR

3-WIRE

CABLE

SIGNAL CABLE

5V DC

ADAPTOR

PARALLEL CABLE

Figure 4-1. Setup 1, With Signal Generator

MONITOR

INTERFACE

BOARD VER. 2.0

PC

3-WIRE CABLE

SIGNAL CABLE

PARALLEL CABLE

D-SUB

CONNECTOR

5V DC

ADAPTOR

Figure 4-2. Setup 2, Without Signal Generator

Page 3

4-2-1 HIGH VOLTAGE ADJUSTMENT

Signal: 1024 x 768 (68 kHz/85 Hz)

Display image: Don’t care

Contrast: Manimum

Brightness: Manimum

Limit: 26.0 kV ± 0.3 kV

Measure the hight voltage level at the anode cap.

High voltage should be within the limit as above.

If the high voltage needs adjustment use the

following procedure.

PROCEDURE

1. Turn the power off and disconnect the AC line

cord from the power source.

2. Turn the power on after connecting high

voltage Probe.

3. Using the jig, adjust the high voltage to the

specification.

* High Voltage Adjustment PROCEDURE using Softjig

① Select matching model name in “Model” field.

➁ Select “ @7: Zero Beam” in menu after

selecting “Extra 1”

➂ Adjust high voltage using control bar after

selecting “HV VOL”

➃ Turn the power off/on after adjustment

finished.

➄ Check the high voltage has been fixed with

adjusted value after reselecting “@7: Zero Beam”.

4-2-2 SCREEN VOLTAGE CHECK

CONDITIONS

Signal: 1024 x 768 (68 kHz/85 Hz)

Display image: Don’t care

Contrast: Manimum

Brightness: Manimum

Limit: 520 V ± 10 V

Screen Voltage adjustment procedure using softjig

is all the same as 4-2-1 but selecting “G2 CONT”

on the contary to “HV Min”.

4-2-3 CENTER RASTER

Adjust SW401 so that the back raster comes to the

center when you apply each basic mode.

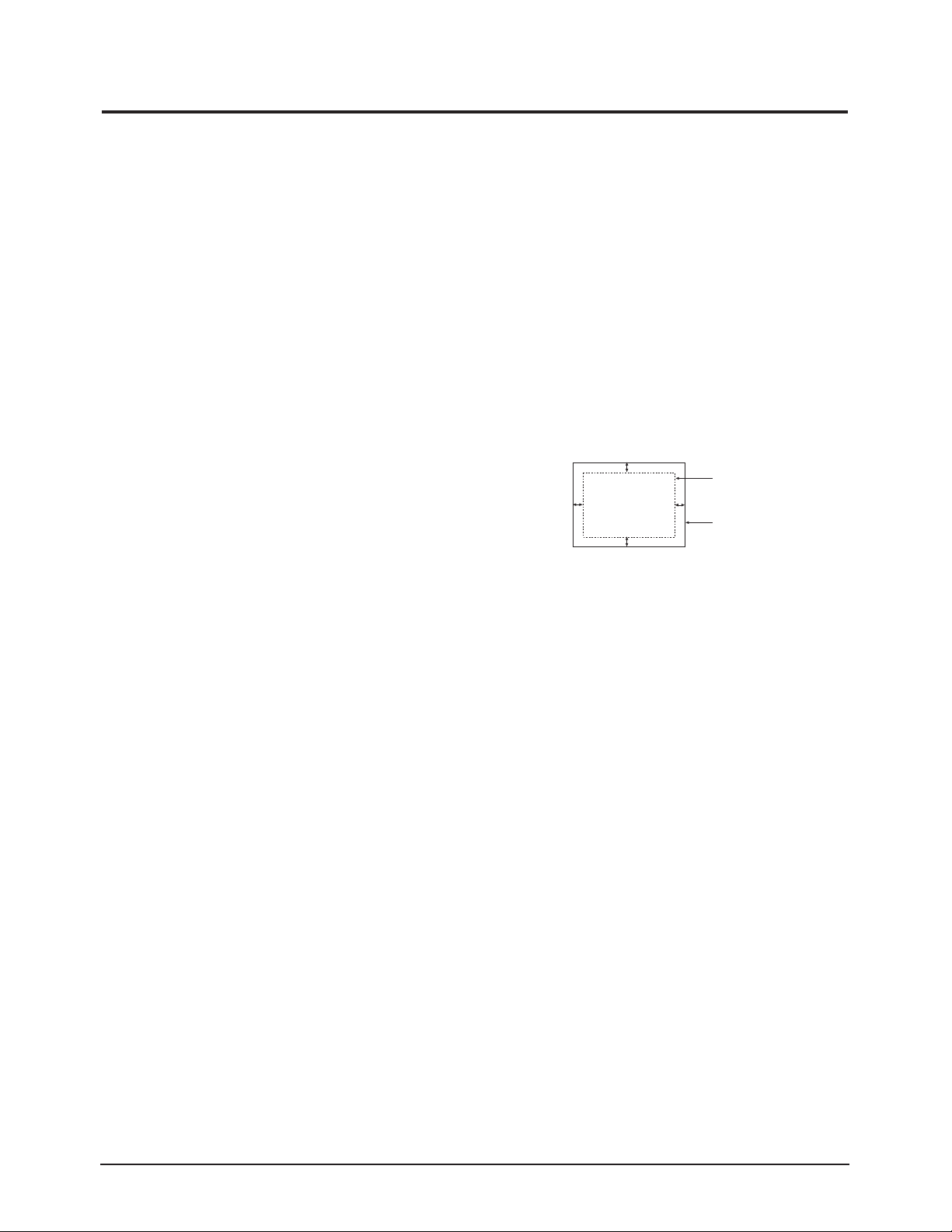

4-2-4 Centering

Centering means to position the center point of

the display in the middle of the display area.

Horizontal size and position and vertical size and

position control the centering of the display.

Adjust the horizontal size and vertical size to their

optimal settings: 312 mm (H) x 234 mm.

Adjust the horizontal position and vertical

position to ≤ 4.0 mm of the center point of the

screen.

|A-B| ≤ 4.0 mm |C-D| ≤ 4.0 mm

Figure 4-3. Centering

4-2-4 (a) HORIZONTAL SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “SIZE B+” in left

menu to adjust the horizontal size of the display

pattern to 312 mm .(Tolerance: ± 4 mm.)

Specially run “All mode save” after horizontal

size adjustment in order to save “SIZE B+” values

of other modes automatically.

4-2-4 (b) VERTICAL SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “V-SIZE” in left

menu to adjust the vertical size of the display

pattern to 234 mm. (Tolerance: ± 3 mm.)

4 Alignment and Adjustments

PN17MT/MO 4-3

4-2 Display Control Adjustments

C

A

DISPLAY AREA

EDGE OF BEZEL

B

D

Page 4

4-2-4 (c) HORIZONTAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Use control bar after selecting “H-POSITION” in

left menu to center the horizontal image on the

raster.

4-2-4 (d) VERTICAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Use control bar after selecting “V-POSITION” in

left menu to center the vertical image on the

raster.

4-2-5 Linearity

Linearity affects the symmetry of images as they

appear on the screen. Unless each row or column

of blocks in a crosshatch pattern is of equal size,

or within the tolerances shown in Table 4-1 an

image appears distorted, elongated or squashed.

Horizontal Linearity = 2x x100

Vertical Linearity = 2x x100

Table 4-1

❈ Preset Mode : 68KHz / 85Hz

Pre-load Mode : Refer to Timing Chart

4-2-5 (a) HORIZONTAL LINEARITY ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

To adjust the Horizontal Linearity, refer to Table

4-1 for the tolerance range.

Increase or decrease H_LIN to optimize the

image.

4-2-5 (b) VERTICAL LINEARITY ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

To adjust the Vertical Linearity, refer to Table 4-1

for the tolerance range.

Use control bar after selecting “V-LINEARITY

BAL” in left menu to optimize the image.

4 Alignment and Adjustments

4-4 PN17MT/MO

Preset mode ≤ 4% ≤ 8%

Adjacent Linearity

Entire Linearity

Pre-load mode (48kHz~) ≤ 5% ≤ 10%

Pre-load mode (under 48kHz) ≤ 5% ≤ 14%

X max-X min

X max+X min

Y max-Y min

Y max+Y min

Page 5

4-2-6 Trapezoid Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “TRAPEZOID” in

left menu to make the image area rectangular.

Figure 4-4. Trapezoid

4-2-7 Pinbalance Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “PINBALANCE” in

left menu to optimize the image.

4-2-8 Parallelogram Adjustment

CONDITIONS

Scanning Frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “PARALLEL” in

left menu to make the image area rectangular.

Figure 4-6. Parallelogram

4-2-9 Side Pincushion Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Use control bar after selecting “PINCUSHION” in

left menu to straighten the sides of the image area.

4-2-10 Tilt Adjustment

CONDITIONS

Scanning Frequency: 68 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Use control bar after selecting “ROTATION” in

left menu to correct the tilt of the display.

4-2-11 Degauss

No adjustments are available for the degaussing

circuit. The degaussing circuit can effectively

function only once per 30 minutes.

4-2-12 To Delete the User Mode Data

To delete the adjustment data from the user

modes, click “@4: USER DELETE” in right ment.

4-2-13 Save the Data

To save the adjustment data for a mode, press

“@3: ALL MODE SAVE” in right ment.

4 Alignment and Adjustments

PN17MT/MO 4-5

| A - B | < 4 mm

A

4 mm

B

B

A

D1 D2 D1

Figure 4-5. Pinbalance

| C1 |, | C2 | ≤ 2.0 mm, | D1 |, | D2 | ≤ 2.0 mm.

Figure 4-7. Pincushion

C2

C1

D1 D2

Page 6

CAUTION: Check below condition before color

adjustment Video signal : Analog 0.7

Vp-p (at 75 Ω)

Sync : TTL level (H, V seperate signal)

* Select “Color” in Softjig menu for color adjustment.

4-3-1 Color Coordinates (Temperature)

Color temperature is a measurement of the

radiant energy transmitted by a color. For

computer monitors, the color temperature refers

to the radiant energy transmitted by white. Color

coordinates are the X and Y coordinates on the

chromaticity diagram of wavelengths for the

visible spectrum.

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 68 kHz/85 Hz

Display image: White flat field at

center of display area

Luminance: Maximum

PROCEDURE

Use the directions in sections 4-3-2 through 4-3-3

to adjust the color coordinates for:

9300K to x = 0.283 ± 0.02, y = 0.298 ± 0.02

6500K to x = 0.313 ± 0.02, y = 0.329 ± 0.02

4-3-2 Color Adjustments for 9300K

4-3-2 (a) BACK RASTER COLOR ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Back raster pattern

Brightness: Maximum

Contrast: Maximum

1. Select “@1: CHANNEL 1” in right menu to

control the color for 9300K.

2. Adjust the luminance of the back raster to

between 0.5 to 0.7 ft-L using contron bar after

selecting “GREEN CUTOFF” in the menu.

3. Use control bar after selecting “BLUE

CUTOFF” in left menu to set the “y”

coordinate to 0.298 ± 0.02

4. Use control bar after selecting “RED

CUTOFF” in left menu to 0.283 ± 0.02

* If color values would not be matched desirable

values, repeat sequence 3 and 4 after readjusting

“GREEN CUTOFF” control a little different.

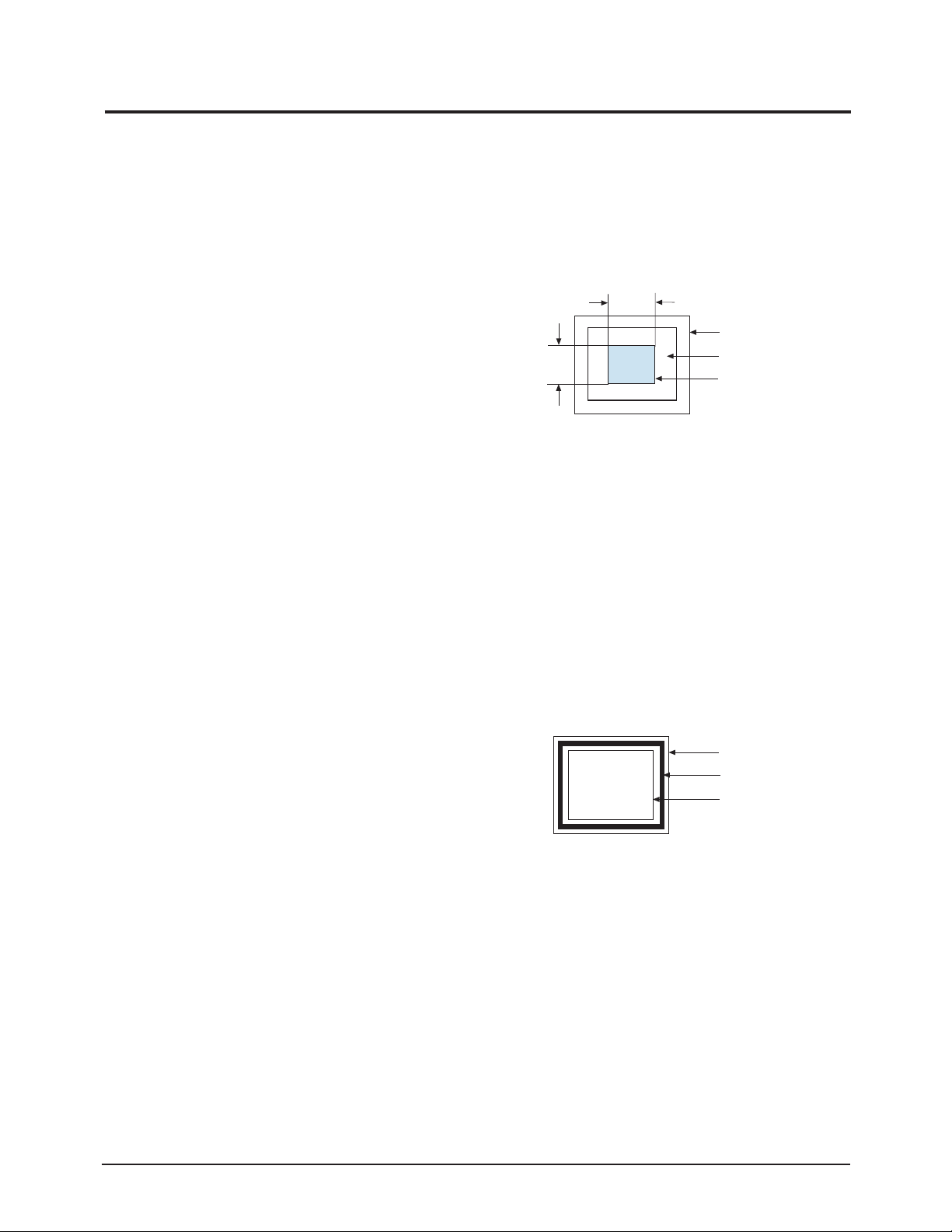

4-3-2 (b) WHITE BALANCE ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: White box pattern

Brightness: 0.06ft-L at Back Raster

Pattern Display

Contrast: Maximum

Figure 4-8. White Box Pattern

1. Use control bar after selecting “RED GAIN”,

“GREEN GAIN” and “BLUE GAIN” to adjust

the luminance to 40 ft-L with the color

coordinates ranged for

9300K to x = 0.283 ± 0.02, y = 0.298 ± 0.02.

4-3-2 (c) ABL ADJUSTMENT

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

Display image: Full white pattern

Brightness: 0.06ft-L at Back Raster

Pattern Display

Contrast: Maximum

Figure 4-9. Full White Pattern

1. Check the ABL. If it is not within the

specifications, use the ABL controls to adjust

it. (29 ± 1 ft-L)

2. Select “@4: COLOR SAVE” to save the data.

3. Select “@6: ALL COLOR SAVE” to save the

CH2.

4-3-2 (d) WHITE BALANCE ADJUSTMENT VERIFICATION

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

1/3H-1/2H

1/3V-1/2V

FRONT BEZEL OPENING

BACK RASTER

WHITE WINDOW

FRONT BEZEL OPENING

BACK RASTER

WHITE WINDOW

4 Alignment and Adjustments

4-6 PN17MT/MO

4-3 Color Adjustments

Page 7

Display image: Back raster pattern

Full White Pattern

X-Y Coordinates: x = 0.283 ± 0.02,

y = 0.298 ± 0.02

ABL Luminance Refer to 4-3-2(c)

Brightness: Maximum

Contrast: 5 ft-L, 24 ft-L

1. Check whether the color coordinates of the

back raster satisfy the above spec.

If they do not, return to 4-3-2 (a) and readjust

all settings.

2. Display a full white pattern.

3. Select “Geometry” in softjig menu.

4. Select “@7: 5-ft “ in right menu.

5. Check whether the white coordinates of the

video meet the above coordinates spec.

6. Select “@8: 24-ft “ in right menu.

7. Check whether the white coordinates of the

video satisfies the above spec.

If they do not, return to 4-3-2 (a) and readjust

all settings.

Select “Color” and click “@2: CHANNEL 2”

for color ajdustment for 6500K

Repeat the sequence of 9300K adjustment.

The luminance values the same as 9300K, but

the color coordinated of back raster and white

box are : x = 0.313 ± 0.02 y = 0.329 ± 0.02

4-3-3 Luminance Uniformity Check

Luminance is considered uniform only if the ratio

of lowest to highest brightness areas on the screen

is not less than 7.5:10.

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

(1024 x 768)

Display image: White flat field

Brightness: Cut off point at 0.06 ft-L

Contrast: Maximum

PROCEDURE

Measure luminance at nine points on the display

screen (see figure below).

4-3-4 Focus Adjustment

CONDITIONS

Scanning frequency: 68 kHz/85 Hz

(1024 x 768)

Display image: “H” character pattern

Brightness: Cut off point

Contrast: Maximum

PROCEDURE

1. Adjust the Focus VR on the FBT to display the

sharpest image possible.

2. Use Locktite to seal the Focus VR in position.

4-3-5 Color Purity Adjustment

Color purity is the absence of undesired color.

Conspicuous mislanding (unexpected color in a

uniform field) within the display area shall not be

visible at a distance of 50 cm from the CRT

surface.

CONDITIONS

Orientation: Monitor facing east

Scanning frequency: 68 kHz/85 Hz

Display image: White flat field

Luminance: Cut off point at the center

of the display area

Note: Color purity adjustments should only be

attempted by qualified personnel.

PROCEDURE

For trained and experienced service technicians only.

Use the following procedure to correct minor

color purity problems:

1. Make sure the display is not affected by

external magnetic fields.

2. Make sure the spacing between the PCM

assembly and the CRT stem is 29 mm ± 1 mm.

3. Display a green pattern over the entire display

area.

4. Adjust the purity magnet rings on the PCM

assembly to display a pure green pattern.

(Optimum setting: x = 0.295 ± 0.015, y = 0.594 ± 0.015)

Table 4-4. Color Purity Tolerances

(For 9300K color adjustment: x = 0.283 ± 0.02, y = 0.298 ± 0.02)

5. When you have the PCMs properly adjusted,

carefully glue them together to prevent their

movement during shipping.

4 Alignment and Adjustments

PN17MT/MO 4-7

Figure 4-10. Luminance Uniformity Check Locations

Red: x = 0.640 ± 0.015 y = 0.323 ± 0.015

Green: x = 0.295 ± 0.015 y = 0.594 ± 0.015

Blue: x = 0.142 ± 0.015 y = 0.066 ± 0.015

Page 8

Memo

4 Alignment and Adjustments

4-8 PN17MT/MO

Loading...

Loading...