PROJECTION TV RECEIVER

Chassis : P51A

Model: PCJ522RX/XAA

PCJ612RX/XAA

PCJ522RX/XAC

PCJ612RX/XAC

PROJECTION TV RECEIVER C O N T E N T S

Precautions

1.

Reference Information

2.

Specifications

3.

Alignment and Adjustments

4.

Troubleshooting

5.

Exploded View and Parts List

6.

Electrical Parts List

7.

Block Diagrams

8.

Wiring Diagram

9.

Schematic Diagrams

10.

ELECTRONICS

© Samsung Electronics Co., Ltd. OCT. 1999

Printed in Korea

3P51A-5201

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between the picture tube and the

cabinet mask, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

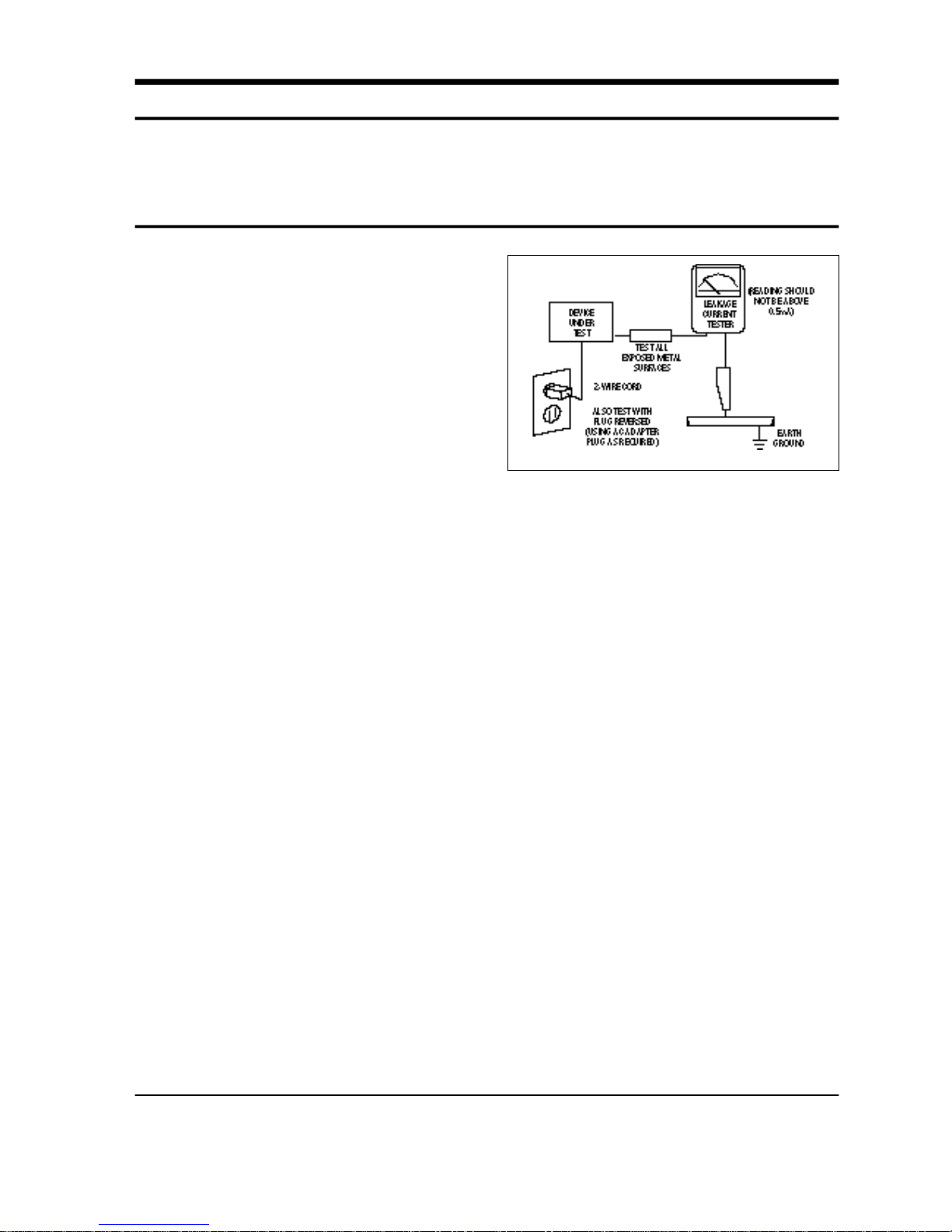

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANIS C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

7. X-ray Limits:

The picture tube is especially designed to prohibit X-ray emissions. To ensure continued

X-ray protection, replace the picture tube only

with one that is the same type as the original.

Carefully reinstall the picture tube shields and

mounting hardware; these also provide X-ray

protection.

8. High Voltage Limits:

High voltage must be measured each time servicing is done on the B+, horizontal deflection

or high voltage circuits. Correct operation of

the X-ray protection circuits must be

reconfirmed whenever they are serviced.

(X-ray protection circuits also may be called

“horizontal disable” or “hold-down”.)

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, and

the Product Safety and X-ray Warning Note on

the service data schematic.

Precautions

Samsung Electronics 1-1

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-1 Safety Precautions (Continued)

9. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

10. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

11. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

12. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

13. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

14. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or overheating, and correct any potential hazards.

15. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

16. Picture Tube Implosion Warning:

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

17. Do not remove, install or handle the picture

tube without first putting on shatterproof

goggles equipped with side shields. Never

handle the picture tube by its neck. Some

“in-line” picture tubes are equipped with a

permanently attached deflection yoke; do not

try to remove such “permanently attached”

yokes from the picture tube.

18. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original—even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

Areplacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Precautions

1-2 Samsung Electronics

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to: (a)

Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the

power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC

plug.

The insulation resistance between each blade

of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

8. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

9. When some parts inside the optical engine

(except lamp) are damaged, replace the whole

optical engine.

Precautions

Samsung Electronics 1-3

Warning 1 : First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a

conflict between the servicing and safety precautions, always follow the safety precautions.

Warning 2 : An electrolytic capacitor installed with the wrong polarity might explode.

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4 Samsung Electronics

Reference Information

Samsung Electronics 2-1

2. Reference Information

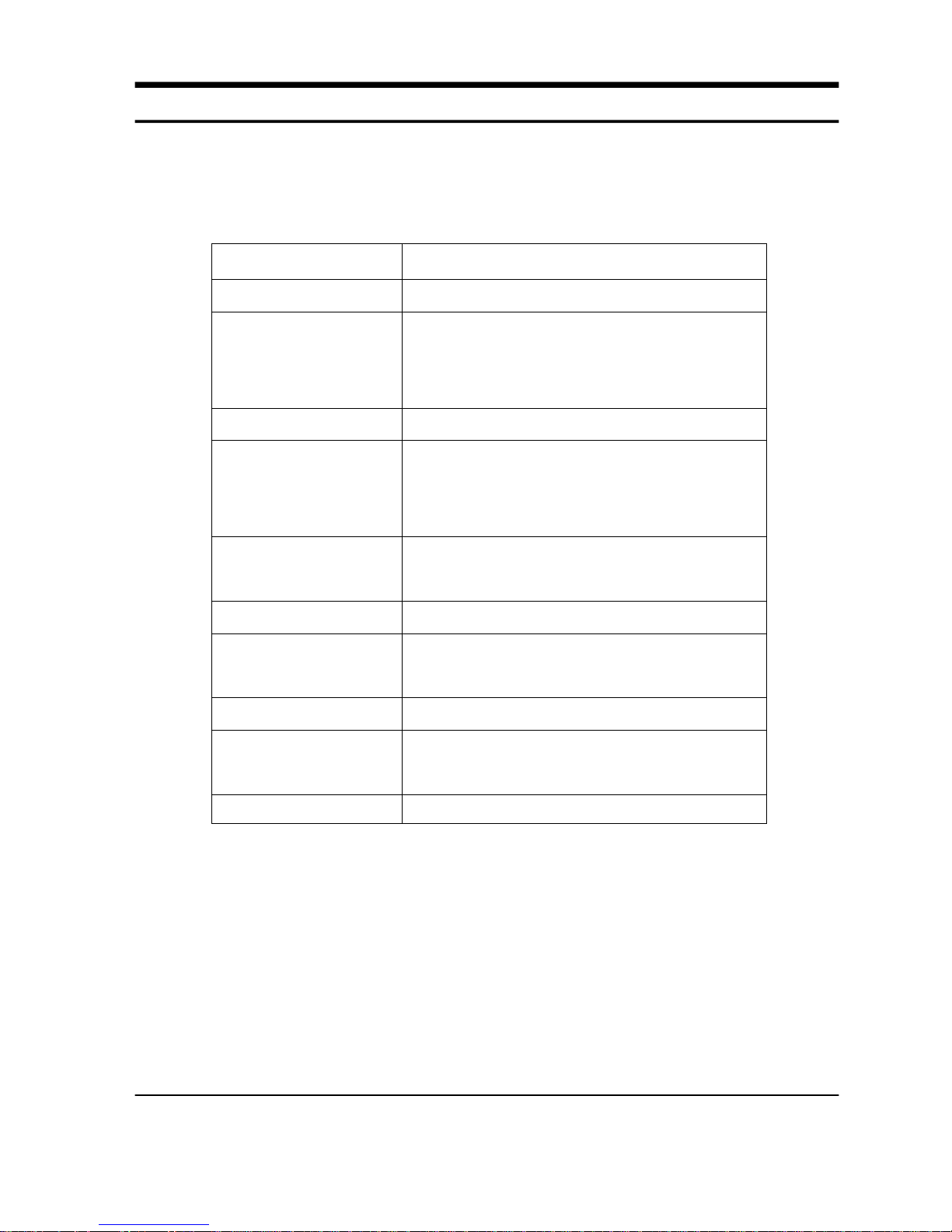

2-1 Tables of Abbreviations and Acronyms

A

Ah

Å

dB

dBm

°C

°F

°K

F

G

GHz

g

H

Hz

h

ips

kWh

kg

kHz

kΩ

km

km/h

kV

kVA

kW

I

MHz

Ampere

Ampere-hour

Angstrom

Decibel

Decibel Referenced to One

Milliwatt

Degree Celsius

Degree Fahrenheit

degree Kelvin

Farad

Gauss

Gigahertz

Gram

Henry

Hertz

Hour

Inches Per Second

Kilowatt-hour

Kilogram

Kilohertz

Kilohm

Kilometer

Kilometer Per Hour

Kilovolt

Kilovolt-ampere

Kilowatt

Liter

Megahertz

MV

MW

MΩ

m

µA

µF

µH

µm

µs

µW

mA

mg

mH

mI

mm

ms

mV

nF

Ω

pF

Ib

rpm

rps

s

V

VA

W

Wh

Megavolt

Megawatt

Megohm

Meter

Microampere

Microfarad

Microhenry

Micrometer

Microsecond

Microwatt

Milliampere

Milligram

Millihenry

Milliliter

Millimeter

Millisecond

Millivolt

Nanofarad

Ohm

Picofarad

Pound

Revolutions Per Minute

Revolutions Per Second

Second (Time)

Volt

Volt-ampere

Watt

Watt-hour

Table 2-1 Abbreviations

Reference Information

2-2 Samsung Electronics

Table 2-2 Table of Acronyms

ABL

AC

ACC

AF

AFC

AFT

AGC

AM

ANSI

APC

APC

A/V

AVC

BAL

BPF

B-Y

CATV

CB

CCD

CCTV

Ch

CRT

CW

DC

DVM

EIA

ESD

ESD

FBP

FBT

FF

FM

FS

GND

G-Y

H

HF

HI-FI

IC

IC

IF

Automatic Brightness Limiter

Alternating Current

Automatic Chroma Control

Audio Frequency

Automatic Frequency Control

Automatic Fine Tuning

Automatic Gain Control

Amplitude Modulation

American National Standards Institute

Automatic Phase Control

Automatic Picture Control

Audio-Video

Automatic Volume Control

Balance

Bandpass Filter

Blue-Y

Community Antenna Television (Cable TV)

Citizens Band

Charge Coupled Device

Closed Circuit Television

Channel

Cathode Ray Tube

Continuous Wave

Direct Current

Digital Volt Meter

Electronics Industries Association

Electrostatic Discharge

Electrostatically Sensitive Device

Feedback Pulse

Flyback Transformer

Flip-Flop

Frequency Modulation

Fail Safe

Ground

Green-Y

High

High-Frequency

High Fidelity

Inductance-Capacitance

Integrated Circuit

Intermediate Frequency

I/O

L

L

LED

LF

MOSFET

MTS

NAB

NEC

NTSC

OSD

PCB

PLL

PWM

QIF

R

RC

RF

R-Y

SAP

SAW

SIF

SMPS

S/N

SW

TP

TTL

TV

UHF

UL

UV

VCD

VCO

VCXO

VHF

VIF

VR

VTR

VTVM

TR

Input/output

Left

Low

Light Emitting Diode

Low Frequency

Metal-Oxide-Semiconductor-Field-Effect-Tr

Multi-channel Television Sound

National Association of Broadcasters

National Electric Code

National Television Systems Committee

On Screen Display

Printed Circuit Board

Phase-Locked Loop

Pulse Width Modulation

Quadrature Intermediate Frequency

Right

Resistor & Capacitor

Radio Frequency

Red-Y

Second Audio Program

Surface Acoustic Wave(Filter)

Sound Intermediate Frequency

Switching Mode Power Supply

Signal/Noise

Switch

Test Point

Transistor Transistor Logic

Television

Ultra High Frequency

Underwriters Laboratories

Ultraviolet

Variable-Capacitance Diode

Voltage Controlled Oscillator

Voltage Controlled Crystal Oscillator

Very High Frequency

Video Intermediate Frequency

Variable Resistor

Video Tape Recorder

Vacuum Tube Voltmeter

Transistor

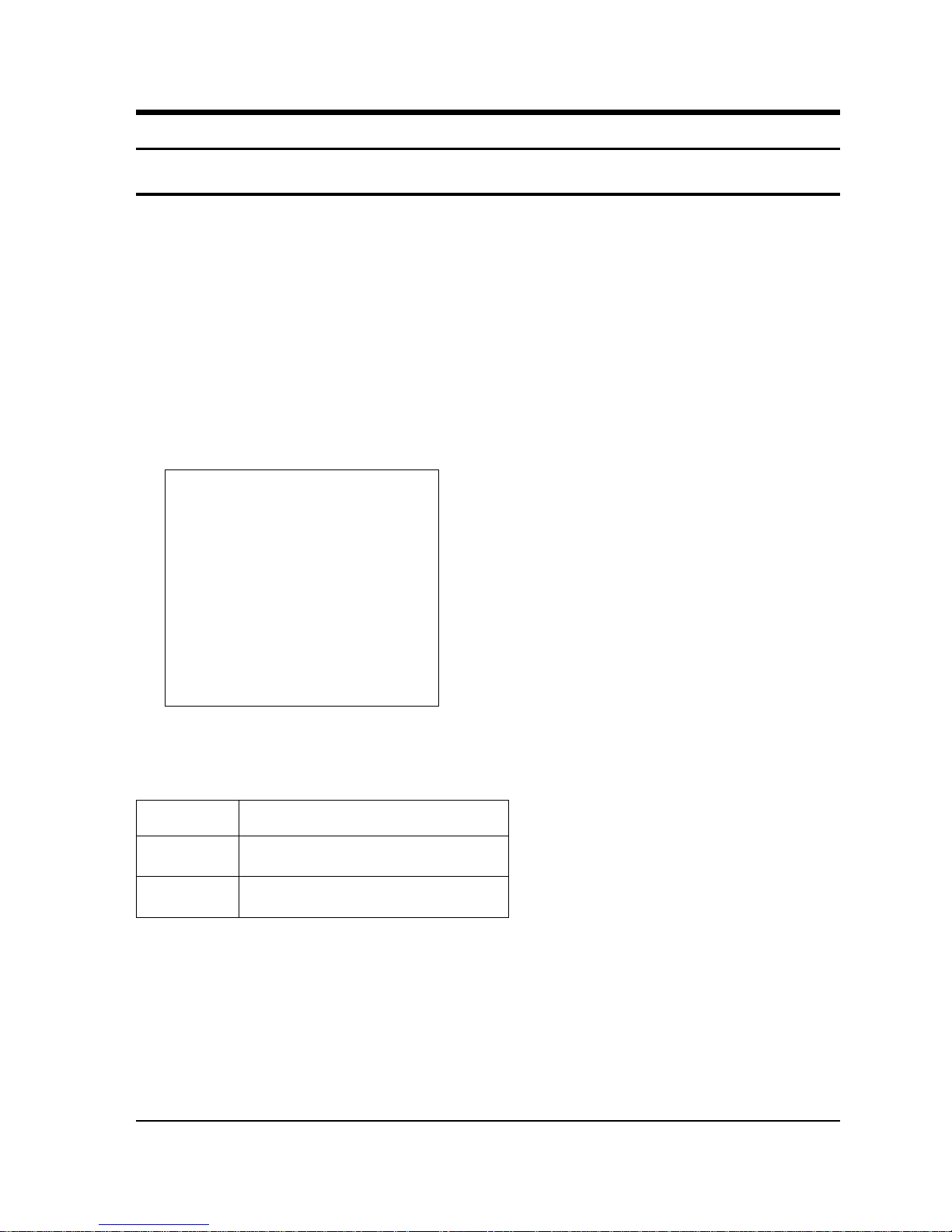

IC665 TDA7265

IC904 KS24C04

ICS801 TNY253P

ICS802 PC123

IC601 TDA7429S

IC602 KA4558

IC905 PCF8574P

ICV01 TA8851BN

ICV02,ICV03 HCF4053BE

ICP01 TDA8601

ICP02 TDA9160A

ICP03 SDA9288X

IC101 TDA9850

IC101 LA7565B

IC471 TL494CN

IC491 74HC123P

ICZ104,ICZ103 STK392-010

IC301 LA7845

IC801 STR-F6656

IC802 SVD001

IC804 SE110N

IC806 PS2561

IC501,IC531,IC561 TDA6111Q

IC01 UPD6488

ICI02 CXA1686M

ICC03 CXD2043Q

1

2

3

4

5

6

7

8

9

10

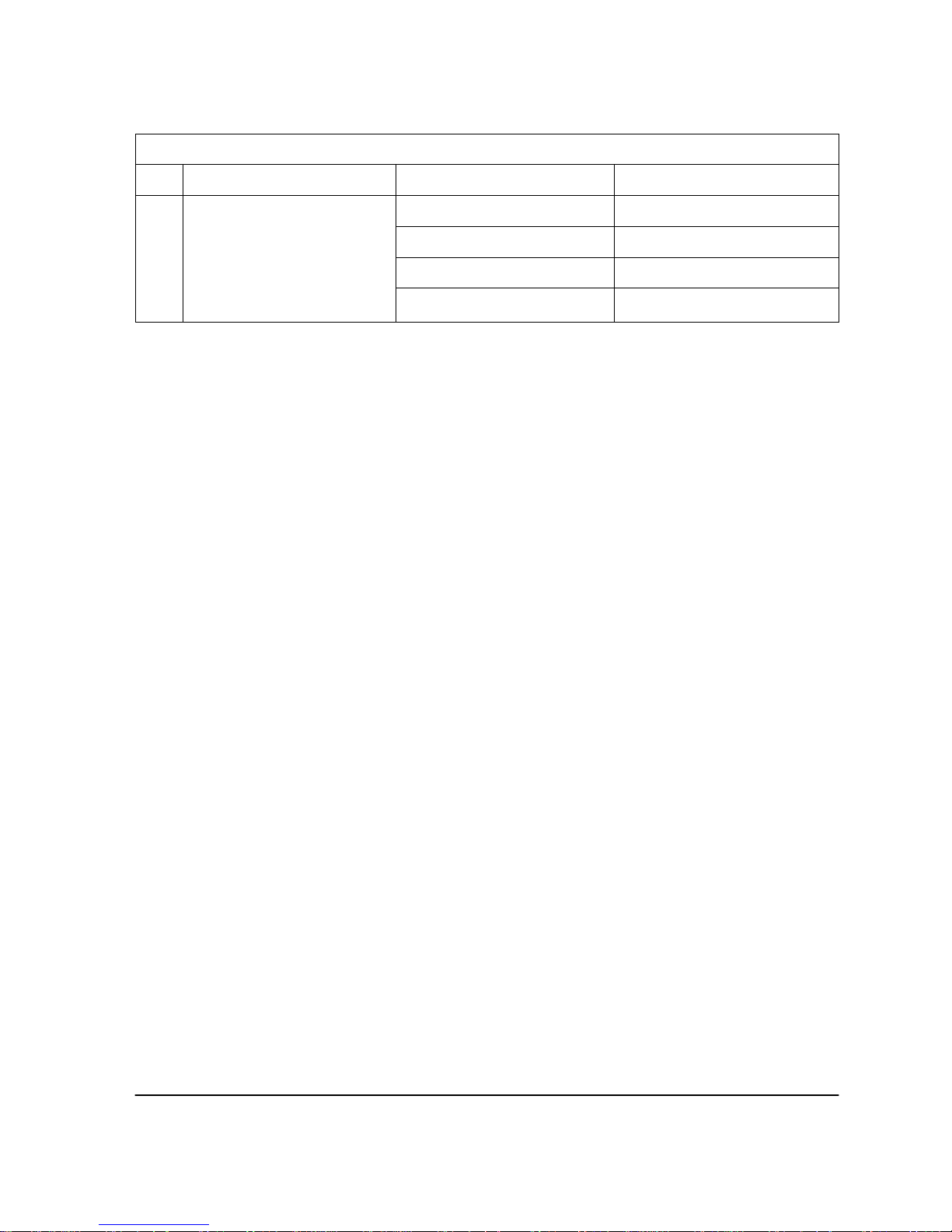

Block NameNo. IC Location IC Name

Table 2 - 3 IC Line - Up

Reference Information

Samsung Electronics 2-3

2-2 IC Line Up

MAIN

TERMINAL BOARD

PIP

MTS MODULE

IF MODULE

HV MODULE

CONVERGENCE

SUB

CRT

2D-COMB

Reference Information

2-4 Samsung Electronics

11

Block NameNo. IC Location IC Name

Table 2 - 3 IC Line - Up (Continued)

CHROMA

IC201 CXA2095S

IC202 TDA9177

IC203 MC14577BP

IC204, IC205 BCF4053B

Reference Information

Samsung Electronics 2-5

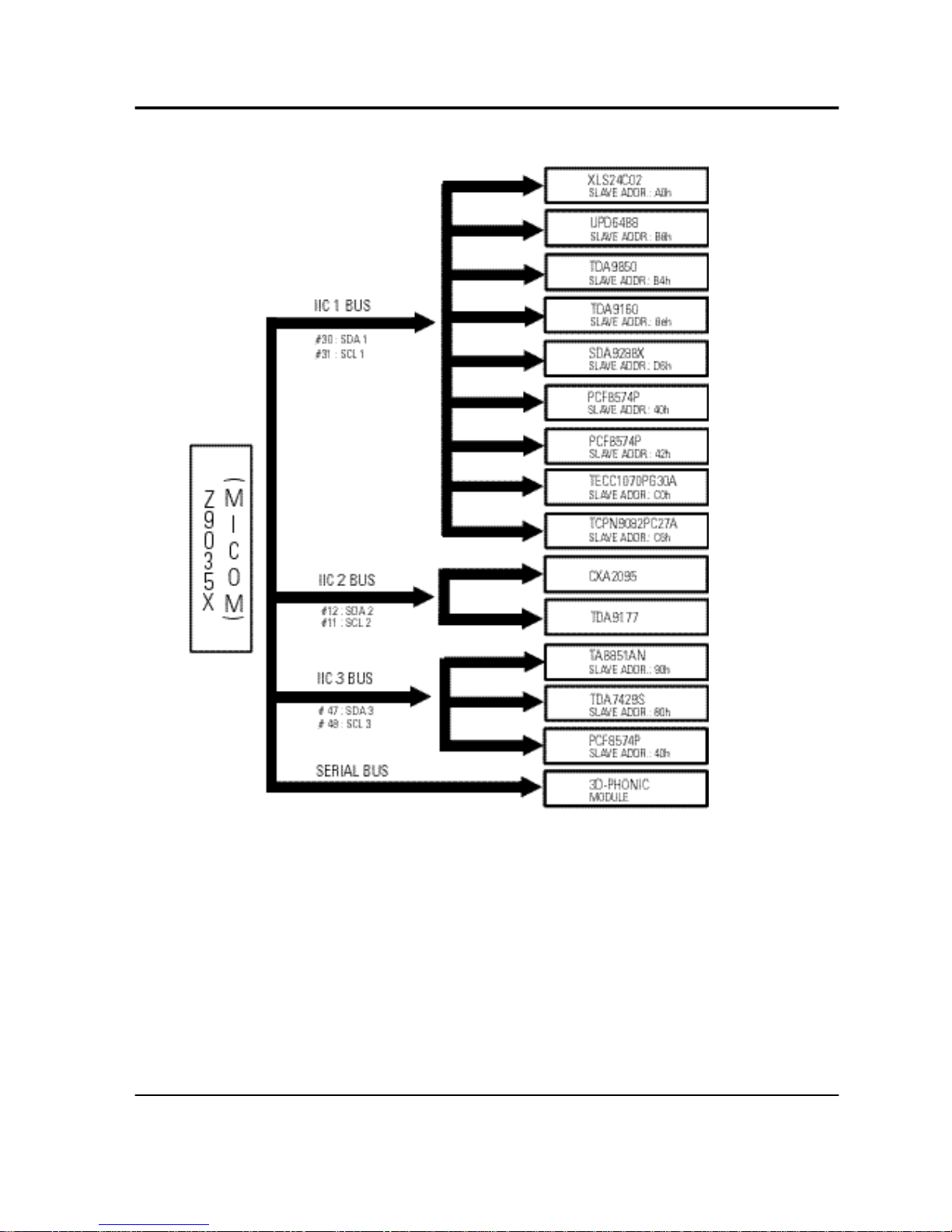

2-3 MICOM IIC BUS LINE -UP

2-6 Samsung Electronics

MEMO

Specifications

Samsung Electronics 3-1

3. Specifications

Broadcasting System

Scanning System

Tuning Range

Antenna Impedance

Intermediate Frequency

Sound Output

Rated Voltage

W/B Coordinates

High Voltage

FUSE

Power Consumption

NTSC

Interlace Scanning

VHF : CH2 ~ CH13

UHF : CH14 ~ CH69

Cable : CH1, CH14 ~ 125

75 ohm Unbalanced

Video : 45.75 MHz

Sound : 42.25 MHz

Chrominance Subcarrier : 42.17 MHz

STD : 15W

FULL MAX : 20 W

120V / 60 Hz

Hx : 292 ± 3 Hy : 270 ± 3 Y : 3.0 ± 0.2

Lx : 278 ± 5 Ly : 246 ± 5 Y : 0.13 ± 0.02

29 KV

250V/6.3A

CODE NO : 3601-000300

230W

3-2 Samsung Electronics

MEMO

Alignment and Adjustments

4.Alignment and Adjustments

4-1 When entering the service mode:

1. Turn on the TV, and then select “STANDARD”on the picture adjustment mode.

2. Turn off the TV (STAND-BY).

3. Enter the service mode by pressing the remote control keys in the following sequence :

MUTE →1→8→2→Power On

Note : If necessary, re-do steps 1~3.

Initial display when the service mode is switched.

FACTORY

GEOMETRIC

PICTURE

SOUND

PIP

OPTION

READ

RESET

1. When a RF signal is received

MAIN MENU MENU DISPLAY

CH UP/DOWN Select item by moving cursor

VOL UP/DOWN Decrease or increase the adjustment values

2. Service Mode Control Keys

Samsung Electronics 4-1

Alignment and Adjustments

4-2 Samsung Electronics

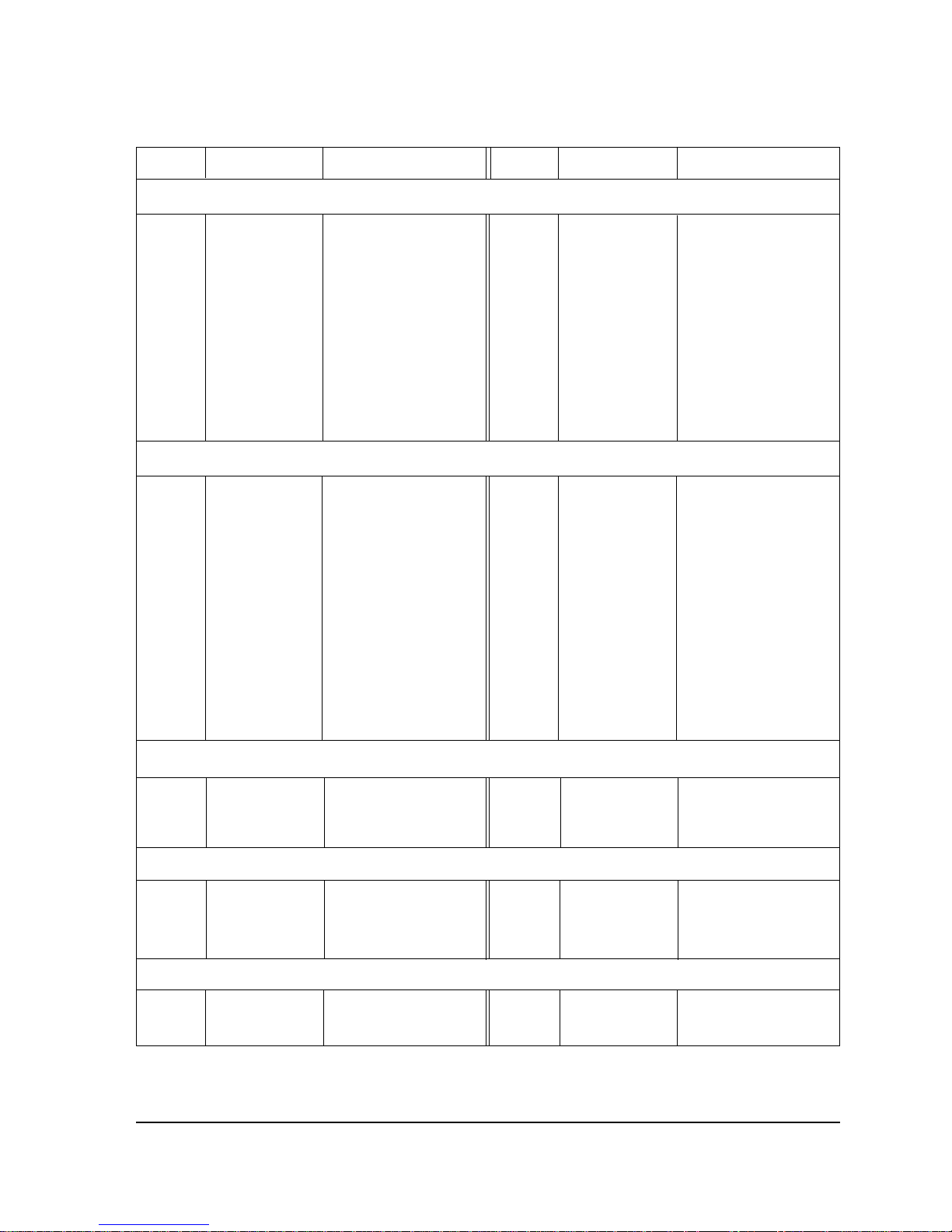

GEOMETRIC

VS 32 V-SHIFT HLC 8 PIN-LO-CORR

VA 32 V-SIZE VAS 40 V-ASPECT-SIZE

VCP 0 V-COMP VSR 25 V-SCROLL

VLN 5 V-LIN VUV 0 V-UP-LIN

VSC 3 V-S-CORR VLV 0 V-LO-LIN

HS 0 H-SHIFT VJS 0 V-JUMP-SW

HPC 17 PIN-AMP VZS 0 V-ZOOM-SW

HA 20 H-SIZE VRP 3 VBLKW

HPP 8 PIN-PHASE VBS 3 V-BLK-SW

HAA 7 V-ANGLE HBS 0 H-BLK-SW

HAB 5 V-BOW HLB 15 H-LEFT-BLK

HUC 8 PIN-UP-CORR HRB 15 H-RIGHT-BLK

PICTURE

DCT 1 GC 8

DPI 1 BC 8

AS 1 GAM 2

DCL 1 AFC 2

ABL 1 TOC 1

POV 3 SSP 40

SFO 1 AMS 1

TA 1 FHS 0

SCT 5 CFS 0

SBT 8 SC 40

SCR 4 LWC 32

STT 11 COR 45

GA 32

BA 32

SOUND

STEREO 9 ALIGN1 27

SAP 9 ALIGN2 25

LEVEL 9 ALIGN3 4

PIP

CONTRAST 10

HUE 32

POS-HOR 137

POS-VER 34

OPTION

BYTE O : 91

BYTE 1 : 00

4-1-1 Factory Data

ITEM

INITIAL VALUE FUNCTION

ITEM

INITIAL VALUE FUNCTION

Alignment and Adjustments

Samsung Electronics 4-3

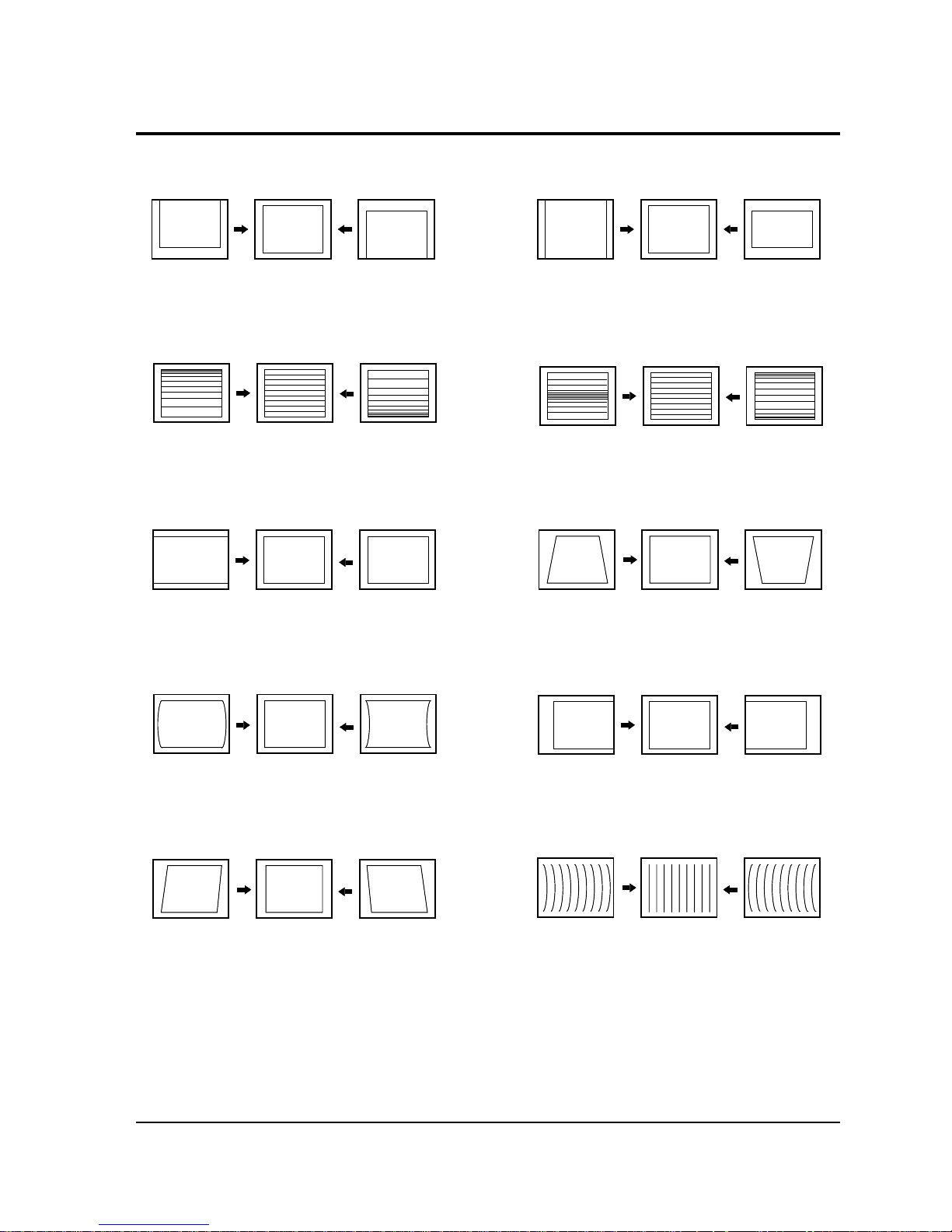

4-2 Screen Change (When adjusting I2C Bus Geometric items)

8

PIN PHASE

10 V BOW

5 V ANGLE

4

PIN AMP

2 V LINEARITY

6 V SIZE

3 H SIZE

9 H SHIFT

7 V - S - CORRECTION

1 V SHIFT

Alignment and Adjustments

4-4 Samsung Electronics

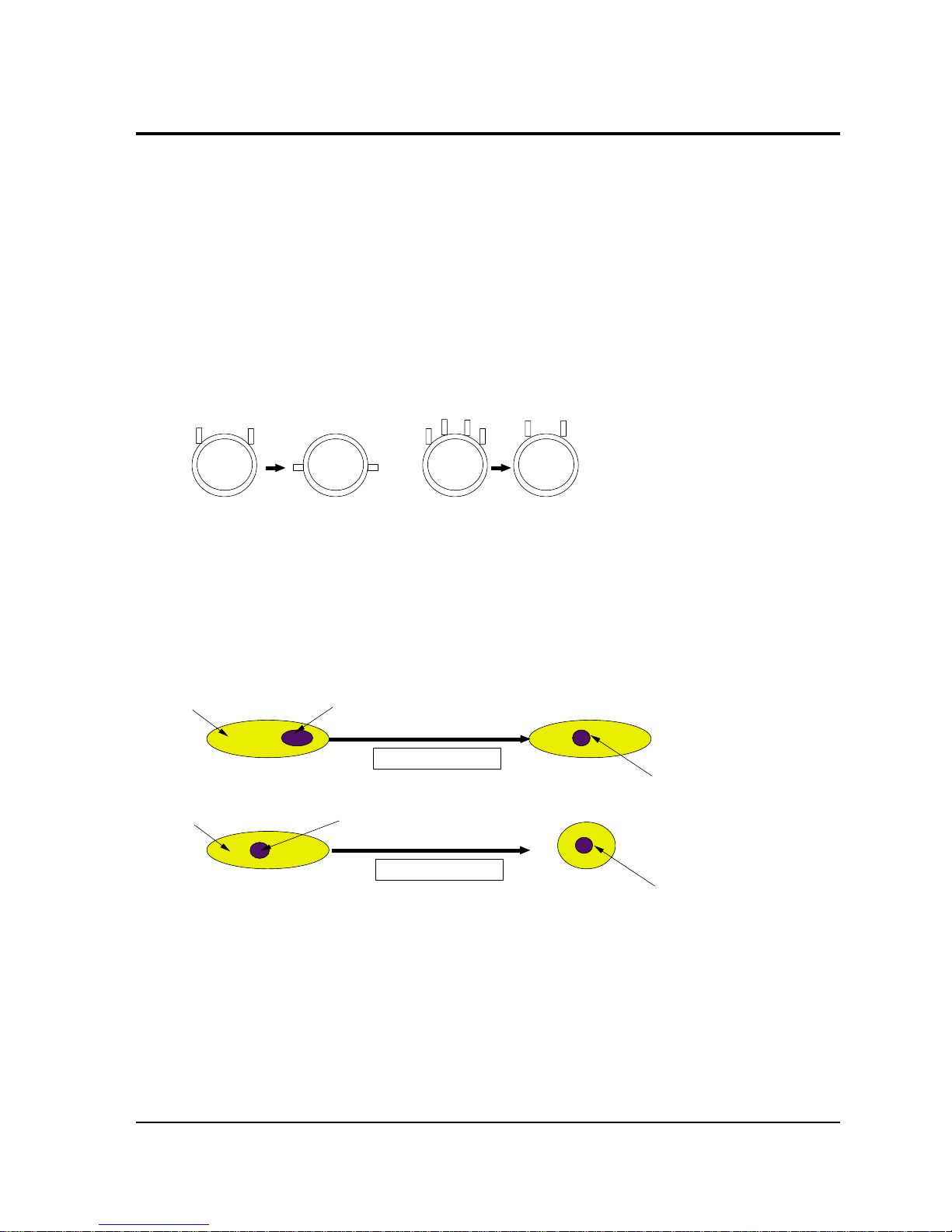

4-3 Beam Alignment

PRECAUTION

1. Input a crosshatch and dot pattern.

2. Select the “STANDARD” video mode.

3. Warm up the TV for at least 10 minutes.

4. Connect an audio oscillator to the pin jig between GT401~GT402 (located on the deflection

PCB) and GND.

5. Determine the ZERO-magnet area (using the beam-alignment CY)

6. Check the squarewave at the point where the focus is misaligned (Use an audio oscillator).

ADJUSTMENT

1. Cover the Red and Blue lenses.

2. Adjust the Green lens as shown in the figures below

3. Adjust the G-Focus until any light around the core disappears.

4. Cover the Green and Blue lenses.

5. Adjust the Red lens using the same method as with the Green lens.

6. Note: The Blue lens is not adjusted because its focus varies little (VM-coil is installed).

7. After the adjustments are completed, disconnect the jig pin connector.

(Creation of CPM Zero Magnet)

(Creation of the 2-pole/4-pole zero magnets)

G-FOCUS

CORE

(Varying G-Focus Pack)

Varying the 2-pole of VM

(Positioning the Core in the Center)

Varying the 4-pole of VM

CORE

G-FOCUS

(When VM 2-Pole Adjustment is completed)

(Adjust until the light around

the core becomes a circle)

Alignment and Adjustments

Samsung Electronics 4-5

4-4 Other Adjustments

4-4-1 Screen Adjustment

1. Warm up the TV for at least 30 minutes.

2. Turn to the Video Mode (No Signal) using a

remote-control.

3. Connect an oscilloscope to RK,GK,BK.

4. Adjust the VR (VR501, VR531, VR561) screen

so that RK, GK, BK pulse is 20Vp-p each.

(Turn the R,G,B VR screen fully

counterclockwise in the area of each flyback

line.)

4-4-2 White Balance Adjustment

1. Select the “STANDARD” video mode.

2. Input 100% white pattern.

3. In the stand-by mode, press the remote-control

keys in the following sequence:

Mute → 1 → 8 → 2 → Power ON

4. Warm up the TV for at least 30 minutes.

5. Input a 10-step signal.

6. R-cut off, B-cut off, and G-cut off by pressing

the Volume +/- keys.

7. Adjust the low light with viewing the dark

side of the screen.

8. Select R-drive, G-drive, and B-drive by

pressing the Volume +/- keys.

9. Adjust the high light with viewing the light

side of the screen.

10. If necessary, redo adjustments 6~9.

11. Press the Menu key to exit.

4-4-3 Sub-Brightness Adjustment

1. Input a sub-brightness adjustment signal.

(TOSHIBA PATTERN)

2. In the stand-by mode, press the remote-control

keys in the following sequence :

Mute - 1 - 8 - 2 - Power ON

3. Select SBT by pressing the Volume +/- keys.

4. Adjust so that the 7th step on the right side of

the screen is not seen (Use the Volume +/keys).

5. Press the Menu key to exit.

4-4-4 High Voltage (31KV) Check

PRECAUTION

1. Input a lion head pattern.

2. Select “STANDARD” video mode.

3. Warm up the TV for at least 10 minutes.

4. Use a 1000:1 probe.

ADJUSTMENT

1. Connect the (+) terminal of the 1000:1 probe to

the high voltage distributor and the (-)

terminal to GND (located on the deflection

board).

2. Adjust VR471 (located on the deflection board)

so that the digital meter indicates

DC 31V ± 0.1V.

Alignment and Adjustments

4-6 Samsung Electronics

4-4-5 F.S. (Fail Safe) Circuit Check

Note : The F.S. Circuit check must be performed

after servicing.

1. Turn on the TV.

2. Select the “STANDARD” video mode.

3. Short GT18, GT17 (located on the

Convergence PCB). Then, both sound and

picture disappear. (Note: Even if the shorted

terminals are removed, both sound and

picture do not appear. This proves the F.S.

circuit is working. )

4. To restore both sound and picture, turn off the

TV and reset it after about 30 seconds.

4-4-6 Static Focus Adjustment

PRECAUTION

1. Select the “STANDARD” video mode.

2. Input a crosshatch pattern.

3. Cover the lenses that are not being adjusted.

4. Connect a convergence jig and read data.

5. Adjust the lens for best focus.

(See Fig, 4-1, next page)

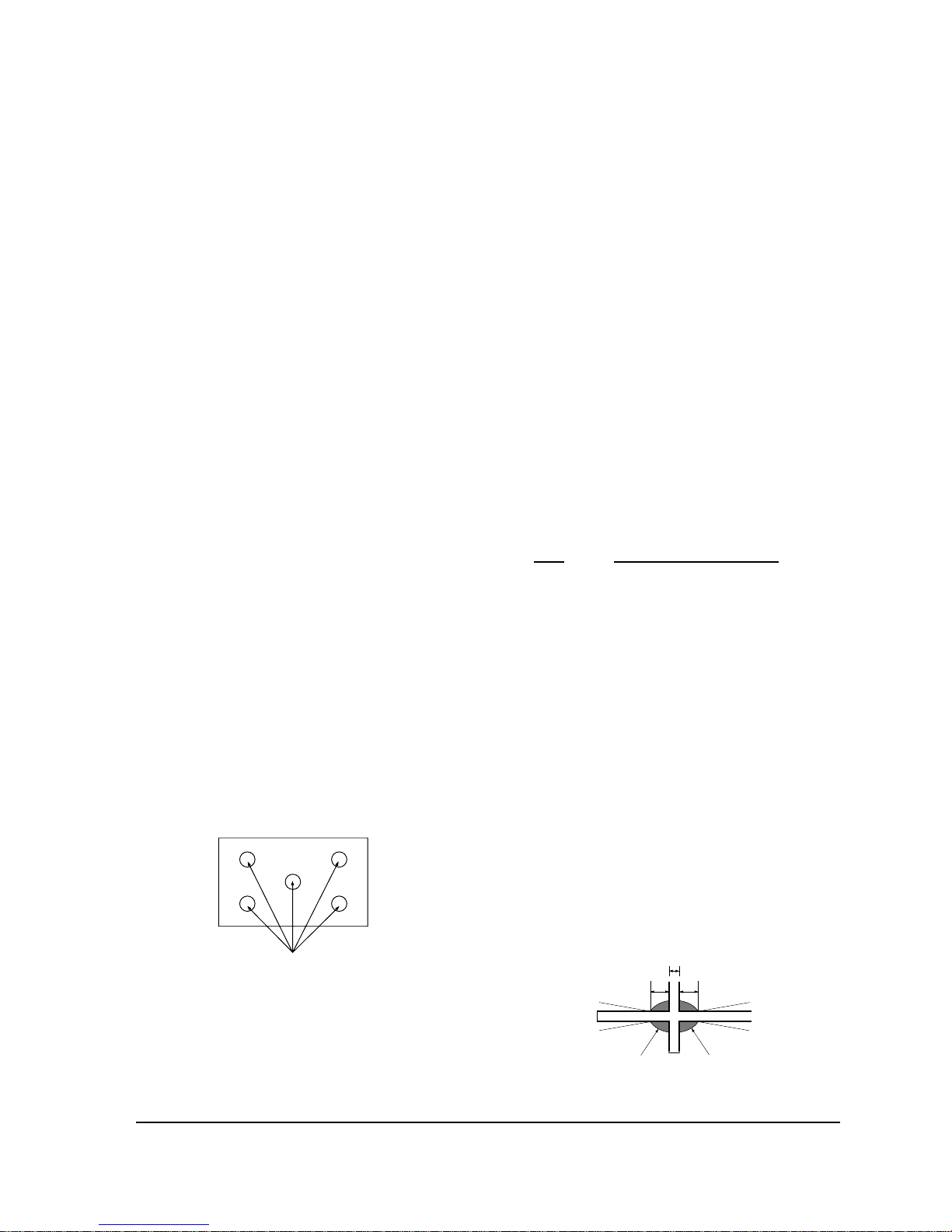

STATIC FOCUS (CONTINUED)

Vary the focus pack VR (Red, Blue) on the

front cabinet. Adjust the TV for best possible

focus around the center of the crosshatch

pattern, without losing overall screen balance.

Figure Crosshatch Pattern

Examine these points together.

4-4-7 Lens Focus Adjustment

PRECAUTIONS

1. Do this adjustment after the static focus

adjustment and the tilt adjustment.

2. Select the “STANDARD” video mode.

(Contrast:64, Brightness:32)

3. Input a crosshatch pattern.

ADJUSTMENT

1. Loosen the lens screws.

2. Cover the two lenses that are not being

adjusted.

3. Adjust the lens, observing the color aberration

vertically and horizontally within 3 blocks of

the center of the crosshatch pattern.

4. When the lens is turned clockwise, the color

aberration will change as follows:

Lens Color Aberration Change

R Orange - Crimson

G Blue - Red

B Purple - Green

5. Green lens adjustment:

Set the lens at the point where Blue just

changes to Red. If the color aberration is

irregular throughout the picture screen, adjust

the lens to show Red color aberration

(approximately 1~3 mm area) within a 3-block

grid around the horizontal center-line. If the

color aberration is irregular, adjust the lens as

shown in the diagram below. (Accurate

alignment of Green is important for overall

color quality.)

6. Red lens adjustment

Set the Red lens at the point where Orange

becomes Crimson.

7. Blue lens adjustment

Set the Blue lens at the point where Purple

becomes Green.

P

L1

L2

RED ABERRATION

BLUE ABERRATION

L1, L2 < P

_

Fig. 4-1 Crosshatch Pattern.

Fig. 4-2 Color Aberration

Examine these points together

Alignment and Adjustments

Samsung Electronics 4-7

4-4-8 Horizontal Dynamic Focus Adjustment

PRECAUTION

1. Input a crosshatch pattern.

2. Select the “STANDARD” video mode.

3. Warm up the set for at least 10 minutes.

ADJUSTMENT

1. Cover the Red and Blue lenses.

2. Adjust VR491 (located on the convergence

PCB, H-Parabola).

3. Balance the left and right sides of the dynamic

focus lines.

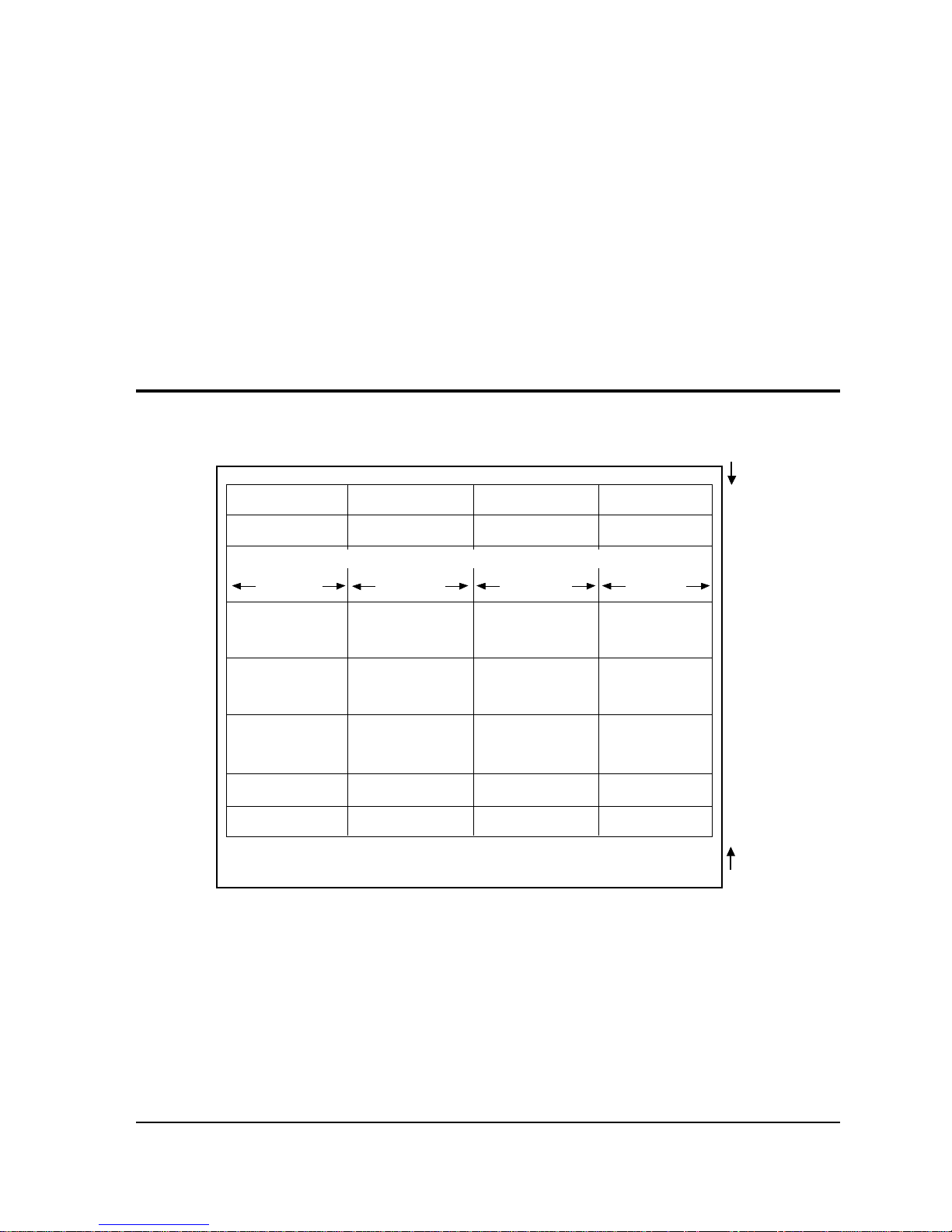

4-5 Screen-Jig

2

0.3

2.5

0.3

11

0.3

22.7

0.3

22.7

0.3

11

0.3

2.5

0.3

2

26.4 26.2

26.2 26.4

(FRONT MASK)

0.3 0.3 0.3

Unit : cm

Alignment and Adjustments

4-8 Samsung Electronics

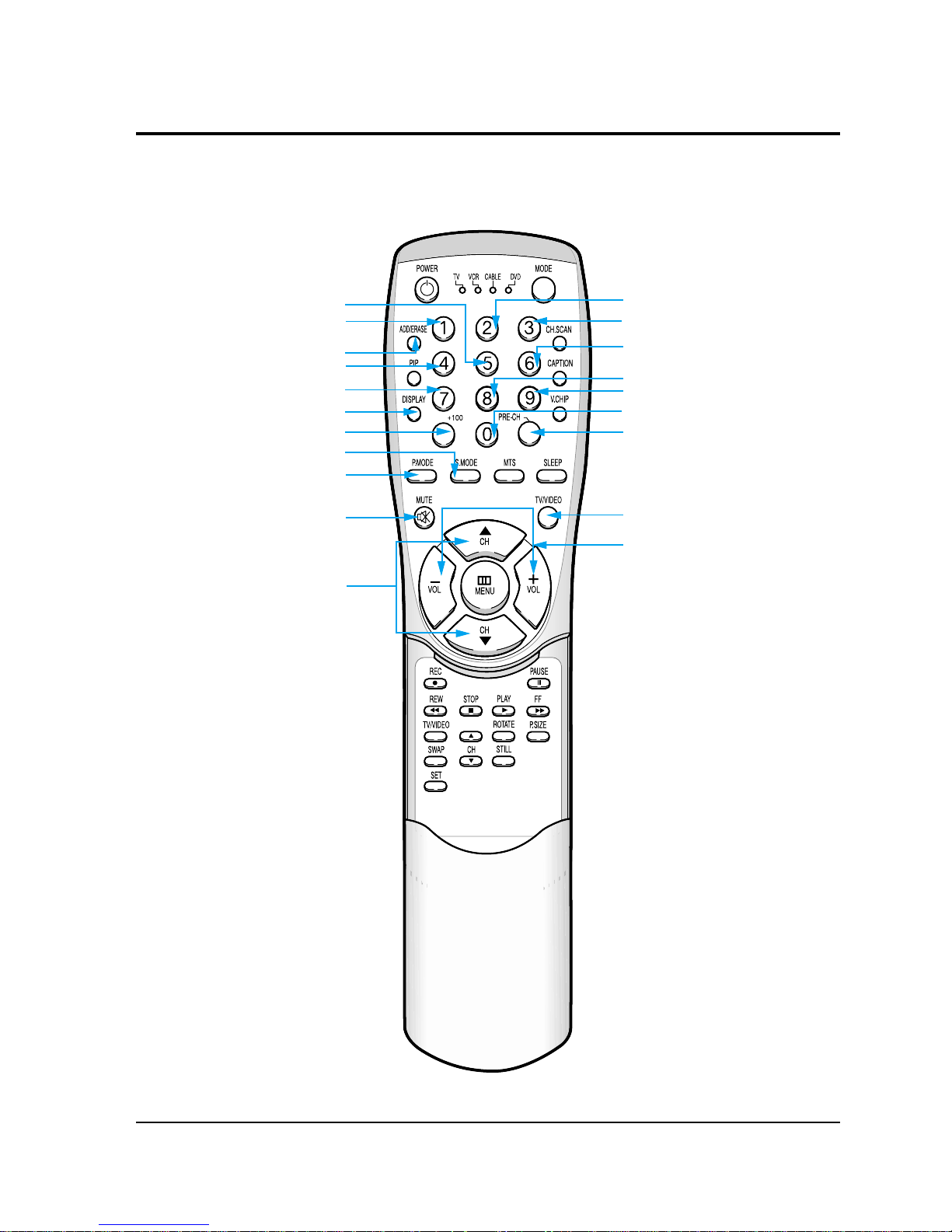

4-6 Remote Control for Servicing (Convergence Mode)

Fine Adjustment Button

Factory Data Select Button

Last Data Save Button

Half Adjustment Button

G-Mute

B-Mute

H/V Direction Select Button

Save Button

Line Shift

R-Select

R-Mute

Exit Button

Move Course Reverse

Move Course Forward

G-Select

B-Select

Convergence Picture

Move Button

Test/Noraml

Convergence data

Increase, decrease button

Convergence Data Zero Button

Alignment and Adjustments

Samsung Electronics 4-9

4-6-1 KEY Function

1. R-SELECT

Press to select RED color.

2. G-SELECT

Press to select GREEN color.

3. B-SELECT

Press to select BLUE color.

4. R-MUTE

Press to mute RED color.

5. G-MUTE

Press to mute GREEN color.

6. B-MUTE

Press to mute BLUE color.

7. CANCEL KEY

Press to revert to the previous data during the Convergence

Adjustment.

8. FINE/COARSE SELECT BUTTON

Press for minor adjustment.

If the width of the big-adjustment step is 1, then the width of the minor

adjustment step is 0.5.

9. TEST/NORMAL

Press to check TV mode in the Convergence Mode.

10. LINE SHIFT

Press to move a line up/down or left/right.

11. FACTORY DATA SELECT BUTTON

Press to call the factory default values.

Alignment and Adjustments

4-10 Samsung Electronics

12. H/V DIRECTION SELECT BUTTON

Press to switch the cursor direction horizontally or vertically.

13. SAVE BUTTON

After the Convergence Adjustments are completed, press to save data.

14. EXIT BUTTON

After the Convergence adjustments are completed, press to exit to

TV mode.

15. MOVE CURSOR FORWARD

Press to move the cursor right or down.

16. MOVE CURSOR REVERSE

Press to move the cursor left or up.

17. CONVERGENCE PICTURE MOVE BUTTON

18. CONVERGENCE DATAZERO BUTTON

Press to zero the convergence correction data.

19. HALF ADJUSTMENT BUTTON

After big adjustments are made, press for improvement of

minor adjustment.

Alignment and Adjustments

Samsung Electronics 4-11

1. Warm up the TV for at least 30 minutes.

2. Input an NTSC Signal. (Use an antenna or AV source.)

Make sure that both deflection and convergence yokes are

properly adjusted so that the center of Green, Red, Blue pattern

is aligned on the center of screen jig.

3. Enter the Convergence Mode by pressing the remote control keys in the following sequence:

If OSD is displayed as shown in figure below, press the key to exit.

Then, redo step 3 to enter the Convergence Mode.

After entering the Convergence Mode, Stand by for about five seconds before

doing the adjustments.

NOTE

NOTE

4-7 Convergence Adjustment

Alignment and Adjustments

4-12 Samsung Electronics

4. To adjust GREEN, first press the and the keys, and then press the key.

5. The key moves the cursor right, and the key moves the cursor left.

Alignment and Adjustments

Samsung Electronics 4-13

6. The key moves the cursor horizontally or vertically.

NOTE

When the key is pressed once again, the cursor moves horizontally.

Alignment and Adjustments

4-14 Samsung Electronics

7. Use the key for overall balance.

8. After the Line Shift is cancelled by pressing the key, use the Channel

and Volume keys (Up/Down) to make big adjustments.

9. After the green convergence adjustments are completed, press the key to

save the data (The minor adjustments can be done only when adjusting Red and Blue).

Alignment and Adjustments

Samsung Electronics 4-15

10. Superimpose the Red and Green colors by pressing the and

the keys.

11. To adjust RED, redo steps 5~8.

12. Use the key to make minor adjustments.

(Or the key can be used for minor adjustment.)

Cursor Movement (when making minor adjustments)

Alignment and Adjustments

4-16 Samsung Electronics

When the cursor moves vertically

13. To superimpose the blue and green colors, press (1) the key for

R-Mute, (2) the key to cancel the B-Mute, and (3) the key

for B-select.

14. To adjust BLUE, redo steps 5 ~ 8, 12.

15. If any color is not properly adjusted when displaying the red, blue and

green colors, readjust the color.

When readjusting a color, enter the minor adjustment mode.

Otherwise, the existing adjustment data might be distorted.

NOTE

Alignment and Adjustments

Samsung Electronics 4-17

16. After the color adjustments are completed, press the ( ) key to save the data.

The cursor moves to center, and then automatically moves up and

to the left about five seconds later.

17. After the Convergence Adjustments are completed, press the key to exit.

NOTE

Alignment and Adjustments

4-18 Samsung Electronics

4-8 MICOM and Pins Voltage

4-8-1 Pin Layput

POWER

IR-IN

V-MUTE

3D-SDA

N.C

CRTL 3

PROTECT

SCL 2

SDA 2

CVBS

LOOP FILTE R

ANALOG GND

SUB-AFT

KEY1

MAIN-AF T

KEY2

KEY3

ANALOG GND

HALF TONE

OSD B

ANALOG VCC

OSD G

OSD R

D2

CTRL 1

BUS-STOP

HOLD

SCL-3

SDA-3

TIMER-LED

S/W-MUTE

D1

AMP-M UTE

N.C

XTAL GND

VCC

GND

XTAL2

XTAL1

/RESET

N.C

N.C

D3

SCL-1

SDA-1

VSYNC

HSYNC

BLANK

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

27

Z

9

0

3

5

1

1

2

P

S

C

N.C

N.C

N.C

CTRL 2

Alignment and Adjustments

Samsung Electronics 4-19

4-8-2 Micom Pins

1 POWER POWER ON/OFF RELAY CONTROL H--> L

2 IR IN REMOCON INPUT 5V

3 V-MUTE VIDEO SIGNAL MUTE 3V

4 N.C N.C 5 N.C N.C 6 CRTL 3 CONTROL-3PORT 5V

7 N.C N.C 8 N.C N.C 9 PROTECT PROTECT PORT 10 N.C N.C 11 SCL 2 CLOCK BUS LINE 4.5V

12 SDA 2 DATA BUS LINE 4.5V

13 CVBS CVBS 1.7V

14 LOOP FILTER LOOP FILTER 1.9V

15 ANALOG GND GND GND

16 SUB-AFT SUB AUTO FINE TURNING CONTROL 2.64V

17 KEY 1 KEY SCAN 1 4.84V

18 MAIN-AFT MAIN TUNER AFT 1.9V

19 KEY 2 KEY SCAN 2 20 KEY 3 KEY SCAN 3 21 ANALOG GND GND 22 ANALOG VCC VCC 5V

23 HALF TONE SIGNAL FOR OSC-FREQUENCY OSD CONTROL 24 OSD B ON SCREEN DISPLAY BLUE OUTPUT 25 OSD G ON SCREEN DISPLAY GREEN OUTPUT 26 OSD R ON SCREEN DISPLAY RED OUTPUT -

PIN NO. ITEM FUNCTION OUT VOLT

Alignment and Adjustments

4-20 Samsung Electronics

27 BLANK BLAKING SIGNAL OUTPUT 28 HSYNC HORIZONTAL SYNC INPUT 29 VSYNC VERTICAL SYNC INPUT 30 SDA-1 DATA BUS LINE 4.5V

31 SCL-1 CLOCK BUS LINE 4.12V

32 D3 CONVERGENCE D3 33 N.C N.C 34 N.C N.C 35 /RESET RESET 4.74V

36 XTAL1 XTAL 1 1.72V

37 XTAL2 XTAL 2 2.2V

38 GND GND 39 VCC VCC 5V

40 XTAL GND GND 41 N.C N.C 42 CRTL 2 CONTROL - 2 PORT 5V

43 AMP-MUTE MAIN AMP MUTE 44 D1 CONVERGENCE D1 45 S/W-MUTE SWITCH MUTE (NOT USED) 46 TIMER-LED TIMER LED 4.7V

47 SDA-3 DATA BUS LINE 4.6V

48 SCL-3 CLOCK BUS LINE 4.6V

49 HOLD HOLD 4.65V

50 BUS-STOP I2C BUS STOP 5V

51 CRTL 1 CONTROL - 1 PORT 4.65V

52 D2 CONVERGENCE D2 -

PIN NO. ITEM FUNCTION OUT VOLT

Alignment and Adjustments

Samsung Electronics 4-21

4-8-3 Chroma MDL

1 N.C N.C 2 GND GND GND

3 CVBS/Y CVBS/Y INPUT 1.76V

4 CIN C-INPUT 2.92V

5 GND GND GND

6 E-Pr/R E-Pr/R INPUT 2.0V

7 E-Y/G E-Y/G INPUT 2.0V

8 E-Pb/B E-Pb/B INPUT 2.0V

9 E-FB FAST BLANKING INPUT 0.25V

10 GND GND GND

11 HS1 1H-SYNC OUT 12 VS1 VS1 OUT 13 GND GND GND

14 SDA-2 SERIAL DATA LINE 2 4.7V

15 SCL-2 SERIAL CLOCK LINE 2 4.8V

16 N.C N.C 17 HD H-DRIVE OUT 1.6V

18 H-BLK H-BLANK INPUT 19 VD+ VERTICAL DRIVE (+VOLTAGE) 2.90V

20 VD- VERTICAL DRIVE (-VOLTAGE) 2.95V

21 ABL ABL INPUT 2.15V

22 V-BLK V-BLANKING 23 EW EAST WEST OUT 2.2V

24 N.C N.C 25 GND GND GND

26 N.C N.C 27 FSC FSC 28 HC 5V INPUT 29 GND GND GND

30 TEST-Y WHEN CG ADJ PATTERN INPUT -

PIN NO. ITEM FUNCTION OUT VOLT

Alignment and Adjustments

4-22 Samsung Electronics

31 N.C N.C 32 N.C N.C 33 N.C N.C 34 CRTL - 3 CRTL - 3 5V

35 CRTL - 1 CRTL - 1 5V

36 GND GND GND

37 OSD-R OSD-R INPUT 38 OSD-G OSD-G INPUT 39 OSD-B OSD-B INPUT 40 YS BLANK(MICOM OUT) 41 YM HALF TONE INPUT 42 V-MUTE VIDEO MUTE (V-CHIP ON) 4.72V

43 GND GND GND

44 9V 9V 9V

45 N.C N.C 46 N.C N.C 47 N.C N.C 48 PIP-F/B N.C 49 GND GND

50 R-OUT R-OUT 51 G-OUT G-OUT 52 B-OUT B-OUT 53 GND GND GND

54 IK IK OUT 3.65V

55 SPOT SPOT OUT 56 GND GND GND

57 VM-Y VM-Y OUT 5.42V

58 CTRL - 2 CTRL - 2 5V

PIN NO. ITEM FUNCTION OUT VOLT

Alignment and Adjustments

Samsung Electronics 4-23

4-8-4 PIP MODULE

1 GND GND GND

2 TV SUB-V INPUT 2.93V

3 GND GND GND

4 N.C N.C 5 8V 8V INPUT 8V

6 N.C N.C 7 PIP-Pr/R PIP-Pr/R (DVD SIG) OUT 2.02V

8 PIP-Y/G PIP-Y/G (DVD SIG) OUT 2.04V

9 PIP-Pb/B PIP-Pb/B (DVD SIG) OUT 2.02V

10 PIP-FB PIP FAST BLANKING 2.02V

11 12V 12V INPUT 12V

12 PIP-F/B N.C N.C

13 PIP-B DVD-B IN 14 PIP-G DVD-G IN 15 PIP-R DVD-R IN 16 N.C N.C 17 V-SYNC V-SYNC INPUT 18 H-SYNC H-SYNC INPUT 19 SCL SERIAL CLOCK LINE 4.11V

20 SDA SERIAL DATA LINE 4.5V

21 5V 5V INPUT 5V

22 GND GND GND

PIN NO. ITEM FUNCTION OUT VOLT

Alignment and Adjustments

4-24 Samsung Electronics

4-8-5 2D/COMB MODULE

1 VIDEO MAIN VIDEO INPUT 2.74V

2 GND GND GND

3 9V 9V INPUT 9V

4 GND GND GND

5 FSC FSC 6 N.C N.C 7 N.C N.C 8 5V 5V INPUT 5V

9 Y-OUT MAIN Y OUT 10 GND GND GND

11 C-OUT MAIN C OUT 12 GND GND GND

1 SIF SIF OUT 3.25V

2 9V 9V INPUT 9V

3 GND GND GND

4 IF IF INPUT 4.5V

5 GND GND GND

6 AGC RF AGC IN 5.37V

7 TV-VIDEO TV-VIDEO OUT 8 AFT MAIN AFT INPUT 2V

9 GND GND GND

PIN NO. ITEM FUNCTION OUT VOLT

PIN NO. ITEM FUNCTION OUT VOLT

4-8-6 IF MODULE

Alignment and Adjustments

Samsung Electronics 4-25

4-8-7 MTS MODULE

PIN NO. ITEM FUNCTION OUT VOLT

1 TV-R TV R-SOUND OUT 2 TV-L TV L-SOUND OUT 3 SCL SERIAL CLOCK LINE 4 SDA SERIAL DATA LINE 5 N.C N.C 6 GND GND GND

7 SIF SIF INPUT 8 N.C N.C 9 N.C N.C 10 9V 9V INPUT 9V

Alignment and Adjustments

4-26 Samsung Electronics

4-8-8 H/V MODULE

1 12V 12V INPUT 12V

2 GND GND GND

3 HD H-DRIVE INPUT 1.6V

4 V-BLK V-BLANK INPUT 0.72V

5 H-BLK H-BLANK OUT 0.54V

6 GND GND GND

7 PROTECT PROTECT ACTIV H

8 FBT-DC FBT DC FEED BACK 4.87V

9 X-RAY X-RAY PROTECT F/B 2.10V

10 N.C N.C 11 HV-REG HV-REG 3.54V

12 HV-DRIVE HIGH VOLTAGE DRIVE 0.32V

13 H-DRIVE H-DRIVE OUT 25V

14 GND GND GND

15 HEATER HEATER INPUT AC[0.7V]

16 N.C N.C 17 208V 208V INPUT 208V

18 N.C N.C 19 GND GND GND

20 V2 V2 INPUT

21 N.C N.C 22 N.C N.C 23 D-FOCUS DYNAMIC FOCUS OUT 24 N.C N.C 25 N.C N.C 26 SCREEN SCREEN INPUT 1356V

PIN NO. ITEM FUNCTION OUT VOLT

Alignment and Adjustments

Samsung Electronics 4-27

4-8-9 CONV- MODULE

1 SDA D2 2 SCL D1 3 GND GND GND

4 BV BLUE VERTICAL OUT 5 BH BLUE HORIZONTAL OUT 6 GV GREEN VERTICAL OUT 7 GH GREEN HORIZONTAL OUT 8 RV RED VERTICAL OUT 9 RH RED HORIZONTAL OUT 10 -5.4V -5.4V INPUT -5.4V

11 5.4V 5.4V INPUT +5.4V

12 V-BLK V-BLK INPUT 13 GND GND GND

14 H-BLK H-BLK INPUT 0.52V

15 COMP COMP VIDEO OUTPUT (N.C) 16 IR INPUT REMOCON 3V

17 CTRL CTRL (N.C) N.C

18 D3/SEL D3 0.2V

19 B WHEN TEST PATTERN B OUT 20 G(TEST) WHEN TEST PATTERN G OUT N.C

21 R WHEN TEST PATTERN R OUT 22 SYNC SYNC OUTPUT 4.41V

PIN NO. ITEM FUNCTION OUT VOLT

4-28 Samsung Electronics

MEMO

Troubleshooting

Samsung Electronics 5-1

5. Troubleshooting

5-1 Convergence Misaligned

5-2 No Sound

Troubleshooting

5-2 Samsung Electronics

Troubleshooting

Samsung Electronics 5-3

5-3 No Raster (Sound OK)

MEMO

5-4 Samsung Electronics

6. Exploded View & Parts List

6-1 PCJ522R

Exploded View & Parts List

Samsung Electronics 6-1

1 ASSY-CABINET,FRONT AA91-10419M HIPS HB BLK 1

1-1 SUN-SCREEN AA67-70048A 52 PMMA 1

1-2 SCREEN-TINT AA67-70065A 52 DNP 1

1-3 HOLDER-SCREEN AA61-00081B A6063 EXTR. L754 2

1-4 SCREW-TAPTITE AA60-10011A HH + M4 L12 ZPC 24

1-5 HOLDER-SCREEN AA61-00081C A6063 EXTR. L1052 2

1-6 SCREW-WOOD AA60-10050W W/H + M4 L20 ZPC 4

1-7 SCREW-TAPPING AA60-10002A RH + M4 L12 ZPC OD14 2

1-8 ASSY-PCB,CONTROL AA95-00265B P51A 1

1-9 ASSY-PCB,A/V FRONT AA95-00290C P51A 1

1-10 SCREW-TAPTITE AA60-10011A HH + M4 L12 ZPC 2

2 CABINET-FRONT,BOTTOM AA64-31357A ABS V0 BLK 1

2-1 SCREW-TAPTITE AA60-10011A HH + M4 L12 ZPC 3

3 ASSY-CABINET,MID AA91-00205A WOOD 1

3-1 SCREW-WOOD AA60-10051A PH + M4 L16 ZPC 24

3-2 SPEAKER 3001-001107 20W 8ohm 95+-2DB 2

3-3 SPEAKER 3001-000176 30W 8ohm 93+-2DB 2

3-4 SCREW-WOOD AA60-10050W W/H + M4 L20 ZPC 2

3-5 MODULE-FOCUS,PACK AA59-40003P F300,NTSC,43,64x62, 1

4 CABINET-BACK,TOP AA64-30714A HIPS HB BLK 1

4-1 SCREW-TAPTITE 6003-001026 RH + M4 L15 ZPC 16

4-2 BRACKET-MIRROR,C AA61-10242A SECC T1.0 2

4-3 BRACKET-MIRROR AA61-10361A SECC T1.0 5

4-4 SPACER-MIRROR AA63-00021G PVC BLK L420 2

4-5 MIRROR-BACK SURFACE AA67-20026A 52 GLASS T3 1

4-6 SPACER-MIRROR AA63-00021G PVC BLK L970 1

4-7 SPACER-MIRROR AA63-00021G PVC BLK L680 1

4-8 SCREW-WOOD AA60-10050W W/H + M4 L20 ZPC 8

5 CABINET-BACK,BOARD AA64-00501A HIPS V0 BLK 1

5-1 SCREW-WOOD AA60-10050W W/H + M4 L20 ZPC 14

5-2 LABEL-WARNING AA68-00233A A/P 90(G) 1

6 ASSY-BRACKET,MAIN AA91-00241A SECC T1.6 1

6-1 SCREW-ASSY AA60-10001A WP + M6 L20 SCM30C 4

6-2 SCREW-TAPTITE AA60-10011A HH + M4 L12 ZPC 1

6-3 ASSY-CRT(R) AA94-01640A P16LNM07RJA,+380MG,7,BARE 1

ASSY-CRT(G) AA94-01641A 16LNM07HKA,+380MG,7,BARE 1

ASSY-CRT(B) AA94-01642A P16LNM07BMB,+380MG,7,BARE, 1

6-4 SPACER-COVER,DUST AA60-00027A SPONGE T2 1

7 HOLDER-CHASSIS AA61-00051B ABS V0 GRAY 1

7-1 ASSY-PCB,MAIN(OPT) AA94-01636A PCJ522RX/XAA,P51A,U.S 1

7-2 ASSY-PCB,SUB AA94-01636A PCJ522RX/XAA,P51A,U.S 1

7-3 ASSY-CONV.AMP AA95-00055E P51A 1

7-4 SCREW-TAPPING 6003-001023 RWH + B M3 L10 ZPC 21

7-5 ASSY-TERMINAL,BOARD AA91-00158H HIPS V0 VLK 1

DESCRIPTION CODE - NO SPECIFICATION Q’TYNo.

1 ASS`Y-CABINET,MASK AA91-00140E HB BLK SEA PCJ612R 1

2 SUN-SCREEN AA67-70057A 61’ DNP 1283*973 1

3 SCREEN-TINT AA67-70056A 61’ DNP 1283*973 1

4 HOLDER-SCREEN AA61-00079C PCJ613R ABS HB BLK L945 2

5 HOLDER-SCREEN AA61-00079B PCJ613R ABS HB BLK L1255 2

6 COVER-FRONT,WOOD AA63-00183A WOOD 612R 2

7 ASS`Y-CABINET,BOT AA91-00014G VO DG707M ALL PCJ612R 1

8 ASSY-PCB,CONTROL AA95-00265B P51A 1

9 ASSY-PCB,A/V FRONT AA95-00290L P51A 1

10 SPEAKER 3001-001107 20W 8ohm 95+-2DB 1

11 SPEAKER 3001-000176 30W 8ohm 93+-2DB 1

12 SCREW-TAPTITE 6003-001023 RWH + M3 L10 ZPC(YEL) 2

13 MODULE FOCUS-PACK AA59-40003P F300,NTSC,43,64X62,BK 1

14 ASS`Y-CABINET,MIDDLE AA91-00207A WOOD PCJ612R 1

15 SPACER-COVER,DUST AA60-00027B SPONGE T2.0 612R 1

16 ASSY-CRT(R) AA94-01676A P16LNM07RJA,+380MG,7,BARE, 1

17 ASSY-CRT(G) AA94-01677A P16LNM07HKA,+380MG,7,BARE, 1

18 ASSY-CRT(B) AA94-01678A P16LNM07BMB,+380MG,7,BARE 1

19 ASS`Y-BRACKET,MAIN AA91-00241A SECC T1.6 7 53J5 1

20 SCREW-TAPTITE AA60-10011A PC M4 L12 ZPC(BLK) 8

21 MIRROR-BACK AA67-00020A GLASS T3.0 1160*754*806 1

22 COVER-MIRROR,WOOD AA63-00082A PCH613R WOOD 1

23 SCREW-WOOD AA60-10050W 10/H M4 L20 ZPC(BLK) 1

24 SCREW-WOOD 6005-001001 TH M4 L28 BLK SWRCH 18A 1

25 CABINET-BACK,TOP AA4-31213B HIPS HB BLK 1

26 SCREW-WOOD AA60-10050W W/H M4 20 ZPC(BLK) 13

27 CABINET-BACK,BOARD AA64-00625A HIPS VO BLK T3.0 1

28 ASSY-CONV,AMP AA95-00055E P51A 1

29 ASSY-SUB AA95-00053F P51A 1

30 ASSY-MAIN AA95-00055E P51A 1

31 ASS`Y-TERMINAL,BOARD AA91-00158H HIPS VO BLK PCJ612R 1

32 HOLDER-CHASSIS AA61-00051B ABS VO GRAY E2 1

DESCRIPTION CODE - NO SPECIFICATION Q’TYNo.

Exploded View & Parts List

6-2 Samsung Electronics

6-2 PCJ612R

7. Electrical Parts List

Electrical Parts List

Samsung Electronics 7-1

ASSY-CABINET

*AA90-00186ASSY-CABINET;612R,PCJ612RX/XAA

SPC AA60-00027BSPACER-COVER,DUST;SPONGE,T2.0,-,-,612R,HDR AA61-00079BHOLDER-SCREEN;-,PCJ613R,ABS,HB,BLK,L1255

HDR AA61-00079CHOLDER-SCREEN;-,PCJ613R,ABS,HB,BLK,L945

COVM AA63-00082ACOVER-MIRROR,WOOD;-,PCJ613R,-,WOOD,-,-,-,COVF AA63-00183ACOVER-FRONT,WOOD;-,PCJ612R,JERSEY,WOOD,-,-,-,SPA AA63-60131ESPACER-FELT;FELT,T0.5,BLK,520X200,PCJ612R,BACK AA64-00625ACABINET-BACK,BOARD;-,613R,-,HIPS,V0,BLK,T3.0,BACK AA64-31213BCABINET-BACK,TOP;-,555J,-,HIPS,HB,BLK,-,MIRB AA67-00020AMIRROR-BACK;613,GLASS,T3.0,-,-,1160*754*806,BSM,SUN AA67-00022ASUN-SCREEN;-,61,H/C,A/S,PMMA,T=82%,T2.0,1283*973,SCRN AA67-70056ASCREEN-TINT;0.515,61’,DNP,896-

985,TINT10%,2.7,1283*973,

AC+BCM AA60-10011ASCREW-TAPTITE;HH,+,PC,M4,L12,ZPC(BLK),SWRCH1

ACB+CM AA60-10050 SCREW-WOOD;W/H,+,M4,20,ZPC(BLK),SWRCH18A,

AV+CFB AA60-10002ASCREW-TAPPING;RH,+,M4,L12,ZPC(YEL),-,OD14

BCM AA63-60040BSPACER-DIECAST;PU,-,-,225X23,S4388,BCM+CM AA60-00015ASCREW-ASSY;-,WP,-,M8,L25,SCM30C,-,CMW AA60-10050 SCREW-WOOD;W/H,+,M4,20,ZPC(BLK),SWRCH18A,

CMW+CM 6005-001001 SCREW-WOOD;TH,+,M4,L28,BLK,SWRCH18A

CP+CFB AA60-10002ASCREW-TAPPING;RH,+,M4,L12,ZPC(YEL),-,OD14

FP+BF 6003-001023 SCREW-TAPTITE;RWH,+,B,M3,L10,ZPC(YEL),SWRCH1

HC+CM AA60-10050 SCREW-WOOD;W/H,+,M4,20,ZPC(BLK),SWRCH18A,

HS+CM AA60-00021ASCREW-WOOD;RH,+,M3.5,L22,ZPC(BLK),SWRCH18,HSS+CM AA60-00021ASCREW-WOOD;RH,+,M3.5,L22,ZPC(BLK),SWRCH18,HV+BCM 6003-001024 SCREW-TAPTITE;RWH,+,B,M4,L12,ZPC(YEL),SWRCH1

RNGBCM 6003-001024 SCREW-TAPTITE;RWH,+,B,M4,L12,ZPC(YEL),SWRCH1

TBACBW 6003-001024 SCREW-TAPTITE;RWH,+,B,M4,L12,ZPC(YEL),SWRCH1

VBW+CM AA60-10050 SCREW-WOOD;W/H,+,M4,20,ZPC(BLK),SWRCH18A,

ASSY-CABINET,BOT

* AA91-00014GASSY-CABINET,BOT;-,V0,DG707M ALL,PCJ612R

BADGE AA64-00406EBADGE-BRAND;AL,DG-707M SAMSUNG,SILVER,72,FORG

ING,-,CAFRBOT AA61-30001ALATCH-DOOR;-,-,-,KIFUCO LA701,CAFRBOT AA61-60005ASPRING-CS;-,SUS304,0.6,OD10.7,H10,N4,-,CAFRBOT AA64-10764BKNOB-CONTROL;-,-,CHAMPAINE GOLD+UV,ABS ,HB,NTR

CAFRBOT AA64-40494AWINDOW-REMOCON;-,SVP-434J,-,PC,-,VIOLET,DOOR AA64-00090DDOOR-A/V;-,PCJ612R,DG707M ALL,ABS,HB,BLK,-,FRONT AA64-00088JCABINET-FRONT,BOT;-,PCJ612R,DG707M

SEA,SECA,HIPS,V0,BLK,-,-

KC+CFB 6003-001022 SCREW-TAPTITE;RH,+,B,M3,L12,ZPC(BLK),SWRCH18

LAB AA68-00046CLABEL-DOOR,AV;TETRON MAT P,E,PCJ533R,P51A EL,-,-,WIN AA64-40493AINDICATOR-LED;-,SVP-434JA,-,ABS,-,CLR,WR+CFB 6003-001022 SCREW-TAPTITE;RH,+,B,M3,L12,ZPC(BLK),SWRCH18

ASSY-CABINET,MASK

* AA91-00140EASSY-CABINET,MASK;-,HB,BLK,DG902+BK901

SEA,PCJ612R

FRONT AA64-00257BCABINET-FRONT,MASK;-,PCJ613R,L1251,ABS,HB,BLK,-,-

FRONT AA64-00257CCABINET-FRONT,SIDE;-,PCJ613R,L941,ABS,HB,BLK,-,HDRC AA61-00078BHOLDER-CORNER;-,PCJ613R,ABS,HB,BLK,-

SPA AA63-00063ASPACER-DUAL,LOCK;#400,-,-,19X19,SVP-614J,-

ASSY-CABINET,MIDDLE

* AA91-00207AASSY-CABINET,MIDDLE;-,WOOD,-,PCJ612R

AL 2401-003493 C-AL;1.75uF,10%,100V,BP,BK,10x13mm,5

BCKT AA61-10247ABRACKET-FOCUS;-,S46DS,SECC,T1.0,-,-,BF+CM AA60-10051ASCREW-WOOD;PH,+,M4,L16,ZPC(BLK),SWRCH18A,

CABMID AA64-00514ACABINET-MIDDLE;-,PCJ612R,-,WOOD,-,BLK,-,CABMID 3001-000153 SPEAKER;20W,8ohm,93dB,1.3KHz

CABMID 3001-000176 SPEAKER;30W,8OHM,93DB+-2DB,65HZ

CABMID AA61-00030ACASTER;SVP-614JM,POLYURETHANE,-,50,23,-,H63,CABMID AA61-00080BHOLDER-MASK;-,PCJ613R,ABS,HB,NTR,L80

CABMID AA63-00105ASPACER-FELT;FELT,T2.0,BLK,32X878,PCJ613R,CABMID AA63-00105BSPACER-FELT;FELT,T2.0,BLK,32X1211,PCJ613R,HDRP AA61-00146AHOLDER-PIN,LOCKER;-,PRJT,ABS,HB,BLK,WOOD

LEAD AA39-20609ALEAD CONNECTOR-ASSY;-,SMH250-

02,REC,2P,400mm,1007#

SPA AA63-00066BSPACER-DUAL,LOCK;#250,-,-,11X25,PROJECTION,SPAF AA63-60126ASPACER-FELT;FELT,T2,BLK,1160X15,PRJT43,52,

SPAF AA63-60126DSPACER-FELT;FELT,T2,-,400X15,PRJ61,SPK AA39-20505RLEAD CONNECTOR-ASSY;-,YSH250-

04,REC,4P,1400,900,1007#22

ASSY-CRT-(R)

* AA94-01676AASSY-CRT-(R);P16LNM07RJA,+380MG,7,BARE,PCJ612R,-

LENS AA67-10066ALENS-ASSY;DELTA 37,-,-,CLEAR A/B,-,-,-

ASSY-CRT-(G)

* AA94-01677AASSY-CRT-(G);P16LNM07HKA,+380MG,7,BARE,PCJ612R,-

LENS AA67-10066ALENS-ASSY;DELTA 37,-,-,CLEAR A/B,-,-,-

ASSY-CRT-(B)

* AA94-01678AASSY-CRT-(B);P16LNM07BMB,+380MG,7,BARE,PCJ612R,-

LENS AA67-10066ALENS-ASSY;DELTA 37,-,-,CLEAR A/B,-,-,-

ASSY-PCB,CRT

* AA95-00344DASSY-PCB,CRT;-,P51A,-,USA,PCJ612R

BDW-GND AA39-20009KLEAD CONNECTOR-ASSY;-,YFH800-01,-

,1P,1617#22,1000MM

CNW401 AA39-20027DLEAD-CONNECTOR,ASSY;-,67096-006,S,6P,600,1007#26

CNW501 AA39-20030DLEAD-CONNECTOR,ASSY;-,67096-008,S,8P,600,1007#26

GDW-GND AA39-20009GLEAD-CONNECTOR,ASSY;-,YFH800-01,-,1P,700,1617#22

RDW-GND AA39-20009CLEAD CONNECTOR-ASSY;-,YFH800-01,-,1P,400,1617#22

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

7-1 PCJ612RX/XAA (PCJ522RX/XAA and PCJ612RX/XAA Dissimilar Parts)

Electrical Parts List

7-2 Samsung Electronics

ASSY-CABINET,FRONT

* AA91-00251AASSY-CABINET,FRONT;-,524J,D703+B702

COMPAC,HB,BLK

CMPRTVFRONTTOPAA64-31356NCABINET-FRONT,TOP;-,524J,D703+B702

C/THEATRE,HIPS,HB,BLK,-,-

ASSY-ACCESSORY

* AA94-01639AASSY-ACCESSORY;PCJ522RX/XAC,P51A,CANADA,SECA

CMPRTV IBAA68-00533AMANUAL-USERS;P51A,W/P100(G),-,FRE,-,-,B5,-,-

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

7-2 PCJ522RX/XAC (PCJ522RX/XAA and PCJ522RX/XAC Dissimilar Parts)

ASSY-CABINET

* AA90-00186AASSY-CABINET;612R,PCJ612RX/XAC

AC+BCM AA60-10011ASCREW-TAPTITE;HH,+,PC,M4,L12,ZPC(BLK),SWRCH1

ACB+CM AA60-10050WSCREW-WOOD;W/H,+,M4,20,ZPC(BLK),SWRCH18A,

AP2273 AA68-50509ALABEL-BOX;A/P 90(G),ALL MODEL,-,WHT,L250

AV+CFB AA60-10002ASCREW-TAPPING;RH,+,M4,L12,ZPC(YEL),-,OD14

BACK AA64-00625ACABINET-BACK,BOARD;-,613R,-,HIPS,V0,BLK,T3.0,BACK AA64-31213BCABINET-BACK,TOP;-,555J,-,HIPS,HB,BLK,-,BCM AA63-60040BSPACER-DIECAST;PU,-,-,225X23,S4388,BCM+CM AA60-00015ASCREW-ASSY;-,WP,-,M8,L25,SCM30C,-,CMW AA60-10050WSCREW-WOOD;W/H,+,M4,20,ZPC(BLK),SWRCH18A,

CMW+CM 6005-001001 SCREW-WOOD;TH,+,M4,L28,BLK,SWRCH18A

COVERF AA63-00183ACOVER-FRONT,WOOD;-,PCJ612R,JERSEY,WOOD,-,-,-,COVERM AA63-00082ACOVER-MIRROR,WOOD;-,PCJ613R,-,WOOD,-,-,-,CP+CFB AA60-10002ASCREW-TAPPING;RH,+,M4,L12,ZPC(YEL),-,OD14

FP+BF 6003-001023 SCREW-TAPTITE;RWH,+,B,M3,L10,ZPC(YEL),SWRCH1

HC+CM AA60-10050WSCREW-WOOD;W/H,+,M4,20,ZPC(BLK),SWRCH18A,

HDRS AA61-00079BHOLDER-SCREEN;-,PCJ613R,ABS,HB,BLK,L1255

HDRS AA61-00079CHOLDER-SCREEN;-,PCJ613R,ABS,HB,BLK,L945

HS+CM AA60-00021ASCREW-WOOD;RH,+,M3.5,L22,ZPC(BLK),SWRCH18,HSS+CM AA60-00021ASCREW-WOOD;RH,+,M3.5,L22,ZPC(BLK),SWRCH18,HV+BCM 6003-001024 SCREW-TAPTITE;RWH,+,B,M4,L12,ZPC(YEL),SWRCH1

MIRB AA67-00020AMIRROR-BACK;613,GLASS,T3.0,-,-,1160*754*806,BSM,RNGBCM 6003-001024 SCREW-TAPTITE;RWH,+,B,M4,L12,ZPC(YEL),SWRCH1

SCRT AA67-70056ASCREEN-TINT;0.515,61’,DNP,896-

985,TINT10%,2.7,1283*973,

SPA AA60-00027BSPACER-COVER,DUST;SPONGE,T2.0,-,-,612R,SPA AA63-60131ESPACER-FELT;FELT,T0.5,BLK,520X200,PCJ612R,SUN AA67-00022ASUN-SCREEN;-,61,H/C,A/S,PMMA,T=82%,T2.0,1283*973,TBACBW 6003-001024 SCREW-TAPTITE;RWH,+,B,M4,L12,ZPC(YEL),SWRCH1

VBW+CM AA60-10050WSCREW-WOOD;W/H,+,M4,20,ZPC(BLK),SWRCH18A,

ASSY-CABINET,BOT

* AA91-00014GASSY-CABINET,BOT;-,V0,DG707M ALL,PCJ612R

BADGE AA64-00406EBADGE-BRAND;AL,DG-707M SAMSUNG,SILVER,72,FORG

ING,-,CAFRBOT AA61-30001ALATCH-DOOR;-,-,-,KIFUCO LA701,CAFRBOT AA61-60005ASPRING-CS;-,SUS304,0.6,OD10.7,H10,N4,-,CAFRBOT AA64-10764BKNOB-CONTROL;-,-,CHAMPAINE GOLD+UV,ABS ,HB,NTR

CAFRBOT AA64-40494AWINDOW-REMOCON;-,SVP-434J,-,PC,-,VIOLET,DOORAV AA64-00090DDOOR-A/V;-,PCJ612R,DG707M ALL,ABS,HB,BLK,-,FRONT AA64-00088JCABINET-FRONT,BOT;-,PCJ612R,DG707M

SEA,SECA,HIPS,V0,BLK,-,KC+CFB 6003-001022 SCREW-TAPTITE;RH,+,B,M3,L12,ZPC(BLK),SWRCH18

LABEL AA68-00046CLABEL-DOOR,AV;TETRON MAT P,E,PCJ533R,P51A EL,-,-,WIN AA64-40493AINDICATOR-LED;-,SVP-434JA,-,ABS,-,CLR,WR+CFB 6003-001022 SCREW-TAPTITE;RH,+,B,M3,L12,ZPC(BLK),SWRCH18

ASSY-CABINET,MASK

* AA91-00140DASSY-CABINET,MASK;-,HB,BLK,DG902+BK901

SECA,PCJ612R

FRONT AA64-00257BCABINET-FRONT,MASK;-,PCJ613R,L1251,ABS,HB,BLK,-,FRONT AA64-00257CCABINET-FRONT,SIDE;-,PCJ613R,L941,ABS,HB,BLK,-,HDR AA61-00078BHOLDER-CORNER;-,PCJ613R,ABS,HB,BLK,SPA AA63-00063ASPACER-DUAL,LOCK;#400,-,-,19X19,SVP-614J,-

ASSY-CABINET,MIDDLE

* AA91-00207AASSY-CABINET,MIDDLE;-,WOOD,-,PCJ612R

AL 2401-003493 C-AL;1.75uF,10%,100V,BP,BK,10x13mm,5

BCKT AA61-10247ABRACKET-FOCUS;-,S46DS,SECC,T1.0,-,-,BF+CM AA60-10051ASCREW-WOOD;PH,+,M4,L16,ZPC(BLK),SWRCH18A,

CABMID 3001-000153 SPEAKER;20W,8ohm,93dB,1.3KHz

CABMID 3001-000176 SPEAKER;30W,8OHM,93DB+-2DB,65HZ

CABMID AA61-00030ACASTER;SVP-614JM,POLYURETHANE,-,50,23,-,H63,CABMID AA61-00080BHOLDER-MASK;-,PCJ613R,ABS,HB,NTR,L80

CABMID AA63-00105ASPACER-FELT;FELT,T2.0,BLK,32X878,PCJ613R,CABMID AA63-00105BSPACER-FELT;FELT,T2.0,BLK,32X1211,PCJ613R,HDR AA61-00146AHOLDER-PIN,LOCKER;-,PRJT,ABS,HB,BLK,WOOD

LEAD AA39-20609ALEAD CONNECTOR-ASSY;-,SMH250-

02,REC,2P,400mm,1007#

MIDCAB AA64-00514ACABINET-MIDDLE;-,PCJ612R,-,WOOD,-,BLK,-,SPA AA63-00066BSPACER-DUAL,LOCK;#250,-,-,11X25,PROJECTION,SPA AA63-60126ASPACER-FELT;FELT,T2,BLK,1160X15,PRJT43,52,

SPA AA63-60126DSPACER-FELT;FELT,T2,-,400X15,PRJ61,SPK AA39-20505RLEAD CONNECTOR-ASSY;-,YSH250-

04,REC,4P,1400,900,1007#22

ASSY-ACCESSORY

* AA94-01639AASSY-ACCESSORY;PCJ522RX/XAC,P51A,CANADA,SECA

IB AA68-00533AMANUAL-USERS;P51A,W/P100(G),-,FRE,-,-,B5,-,-

ASSY-CRT-(R)

* AA94-01676AASSY-CRT-(R);P16LNM07RJA,+380MG,7,BARE,PCJ612R,-

LENS AA67-10066ALENS-ASSY;DELTA 37,-,-,CLEAR A/B,-,-,-

ASSY-CRT-(G)

* AA94-01677AASSY-CRT-(G);P16LNM07HKA,+380MG,7,BARE,PCJ612R,-

LENS AA67-10066ALENS-ASSY;DELTA 37,-,-,CLEAR A/B,-,-,-

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

7-3 PCJ612RX/XAC (PCJ522RX/XAA and PCJ612RX/XAC Dissimilar Parts)

ASSY-CRT-(B)

* AA94-01678AASSY-CRT-(B);P16LNM07BMB,+380MG,7,BARE,PCJ612R,-

LENS AA67-10066ALENS-ASSY;DELTA 37,-,-,CLEAR A/B,-,-,-

ASSY-PCB,CRT

* AA95-00344DASSY-PCB,CRT;-,P51A,-,USA,PCJ612R

BDW-GND AA39-20009KLEAD CONNECTOR-ASSY;-,YFH800-01,-

,1P,1617#22,1000MM

CNW401 AA39-20027DLEAD-CONNECTOR,ASSY;-,67096-006,S,6P,600,1007#26

CNW501 AA39-20030DLEAD-CONNECTOR,ASSY;-,67096-008,S,8P,600,1007#26

GDW-GND AA39-20009GLEAD-CONNECTOR,ASSY;-,YFH800-01,-,1P,700,1617#22

RDW-GND AA39-20009CLEAD CONNECTOR-ASSY;-,YFH800-01,-,1P,400,1617#22

Electrical Parts List

Samsung Electronics 7-3

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

ASSY-PCB,MAIN(OPT)

* AA94-01636AASSY-PCB,MAIN(OPT);PCJ522RX/XAA,P51A,U.S

C101 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C102 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C103 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C104 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

C105 2401-002619 C-AL;47uF,20%,25V,GP,TP,5x11,5

C106 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C107 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C108 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C109 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C110 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

C112 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C113 2401-002009 C-AL;100uF,20%,16V,GP,TP,6.3x7,5

C114 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C116 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C117 2301-000310 C-FILM,PEF;68nF,5%,50V,TP,8.0X8.5X4.0X5,

C118 2201-000180 C-CERAMIC,DISC;10nF,10%,50V,Y5V,TP,6.5*3

C119 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C121 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C125 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C126 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C129 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C130 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C132 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C133 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

C180 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C185 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

C191 2401-002619 C-AL;47uF,20%,25V,GP,TP,5x11,5

C193 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C195 2401-002619 C-AL;47uF,20%,25V,GP,TP,5x11,5

C501 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C502 2401-001397 C-AL;470uF,20%,25V,GP,TP,10x16,5

C503 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C504 2401-000832 C-AL;220uF,20%,25V,GP,TP,8x11.5,5

C505 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C506 2401-002594 C-AL;220uF,20%,16V,GP,TP,8x11.5,5

C507 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C508 2401-002286 C-AL;470uF,20%,16V,WT,TP,10x12.5,5

C513 2401-002594 C-AL;220uF,20%,16V,GP,TP,8x11.5,5

C514 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C515 2201-000573 C-CERAMIC,DISC;47pF,5%,50V,CH,TP,6.5x3.0

C516 2201-000573 C-CERAMIC,DISC;47pF,5%,50V,CH,TP,6.5x3.0

C517 2401-002594 C-AL;220uF,20%,16V,GP,TP,8x11.5,5

C518 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C519 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C520 2401-002594 C-AL;220uF,20%,16V,GP,TP,8x11.5,5

C521 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C522 2401-002286 C-AL;470uF,20%,16V,WT,TP,10x12.5,5

C537 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C538 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C539 2401-001840 C-AL;100uF,20%,16V,GP,TP,6.3x11,5

C540 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C543 2201-000144 C-CERAMIC,DISC;100pF,5%,50V,CH,TP,8x3,5

C544 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C545 2201-000573 C-CERAMIC,DISC;47pF,5%,50V,CH,TP,6.5x3.0

C547 2201-000573 C-CERAMIC,DISC;47pF,5%,50V,CH,TP,6.5x3.0

C549 2401-002594 C-AL;220uF,20%,16V,GP,TP,8x11.5,5

C550 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C551 2401-000360 C-AL;100uF,20%,50V,GP,TP,8x11.5,5

C552 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C639 2401-002009 C-AL;100uF,20%,16V,GP,TP,6.3x7,5

C640 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C664 2401-001068 C-AL;3300uF,20%,50V,GP,BK,22x40,10

C665 2401-000737 C-AL;2200uF,20%,50V,GP,TP,18x35.5,7.5

C666 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C667 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C668 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C669 2401-000962 C-AL;22uF,20%,50V,GP,TP,5x11,5

C670 2401-000603 C-AL;1uF,20%,50V,GP,TP,5x11,5

C671 2401-001537 C-AL;47uF,20%,25V,GP,TP,6.3x7mm,5mm

C672 2401-000360 C-AL;100uF,20%,50V,GP,TP,8x11.5,5

C676 2401-001192 C-AL;33uF,20%,50V,GP,TP,6.3x11,5

C686 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

C687 2301-000192 C-FILM,PEF;1nF,5%,50V,TP,5.3x10mm,5mm

C688 2401-000192 C-AL;1000uF,20%,50V,GP,TP,16x25,7.5

C689 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C690 2305-000665 C-FILM,MPEF;100nF,5%,63V,TP,7.5x4.0x5.0m

C691 2401-000192 C-AL;1000uF,20%,50V,GP,TP,16x25,7.5

C701 2401-000027 C-AL;4.7uF,20%,50V,GP,TP,5x11,5

C801 2401-002300 C-AL;47uF,20%,50V,GP,TP,6.3x11,5

C901 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3,5

C904 2202-002037 C-CERAMIC,MLC-AXIAL;100nF,80-20%,50V,Y5V

C905 2401-001496 C-AL;47uF,20%,16V,GP,TP,5x7,5

C906 2305-000149 C-FILM,MPEF;100nF,5%,100V,TP,12x12.5x6.5

C907 2301-000111 C-FILM,PEF;1.8nF,5%,50V,TP,6.5x3.0x5.5mm

C908 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3,5

C909 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3,5

C910 2201-000292 C-CERAMIC,DISC;1nF,10%,50V,Y5P,TP,5x3,5

C911 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C912 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP ,

C913 2201-000193 C-CERAMIC,DISC;10pF,0.3pF,50V,CH,TP,5x3,

C914 2201-000573 C-CERAMIC,DISC;47pF,5%,50V,CH,TP,6.5x3.0

C915 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C916 2401-002042 C-AL;220uF,20%,10V,GP,TP,6.3x11,5

C917 2401-002144 C-AL;47uF,20%,16V,GP,TP,5x11,5

C918 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C919 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

C920 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C925 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

C926 2401-000480 C-AL;10uF,20%,50V,GP,TP,5x11,5

CLAMPF AA65-30109ACLAMP-FBT;NYLON-66,V2,BLK,-,-,CLAMPW AA65-30105BCLAMP-WIRE;NYLON 66,V2,NTR,25MM,ALL MODE

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

7-4 PCJ522RX/XAA

CLAMPW AA65-30013ACLAMP-WIRE;NYLON-66,V0,NTR,DAWH-45N,-,CLAMPW AA65-30018ACLAMP-WIRE;NYLON-66,-,-,DATL-600,DONG-A,

CN201 3711-002647 CONNECTOR-HEADER;BOX,8P,1R,2.5mm,STRAIGH

CN202 3711-002641 CONNECTOR-HEADER;BOX,10P,1R,2.54mm,STRAI

CN501 3711-002647 CONNECTOR-HEADER;BOX,8P,1R,2.5mm,STRAIGH

CN601 3711-002643 CONNECTOR-HEADER;BOX,4P,1R,2.5MM,STRAIGH

CN801 3711-003641 CONNECTOR-HEADER;BOX,12P,1R,2.5mm,STRAIG

CNT01 3710-001208 CONNECTOR-SOCKET;32P,2R,2.54mm,STRAIGHT,

CNT02 3710-001208 CONNECTOR-SOCKET;32P,2R,2.54mm,STRAIGHT,

CNY01 3711-000628 CONNECTOR-HEADER;-,11P,1R,2.5mm,STRAIGHT

CS801 2201-000332 C-CERAMIC,DISC;2.2nF,20%,250VAC,Y5U,TP,1

CS802 2201-000332 C-CERAMIC,DISC;2.2nF,20%,250VAC,Y5U,TP,1

CS803 2401-003066 C-AL;10uF,20%,450V,GP,TP,13x20mm,5m

CS804 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

CS805 2401-001101 C-AL;330uF,20%,16V,GP,TP,8x11.5,5

CS807 2201-000119 C-CERAMIC,DISC;100nF,+80-20%,50V,Y5V,TP,

CS808 2401-001363 C-AL;470uF,20%,16V,GP,TP,10x12.5,5

CS809 2201-000556 C-CERAMIC,DISC;470pF,10%,500V,Y5P,TP,7x4

CS810 2201-000446 C-CERAMIC,DISC;3.3nF,20%,400V,Y5U,TP,18x

CS811 2201-000446 C-CERAMIC,DISC;3.3nF,20%,400V,Y5U,TP,18x

CS812 2201-002076 C-CERAMIC,DISC;0.068nF,5%,1kV,SL,TP,8x4m

D501 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D502 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D664 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T

D665 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D666 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D667 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D668 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D669 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D671 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D672 0402-000132 DIODE-RECTIFIER;1N4004,400V,1A,DO-41,TP

D701 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D702 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D703 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D901 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D902 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

D903 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500m

D904 0403-000546 DIODE-ZENER;MTZ3.6B,3.6V,3.6-3.845V,500m

D905 0401-000005 DIODE-SWITCHING;1N4148,100V,200MA,DO-35,

DS801 0402-000102 DIODE-BRIDGE;D2SB60,600V,1.5A,DS802 1405-001036 VARISTOR;430V,2500A,14x8.5mm,TP

DS803 0403-000300 DIODE-ZENER;MTZ8.2B,8.2V,7.78-8.19V,500m

DS804 0403-000294 DIODE-ZENER;MTZ4.7B,4.7V,4.55-4.80V,500m

DS805 0402-000534 DIODE-RECTIFIER;RG10V,400V,1.2A,DO-201,T

DS806 1405-001030 VARISTOR;120V,2500A,14x8.5mm,TP

DS807 0402-000546 DIODE-RECTIFIER;TVR10G,400V,1.0A,DO-41,T

DS808 1405-001036 VARISTOR;430V,2500A,14x8.5mm,TP

DS810 1405-001036 VARISTOR;430V,2500A,14x8.5mm,TP

DZ107 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ108 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ109 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ110 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ501 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ502 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ503 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500m

DZ504 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500m

DZ505 0403-000563 DIODE-ZENER;MTZ9.1B,9.1V,8.57-9.01V,500m

DZ506 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500m

DZ507 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ508 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ510 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ665 0403-001039 DIODE-ZENER;MA2560,56V,52-60V,1W,DO-41,T

DZ666 0403-000656 DIODE-ZENER;MTZ15C,15V,14.35-15.09V,500m

DZ667 0403-000355 DIODE-ZENER;UZ5.1BSB,5.1V,4.97-5.18V,500

DZ701 0403-000289 DIODE-ZENER;MTZ10C,10V,9.7-10.2V,500mW,D

DZ801 0403-000700 DIODE-ZENER;TZP33A,33V,31-35V,1W,DO-41,T

DZ901 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ902 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ903 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ904 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ905 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ906 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ907 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ909 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ910 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ911 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500m

DZ912 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500m

DZ913 0403-000296 DIODE-ZENER;MTZ5.6B,5.6V,5.45-5.73V,500m

DZ914 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ915 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ916 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ917 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

DZ918 0403-000297 DIODE-ZENER;MTZ6.2B,6.2V,5.96-6.27V,500m

F101 2903-000135 FILTER-CERAMIC;BP,4.5MHz,+-60KHz,6dB,-,T

F102 2903-000129 FILTER-CERAMIC;TR,4.5M/4.72MHZ,-,-,-,TP,

F901 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

H001 AA40-10005RTUNER-F/S,LNA;TECC1070PG30A(S),NTSC/USA,

H002 AA40-10005UTUNER-F/S;TCPN9082PC27A(S),NTSC/USA,TR,1

H003 AA59-40003QMODULE-MTS;-,MZ-201,ZENITH,US,43X54,H004 AA59-00028AMODULE-IF;-,SP-222,NTSC,USA,74X54,IC101 1204-001435 IC-IF SYSTEM;LA7565B,DIP,24P,300MIL,PLAS

IC101 1204-001204 IC-DECODER;TDA9850,DIP,32P,4000MIL,PLAST

IC101 1203-000577 IC-VOLTAGE REGUATOR;3090,ZIP,5P,-,PLASTI H/SINK

IC102 1203-000203 IC-POSI.ADJUST REG.;3050,TO-220,5P,-,PLA H/SINK

IC501 1203-000165 IC-POSI.ADJUST REG.;78R12,TO-220,3P,-,-, H/SINK

IC502 1203-000203 IC-POSI.ADJUST REG.;3050,TO-220,5P,-,PLA H/SINK

IC504 1203-000203 IC-POSI.ADJUST REG.;3050,TO-220,5P,-,PLA H/SINK

IC506 1203-000006 IC-POSI.FIXED REG.;7808,TO-220,3P,-,PLAS

IC665 1201-001026 IC-POWER AMP;7265,ZIP,11P,19.6MIL,DUAL,1 H/SINK

IC807 1203-000274 IC-POSI.FIXED REG.;7805,TO-220,3P,-,PLAS H/SINK

IC901 AA13-00054AIC-MCU;-,Z9035112PSC-OTP,16BIT,SDIP,C

IC902 1103-001105 IC-EEPROM;24C040,4Kx1BIT,DIP,8P,300MIL,1

IC903 1203-001274 IC-VOL. DETECTOR;7545,TO-92,3P,-,PLASTIC

IC904 1203-000515 IC-VOL. DETECTOR;7042,TO-92,3P,177MIL,PL

ICS801 AA13-00024AIC-HYBRID;-,TNY253P,-,8PIN,-,ICS802 0604-001032 PHOTO-COUPLER;TR,170-260%,300mW,DIP-4,ST

IF AA39-30007AIF-CABLE;-,T,100mm,1365#26

J244 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

J317 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L101 2701-001040 INDUCTOR-AXIAL;10UH,10%,14X4.5MM

L102 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L103 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L104 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L106 2701-001040 INDUCTOR-AXIAL;10UH,10%,14X4.5MM

L107 2701-000116 INDUCTOR-AXIAL;10uH,10%,4.2x9.8mm

L108 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L201 AA27-10001CCOIL-CHOKE;-,100uH,K,-,5.0A,ST,700UH-K(R

L502 2701-000116 INDUCTOR-AXIAL;10uH,10%,4.2x9.8mm

L505 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L506 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L507 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L509 2701-001040 INDUCTOR-AXIAL;10UH,10%,14X4.5MM

L510 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L511 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L512 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L514 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L516 2701-001040 INDUCTOR-AXIAL;10UH,10%,14X4.5MM

L601 AA29-00004AFILTER-LINE;-,20UH,3A,AC80-260V,TQ20 20U

L902 2701-000115 INDUCTOR-AXIAL;10uH,10%,2.8x7mm

L903 2701-001040 INDUCTOR-AXIAL;10UH,10%,14X4.5MM

L909 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L910 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

L912 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

LEADC AA39-00025ALEAD CONNECTOR-ASSY;-,YFH800-02,YFH800-0

LEADC AA39-20577ALEAD CONNECTOR-ASSY;-,YFH806-06,-,6(3)P,

LS801 2901-000297 FILTER-EMI ON BOARD;-,3A,-,-,3.5x5,TP,LS802 2901-000297 FILTER-EMI ON BOARD;-,3A,-,-,3.5x5,TP,LS803 3301-000287 CORE-FERRITE BEAD;AA,3.5x1x6mm,1500,2400

MDLF AA59-40003PMODULE-FOCUS,PACK;-,F300,NTSC,43,64x62,

PCB AA41-11053CPCB-MAIN;P51A,1L,FR-1,330x245x1.6T,1A,PCBM AA41-11040APCB-MTS MODULE;PLT51A,1L,FR-1,245x245x1.

Q501 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q502 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q503 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q665 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q666 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q667 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q701 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q702 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q901 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q902 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

Q909 0501-000283 TR-SMALL SIGNAL;KSA539,PNP,400mW,TO-92,T

Q910 0501-000389 TR-SMALL SIGNAL;KSC815,NPN,400mW,TO-92,T

QS801 0501-000369 TR-SMALL SIGNAL;KSC2331-Y,NPN,1W,TO-92L,

Electrical Parts List

7-4 Samsung Electronics

Loc. No. Code No. Description ; Specification Remark Loc. No. Code No. Description ; Specification Remark

R121 2008-000266 R-FUSIBLE(S);1ohm,5%,2W,AF,TP,3.9x10mm

R123 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R125 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R126 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R128 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R129 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R130 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R131 2001-000739 R-CARBON;4.7MOHM,5%,1/8W,AA,TP,1.8X3.2M

R132 2001-000739 R-CARBON;4.7MOHM,5%,1/8W,AA,TP,1.8X3.2M

R133 2001-000449 R-CARBON;2.2KOHM,5%,1/8W,AA,TP,1.8X3.2M

R134 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

R143 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R144 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R501 2001-000066 R-CARBON(S);10KOHM,5%,1/2W,AA,TP,2.4X6.4

R502 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R503 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R504 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R505 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R506 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3.2MM

R507 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3.2MM

R508 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R510 2008-000266 R-FUSIBLE(S);1ohm,5%,2W,AF,TP,3.9x10mm

R511 2008-001088 R-FUSIBLE(S);1ohm,5%,2W,AG,TP,3.9x12mm

R512 2001-000003 R-CARBON;330ohm,5%,1/8W,AA,TP,1.8x3.2mm

R513 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R515 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R516 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R524 2001-000739 R-CARBON;4.7MOHM,5%,1/8W,AA,TP,1.8X3.2M

R525 2001-000739 R-CARBON;4.7MOHM,5%,1/8W,AA,TP,1.8X3.2M

R528 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R531 2001-000739 R-CARBON;4.7MOHM,5%,1/8W,AA,TP,1.8X3.2M

R532 2001-000037 R-CARBON(S);330OHM,5%,1/2W,AA,TP,2.4X6.4

R626 2001-000411 R-CARBON;18KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R627 2001-000411 R-CARBON;18KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R661 2004-001970 R-METAL;1.8Kohm,1%,1/2W,AA,TP,6.5x2.5m

R662 2004-001970 R-METAL;1.8Kohm,1%,1/2W,AA,TP,6.5x2.5m

R665 2001-000052 R-CARBON(S);3.3KOHM,5%,1/2W,AA,TP,2.4X6.

R666 2001-000052 R-CARBON(S);3.3KOHM,5%,1/2W,AA,TP,2.4X6.

R668 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM

R669 2001-001144 R-CARBON(S);4.7KOHM,5%,1/2W,AA,TP,2.4X6.

R670 2001-000085 R-CARBON(S);100KOHM,5%,1/2W,AA,TP,2.4X6.

R671 2001-000066 R-CARBON(S);10KOHM,5%,1/2W,AA,TP,2.4X6.4

R672 2001-000066 R-CARBON(S);10KOHM,5%,1/2W,AA,TP,2.4X6.4

R673 2001-001086 R-CARBON(S);18KOHM,5%,1/2W,AA,TP,2.4X6.4

R673A 2001-001144 R-CARBON(S);4.7KOHM,5%,1/2W,AA,TP,2.4X6.

R674 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM

R675 2001-000066 R-CARBON(S);10KOHM,5%,1/2W,AA,TP,2.4X6.4

R676 2001-000812 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X3.2M

R677 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R678 2001-000008 R-CARBON;15KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R679 2001-001071 R-CARBON(S);12KOHM,5%,1/2W,AA,TP,2.4X6.4

R680 2001-001000 R-CARBON;82KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R681 2004-001970 R-METAL;1.8Kohm,1%,1/2W,AA,TP,6.5x2.5m

R682 2004-002019 R-METAL(S);33Kohm,1%,1/2W,AA,TP,2.5x6.5m

R683 2004-002019 R-METAL(S);33Kohm,1%,1/2W,AA,TP,2.5x6.5m

R684 2004-001970 R-METAL;1.8Kohm,1%,1/2W,AA,TP,6.5x2.5m

R685 2004-001390 R-METAL(S);1Kohm,2%,1/2W,AA,TP,2.4x6.4mm

R686 2004-001390 R-METAL(S);1Kohm,2%,1/2W,AA,TP,2.4x6.4mm

R687 2001-001146 R-CARBON(S);4.7OHM,5%,1/2W,AA,TP,2.4X6.4

R689 2001-001146 R-CARBON(S);4.7OHM,5%,1/2W,AA,TP,2.4X6.4

R701 2001-000786 R-CARBON;47KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R702 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R703 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R704 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R801 2003-002161 R-METAL OXIDE(S);22KOHM,5%,3W,AG,TP,6X16

R802 1404-000187 THERMISTOR-NTC;4.7ohm,15%,2800K,27.2mW/C

R901 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

R903 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R904 2001-000290 R-CARBON;10KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R905 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

R906 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R907 2001-000429 R-CARBON;1KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R908 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3.2MM

R909 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3.2MM

R910 2001-000515 R-CARBON;220OHM,5%,1/8W,AA,TP,1.8X3.2MM

R912 2001-000003 R-CARBON;330ohm,5%,1/8W,AA,TP,1.8x3.2mm

R913 2001-000786 R-CARBON;47KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R914 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R915 2001-000281 R-CARBON;100OHM,5%,1/8W,AA,TP,1.8X3.2MM

R916 2001-000472 R-CARBON;2.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

R917 2001-000472 R-CARBON;2.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

R918 2001-000734 R-CARBON;4.7KOHM,5%,1/8W,AA,TP,1.8X3.2M

R919 2001-000411 R-CARBON;18KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R920 2001-000780 R-CARBON;470OHM,5%,1/8W,AA,TP,1.8X3.2MM

R921 2001-000812 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X3.2M

R922 2001-000812 R-CARBON;5.6KOHM,5%,1/8W,AA,TP,1.8X3.2M

R923 2001-000786 R-CARBON;47KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R924 2001-000786 R-CARBON;47KOHM,5%,1/8W,AA,TP,1.8X3.2MM

R925 2001-001050 R-CARBON(S);1.5KOHM,5%,1/2W,AA,TP,2.4X6.

R926 2001-001050 R-CARBON(S);1.5KOHM,5%,1/2W,AA,TP,2.4X6.