Page 1

TFT-LCD TV/MONITOR

NK15A*/NK17A*

Manual

SERVICE

TFT-LCD TV/MONITOR CONTENTS

1. Precautions

2. Product Specifications

3. Disassembly & Reassembly

4. Alignment & Adjustments

5. Troubleshooting

6. Exploded View & Parts List

7. Electrical Parts List

8. Block Diagram

9. Wiring Diagram

10. Schematic Diagrams

11. Panel Description

CONFIDENTIAL

Page 2

1-1-1 Warnings

1. For continued safety, do not attempt to modify the

circuit board.

2. Disconnect the AC power and DC Power Jack

before servicing.

1-1-2 Servicing the LCD Monitor

1. When servicing the LCD Monitor Disconnect the

AC line cord from the AC outlet.

2. It is essential that service technicians have an

accurate voltage meter available at all times. Check

the calibration of this meter periodically.

1-1-3 Fire and Shock Hazard

Before returning the monitor to the user, perform the

following safety checks:

1. Inspect each lead dress to make certain that the

leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as nonmetallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3. Leakage Current Hot Check (Figure 1-1):

WARNING: Do not use an isolation transformer during

this test.

Use a leakage current tester or a metering system

that complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

Figure 1-1. Leakage Current Test Circuit

4. With the unit completely reassembled, plug the AC

line cord directly into a 120V AC outlet. With the

unit’s AC switch first in the ON position and then

OFF, measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including: metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp. Reverse

the power-plug prongs in the AC outlet and repeat

the test.

1-1-4 Product Safety Notices

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection. The protection they give

may not be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified by

on schematics and parts lists. A substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire and / or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate.

NK15A*/NK17A* 1-1

CONFIDENTIAL

1 Precautions

Follow these safety, servicing and ESD precautions to prevent damage and to protect against potential hazards such as

electrical shock.

1-1 Safety Precautions

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE 0.5mA)

LEAKAGE

CURRENT

TESTER

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

!

Page 3

1-2-1 General Servicing Precautions

1. Always unplug the unit’s AC power cord from the

AC power source and disconnect the DC Power

Jack before attempting to:

(a) remove or reinstall any component or assembly,

(b) disconnect PCB plugs or connectors, (c) connect

a test component in parallel with an electrolytic

capacitor.

2. Some components are raised above the printed

circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

3. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the area around the

serviced part has not been damaged.

1. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wriststrap device. To avoid a shock hazard, be sure to

remove the wrist strap before applying power to

the monitor.

2. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a grounded-tip soldering iron to solder or

desolder ESDs.

5. Use only an anti-static solder removal device. Some

solder removal devices not classified as “anti-static”

can generate electrical charges sufficient to damage

ESDs.

4. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples:

metal panels, input terminals and earphone jacks).

5. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter

(500 V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see

above) should be greater than 1 megohm.

6. Always connect a test instrument’s ground lead to

the instrument chassis ground before connecting

the positive lead; always remove the instrument’s

ground lead last.

6. Do not remove a replacement ESD from its

protective package until you are ready to install it.

Most replacement ESDs are packaged with leads

that are electrically shorted together by conductive

foam, aluminum foil or other conductive materials.

7. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

Caution: Be sure no power is applied to the

chassis or circuit and observe all

other safety precautions.

8. Minimize body motions when handling

unpackaged replacement ESDs. Motions such as

brushing clothes together, or lifting your foot from

a carpeted floor can generate enough static

electricity to damage an ESD.

1 Precautions

1-2 NK15A*/NK17A*

CONFIDENTIAL

1-3 Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated circuits and some fieldeffect transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1-2 Servicing Precautions

WARNING: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before servicing units covered by this service manual, read and follow the Safety Precautions

section of this manual.

Note: If unforeseen circumstances create conflict between the following servicing precautions and any of the

safety precautions, always follow the safety precautions.

Page 4

CONFIDENTIAL

2 Product Specifications

2-1 Specifications

LCD Panel TFT-LCD panel, RGB vertical stripe, normaly TFT-LCD panel, RGB vertical stripe, normaly

white, 15-Inch viewable, 0.261 mm pixel pitch white, 17-Inch viewable, 0.2895 mm pixel pitch

Scanning Frequency Horizontal : 30 kHz ~ 61 kHz (Automatic)

Vertical : 56 Hz ~ 75 Hz (Automatic)

Display Colors 16.2 Million colors

Maximum Resolution Horizontal : 1280 Pixels 1280 Pixels

Vertical : 768 Pixels 768 Pixels

Input Video Signal Analog 0.7 Vp-p ± 5% positive at 75 Ω, internally terminated

Input Sync Signal Type : Seperate H/V

Level : TTL level

Maximum Pixel Clock rate 80 MHz 80 MHz

Active Display

Horizontal/Vertical

AC power voltage & Frequency

AC 90 ~ 264 Volts, 60 / 50 Hz ± 3 Hz

Power Consumption 50 W (Max) 53 W (Max)

Dimensions

Unit (W x D x H)

19.6 x 8.0 x 14.7 Inches (498 x 204.5 x 374 mm)

21.1 x 8.0 x 15.8 Inches (536 x 204.5 x 402 mm)

Carton (W x D x H)

22.5 x 17.4 x 10.6 Inches (571 x 441 x 269 mm)

24.0 x 18.3 x 10.6 Inches (609 x 465 x 269 mm)

Weight 3.95 Kg (8.7 Ibs) 4.8 Kg (10.6 Ibs)

Environmental Considerations Operating Temperature : 50 °F ~ 104 °F (10 °C ~ 40 °C)

Humidity : 10 % ~ 80 %

Storage Temperature : -4 °F ~ 113 °F (-20 °C ~ 45 °C)

Humidity : 5 % ~ 95 %

TV System

Antena Input 75Ω, Coaxial Cable

– MAX Internal speaker Out : Right => 3W Right => 5W

Left => 3W Left => 5W

Sound Characteristic

– BASS Control Range : -12 dB~ + 12 dB

– TREBLE Control Range : -12 dB~ + 12 dB

– Headphone Out: 5mW max (400m Vrms)

– Output Frequency : RF => 80 Hz ~ 15 kHz

A/V => 80 Hz ~ 15 kHz

NK15A*/NK17A* 2-1

Item

Description

NK15A* NK17A*

334.08 mm / 200.44 mm 370.560 mm / 222.336 mm

Tunning Frequency Synthesize

System PAL, SECAM, NTSC 4.4

Sound BG, DK, I, L, L’

Page 5

CVBS

Audio L

GND

Audio R

GND

CONFIDENTIAL

2 Product Specifications

2-2 NK15A*/NK17A*

2-2 Pin Assignments

Pin

Separate

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Red

Green

Blue

GND

GND (DDC Return)

GND-Red

GND-Green

GND-Blue

No Connection

GND-Sync./Self Test

GND

DDC Data

H-Sync.

V-Sync.

DDC Clock

Pin

Separate

1

2

3

4

5

GND

Y

C

GND

GND

2-2-1 D-SUB

2-2-3 S-Video

2-2-2 SCART1, SCART2

RCA White

RCA Red

2-2-4 A/V

RCA Yellow

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

Items Scart1 Scart2

Pin

No

Audio Out (R;500mV/1KΩ)

Audio IN (R;500mV/10KΩ)

Audio Out (L;500mV/1KΩ)

Audio Common GND

Blue GND

Audio IN (L;500mV/10K)

Blue IN (700mV/75Ω)

Function S/W

(0~2V/9, 5V~12V)

Green GND

No Connection

Green IN (700mV/75Ω)

No connection

Red GND

F/B GND

Red IN (700mV/75Ω)

RGB F/B (0~0, 4V/1~3V)

Video Output GND

Video Input GND

CVBS Out (1V/75Ω)

CVBS IN (1V/75Ω)

Common GND

OO

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

O

Page 6

CONFIDENTIAL

2 Product Specifications

NK15A*/NK17A* 2-3

2-3 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard

for computer-generated video signals.

µs

µs

µs

µs

µs

µs

µs

µs

2-3-1 LCD Panel Mode : 1 mode

Page 7

CONFIDENTIAL

2 Product Specifications

2-4 NK15A*/NK17A*

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

2-3-2 Supported Modes (1)

Page 8

CONFIDENTIAL

2 Product Specifications

NK15A*/NK17A* 2-5

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

2-3-2 Supported Modes (2)

Page 9

CONFIDENTIAL

2 Product Specifications

2-6 NK15A*/NK17A*

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

µs

2-3-2 Supported Modes (3)

Page 10

3-1 General Alignment Instuction

1. Usually, a color TV-VCR needs only slight

touch-up adjustment upon installation.

Check the basic characteristics such as height,

horizontal and vertical sync.

2. Use the specified test equipment or its

equivalent.

3. Correct impedance matching is essential.

4. Avoid overload. Excessive signal from a

sweep generator might overload the front-end

of the TV. When inserting signal markers,

do not allow the marker generator to distort

test result.

5. Connect the TV only to an DC power source

with voltage and frequency as specified on

the backcover nameplate.

6. Do not attempt to connect or disconnect any

wire while the TV is turned on. Make sure

that the power cord is disconnected before

replacing any parts.

7. To protect aganist shock hazard,use an

isolation transform.

NK15A*/NK17A* 3-1

CONFIDENTIAL

3 Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the

NK15A*/NK17A* monitor.

WARNING: This monitor contains electrostatically sensitive devices. Use caution when handling

these components.

3-1 Disassembly

Cautions:1. Disconnect the monitor from the power source before disassembly.

2. Follow these directions carefully; never use metal instruments to pry apart the cabinet.

1. After confirm there is nothing

on the desk

Turn the LCD module over

and put it on a flat desk set to

the ground.

3-2 Replacement Order of Lamp Assemblies

Page 11

CONFIDENTIAL

3 Disassembly and Reassembly

3-2 NK15A*/NK17A*

2. Push down the stopper and

slide the lamp unit.

3. Please take out the lamp

units from the LCD module.

4. Please fix the new lamp

units on the LCD module :

opposite process 2 and 3

3-3 Reassembly

Reassembly procedures are in the reverse order of Disassembly procedures.

* Replacement of lamp unit should be done at the power off state and recommended clean bench

condition.

Page 12

CONFIDENTIAL

NK15A*/NK17A* 4-1

4 Alignments and Adjustments

4-1 General Alignment Instuction

1. Usually, a color TV-VCR needs only slight touch-up adjustment upon installation.

Check the basic characteristics such as height, horizontal and vertical sync.

2. Use the specified test equipment or its equivalent.

3. Correct impedance matching is essential.

4. Avoid overload. Excessive signal from a sweep generator might overload the front-end

of the TV. When inserting signal markers,do not allow the marker generator to distort

test result.

5. Connect the TV only to an DC power source with voltage and frequency as specified on

the backcover nameplate.

6. Do not attempt to connect or disconnect any wire while the TV is turned on. Make sure

that the power cord is disconnected before replacing any parts.

7. To protect aganist shock hazard,use an isolation transform.

Page 13

4 Alignments and Adjustments

4-2 NK15A*/NK17A*

CONFIDENTIAL

4-2 Factory Mode Adjustments

4-2-1 Entering Factory Mode

1. To enter “Service Mode” Press the remote - control keys in this sequence :

- If you do not have Factory remote - control

- If you have Factory remote - control

4-2-2 Factory Mode Tree

Page 14

4 Alignments and Adjustments

NK15A*/NK17A* 4-3

CONFIDENTIAL

Page 15

Memo

4 Alignments and Adjustments

4-4 NK15A*/NK17A*

CONFIDENTIAL

Page 16

CONFIDENTIAL

NK15A*/NK17A* 5-1

5 Troubleshooting

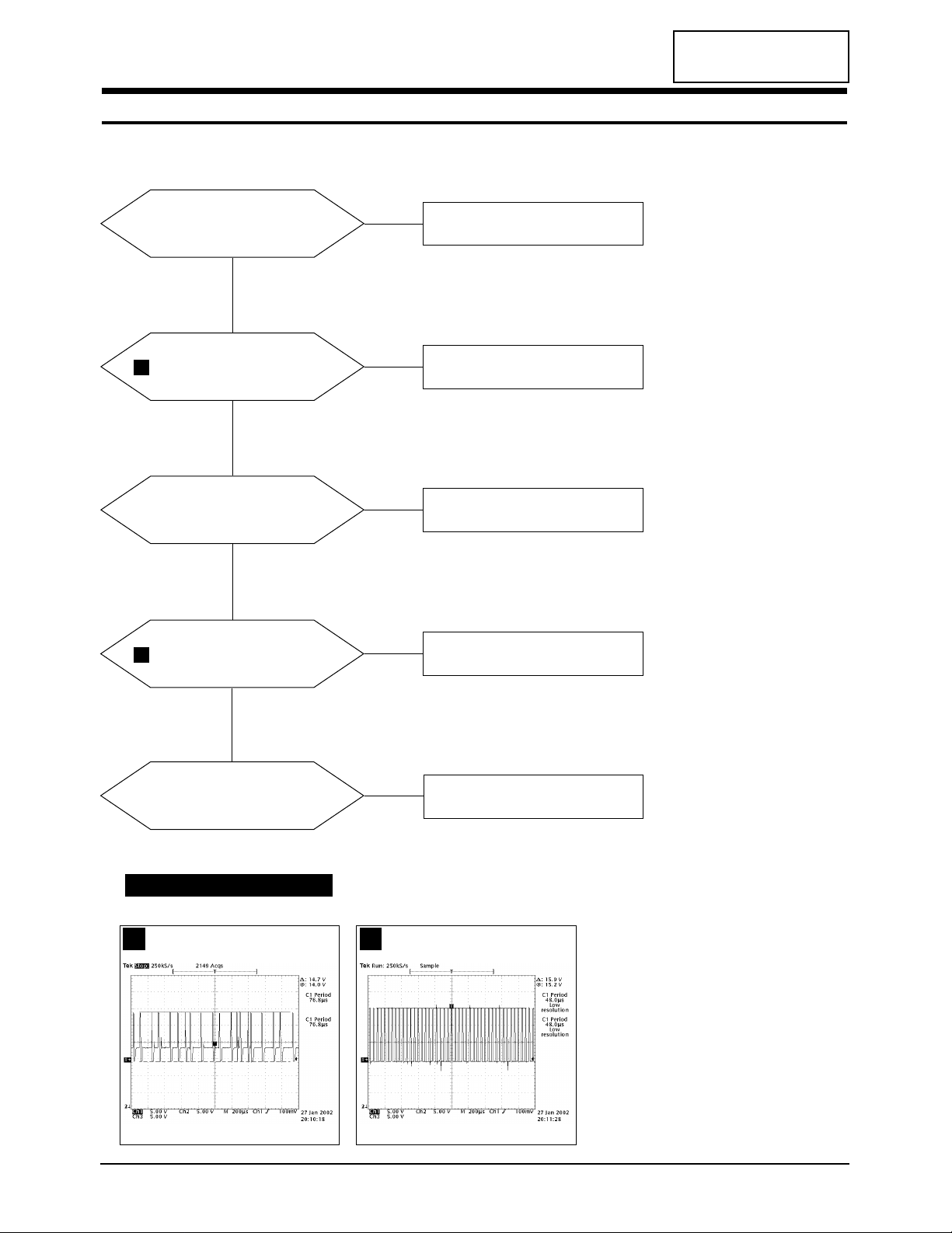

5-1 No Power

Does proper DC 14V appear at DC

jack connected to CN801?

Check SMPS PCB and Adapter.

Yes

No

No

No

No

No

Does proper DC 3.3V_A

appear at FT852?

Check IC801. (#2)

Yes

Does proper DC 2.5V_A

appear at Pin 3 of IC802?

Check IC802.

Yes

Does proper DC 3.3V_B

appear at FT822?

Check IC805. (#1)

Yes

Does proper DC 2.5V_B

appear at Pin 3 of IC806?

Check IC806.

WAVEFORMS

IC801 #2

1

IC805 #1

2

1

2

Page 17

CONFIDENTIAL

5 Troubleshooting

5-2 NK15A*/NK17A*

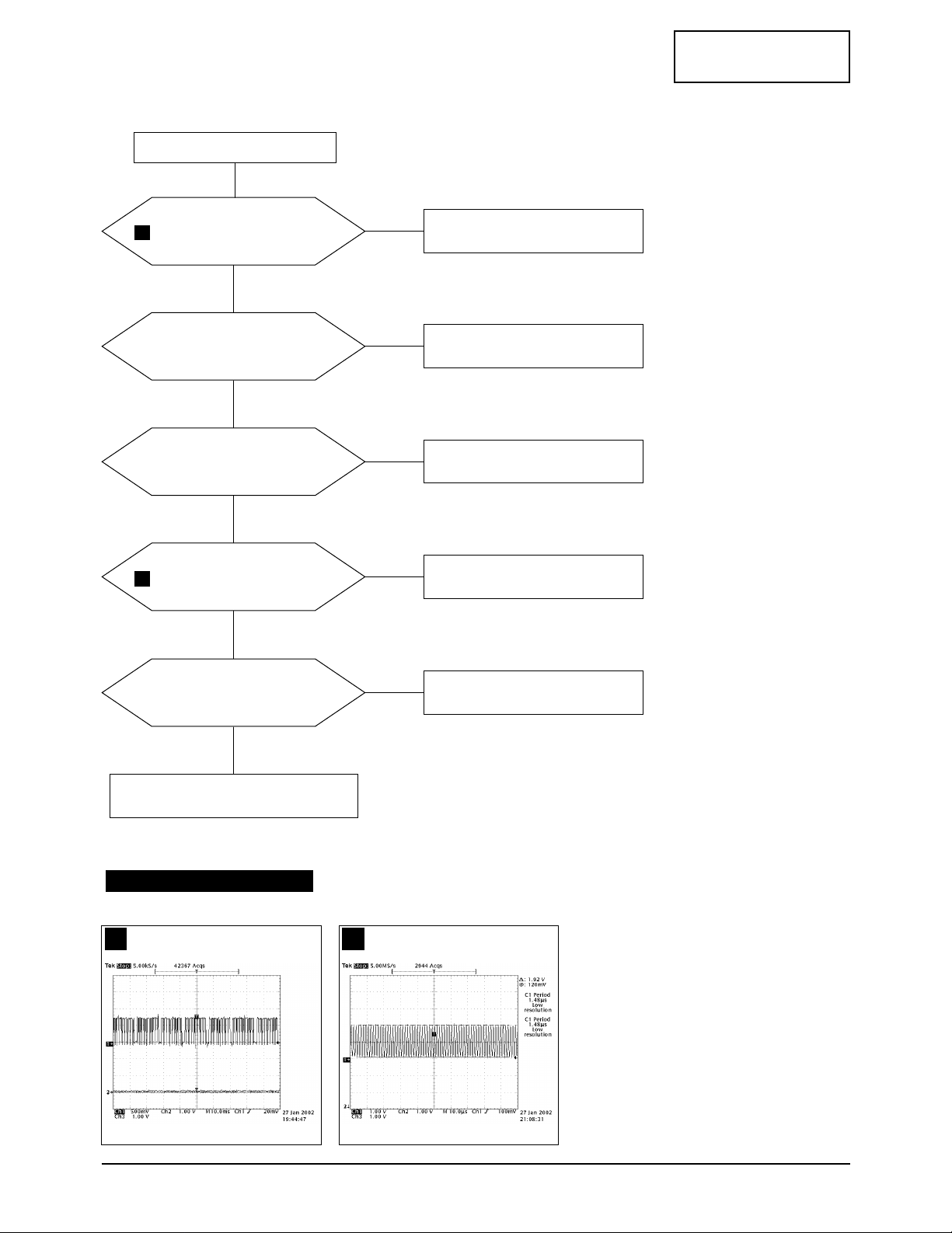

5-2 No Video (PC Signal)

Power indicator is green.

Does the signal appear

at C306, C398, C397

of R, G, B input?

Check CN401 and cable.

Yes

No

No

No

No

No

Yes

Yes

Yes

Yes

Yes

Does the clock pulse appear at

output of RA351 ~ RA356?

Check related circuit of IC350.

Does the clock pulse

appear at R354?

Check R354 and related

circuit of R354.

Does the clock pulse

appear at X201?

Check X201 and related

circuit of X201.

Does the clock pulse appear at

output of RA301~RA306?

Replace RA301 ~ RA306, IC300.

Replace LCD Panel.

WAVEFORMS

Full White R, G, B Input (C306, 398, 397)3X201

4

3

4

Page 18

CONFIDENTIAL

5 Troubleshooting

NK15A*/NK17A* 5-3

5-3 No Picture (TV, Video, S-Video, SCART)

Check the CO44, CO45(S-Video),

CO46(VCR) and CO42(RF-CVBS).

IC011 #1 RF-CVBS

IC011 #5 S-Video

IC011 #8 VCR

Check the CN888(Tuner)

and the CN702_1.

Yes

No

Does the signal appear at IC010.

Check the #19 and

related circuit of IC011.

Yes

No

Does the signal appear at

IC200 and 3.3V_BA.

Check the IC010 (#31~34,

37~44, 47~50) Data out

and related circuit of IC010.

Yes

No

Does the signal appear at

IC300 and 3.3V_BD.

Check the IC200 and

related circuit of IC200.

Yes

No

Check the IC901 and CN901.

5-1

5-2

5-3

6

7

Page 19

5 Troubleshooting

5-4 NK15A*/NK17A*

CONFIDENTIAL

WAVEFORMS

IC011 #1 RF-CVBS

5-1 5-2 5-3

IC011 #5 S-Video IC011 #8 VCR

IC011 #19

6

IC010 Data Out

7

Page 20

5 Troubleshooting

NK15A*/NK17A* 5-5

CONFIDENTIAL

Does the signal appear at

Pin 67 (Tuner sound signal) and Pin

47, 48 (PC sound) and Pin 56, 57

(SCART1 sound) and Pin 53, 54

(SCART2) Pin 50, 51 (VCR) of

IC 919 (MSP3451)?

Check the CN403 (PC conector) and the

CN402 (CN001) and the CN200 (CN002)

and the CN888 (Tuner) and the CN702_1.

Yes

No

Does the signal appear at Pin 27,

28 of IC919 (MSP3451)?

Check the IC919 and

related circuit of IC919.

Yes

No

Does the signal appear

at L501 ~L504?

Check the IC501 (Audio amp) and

related circuit of IC501.

Yes

No

Replace the speaker.

5-4 No Sound

Page 21

Memo

5 Troubleshooting

5-6 NK15A*/NK17A*

CONFIDENTIAL

Page 22

CONFIDENTIAL

NK15A*/NK17A* 6-1

6 Exploded View and Parts List

6-1 NK15A*

Page 23

6-2 NK17A*

6 Exploded View & Parts List

6-2 NK15A*/NK17A*

CONFIDENTIAL

Page 24

BN90-00217A - ASSYSTAND NK17NS SNA

BN96-00204A STD ASSYSTANDP EOS/NIKE17",SILVERSPRAY SNA

6003-000009 STD SCREW-TAPTITE BH,+,B,M4,L16,ZPC(YEL),SWRCH18 SNA

6003-001010 STD SCREW-TAPTITE FH,+,B,M3,L6,ZPC(YEL),SWRCH18A

6003-001315 STD SCREW-TAPTITE BH,+,B,M4,L20,ZPC(YEL),SWRCH18A SNA

BH73-60339A STD RUBBER-LEG SLC1400,EVA,GRAY,65HB,DIA13*H2 SNA

BN61-00184A STD STAND-BASE ES15AS,ABSPC,GR40,SV-012P SNA

BN61-00266A STD FRAME-STANDBASE EOS/NIKE,EGIT1.2

BN72-00254A STD STAND-COVERREAR EOS15,ABS,HB,IV16,SPRAY SNA

BN72-00257A STD STANDFRONT EOS15,ABS,HB,16,SPRAY SNA

BN75-00211A STD UNIT-HINGE EOS15,-,SECCT2.0,-,-,-,-,- SNA

BN90-00247G - ASSYCOVERREAR NK17AS SNA

BN90-00263B CIS ASSYREAR NK17AS(PAL),ABSHB,SV-012P,SPRAY

BN63-00102A CIS COVER-REAR NIKE17",ABS,-,-,-,HB,-,IV16,NONE,1.5 SNA

BN70-00176A CIS BRACKETVESA RB15AS,SECC,1 SNA

BN90-00303J - ASSYCOVERFRONT NK17AS SNA

6003-001319 C/F+C/R SCREW-TAPTITE BH,+,B,M3,L10,NIPLT,SWRCH18A,- SNA

BN90-00021B CIS ASSYCOVERFRONT NK17AS(PAL),-,ABS,HB,-,BL-903P,-,-,SPRAY

6003-000259 CIS SCREW-TAPTITE BH,+,B,M3,L8,ZPC(YEL),SWRCH18A SNA

6003-000276 CIS SCREW-TAPTITE BH,+,B,M3,L10,ZPC(YEL),SWCH10 SNA

BN59-00233A CIS BOARD-FUNCTION NK17NS,-,-,FUNCTIONPCB,-,-,- SNA

BN59-00234A CIS BOARD-IRPCB NK17NS,-,-,IRPCB,-,-,- SNA

BN59-00263A CIS SPEAKERSYSTEM EOS/NIKE17,EOS/NIKE17-L,100X42,WIRE:240MM SNA

BN59-00274A CIS SPEAKERSYSTEM NIKE17,NIKE17-R,100X42,WIRE:630MM SNA

BN63-00039A CIS GASKET-EMI CN18ASE,-,0.3MM,7MM,380MM,-,-,- SNA

BN63-00101A CIS COVER-FRONT NIKE17",ABS,-,-,-,HB,-,IV16,NONE,1.5 SNA

BN64-00031A CIS BADGE-BRAND RB15AS,AL,T1.4,6.3,40.1,-,SILIVER,- SNA

BN64-00048A CIS KNOB-FUNCTION NIKE17",ABS,-,-,-,HB,IV16,-,SPRAY SNA

BN67-00020A CIS LENS-LED EOS15,ACRYL,CLEAR,-,-,-,BN91-00247A - ASSYCHASSIS NK17AS

BN94-00270A - ASSYPCBMAIN NK17AS SNA

0201-001223 CIS ADHESIVE-TS HT-130S,RED,700+/-50,- SNA

0202-001044 CIS SOLDER-WIRE. S63S-W3.0,S63S,D3,63Sn/37Pb,- SNA

0202-001046 CIS SOLDER-WIREFLUX CF-110VH-2A,-,-,-,- SNA

0202-001222 CIS SOLDER-WIREFLUX RS-107,RS60-1.2AA,D1.2,SN60/PB40,- SNA

0204-001095 CIS THINNER #4520,-,-,- SNA

0402-000208 CIS DIODE-RECTIFIER EK-04,40V,1.5A,DO-41

2004-000970 CIS R-METAL 470ohm,1%,1/4W,AA,TP,2.4x6.4mm

2401-000010 C845 C-AL 220uF,20%,16V,GP,-,6.3x11mm,2.

2401-000010 C851 C-AL 220uF,20%,16V,GP,-,6.3x11mm,2.

2401-000010 C857 C-AL 220uF,20%,16V,GP,-,6.3x11mm,2.

2401-001363 C971 C-AL 470uF,20%,16V,GP,TP,10x12.5,5

2401-001363 C981 C-AL 470uF,20%,16V,GP,TP,10x12.5,5

2401-003224 C876 C-AL 470uF,20%,16V,WT,TP,8X11.5,5mm

2409-001044 C847 C-ORGANIC 100UF,+-20%,16V,WT,TP,8X10.5,5

2701-000146 L151 INDUCTOR-AXIAL 2.2uH,10%,2.5x3.4mm

2701-000146 L152 INDUCTOR-AXIAL 2.2uH,10%,2.5x3.4mm

2701-000146 L804 INDUCTOR-AXIAL 2.2uH,10%,2.5x3.4mm

3701-001219 CN401 CONNECTOR-DSUB 15P,3R,FEMALE,ANGLE,AUF

3711-000057 CN706_1 CONNECTOR-HEADER BOX,3P,1R,2.5mm,ANGLE,SN SNA

3711-000654 CNJIG CONNECTOR-HEADER BOX,12P,1R,2.5mm,STRAIGHT,SN

3711-004270 CN501 CONNECTOR-HEADER BOX,2P,1R,2MM,ANGLE,SN SNA

3711-004386 CN502 CONNECTOR-HEADER BOX,3P,1R,2mm,ANGLE,SN SNA

3722-000110 CN810 JACK-DCPOWER 1P,-,NI,BLACK,3722-000117 CN801 JACK-DCPOWER 3P,3.5MM,AG,BLK,NO SNA

3722-001055 CN403 JACK-PHONE 5P/2C,3.6PI,AG,BLK,#16-22

3722-001806 CN001 JACK-SCART 21P,-,SNPB,BLK,-

Page1

3722-001806 CN002 JACK-SCART 21P,-,SNPB,BLK,6003-000117 IN/PCB+SH/PCB SCREW-TAPTITE BH,+,B,M3,L6,ZPC(YEL),SWRCH18A SNA

Page 25

6003-000117 M/PCB+SH/PCB SCREW-TAPTITE BH,+,B,M3,L6,ZPC(YEL),SWRCH18A SNA

6003-000117 SH/D_SUB+SH/PCB SCREW-TAPTITE BH,+,B,M3,L6,ZPC(YEL),SWRCH18A SNA

AA39-00046A CIS LEADCONNECTOR-ASSY ,1P,JUMPER,BLK,60MM,1007#22

BN39-00002A CIS CBF-HARNESS -,60,BLU/WHT,-,26,BN39-00247B CIS LEADCONNECTOR-ASSY NK17AS,UL2835#28,UL/CSA,6P,#28,12505HS-06,12505HS-06,BK,180MM,2835#28,SJ02-01-00

BN40-00005A CN888 RFMODULATOR-PAL TCPQ9091PD27D,PAL,-,-,-,5V,-10TO+65C,50DB,55DB

BN44-00041A CIS INVERTER ML17,SIC1803,48KHz,14VDC,1.5mArms,7.2mArms,48Khz,160*45*17,4LAMP,48Khz,-,BN83-00065A CIS CKD-BN44-00056A BN44-00056A,1203-000560 SNA

BN83-00066A CIS CKD-BN44-00056A BN44-00056A,1201-000471 SNA

BN83-00067A CIS CKD-BN44-00056A BN44-00056A,1202-000104 SNA

BN83-00068A CIS CKD-BN44-00056A BN44-00056A,0504-000158 SNA

BN83-00069A CIS CKD-BN44-00056A BN44-00056A,0501-000457 SNA

BN83-00070A CIS CKD-BN44-00056A BN44-00056A,0504-000129 SNA

BN83-00071A CIS CKD-BN44-00056A BN44-00056A,0501-000462 SNA

BN83-00074A CIS CKD-BN44-00056A BN44-00056A,0407-000114 SNA

BN83-00076A CIS CKD-BN44-00056A BN44-00056A,0407-000122 SNA

BN83-00081A CIS CKD-BN44-00056A BN44-00056A,2203-000206 SNA

BN83-00082A CIS CKD-BN44-00056A BN44-00056A,2203-001458 SNA

BN83-00083A CIS CKD-BN44-00056A BN44-00056A,2203-000455 SNA

BN83-00084A CIS CKD-BN44-00056A BN44-00056A,2203-000590 SNA

BN83-00085A CIS CKD-BN44-00056A BN44-00056A,2203-001130 SNA

BN83-00086A CIS CKD-BN44-00056A BN44-00056A,2203-002793 SNA

BN83-00092A CIS CKD-BN44-00056A BN44-00056A,2007-000872 SNA

BN83-00106A CIS CKD-BN44-00056A BN44-00056A,2104-000224 SNA

BN83-00108A CIS CKD-BN44-00056A BN44-00056A,3601-001038 SNA

BN83-00110A CIS CKD-BN44-00056A BN44-00056A,3711-000556 SNA

BN83-00111A CIS CKD-BN44-00056A BN44-00056A,3711-004702 SNA

BN83-00264A CIS CKD-0402-000554 INVERTER

BN83-00265A CIS CKD-0501-002218 INVERTER

BN83-00266A CIS CKD-0505-001220 INVERTER

BN83-00267A CIS CKD-0505-001348 INVERTER

BN83-00268A CIS CKD-2007-000003 INVERTER

BN83-00269A CIS CKD-2007-000029 INVERTER

BN83-00270A CIS CKD-2007-000221 INVERTER

BN83-00271A CIS CKD-2007-000282 INVERTER

BN83-00272A CIS CKD-2007-000300 INVERTER

BN83-00273A CIS CKD-2007-000534 INVERTER

BN83-00274A CIS CKD-2007-000546 INVERTER

BN83-00275A CIS CKD-2007-000615 INVERTER

BN83-00276A CIS CKD-2007-000689 INVERTER

BN83-00277A CIS CKD-2007-000703 INVERTER

BN83-00278A CIS CKD-2007-000793 INVERTER

BN83-00279A CIS CKD-2007-000830 INVERTER

BN83-00280A CIS CKD-2007-000844 INVERTER

BN83-00281A CIS CKD-2007-000941 INVERTER

BN83-00282A CIS CKD-2007-001039 INVERTER

BN83-00283A CIS CKD-2007-001113 INVERTER

BN83-00284A CIS CKD-2007-001241 INVERTER

BN83-00285A CIS CKD-2007-001710 INVERTER

BN83-00286A CIS CKD-2007-002529 INVERTER

BN83-00287A CIS CKD-2201-002115 INVERTER

BN83-00288A CIS CKD-2203-002494 INVERTER

BN83-00289A CIS CKD-2301-001359 INVERTER

BN83-00291A CIS CKD-2401-003549 INVERTER

BN83-00293A CIS CKD-LH26-00135A INVERTER

BN83-00295A CIS CKD-LH26-00136A INVERTER

BN83-00297A CIS CKD-LH27-00145A INVERTER

Page2

BN83-00299A CIS CKD-LH41-00227A INVERTER

BN83-00300A CIS CKD-LH72-00173A INVERTER

Page 26

BN83-00301A CIS CKD-LH93-05016Z INVERTER

BN83-00302A CIS CKD-LH93-10009P INVERTER

BN83-00303A CIS CKD-LH93-20016M INVERTER

BN62-00003A HS200 HEATSINK-IC NK,SUN,A6063S,T2.5,W28,L28,-,BH62,- SNA

BN62-00003A HS300 HEATSINK-IC NK,SUN,A6063S,T2.5,W28,L28,-,BH62,- SNA

BN75-00237A CIS UNIT-SHIELDPCB NIKE17",-,SECC,T0.8,-,-,-,- SNA

BN90-00046B CIS ASSYSHIELD-D-SUB NK15AS(PAL),-,SPTE,T0.5,-,-,-,- SNA

BN96-00048A CIS ASSYMISCP-SHIELDCOVER NK15NS,NK17NS SNA

BN39-00254A CIS LEADCONNECTOR-ASSY NK15AS,UL1015#18,UL/CSA,1P,BLK,#18,35750-1010,35798-9810,BK,100MM,1015#18,SJ02-0

BN63-00163A CIS GASKET GH17PSS,CONDUCTIVEFABRIC,8MM,60MM,90MM,GRAY,71TSSK60-8-90-13,71TSSK60-8-90-13 SNA

BN63-00206A CIS SHIELD-COVER NK15NS,SPTE,T0.3 SNA

BN97-00065B - ASSYMICOM NK17AS,-,-,-,-,-,-,-,1102-001129 IC620 IC-EPROM M27W401,512KX8BIT,PLCC,32P,11.35X13.89MM,80NS,3.3V,10%,PLASTIC,-40TO+85C,-,CMOS,

BN46-00010B CIS S/WMICOM NK17AS,-,-,-,-,-,- SNA

BN97-00069A - ASSYSMD-MAIN NK17AS SNA

0202-001162 CIS SOLDER-CREAM RMA-20-21L,S63,-,SN63/PB36.6/AG0.4,FLUX9.5% SNA

0401-001056 D406 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D407 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D408 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D501 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D681 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0401-001056 D804 DIODE-SWITCHING MMBD4148SE,75V,200MA,SOT-23,TP

0402-000553 D802 DIODE-RECTIFIER SS24,40V,2.0A,DO-214AA

0402-001098 D803 DIODE-RECTIFIER SK34,40V,3A,SMC,TP

0403-000579 D401 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 D402 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 D403 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 D404 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 D601 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 D602 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-000579 D604 DIODE-ZENER BZX84C5V1,5.1V,5%,200mW,SOT-23

0403-001048 D001 DIODE-ZENER BZX84C16,16V,15.3-17.1V,225mW,

0403-001048 D010 DIODE-ZENER BZX84C16,16V,15.3-17.1V,225mW,

0403-001052 D002 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D003 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D004 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D005 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D006 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D007 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D008 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D009 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D011 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D012 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D013 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D014 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D015 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D016 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D017 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D018 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D019 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D020 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D021 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D022 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D023 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D024 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D025 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D026 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

Page3

0403-001052 D101 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D102 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

Page 27

0403-001052 D103 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D104 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D116 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D117 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D118 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D119 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D120 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D121 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D122 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D543 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D545 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D570 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001052 D571 DIODE-ZENER RD8.2MB,8.2V,7.7-8.64V,200mW,S

0403-001435 D502 DIODE-ZENER QZX363C5V6,5.32-5.88,200MW,SOT-363,TP

0404-001166 D801 DIODE-SCHOTTKY MBRM130LT3,30V,1000MA,D0-216AA,TP

0404-001166 D880 DIODE-SCHOTTKY MBRM130LT3,30V,1000MA,D0-216AA,TP

0407-000123 D405 DIODE-ARRAY DAN202K,80V,100MA,CA2-3,SOT-23,TP

0501-000342 Q020 TR-SMALLSIGNAL KSC1623-Y,NPN,200mW,SOT-23,TP,135-270

0501-000342 Q201 TR-SMALLSIGNAL KSC1623-Y,NPN,200mW,SOT-23,TP,135-270

0501-000342 Q501 TR-SMALLSIGNAL KSC1623-Y,NPN,200mW,SOT-23,TP,135-270

0501-000342 Q555 TR-SMALLSIGNAL KSC1623-Y,NPN,200mW,SOT-23,TP,135-270

0501-000342 Q601 TR-SMALLSIGNAL KSC1623-Y,NPN,200mW,SOT-23,TP,135-270

0501-000342 Q611 TR-SMALLSIGNAL KSC1623-Y,NPN,200mW,SOT-23,TP,135-270

0501-002080 Q001 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q002 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q602 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q711 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q713 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q808 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q812 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0501-002080 Q813 TR-SMALLSIGNAL 2SC2412K,NPN,200mW,SC-59,TP,120-270

0505-001170 IC808 FET-SILICON SI9933ADY-T1,P,-20V,3.4A,0.06ohm,2W,SO-8

0801-002267 IC406 IC-CMOSLOGIC 74LCX14,-,SOIC,14P,150MIL,-,TP,-,-,-,3.6V,-40TO+85C,-,5.5V,-,-,24MA

0904-001009 IC631 IC-I/OSUPPORTCHIP 8574A,-,SOP,16P,300MIL,100KHz,

0904-001009 IC632 IC-I/OSUPPORTCHIP 8574A,-,SOP,16P,300MIL,100KHz,

1001-001082 IC013 IC-VIDEOSWITCH BA7657F,-,SOP,24P,300MIL,SINGL

1001-001109 IC012 IC-ANALOGSWITCH FST3125M,BUSSWITCH&CMOS,SOIC,17P,150MIL,QUAD,7V,-40TO+85C,PLASTIC,-,4.0OHM,5.

1001-001109 IC681 IC-ANALOGSWITCH FST3125M,BUSSWITCH&CMOS,SOIC,17P,150MIL,QUAD,7V,-40TO+85C,PLASTIC,-,4.0OHM,5.

1001-001177 IC011 IC-VIDEOSWITCH TEA6425D,VIDEOSWITCH,SOIC,20P,300MIL,-,8.8V,0TO+70C,PLASTIC,-,-,-,-,2UA,ST,1001-001190 IC001 IC-ANALOGSWITCH FST16233MTD,BUSSWITCH,TSSOP,56P,240MIL,-,5.5V,-40TO+85C,PLASTIC,-,20OHM,8.5NS,7

1002-001292 IC350 IC-A/DCONVERTER AD9883AKST-110,8BITS,QFP,80P,551MIL,±0.5LSB,TR,CMOS,PLASTIC,3.3V,-25TO+85C,650M

1003-001419 IC300 IC-DISPLAYDRIVER MN82860,QFP,208P,1102MIL,-,-,TR,PLASTIC,3.3V,-,2.3W,-,1103-000129 IC401 IC-EEPROM 24C02,256x8BIT,SOP,8P,150MIL,1

1103-000138 IC603 IC-EEPROM 24C16,2Kx8BIT,SOP,8P,150MIL,10

1109-001195 IC210 IC-VIDEORAM K4G323222A,2X512KX32BIT,PQFP,100P,-,6NS,3.3V,10%,PLASTIC,0TO+70C,2MA,CMOS,TR

1109-001195 IC211 IC-VIDEORAM K4G323222A,2X512KX32BIT,PQFP,100P,-,6NS,3.3V,10%,PLASTIC,0TO+70C,2MA,CMOS,TR

1201-001495 IC530 IC-AUDIOAMP 7050,SOP,8P,150MIL,DUAL,26DB,PLASTIC,6V,0.25W,-,40DB,-,-,20NA,1201-001681 IC501 IC-AUDIOAMP 1101,SOP,30P,433MIL,-,-,PLASTIC,13.2V,-,0to+70C,-,-,-,-,-,TP

1203-000404 IC801 IC-DC/DCCONVERTER 34063,SOP,8P,150MIL,PLASTIC,1.0/1.3V,-,0TO+70C,4.0MA,-,ST

1203-000404 IC810 IC-DC/DCCONVERTER 34063,SOP,8P,150MIL,PLASTIC,1.0/1.3V,-,0TO+70C,4.0MA,-,ST

1203-001212 IC604 IC-VOL.DETECTOR 7029,SOT-89,3P,-,PLASTIC,-,500

1203-001293 IC811 IC-POSI.FIXEDREG. 033,T0-252,3P,6.5MIL,PLASTIC,3

1203-001448 IC804 IC-SWITCHVOL.REG. 2596,TO-263,5P,-,PLASTIC,4.750

1203-001779 IC807 IC-POSI.FIXEDREG. 7812,D2PAK,3P,-,PLASTIC,11.5/12.5V,-,-40TO+125CC,1A,-,TP

1203-001816 IC803 IC-POSI.FIXEDREG. 78M08,TO-252,3P,-,PLASTIC,7.7/8.3V,1.0W,-40TO+85C,0.5A,-,TP

1203-001830 IC805 IC-SWITCHVOL.REG. 2676,TO-263,7P,-,PLASTIC,3.234/3.336V,-,-40TO+125C,3A,-,TP

1203-001890 IC802 IC-VOLTAGEREGULATOR 3961,SOT223-5,5P,-,PLASTIC,2.5V,-,-40to+125C,800mA,-,TR

Page4

1203-001890 IC806 IC-VOLTAGEREGULATOR 3961,SOT223-5,5P,-,PLASTIC,2.5V,-,-40to+125C,800mA,-,TR

1204-001675 IC919 IC-SOUNDPROCESSOR MSP3451G,QFP,80P,-,PLASTIC,9V,1000mW,0to+70C,TR,MultistandardSound

Page 28

1204-001911 IC200 IC-VIDEOPROCESS DPTV-3D-6730,PQFP,208P,28X28MM,PLASTIC,4.6V,-,0TO+70C,TR,1204-001912 IC601 IC-DECODER SDA5550M,P-MQFP,100P,-,PLASTIC,3.3V,1.5W,0TO+70C,TR,1204-001926 IC010 IC-VIDEOPROCESS VPC3230D-C5,PQFP,80P,-,PLASTIC,6V,-,0TO65C,TP,VPC3230D-C5

1205-001740 IC901 IC-TRANSMITTER DS90C385,TSSOP,56P,240MIL,PLASTIC,4V,1.63W,-10TO+70C,ST,FPDLINK-85MHZ(LVDS)

2007-000070 R00B R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R00G R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R00R R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R0HS R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R0VS R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R215 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R216 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R217 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R218 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R222 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R303 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R328 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R351 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R534 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R537 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R652 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000070 R902 R-CHIP 0ohm,5%,1/16W,DA,TP,1608

2007-000071 R002 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R003 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R004 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R102 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R105 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R108 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R304 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R354 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R355 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000071 R367 R-CHIP 22ohm,5%,1/16W,DA,TP,1608

2007-000072 R238 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R329 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R521 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R522 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R526 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R528 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R532 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R533 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R903 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R904 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R905 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R907 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000072 R908 R-CHIP 47ohm,5%,1/16W,DA,TP,1608

2007-000074 R001 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R005 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R025 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R026 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R111 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R112 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R113 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R117 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R118 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R119 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R120 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R207 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R209 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

Page5

2007-000074 R211 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R212 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

Page 29

2007-000074 R232 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R233 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R234 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R242 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R249 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R322 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R323 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R324 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R359 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R360 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R361 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R362 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R423 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R424 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R425 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R426 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R492 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R507 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R508 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R523 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R524 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R525 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R535 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R536 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R539 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R561 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R562 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R563 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R564 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R580 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R600 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R608 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R611 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R615 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R616 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R618 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R624 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R625 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R626 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R627 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R628 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R629 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R632 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R633 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R634 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R637 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R638 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R643 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R644 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R647 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R651 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R662 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R663 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R664 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R667 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R685 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R686 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R803 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000074 R804 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

Page6

Page 30

2007-000074 R805 R-CHIP 100ohm,5%,1/16W,DA,TP,1608

2007-000075 R039 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

2007-000075 R040 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

2007-000075 R604 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

2007-000075 R639 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

2007-000075 R640 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

2007-000075 R641 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

2007-000075 R642 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

2007-000075 R649 R-CHIP 220ohm,5%,1/16W,DA,TP,1608

2007-000076 R045 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R047 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R048 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R053 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R665 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R666 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R669 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R671 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R672 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R673 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R773 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000076 R775 R-CHIP 330ohm,5%,1/16W,DA,TP,1608

2007-000077 R044 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000077 R046 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000077 R051 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000077 R052 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000077 R470 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000077 R479 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000077 R529 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000077 R531 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000077 R606 R-CHIP 470ohm,5%,1/16W,DA,TP,1608

2007-000078 R015 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R016 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R017 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R036 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R114 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R115 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R437 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R553 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R554 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R555 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R636 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000078 R691 R-CHIP 1Kohm,5%,1/16W,DA,TP,1608

2007-000081 R042 R-CHIP 2.7Kohm,5%,1/16W,DA,TP,1608

2007-000081 R054 R-CHIP 2.7Kohm,5%,1/16W,DA,TP,1608

2007-000082 R356 R-CHIP 3.3Kohm,5%,1/16W,DA,TP,1608

2007-000084 R028 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R037 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R038 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R064 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R065 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R127 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R128 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R129 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R213 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R221 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R225 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R239 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R243 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R302 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

Page7

Page 31

2007-000084 R504 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R527 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R617 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R631 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R646 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R648 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R774 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R776 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R811 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R821 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R822 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R841 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000084 R842 R-CHIP 4.7Kohm,5%,1/16W,DA,TP,1608

2007-000090 R006 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R043 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R050 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R061 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R107 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R116 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R208 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R241 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R248 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R301 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R327 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R357 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R358 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R491 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R516 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R517 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R601 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R607 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R609 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R621 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R622 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R653 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R654 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R655 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R656 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R657 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R658 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R659 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R661 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R668 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R674 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R675 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R676 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R677 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R678 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R679 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R681 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R682 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R684 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R823 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R824 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R862 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R863 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000090 R873 R-CHIP 10KOHM,5%,1/16W,DA,TP,1608

2007-000091 R101 R-CHIP 12Kohm,5%,1/16W,DA,TP,1608

2007-000091 R104 R-CHIP 12Kohm,5%,1/16W,DA,TP,1608

Page8

Page 32

2007-000091 R512 R-CHIP 12Kohm,5%,1/16W,DA,TP,1608

2007-000091 R513 R-CHIP 12Kohm,5%,1/16W,DA,TP,1608

2007-000092 R406 R-CHIP 15Kohm,5%,1/16W,DA,TP,1608

2007-000092 R407 R-CHIP 15Kohm,5%,1/16W,DA,TP,1608

2007-000093 R505 R-CHIP 20Kohm,5%,1/16W,DA,TP,1608

2007-000093 R506 R-CHIP 20Kohm,5%,1/16W,DA,TP,1608

2007-000093 R514 R-CHIP 20Kohm,5%,1/16W,DA,TP,1608

2007-000093 R515 R-CHIP 20Kohm,5%,1/16W,DA,TP,1608

2007-000094 R103 R-CHIP 22Kohm,5%,1/16W,DA,TP,1608

2007-000094 R106 R-CHIP 22Kohm,5%,1/16W,DA,TP,1608

2007-000096 R605 R-CHIP 30Kohm,5%,1/16W,DA,TP,1608

2007-000097 R199 R-CHIP 47Kohm,5%,1/16W,DA,TP,1608

2007-000097 R603 R-CHIP 47Kohm,5%,1/16W,DA,TP,1608

2007-000098 R602 R-CHIP 56Kohm,5%,1/16W,DA,TP,1608

2007-000102 R864 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

2007-000102 R865 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

2007-000102 R874 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

2007-000102 R875 R-CHIP 100Kohm,5%,1/16W,DA,TP,1608

2007-000109 R305 R-CHIP 1Mohm,5%,1/16W,DA,TP,1608

2007-000109 R309 R-CHIP 1Mohm,5%,1/16W,DA,TP,1608

2007-000109 R317 R-CHIP 1Mohm,5%,1/16W,DA,TP,1608

2007-000109 R503 R-CHIP 1Mohm,5%,1/16W,DA,TP,1608

2007-000113 R121 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R122 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R123 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R124 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R125 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R126 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R201 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R202 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R203 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R204 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R205 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000113 R206 R-CHIP 33ohm,5%,1/16W,DA,TP,1608

2007-000118 R231 R-CHIP 390ohm,5%,1/16W,DA,TP,1608

2007-000120 R645 R-CHIP 680ohm,5%,1/16W,DA,TP,1608

2007-000219 R890 R-CHIP 1.2Kohm,1%,1/16W,DA,TP,1608

2007-000219 R894 R-CHIP 1.2Kohm,1%,1/16W,DA,TP,1608

2007-000239 R244 R-CHIP 1.5Kohm,1%,1/16W,DA,TP,1608

2007-000239 R612 R-CHIP 1.5Kohm,1%,1/16W,DA,TP,1608

2007-000239 R613 R-CHIP 1.5Kohm,1%,1/16W,DA,TP,1608

2007-000309 R027 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R062 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R063 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R214 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R219 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R224 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R438 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R441 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R501 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R502 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R635 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R692 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 R693 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ01 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ02 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ03 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ04 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ05 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

Page9

Page 33

2007-000309 RJ06 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ07 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ08 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ09 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ10 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ11 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ12 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ13 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ14 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ15 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ16 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ17 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ18 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000309 RJ19 R-CHIP 10ohm,5%,1/16W,DA,TP,1608

2007-000458 R591 R-CHIP 18Kohm,5%,1/16W,DA,TP,1608

2007-000512 R109 R-CHIP 2.4Kohm,5%,1/16W,DA,TP,1608

2007-000616 R318 R-CHIP 24Kohm,5%,1/16W,DA,TP,1608

2007-000669 R895 R-CHIP 2Kohm,1%,1/16W,DA,TP,1608

2007-000701 R891 R-CHIP 3.6Kohm,1%,1/16W,DA,TP,1608

2007-000726 R808 R-CHIP 300ohm,1%,1/16W,DA,TP,1608

2007-000821 R807 R-CHIP 390ohm,1%,1/16W,DA,TP,1608

2007-000882 R518 R-CHIP 4.7ohm,5%,1/16W,DA,TP,1608

2007-000882 R519 R-CHIP 4.7ohm,5%,1/16W,DA,TP,1608

2007-001010 R312 R-CHIP 51Kohm,5%,1/16W,DA,TP,1608

2007-001044 R551 R-CHIP 56ohm,5%,1/16W,DA,TP,1608

2007-001044 R552 R-CHIP 56ohm,5%,1/16W,DA,TP,1608

2007-001164 R314 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R315 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R316 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R321 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R325 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R326 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R411 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R412 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R413 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R870 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R871 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001164 R872 R-CHIP 75ohm,1%,1/16W,DA,TP,1608

2007-001167 R007 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R008 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R009 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R014 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R019 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R022 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R023 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R024 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R035 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R041 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R049 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R067 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R236 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001167 R619 R-CHIP 75ohm,5%,1/16W,DA,TP,1608

2007-001175 R511 R-CHIP 8.2Kohm,1%,1/16W,DA,TP,1608

2007-008433 R892 R-CHIP 0.33OHM,1%,1W,DA,TP,6432

2007-008433 R893 R-CHIP 0.33OHM,1%,1W,DA,TP,6432

2011-000002 IC002 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 IC003 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 IC004 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 IC005 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

Page10

Page 34

2011-000002 IC006 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 IC007 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 IC008 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 IC009 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA301 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA302 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA303 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA304 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA305 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA306 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA311 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA312 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA313 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA351 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA352 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA353 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA354 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA355 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000002 RA356 R-NETWORK 22ohm,5%,63mW,L,CHIP,8P,TP

2011-000515 IC641 R-NETWORK 4.7Kohm,5%,1/16W,L,CHIP,8P,TP

2011-000515 IC642 R-NETWORK 4.7Kohm,5%,1/16W,L,CHIP,8P,TP

2011-000651 IC621 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2011-000651 IC622 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2011-000651 IC623 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2011-000651 IC624 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2011-000651 IC625 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2011-000651 IC626 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2011-000651 IC627 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2011-000651 IC628 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2011-000651 IC629 R-NETWORK 10ohm,5%,63mW,L,CHIP,8P,TP

2203-000140 C004 C-CERAMIC,CHIP 1.5nF,10%,50V,X7R,TP,1608,2203-000140 C008 C-CERAMIC,CHIP 1.5nF,10%,50V,X7R,TP,1608,2203-000140 C016 C-CERAMIC,CHIP 1.5nF,10%,50V,X7R,TP,1608,2203-000140 C019 C-CERAMIC,CHIP 1.5nF,10%,50V,X7R,TP,1608,2203-000140 C038 C-CERAMIC,CHIP 1.5nF,10%,50V,X7R,TP,1608,2203-000140 C538 C-CERAMIC,CHIP 1.5nF,10%,50V,X7R,TP,1608,2203-000140 C574 C-CERAMIC,CHIP 1.5nF,10%,50V,X7R,TP,1608,2203-000189 C112 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C304 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C338 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C504 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C505 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C506 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C524 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C525 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C526 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C541 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C542 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C559 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C565 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C570 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C589 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C620 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C624 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C821 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C842 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C844 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

Page11

2203-000189 C846 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C852 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

Page 35

2203-000189 C853 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C856 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C858 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C862 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C864 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C868 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C871 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C881 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C894 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C895 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C908 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C909 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C910 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C912 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000189 C972 C-CERAMIC,CHIP 100nF,+80-20%,25V,Y5V,TP,1608,

2203-000236 C050 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C051 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C056 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C061 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C069 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C070 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C091 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C101 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C102 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C103 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C104 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C105 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C106 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C219 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C222 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C227 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C228 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C232 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C234 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C235 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C237 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C239 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C242 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C246 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C248 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C257 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C259 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C268 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C271 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C283 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C409 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C410 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C465 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C470 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C550 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C617 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C618 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C811 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 C888 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 CB01 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 CG01 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

2203-000236 CR01 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,1608

Page12

2203-000239 C314 C-CERAMIC,CHIP 0.1nF,5%,50V,NP0,TP,2012

2203-000257 C114 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

Page 36

2203-000257 C116 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C118 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C120 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C122 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C124 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C383 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C623 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C825 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C859 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C863 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C866 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000257 C921 C-CERAMIC,CHIP 10nF,10%,50V,X7R,TP,1608

2203-000280 C023 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C025 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C026 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C027 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C028 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C029 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C030 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C057 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C058 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C059 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C060 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C355 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C356 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C527 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000280 C572 C-CERAMIC,CHIP 0.01nF,0.5pF,50V,NP0,TP,1608

2203-000357 C608 C-CERAMIC,CHIP 0.15nF,5%,50V,NP0,TP,1608

2203-000440 C062 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C063 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C064 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C065 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C301 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C536 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C537 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C539 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C547 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C901 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C902 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000440 C905 C-CERAMIC,CHIP 1nF,10%,50V,X7R,TP,1608,2203-000491 C544 C-CERAMIC,CHIP 2.2nF,10%,50V,X7R,TP,1608,2203-000491 C548 C-CERAMIC,CHIP 2.2nF,10%,50V,X7R,TP,1608,2203-000491 C595 C-CERAMIC,CHIP 2.2nF,10%,50V,X7R,TP,1608,2203-000491 C596 C-CERAMIC,CHIP 2.2nF,10%,50V,X7R,TP,1608,2203-000552 C225 C-CERAMIC,CHIP 0.02nF,5%,50V,NP0,TP,1608

2203-000552 C226 C-CERAMIC,CHIP 0.02nF,5%,50V,NP0,TP,1608

2203-000552 C614 C-CERAMIC,CHIP 0.02nF,5%,50V,NP0,TP,1608

2203-000552 C615 C-CERAMIC,CHIP 0.02nF,5%,50V,NP0,TP,1608

2203-000626 C922 C-CERAMIC,CHIP 0.022nF,5%,50V,NP0,TP,1608

2203-000626 C923 C-CERAMIC,CHIP 0.022nF,5%,50V,NP0,TP,1608

2203-000626 C924 C-CERAMIC,CHIP 0.022nF,5%,50V,NP0,TP,1608

2203-000726 C381 C-CERAMIC,CHIP 3.9nF,10%,50V,X7R,TP,1608,2203-000783 C088 C-CERAMIC,CHIP 0.33nF,5%,50V,NP0,TP,1608

2203-000815 C244 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C290 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C291 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C292 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

Page13

2203-000815 C293 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C294 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

Page 37

2203-000815 C295 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C296 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C297 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C298 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C299 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C308 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C309 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C366 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C368 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C371 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C373 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C375 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C376 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A1 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A2 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A3 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A4 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A5 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A6 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A7 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A8 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3A9 C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3AA C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3AB C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3AC C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000815 C3AD C-CERAMIC,CHIP 0.033nF,5%,50V,NP0,TP,1608

2203-000839 C313 C-CERAMIC,CHIP 0.39nF,5%,50V,NP0,TP,2012

2203-000903 C011 C-CERAMIC,CHIP 0.0047nF,0.25pF,50V,NP0,TP,1608

2203-000903 C012 C-CERAMIC,CHIP 0.0047nF,0.25pF,50V,NP0,TP,1608

2203-000972 C005 C-CERAMIC,CHIP 47nF,10%,16V,X7R,TP,1608

2203-000972 C007 C-CERAMIC,CHIP 47nF,10%,16V,X7R,TP,1608

2203-000972 C013 C-CERAMIC,CHIP 47nF,10%,16V,X7R,TP,1608

2203-000972 C021 C-CERAMIC,CHIP 47nF,10%,16V,X7R,TP,1608

2203-000972 C379 C-CERAMIC,CHIP 47nF,10%,16V,X7R,TP,1608

2203-000972 C576 C-CERAMIC,CHIP 47nF,10%,16V,X7R,TP,1608

2203-000998 C040 C-CERAMIC,CHIP 0.047nF,5%,50V,NP0,TP,1608

2203-000998 C052 C-CERAMIC,CHIP 0.047nF,5%,50V,NP0,TP,1608

2203-000998 C086 C-CERAMIC,CHIP 0.047nF,5%,50V,NP0,TP,1608

2203-000998 C087 C-CERAMIC,CHIP 0.047nF,5%,50V,NP0,TP,1608

2203-000998 C089 C-CERAMIC,CHIP 0.047nF,5%,50V,NP0,TP,1608

2203-001071 C567 C-CERAMIC,CHIP 0.056nF,5%,50V,NP0,TP,1608

2203-001071 C568 C-CERAMIC,CHIP 0.056nF,5%,50V,NP0,TP,1608

2203-001071 C571 C-CERAMIC,CHIP 0.056nF,5%,50V,NP0,TP,1608

2203-001126 C892 C-CERAMIC,CHIP 0.68nF,10%,50V,X7R,TP,1608

2203-001140 C002 C-CERAMIC,CHIP 68nF,10%,16V,X7R,TP,1608,2203-001140 C003 C-CERAMIC,CHIP 68nF,10%,16V,X7R,TP,1608,2203-001140 C006 C-CERAMIC,CHIP 68nF,10%,16V,X7R,TP,1608,2203-001402 C015 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C020 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C031 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C032 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C033 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C034 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C035 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C036 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C039 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C047 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

Page14

2203-001402 C049 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001402 C848 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

Page 38

2203-001402 C849 C-CERAMIC,CHIP 220nF,+80-20%,16V,Y5V,TP,1608

2203-001656 C017 C-CERAMIC,CHIP 0.47nF,5%,50V,NP0,TP,1608

2203-001656 C024 C-CERAMIC,CHIP 0.47nF,5%,50V,NP0,TP,1608

2203-001656 C037 C-CERAMIC,CHIP 0.47nF,5%,50V,NP0,TP,1608

2203-001656 C543 C-CERAMIC,CHIP 0.47nF,5%,50V,NP0,TP,1608

2203-001656 C569 C-CERAMIC,CHIP 0.47nF,5%,50V,NP0,TP,1608

2203-005005 C010 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C201 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C202 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C203 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C204 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C205 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C206 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C207 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C208 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C209 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C211 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C212 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C213 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C214 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C215 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C216 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C217 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C229 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C238 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C245 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C267 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C274 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C275 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C276 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C277 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C278 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C279 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C282 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C302 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C306 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C310 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C312 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C315 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C318 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C319 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C321 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C322 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C323 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C327 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C328 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C331 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C332 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C333 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C334 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C337 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C341 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C342 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C344 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C347 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C348 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C349 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

Page15

2203-005005 C352 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C353 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

Page 39

2203-005005 C354 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C357 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C359 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C363 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C364 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C365 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C367 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C369 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C372 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C374 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C377 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C378 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C384 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C385 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C386 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C387 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C388 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C389 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C391 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C393 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C397 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C398 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C408 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C503 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C549 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C551 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C601 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C602 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C605 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C606 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C607 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C609 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C612 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C613 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C619 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C625 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C626 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C627 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C824 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C873 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C874 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005005 C875 C-CERAMIC,CHIP 100nF,10%,16V,X7R,TP,1608

2203-005015 C501 C-CERAMIC,CHIP 150nF,+80-20%,16V,Y5V,TP,1608

2203-005015 C502 C-CERAMIC,CHIP 150nF,+80-20%,16V,Y5V,TP,1608

2203-005015 C507 C-CERAMIC,CHIP 150nF,+80-20%,16V,Y5V,TP,1608

2203-005015 C508 C-CERAMIC,CHIP 150nF,+80-20%,16V,Y5V,TP,1608

2203-005015 C509 C-CERAMIC,CHIP 150nF,+80-20%,16V,Y5V,TP,1608