Page 1

Contents

Revision History -------------------------------------------------------------------------------------------- (3)

General Description --------------------------------------------------------------------------------------- (4)

General Information --------------------------------------------------------------------------------------- (4)

1. Absolute Maximum Ratings -------------------------------------------------------------------------- (5)

2. Optical Characteristics --------------------------------------------------------------------------------- (7)

3. Electrical Characteristics -------------------------------------------------------------------------------(10)

3.1 TFT LCD Module

3.2 Back Light Unit

4. Block Diagram ------------------------------------------------------------------------------------------- (12)

5. Input Terminal Pin Assignment --------------------------------------------------------------------- (13)

5.1 Input Signal & Power of Control Board

5.2 LS Bar Input Pin Configuration

5.3 LVDS Interface

5.4 Input Signals, Basic Display Colors and Gray Scale of Each Color

6. EDID Information --------------------------------------------------------------------------------------- (18)

6.1 EEPROM Data

6.2 EEPROM Data Map

7. Interface Timing ---------------------------------------------------------------------------------------- (20)

7.1 Timing Parameters (DE only mode)

7.2 Timing Diagrams of interface Signal (DE only mode)

7.3 Power ON/OFF Sequence

8. Outline Dimension -------------------------------------------------------------------------------------- (23)

9. EMI Specification --------------------------------------------------------------------------------------- (30)

10. UL Approval

11. Reliability Test ----------------------------------------------------------------------------------------- (31)

12. Packing ------------------------------------------------------------------------------------------------ (32)

13. Marking & Others ------------------------------------------------------------------------------------- (33)

14. General Precaution ---------------------------------------------------------------------------------- (34)

14.1 Handling

14.2 Storage

14.3 Operation

14.4 Operation Condition Guide

14.5 Others

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

2/36

Page 2

* Revision History

Date

Mar.

2

2012

Apr.

27,

2012

Oct.

17,

2012

Rev.

No

000 - First Issued

001 -

002 -

Page Summary

・Improved Dr-IC Application

- AS IS : MT3196B, TO BE : MT3196C

- Model Code Changed : LTY[Z]320AN05-A01 LTY[Z]320AN05-A02

• LCM site multiplication

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

3/36

Page 3

General Description

Description

LTY[Z]320AN05 is a color active matrix liquid crystal display (LCD) that uses amorphous

silicon TFT(Thin Film Transistor) as switching components. This model is composed of a

TFT LCD panel, a driver circuit and a back light unit. The resolution of a 32.0“ is 1366 x

768 and this model can display up to 16.7million colors with wide viewing angle of 89° or

higher in all directions. This panel is intended to support applications to provide a excellent

performance for Flat Panel Display such as Home-alone Multimedia TFT-LCD TV, Display

terminals for AV application products, and High Definition TV (HDTV).

Features

RoHS compliance (Pb-free)

High contrast ratio, high aperture ratio, fast response time

PVA mode

Wide viewing angle (±89°)

WXGA (1366 x 768 pixels) resolution (16:9)

Low Power consumption

WLED (White Light Emitting Diode) Backlight

LVDS (Low Voltage Differential Signaling) interface

General Information

Items Specification Unit Note

Module Size

Weight 5500(Max) g

Pixel Pitch

Active Display Area 697.6845(H) x 392.256(V) mm

Surface Treatment Haze 0.8%, Hard-coating (2H)

Display Colors 8 bit- 16.7M colors

Number of Pixels 1366 x 768 pixel

Pixel Arrangement RGB Horizontal stripe

Display Mode Normally Black

Luminance of White 430 cd/m

727.6(H

0.51075(H) × 0.17025 (V) * 3

) x 424.0(V

TYP

24.8(D

MAX

)

TYP

)

mm

mm

±1.0mm

2

Typ.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

4/36

Page 4

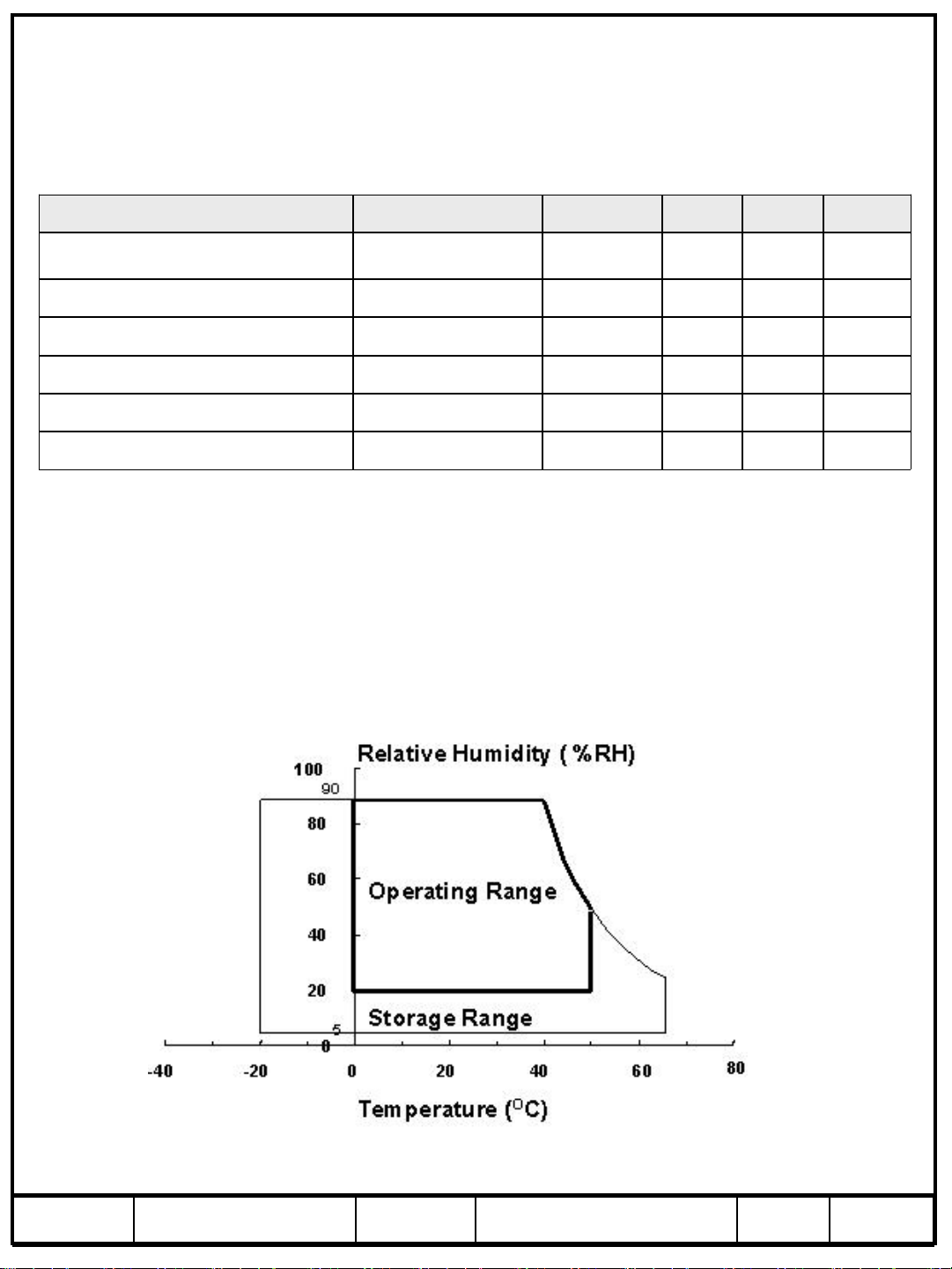

1. Absolute Maximum Ratings

1-1 Operating Condition

If the condition exceeds maximum ratings, it can cause malfunction or unrecoverable

damage to the device.

Item Symbol Min. Max. Unit Note

Power Supply Voltage V

Module Storage Temperature T

Operating Temperature T

Panel surface Temperature T

Shock ( non – operating ) S

Vibration ( non – operating ) V

Note (1) Ta= 25 ± 2 °C

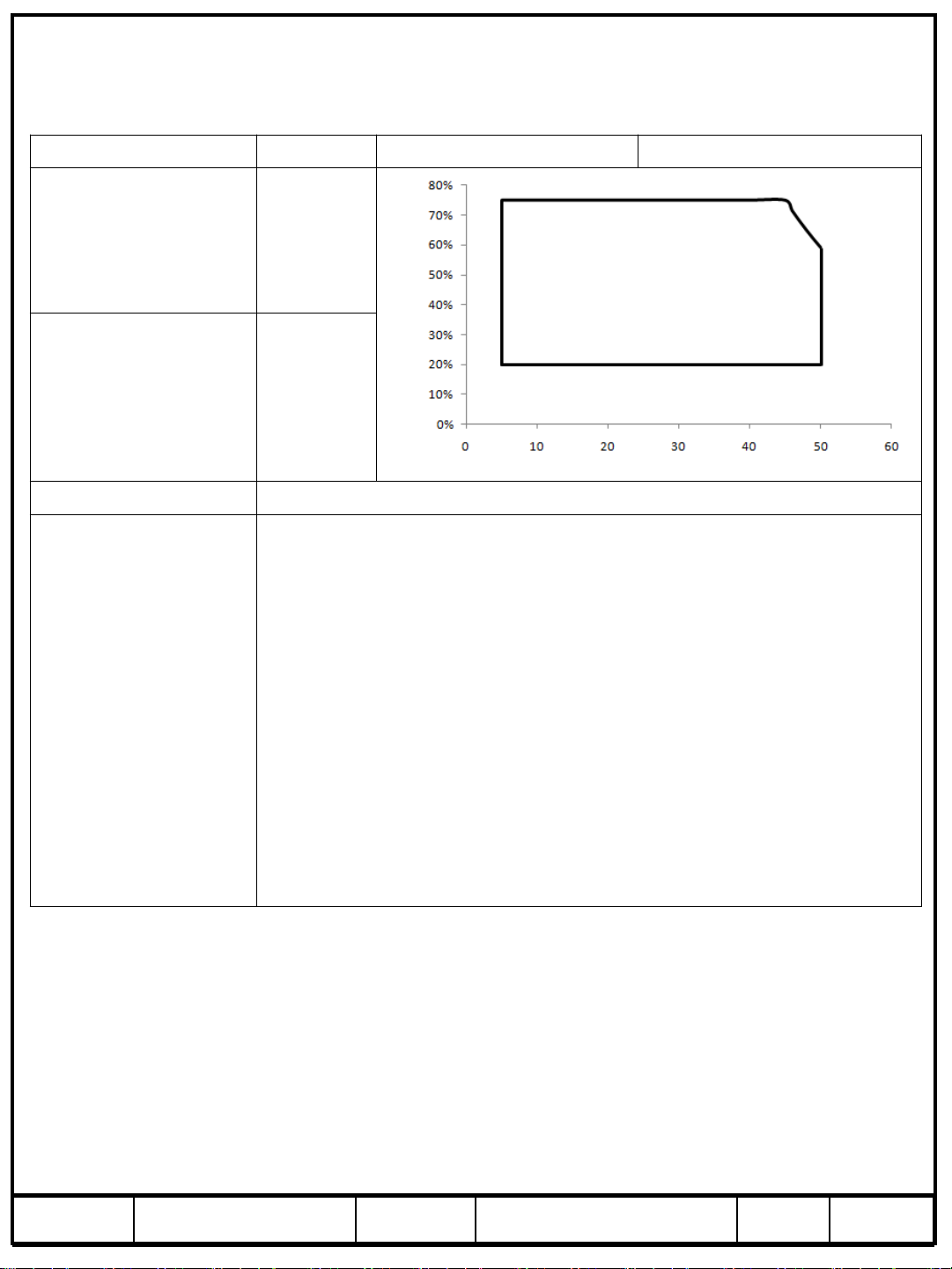

(2) Temperature and relative humidity range are shown in the figure below.

a. 93.8 % RH Max. (Ta ≤ 40 °C)

b. Maximum wet-bulb temperature at 40 °C or less. (Ta ≤ 40 °C)

c. No condensation

(3) Polarizer will not be damaged in this range, even though abnormal visual problems occur

in T

(4) 11ms, sine wave, one time for ±X, ±Y, ±Z axis

(5) 10-300 Hz, Sweep rate 10min, 30min for X, Y, Z axis

SUR

range.

DD

STG

OPR

SUR

NOP

- 1.5 G (5)

NOP

GND-0.5 13 V (1)

-20 65

0 50

0 65

℃

℃

℃

(2)

(2)

(3)

- 50 G (4)

(40, 93.8)

(50, 50.4)

(65, 27.7)

Fig. Temperature and Relative humidity range

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

5/36

Page 5

1-2 Pallet Storage Condition (Not Included Transportation)

※except for service Panel

ITEM Unit Min. Max.

Storage Temperature (℃)

(5,75)

Pallet Storage Condition

(45,75)

(50,59)

(5,20)

Storage Humidity (%rH)

Relative Humidity (%RH)

Temperature (℃)

Storage life from S2-In 12 months

- The storage room should provide good ventilation and temperature control.

- Products should not be placed on the floor,

but on the Pallet away from a wall.

- Prevent products from direct sunlight, moisture nor water;

Be cautious of a build up of condensation.

Storage Condition

- Avoid other hazardous environment while storing goods.

- If products delivered or kept in conditions of over the storage period of

3 months, the recommended temperature or humidity range,

we recommend you leave them at a temperature of 20℃ and a humidity

of 50% for 24 hours.

(50,20)

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

6/36

Page 6

2. Optical Characteristics

The optical characteristics should be measured in a dark room or equivalent.

Measuring equipment : TOPCON BM-7,SPECTRORADIOMETER SR-3

(LED Input Current = 110mA, Ta = 25 ± 2°C, VDD=12V, fv= 60Hz, f

Item Symbol Condition Min. Typ. Max. Unit Note

Contrast Ratio

(Center of screen)

Response

Time

G-to-G

[AVE]

Luminance of White

(Center of screen)

Red

Color

Green

Chromaticity

(CIE 1931)

Blue

White

Color Gamut - - 72 - %

C/R

*3000 5000 -

Tg - 8 18 msec

Y

L

360 430 - cd/m

Normal

Rx

Ry 0.331

Gx 0.315

Gy 0.616

Bx 0.156

qL,R=0

qU,D=0

Viewing

Angle

TYP.

-0.03

0.645

TYP.

+0.03

By 0.048

Wx 0.280

Wy 0.285

=80MHz, Dim = 100%)

DCLK

2

(3)

SR-3A

(5)

RD-80S

(6)

SR-3A

(7),(8)

SR-3A

(7)

SR-3A

Color Temperature - - 10000 - K

2Point Gamma γ

Hor.

Viewing

Angle

Ver.

Brightness Uniformity

(9 Points)

q

L

q

R

q

U

q

D

B

uni

7G ~ 57G

(Full = 64G)

1.7 2.2 2.7

79 89 -

79 89 -

C/R≥10

Degree

79 89 79 89 -

- - 30 %

EZ-Contrast

* CR = (White at point ⑤ of Note 2) / (Most Dark Point of Black Pattern at area ⓐ of Note 2)

Note (1) Test Equipment Setup

The measurement should be executed in a stable, windless and dark room between

40min and 60min after lighting the back light at the given temperature for stabilization

of the back light. This should be measured in the center of screen.

Single lamp current @ Vdim = 100%

Environment condition : Ta = 25 ± 2 °C

(9)

(8)

(4)

SR-3

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

7/36

Page 7

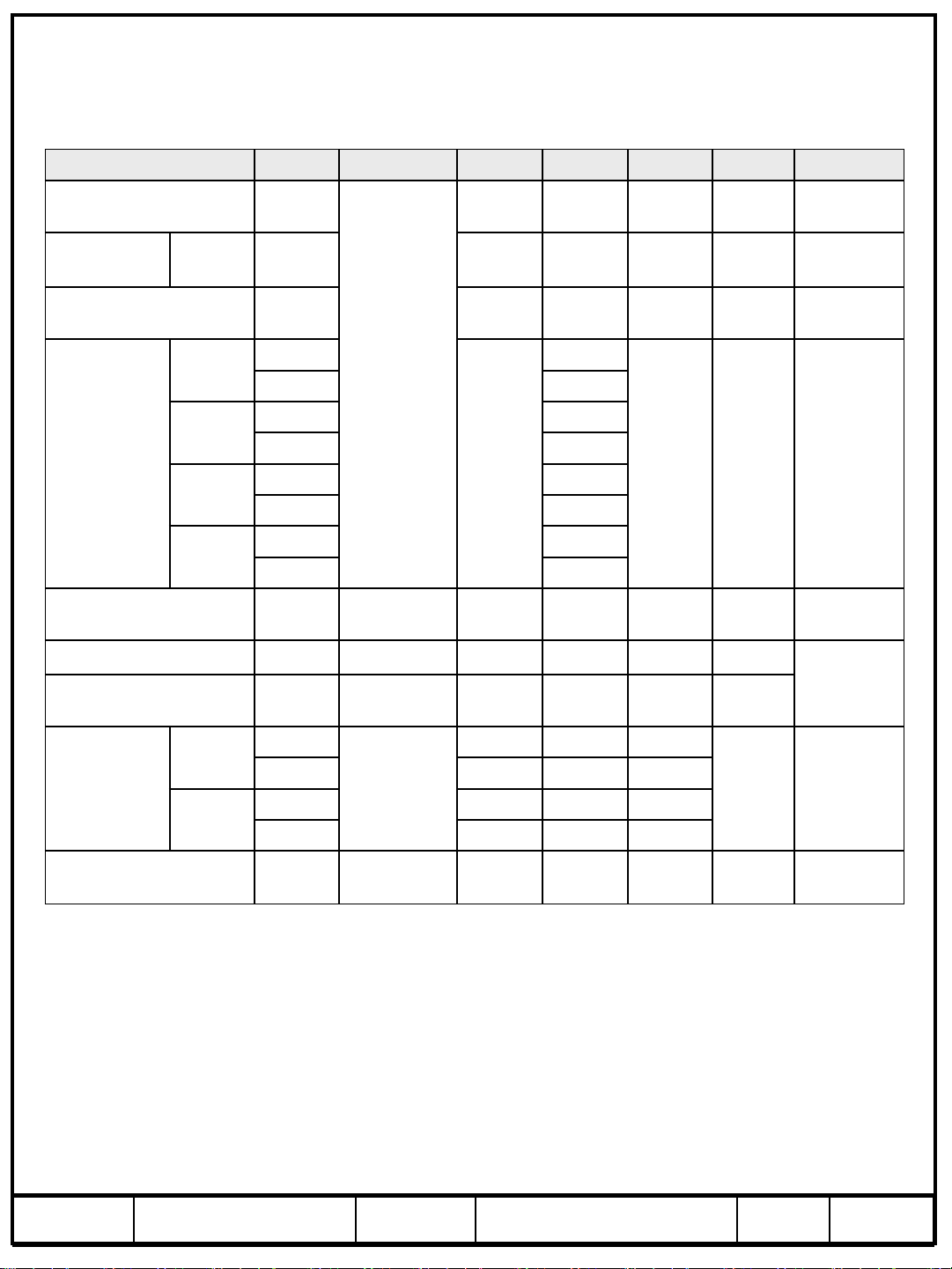

Photo detector Field

C R

G

G

/

max

min

Photo detector

SR-3

BM-7

TFT - LCD Module

Note (2) Definition of test point

228 683 1138

128

⑨

1°

2°

⑧

Field

The center of the screen

⑦

SR-3 : 50㎝

BM-7 : 50㎝

LCD Panel

Active Area

Area ⓐ

384

640

Note (3) Definition of Contrast Ratio (C/R)

: Ratio of gray max (Gmax) & gray min (Gmin) at the center point ⑤ of the panel

Gmax : Luminance with all pixels white

Gmin : Luminance with all pixels black

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

⑥

⑤ ④

② ③

455 911

256

512

①

Test Point

CR Measured Area

8/36

Page 8

Note (4) Definition of 9 points brightness uniformity

Buni

B B

B

100

( max min)

max

Gamma X Y

X Z B B B

Y Measurement Level Z Measurement Brightness

B Maximum Brightness B Minimum Brightness

lum

lum

log log

: / :

: / :

min max min

max min

100 100

100

Bmax : Maximum brightness

Bmin : Minimum brightness

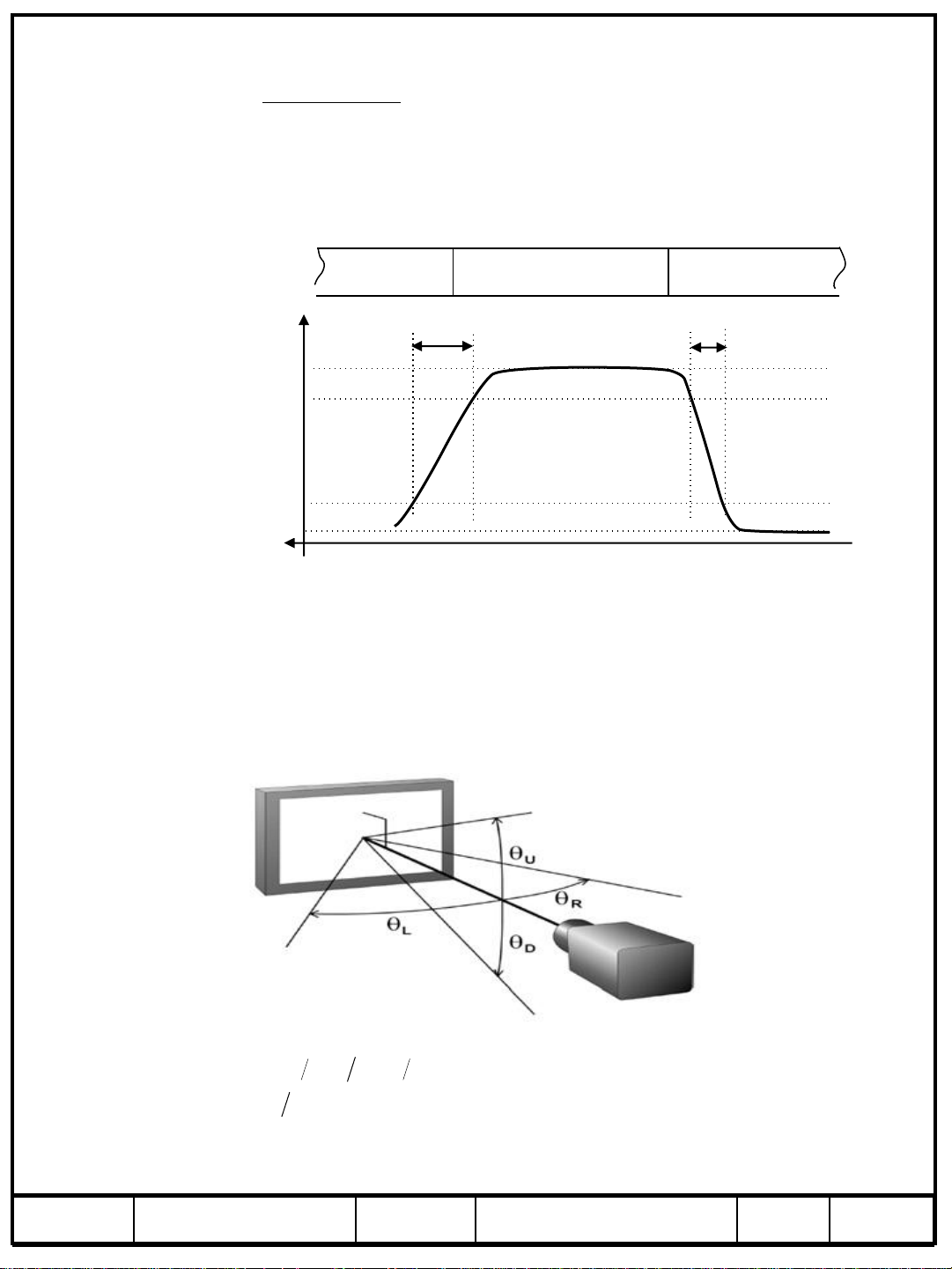

Note (5) Definition of Response time : Sum of Tr, Tf

Display data

Optical Instruments

Response

Note (6) Definition of Luminance of White : Luminance of white at center point ⑤

Note (7) Definition of Color Chromaticity (CIE 1931)

Color coordinate of Red, Green, Blue & White at center point ⑤

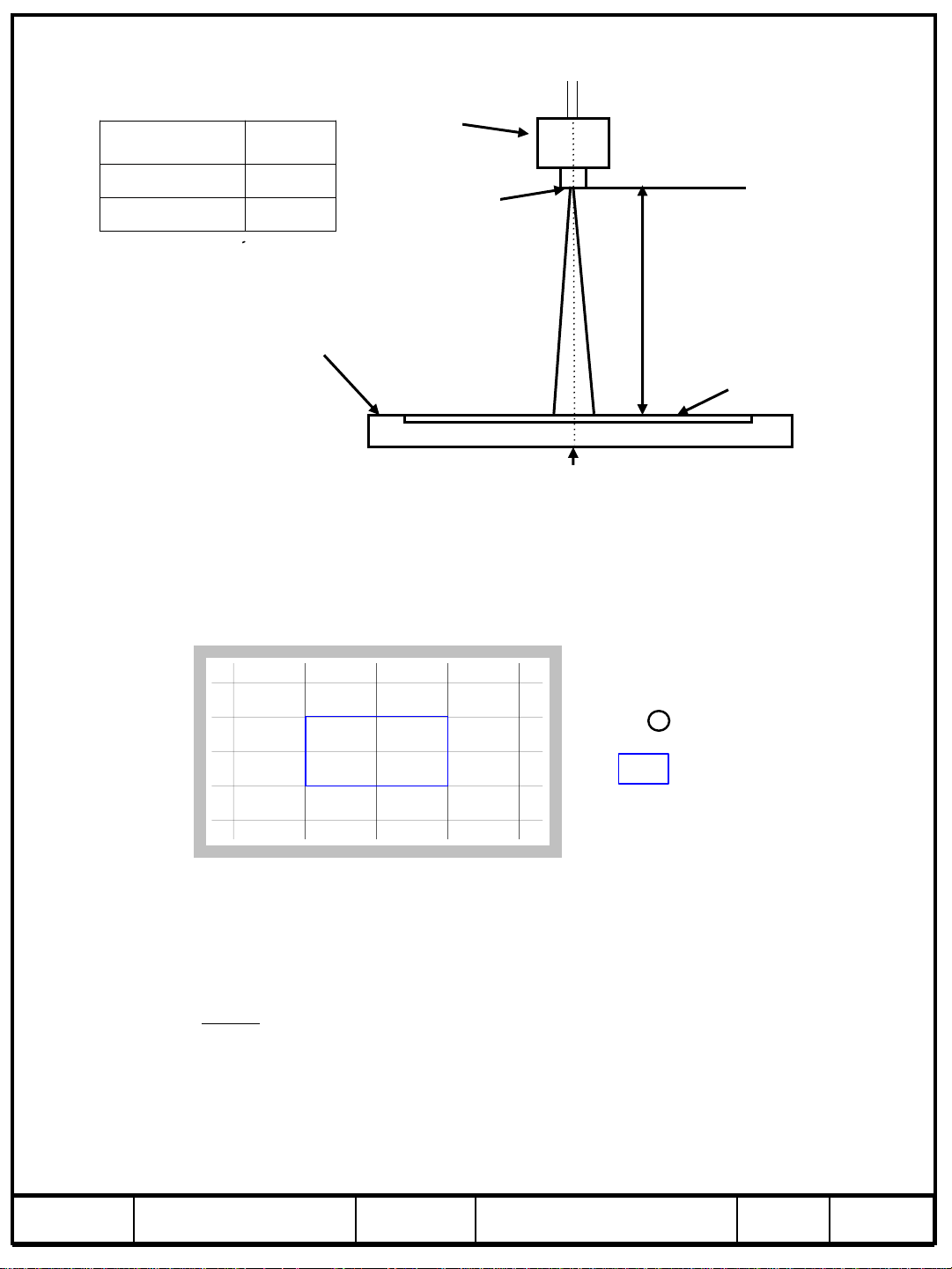

Note (8) Definition of Viewing Angle

: Viewing angle range (C/R ≥10)

100%

90%

10%

0%

Black (data off)

TR

White (data on)

White (data off)

TF

TIME

Note (9) Definition of 2 point Gamma

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

9/36

Page 9

3. Electrical Characteristics

3.1 TFT LCD Module

The connector for display data & timing signal should be connected.

Ta = 25°C ± 2 °C

Item Symbol Min. Typ. Max. Unit Note

Voltage of Power Supply VDD 11 12 13 V (1)

Current

of Power

Supply

(a) Black

(b) White - 350 450

IDD

(c) Mosaic - 365 -

- 375 -

mA (2),(3)

(4) Max Pattern - 670 770

Vsync Frequency fV 47 60 63 Hz

Hsync Frequency fH 45 48.6 53 kHz

Main Frequency f

Rush Current I

Note (1) The ripple voltage should be controlled under 10% of V

(2) fV=60Hz, fDCLK = 80MHz, V

65 80 86 MHz

DCLK

- - 3 A (4)

RUSH

.

DD

= 12.0V, DC Current.

DD

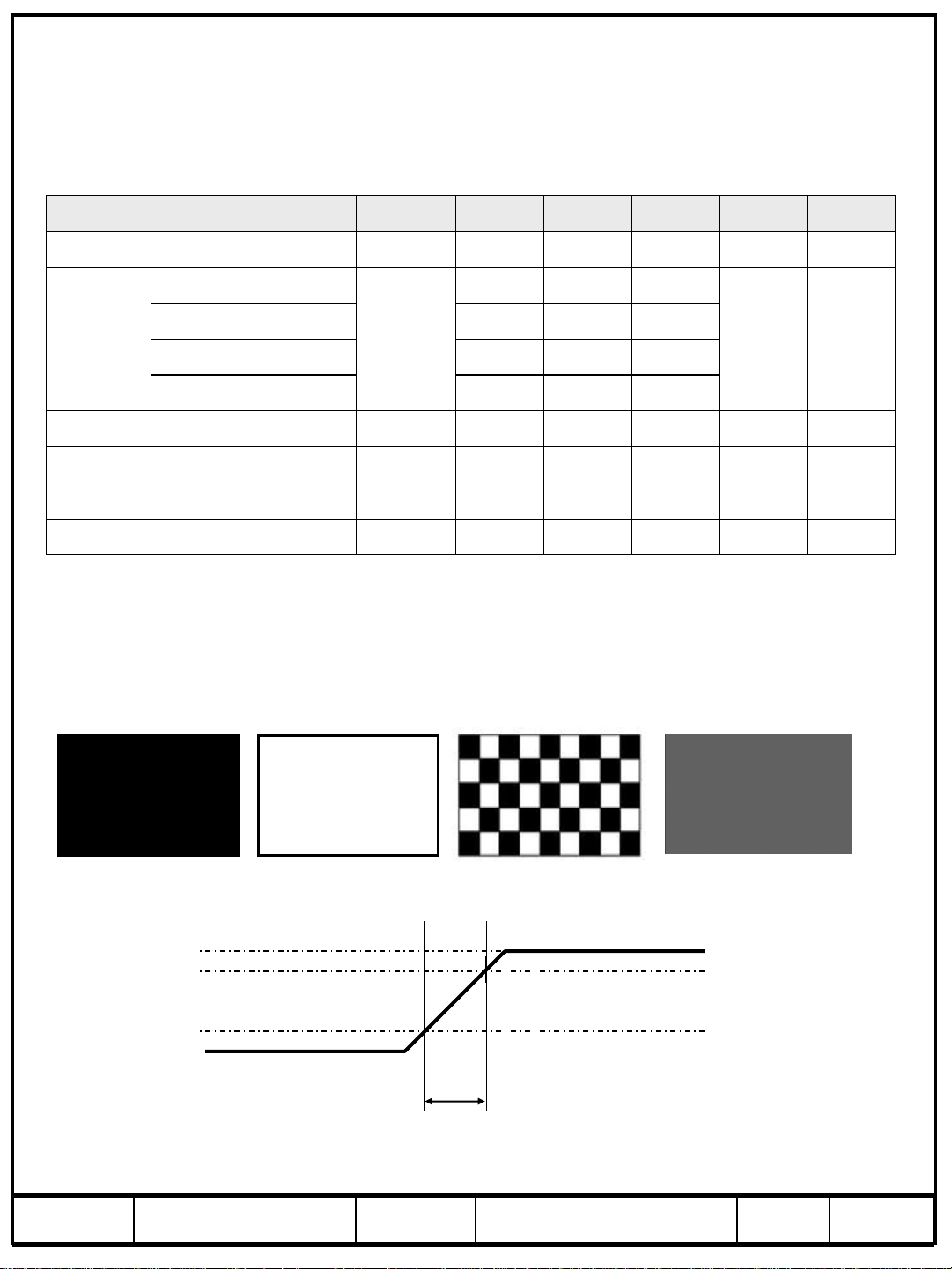

(3) Power dissipation check pattern (LCD Module only)

a) Black Pattern b) White Pattern c) Mosaic d) Max. Pattern

(4) Measurement Conditions

V

100%

90%

10%

GND

Rush Current I

T

RUSH

can be measured when T

RUSH

=470us

RUSH

. is1ms

DD

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

10/36

Page 10

3.2 Back Light Unit

The back light contains 60 LEDs.

The characteristics of lamps are shown in the following tables.

Ta=25 ± 2°C

Item Symbol Min. Typ. Max. Unit Note

Operating Life Time Hr 30,000 - - Hour (1)

Operating

Current

Operating

Voltage

Range of Voltage

(Power Consumption)

Note (1) It is defined as the time to take until the brightness reduces to 50% of its original value at

each Srting, Iop=.110.0mArms

[Definition of Operating Voltage : At each Strings, Iop = 140.0 mArms (typ.)]

Continuous Iop - 110 200 mA -

@110mA

Continuous Vop 171 - 194 V

⊿Vf

-

- - 11.5 V @140mA(/String)

(18.8) - (21.3) -

/ 30LEDs

@Tj 25℃

Iop=110mA

@Tj 25℃

3.2.1 Review and Update for Electrical Specification

According to the improvement of efficiency for devices, the electrical specification would be revie

wed and revised after initial values had been established.This revision mentioned above should be

discussed at appropriate time.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

11/36

Page 11

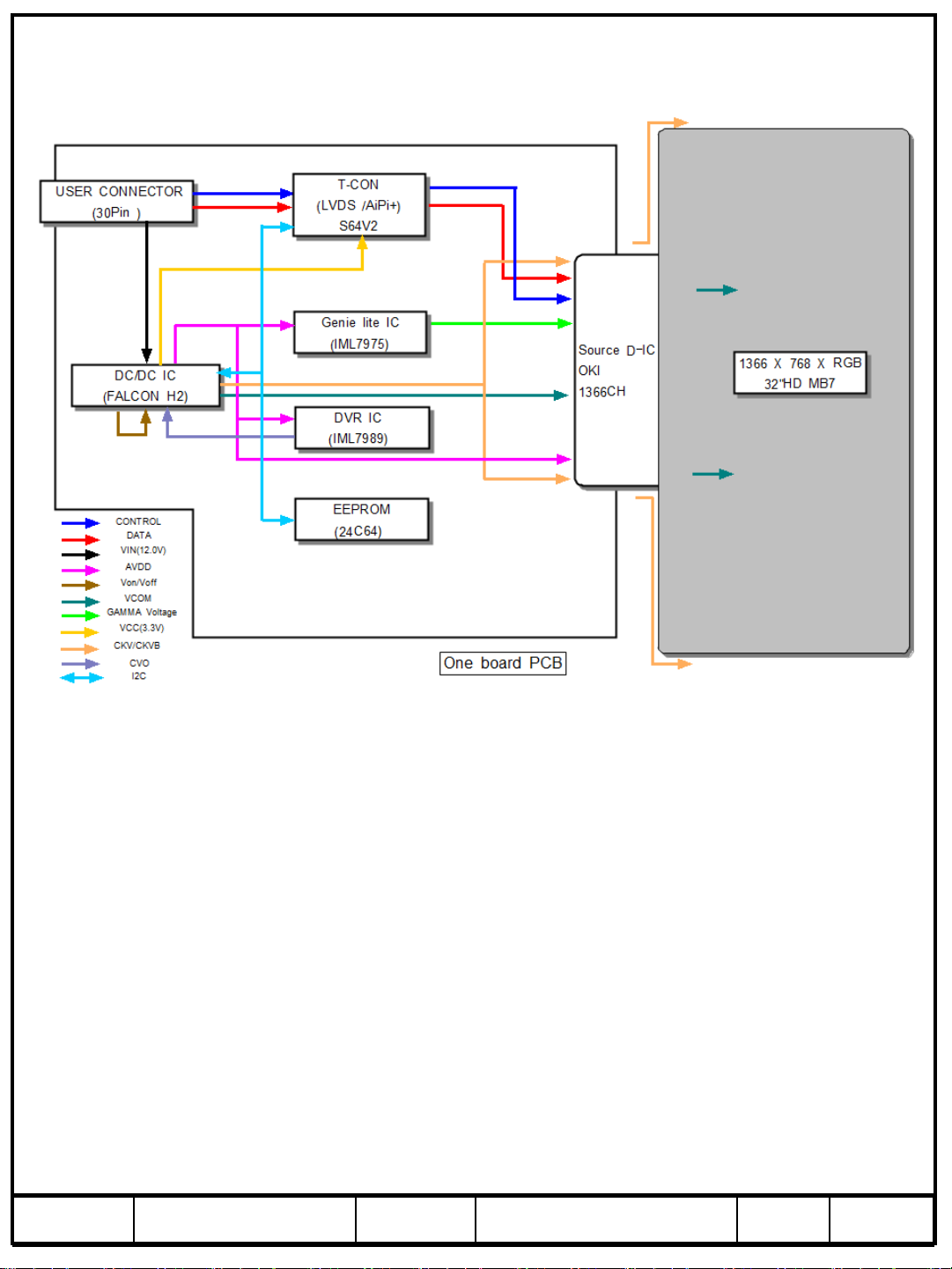

4. Block Diagram

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

12/36

Page 12

5. Input Terminal Pin Assignment

5.1. Input Signal & Power of Control Board

Connector : 196260-30041 (P-TWO Industries)

PIN No. Signal Description PIN No. Signal Description

1 N.C. No Connection 16 GND GND

2 SCL_I I2C Clock 17 LV3_NI LVDS Signal 3 SDA_I I2C Data 18 LV3_PI LVDS Signal +

4 GND GND 19 GND GND

5 LV0_NI LVDS Signal - 20 N.C. No Connection

6 LV0_PI LVDS Signal + 21 LVDS_SEL LVDS Selection

7 GND GND 22 WPN Bus Release

8 LV1_NI LVDS Signal - 23 GND GND

9 LV1_PI LVDS Signal + 24 GND GND

10 GND GND 25 N.C. No Connection

11 LV2_NI LVDS Signal - 26 Power V

12 LV2_PI LVDS Signal + 27 Power V

13 GND GND 28 Power V

14 LVCLK_NI LVDS Clock - 29 Power V

15 LVCLK_PI LVDS Clock + 30 Power V

■ Option Pin Description

These pins are CMOS interface.

Please use within the range of the following restriction.

VIH:2.4V(min) / 3.5V(max)

VIL:0.0V(min) / 0.4V(max))

DD

DD

DD

DD

DD

■SCL : Pull up 22Ω/ 4.7kΩ

■SDA : Pull up 22Ω/ 4.7kΩ

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

13/36

Page 13

Note(1) Pin number starts from Right side

PCB

▼

Pin No. 1 Pin No. 30

#1

connect name

#1

#30

#30

Fig. Connector diagram

a. All GND pins should be connected together and also be connected to the LCD’s

metal chassis.

b. All power input pins should be connected together.

c. All NC pins should be separated from other signal or power.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

14/36

Page 14

5.2. LS Bar Input Pin Configuration

1. CONNECTOR : Morex/51103-040

Pin

1 DC Voltage (+)

2 N.C.

3 N.C.

4

2. CONNECTOR : Morex/51103-0500

Pin

1

2

3

4 Feedback

5 N.C.

Pin Configuration (Function)

DC Voltage (+)

Pin Configuration (Function)

Feedback

N.C.

N.C.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

15/36

Page 15

5.3 LVDS Interface

LVDS pin JEIDA - Data Normal Data

TxIN/RxOUT0 R2 R0

TxIN/RxOUT1 R3 R1

TxIN/RxOUT2 R4 R2

TxOUT/RxIN0

TxOUT/RxIN1

TxOUT/RxIN2

TxIN/RxOUT3 R5 R3

TxIN/RxOUT4 R6 R4

TxIN/RxOUT6 R7 R5

TxIN/RxOUT7 G2 G0

TxIN/RxOUT8 G3 G1

TxIN/RxOUT9 G4 G2

TxIN/RxOUT12 G5 G3

TxIN/RxOUT13 G6 G4

TxIN/RxOUT14 G7 G5

TxIN/RxOUT15 B2 B0

TxIN/RxOUT18 B3 B1

TxIN/RxOUT19 B4 B2

TxIN/RxOUT20 B5 B3

TxIN/RxOUT21 B6 B4

TxIN/RxOUT22 B7 B5

TxIN/RxOUT24 HSYNC HSYNC

TxIN/RxOUT25 VSYNC VSYNC

TxIN/RxOUT26 DEN DEN

TxIN/RxOUT27 R0 R6

TxIN/RxOUT5 R1 R7

TxIN/RxOUT10 G0 G6

TxOUT/RxIN3

TxIN/RxOUT11 G1 G7

TxIN/RxOUT16 B0 B6

TxIN/RxOUT17 B1 B7

TxIN/RxOUT23 RESERVED RESERVED

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

16/36

Page 16

5.4 Input Signals, Basic Display Colors and Gray Scale of Each Color

DATA SIGNAL

COLOR

BASIC

COLOR

GRAY

SCALE

OF

RED

DISPLAY

(10bit)

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -

BLUE 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 -

GREEN 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 -

CYAN 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 -

RED 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 -

MAGENTA 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 -

YELLOW 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 -

WHITE 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R0

DARK

LIGHT

RED 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1023

R0 R1 R2 R3 R4 R5 R6 R7 R8 R9 G0 G1 G2 G3 G4 G5 G6 G7 G8 G9 B0 B1 B2 B3 B4 B5 B6 B7 B8 B

1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1

0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R2

↑

: : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : :

↓

1 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1021

0 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 R1022

RED GREEN BLUE

GRAY

SCALE

LEVEL

9

R3~

R1020

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G0

0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G1

GRAY

SCALE

OF

GREEN

GRAY

SCALE

OF

BLUE

DARK

LIGHT

GREEN 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 G1023

BLACK 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 B0

DARK

LIGHT

BLUE 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 B1023

0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 G2

↑

: : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : :

↓

0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 G1021

0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 0 0 0 0 0 0 0 0 0 0 G1022

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 B1

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 B2

↑

: : : : : : : : : : : : : : : : : :

: : : : : : : : : : : : : : : : : :

↓

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 0 1 1 1 1 1 1 1 1 B1021

0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 B1022

Note) Definition of Gray :

Rn : Red Gray, Gn : Green Gray, Bn : Blue Gray (n = Gray level)

Input Signal : 0 = Low level voltage, 1 = High level voltage

G3~

G1020

B3~

B1020

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

17/36

Page 17

6. EDID Information

6.1 EEPROM Data

EEPROM Data

No Item Spec Address Data Remark

Panel Product

1

Vender

2 Screen Size 32 01 20

3 H-Resolution 1366 02,03 05,56

4 V-Resolution 768 04,05 03,00

Vertical

5

Frequency

6 Data Format 8bit 07 01 - Note 3

FRC Revision

7

Information

8 Part Number LTY320AN0501 E0~EB

※ Note 1. ※ Note 2. ※ Note 3.

Data Panel Vender Code

00 HDLCD(SDC)

HDLCD 00 00

50/60Hz 06 00 - Note 2

1st ED 00

4C,54,59,33,32,30,

41,4E,30,35,30,31

Data V-Frequency

00 50/60Hz

Data Data Format

00 6Bit

SONY Choice

- Note 5, 6

- Note 1

16進

16進

16進

ASCII

- Note 4

ASCII

01 Others

02 Others

03 Others

04 Others

05 Others

※ Note 4.

- FRC Revision Code will be Changed from “00” to “41” (A)

When FRC IC is changed. At First MP. This Code will be “00”

※ Note 5.

- LTY[Z]XXXXXXX Only for SDC Model

※ Note 6.

- Rest of them must be “00” (Null)

01 100/120HZ

02 200/240Hz

01 8Bit

02 10Bit

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

18/36

Page 18

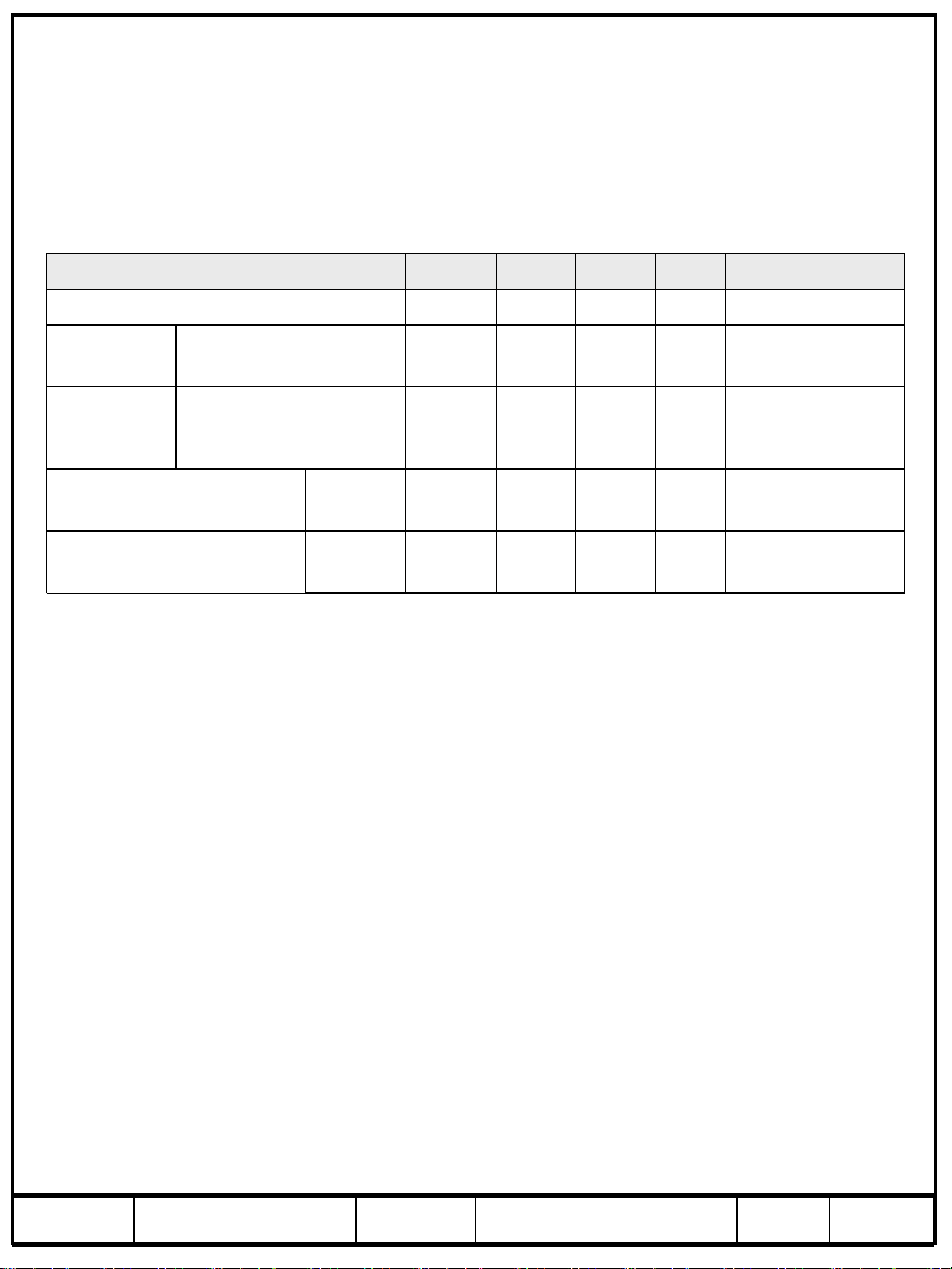

6.2 EEPROM Data Map

0 1 2 3 4 5 6 7 8 9 A B C D E F

0 00 20 05 56 03 00 00 01 00 00 00 00 00 00 00 00

1 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

2 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

3 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

4 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

5 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

6 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

7 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

8 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

9 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

A 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

B 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

C 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

D 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

E 4C 54 59 33 32 30 41 4E 30 35 30 31 00 00 00 00

F 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

19/36

Page 19

7. Interface Timing

7.1 Timing Parameters ( DE only mode )

SIGNAL ITEM SYMBOL MIN. TYP. MAX. Unit NOTE

Clock

Hsync F

Frequency

Vsync F

1/T

C

H

V

65 80 86 MHz 45 48.6 53 KHz -

47 60 63 Hz -

Active

Vertical

Display

Period

T

VD

768 768 768 lines -

Display Term

Vertical

Total

T

VB

775 810 1300 Lines -

Active

Horizontal

Display

Period

T

HD

1366 1366 1366 clocks -

Display Term

Horizontal

Total

T

H

1450 1648 2000 clocks -

Note) This product is DE only mode. The input of Hsync & Vsync signal does

not have an effect on normal operation.

(1) Test Point : TTL control signal and CLK at LVDS Tx input terminal in system

(2) Internal VDD = 3.3V

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

20/36

Page 20

7.2 Timing diagrams of interface signal ( DE only mode )

TV

DE

DE

DCLK

DATA

SIGNALS

TVD

TVB

TH

THD

TC

TC

TCH

DCLK

TDS TDH

DISPLAY

DATA

TES

DE

TCL

0.5

V

0.5

V

CC

0.5

V

CC

CC

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

21/36

Page 21

7.3 Power ON/OFF Sequence

To prevent a latch-up or DC operation of the LCD Module, the power on/off

sequence should be as the diagram below.

The supply voltage of the external system for the Module input should be the same

as the definition of VDD.

Apply the lamp voltage within the LCD operation range. When the back light turns on

before the LCD operation or the LCD turns off before the back light turns off,

the display may momentarily show abnormal screen.

In case of VDD = off level,

please keep the level of input signals low or keep a high impedance.

T4 should be measured after the Module has been fully discharged between power off

and on period.

Interface signal should not be kept at high impedance when the power is on.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

22/36

Page 22

8.1 Outline Dimension

a. Front View

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

23/36

Page 23

8.1 Outline Dimension

b. Rear View

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

24/36

Page 24

8.1 Outline dimension (Stud and Tap Type)

4

3

6

10

21 22

23 24

2 1 3

4

7

8

11

1 2 3 4

14

15

15

12

25

16

13

26

1

5

9

1

5

17 18

5

19

6 7

:M4 tap (8 pcs)

:M3 tap (28 pcs)

27 28

6

8 7

8

20

:M3 stud (8 pcs)

:M4 stud (1 pc)

2

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

25/36

Page 25

8.1 Outline dimension (Dowel Type)

1 2

3

8

1

8 9

2

10

4

9

6

5

:Type B1 (11 pcs)

:Type B2 (1 pc)

11

1

7

:Type B3 (2 pcs)

:Type S1 (2 pcs)

2

1

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

26/36

Page 26

8.2 General item

●General tolerance

Distance (mm) X ≤ 16

Tolerance ±0.1 ±0.2 ±0.3 ±0.45 ±0.6 ±0.8 ±1°

16 < X ≤ 64 64 < X ≤ 256 256 <X≤ 512 512 <X≤ 1024 1024 < X

●Black matrix

D

B

C

E

|B-C|

|D-E|

1

Max 2

2

Max 2

F G

|F-G|

3

Max 2

Bending

Angle

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

27/36

Page 27

⊥

φ0.5

A

8.3 Stud

●Stud dimension

- M3 stud

●Stud durability

Stud

Type

M3

M4 0.42(43) 2.9(30)

M5 0.42(43) 5.9(60)

M6 0.84(86) 5.9(60)

Base

Material

Al

SECC

Extraction Force

kN(kgf)

Min Min

0.25(25) 2.1(21)

Extraction Force

●Stud squareness tolerance

Torque

N・m(kgf・cm)

Torque

(with screw)

Stud

Base Material

A

STUD center line

Vertical cylinder to A

Datum A

φ0.5

*) STUD center line

should be in the vertical

cylinder of φ0.5 to A.

Squareness definition

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

28/36

Page 28

8.4 Dowel and Tap

●Dowel dimension and durability

Shearing force ≧ 50N

[D]±0.1

[mm]

Type Part Dim [D] Dim [H]

B1 BACK CHASSIS 4.2 1.5 0.5

B2 BACK CHASSIS 3.7 1.5 0.5

B3 BACK CHASSIS 6.0 3.0 1.0

S1 SOURCE SHIELD (R) 4.2 0.7 0.3

S2 SOURCE SHIELD (L) 4.2 0.9 0.3

※

●Tap dimension

[S] is guaranteed by JIG inspection presented by MIF, not by value.

Dim [S]

※

[S]

[H]±0.15

Straight end

- Thread compliant to ISO class 6H

●Tap durability

■The screw torque must satisfy the following.

M3 : 0.7N・m X 10 times

M4 : 1.0N・m X 10 times

※Standard driver : Nitto Kohki / Delvo DLV8231-EJN

■Evaluate all of burring tap using following board.

M3 Burring : Board thickness t1.2 / Hole size φ4

M4 Burring : Board thickness t0.8 / Hole size φ6

Screw(M3/M4) with spring and washer

・M3 : Φ5.3 x t0.7 spring + Φ6 x t0.5 washer (ISO compliant)

・M4 : Φ6.8 x t1.0 spring + Φ8 x t0.8 washer (ISO compliant)

Evaluated Burring

Using Board with hole.

(M3: t1.2 φ4/M4:t0.8 φ6)

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

29/36

Page 29

9. EMI Specification

: -3dB at CISPR22 Class B

This EMI Recommendation is recommended to be measured as SET Condition.

10. UL Approval

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

30/36

Page 30

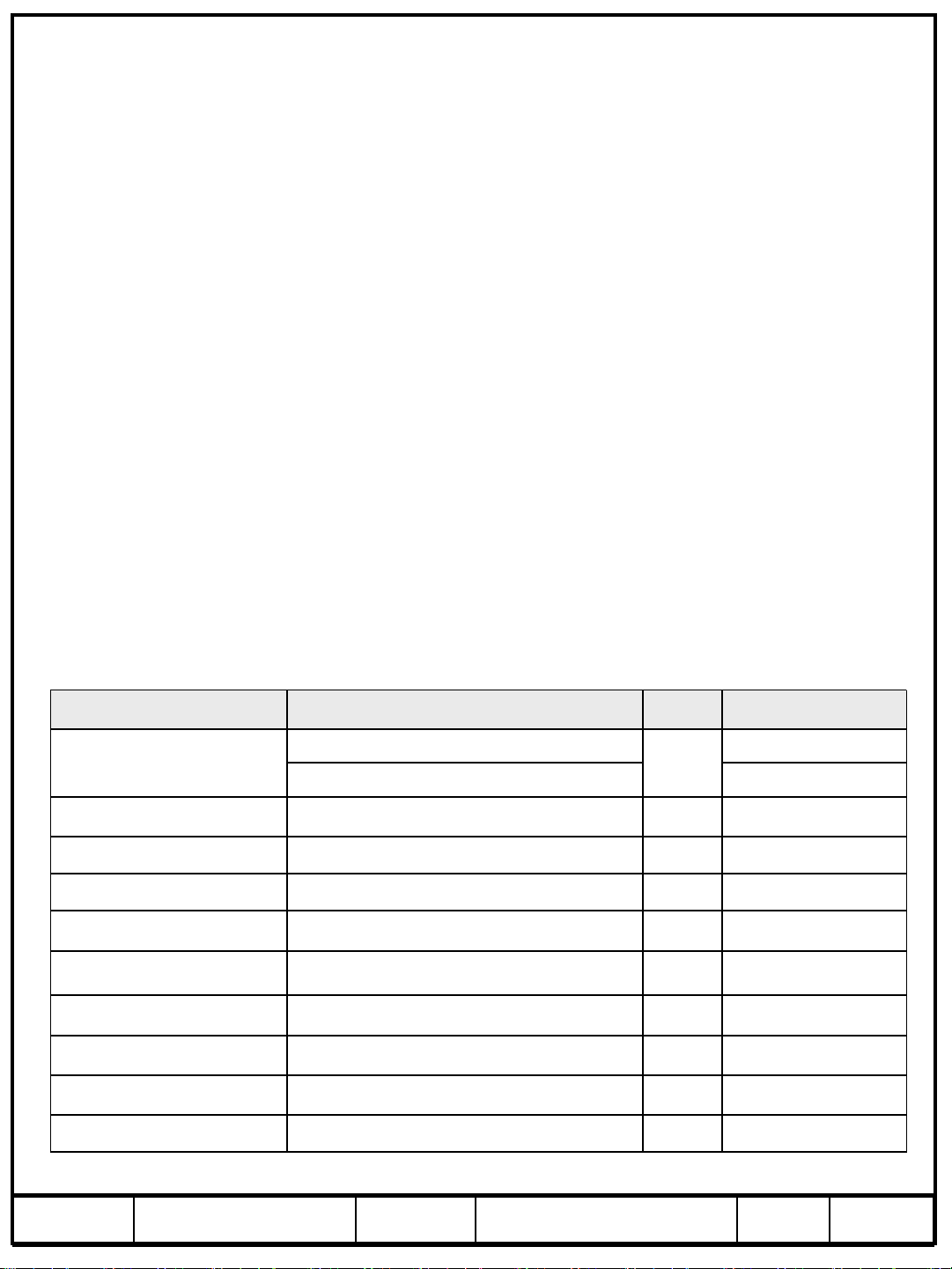

11. Reliability Test

Item Test condition Quantity

Temperature

Step Stress

HTOL

LTOL

RTOL

HTS

LTS

THB

WHTS

T/C

ESD

(non-operation)

ESD(operation)

Input Con. ESD

0 ∼ 50℃,439Cycle determination

50℃, 1000hr (500hr determination)

0℃, 1000hr (500hr determination)

20 ℃, continue ~

70℃, 1000hr (500hr determination)

-30℃,1000hr (500hr determination)

40℃ / 95%RH,1000hr (500hr determination)

60℃ / 75%RH, 1000hr (500hr determination)

-20 ℃ ~ 60 ℃, 200cycle (100cycle determination)

±10 kV,200㎊/100 Ω,9Point,3times/Point

contact : ±8 kV ,150㎊/330Ω,210Point,1 time/Point

non-contact : ±15 kV,150㎊/330Ω,100Point,1 time/Point

contact : ±2kV,200㎊/100,Input Con.Pin,3 times/Pin

4EA

8EA

4EA

4EA

4EA

4EA

4EA

4EA

4EA

3EA

3EA

3EA

POWER

ON/OFF

Vibration 10~300Hz/1.5G/10minSR, XYZ, 30min/axis 3EA

Shock

PALLET

Vibration

PALLET Drop 20cm, Bottom, Front, Rear 1times 26EA (1BOX)

30sec (on) / 30sec(off) : 12,000 times 4EA

Condition : 11msec, ±XY Z 1time/axis 50G

1.05 Grms, 2~200Hz, Random, Z axis 1Hr 26EA (1BOX)

3EA

[ Result Evaluation Criteria]

Under the display quality test conditions with normal operation state, these shall

be no change which may affect practical display function.

HTOL/ LTOL : High/Low Temperature Operating Life,

THB : Temperature Humidity Bias

HTS/LTS : High/Low Temperature Storage

WHTS : Wet High Temperature Storage

[Moving Distance Assurance]

This test is assumed that ground moving distance is 1000km.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

31/36

Page 31

12. PACKING

12.1 CARTON (Internal Package)

(1) Packing Form

Corrugated fiberboard box and corrugated cardboard as shock absorber

(2) Packing Method

Packing Box

Module(52EA)

Pallet

→ Direction be able to Open

12.2 Packing Specification

Item Specification Remark

LCD Packing

Desiccant (Drier) 4ea / LCD 10g/ea, Cobalt-dichloride-free

Pallet 2Box / Pallet Pallet weight : 5.3kg

Packing Direction Vertical -

Total Pallet Size L x W x Height 1150mm x 850mm x 1085mm

Total Pallet Weight 297kg

Stack Layer

Shielding Bag

26ea / (Packing Box)

3 layer in warehouse.

2 layer in container.

Compound PE /

Sealing / 70㎛

1. 260kg/LCD(52ea)

2. 30kg/Packing Box(2set)

3. Packing Box Material : Paper

Pallet(5.3kg) + Module( 52 x 5kg = 260kg) +

Packing BOX(15 x 2 = 30kg) +

Desiccant(0.03kg x 52 = 1.56kg)

Material / Adhesive tape / Thickness

POL Protection

Film

PET / 0.125mm Material / Thickness

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

32/36

Page 32

0703

13. MARKING & OTHERS

A nameplate bearing followed by is affixed to a shipped product at the specified

location on each product.

(1) Parts number : LTY[Z]320AN05-XXX

(2) Revision: One letters

(3) Lot number : X X X X XXX XX X

Cell Position No. (In the Glass)

Glass No. (In the one Lot)

Lot No. (Glass)

Month

Year (Note1)

Product code

(4) Nameplate Indication

LTY[Z]320AN05

XXXXXX

XXXXXXXXXX xxx

Line

Week code : 05 29

40mm

Revision code

week

year

LTY[Z]320AN05XXX

80mm

(5) Packing box attach

100mm

LTY[Z]320AN05-XXX

XXX

Lot number

Part number

Revision code

52

Box serial number

(6) Others

1. After service part

Lamps cannot be replaced because of the narrow bezel structure.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

33/36

Page 33

14. General Precautions

14.1 Handling

(a) When the Module is assembled, it should be attached to the system firmly

using all mounting holes. Be careful not to twist and bend the Module.

(b) Because the inverter use high voltage, it should be disconnected from power

before it is assembled or disassembled.

(c) Refrain from strong mechanical shock and / or any force to the Module.

In addition to damage, this may cause improper operation or damage to the Module

and back light.

(d) Note that polarizers are very fragile and could be damage easily.

Do not press or scratch the surface harder than a HB pencil lead.

(e) Wipe off water droplets or oil immediately. If you leave the droplets for a long

time, staining or discoloration may occur.

(f) If the surface of the polarizer is dirty, clean it using absorbent cotton or soft cloth.

(g) Desirable cleaners are water, IPA(Isopropyl Alcohol) or Hexane.

Do not use Ketone type materials(ex. Acetone), Ethyl alcohol, Toluene, Ethyl acid

or Methyl chloride. It might permanent damage to the polarizer due to chemical

reaction.

(h) If the liquid crystal material leaks from the panel, it should be kept away

from the eyes or mouth . In case of contact with hands, legs or clothes, it must

be washed away with soap thoroughly.

(i) Protect the Module from static, or the CMOS Gate Array IC would be damaged.

(j) Use finger-stalls with soft gloves in order to keep display clean during the

incoming inspection and assembly process.

(k) Do not disassemble the Module.

(l) Do not pull or fold the LED FFC.

(m) Do not adjust the variable resistor located on the Module.

(n) Protection film for polarizer on the Module should be slowly peeled off just before use

so that the electrostatic charge can be minimized.

(o) Pins of I/F connector should not be touched directly with bare hands.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

34/36

Page 34

14.2 Storage

(a) Do not leave the Module in high temperature, and high humidity for a long time.

It is highly recommended to store the Module with temperature from 5 to 40℃

and relative humidity of less than 70%.

(b) Do not store the TFT-LCD Module in direct sunlight.

(c) The Module should be stored in a dark place. It is prohibited to apply sunlight or

fluorescent light in storing.

(d) Storage period is recommended not to exceed 1 year.

14.3 Operation

(a) No Connection or disconnect the Module in the "Power On" condition.

(b) Power supply should always be turned on/off by the "Power on/off sequence"

(c) Module has high frequency circuits. Sufficient suppression to the electromagnetic

interference should be done by system manufacturers. Grounding and shielding methods

may be important to minimize the interference.

(d) The cable between the back light connector and its Converter power supply should

be connected directly with a minimized length. A longer cable between

the back light and the inverter may cause lower luminance of LED and

may require higher startup voltage(Vs).

14.4 Operation Condition Guide

(a) The LCD product should be operated under normal conditions.

Normal condition is defined as below;

- Temperature : 20±15℃

- Humidity : 55±20%

- Display pattern : continually changing pattern (Not stationary)

(b) If the product will be used in extreme conditions such as high temperature,

humidity, display patterns or operation time etc.., It is strongly recommended

to contact SDC for Application engineering advice. Otherwise, its reliability and

function may not be guaranteed. Extreme conditions are commonly found at

Airports, Transit Stations, Banks, Stock market, and Controlling systems.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

35/36

Page 35

14.5 Others

(a) Ultra-violet ray filter is necessary for outdoor operation.

(b) Avoid condensation of water. It may result in improper operation or disconnection

of electrode.

(c) Do not exceed the absolute maximum rating value. ( supply voltage variation,

input voltage variation, variation in part contents and environmental temperature,

and so on)

Otherwise the Module may be damaged.

(d) If the Module keeps displaying the same pattern for a long period of time,

the image may be "sticked" to the screen.

To avoid image sticking, it is recommended to use a screen saver.

(e) This Module has its circuitry PCB's on the rear side and should be handled

carefully in order not to be stressed.

(f) Please contact SDC in advance when you display the same pattern for a long time.

MODEL LTY[Z]320AN05 Doc. No 05-002-S-121017 Page

36/36

Loading...

Loading...