Samsung HPL5025X service manual

PLASMA DISPLAY TV

Chassis : D52A

Model: HPL5025X/XAA

PPM50H2X/XAA

PLASMA DIAPLAY TV CONTENTS

Precautions

Reference Information

Specifications

Exploded View and Parts List

Alignment and Adjustments

Circuit Operation Description

Troubleshooting

Handling Description

Wiring Diagram

Electric Parts List

Glossary

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

ELECTRONICS

© Samsung Electronics Co., Ltd. SEP. 2001

Printed in Korea

AA68-

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between fornt cabinet and back

cabinet, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

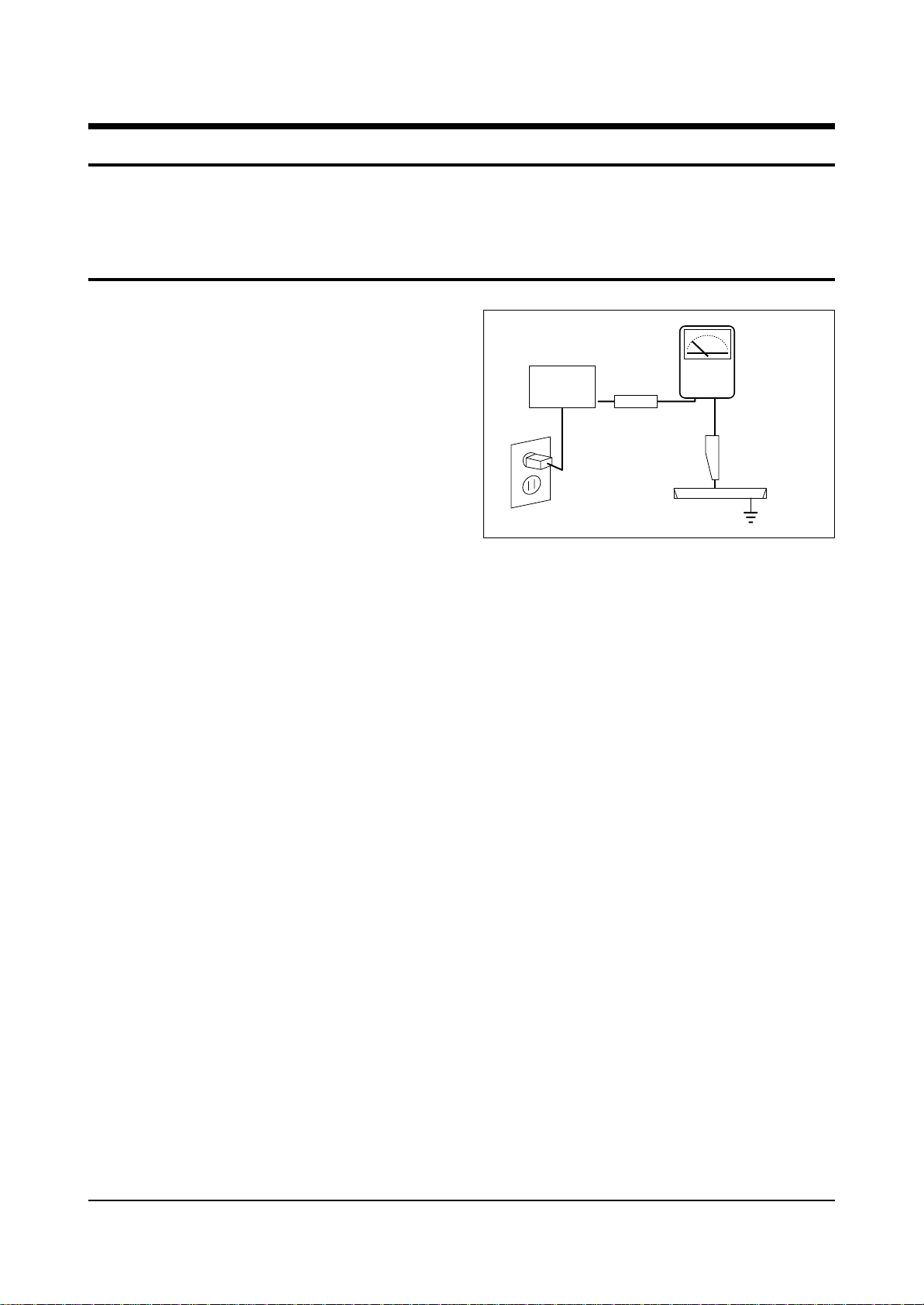

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1950.5.2).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 3.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

Precautions

Samsung Electronics 1-1

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

3-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

(READING SHOULD

NOT BE ABOVE

3.5mA)

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-2 Safety Precautions (Continued)

7. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

8. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

9. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

10. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

11. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

12. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or overheating, and correct any potential hazards.

13. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

14. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original—even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

15. Littum battery replace warning:

Danger of explosion if battery is incorrectly

replaced, Replace only with the same or

eqivalent type.

Precautions

1-2 Samsung Electronics

“CAUTION, Double-pole/neutral fusing”

CAUTION

Danger of explosion if battery is incorrectly

replaced.

Replace only with the same or equivalent type

recommended by the manufacturer.

Dispose of used batteries according to the manufacturer’s instructions.

1-3 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to: (a)

Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

7. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

8. Plasma display panels have partial afterimages when a same picture continues to be displayed for a certain time. This happens due to

the degradation of brightness caused by a

scale-down effect.

To prevent such afterimages when displaying

a same picture for a certain time, be sure to

reduce the level of brightness and contrast.

ex) Contrast : 50 or 75, Brightness : 25

9. Plasma display is an array of pixels(cells).

Therefore, if at least 99.9% pixels keep normal,

the appropriate panel is judged as ‘approved

product.’ Even though some of pixels keep

luminescent or always light off, do not worry

because the panel is approved.

Precautions

Samsung Electronics 1-3

Warning 1 : First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a

conflict between the servicing and safety precautions, always follow the safety precautions.

Warning 2 : An electrolytic capacitor installed with the wrong polarity might explode.

1-4 Precautions for Electrostatically Sensitive Devices (ESDs)

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4 Samsung Electronics

CAUTION

These servicing instructions are for use by

qualified service personnel only.

To reduce the risk of electric shock do not

perform any servicing other than that contained

in the operating instructions unless you are

qualified to do so.

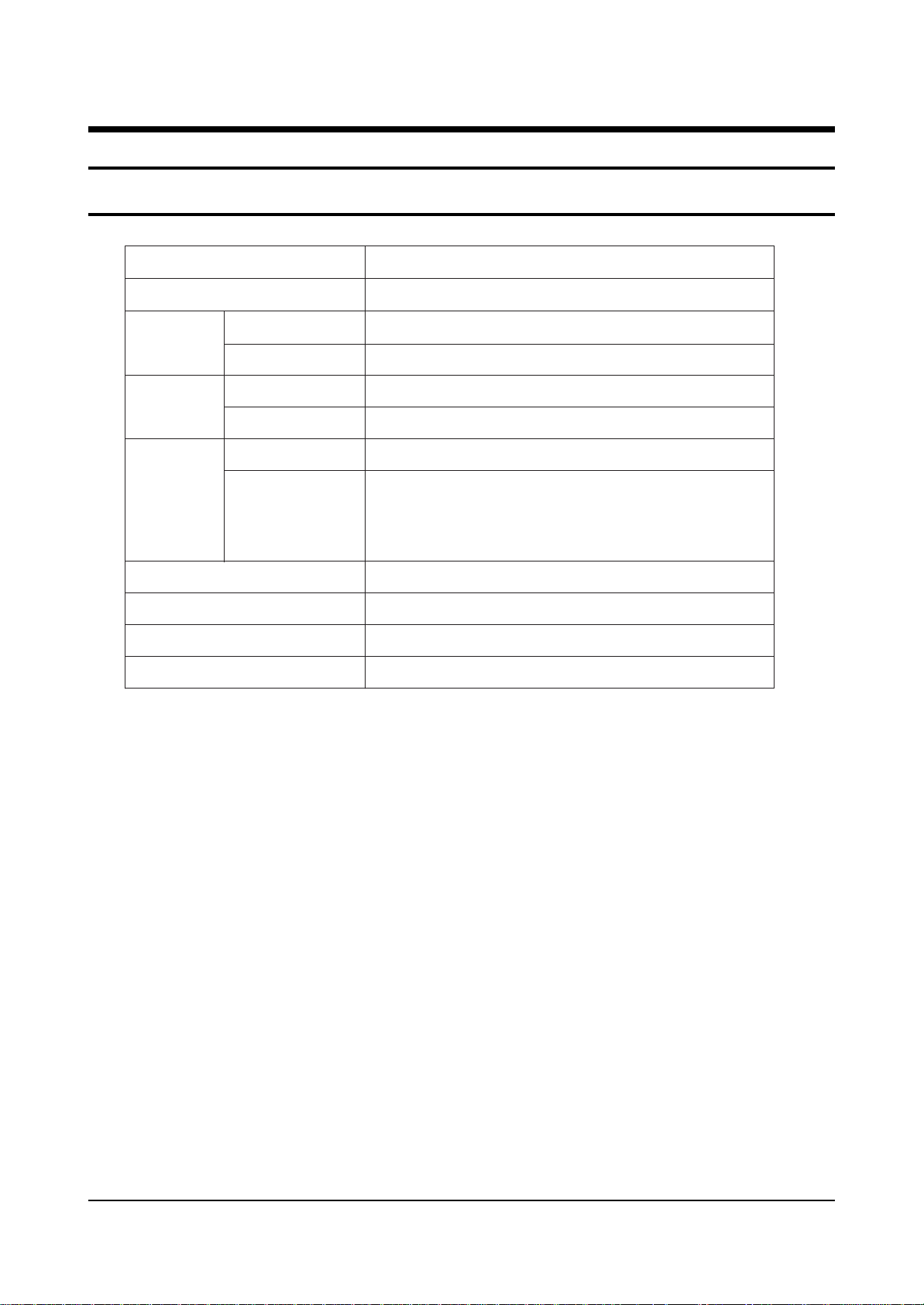

Specifications

Samsung Electronics 3-1

3. Specifications

MODEL

SCREEN SIZE

3-1 Display(PDP Monitor)

Display

Remote Control

Display

Remote Control

Front

Back

Power Supply

Power Consumption

Screen Size

Adjustment System

Dimensions

(mm/inch)

Terminal

In/Out

Terminals

HPL5025/PPM50H2

16:9

1208.5(W) x 89(D) x 724(H) mm/47.58(W) x 3.5(D) x 28.50(H) Inches

54(W) x 31.5(D) x 220(H)mm/2.13(W) x 1.24(D) x 8.66(H) Inches

42Kg/92.59Ibs

150g/0.33Ibs

POWER Button, SOURCE, MENU, VOLUME, SELECT, MUTE

Exrernal Speaker Out, RGB1In (mD-Sub 15pin), RGB2 In(BNC jack)

SD/HD Cpmponent Video In, VIDEO In, S-VHS In,

Audio In(Video, Component, PC), RC-2332C In,

RS-232C Out (PPM50H2 Only), AC 120V

AC120V 60Hz

540W

1106.5(H) x 622(V)/43.56 x 24.49

Electronic Function Adjustment

Specifications

3-2 Samsung Electronics

MENO

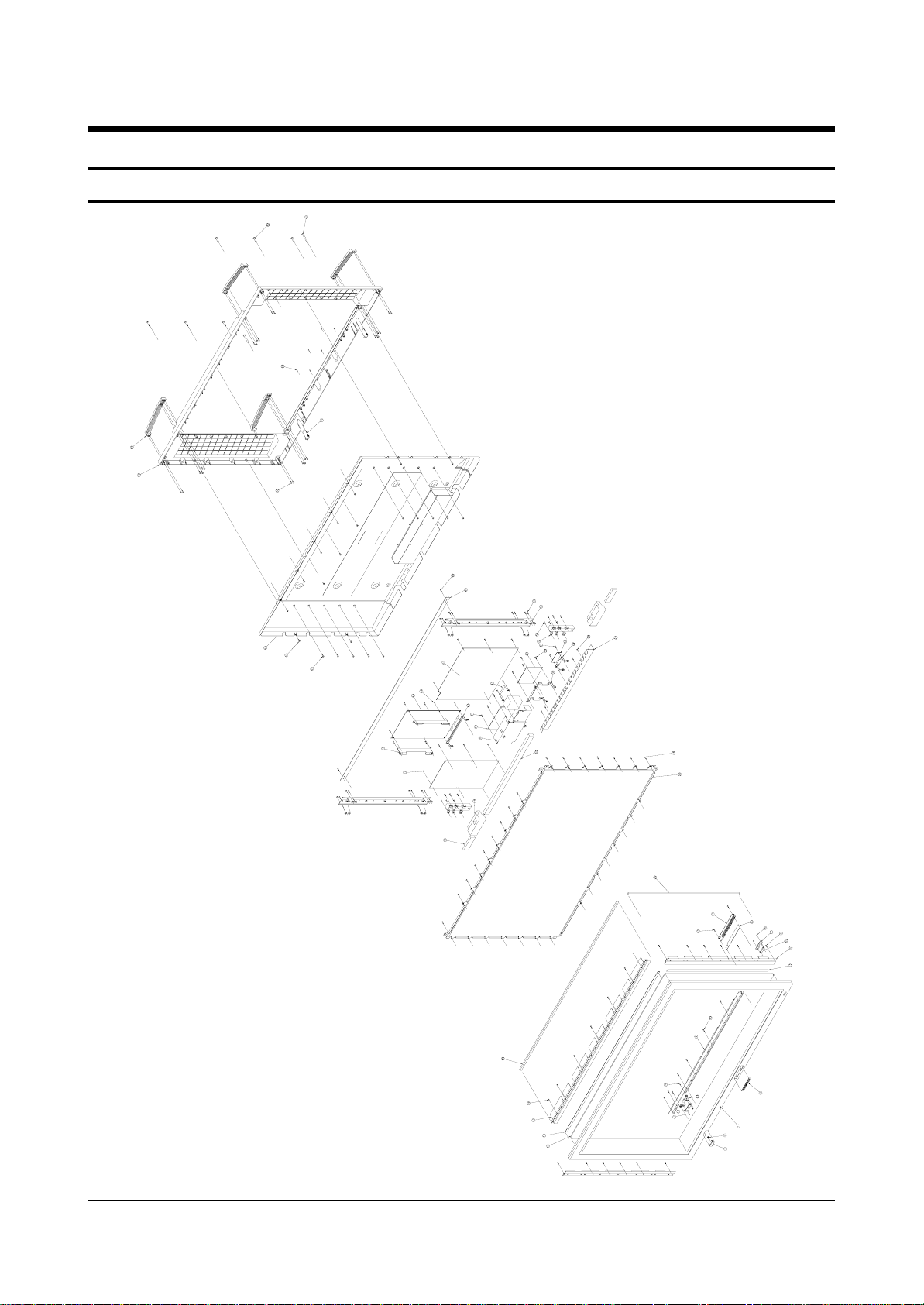

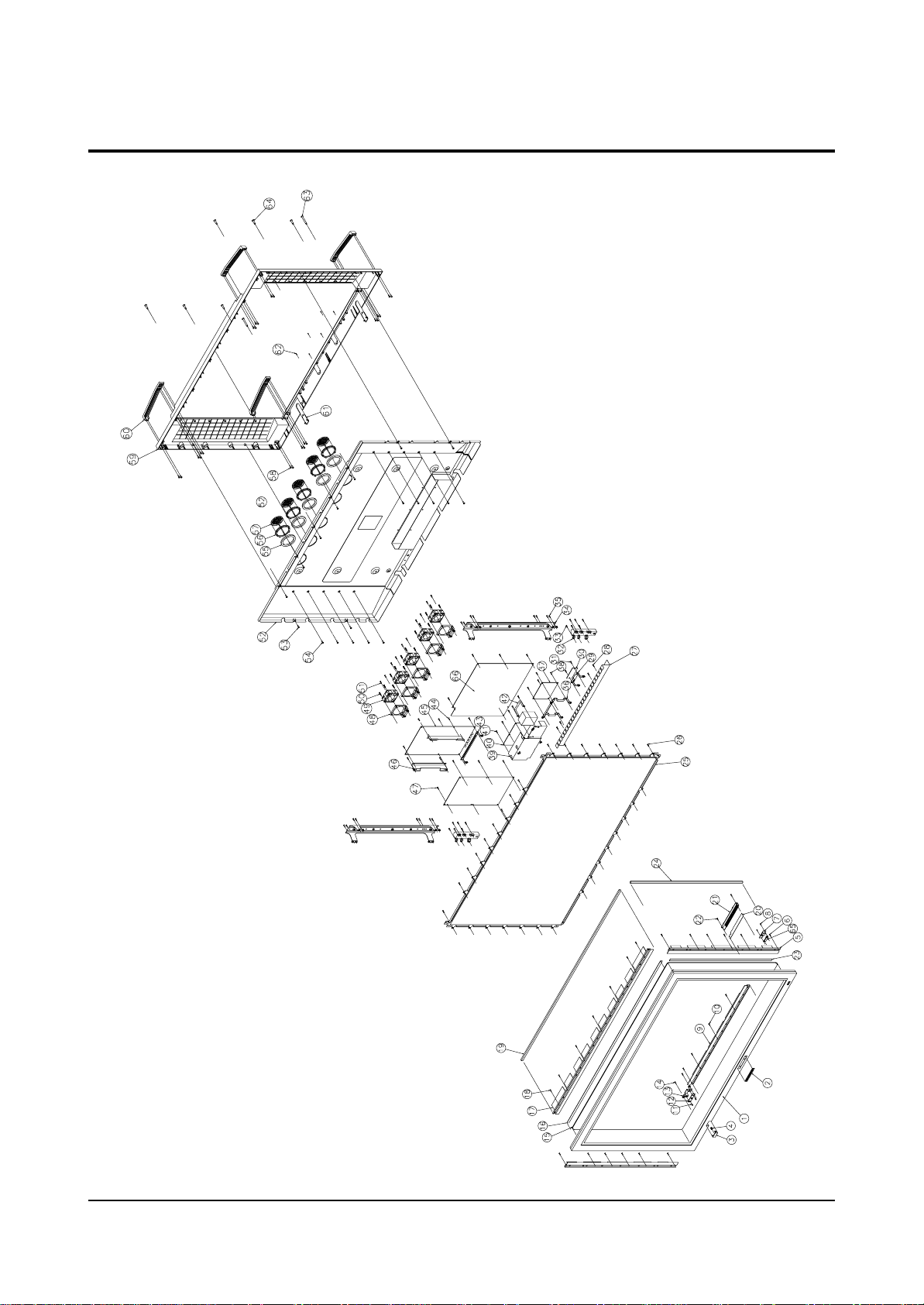

Exploded View and Parts List

Samsung Electronics 4-1

4. Exploded View and Parts List

4-1 HPL5025X/XAA

Exploded View and Parts List

4-2 Samsung Electronics

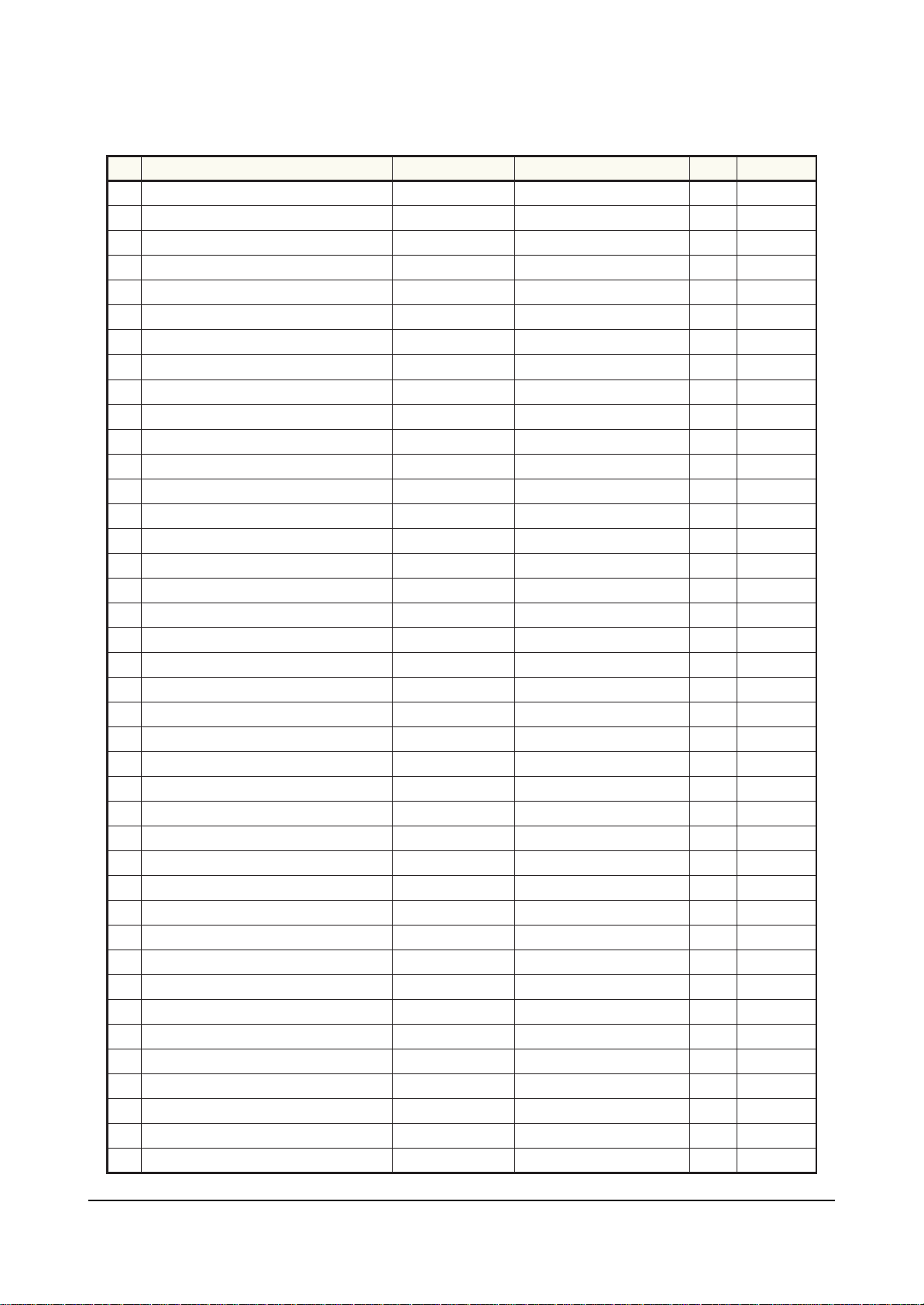

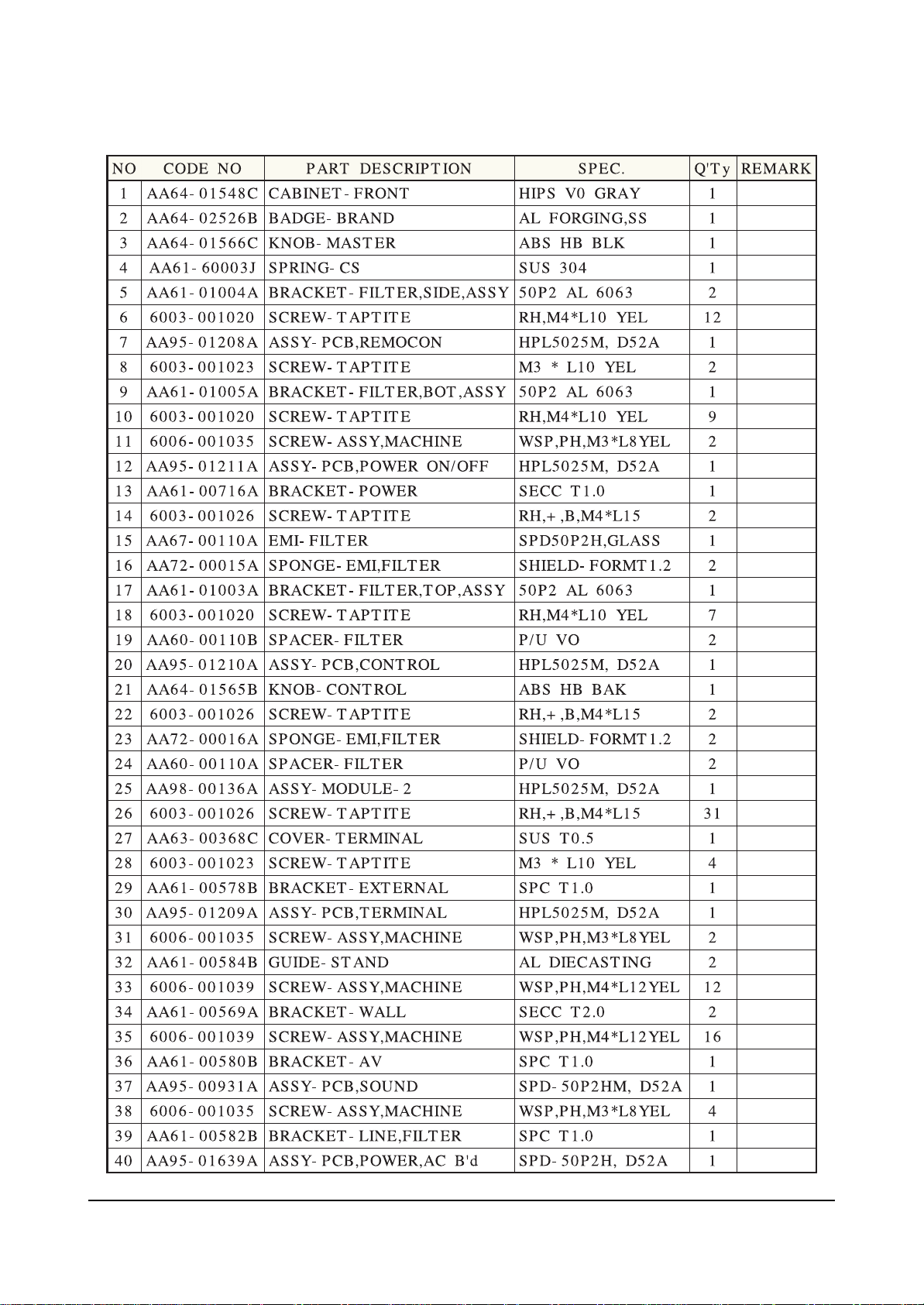

NO PART DESCRIPTION CODE NO SPEC. Q’Ty REMARK

1 CABIN ET- FRONT AA64- 01548B HIPS V0 GRAY 1

2 BADGE - BRAND AA64- 01560B AL FORGING,SS 1

3 KNOB- MASTE R AA64-0 1566B ABS H B BLK 1

4 SPRING-CS AA61- 60003J SUS 304 1

5 BRACKET- F ILT ER,SIDE,ASSY AA61- 01004A 50P2 AL 6063 2

6 SCREW- T APTITE 6003-001020 RH,M4 *L10 YEL 12

7 ASSY- P CB,REMOCON AA95- 01208A D52A 1

8 SCREW- T APTITE 6003-001023 M3 * L 10 YEL 2

9 BRACKE T- FILT E R,BOT,ASS Y AA61- 01005A 50P2 AL 6063 1

10 SCREW- T APT ITE 6003- 001020 RH ,M4*L10 YEL 9

11 SCREW- ASSY,MACHINE 6006- 001035 WSP,PH,M3*L8YEL 2

12 ASSY- PCB,POWER ON/OFF AA95- 01211A HPL5025M,D52A 1

13 BRACKET - POWER AA61- 00716A SECC T 1 .0 1

14 SCREW- T APT ITE 6003- 001026 RH,+ ,B,M4 *L15 2

15 EMI- F ILTER AA95- 01207A HPL5025M,D52A 1

16 SPONGE- EMI,FILTER AA72- 00015A SHIELD-FORMT1 .2 2

17 BRACKET - FILTE R,T OP ,ASS Y AA61- 01003A 50P2 AL 6063 1

18 SCREW- T APT ITE 6003- 001020 RH ,M4*L10 YEL 7

19 SP ACER- FILTER AA60- 00110B P/U VO 2

20 ASS Y- P CB,CONTROL AA95- 01210A HPL5025M,D52A 1

21 KNOB- CON T ROL AA64- 01565B ABS HB BAK 1

22 SCREW- T APT ITE 6003- 001026 RH,+ ,B,M4 *L15 2

23 SPONGE- EMI,FILTER AA72- 00016A SHIELD-FORMT1 .2 2

24 SP ACER- FILTER AA60- 00110A P/U VO 2

25 ASSY- MODULE- 3 AA98- 00136A HPL5025M,D52A 1

26 SCREW- T APT ITE 6003- 001026 RH,+ ,B,M4 *L15 31

27 COVER- TERMINAL AA63- 00368B SUS T0 .5 1

28 SCREW- T APT ITE 6003- 001023 M3 * L10 YEL 4

29 B RAC K ET- E XTERNAL AA61- 00578B SPC T 1.0 1

30 ASSY- PCB,TERMINAL AA95- 01209A HPL5025M,D52A 1

31 SCREW- ASSY,MACHINE 6006- 001035 WSP,PH,M3*L8YEL 2

32 GU IDE- S TAND AA61- 00584B AL DIEC ASTIN G 2

33 SCREW- ASSY,MACHINE 6006- 001039 WSP,PH,M4*L12YEL 12

34 BRACKET - WALL AA61-00569A SECC T 2.0 2

35 SCREW- ASSY,MACHINE 6006- 001039 WSP,PH,M4*L12YEL 16

36 B RAC K ET- AV AA61- 00580B SPC T 1.0 1

37 ASSY- PCB,SOUND AA95- 00931A SPD- 50P2HM,D52A 1

38 SCREW- ASSY,MACHINE 6006- 001035 WSP,PH,M3*L8YEL 4

39 BRACKET - LINE,F ILT ER AA61- 00582B SPC T1 .0 1

40 ASS Y- P CB,POWER,AC B’d AA95- 01212A HPL5025M,D52A 1

Samsung Electronics 4-3

Exploded View and Parts List

NO PART DESCRIPTION CODE N O SPEC. Q’Ty REMARK

41 SCREW- ASSY,MACHINE 6006-001035 WSP,PH,M3*L8YEL 10

42 BRACKET- NOISE,F ILT ER AA61- 00589B SUS T 0.5 1

43 BRACK ET- SCALE R, SU B AA61-0 0581B SPC T 0.5 1

44 SCREW- ASSY,MACHINE 6006-001035 WSP,PH,M3*L8YEL 6

45 ASSY- P CB,MAIN(OPT) AA94- 05542A HPL5025M,D52A 1

46 BRACK ET- SCALE R, MAIN AA61- 00573B SPC T 1 .0 2

47 SCREW- ASSY,MACHINE 6006-001035 WSP,PH,M3*L8YEL 6

48 BRACKET- F AN,BASE AA61- 005 79B SECC T 1.6 5

49 FAN

50 SCREW- ASSY,MACHINE 6006-001017 WSP,PH,M4*L35YEL 10

51 SCREW- ASSY,MACHINE 6006-001035 WSP,PH,M3*L8YEL 10

52 COVER- BACK AA63-00364B AL 3003- 0 T 1.2 1

53 SCREW- T APT IT E 6003- 001019 M4 * L12 YEL 19

54 SCREW- T APT IT E 6003- 001020 M4 * L10 YEL 10

55 SPACER- FAN AA60- 00109A P/U FORM V0 BLK 5

56 HOLDER- F AN AA61- 00597B ABS V0 BL K 5

57 COVER- F AN AA63- 00366B SUS T 0.5 5

58 SCREW- T APT IT E 6003- 001026 M4 * L15 YEL 24

59 CABINET - BACK AA64- 01550B HIP S V0 BLK 1

60 HANDLE- SET AA64- 01551B ABS HB BLK 4

61 COVER- S ET AA63- 00365B ABS H B BLK 2

62 SCREW- ASSY,MACHINE 6006-001035 WSP,PH,M3*L8YEL 6

63 SCREW- ASSY,MACHINE 6006-001017 WSP,PH,M4*L35YEL 2

64 SCREW- ASSY,MACHINE 6006-001112 WSP,PH,M8*L16YEL 6

65 WINDOW- REMOCON AA64- 01549B ACRYL VIOLET 2:1 1

66 ASSY- P CB,SMPS,MAIN AA9 8- 00149A HPL5025M,D52A 1

Exploded View and Parts List

4-4 Samsung Electronics

4-2 PPM50H2/XAA

Samsung Electronics 4-5

Exploded View and Parts List

Exploded View and Parts List

4-6 Samsung Electronics

Alignment and Adjustments

Samsung Electronics 5-1

5. Alignment and Adjustments

5-1 Service Mode

5-1-1 SERVICE MODE ENTRY METHOD (General Transmitter)

1. Turn off the power to make the SET STAND-BY mode.

2. In order to enter the Service Mode, select MUTE-1-8-2-POWER.

Press the ‘Screen Display – Factory’ button when the system is turned on.

In case entry into SERVICE MODE is unsuccessful, repeat the procedures above.

5-1-2 Initial DISPLAY State in times of SERVICE MODE Switch overs

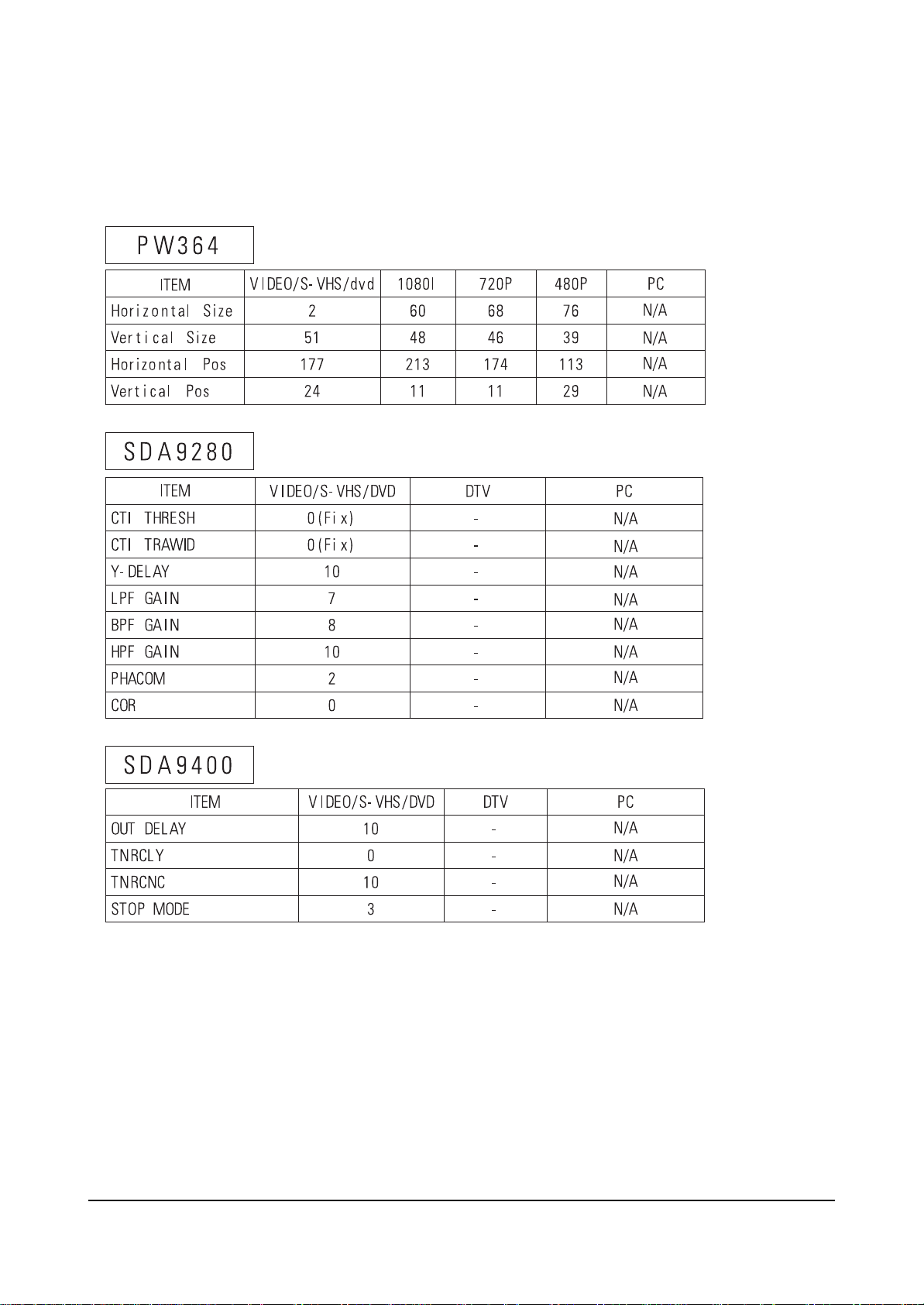

PW364

INITIAL DISPLAY

SDA928 0 VP C3230 SDA9400

1, PW

364

2, SD

A928 0

3, V

PC3230

4, SD

A940 0

5, C

XA2101

6, A

D98 84

7, O

SD POSITION

8, O

PTION

9, R

ESET

10, A

GING

H

orizont alSize

V

er tical

Horizontal

Ve r t i c a l

Si

ze

Pos

Pos

CTIT

HRESH

CTIT

RAWID

Y- D

ELAY

L

PF GAIN

B

PF GAIN

H

PF GA IN

PH

ACOM

C

OR

B

RIGHT YUV

C

ONT YUV

I

FCOMP

ChromaB

and

L

uma LPF

H

PLL Speed

L

uma Delay

3230 Bri

ght

3230 C

ontr ast

HL

PF Y/C

L

PF Chroma

HHPeak Fil

ter

PeakingG

ain

C

oaring off / on

O

UT DELA Y

TNRCLY

CLY

TNRCLC

CLY

ST

OP MODE

Alignment and Adjustments

5-2 Samsung Electronics

5-1-3 Buttons Operations within SERVICE MODE

#Notice

The existing service data may be deleted after downloading a program. Be sure to make a backup copy of

your data before downloading and then restore the data after completing the download.

Menu

Channel UP/DOWN

Volume UP/DOWN

Entire menu display

Cursor move to select items

Enable to increase and decrease the data of the selected items

Limit Level

Sys t em

D-Color

R-DRIVE

-DRIVE

G

-DRIVE

B

R-Cutoff

G-Cutoff

-C ut off

B

ABL MODE

ABL TH

HSEPSEL

CONT RAST

BRI GHT

CR OFFSET

CB

OFFSET1

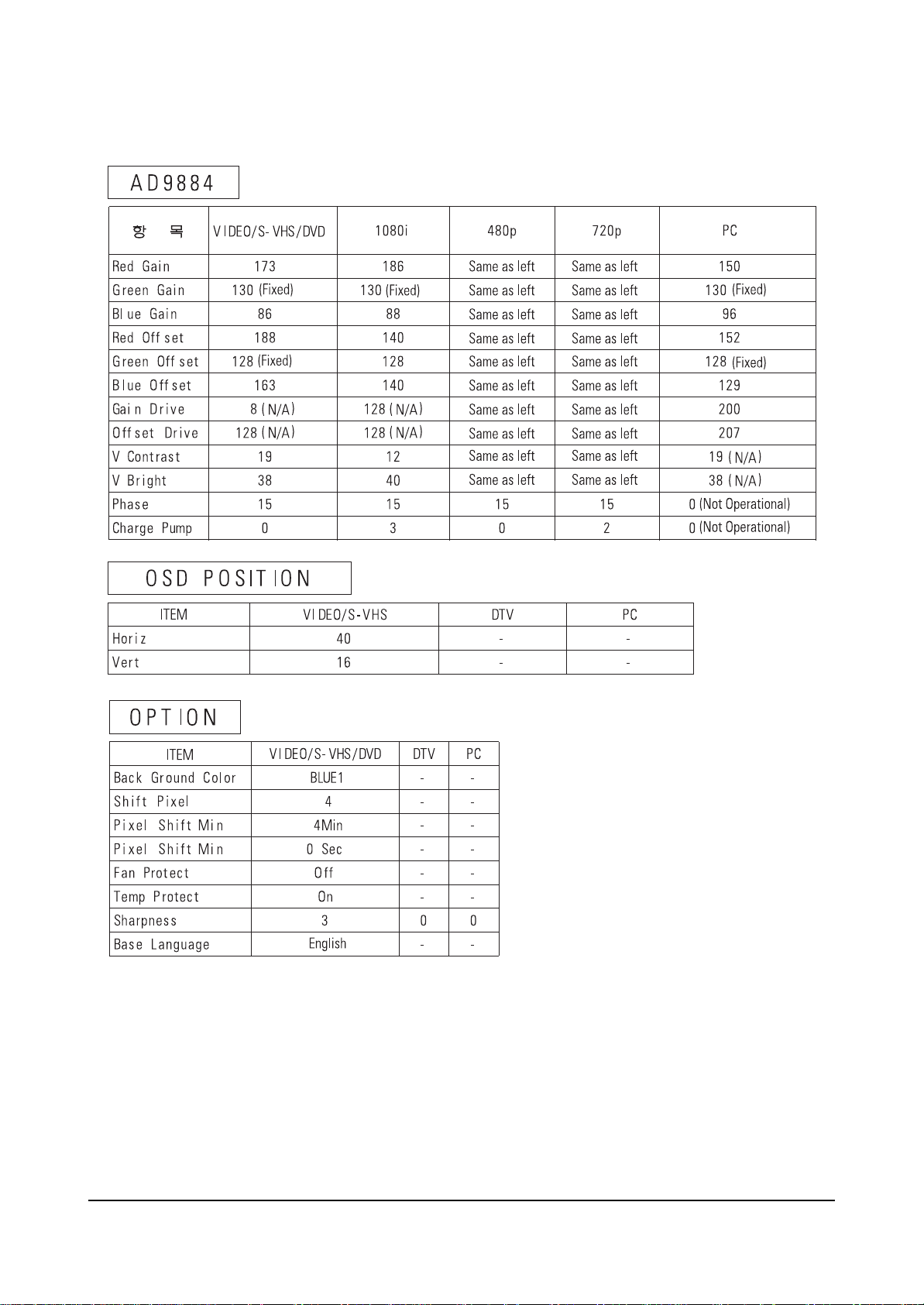

CXA2101 AD9884

DRIVE

SUB BRI GHT

SUB CONT

SUB COLOR

SUB HUE

SUB SHP

R-Y/R

R-Y/B

GG-Y/R

-Y/B

P

ABL LEVEL

SHP FO

PRE/OVER

CTI LEVEL

1

LTI LEVEL

DC -T RAN

D-PIC

RED

Gain

GREEN

BLUE

OFFSET

RED

GREEN

BLUE

GAIN DRIVE

OFFSET DIRVE

V CONTRAST

V BRIGHT

PHASE

CHANGE PUMP

Gain

Gain

OFFSET

OFFSET

OSD

POSITION

HORIZ

VE RT

OP TION

1, BACK GROUND COLOR

SHIFT P IXEL

2,

PIXEL SHIFT

3,

PIXEL SHIFT

4,

FAN PROTECT

5,

TEMP

6,

7,

8, BASE LANGUAGE

PROTECT

SHARPNESS

MIN

SEC

Alignment and Adjustments

Samsung Electronics 5-3

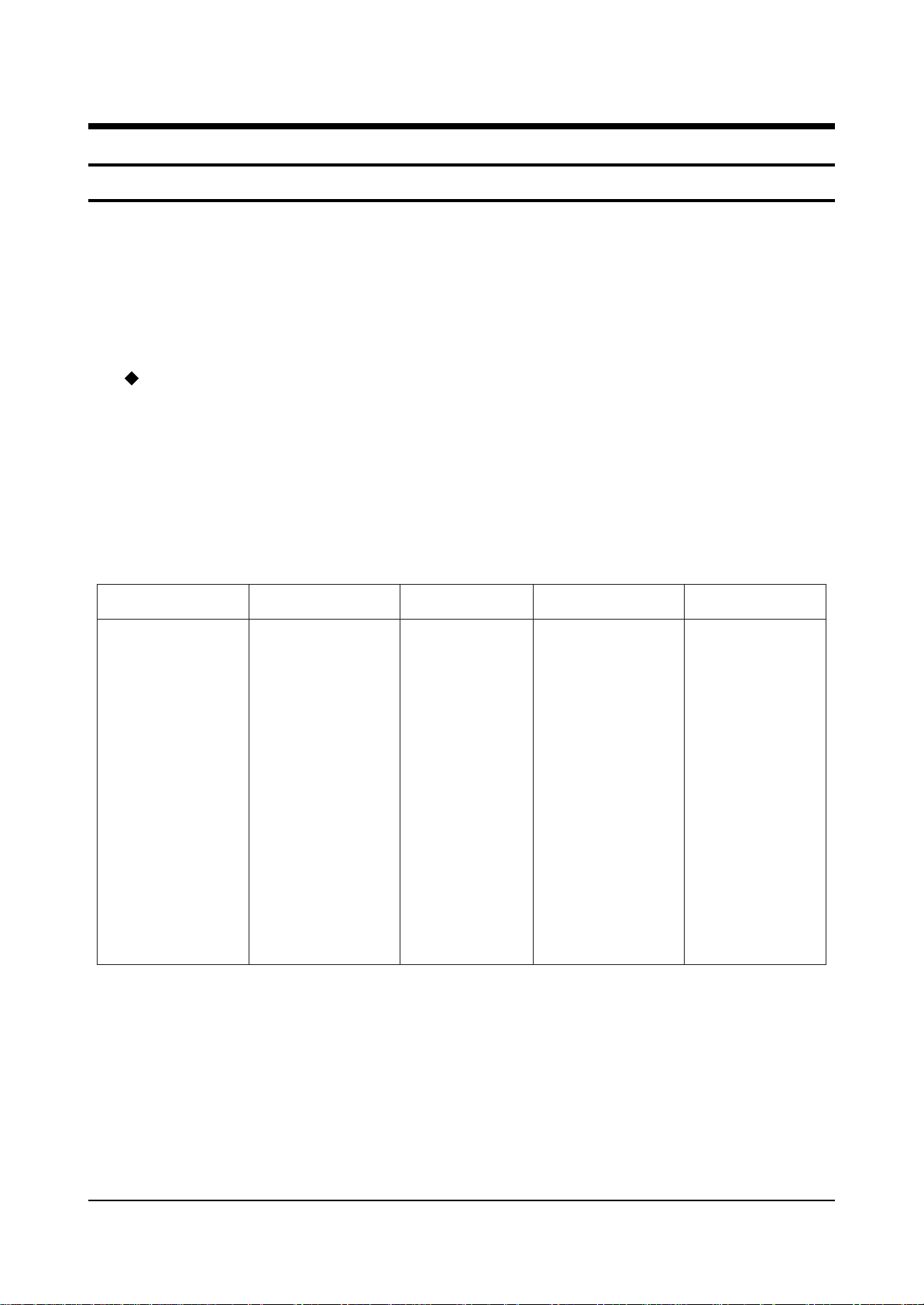

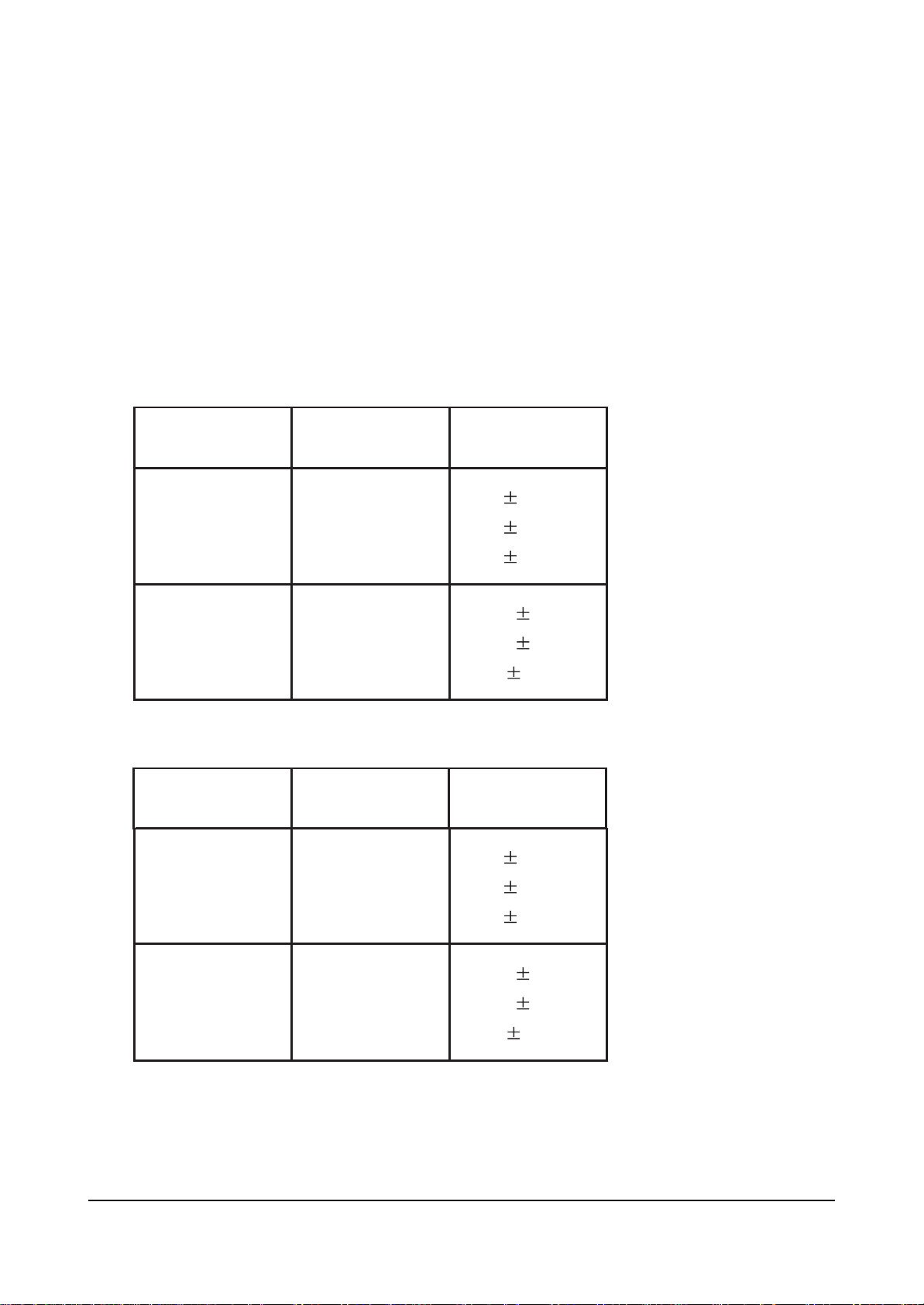

5-1-4 White Balance Adjust Method

1. Press MUTE-1-8-2-POWER to enter the factory mode.

2. Enter AD9884

3. Adjust LOW coordinates as R, B OFFSET and HIGH coordinates as R, B GAIN.(GREEN is fixed.)

4. In AD9884, adjust brightness with V CONTRAST / V BRIGHT for VIDEO / DTV, and adjust with

GAIN DRIVE / OFFSET DRIVE for PC.

1. VIDEO MODE (SPR-3100, input TOSHIBA PATTERN)

2. DTV MODE (SPR-3100, input TOSHIBA PATTERN)

A

dj ustme

nt

Adjus tme

nt

Coor dinates

Coor dinates

Value

Deviation

A

dj ustme

nt

Adjus tme

nt

Coor dinates

Coor dinates

Value

Deviation

H

-LIGHT

-LIGHT

x:286

y

:

274

Y

:

18.7(fL)

3

3

3

L

H-LIGHT

-LIGHT

L

x:278

y

:

272

Y

:0.53(f L)

(f L)

5

5

0. 1

x:288

y

:

277

Y: 16.1

Y:

3

3

3

x:280

y

:277

0.71

5

5

0. 1

- W/B Adjustment SPEC (Suwom Factory Toshiba PATTERN)

Alignment and Adjustments

5-4 Samsung Electronics

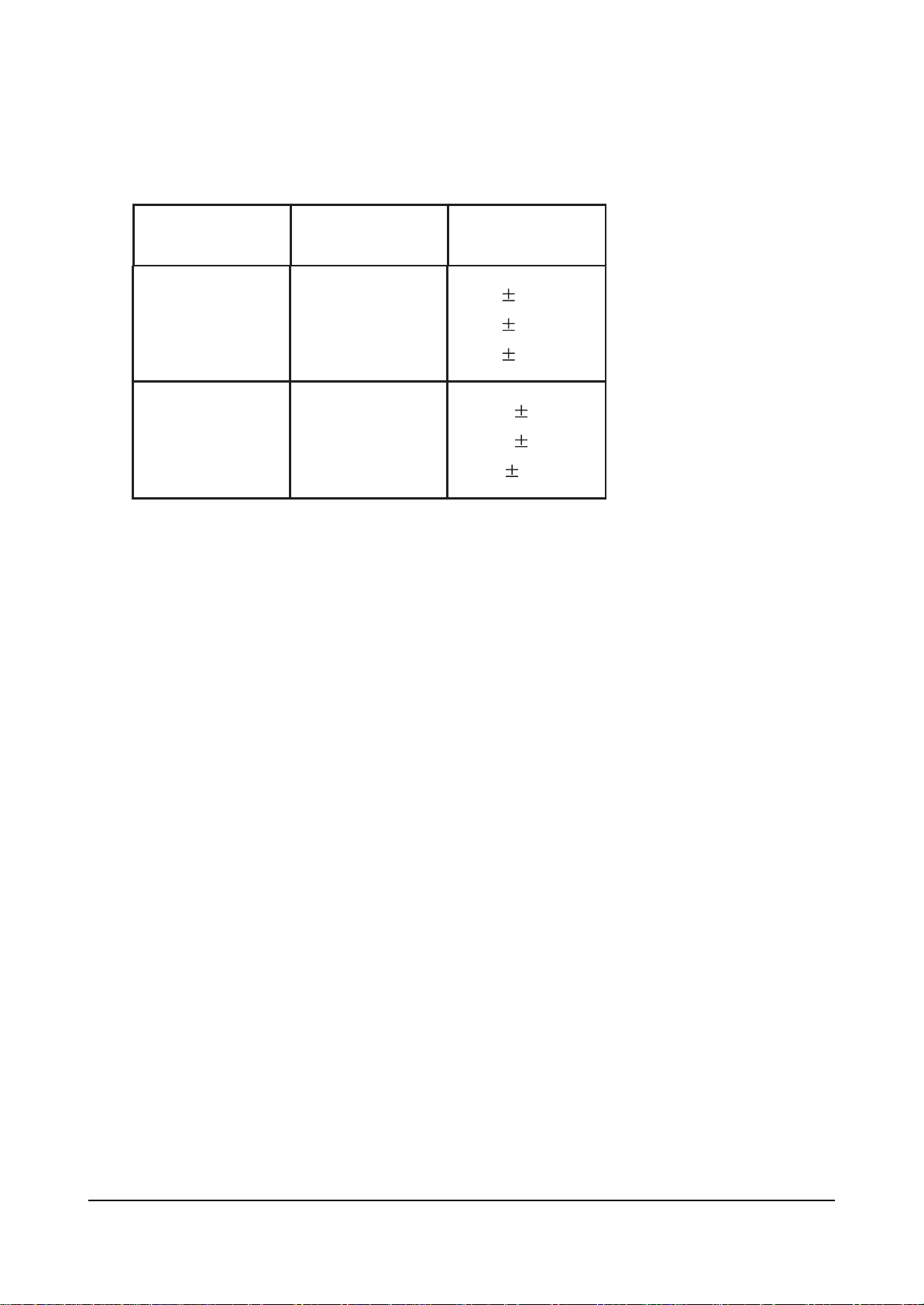

2. PC MODE (VG828, input TOSHIBA PATTERN)

A

dj ustme

nt

Adjus tme

nt

Coor dinates

Coor dinates

Value

Deviation

H-LIGHT

-LIGHT

L

x:287

y:288

Y: 21.3(fL)

Y:

x:287

y:294

2.17

3

3

3

5

5

0. 1

Alignment and Adjustments

Samsung Electronics 5-5

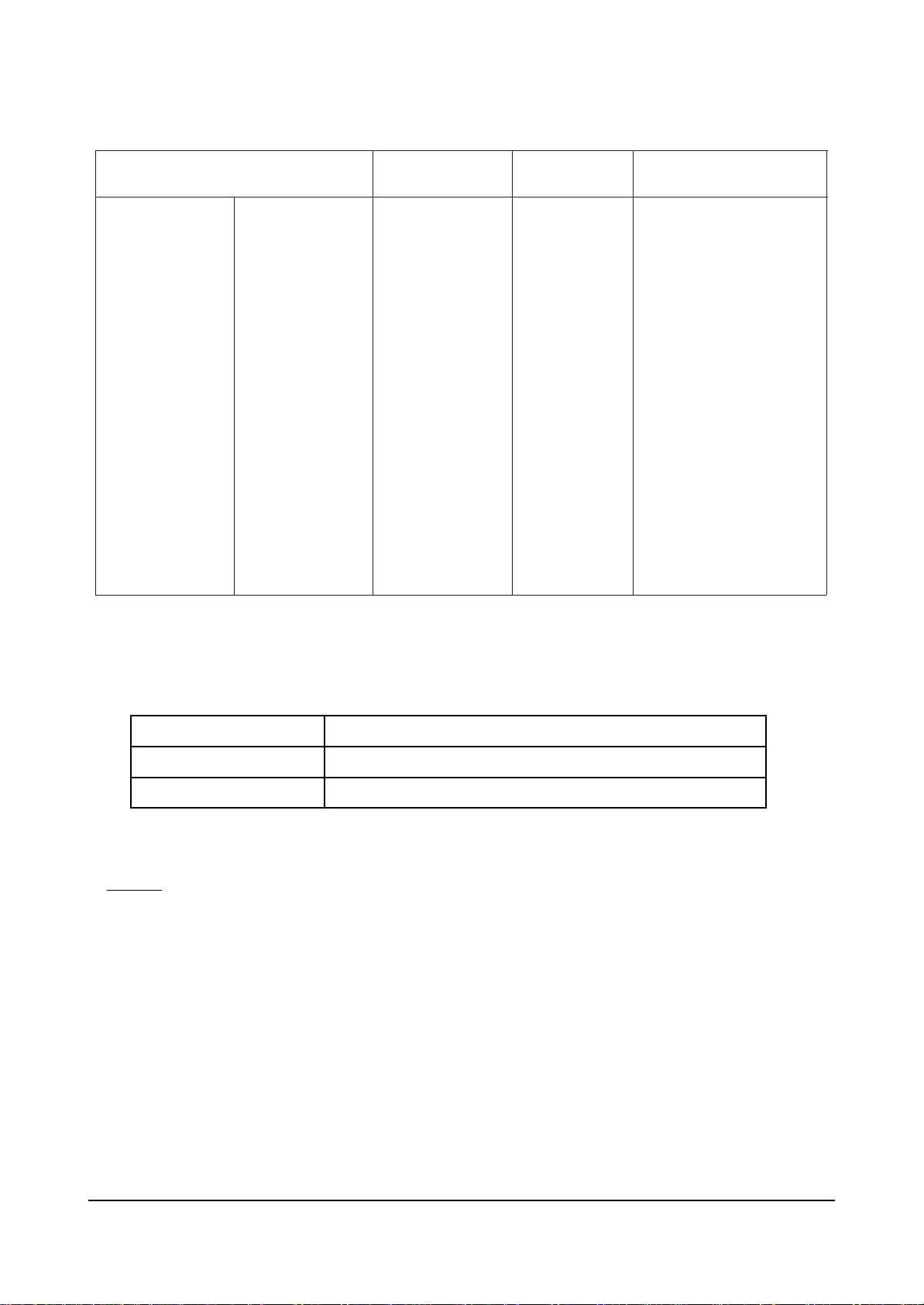

5-1-4 SCALAR FACTORY DATA DEFAULT VALUES

Alignment and Adjustments

5-6 Samsung Electronics

Alignment and Adjustments

Samsung Electronics 5-7

5-8 Samsung Electronics

Alignment and Adjustments

HPL5025/PPM50H2

VGA

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Video signal Dot X Line

640 X 350

640 X 400

VGA

WVGA

720 X 400

640 X 480

848 X 480

Ve rtical

Frequency (Hz)

70.086

85.080

85.080

70.087

85.039

59.940

72.809

75.000

85.008

60.000

72.000

75.000

85.000

56.250

Horizontal

Frequency (kHz)

31.469

37.861

37.861

31.469

37.927

31.469

37.861

37.500

43.269

29.838

35.156

36.072

37.650

42.925

Ve rtical

polarity

N

N

P

P

P

N

N

N

N

P

P

P

P

N/P

Horizontal

polarity

P

P

N

N

N

N

N

N

N

N

N

N

N

N/P

15

16

17

18

19

20

21

22

23

24

25

26

27

SVGA

XGA

WXGA

SXGA

800 X 600

1024 X 768

1152 X 864

1280 X 768

1280 X 1024

60.317

72.188

75.000

85.061

60.004

70.069

75.029

84.997

75.000

60

75

60.020

75.025

37.879

48.077

46.875

53.674

48.363

56.476

60.023

68.677

67.500

47.700

60.150

63.981

79.976

P

P

P

P

N

N

P

P

P

P

P

P

P

P

P

P

P

N

N

P

P

P

N

N

P

P

Alignment and Adjustments

Samsung Electronics 5-9

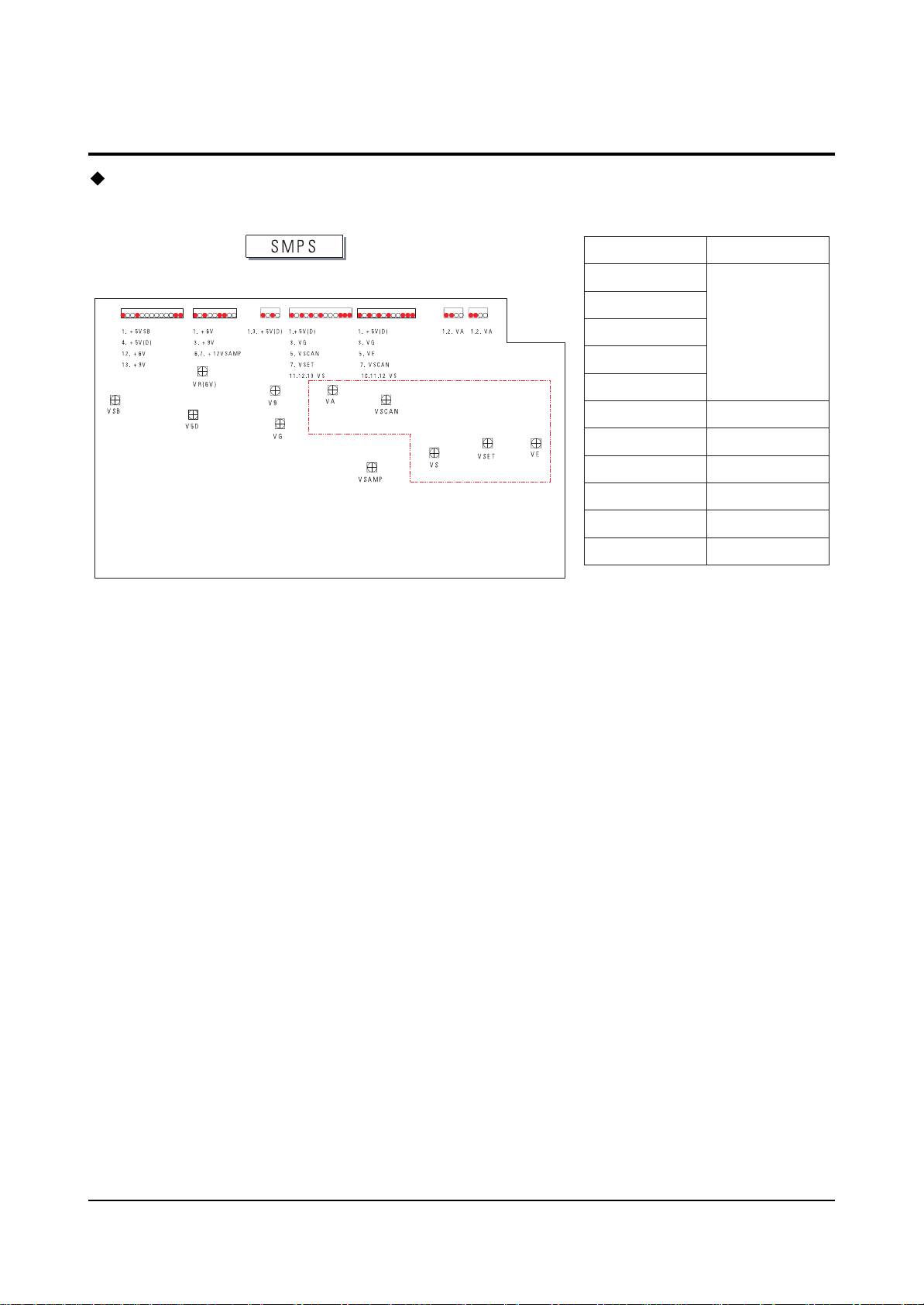

5-3 Adjusting the Discharge Voltage Of the Main Unit While Replacing ASS'Y (Body Part)

_ Turning the variable resistor clockwise reduces voltage except VG, V9, and VR(6).

OUTPUT

VE

VSET

VS

VSCAN

VA

VSAMP

VG

V9

V5D

VR(6)

VSB

Voltage(V)

See the labels

attached on the

base chassis

12

18.3

9

5.3

6

5.2

Alignment and Adjustments

5-10 Samsung Electronics

Alignment and Adjustments

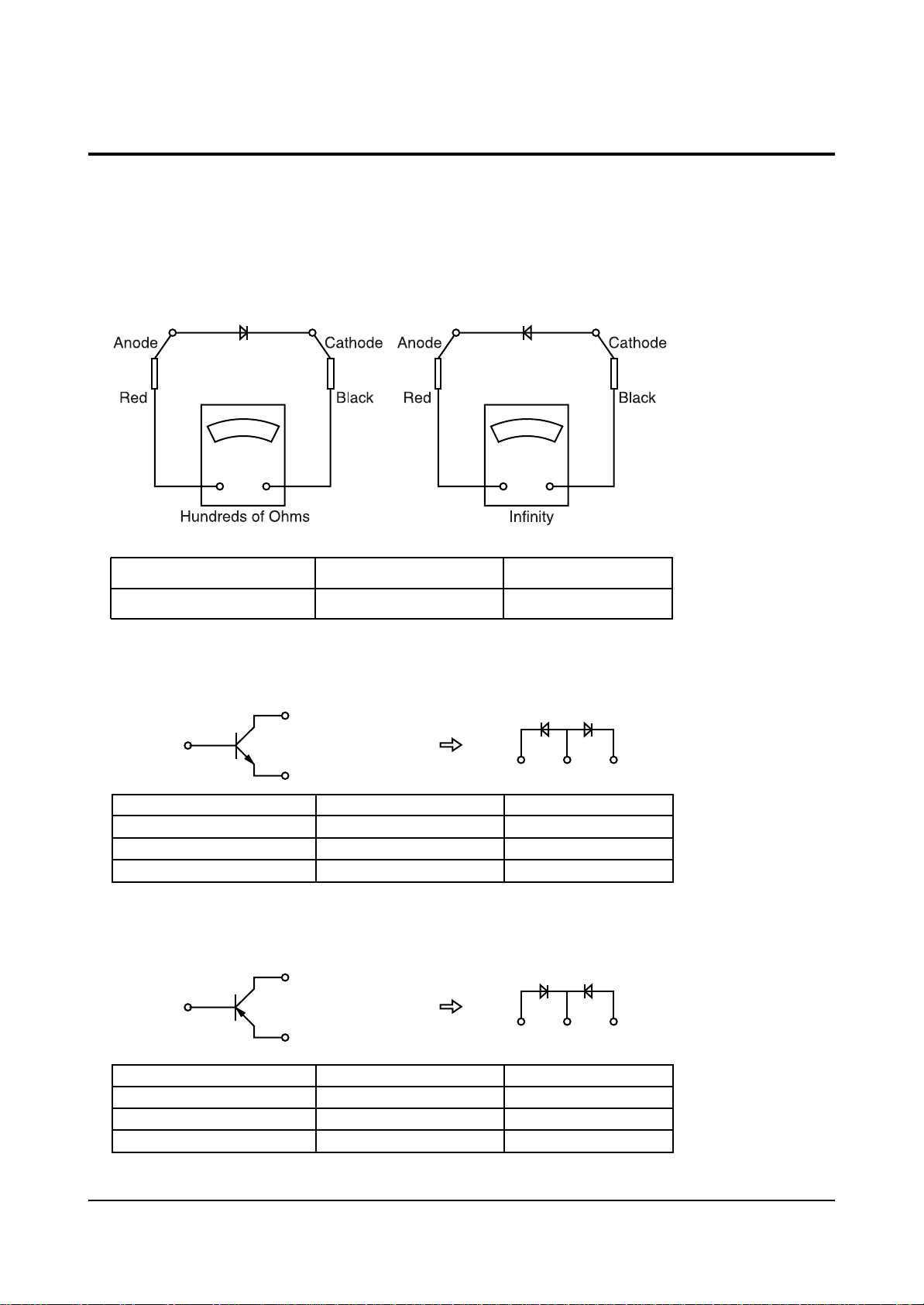

5-3 Fault Finding Using MULTI METER

Parts defects can be found for DIODE TRANSISTOR IC, using MULTI TEST including

Forward/Reverse direction Multi Test. Of course, in case resistance of several ohms and COIL are connected in parallel circuit, the lock out circuit parallel connected to part must be severed.

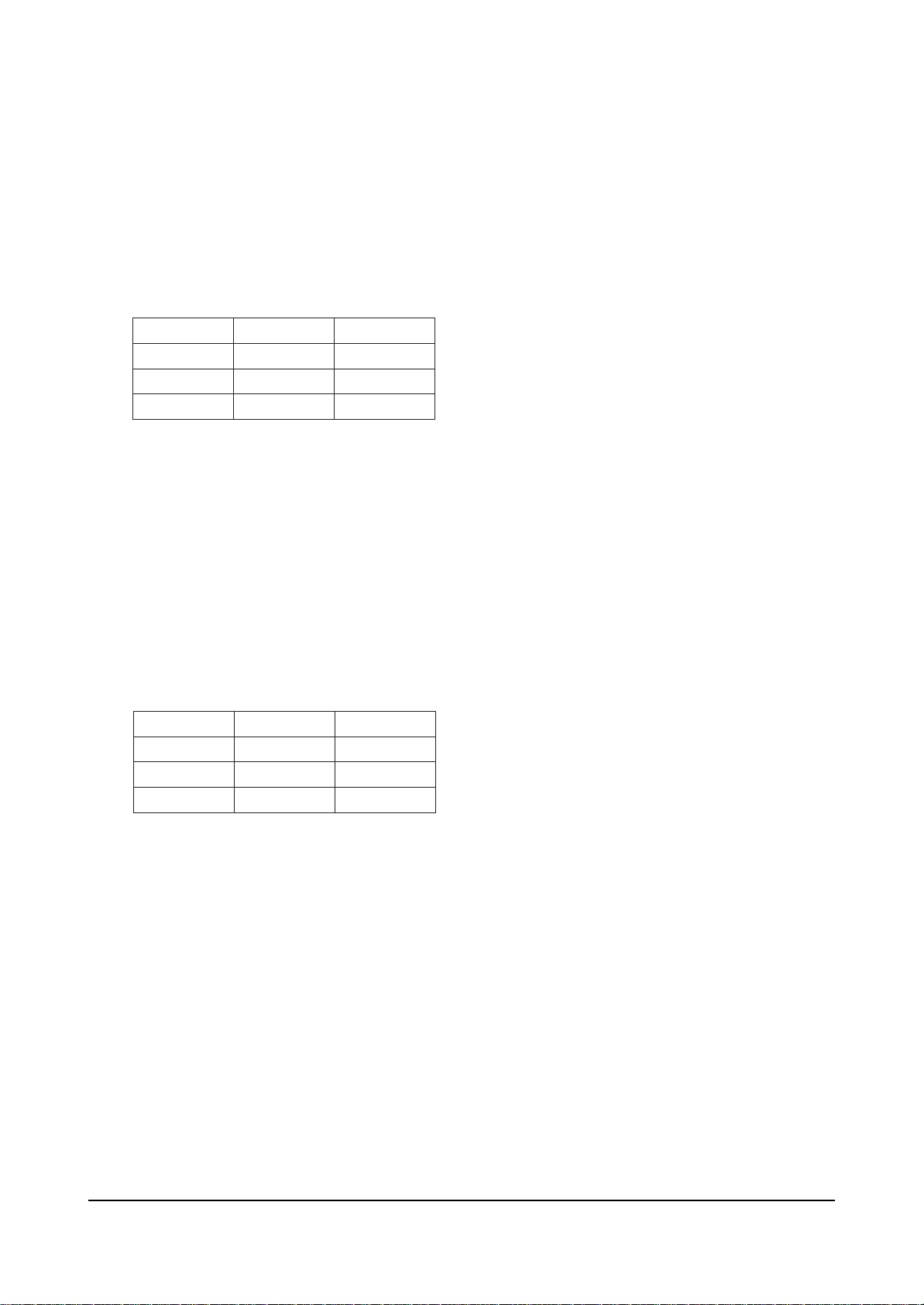

1.DIODE

2. TRANSISTOR

l For NPN(KSC815-Y, 2SC2068, 2SC2331-Y)

l For PNP(KSA539-Y)

Forward Direction

Hundreds of ohms

Reverse Direction

Infinity

Between Anode and Cathode

C (COLLECTOR)

E

B(BASE)

BC

C (COLLECTOR)

E

B(BASE)

BC

E (EMITTER)

E (EMITTER)

Forward Direction

Hundreds of ohms

Hundreds of ohms

Infinity

Reverse Direction

Infinity

Infinity

Infinity

Between B and E

Between B and C

Between E and C

Forward Direction

Hundreds of ohms

Hundreds of ohms

Infinity

Reverse Direction

Infinity

Infinity

Infinity

Between B and E

Between B and C

Between E and C

+- +-

Alignment and Adjustments

Samsung Electronics 5-11

Alignment and Adjustments

3. IC (INTEGRATED CIRCUIT)

IC has built in DIODE against overvoltage in PIN. Generally, except for internal circuit defects, IC defects

can be found, by measuring the DIODE.

- Defects have SHORT(0 ohm) for both forward and reverse direction.

Hundreds of ohms

Forward Direction

Reverse Direction

Varying depending on IC but generally normal

Infinity in DIODE TEST MODE

5-12 Samsung Electronics

MEMO

Circuit Operation Description

Samsung Electronics 6-1

6. Circuit Description

6-1 Power supply

6-1-1 Outline(PDP SMPS)

Considering various related conditions, the switching regulator with good efficiency and allowing for its

small size and light weight was used as the power supply for PDP 50inch, VS requiring high power consumption used forward converter and 12VSAMP used the simple flyback converter and other high voltage

(VSCAN,VSET,VE)used DC/DC converter. To comply with the international harmonics standards and

improve the power factor, active PFC(Power Factor Correction) was used to rectify AC input into +400V

DC output, which in turns used as input to the switching regulator.

6-1-2 50" SMPS Specification

(1) Input

The power supply shall be capable of supplying full rated output power over free voltage ranges that

are rated 100 VAC - 240 VAC RMS nominal. Operating voltage : 90 VAC - 264 VAC.

The power supply must be able to start up under peak loading at 90V AC. The power supply shall

automatically recover from AC power loss. (Note that nominal voltages for test purposes are considered

to be with +/- 1.0V of nominal).

+5VSB is a SELV standby voltage that is always present when AC mains voltage present.

(2) Output

This power supply is 13output switching power supply for PDP 50inch. The output voltage, and current

requirements for continuous operation are stated below. (Table1.)

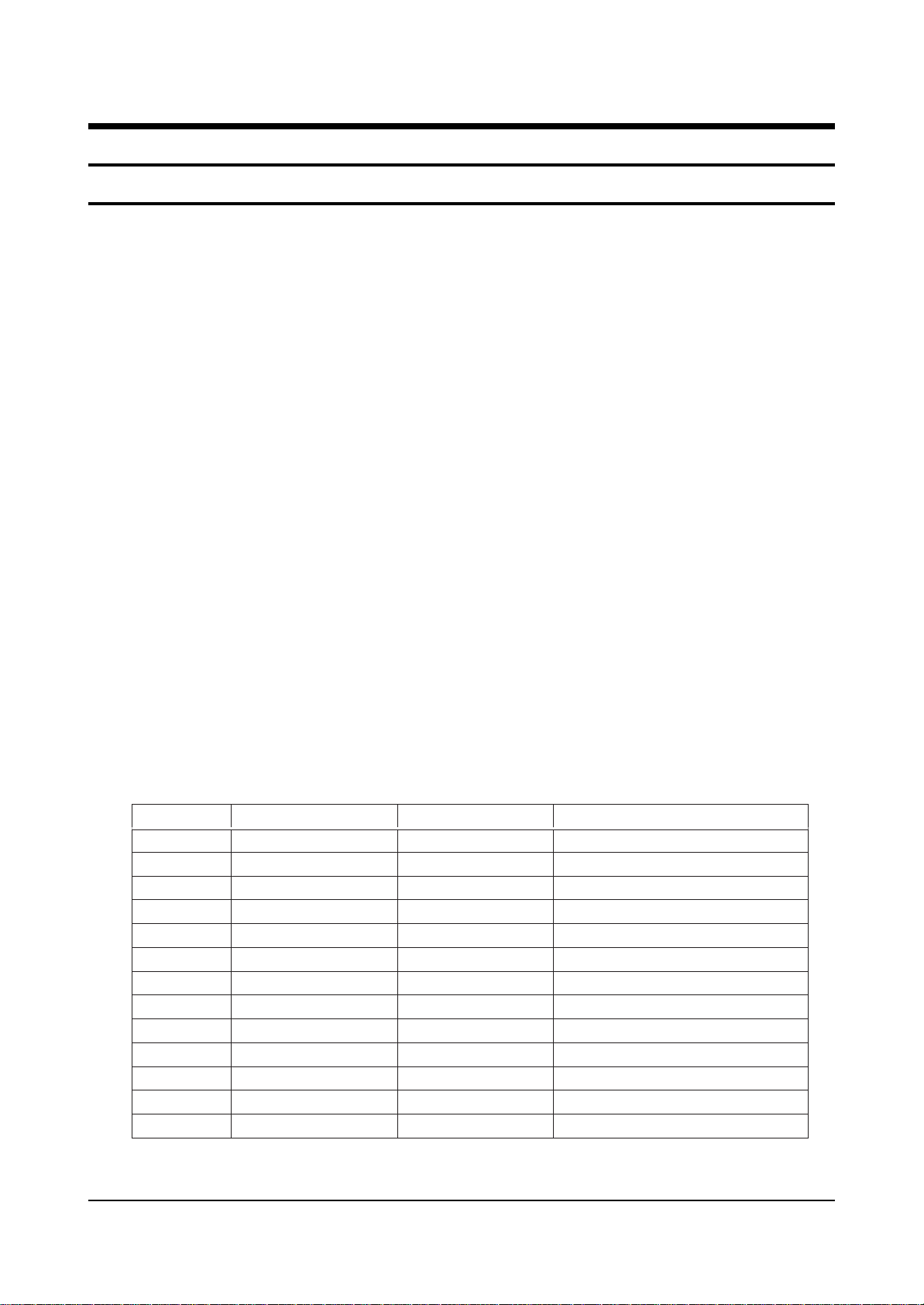

Table1. Specifications of Output Power Supplies for PDP SMPS

Output Name Output Voltage Output Current(Max.) UsinginPDPDriving

Vsustain +160V ~ 200V (165V) 1.8A Sustain Voltage of Drive Board

Vaddress +58V ~ 73V (65V) 0.5A Address Voltage of Drive Board

Vscan +60V ~ 78V (70V) 0.05A

Vset +195V ~ 230V (215V) 0.05A

Ve +180V ~ 210V (185V) 0.05A

Vg +1V ~ 20V (18.4V) 0.3A Driving Voltage of Fet

Vfan +10V ~ 12V (11V) 0.8A Driving Voltage of Fan

V9 +1V ~ 10V (9.0V) 0.3A

V6 +1V ~ 8V (6.0V) 1.0A IC Driving Voltage of Logic Board

V5(D) +5.1V ~ 5.9V (5.4V) 3.5A

Vsb +4.8V ~ 5.4 V (5.2V) 0.4A Standby for Remote Control

V12 +10V ~ 12V (11V) 1.2A

Vsamp +10V ~ 13V (12V) 1.5A Amp Voltage of Audio Board

Circuit Operation Description

6-2 Samsung Electronics

(3) Over voltage Protection

The over voltage sense circuitry and reference shall reside in package that are separate and distinct from

the regulator control circuitry and reference. No single point fault shall be able to cause a sustained over

voltage condition on any of all outputs. The supply shall provide latch-mode Over Voltage Protection as

defined below. (Table2.)

Table2. Over voltage Protection.

(4) Short Circuit and Over current Protection.

An output short circuit is defined as output impedance of less than 300mohms. The power supply shall

shutdown and latch off for shorting VS DC rails to return or any other rail. Shorts between main output

rails and 5VSB shall not cause any damages to the power supply. The power supply shall either shutdown and latch off for shorting is removed, the P/S shall recover. The power supply shall be capable of

withstanding a continuous shot-circuit to the output without damage or over stress to the unit (components, PCB traces, connectors,etc.) under the input conditions specified in Section2 above.

Current Protection as defined below. (Table3.)

Table3. Over Current Protection.

Parameter Min Unit

VS(169V) 3.0 ~ A

VA(65V) 2.0 ~ A

5V(D) 10 ~ A

Parameter Min Unit

VS(169V) 195 ~ V

VA(65V) 90 ~ V

5V(D) 5.5 ~ V

Circuit Operation Description

Samsung Electronics 6-3

(5) Function of Board

REMOTE CONTROL

Using a 250V/10A relay, the board makes remote control available.

FREE VOLTAGE

The board is designed so that the input voltage can be used within 90VAC to 264VAC.

Improvement of power factor

The board is designed using the active PFC circuit so that the Power Factor can be over 9.0.

Protection

The OCP(Over current Protection), OVP(Over voltage Protection), Short Circuit Protection functions

are added against system malfunction.

(6) Part Block Diagram and Part Function.

AC-DC Converter

The Power supply output +400V DC from the common AC power supply using the active PFC

booster converter. This converter is designed for improving the power factor and preventing the

noise with high frequency and finally becomes the input power system for the switching regulator on

the output side.

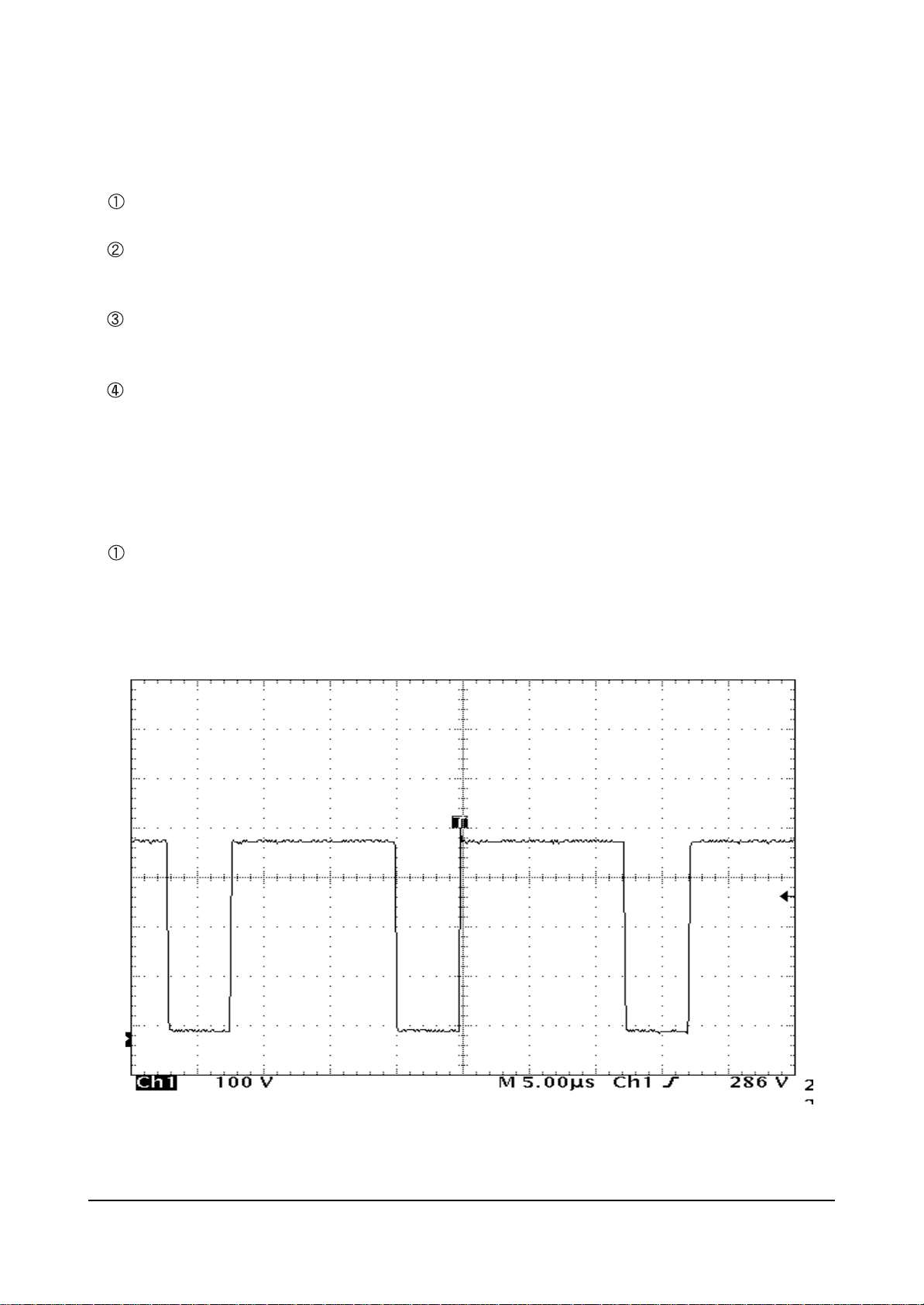

Picture1. PFC Drive FET(2SK2372) Drain pulse

Circuit Operation Description

6-4 Samsung Electronics

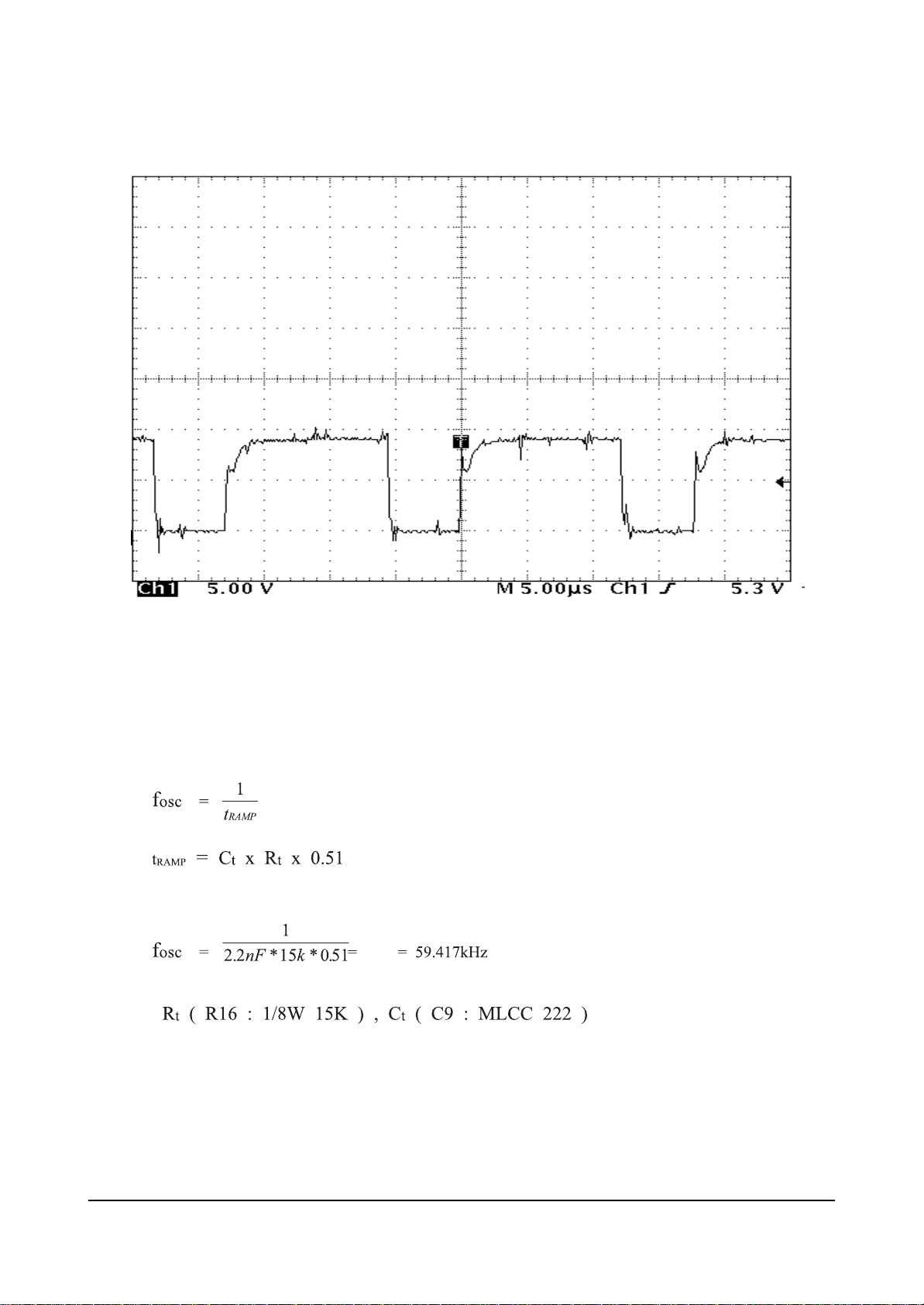

- Oscillator Frequency

Oscillator Frequency is determined by the values of Rt and Ct, which determine the ramp and

off-time of the oscillator output clock

Oscillator Frequency is derived from the following equation

For the circuit shown in the PDP50, with the oscillator running at

Picture2. PFC Drive FET(2SK2372) Gate pulse

Loading...

Loading...