Samsung hlr4266wx service manual

DLP TV

Chassis : L64C(N_ATSC)_Hurricane-2

Basic Model : HLR4266WX/XAA (HL-R4266W)

Model : SP42L6HNX/XAX (SP-42L6HN)

DLP TV FEATURES

■■

HD Built in TV

■

NTSC/ATSC Tuner Embedded

■

■

AV network system (Anynet)

■

Digital Audio output (OPTICAL) jack

■

■

Firmware upgrade by USB Port

SERVICE

Manual

SP-42L6HN

Table of Contents

Chapter 1 Precaution

■ 1-1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

■ 1-2 Servicing Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

■ 1-3 Static Electricity Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

■ 1-4 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2 Product Specification

■ 2-1 Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

■ 2-2 Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

■ 2-3 Specifications Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

■ 2-4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Chapter 3 Alignment & Adjustment

■ 3-1 Service Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

■ 3-2 How to Access Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

■ 3-3 Factory Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

■ 3-4 Service Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

■ 3-5 Software Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

■ 3-6 Replacements & Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Chapter 4 Exploded View & Part List

■ 4-1 SP42L6HNX/XAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chapter 5 Electrical Part List

■ 5-1 SP42L6HNX/XAX Service Item . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chapter 6 Troubleshooting

■ 6-1 Checkpoints by Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

■ 6-2 Troubleshooting Procedures by Error Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

■ 6-3 Troubleshooting Procedures by ASS'Y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-9

Chapter 7 Block Diagram

■ 7-1 Overall Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

■ 7-2 Partial Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter 8 Wiring Diagram

■ 8-1 Overall Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

■ 8-2 Connection between Analog and Digital Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Chapter 9 PCB Diagram

■ 9-1 Power Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

■ 9-2 Digital Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

■ 9-3 Analog Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

■ 9-4 DMD Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Chapter 10 Schematic Diagram

■ 10-1 Analog Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

■ 10-2 Digital Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-10

■ 10-3 DMD Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-28

■ 10-4 Actuator Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-35

■ 10-5 Ballast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-36

■ 10-6 Power Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-37

■ 10-7 Combined Bridge and Control Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-38

■ 10-8 Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

■ 10-9 Side-AV . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

■ 10-10 Key Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

■ 10-11 RMC-LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-40

1. Make sure all protective devices are properly installed

including non-metallic handles and compartment covers

when installing or re-installing the chassis or chassis

assemblies.

2. Make sure that no gaps exist between the cabinets for

children to insert their fingers in to prevent children from

receiving electric shocks.

Errors may occur when the resistance is below 1.0 ㏁ or

over 5.2 ㏁.

In these cases, make sure that the device is repaired

before sending it back to the customer.

3. Check for Electricity Leakage (Figure 1-1)

Warning: Do not use an insulated transformer for checking the leakage. Use only those current leakage testers

or mirroring systems that comply with ANSIC 101.1 and

the Underwriter Laboratory's specifications (UL1410,

59.7).

Fig. 1-1 AC Leakage Test

4. A high voltage is maintained within the specified limits

using safety parts, calibration and tolerances. When

voltage exceeds the specified limits, check each special

part.

5. Warning for Engineering Changes:

Never make any changes or additions to the circuit

design or the internal part for this product.

Ex: Do not add any audio or video accessory

connectors. This might cause physical damage.

Furthermore, any changes or additions to the original

design/engineering will invalidate the warranty.

6. Warning - Hot Chassis:

Some TV chassis are directly connected to one end of

the AC power cord for electrical reasons.

Without insulated transformers, the product can only be

repaired safely when the chassis is connected to the

earthed end of the AC power source.

To make sure the AC power cord is properly connected,

follow the instructions below. Use the voltmeter to

measure the voltage between the chassis and the

earthed ground. If the measurement is over 1.0V, unplug

the AC power cord and change the polarity before reinserting it. Measure the voltage between the chassis

and the ground again.

7. Some TV chassis are shipped with an additional

secondary grounding system. The secondary system is

adjacent to the AC power line. These two grounding

systems are separated in the circuit using an

unbreakable/unchangeable insulation material.

8. When any parts, material or wiring appear overheated or

damaged, replace them with new regular ones

immediately. When any damage or overheating is

detected, correct this immediately and make a regular

check of possible errors.

9. Check for the original shape of the lead, especially that

of the antenna wiring, any sharp edges, the AC power

and the high voltage power. Carefully check if the wiring

is too tight, incorrectly placed or loose. Never change the

space between the part and the printed circuit board.

Check the AC power cord for possible damages. Keep

the part or the lead away from any heat-emitting

materials.

Precaution

Samsung Electronics 1-1

To avoid possible damages or electric shocks or exposure to radiation, follow the instructions below with regard to safety,

installation, service and ESD.

1. Precaution

1-1 Safety Precautions

(READING SHOULD

DEVICE

UNDER

TEST

EXPOSED METAL

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

SURFACES

LEAKAGE

CURRENT

TESTER

NOT BE ABOVE

0.5mA)

EARTH

GROUND

10. Safety Indication:

Some electrical circuits or device related materials

require special attention to their safety features, which

cannot be viewed by the naked eye. If an original part is

replaced with another irregular one, the safety or

protective features will be lost even if the new one has a

higher voltage or more watts.

Critical safety parts should be bracketed with ( ).

Use only regular parts for replacements (in particular,

flame resistance and dielectric strength specifications).

Irregular parts or materials may cause electric shock or

fire.

11. Pay additional attention to the current leakage as the

voltage between the power board and the ballast is 220

to 440v, i.e. very high.

And also beware of possible electric shock from the

primary power source.

Precaution

1-2 Samsung Electronics

!

1. The service instructions are printed on the cabinet, and

should be followed by any service personnel.

2. Make sure to unplug the AC power cord from the power

source before starting any repairs.

(a) Remove or re-install parts or assemblies.

(b) Disconnect the electric plug or connector, if any.

(c) Connect the test part in parallel with the electrolytic

capacitor.

3. Some parts are placed at a higher position than the

printed board. Insulated tubes or tapes are used for this

purpose. The internal wiring is clamped using buckles to

avoid contact with heat emitting parts. These parts are

installed back to their original position.

4. After the repair, make sure to check if the screws, parts

or cables are properly installed. Make sure no damage is

caused to the repaired part and its surroundings.

5. Check for insulation between the blade of the AC plug

and that of any conductive materials (i.e. the metal

panel, input terminal, earphone jack, etc).

6. Insulation Check Process: Unplug the power cord from

the AC source and turn the switch on. Connect the insulating resistance meter (500v) to the AC plug blade.

The insulating resistance between the blade of the AC

plug and that of the conductive material should be more

than 1 ㏁.

7. Any B+ interlock should not be damaged.

If the metal heat sink is not properly installed, no

connection to the AC power should be made.

8. Make sure the grounding lead of the tester is connected

to the chassis ground before connecting to the positive

lead. The ground lead of the tester should be removed

last.

9. Beware of risks of any current leakage coming into

contact with the high-capacity capacitor.

10. The sharp edges of the metal material may cause

physical damage, so ensure wearing protective gloves

during the repair.

Precaution

Samsung Electronics 1-3

Warning 1: First carefully read the "Safety Instruction" in this service manual.

When there is a conflict between the service and the safety instructions, follow the safety instruction at all times.

Warning 2: Any electrolytic capacitor with the wrong polarity will explode.

1-2 Servicing Precautions

1-3 Static Electricity Precautions

1. Some semi-conductive ("solid state") devices are

vulnerable to static electricity. These devices are known

as ESD. ESD includes the integrated circuit and the field

effect transistor. To avoid any materials damage from

electrostatic shock, follow the instructions described

below.

2. Remove any static electricity from your body by

connecting the earth ground before handling any

semi-conductive parts or ass'ys. Alternatively, wear a

dischargeable wrist-belt.

(Make sure to remove any static electricity before

connecting the power source - this is a safety instruction

for avoiding electric shock)

3. Remove the ESD ass'y and place it on a conductive

surface such as aluminum foil to prevent accumulating

static electricity.

4. Do not use any Freon-based chemicals.

Such chemicals will generate static electricity that

causes damage to the ESD.

5. Use only grounded-tip irons for soldering purposes.

6. Use only anti-static solder removal devices.

Most solder removal devices do not support an

anti-static feature. A solder removal device without an

anti-static feature can store enough static electricity to

cause damage to the ESD.

7. Do not remove the ESD from the protective box until the

replacement is ready. Most ESD replacements are

covered with lead, which will cause a short to the entire

unit due to the conductive foam, aluminum foil or other

conductive materials.

8. Remove the protective material from the ESD

replacement lead immediately after connecting it to the

chassis or circuit ass'y.

9. Take extreme caution in handling any uncovered ESD

replacements. Actions such as brushing clothes or lifting

your leg from the carpet floor can generate enough static

electricity to damage the ESD.

Precaution

1-4 Samsung Electronics

CAUTION

These servicing instructions are for use by

qualified service personnel only.

To reduce the risk of electric shock do not

perform any servicing other than that contained in the

operating instructions unless you are qualified to do so.

Precaution

Samsung Electronics 1-5

1-4 Installation Precautions

1. For safety reasons, more than two people are required

for carrying the product.

2. Keep the power cord away from any heat emitting

devices, as a melted covering may cause fire or electric

shock.

3. When installing the product, make sure to keep it away

from the wall (more than 10cm/4 inches) for ventilation

purposes.

Poor ventilation may cause an increase in the internal

temperature of the product, resulting in a shortened

component life and degraded performance.

4. Bend the external antenna cable when connecting it to

the product. This is a measure to protect it from being

exposed to moisture. Otherwise, it may cause a fire or

electric shock.

5. Make sure to turn the power off and unplug the power

cord from the outlet before repositioning the product.

Also check the antenna cable or the external connectors

if they are fully unplugged. Damage to the cord may

cause fire or electric shock.

6. Keep the antenna far away from any high-voltage cables

and install it firmly. Contact with the high-voltage cable or

the antenna falling over may cause fire or electric shock.

7. When connecting the RF antenna, check for a DTV

receiving system and install a separate DTV reception

antenna for areas with no DTV signal.

8. Check the basics of the screen test.

- Image position/size, Tilt adjustment, Actuator activation

1-6 Samsung Electronics

MEMO

Product Specification

Samsung Electronics 2-1

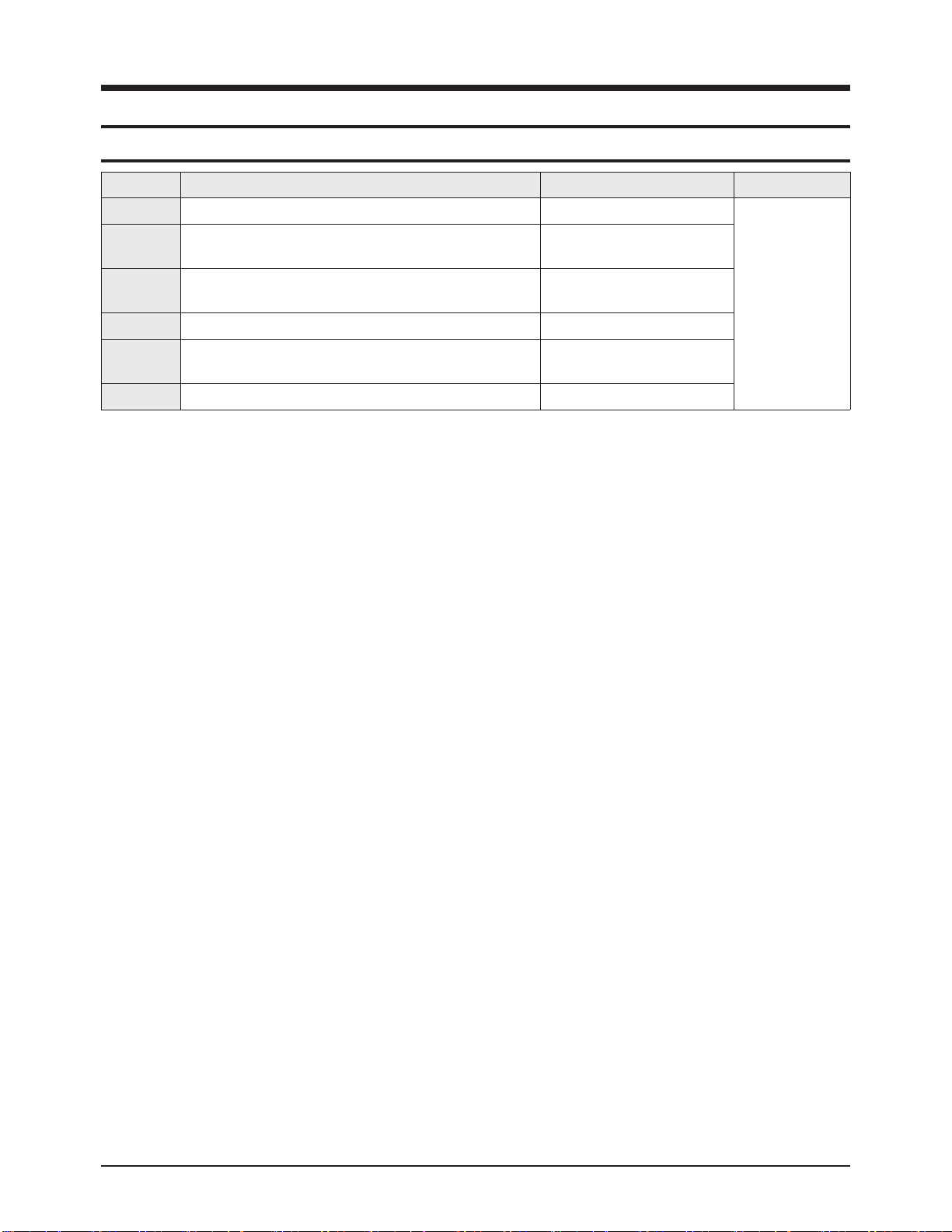

2. Product Specification

2-1 Product Features

Block Specfication Major IC Remark

DMD - Panel Resolution : 1280 x 720 (Diamond Pixel) HD4 DMD Panel(L620 Engine)

RF

- Integrated HDTV Tuner

(NTSC/ATSC TUNER Embedded)

ATI T313

Power

- Input Voltage : AC110V

- Stand-By : under 30W

Stand-by (KA1M0565)

Video - DNIe3- NTSC, ATSC- HDM ADV7401, ATI X226B

Sound

- Speaker : 15W x 2

- Dolby Digital

MSP4440

Cabinet - L3 Design

■ Chip Description

- ATI x226B : Xilleon 226 is the most advanced and highly integrated component for digital set-top boxes, information appliances,

and televisions. Xilleon 226 provides dual-stream high-definition decode and display, an assortment of peripheral

device controllers, and an embedded microprocessor.

- ADV7401 : The ADV7401 is an integrated video decoder that automatically indicates and converts High Definition or Standard

Definition analog baseband television signal into a 4:2:2 component digital video data stream compatible with 20/16bit or 10/8-Bit CCIR601/CCIR656 outputs for standard definition & SMPTE293M/296M/274M & ITU-R.BT1358 for

High definition. All RGB graphics signals are output as 30-bit 4:4:4 RGB or 20-bit 4:2:2 YCrCb.

- MSP4440 : The MSP 44x0G family of single-chip Multistandard Sound Processors covers the sound processing of all analog

TV-Standards worldwide, as well as the NICAM digital sound standards.

Product Specification

2-2 Samsung Electronics

2-2 Key Features

Model SP-42L6HN SP-46L6HN SP-50L6HN

Voltage AC 110-120V~ AC 110-120V~ AC 110-120V~

Frequency of Operation 60Hz 60Hz 60Hz

Power Consumption 230 watts 230 watts 230 watts

Dimensions

(W x D x H)

39.33 x 13.03 x 30.53 inches

999 x 331 x 755.5 mm

43.07 x 13.35 x 32.05 inches

1094 x 339 x 814 mm

46.54 x 14.13 x 34.25 inches

1182 x 359 x 870 mm

Weight 28 Kg / 61.72 lbs 32.5 Kg / 71.65 lbs 36 Kg / 79.37 lbs

■ H/W Configuration

- DMD Panel : 0.55" (1280 x 720p, TI)

- 1 Optical Engine for the Panel : Slim and Cost-effective

- Color Wheel : R/G/B Color Implementation

- Lamp : 100W (10,000 hours) → Dynamic Mode 120W Drive (6,000 hours)

- Support HDMI Interface : Adopts DVI/HDMI systems for digital HDs including STB.

- DNIe3 : High quality image implementation

- AnyNet Feature : An enhanced interface for various external devices

- USB Interface : Use the USB interface for service purposes (S/W Upgrade)

■ S/W Configuration

- MCU : Built-in 300 MHz MIPS X226B CPU

- 4-Layered Architecture : Device Driver/OS/Hardware Abstraction/Application

- OSD : 32Bit True Color Graphics OSD

- Enhanced system stability by separating the DTV control and the application control systems into multi-processes.

■ Picture

- DMD Panel

*Panel Size : 0.55"

*Panel Resolution : 1280 x 720 (Diamond Pixel)

- Tuner : Integrated HDTV Tuner (NTSC/ATSC TUNER Embbeded)

- Display Format : 1280 x 720 (Diamond Pixel)

■ Sound

- Sound System : Dolby Digital

- Amp/Channel : 2 Channel Digital Amp

- Speaker System & Output(RMS)

*Main L/R : 15W + 15W

*Sound (RMS) : 15W + 15W

■ In/Out Terminals

- Side : 1 CVBS In, 1 S-VHS In

- Rear : 2 RF In, 2 CVBS In, 2 S-VHS In, 2 Component In,

1 HDMI In(DVI Comportable With Adaptive Jack Only), 1 Anynet port, 1 Optical audio

Product Specification

Samsung Electronics 2-3

■ Feature

- Component Interface (480i/480p/720p/1080i, Y/Pb/Pr)

- Digital Interface : HDMI

- Language : English/French/Spanish

- Picture Size : 4:3/16:9/Zoom1/Zoom2/Panorama

- V-CHIP

- Closed Caption

- Sleep Timer : 180 Min.

- Anynet Interface

- Optical sound output

■ Remocon

- TM76

■ Power Supply

- 110V

Product Specification

2-4 Samsung Electronics

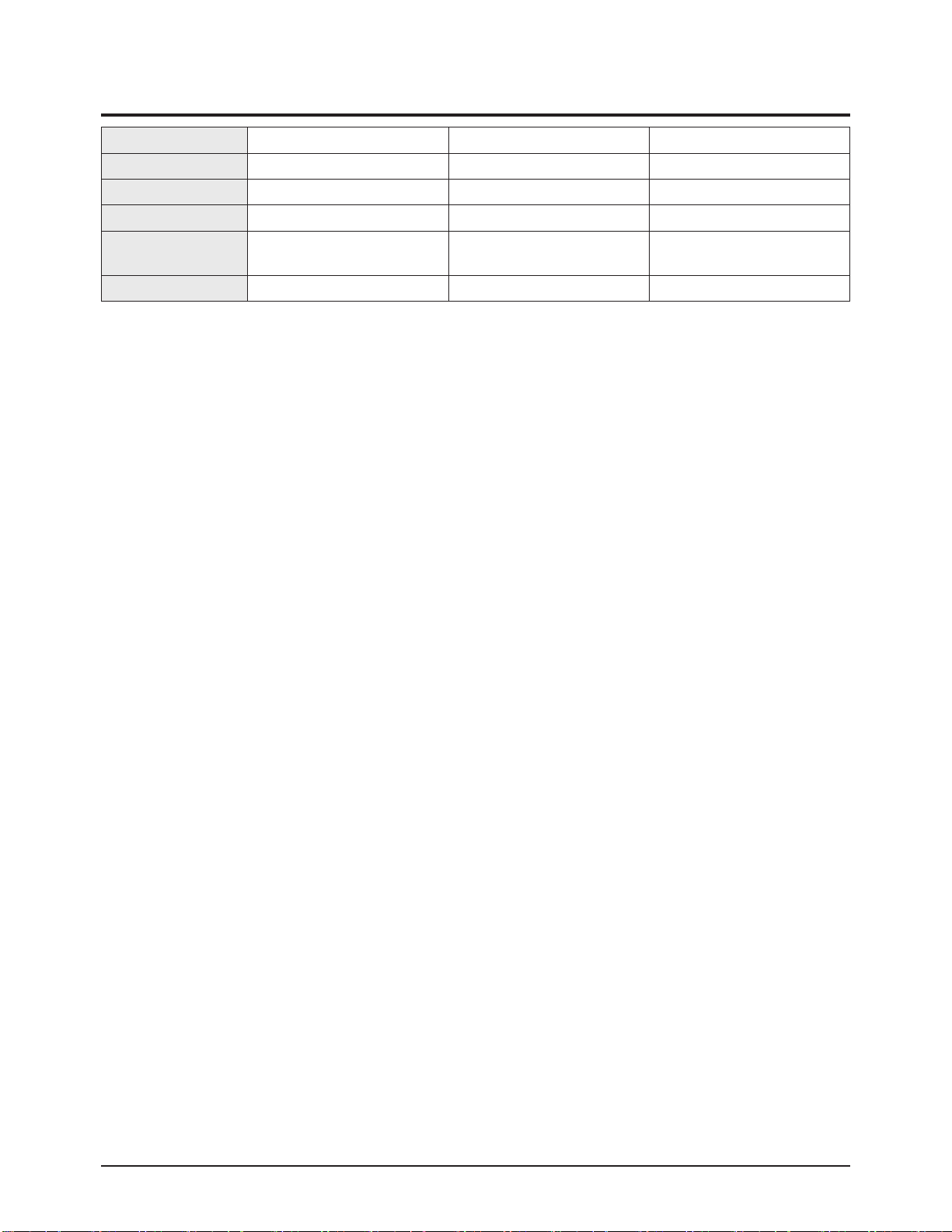

2-3 Specifications Analysis

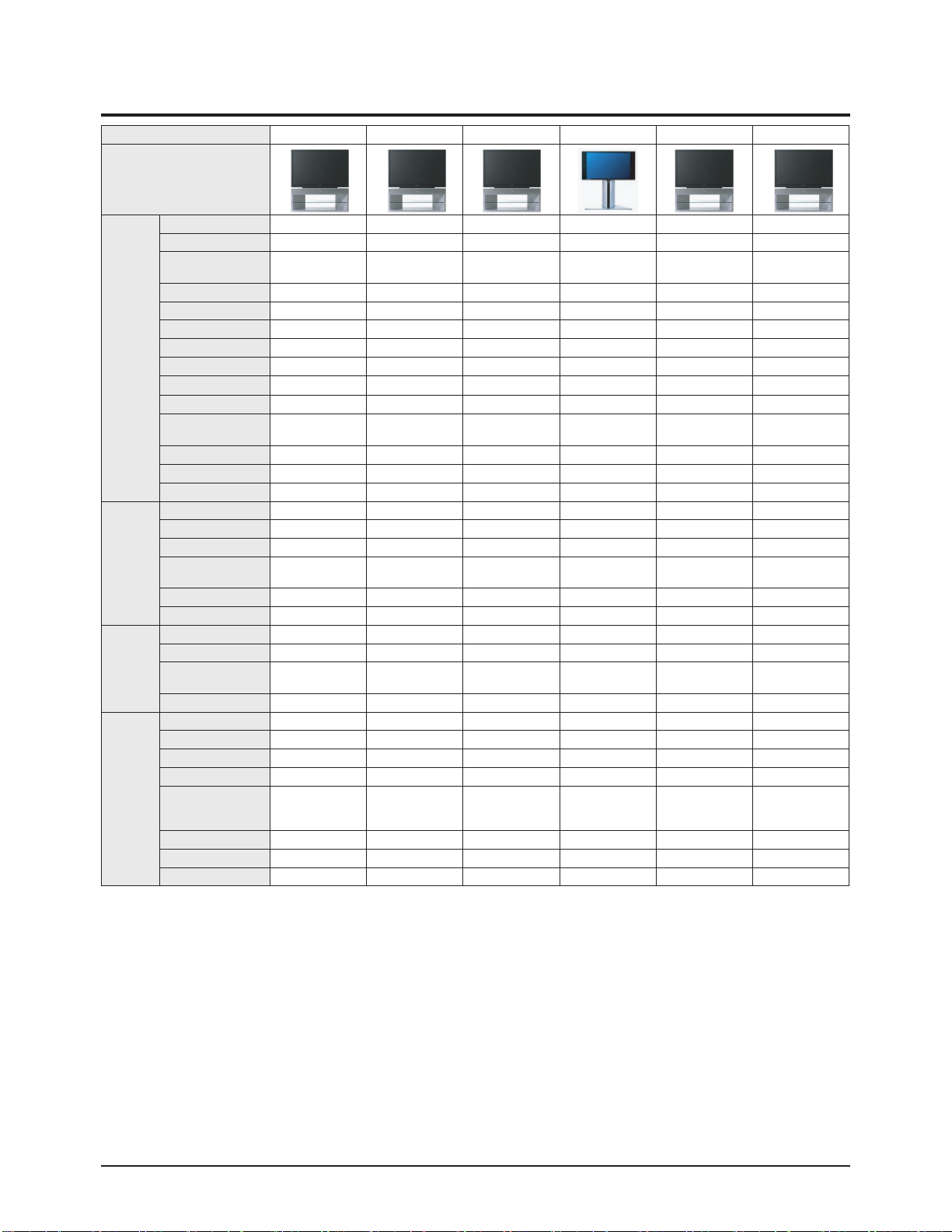

Model SP-42L6HN SP-46L6HN SP-50L6HN HL-R5087W HL-R6156W HL-R4266W

Design

Picture

Display Device DLP DLP DLP DLP DLP DLP

Built-in Tuner ATSC, NTSC ATSC, NTSC ATSC, NTSC ATSC, NTSC ATSC, NTSC ATSC, NTSC

Display Format

1080i, 720p, 480p,

480i

1080i, 720p, 480p,

480i

1080i, 720p, 480p,

480i

1080i, 720p, 480p,

480i

1080i, 720p, 480p,

480i

1080i, 720p, 480p,

480i

Screen Size 42 inch 46 inch 50 inch 50 inch 56 inch 42 inch

Aspect ratio 16:9 16:9 16:9 16:9 16:9 16:09

Progressive scan Yes Yes Yes Yes Yes Yes

Digital Comb Filter 4H Comb 4H Comb 4H Comb 3D Comb 4H Comb 4H Comb

First Surface Mirror Yes Yes Yes Yes Yes Yes

Brightness

750cd/㎡ 750cd/㎡ 750cd/㎡ 800cd/㎡ 750cd/㎡

750cd/§³

Contrast 1500:1 1500:1 1500:1 2500:1 1500:1 1500:1

Color Wheel Size/Bearing

7segment/65¢,

Air Bearing

7segment/65¢,

Air Bearing

7segment/65¢,

Air Bearing

7segment/65¢,

Air Bearing

7segment/65¢,

Air Bearing

7segment/65¥õ

Air Bearing

Anti-glare Sun Screen Yes Yes Yes Yes Yes Yes

Screen Pitch 0.098mm 0.098mm 0.098mm 0.098mm 0.098mm 0.098mm

Image enhancer DNIe3 DNIe3 DNIe3 DNIe3 DNIe3 DNie3

Audio

Base/Tremble/Balance No No No No No No

Equalizer 5 Band 5 Band 5 Band 5 Band 5 Band 5 Band

Auto Volume Leveler Yes Yes Yes Yes Yes Yes

Surround Sound

DNSE

Dolby Digital

DNSE

Dolby Digital

DNSE

Dolby Digital

TruSurround XT

Dolby Digital

DNSE

Dolby Digital

DNSE

Dolby Digital

Speaker system 2 Way 4 Speaker 2 Way 4 Speaker 2 Way 4 Speaker 2 Way 4 Speaker 2 Way 4 Speaker 2 Way 4 Speaker

Output Power 15Wx2 15Wx2 15Wx2 15Wx2 15Wx2 15Wx2

Features

2-Tuner Split-Screen PIP No No No Yes(HD/SD) No Yes(HD/SD)

Split-screen Side-by-Side No No No Yes No Yes

MTS with dbx Noise

Reduction/SAP

Yes Yes Yes Yes Yes Yes

Still Picture Ye s Yes Yes Yes Yes Yes

Connections

Plug & Play Yes Yes Yes Yes Yes Yes

EPG No No No Gemstar EPG No No

Anynet Yes Yes Yes Yes Yes Yes

S-Video In Rear 2/Side 1 Rear 2/Side 1 Rear 2/Side 1 Rear 2 Rear 2 Rear 2/Side 1

HDTV Component

Video Input (Y, Pb, Pr)

1080i/480P/480i

Rear 2 Rear 2 Rear 2 Rear 2 Rear 2 Rear 2

PC No No No No No No

HDMI Yes Ye s Ye s Yes Yes Yes

Digital Sound Optical 1 Optical 1 Optical 1 Optical 1 Optical 1 Optical 1

Product Specification

Samsung Electronics 2-5

2-4 Accessories

Accessories Item Item code Remark

Supplied Accessories

Remocon

Alkaline Battery

BP59-00084B

4301-000103

Samsung Service center

Manual BP68-00524A

ANYNET cable BN39-00518B

Accessories that can be purchased

additionally

Video Cable /

Audio Cable

-

Internal shopping mall

Antenna Cable -

Component Cable -

Optical Cable -

2-6 Samsung Electronics

MEMO

Alignment & Adjustment

Samsung Electronics 3-1

3. Alignment & Adjustment

3-1 Service Instruction

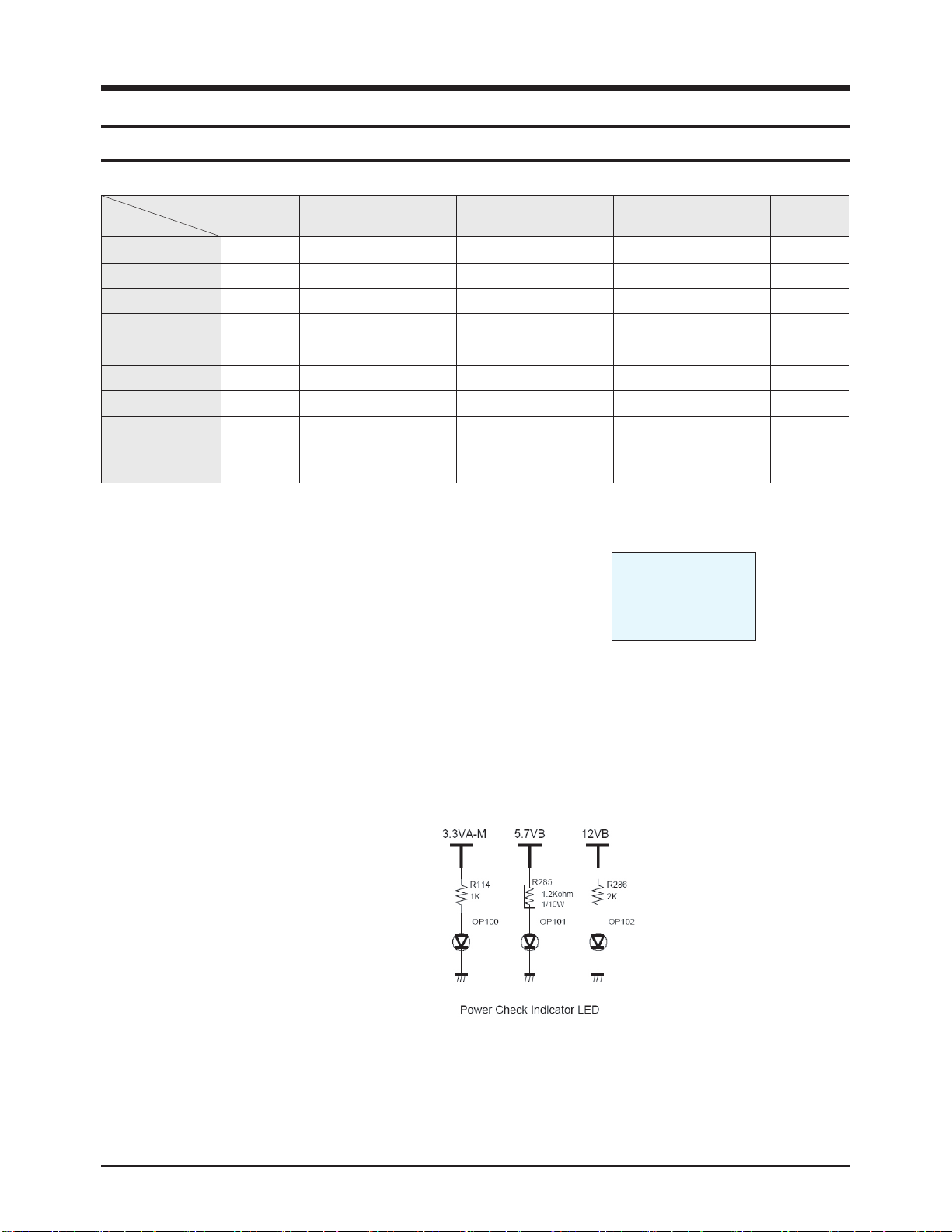

■ Check items listed after changing each

※ If you change digital board and optical engine, check in order.

( For example, in case of "D/B", first 'S/W', second 'V/H position' and third 'Index'...)

1. Software version check :

After Entering the Service mode, Check the list below

* S/W Notation

"T_HUR3AUS5_4002" indicates "HURRICANE3 BASIC MODEL USA, ver. 4002".

2. Front LED check : See page 6-11.

3. Index Delay adjustment : See page 3-13.

4. Actuator Gain adjustment : See page 3-15.

5. Vertical / Horizontal Position adjustment : See page 3-13.

6. CCA : See page 3-14.

7. Board LED check : Check all the LED are turned on.

8. Tilt/Focus adjustment : See page 3-17.

Check Items

Replaced Items

S/W Version Front LED Index Delay

Actuator

Gain

V-Position

H-Position

CCA Board LED Tilt Focus

Digital Board

●(1st) ●(3rd) ●(5th) ●(2nd) ●(4th)

Analog Board

● ●

Power Board

● ●

Optical Engine

●

●(3rd) ●(5th) ●(2nd) ●(4th) ●(1st)

DMD Board

● ●

Lamp

● ●

Color Wheel

●

Front LED Assy

●

Actuator

Subdetector Board

●

T_HUR3AUS0_XXXX

200X_XX_XX

T-HURUCOM5-XXXX

T-HUR3AUS1_XXXX

Alignment & Adjustment

3-2 Samsung Electronics

3-2 How to Access Service Mode

1. Turn off the power to put the unit into the STAND-BY mode.

2. In order to enter the Service Mode, Press "Mute" → "1” → "8" → "2" → "POWER" button on the Remote Control.

In case entry into SERVICE MODE is unsuccessful, repeat the procedures above.

3. Initial DISPLAY State in times of Service Mode Switch overs

4. Buttons operations within Service Mode

DDP1011(L6)

DNIe

ADV7401(M)

ADV7401(S)

uPD64083

MSP4440

CCA(ON)

Cinema CCA

SP Actuator

ESP

CHECKSUM 0000

OPTION

SERVICE

T_HUR3AUS0_XXXX

200X_XX_XX

T-HURUCOM5-XXXX

T-HUR3AUS1_XXXX

MENU Full Menu Display / Move to Parent Menu

Direction keys ▲ / ▼

Item Selection by Moving the Cursor

Direction keys ◀ / ▶

Data Increase/Decrease for the Selected Item

Source Cycles through the active input source that are connected to the unit

Alignment & Adjustment

Samsung Electronics 3-3

3-3 Factory Data

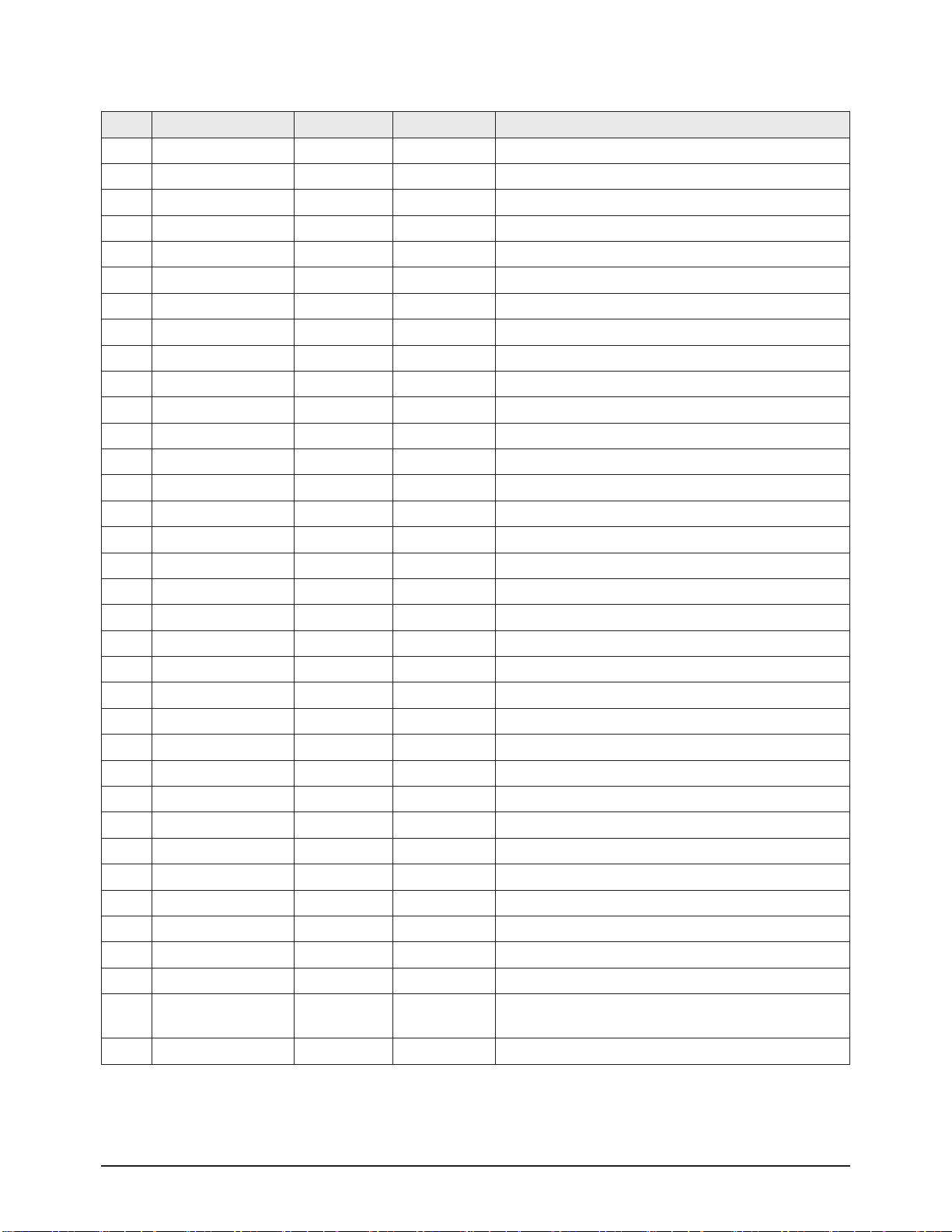

1. DDP1011

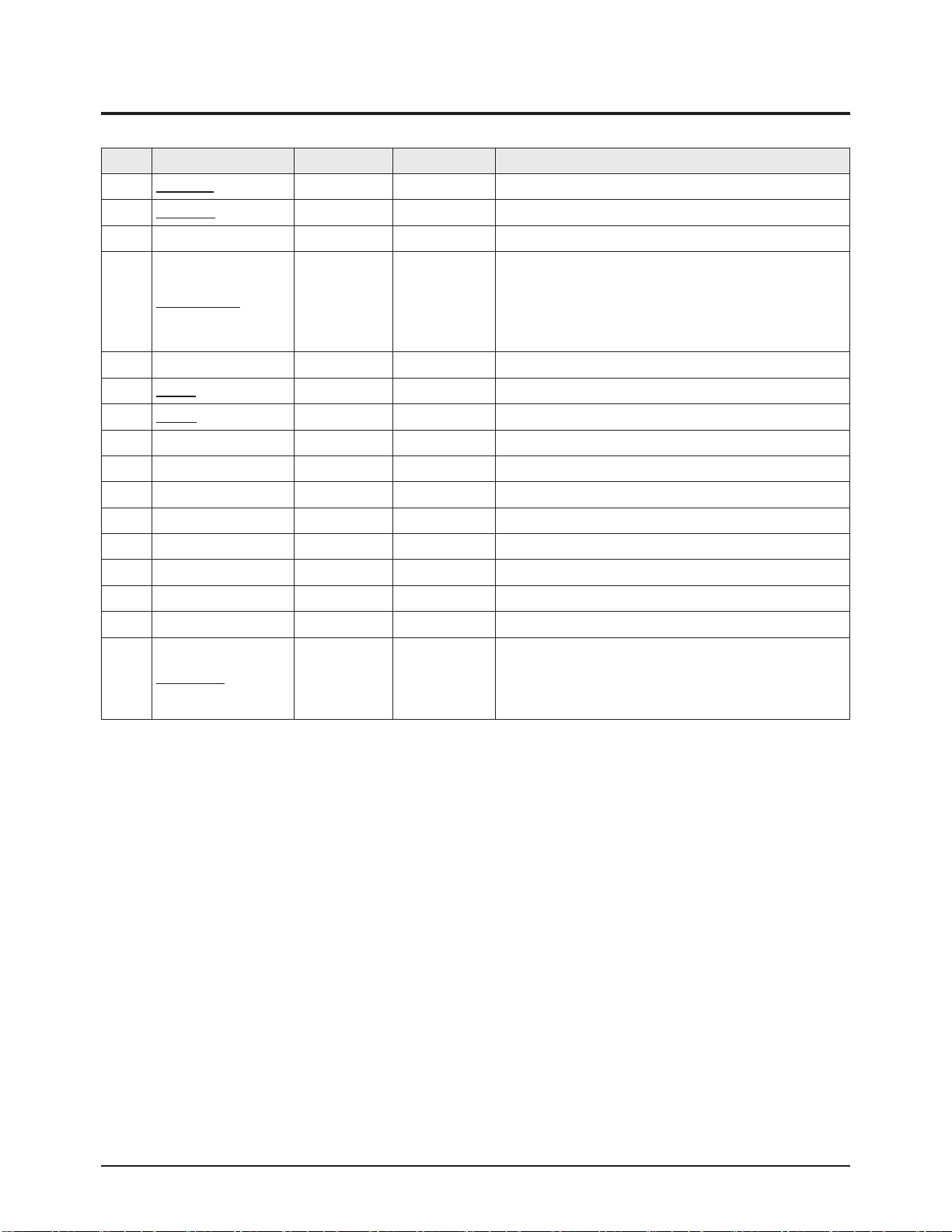

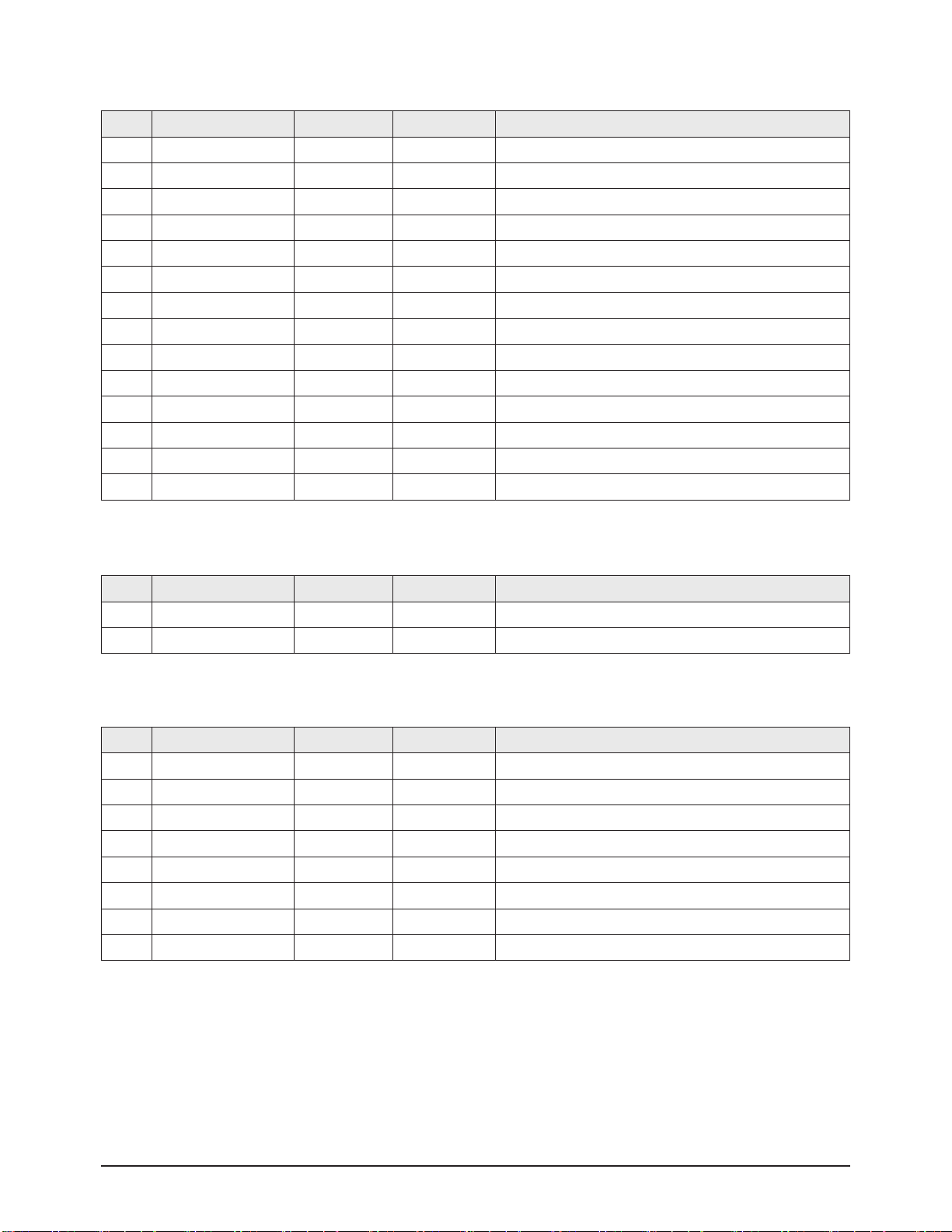

No Item Range Default Remark

1 V

-Position

0-60 36 Screen upper and lower adjustment

2 H-Position 0~120 60 Screen left and right adjustments

3 LAMP SYNC Pulse(P) Pulse(P), Pass(T)

4 INDEX DELAY 0~359 40

Synchronizes the base position of the color wheel with the

corresponding color signal.

This is critical to the natural color display. If the index delay

is not properly set, even the correct CCA cordinates will not

help when displaying natural colors.

5 SEQ SELECT 0~15 5 Sequence Selection

6 V-FLIP Normal/Flip Normal Vertica Flip Operation

7 H-FLIP Normal/Flip Normal Horizontal Flip Operation

8 GAMMA 0 ~ 15 2 Gamma Table Selection

9 SLR OFF/ON OFF SLR Funcion On/Off

10 DMD_BIAS B,C,D,E E DMD Bias pin voltage selection

11 Lamp Boost 0~63 20 Lamp Boost value selection

12 Lamp Sync Delay 0~4095 0 Lamp Sync delay value selection

13 Engine Select SAMSUNG SAMSUNG and ZEISS Selection

14 Lamp Watt 120W 120W/132W Selection

15 Lamp Select Philips Philips/Osram/Ushio

16 T

est Pattern

0

This displays the built-in pattern of the DDP1011 chip.

DDP1011 drives the DMD panel, so displaying this pattern

means there is no error in the DDP1011 projection function

and the panel itself.

★ The underlined are items applied during the service adjustment. None of the others should be adjusted.

Alignment & Adjustment

3-4 Samsung Electronics

2. DNIe

No Item Range Default Remark

1 Test Pattern 0 Test Pattern Selection

2 NR_MAX Y/C 0~255 48 Temporal NR Gain

3 NR_MIN Y/C 0~255 16 Temporal NR Gain

4 Core 0~15 4 NEOnDCE User Set Up

5 B_RATIO 12000 Low level information for the minimum value

6 BLACK_TILT 0~255 120 Black Stretch Area

7 W_RATIO 12000 High level information for the minimum value

8 WHITE_TILT 0~255 200 White Stretch Area

9 GAIN1X 0~63 30 Gain of horizontal high frequency region

10 GAIN1Y 0~63 20 Gain of vertical high frequency region

11 GAIN2X 0~63 17 Gain of horizontal middle frequency region

12 GAIN2Y 0~63 13 Gain of vertical middle frequency region

13 GAIN3X 0~63 11 Gain of horizontal low frequency region

14 NDON ON ON,OFF Background Noise Detection ON/OFF Switch

15 CORING_ON ON ON,OFFCoring On/Off

16 SCALE_R 0~255 160 Log Mapping Gain

17 WTE_CSC YCCRGB YCCRGB,YPPRGB

18 DITHER_MOD 0 1,2,3

19 RED_C_COEFF 128 Gain adjustment of the contrast for the Red signal

20 GRN_C_COEFF 128 Gain adjustment of the contrast for the Green signal

21 BLU_C_COEFF 128 Gain adjustment of the contrast for the Blue signal

22 RED_B_COEFF 128 Gain adjustment of the brightness for the Red signal

23 GRN_B_COEFF 128 Gain adjustment of the brightness for the Green signal

24 BLU_B_COEFF 128 Gain adjustment of the brightness for the Blue signal

25 Sub Contrast 0~150 120 Brightness adjustment for the high-light parts of the screen

26 Sub Brightness 230 Brightness adjustment for the low-light parts of the screen

27 ALPMAU/L 0~255 50

Alignment & Adjustment

Samsung Electronics 3-5

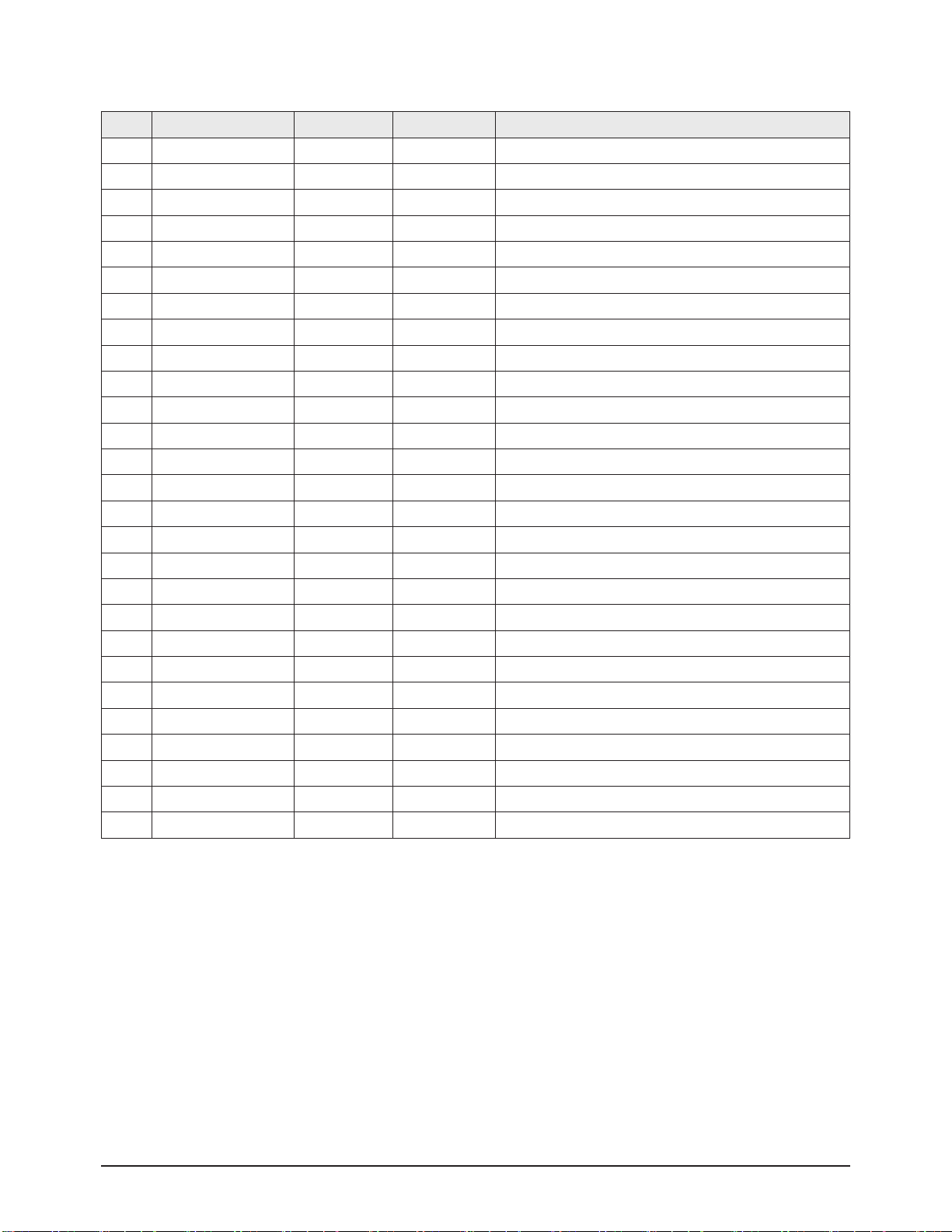

3. ADV7401(M)

No Item Range Default Remark

1 AUTO COLOR Auto Color function execution

2 SOG_SYNC_LEV Embedded Sync Trigger Level

3 AGC_TIM AGC Time Constant Selection

4 GAIN_MAN ON,OFF Manual Gain Control Enable

5 A_GAIN Manual Gain Value for Channel A

6 B_GAIN Manual Gain Value for Channel B

7 C_GAIN Manual Gain Value for Channel C

8 A_OFFSET Channel A Offset

9 B_OFFSET Channel B Offset

10 C_OFFSET Channel C Offset

11 YPM 0~7 4 Y Peaking Filter Mode

12 YSFM 0~32 1 Y Shaping Filter Mode

13 WYSFM 0~32 19 Wide Band TY Shaping Filter Mode

14 CSFM 0 C Shaping Filter Mode

15 Contrast 0~255 128 Contrast Adjust

16 Brightness 0~255 128 Brightness Adjust

17 Hue 0~255 128 Hue Adjust

18 CKILLTHR 0~7 3 Colour Kill Threshold

19 SD_OFF_Cb 0~255 128 SD Offset Cb Channel

20 SD_OFF_Cr 0~255 128 SD Offset Cr Channel

21 SD_SAT_Cb 0~255 128 Saturation Cb Channel

22 SD_SAT_Cr 0~255 128 Saturation Cr Channel

23 IFFILTSEL 0~7 3 IF Filter Select

24 LTA 0~3 0 Luma Timing Adjust

25 CTA 0~7 2 Chroma Timing Adjust

26 DNR_TH1 0~255 0 DNR Noise Threshold

27 DCT 0~3 0 Digital Clamp Timing

28 LAGC 0~7 0 Luma Automatic Gain Control

29 LAGT 0~3 3 Luma Automatic Gain Timing

30 LMG 1144 Luma Manual Gain

31 CAGC 0~7 5 Chroma Automatic Gain Control

32 CAGT 0~3 3 Chroma Automatic Gain Timing

33 CMG 2458 Chroma Manual Gain

34 CTI_AB_EN ON

ON,OFF Chroma Transient Improvement Alpha Blend

Enable

35 CTI_AB 0~3 3 Chroma Transient Improvement Alpha Blend

Alignment & Adjustment

3-6 Samsung Electronics

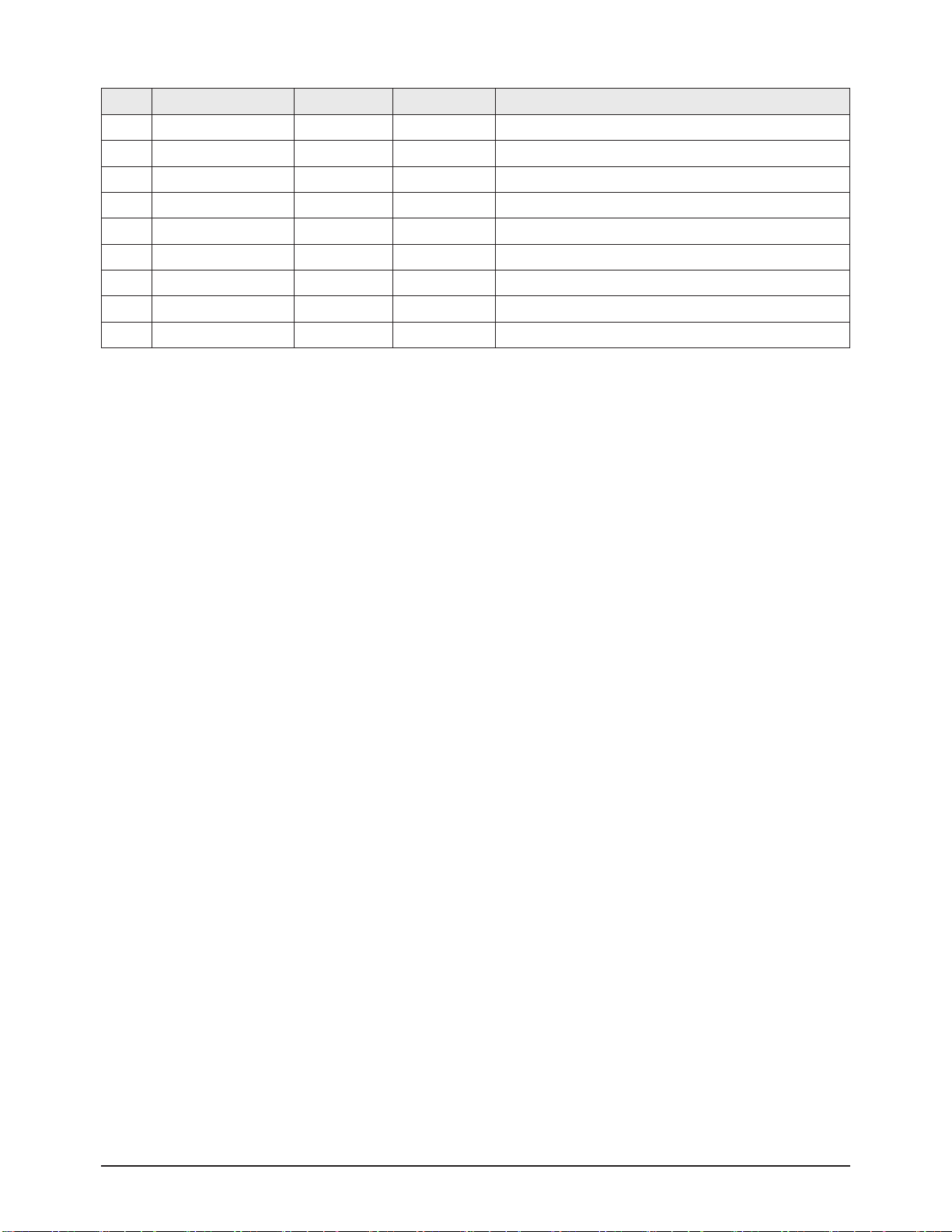

No Item Range Default Remark

36 CTI_C_TH 0~255 8 CTI Chroma Threshold

37 NSFSEL 0~3 0 Split Filter Selection NTSC

38 CTAPSN 0~3 2 Chroma Comb Taps NTSC

39 CCMN 0~7 0 Chroma Comb mode NTSC

40 YCMN 0~7 0

41 HSSLICE

42 VSSLICE

43 DLL_PH

44 ST_NOISE OxFFFF

45 ALIAS_FILTER_EN

46 DNR_TH2 4

Alignment & Adjustment

Samsung Electronics 3-7

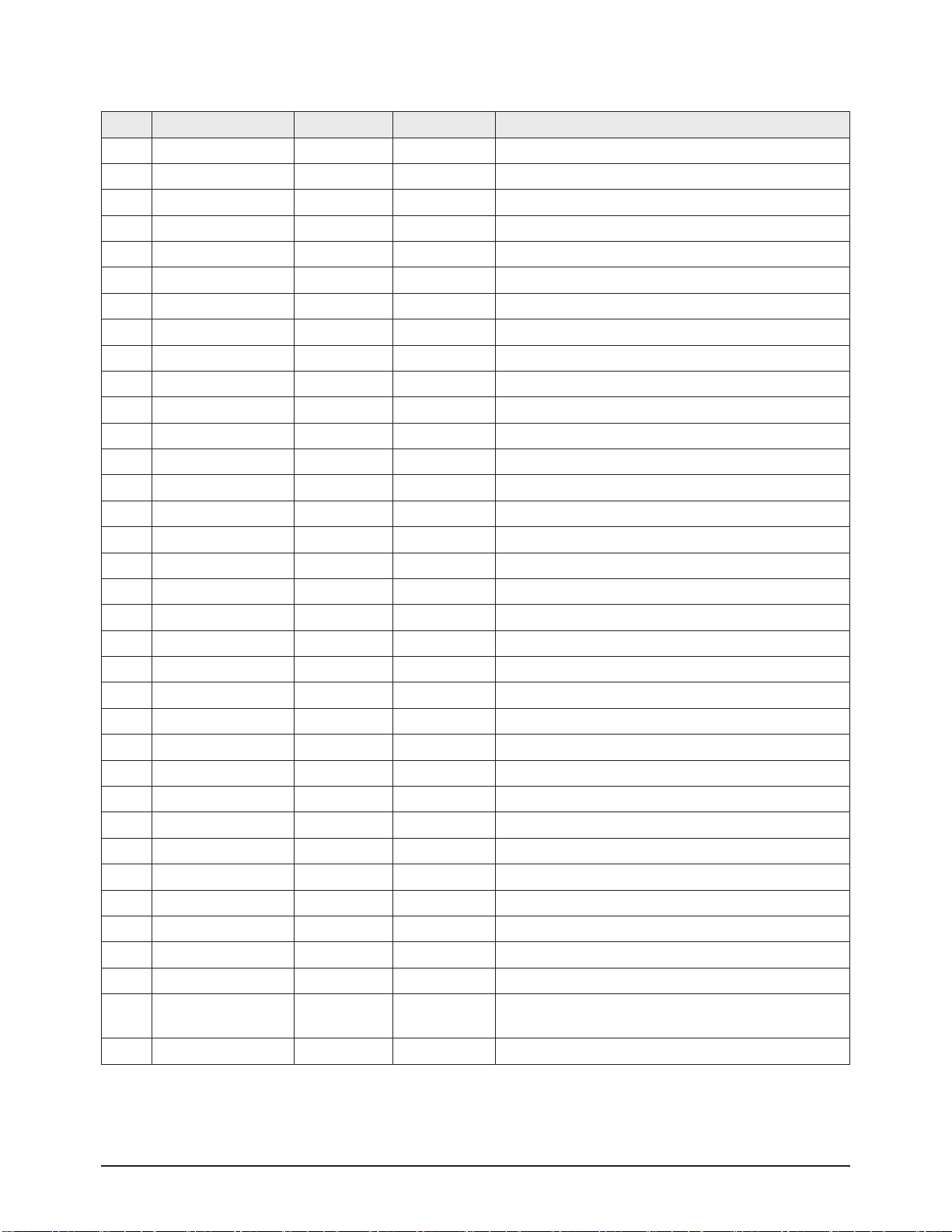

4. ADV7401(S)

No Item Range Default Remark

1 AUTO COLOR Auto Color function execution

2 SOG_SYNC_LEV 0~31 11 Embedded Sync Trigger Level

3 AGC_TIM 0~7 0 AGC Time Constant Selection

4 GAIN_MAN ON ON,OFF Manual Gain Control Enable

5 A_GAIN 0~1024 275 Manual Gain Value for Channel A

6 B_GAIN 0~1024 287 Manual Gain Value for Channel B

7 C_GAIN 0~1024 287 Manual Gain Value for Channel C

8 A_OFFSET 0~1024 0 Channel A Offset

9 B_OFFSET 0~1024 512 Channel B Offset

10 C_OFFSET 0~1024 512 Channel C Offset

11 YPM 0~7 4 Y Peaking Filter Mode

12 YSFM 0~32 1 Y Shaping Filter Mode

13 WYSFM 0~32 19 Wide Band TY Shaping Filter Mode

14 CSFM (0~7) 0 C Shaping Filter Mode

15 Contrast 0~255 128 Contrast Adjust

16 Brightness 0~255 126 Brightness Adjust

17 Hue 0~255 128 Hue Adjust

18 CKILLTHR 0~7 3 Colour Kill Threshold

19 SD_OFF_Cb 0~255 128 SD Offset Cb Channel

20 SD_OFF_Cr 0~255 128 SD Offset Cr Channel

21 SD_SAT_Cb 0~255 128 Saturation Cb Channel

22 SD_SAT_Cr 0~255 128 Saturation Cr Channel

23 IFFILTSEL 0~7 3 IF Filter Select

24 LTA 0~3 0 Luma Timing Adjust

25 CTA 0~7 3 Chroma Timing Adjust

26 DNR_TH 0~255 0 DNR Noise Threshold

27 DCT 0~3 0 Digital Clamp Timing

28 LAGC 0~7 0 Luma Automatic Gain Control

29 LAGT 0~3 3 Luma Automatic Gain Timing

30 LMG 0~4096 1064 Luma Manual Gain

31 CAGC 0~7(0~3) 2 Chroma Automatic Gain Control

32 CAGT 0~3 3 Chroma Automatic Gain Timing

33 CMG 0~4096 2458 Chroma Manual Gain

34 CTI_AB_EN ON

ON,OFF Chroma Transient Improvement Alpha Blend

Enable

35 CTI_AB 0~3 3 Chroma Transient Improvement Alpha Blend

Alignment & Adjustment

3-8 Samsung Electronics

No Item Range Default Remark

36 CTI_C_TH 0~255 8 CTI Chroma Threshold

37 NSFSEL 0~3 0 Split Filter Selection NTSC

38 CTAPSN 0~3 2 Chroma Comb Taps NTSC

39 CCMN 0~7 0 Chroma Comb mode NTSC

40 YCMIN 0~7 0

41 HSSLICE 0~3 1

42 VSSLICE 0~3 3

43 DLL_PH

44 ST_NOISE OxFFFF

Alignment & Adjustment

Samsung Electronics 3-9

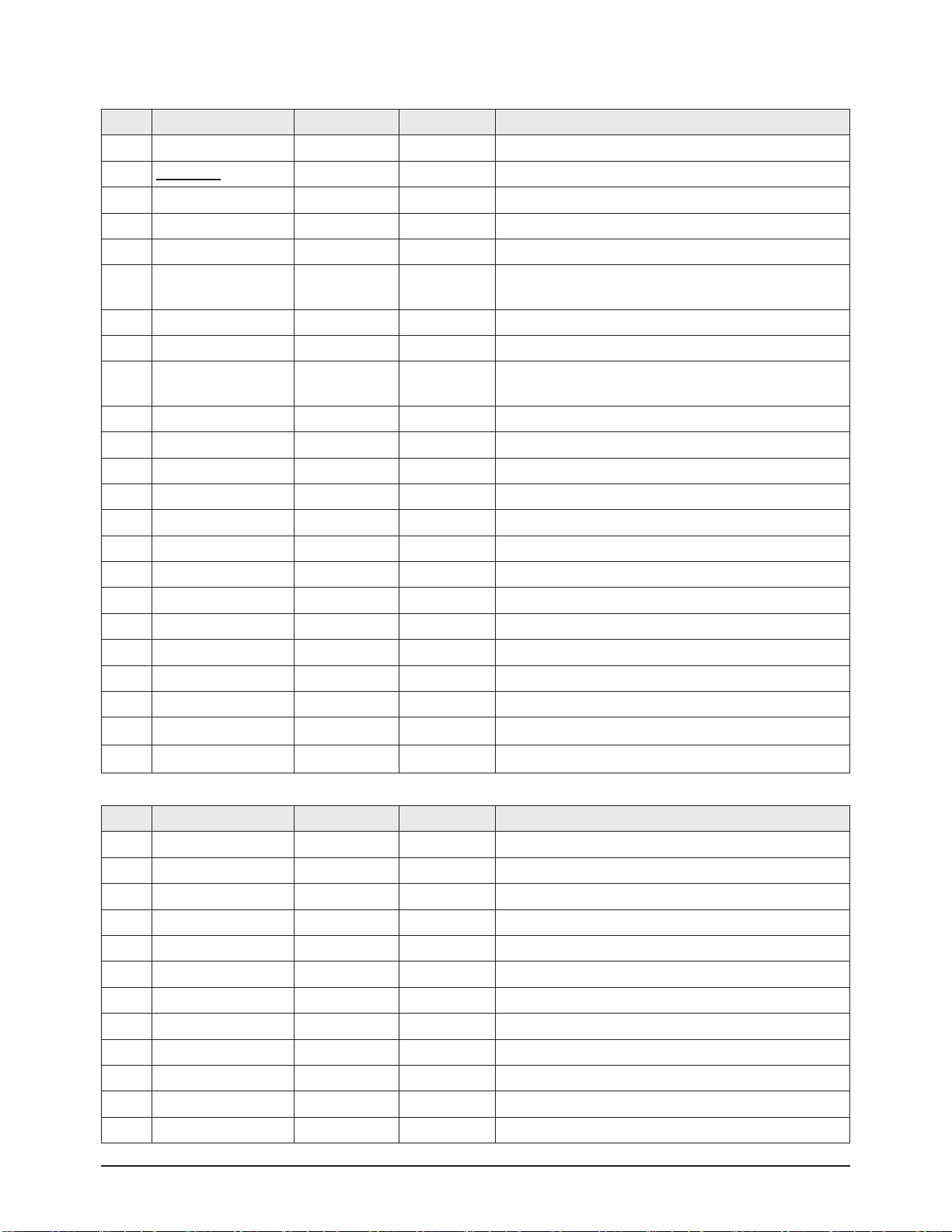

5. Upd64083

No Item Range Default Remark

1 DYCOR 0 ~ 15 2 DY detection coring level

2 DYGAIN 0 ~ 15 9 DY detection gain

3 DCCOR 0 ~ 15 3 DC detection coring level

4 DCGAIN 0 ~ 15 6 DC detection gain

5 YHCOR 0 ~ 3 1 Y output high frequency component coring

6 CDELAY 0 ~ 3 4 C signal output delay

7 YPFT 3 YPFT adjustment

8 YPFG 8 YPFG adjustment

6. MSP4440

No Item Range Default Remark

1 MDB Effect 0~127 56 Micronas Dynamic Bass

2 SRS Dialog 0~127 64 SRS Dialog clarity adjustment

3 PLL Pilot low adjustment

4 PLH Pilot high adjustment

Alignment & Adjustment

3-10 Samsung Electronics

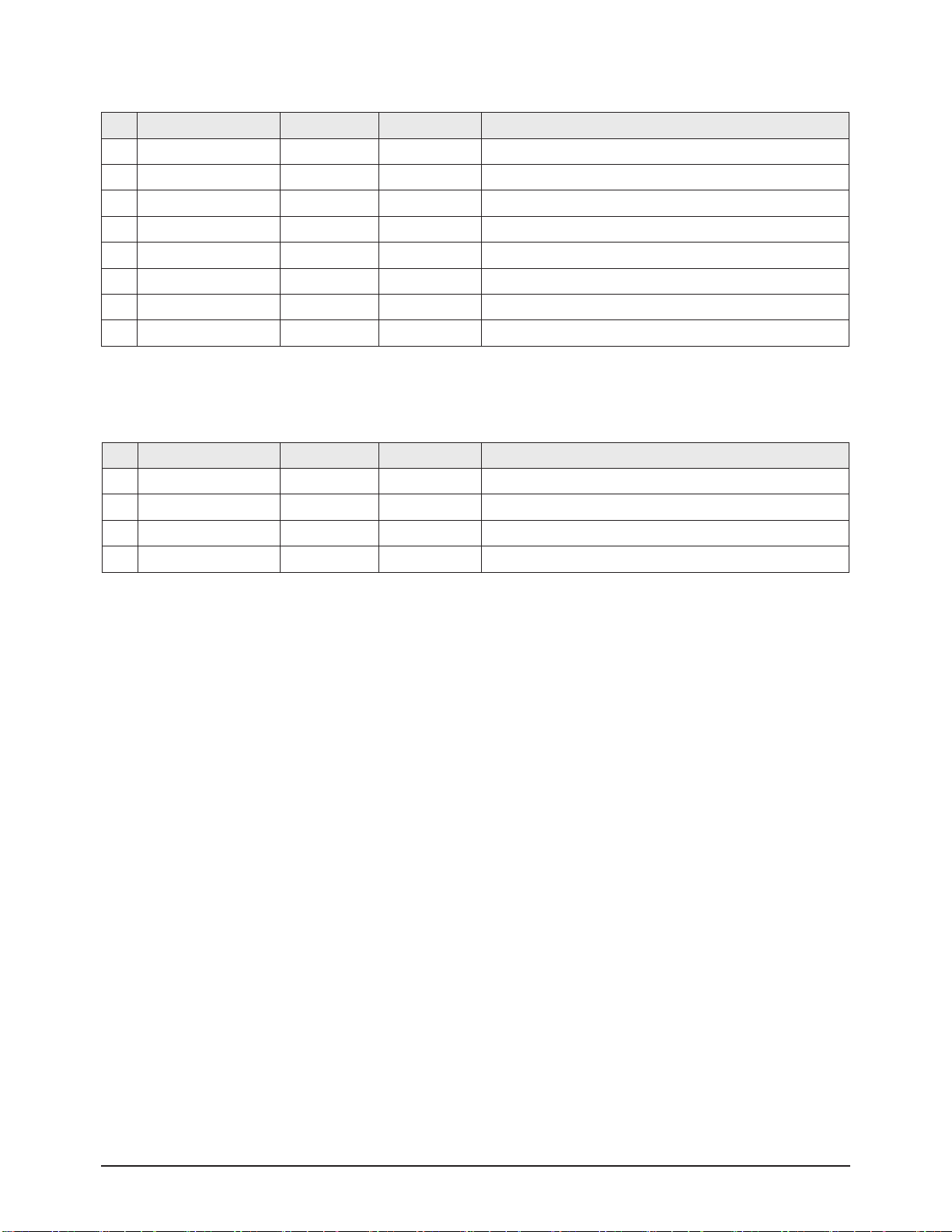

7. CCA(ON)

No Item Range Default Remark

1 CCA On/Off On CCA On/Off Selection

2 Red-x 0~32768 640 Red-x adjustment

3 Red-y 0~32768 340 Red-y adjustment

4 Red-Y 0~32768 86 Red-Y adjustment

5 Green-x 0~32768 300 Green-x adjustment

6 Green-y 0~32768 620 Green-y adjustment

7 Green-Y 0~32768 300 Green-Y adjustment

8 Blue-x 0~32768 150 Blue-x adjustment

9 Blue-y 0~32768 60 Blue-y adjustment

10 Blue-Y 0~32768 53 Blue-Y adjustment

11 White-x 0~32768 291 White-x adjustment

12 White-y 0~32768 300 White-y adjustment

13 White-Y 0~32768 439 White-Y adjustment

14 WB Spread Spread CCA value to all mode

15 Move HDMI Move to the HDMI Mode

16 DRedX Target Red X value for CCA

17 DRedY Target Red Y value for CCA

18 DGreenX Target Green X value for CCA

19 DGreenY Target Green Y value for CCA

20 DBlueX Target Blue X value for CCA

21 DBlueY Target Blue Y value for CCA

22 DCyanX Target Cyan X value for CCA

23 DCyanY Target Cyan Y value for CCA

24 DMagentaX Target Magenta X value for CCA

25 DMagentaY Target Magenta Y value for CCA

26 DYellowX Target Yellow X value for CCA

27 DYellowY Target Yellow Y value for CCA

28 D_White_X Target White X value for CCA

29 D_White_Y Target White Y value for CCA

30 ATV/AV/SV

Alignment & Adjustment

Samsung Electronics 3-11

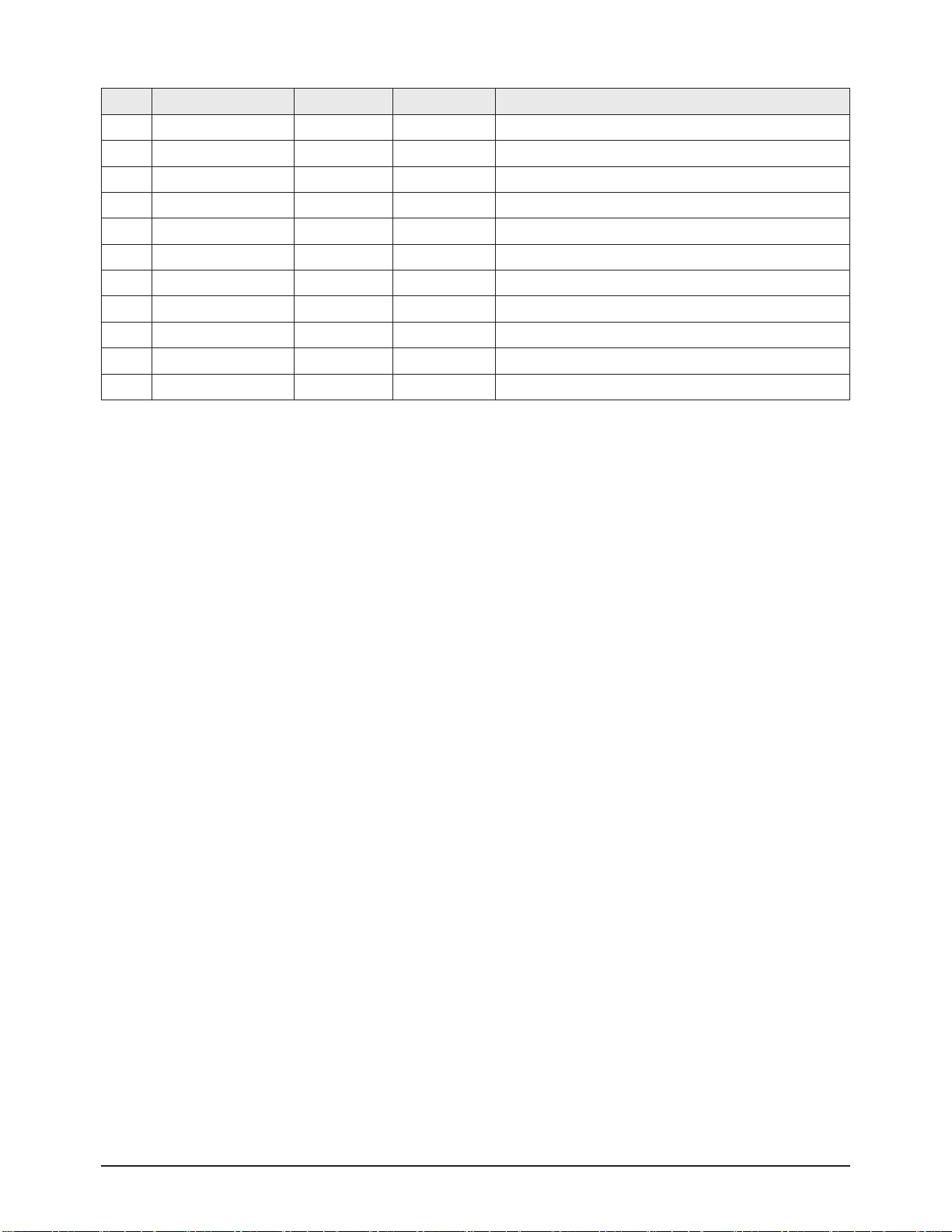

8. Cinema CCA

No Item Range Default Remark

1 DRedX 640 Target Red X value for CCA

2 DRedY 340 Target Red Y value for CCA

3 DGreenX 300 Target Green X value for CCA

4 DGreenY 620 Target Green Y value for CCA

5 DBlueX 150 Target Blue X value for CCA

6 DBlueY 60 Target Blue Y value for CCA

7 DCyanX 205 Target Cyan X value for CCA

8 DCyanY 270 Target Cyan Y value for CCA

9 DMagentaX 290 Target Magenta X value for CCA

10 DMagentaY 140 Target Magenta Y value for CCA

11 DYellowX 425 Target Yellow X value for CCA

12 DYellowY 515 Target Yellow Y value for CCA

13 D-White-X 313 Target White X value for CCA

14 D-White-Y 329 Target White Y value for CCA

10. ESP

No Item Range Default Remark

1 Dynamic Con Off Dynamic Contrast On/Off

2 Dynamic Strength Medium Low/Mid/Mas

3 Dynamic Con Gain 0~100 0 Dynamic Contrast Gain Adjustment

4 Dynamic Sat Off Dynamic Saturation On/Off

5 Dynamic Sat Gain 0~255 176 Dynamic Saturation Gain Adjustment

6 Sharp Picture Off Sharp Picture On/Off

7 Sharp Filter HD Low HD High/HD Low/SD Image

8 Sharp Picture Gain 0~255 176 Sharp Picture Gain Adjustment

9. SP Actuator

11. CHECKSUM 0000

Excute Checksum calcuation

No Item Range Default Remark

1 Actuator Gain 0~175 115 Actuator Gain adjustment

2 Actuator On/Off On Actuator On/Off selection

Alignment & Adjustment

3-12 Samsung Electronics

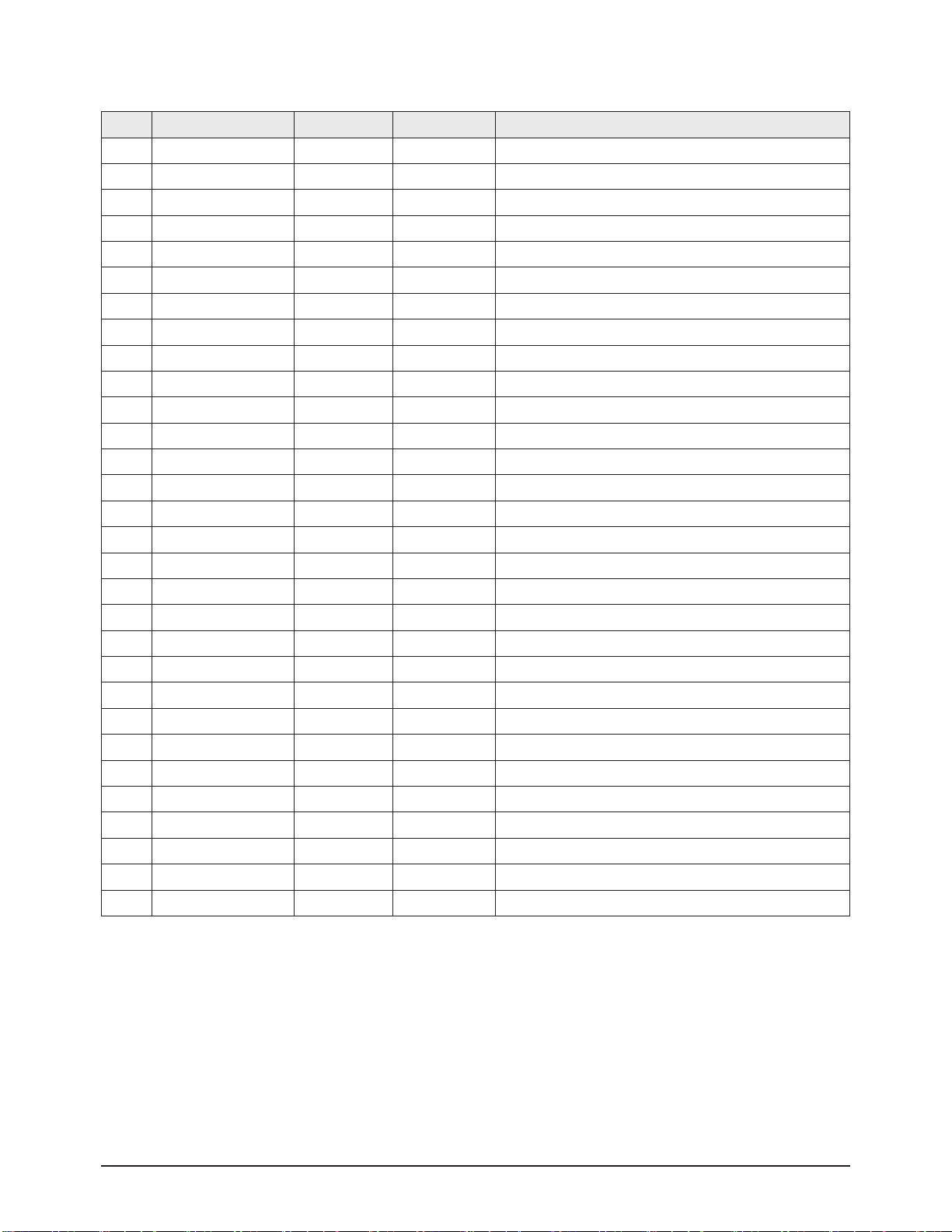

12. OPTION

No Item Range Default Remark

1 Lamp Clear Initialize lamp usage time. Lamp Life is set to zero

2 User Reset All setting is back to the default

3 WB Reset OFF Initialize the White Balance value

4 EER Reset Clear the EEPROM

5 Lamp Life 0h Lamp on time counter

6 AUTO POWER ON/OFF ON

The sets turns on automatically when the power cord is

plugged in

7 DNle DEMO ON/OFF ON DNle Demo function selection

8 Lamp Control Dynamic Dynamic, Always

9 MUTE TIME 600ms

Time which the screen will be black while switching

channels

10 EDID WRITE

11 DELAY MOD ON/OFF OFF Sound Delay Module ON/OFF selection

12 DBG/ANY SEL Debug/AnyNet Select the use of the Anynet jack

13 GEM/GEMIR SEL GemIR/Gemstar Not used

14 226 TEST PATT Xilleon 226 test pattern

15 Set Default Data Initialize Service Data

16 DDC protection OFF DDC write ON/OFF selection

17 LNA Default AUTO LNA setting OFF/Auto selection

18 PROTECT ON Protection ON/OFF selection

19 WATCH DOG Watch Dog ON/OFF selection

20 WD COUNT 0 Count for Watch Dog event

21 Auto Pgm Range 8 Not used

22

DIGITAL→DMD

Transfer engine adjustment data from digital to DMD

23

DMD→DIGITAL

Transfer engine adjustment data from DMD to digital

13. SERVICE

No Item Range Default Remark

1 V-Position 0 ~ 60 30 Screen upper and lower adjustment

2 H-Position 0 ~ 120 60 Screen left right adjustment

3 LAMP SYNC Pulse/Pass Pulse

4 Actuator Gain 105 Actuator Gain adjustment

5 INDEX DELAY 0 ~ 1023 166 Index delay adjustment

6 AUTO COLOR OFF Auto Color function execution

7 CCA CCA menu

8 Lamp Clear Initialize Lamp usage time

9 User Reset All setting is back to the default

10 Engine Select SAMSUNG SAMSUNG and ZEISS Selection

11 Lamp Watt 120W 120W/132W Selection

12 Lamp Select Philips Philips/Osram/Ushio

Alignment & Adjustment

Samsung Electronics 3-13

3-4 Service Adjustment

3-4-1 Vertical / Horizontal Position Adjustment

1. Turn off the power to put the unit into the STAND-BY mode.

2. In order to enter the Service Mode, Press "Mute" → "1" → "8" → "2" → "POWER" button on the Remote Control.

3. Select "Service" on the first display of the Service mode menu.

4. Select the V-position for vertical positioning and H-position for horizontal positioning by using the ▲▼(up, down) buttons.

※ Do not set the V-position value to 34 or 35. (Setting to these values will cause horizontal lines on the right side of the screen.)

3-4-2 INDEX DELAY Adjustment

1. Turn off the power to put the unit into the STAND-BY mode.

2. In order to enter the Service Mode, Press "Mute" → "1" → "8" → "2" → "POWER" button on the Remote Control.

3. Select "Service" on the first display of the Service mode menu.

4. Press the ▲▼(Up or Down) button to move to INDEX DELAY, then press ENTER to select.

5. The INDEX DELAY setup screen (with a red bar at the bottom of the screen) will be displayed.

6. Press the ◀▶ (Left of Right) button to check the red color at the bottom of the screen at its minimum and maximum values of

changing from red to magenta, then adjust to the mean value.

Alignment & Adjustment

3-14 Samsung Electronics

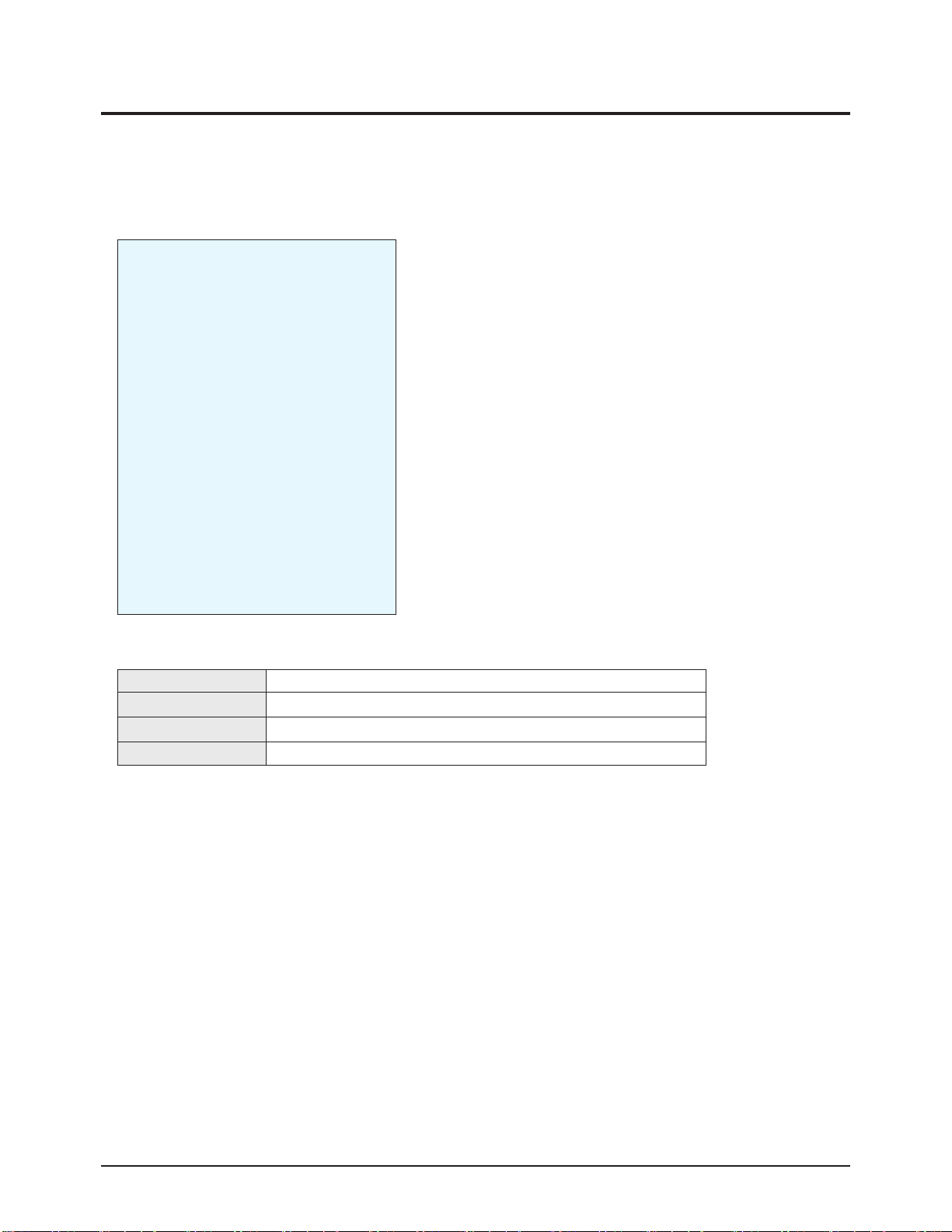

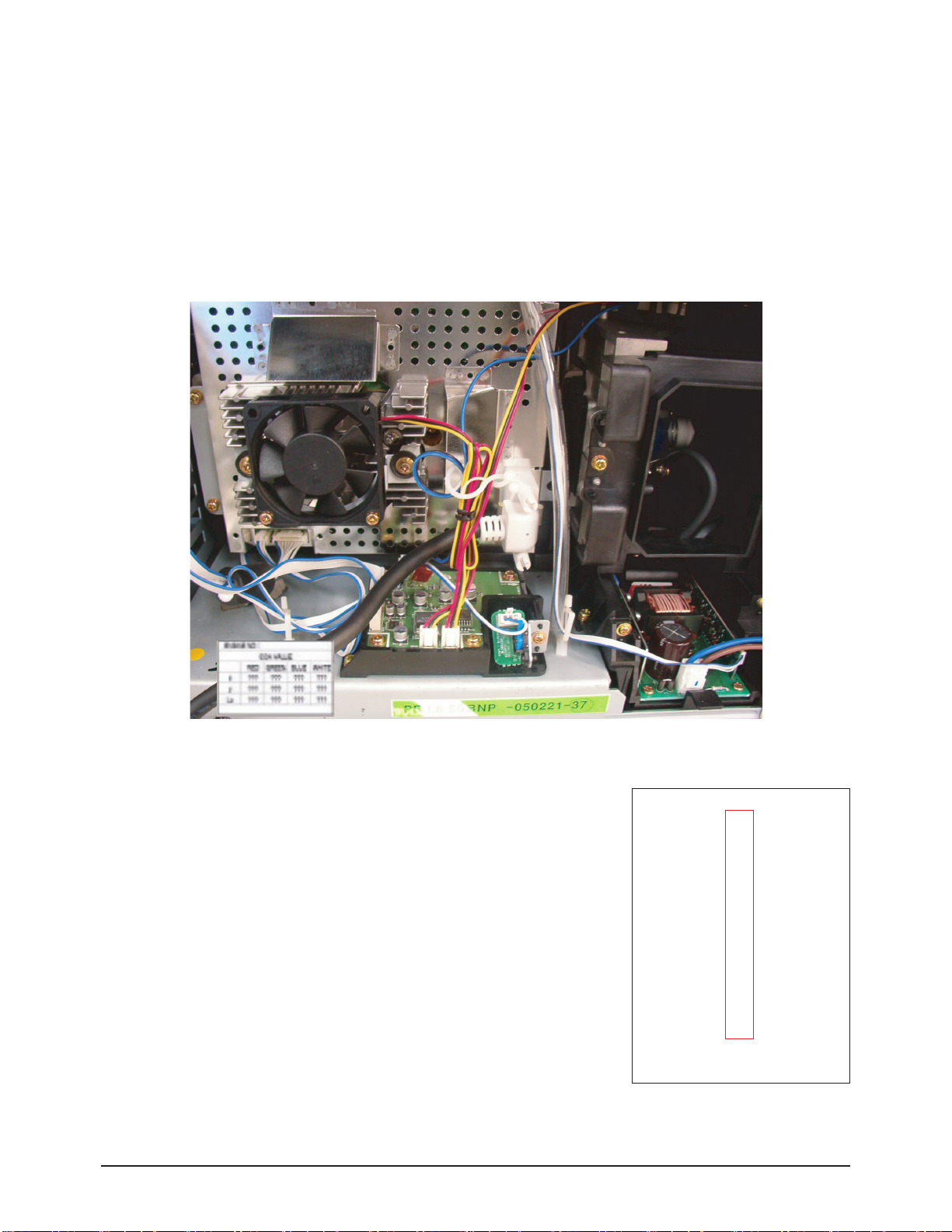

3-4-3 CCA Adjustment Service Methods : CCA Adjustment is needed after changing a light engine or digital board

■ CCA : In DLP TV, even the same RGB color may differ depending on the light engine. CCA (Color Coordinate Adjustment)

corrects the color to achieve the color accuracy. CCA performs color correction after measuring and inputting the current

light engine's data on actual color coordinates for displayed Red, Green, Blue, and White color patterns, using a color

coordinate measuring equipment.

At this moment, color correction is performed on the basis of previously inputted Desired Color Coordinates and

Measured Color Coordinates. Measured Data on Service Engine's color coordinates is presented on the CCA label.

Input the label values to perform CCA color correction.

1. Condition of the CCA Label upon Receipt of the Service Engine

*"CCA LABEL" describes the measured color coordinates on the light engine.

2. CCA Service Procedures

To execute CCA adjustment , perform the following steps :

1) Turn off the power to put the unit into the STAND-BY mode.

2) In order to enter the Service Mode, Press "Mute" → "1" → "8" → "2" → "POWER"

button on the Remote Control.

3) From the Factory Service Mode Menu; select SERVICE > CCA.

4) Switch the CCA OFF.

5) Enter the CCA Red, Green, Blue and White basic engine data to the DLP.

6) Input the D-White-x, y values in the coordinates per destination. (if necessary)

7) Select WB SPREAD, then press Enter to activate the WB Spread SET ensuring that

you adjust until you get the OK sign. After adjusting, exit Factory Mode.

8) When the adjustment is complete, check the picture quality.

*Attention

Performing CCA is independent on current display's resolution and input signal type if you

don't measure color coordinates data.

Measuring color coordinates data requires specific equipment not possessed by service per

sonnel, that makes performing manual adjustment impossible. Adjusting CCA is applied to all the signal mode.

Don't change Desired value because it will be hamful to the color of the SET.

CCA Menu in FACTORY Mode

CCA ON/OFF

Red - x : ???

Red - y : ???

Red - Y : ???

Green - x : ???

Green - y : ???

Green - Y : ???

Blue - x : ???

Blue - y : ???

Blue - Y : ???

White - x : ???

White - y : ???

White - Y : ???

WB SPREAD

Move HDMI

Alignment & Adjustment

Samsung Electronics 3-15

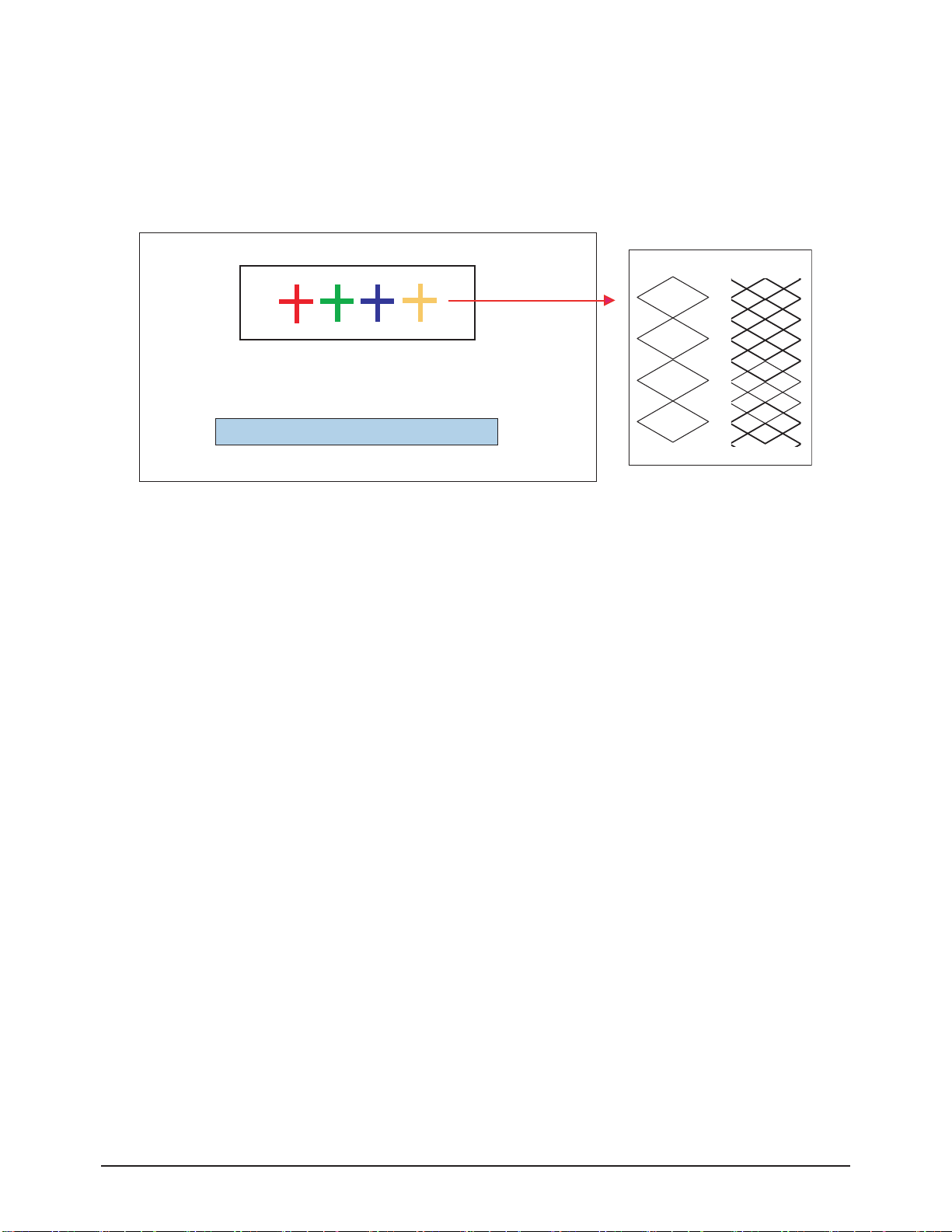

3-4-4 ACTUATOR GAIN Adjustment

1. Before Adjustment

1) Turn off the power to put the unit into the STAND-BY mode.

2) In order to enter the Service Mode, Press "Mute" → "1" → "8" → "2" → "POWER" button on the Remote Control.

3) Select "Service" on the first display of the Service mode menu.

4) Press the ▲▼(Up or Down) button to move to ACTUATOR GAIN, then press ENTER to select.

2. Making Adjustments

1) As shown in the picture above, change the actuator values to eliminate saw tooth shapes.

- To fine tune, increase the data value ensuring that you get the center between the starting and ending points of the

disappearing saw tooth shape.

Before Adjusting After Adjusting

Actuator Gain 115

Loading...

Loading...