Samsung HLN467WX/XAA Schematic

DLP PROJECTION TELEVISION

Chassis : L62A(N) REV.3

Model : HLN467WX/XAA

HLN567WX/XAA

DLP PROJECTION TELEVISION CONTENTS

Precautions

Reference Information

Specifications

Disassembly and Reassembly

Alignment and Adjustments

Operation Check &

Troubleshooting for each PCB

Board

Exploded View and Parts List

Electrical Parts List

Block Diagram

Wiring Diagram

Schematic Diagrams

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

ELECTRONICS

© Samsung Electronics Co., Ltd. JUN. 2003

Printed in Korea

AA82-00784A

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

1. Precautions

1-1 Safety Precautions

1. Be sure that all of the built-in protective

devices are replaced. Restore any missing

protective shields.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including: nonmetallic control knobs

and compartment covers.

3. Make sure that there are no cabinet openings

through which people—particularly

children—might insert fingers and contact

dangerous voltages. Such openings include

the spacing between the picture tube and the

cabinet mask, excessively wide cabinet

ventilation slots, and improperly fitted back

covers.

If the measured resistance is less than 1.0

megohm or greater than 5.2 megohms, an

abnormality exists that must be corrected

before the unit is returned to the customer.

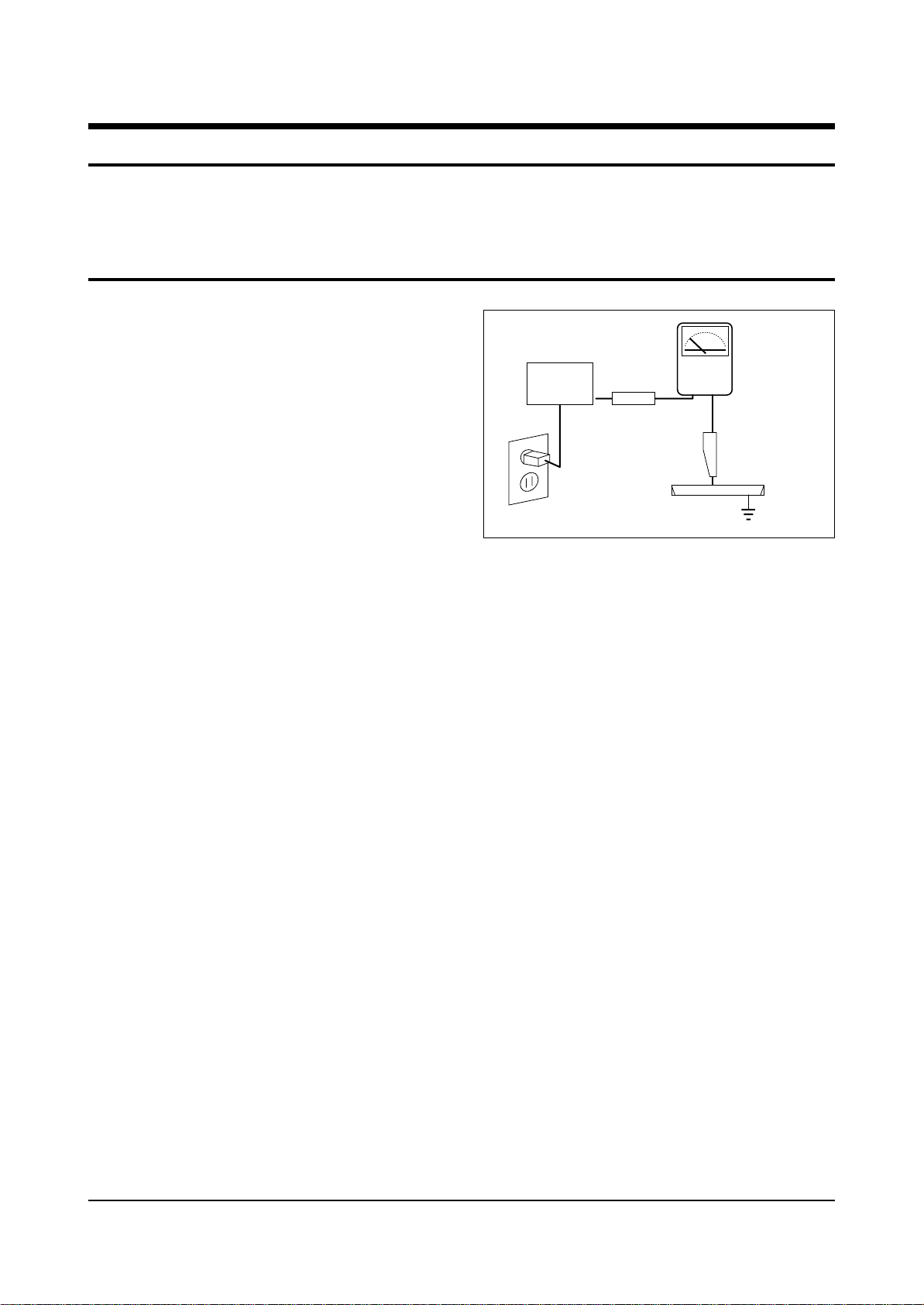

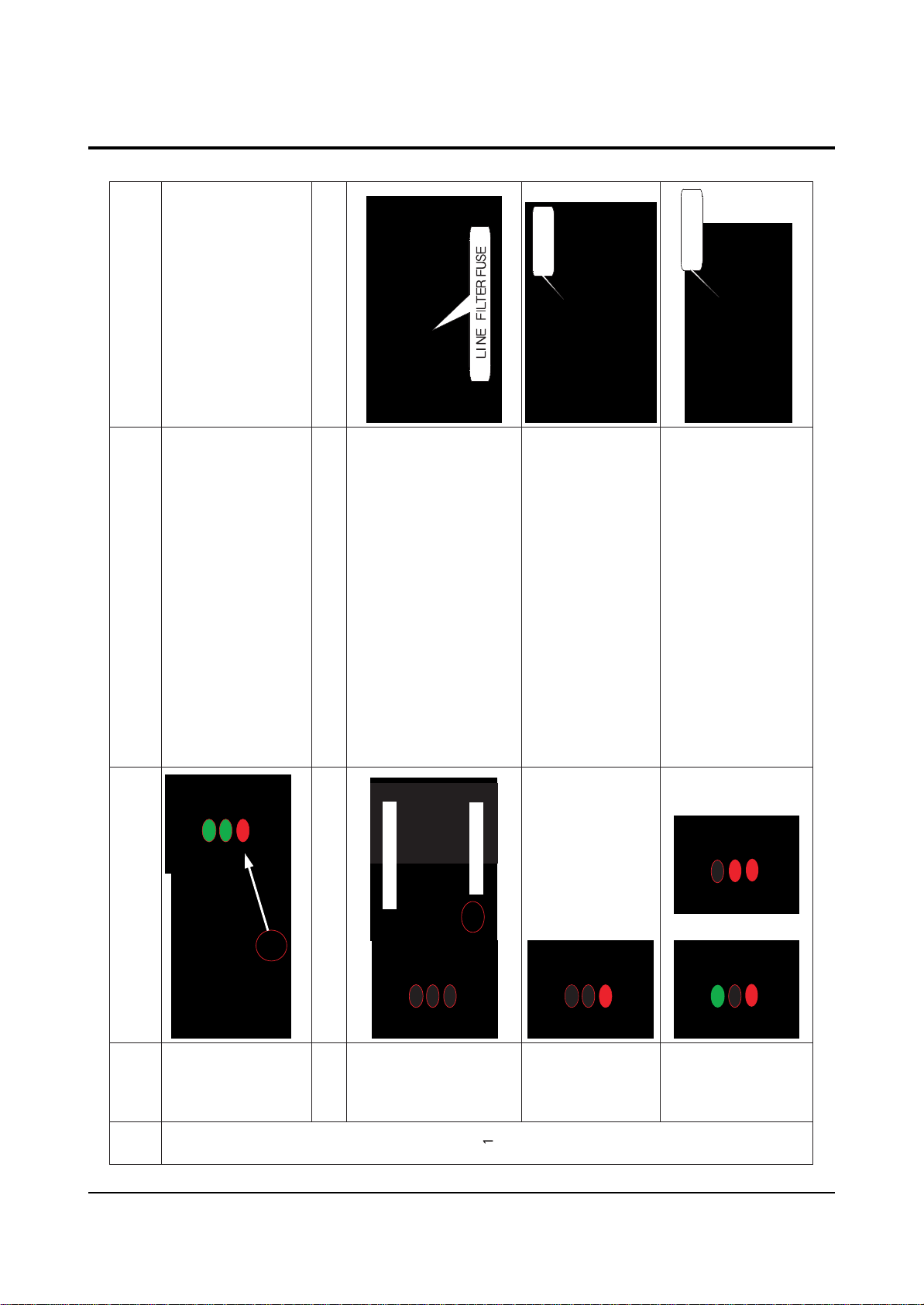

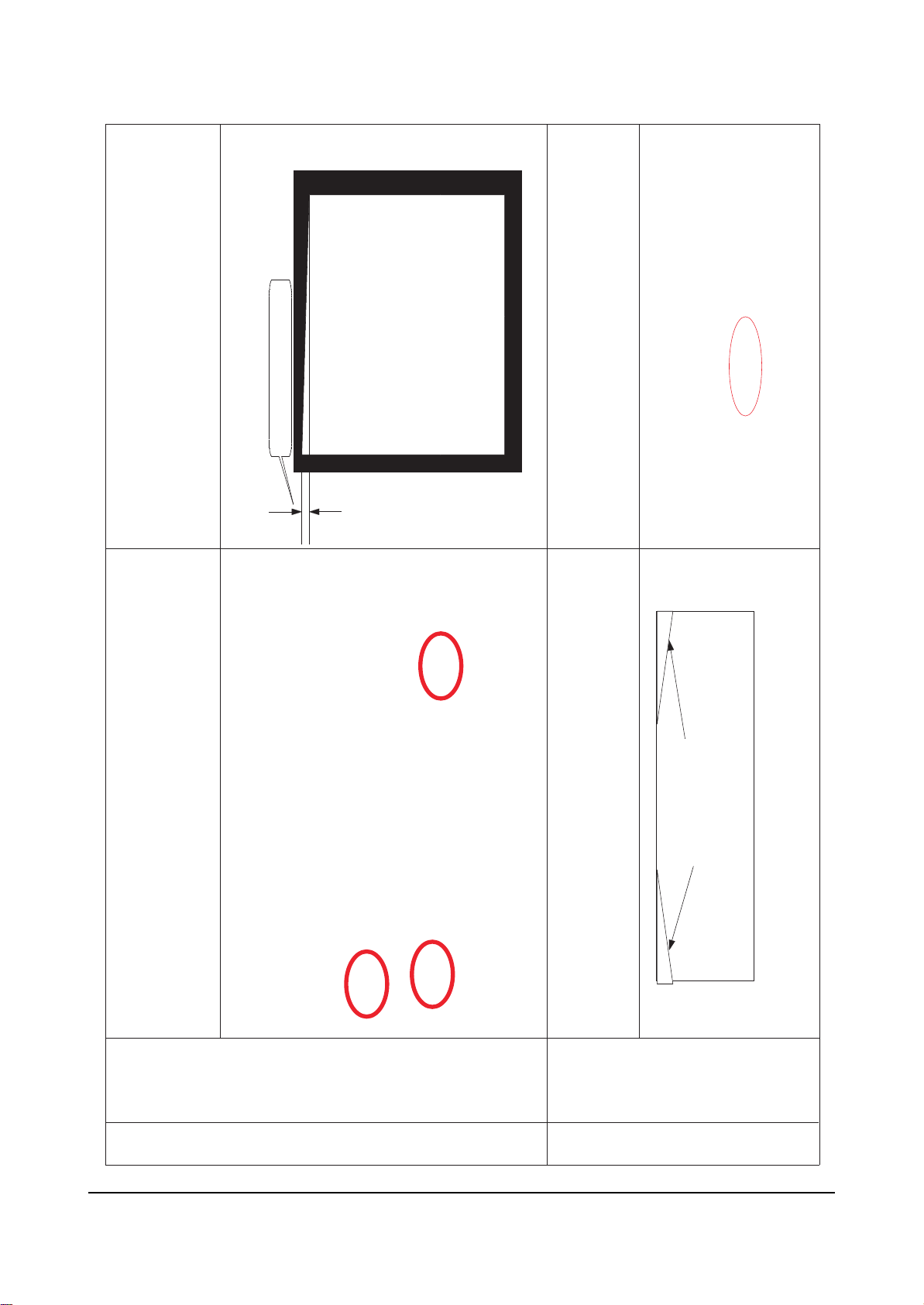

4. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANIS C101.1, Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

5. With the unit completely reassembled, plug

the AC line cord directly into the power

outlet. With the unit’s AC switch first in the

ON position and then OFF, measure the

current between a known earth ground (metal

water pipe, conduit, etc.) and all exposed

metal parts, including: antennas, handle

brackets, metal cabinets, screwheads and

control shafts. The current measured should

not exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat the

test.

Fig. 1-1 AC Leakage Test

6. Antenna Cold Check:

With the unit’s AC plug disconnected from the

AC source, connect an electrical jumper across

the two AC prongs. Connect one lead of the

ohmmeter to an AC prong. Connect the other

lead to the coaxial connector.

7. X-ray Limits:

The picture tube is especially designed to prohibit X-ray emissions. To ensure continued

X-ray protection, replace the picture tube only

with one that is the same type as the original.

Carefully reinstall the picture tube shields and

mounting hardware; these also provide X-ray

protection.

8. High Voltage Limits:

High voltage must be measured each time servicing is done on the B+, horizontal deflection

or high voltage circuits. Correct operation of

the X-ray protection circuits must be

reconfirmed whenever they are serviced.

(X-ray protection circuits also may be called

“horizontal disable” or “hold-down”.)

Heed the high voltage limits. These include

the X–ray Protection Specifications Label, and

the Product Safety and X-ray Warning Note on

the service data schematic.

Precautions

Samsung Electronics 1-1

LEAKAGE

CURRENT

TESTER

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

(READING SHOULD

NOT BE ABOVE

0.5mA)

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential

hazards such as electrical shock and X-rays.

1-1 Safety Precautions (Continued)

9. High voltage is maintained within specified

limits by close-tolerance, safety-related

components and adjustments. If the high

voltage exceeds the specified limits, check

each of the special components.

10. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of this unit. Example: Do not

add auxiliary audio or video connectors. Such

alterations might create a safety hazard. Also,

any design changes or additions will void the

manufacturer’s warranty.

11. Hot Chassis Warning:

Some TV receiver chassis are electrically

connected directly to one conductor of the AC

power cord. If an isolation transformer is not

used, these units may be safely serviced only

if the AC power plug is inserted so that the

chassis is connected to the ground side of the

AC source.

To confirm that the AC power plug is inserted

correctly, do the following: Using an AC

voltmeter, measure the voltage between the

chassis and a known earth ground. If the

reading is greater than 1.0V, remove the AC

power plug, reverse its polarity and reinsert.

Re-measure the voltage between the chassis

and ground.

12. Some TV chassis are designed to operate with

85 volts AC between chassis and ground,

regardless of the AC plug polarity. These units

can be safely serviced only if an isolation

transformer inserted between the receiver and

the power source.

13. Some TV chassis have a secondary ground

system in addition to the main chassis ground.

This secondary ground system is not

isolated from the AC power line. The two

ground systems are electrically separated by

insulating material that must not be defeated

or altered.

14. Components, parts and wiring that appear to

have overheated or that are otherwise

damaged should be replaced with parts that

meet the original specifications. Always

determine the cause of damage or overheating, and correct any potential hazards.

15. Observe the original lead dress, especially

near the following areas: Antenna wiring,

sharp edges, and especially the AC and high

voltage power supplies. Always inspect for

pinched, out-of-place, or frayed wiring. Do

not change the spacing between components

and the printed circuit board. Check the AC

power cord for damage. Make sure that leads

and components do not touch thermally hot

parts.

16. Picture Tube Implosion Warning:

The picture tube in this receiver employs

“integral implosion” protection. To ensure

continued implosion protection, make sure

that the replacement picture tube is the same

as the original.

17. Do not remove, install or handle the picture

tube without first putting on shatterproof

goggles equipped with side shields. Never

handle the picture tube by its neck. Some

“in-line” picture tubes are equipped with a

permanently attached deflection yoke; do not

try to remove such “permanently attached”

yokes from the picture tube.

18. Product Safety Notice:

Some electrical and mechanical parts have

special safety-related characteristics which

might not be obvious from visual inspection.

These safety features and the protection they

give might be lost if the replacement component differs from the original—even if the

replacement is rated for higher voltage,

wattage, etc.

Components that are critical for safety are

indicated in the circuit diagram by shading,

( ) or ( ).

Use replacement components that have the

same ratings, especially for flame resistance

and dielectric strength specifications.

A replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

Precautions

1-2 Samsung Electronics

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit’s AC power cord from

the AC power source before attempting to: (a)

Remove or reinstall any component or

assembly, (b) Disconnect an electrical plug or

connector, (c) Connect a test component in

parallel with an electrolytic capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or

tape is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the portion around

the serviced part has not been damaged.

5. Check the insulation between the blades of the

AC plug and accessible conductive parts

(examples: metal panels, input terminals and

earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the

power switch ON. Connect an insulation

resistance meter (500V) to the blades of the AC

plug.

The insulation resistance between each blade

of the AC plug and accessible conductive parts

(see above) should be greater than 1 megohm.

7. Never defeat any of the B+ voltage interlocks.

Do not apply AC power to the unit (or any of

its assemblies) unless all solid-state heat sinks

are correctly installed.

8. Always connect a test instrument’s ground

lead to the instrument chassis ground before

connecting the positive lead; always remove

the instrument’s ground lead last.

9. When some parts inside the optical engine

(except lamp) are damaged, replace the whole

optical engine.

Precautions

Samsung Electronics 1-3

Warning1: First read the “Safety Precautions” section of this manual. If some unforeseen circumstance creates a conflict between

the servicing and safety precautions, always follow the safety precautions.

Warning2: An electrolytic capacitor installed with the wrong polarity might explode.

WARNING : This cover is provided with an interlock to reduce

the risk of excessive ultraviolet radiation.

Do not defeat its purpose or atempt to service without

removing cover completely.

CAUTION : Replace with same type numer DS001AKB

1. Some semiconductor (“solid state”) devices

are easily damaged by static electricity. Such

components are called Electrostatically

Sensitive Devices (ESDs); examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component damage

caused by static electricity.

2. Immediately before handling any semicon

ductor components or assemblies, drain the

electrostatic charge from your body by

touching a known earth ground. Alternatively,

wear a discharging wrist-strap device. (Be

sure to remove it prior to applying power—

this is an electric shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals. These

can generate electrical charges that damage

ESDs.

5. Use only a grounded-tip soldering iron when

soldering or unsoldering ESDs.

6. Use only an anti-static solder removal device.

Many solder removal devices are not rated as

“anti-static”; these can accumulate sufficient

electrical charge to damage ESDs.

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive materials.

8. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions such

as brushing clothes together, or lifting a foot

from a carpeted floor can generate enough

static electricity to damage an ESD.

Precautions

1-4 Samsung Electronics

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

CAUTION

These servicing instructions are for use by

qualified service personnel only.

To reduce the risk of electric shock do not

perform any servicing other than that contained

in the operating instructions unless you are

qualified to do so.

Reference Information

Samsung Electronics 2-1

2. Reference Information

2-1 Tables of Abbreviations and Acronyms

A

Ah

Å

dB

dBm

°C

°F

°K

F

G

GHz

g

H

Hz

h

ips

kWh

kg

kHz

kΩ

km

km/h

kV

kVA

kW

I

MHz

Ampere

Ampere-hour

Angstrom

Decibel

Decibel Referenced to One

Milliwatt

Degree Celsius

Degree Fahrenheit

degree Kelvin

Farad

Gauss

Gigahertz

Gram

Henry

Hertz

Hour

Inches Per Second

Kilowatt-hour

Kilogram

Kilohertz

Kilohm

Kilometer

Kilometer Per Hour

Kilovolt

Kilovolt-ampere

Kilowatt

Liter

Megahertz

MV

MW

MΩ

m

µA

µF

µH

µm

µs

µW

mA

mg

mH

mI

mm

ms

mV

nF

Ω

pF

Ib

rpm

rps

s

V

VA

W

Wh

Megavolt

Megawatt

Megohm

Meter

Microampere

Microfarad

Microhenry

Micrometer

Microsecond

Microwatt

Milliampere

Milligram

Millihenry

Milliliter

Millimeter

Millisecond

Millivolt

Nanofarad

Ohm

Picofarad

Pound

Revolutions Per Minute

Revolutions Per Second

Second (Time)

Volt

Volt-ampere

Watt

Watt-hour

Table 2-1 Abbreviations

Reference Information

2-2 Samsung Electronics

Table 2-1 Abbreviations

ABL

AC

ACC

AF

AFC

AFT

AGC

AM

ANSI

APC

APC

A/V

AVC

BAL

BPF

B-Y

CATV

CB

CCD

CCTV

Ch

CRT

CW

DC

DVM

EIA

ESD

ESD

FBP

FBT

FF

FM

FS

GND

G-Y

H

HF

HI-FI

IC

IC

IF

Automatic Brightness Limiter

Alternating Current

Automatic Chroma Control

Audio Frequency

Automatic Frequency Control

Automatic Fine Tuning

Automatic Gain Control

Amplitude Modulation

American National Standards Institute

Automatic Phase Control

Automatic Picture Control

Audio-Video

Automatic Volume Control

Balance

Bandpass Filter

Blue-Y

Community Antenna Television (Cable TV)

Citizens Band

Charge Coupled Device

Closed Circuit Television

Channel

Cathode Ray Tube

Continuous Wave

Direct Current

Digital Volt Meter

Electronics Industries Association

Electrostatic Discharge

Electrostatically Sensitive Device

Feedback Pulse

Flyback Transformer

Flip-Flop

Frequency Modulation

Fail Safe

Ground

Green-Y

High

High-Frequency

High Fidelity

Inductance-Capacitance

Integrated Circuit

Intermediate Frequency

I/O

L

L

LED

LF

MOSFET

MTS

NAB

NEC

NTSC

OSD

PCB

PLL

PWM

QIF

R

RC

RF

R-Y

SAP

SAW

SIF

SMPS

S/N

SW

TP

TTL

TV

UHF

UL

UV

VCD

VCO

VCXO

VHF

VIF

VR

VTR

VTVM

TR

Input/output

Left

Low

Light Emitting Diode

Low Frequency

Metal-Oxide-Semiconductor-Field-Effect-Tr

Multi-channel Television Sound

National Association of Broadcasters

National Electric Code

National Television Systems Committee

On Screen Display

Printed Circuit Board

Phase-Locked Loop

Pulse Width Modulation

Quadrature Intermediate Frequency

Right

Resistor & Capacitor

Radio Frequency

Red-Y

Second Audio Program

Surface Acoustic Wave(Filter)

Sound Intermediate Frequency

Switching Mode Power Supply

Signal/Noise

Switch

Test Point

Transistor Transistor Logic

Television

Ultra High Frequency

Underwriters Laboratories

Ultraviolet

Variable-Capacitance Diode

Voltage Controlled Oscillator

Voltage Controlled Crystal Oscillator

Very High Frequency

Video Intermediate Frequency

Variable Resistor

Video Tape Recorder

Vacuum Tube Voltmeter

Transistor

Reference Information

Samsung Electronics 2-3

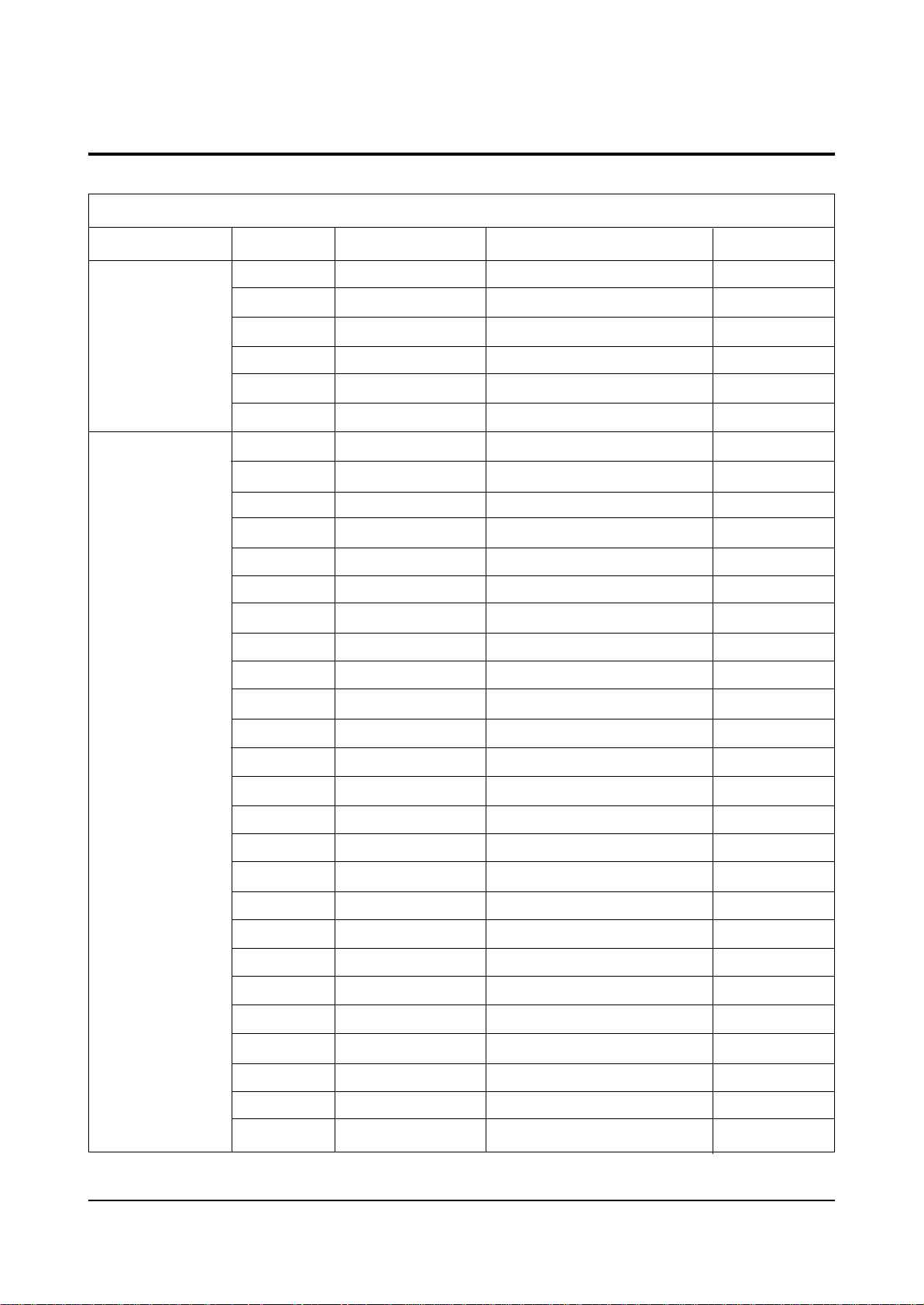

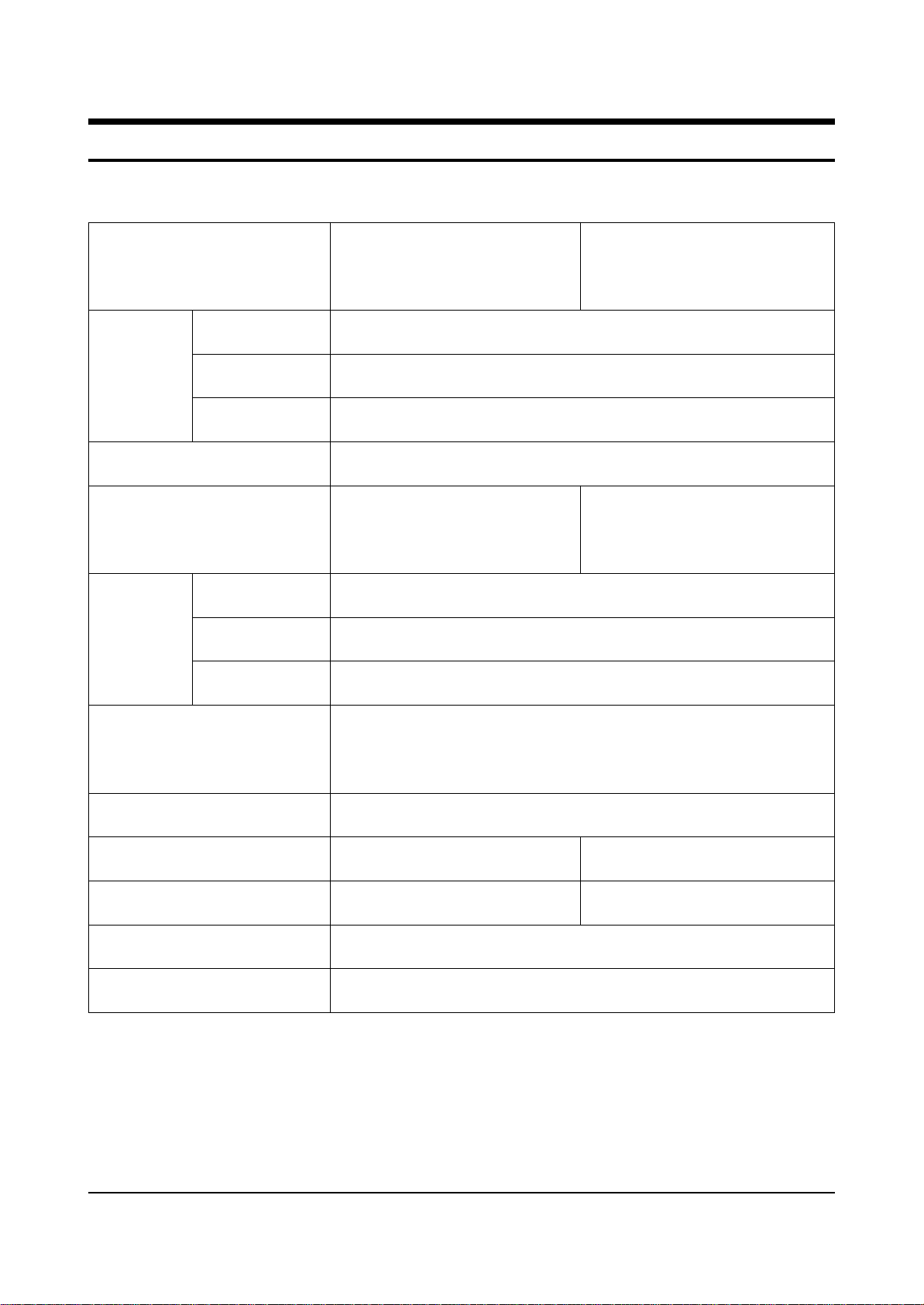

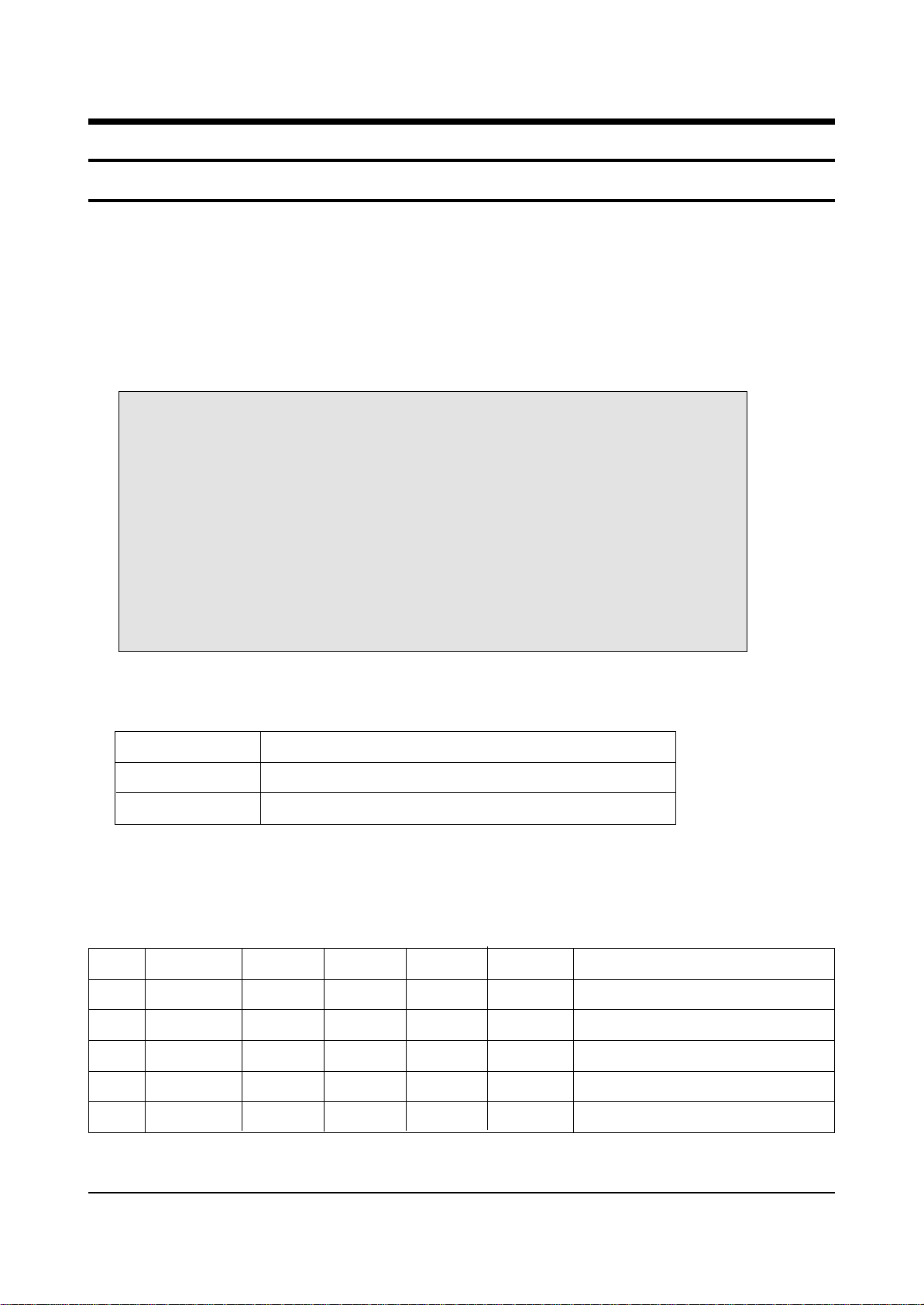

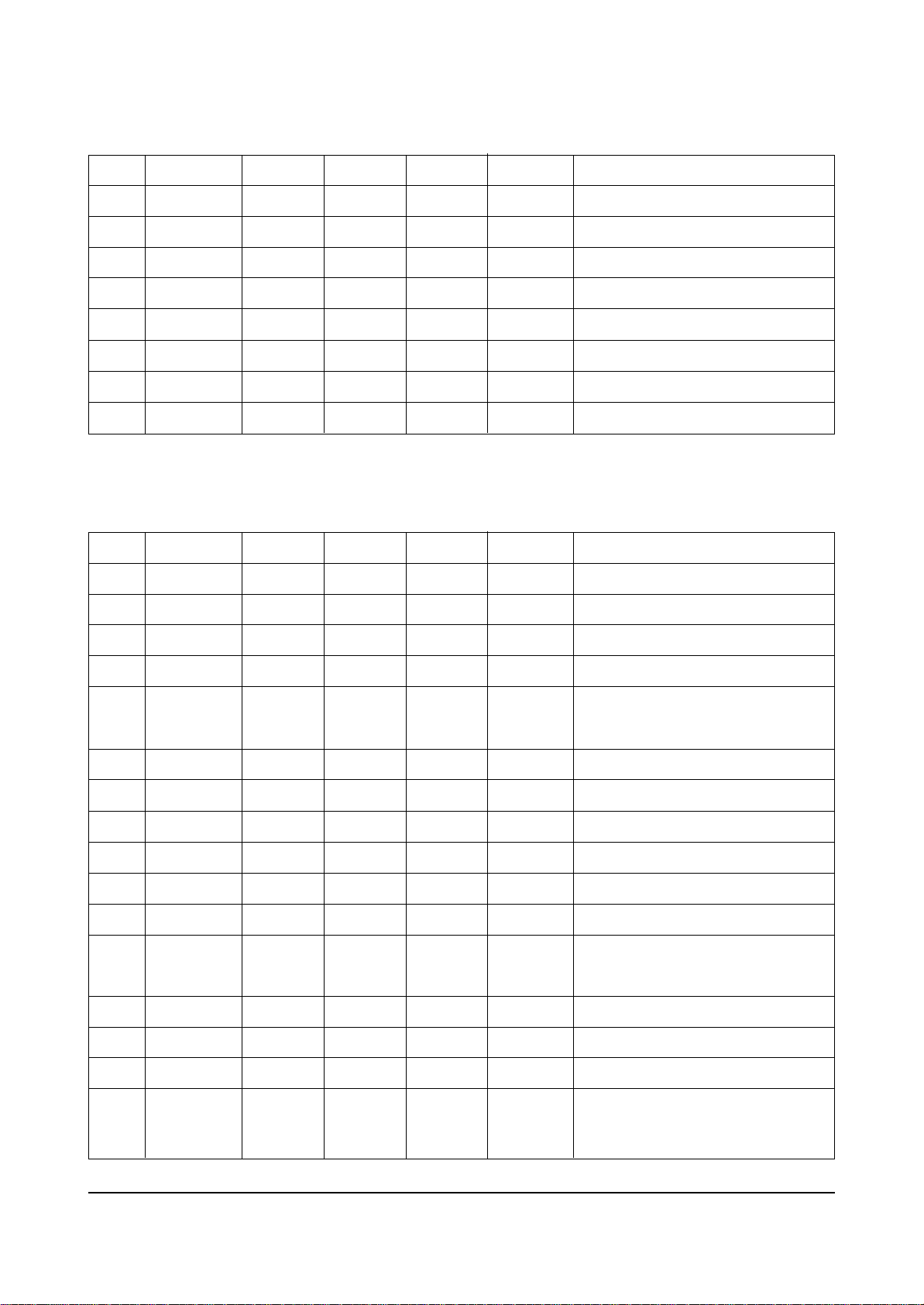

2-2 IC Line Up

Table 2 - 2 IC Line - Up

ASSY

Analog

Board

Digital

Board

LOC NO COMPONENT DESCRIPTION MAKER

IC100 PCF8591 8-bit A/D and D/A converter 1002-001048

IC101 PCF8574 8-bit I/O Expander 0904-001121

IC108 TA8851 A/V Switch for TV s-terminal 1003-001458

IC104 TA2020 SOUND AMP 1201-001885

IC108 MSP3421-B11 SOUND PROCESSOR 1003-001458

IC111 UPD64083 3D Y/C SEPARATOR 1204-001935

IC332 74HC04 Hex inverter 0801-000901

IC317 74LCX125 BUS Buffer 0801-002171

IC335 74VHC244 BUS Buffer 0801-002393

IC315 74LCX74 BUS Buffer 0801-002396

IC337 80251G2 MICOM 0903-001202

IC340 PCF8563 Real time clock & calender 0909-001032

IC320 AD9883A A/D Coverter 1002-001292

IC348 FLI2310 Video Deinterlacer/Line Doubler 1204-002078

IC347 SNI Video Enhancer 1003-001503

IC338 max232 driver/receiver 1006-001076

IC314 sil160 TMDS tranceiver 1205-001778

IC322 sil169 TMDS receiver(with HDCP) 1006-001131I

IC329 24C02 EEPROM 1103-000129

IC341 24C16 EEPROM 1103-000138

IC333 24LC21A EEPROM 1103-001164

IC301 km432s2030c DRAM 1105-001336

IC328 PSD834F2-90M FLASH MEMORY 1107-001373

IC331 ms81v04160 IC-FIFO 1109-001144

IC326 7045 Voltage DETECTOR 1203-001109

IC330 Z86129 Caption decoder 1204-001388

IC313 CXA2171 SELECTOR 1204-002079

IC325 VPC3230D VIDEO PROCESS 1204-001926

IC310 JAGASM LCD CONTROLLER, JAGASM 1205-002028

Reference Information

2-4 Samsung Electronics

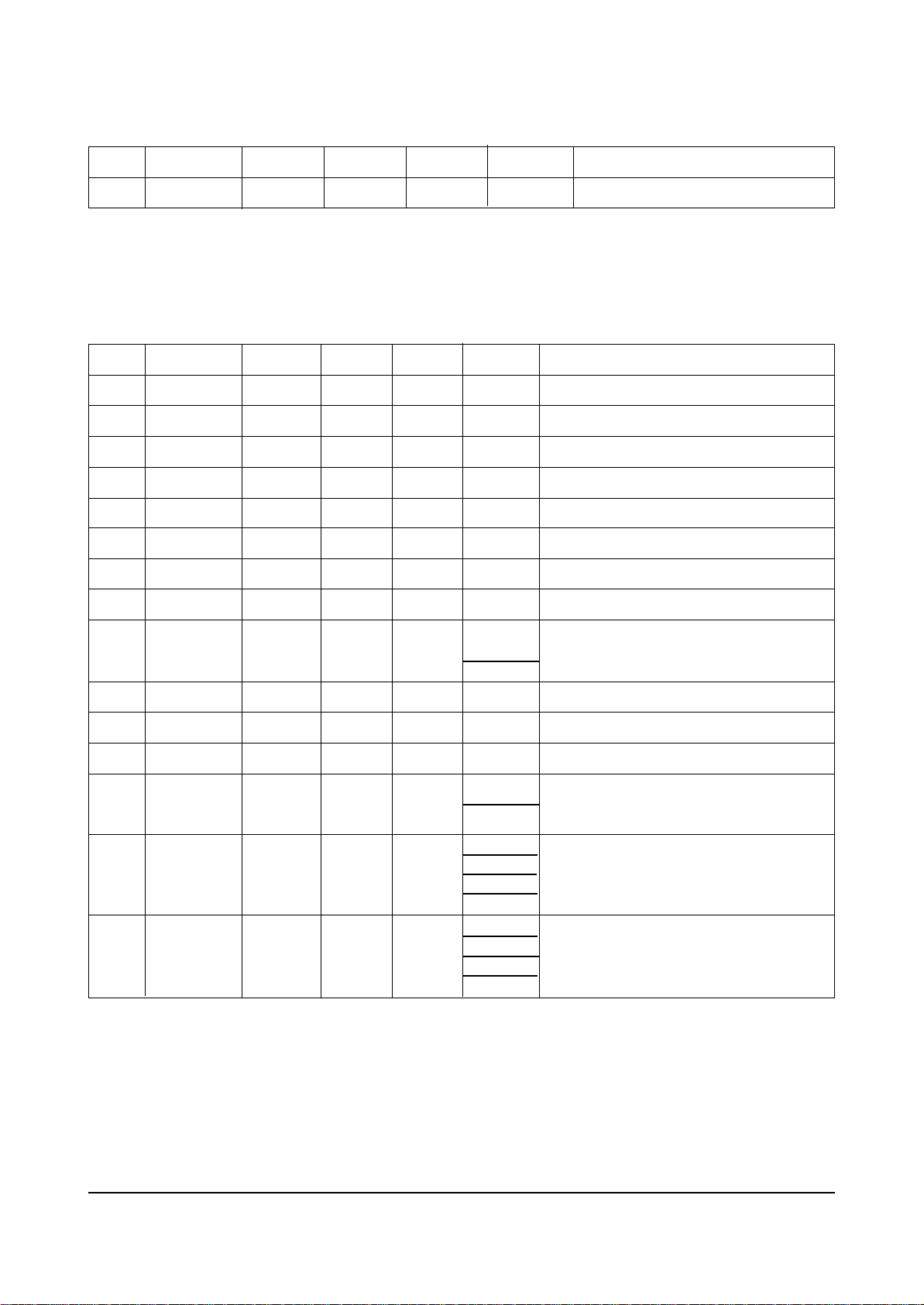

Table 2 - 2 IC Line - Up

ASSY

DMD

Board

Power

Board

LOC NO COMPONENT DESCRIPTION MAKER

IC116 DMD(HD2) DMD 4719-001079

IC115 SIL151B TMDS Receiver 1006-001131

IC109 BA033 REGULATOR 1203-001293

IC118 24C02 EEPROM 1103-000129

IC120 GS1086 REGULATOR 1203-002328

IC117 DDP1010 DMD Signal Processing ASIC 1204-001942

IC111 74F14 IC seperattor 0803-000117

IC119 M29W800AB Flash Memory 1107-001315

IC114 CDCR83 DRAMBUS clock generator 1205-002161

IC113 K4R271669D RAMBUS DRAM 1105-001412

IC108 DAD1000 DMD Power and Reset driver 1003-001458

IC104 SH6742 12V VCM/Spindle Driver 1003-001457

IC107 FDS6930A MOSFET 0505-001630

IC801S ML4824IP1 IC-PFC, PWM, Controller 1203-002268

IC802S TNY253P IC-PWM, Controller AA13-00024A

Reference Information

Samsung Electronics 2-5

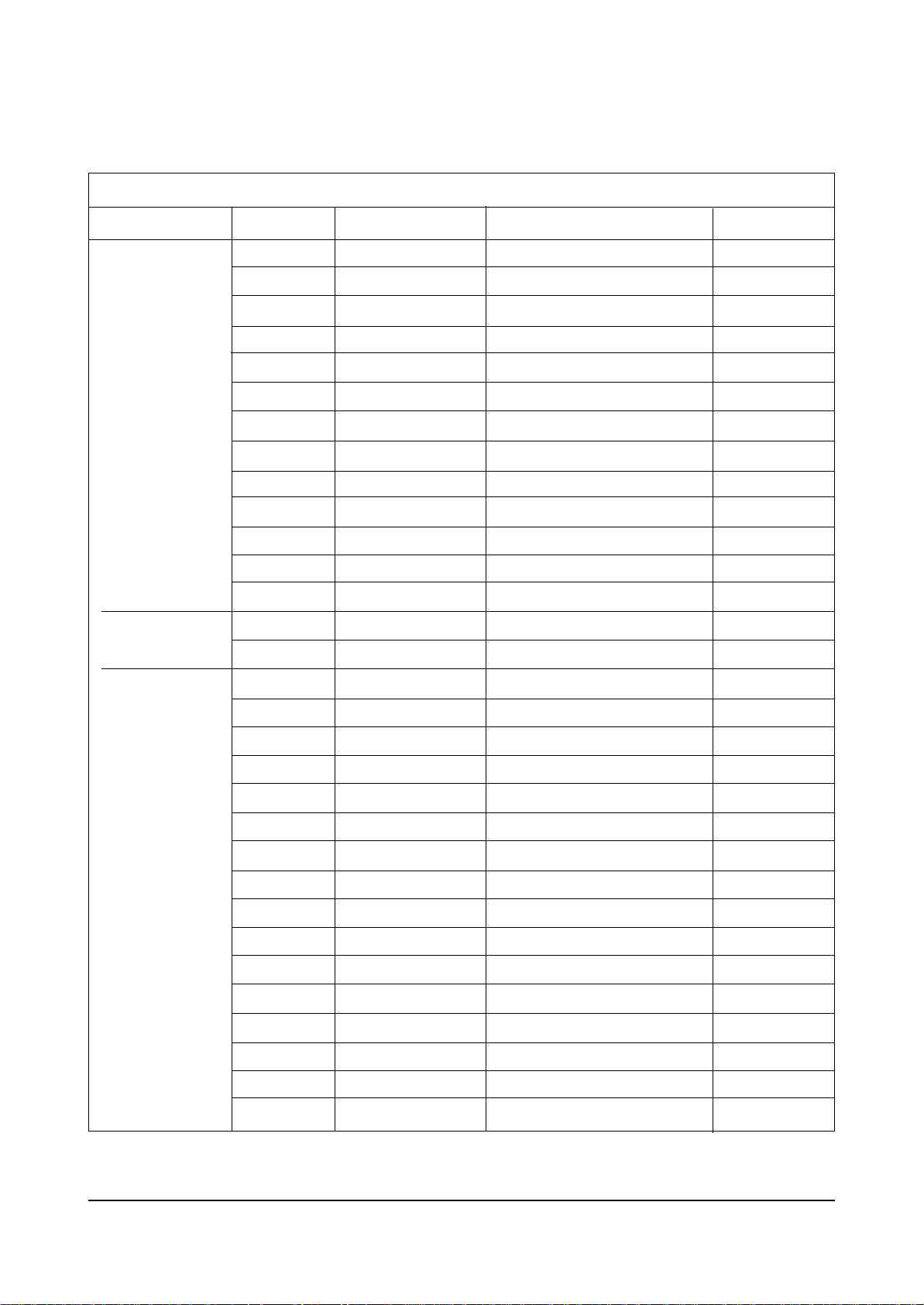

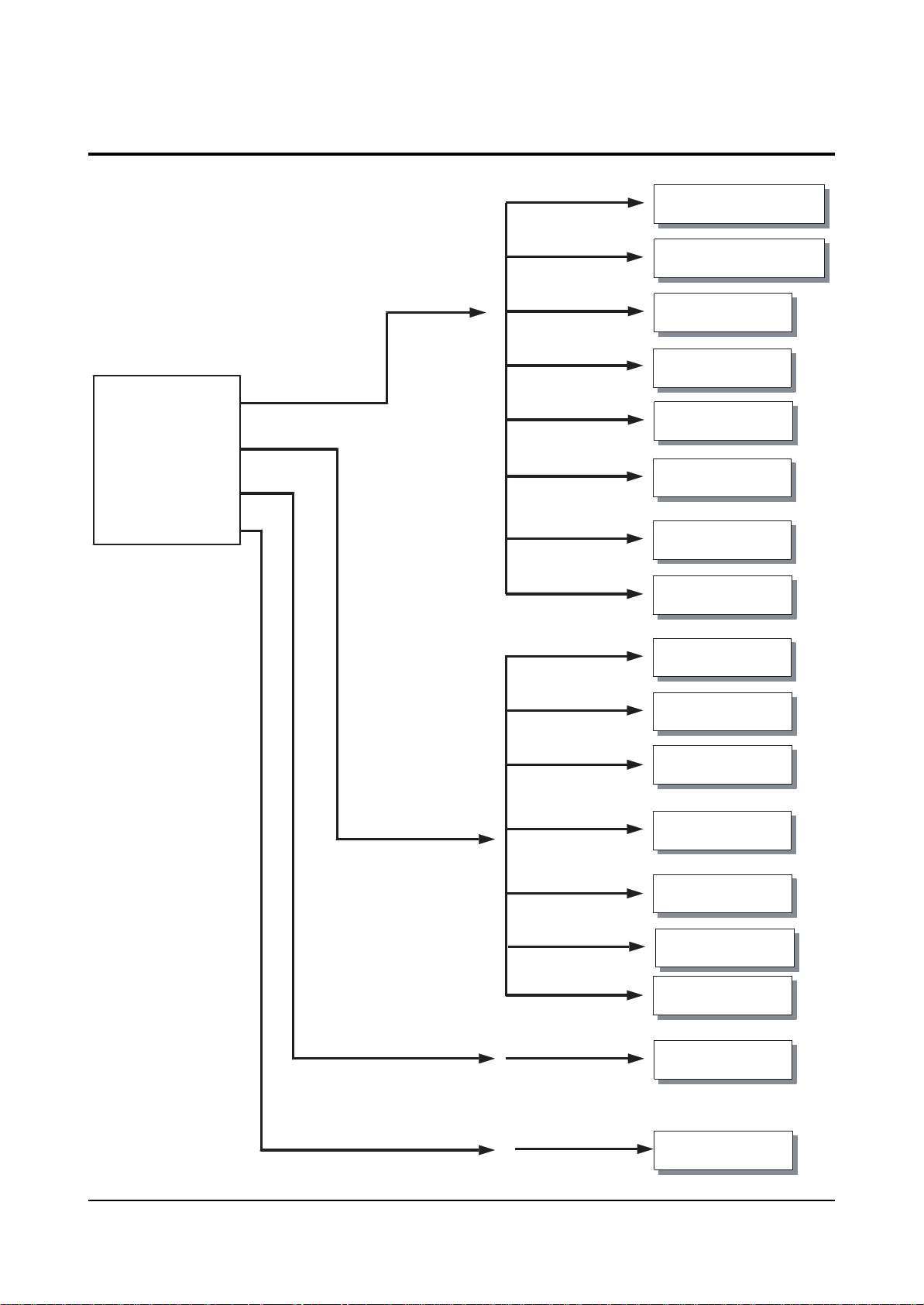

2-3 IMICOM IC BUS LINE-UP

SCL 1:2 SDA1:3

SCL :13 SDA:14

SCL :13 SDA:14

VPC3230D(Main)(IC325)

Slave Addr : 0x88

VPC3230D(Sub)(IC336)

Slave Addr : 0x8E

SCL 2:7 SDA2:8

SCL 3:4 SDA3:5

SCL4:16SDA4:17

T SC80251G2D

(MICOM)

(IC337)

IIC 1 B US

#:SCL1

# :SDA1

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

AD9883 (IC320)

Slave Addr : 0x9A

C X A21 7 1 (IC 3 13 )

Slave Addr : 0x84

DDP1010 (IC117)

Slave Addr : 0x34

F L I 23 1 0 ( IC 34 8)

Slave Addr : 0xc 0

S N I ( IC 3 4 7)

Slave Addr : 0xc 8

Z86129(IC330)

Slave Addr : 0x28

MSP3421G(IC108)

Slave Addr : 0x80

PCF8574(IC107)

Slave Addr : 0x41

IIC 2 B US

#:SCL2

# :SDA2

IIC 3 B US

#:SCL3

#:SDA3

IIC 4 B US

#:SCL4

#:SDA4

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

SCL :13 SDA:14

PCF8591 (IC100)

Slave Addr : 0x92

uPD64083(IC111)

Slave Addr : 0xB8

T A8851(IC108)

Slave Addr : 0x90

Tuner(Main)

Slave Addr : 0xC0

T uner(Sub)

Slave Addr : 0xC6

X24C16 (IC341)

Slave Addr : 0xA0

PCF8563(IC340)

Slave Addr : 0xA2

2-6 Samsung Electronics

MEMO

Specifications

Samsung Electronics 3-1

3. Specifications

HLN467W

MODEL

SYSTEM

TUNING

COLOUR

SOUND

Frequency Synthesizer

NTSC 3.58Mhz

Virtual Dolby

ANTENNA IMPEDANCE

SCREEN SIZE

Width 973 mm

Length558 mm

75 ohm Unbalanced Coaxial

Consumption

Requirements

Frequency

POWER

VHF Channel : 2 ~ 13

UHF Channel : 14 ~ 69

CATV Channel : 1,14 ~ 125

TUNING RANGE

15 Watts/ 2 CH (R/L)

SOUND OUTPUT

DIMENSIONS

(W x D x H)

WEIGHT

1047 x 399 x 779mm

33.5Kg/73.8lbs

PROFILE

TRANSMITTER TYPE

185mm

TM63 47Keys

200Watts ± 20%

AC Input Voltage : 120V

60 Hz

HLN567W

Width 973 mm

Length 558 mm

1268 x 461 x 924mm

49.9Kg/91.5lbs

3-2 Samsung Electronics

MEMO

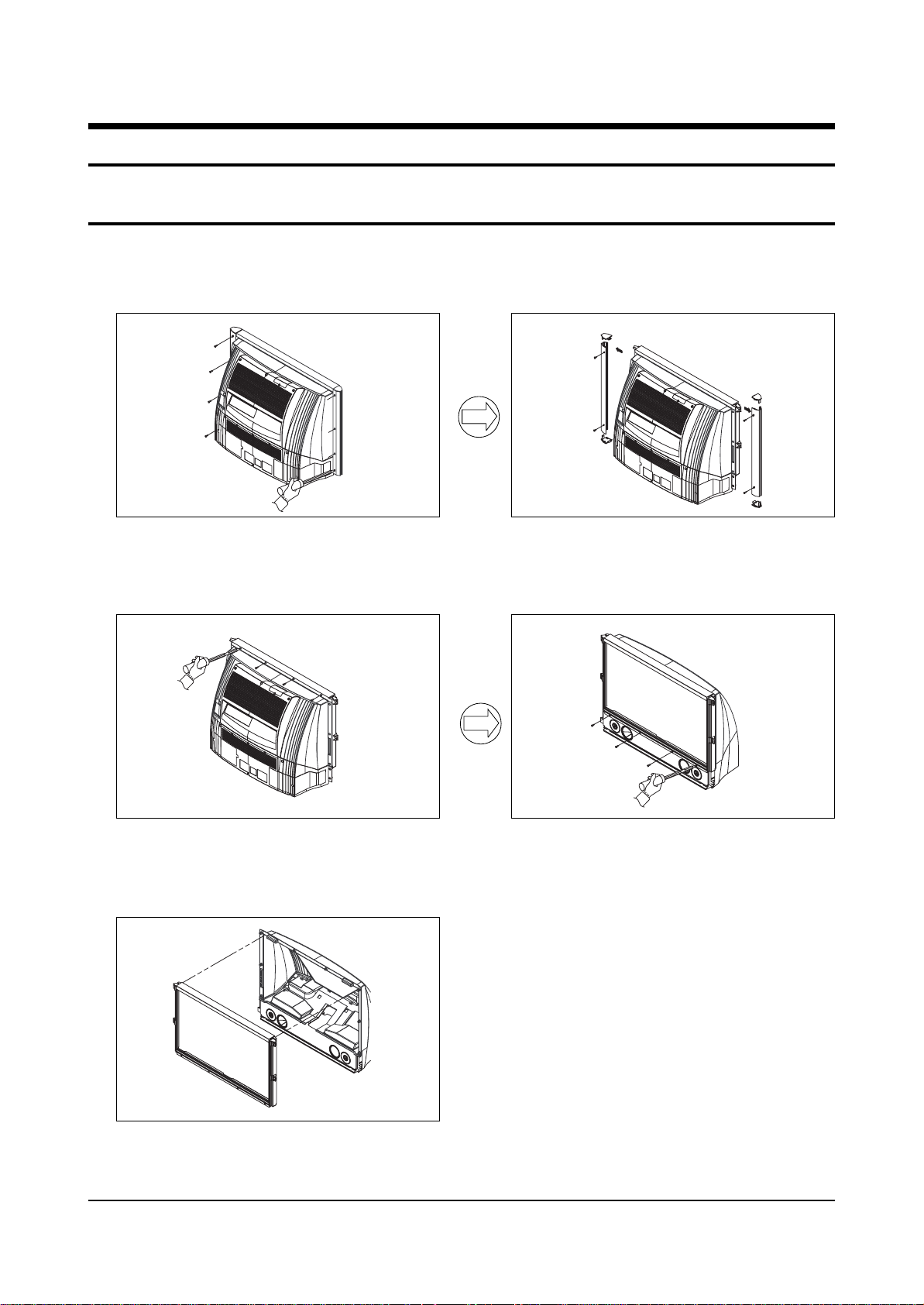

Disassembly and Reassembly

Samsung Electronics 4-1

4. Disassembly and Reassembly

4-1-1 Cabinet Disassembly (HLM4365,HLM5065)

1. After removing the screws, pull the bottom and side holder part of the cabinet back wards.

2. Loosen the screws and remove the supporter.

4. Loosen the screws. Remove the front mask.

3. After loosening the screws, remove the lens

cover and fan duct.

Disassembly and Reassembly

4-2 Samsung Electronics

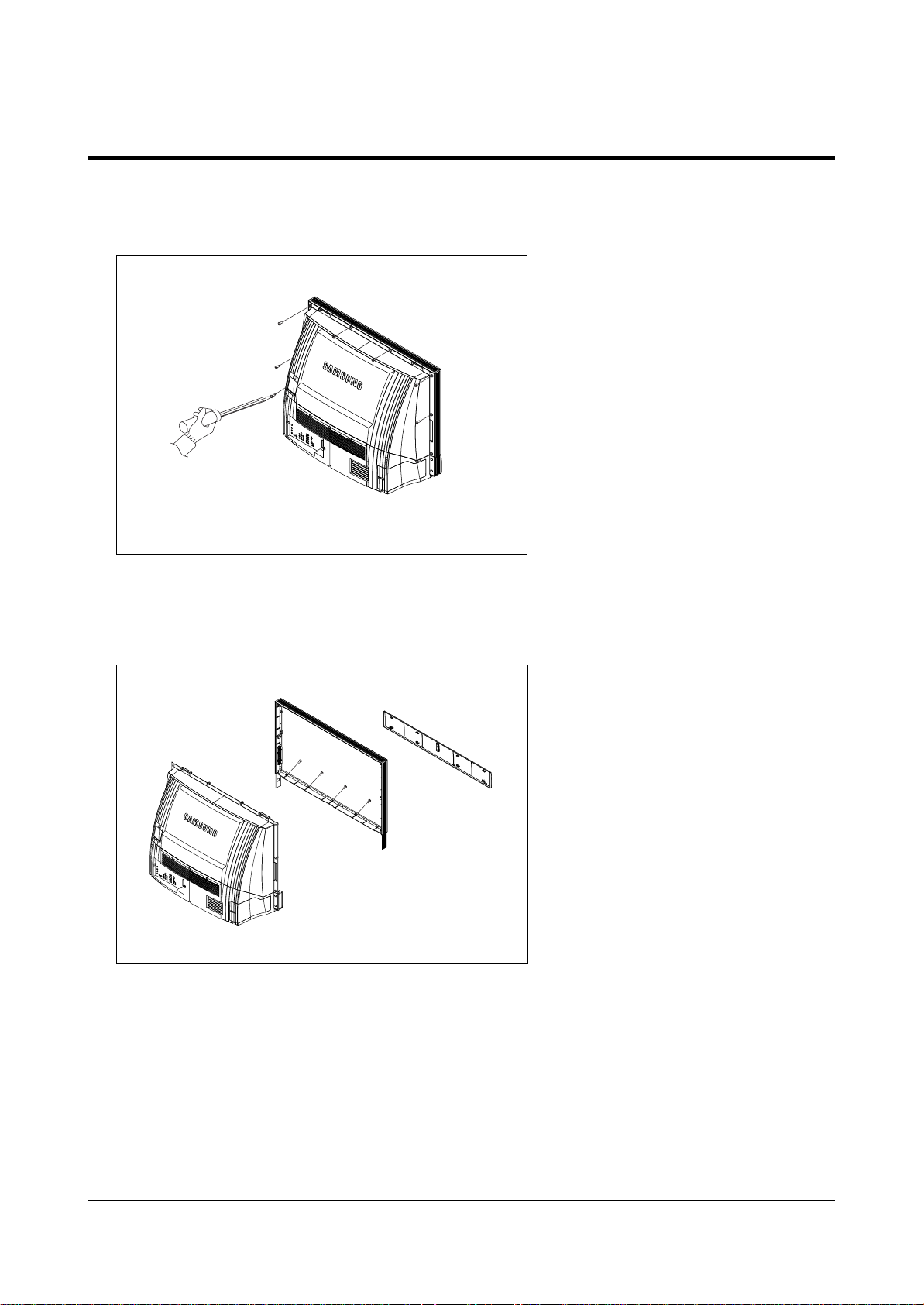

4-1-2 Cabinet Disassembly (HLM437,HLM507)

1. After removing the screws, pull the bottom and side holder part of the

cabinet back wards.

2. Loosen the screws and remove the supporter.

Disassembly and Reassembly

Samsung Electronics 4-3

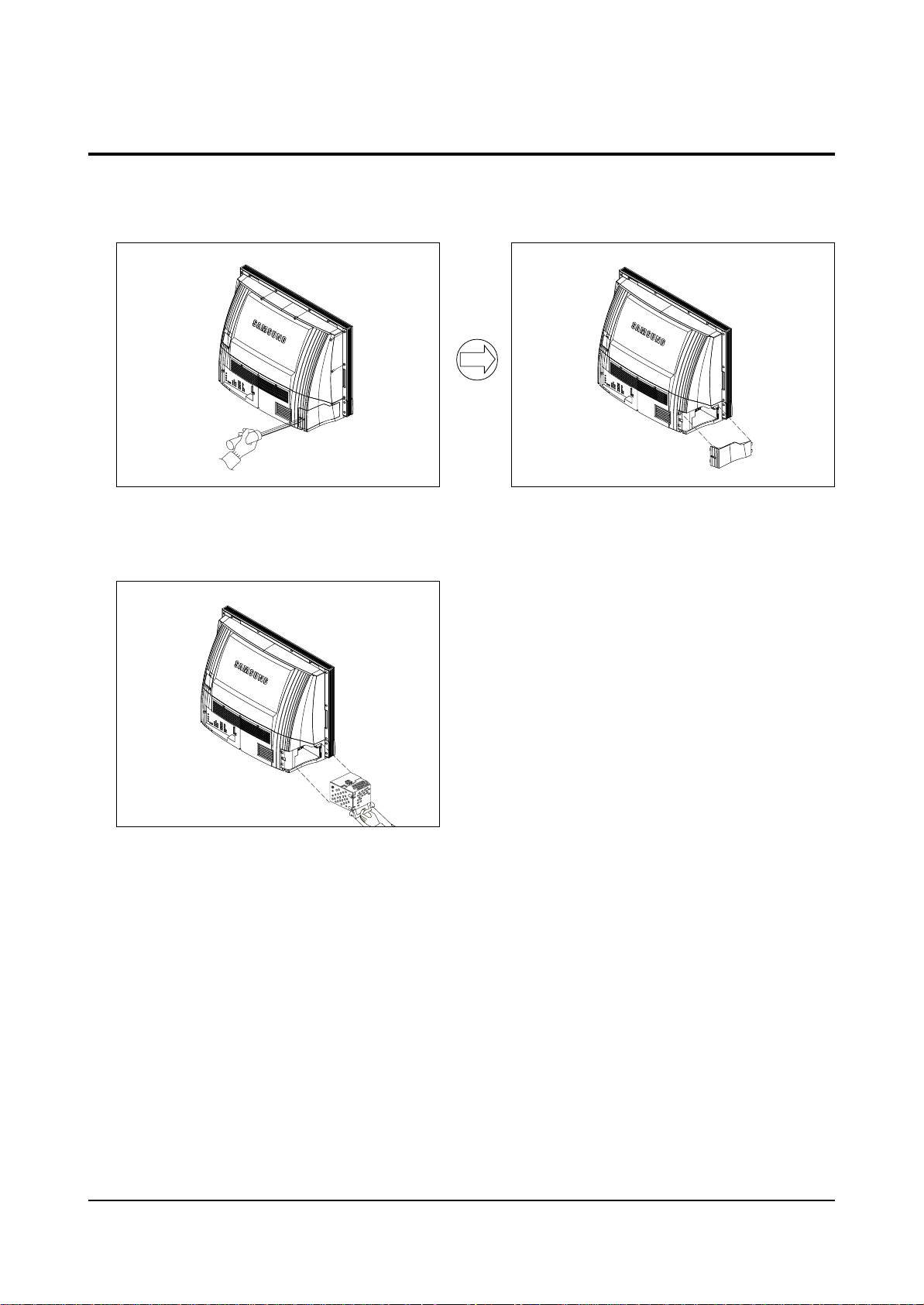

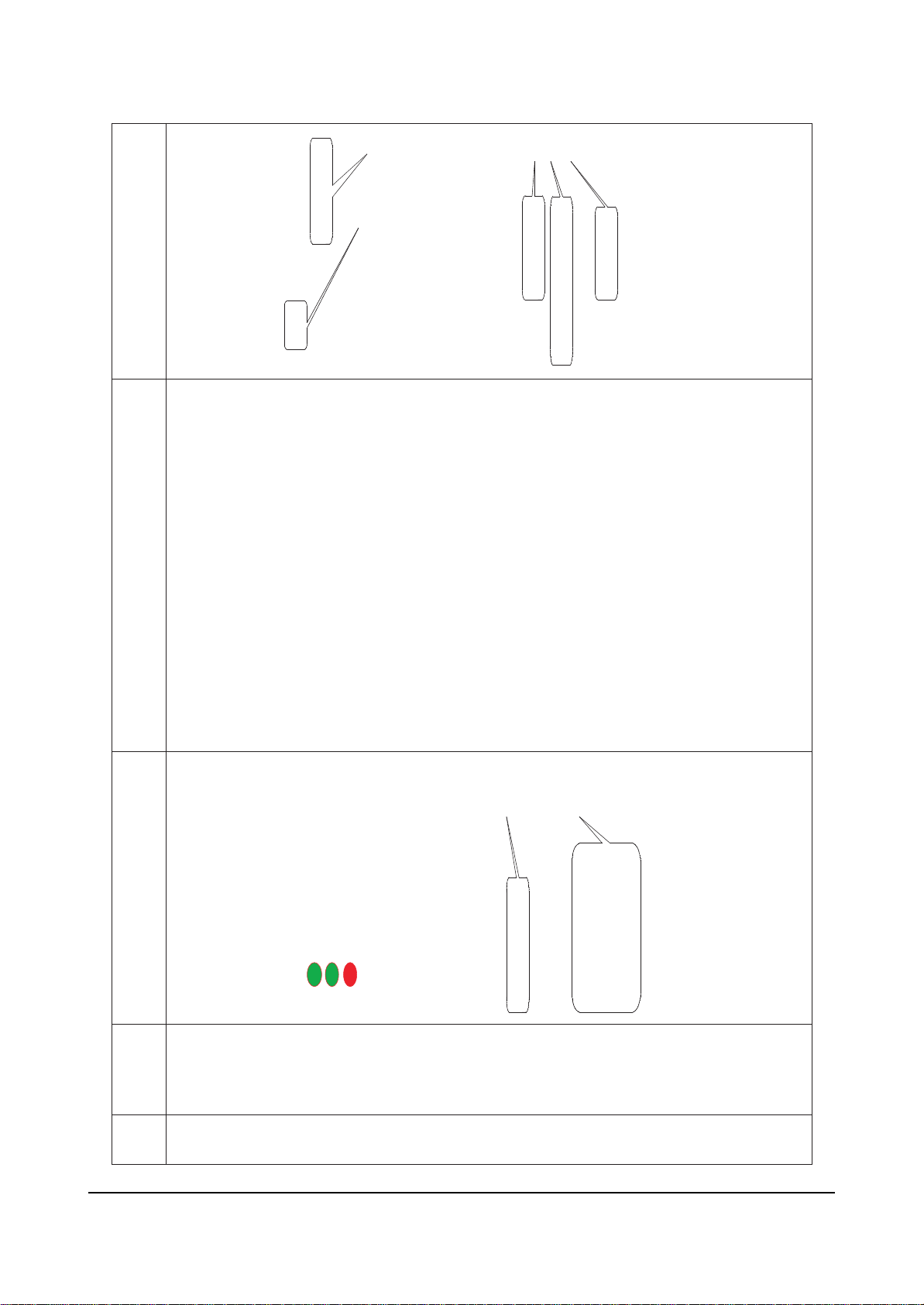

4-2 Lamp Replacement

2. Remove the cover.

4. PROCEDURE

After completing the lamp replacement, enter the

Service Mode

Press the remote control Keys in the following

sequence:

“Power off ➔ Mute ➔ 1 ➔ 8 ➔ 2 ➔ Power On”

The Service Mode Screen appears in 15 ~ 30

seconds.

(1) Select 7(OPTION) with using the joystick

downward, and then select the LAMP

CLEAR with using the joysick in the

displayed menu.

(2) Press the + key to select LAMPCLEAR

OFF.

(3) Press the + key, LAMPCLEAR CLEAR

is displayed in the screen.

(4) Exit factory mode.

3. Pull out the lamp.

1. Loosen the screw.

Disassembly and Reassembly

4-4 Samsung Electronics

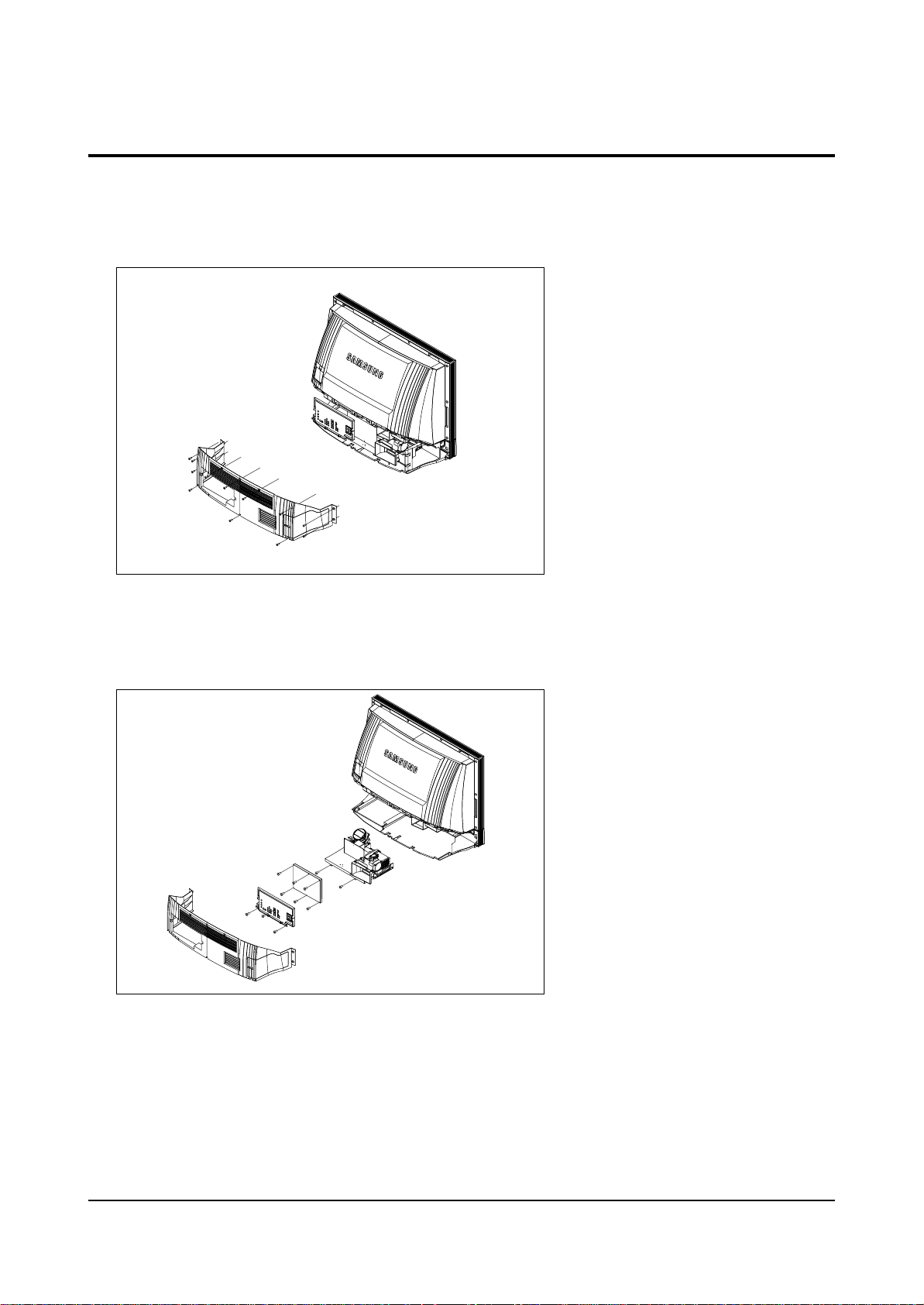

4-3 DLP Engine &PCB Replacement

1. After removing the screws, pull the cabinet backwards.

2. Loosen the screws and pull out the optical engine.

Alignment and Adjustments

Samsung Electronics 5-1

1. DDP1010 (ALL)

2. DNIe (ALL)

3. AD9883 (Component/480P)

4. VPC3230 (RF/VIDEO/480I)

5. JAGADC (PC)

6. FLI2300 (RF/VIDEO/480I)

7. 3D_COMB (ALL)

8. OPTION

SW Version

5-1 When Entering Service Mode:

1. Enter the service mode by pressing the remote control keys in the following sequence :

Mute -> 1 -> 8 -> 2 -> Power On

Note : If necessary, re-do steps 1~3.

2. Initial display when the service mode is switched to below OSD

RELEASE TIME

3. Service Mode Control Key

Main Menu Menu Display

CH UP/DOWN Select item by moving cursor

VOL UP/DOWN Decrease or increase the adjustment values

4. Factory Data :

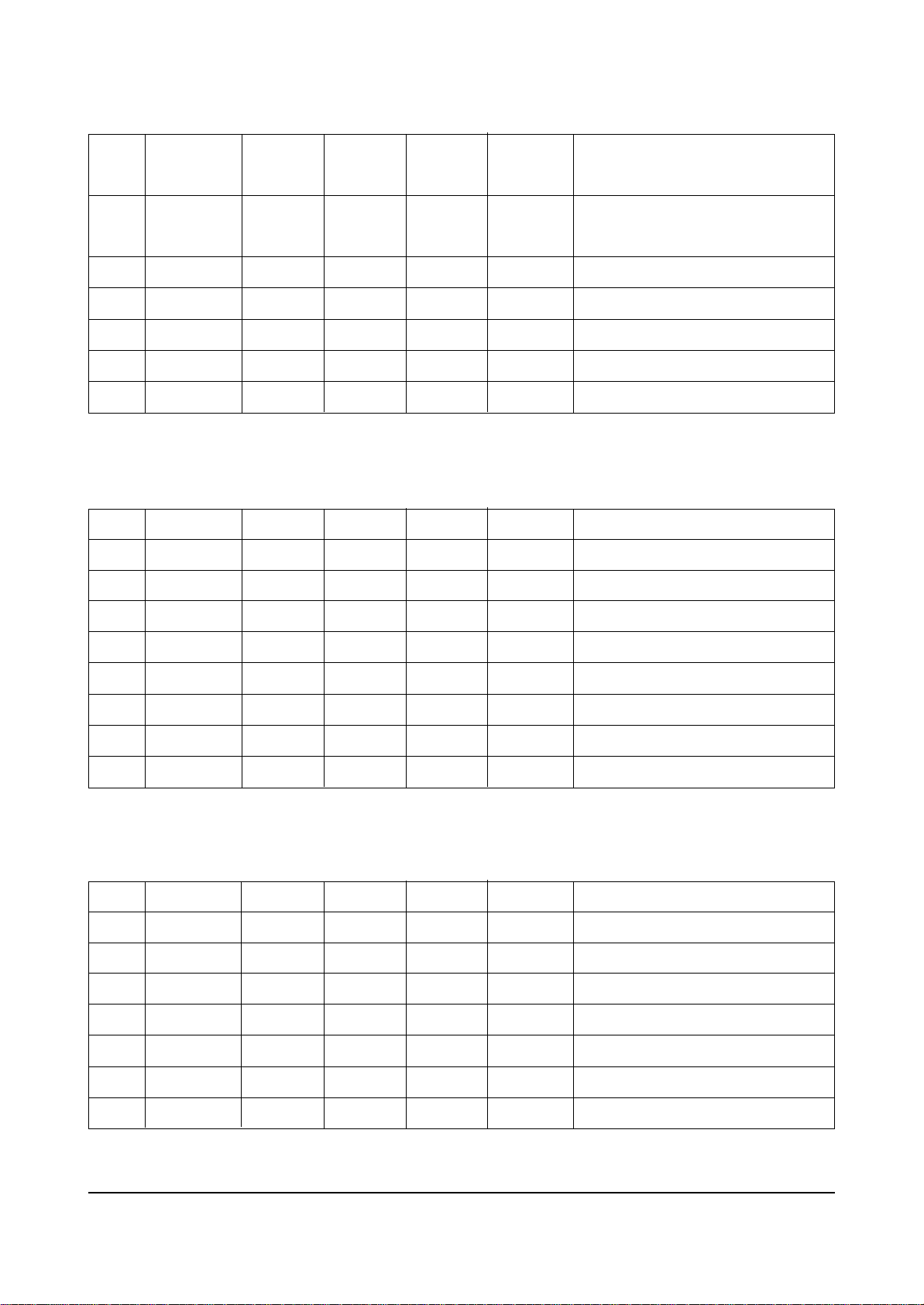

1) DDP1010

1

2

3

4

5

ITEM

POS-Y

POS-X

LAMP

DELAY

V-FLIP

ADRESS

OxEC

OxEC

Ox24

Ox21

Ox3

MIN

0

0

1

0

0

MAX

31

511

2

359

1

DEFAULT

16

147

2

223

1

DESCRIPTION

First Valid line in frame

First active pixel in line

1:OSRAM, 2:TOSH/PHIL

Color wheel index delay calibration value

Vertical Flip Operation

5. Alignment and Adjustments

Alignment and Adjustments

5-2 Samsung Electronics

2) DNIe : ALL

6

7

H-FLIP

GAMMA

Ox3

Ox09

0

0

1

15

1

4

Horizontal Flip Operation

GAMMA Value Selection

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

ITEM

R_GAIN

G_GAIN

B_GAIN

R_OFFSET

G_OFFSET

B_OFFSET

SYNC_MODE

RAST_H

PROC_SET

PATT_SEL

KNOB_RED

KNOBBLUE

C_SEL

S_BR(DDP)

S_CT(DDP)

ADRESS

0x2B1

0x2B1

0x2B2

0x2B2

0x2B3

0x2B3

0x211

0x215

0x220

0x230

0x280

0x281

0x298

0x00

0x01

MIN

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

MAX

255

255

255

255

255

255

1

2047

255

14

2047

2047

1

255

511

DEFAULT

120

120

120

128

128

128

1

1504

PC / DVI:

Ox44

RN : Ox66

0

91

91

RF : 0

RN : 1

DVI : 254

COM : 252

PC: 253

RF : 247

DVI : 106

COM : 118

PC : 107

RF : 135

DESCRIPTION

Red_Gain control

Green_Gain control

Blue_Gain control

Red_Offset control

Green_Offset control

Blue_Offset control

SYNC_MODE selection

H_SYNC Value

SNI enable / disable selection

SNI Pattern select

Slope value selection (when input Cb is positive number)

Slope value selection(when input Cb is negaitive number)

C-A daptation application select

DDP1010 sub_Brightness adjust

DDP1010 sub_contrast adjust

Alignment and Adjustments

Samsung Electronics 5-3

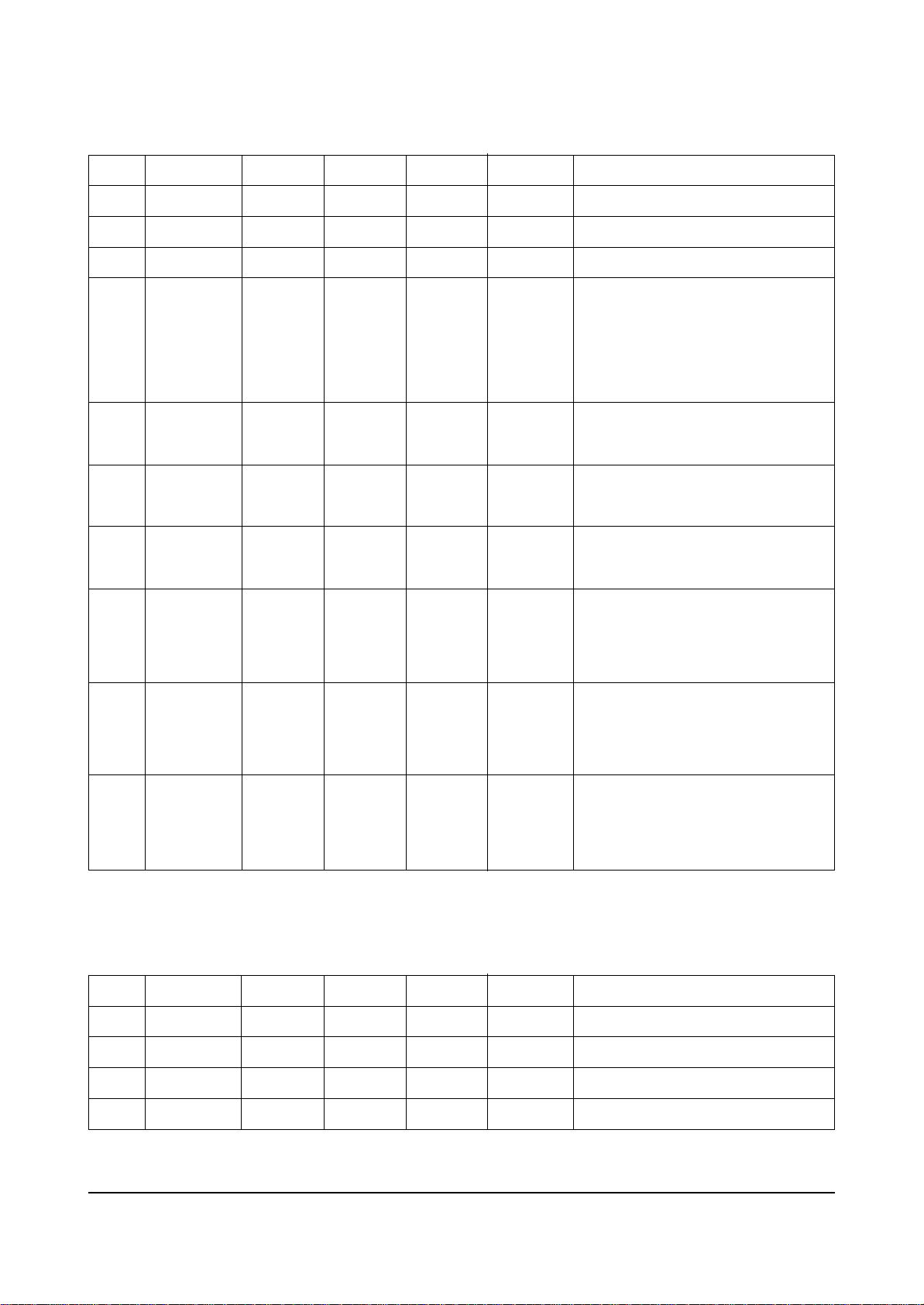

3) AD9883 : COMPONENT 2,3, 480P

1

2

3

4

5

6

7

8

ITEM

Y-GAIN

Y_OFFSET

CR_GAIN

CR_OFFSET

CB_GAIN

CB_OFFSET

AUTOCOLOR

AD_RESET

ADRESS

MIN

0

0

0

0

0

0

MAX

255

127

255

127

255

127

DEFAULT

150

60

150

58

150

58

DESCRIPTION

Red_Gain control

Red_Offset control

Green_Gain control

Green_Offset control

Blue_Gain control

Blue_Offset control

DTV Auto color

4-1) VPC3230 (RF ~ S VIDEO)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

ITEM

BR_M

CT_M

SAT_M

TINT_M

RFS_M

PK_M

PKCOR_M

BR_S

CT_S

SAT_S

TINT_S

PFS_S

PK_S

PKCOR_S

IFC_M

CBW_M

ADRESS

0x52

0x53

0x30

0xDC

0x53

0x53

0x53

0x52

0x53

0x30

0xDC

0x53

0x53

0x53

0x21

0x21

MIN

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

MAX

255

63

4090

255

2

7

1

255

63

4090

255

2

7

1

3

3

DEFAULT

152

36

1900

132

2

2

1

152

36

1900

132

2

2

1

2

3

DESCRIPTION

Main Bright Adjust

Main Contrast Adjust

Main Saturation Adjust

Main Tint value setting

Main Horizontal Peaking Filter Selection

0 : broad, 1 : med, 2 : narrow

Main Peaking Gain Selection

Main Peaking Coaring ON/OFF

Sub Bright Adjust

Sub Contrast Adjust

Sub Saturation Adjust

Sub Tint value setting

Sub Horizontal Peaking Filter Selection

0 : broad, 1 : med, 2 : narrow

Sub Peaking Gain Selection

Sub Peaking Coaring ON/OFF

bit[4:4] IF compensation

bit[6:5] chroma bandwidth selector

00 narrow, 01 normal

10 broad, 11 wide

Alignment and Adjustments

5-4 Samsung Electronics

18

19

20

21

22

23

24

LPF2_M

CBW2_M

IFC_S

CBW_S

LOWP_S

LPF2_S

CBW_S

0x52

0x21

0x21

0x21

0x21

0x52

0x52

0

0

0

0

0

0

0

0

3

1

3

3

1

3

1

0

0

2

3

1

0

0

bit[9:8] horizontal lowpass filter for Y/C

0 bypass, 1 filter 1

2 filter 2, 3 filter 3

bit[10] horizontal lowpass filter for highresolution chroma

0/1 bypass/filter enabled

Sub IF compensation

Sub chroma bandwidth selector

enable Sub luma lowpass filter

Sub Horizontal LPF for Y/C

Sub Horizontal LPF for Chroma

4-2) VPC3230 (480i)

1

2

3

4

5

6

7

8

ITEM

BR_M

CT_M

SATCB_M

SATCR_M

TINT_M

IFC

CBW

LOWP

ADDRESS

0x92

0x92

0x90

0x90

0x91

0x21

0x21

0x21

MIN

0

0

0

0

0

0

0

0

MAX

255

63

63

63

63

3

3

1

DEFAULT

191

31

38

40

32

0

3

1

DESCRIPTION

Main Bright Adjust

Main Contrast Adjust

Main Saturation_Cb Adjust

Main Saturation_Cr Adjust

Main Tint value setting

IF compensation

chroma bandwidth selector

enable luma lowpass filter

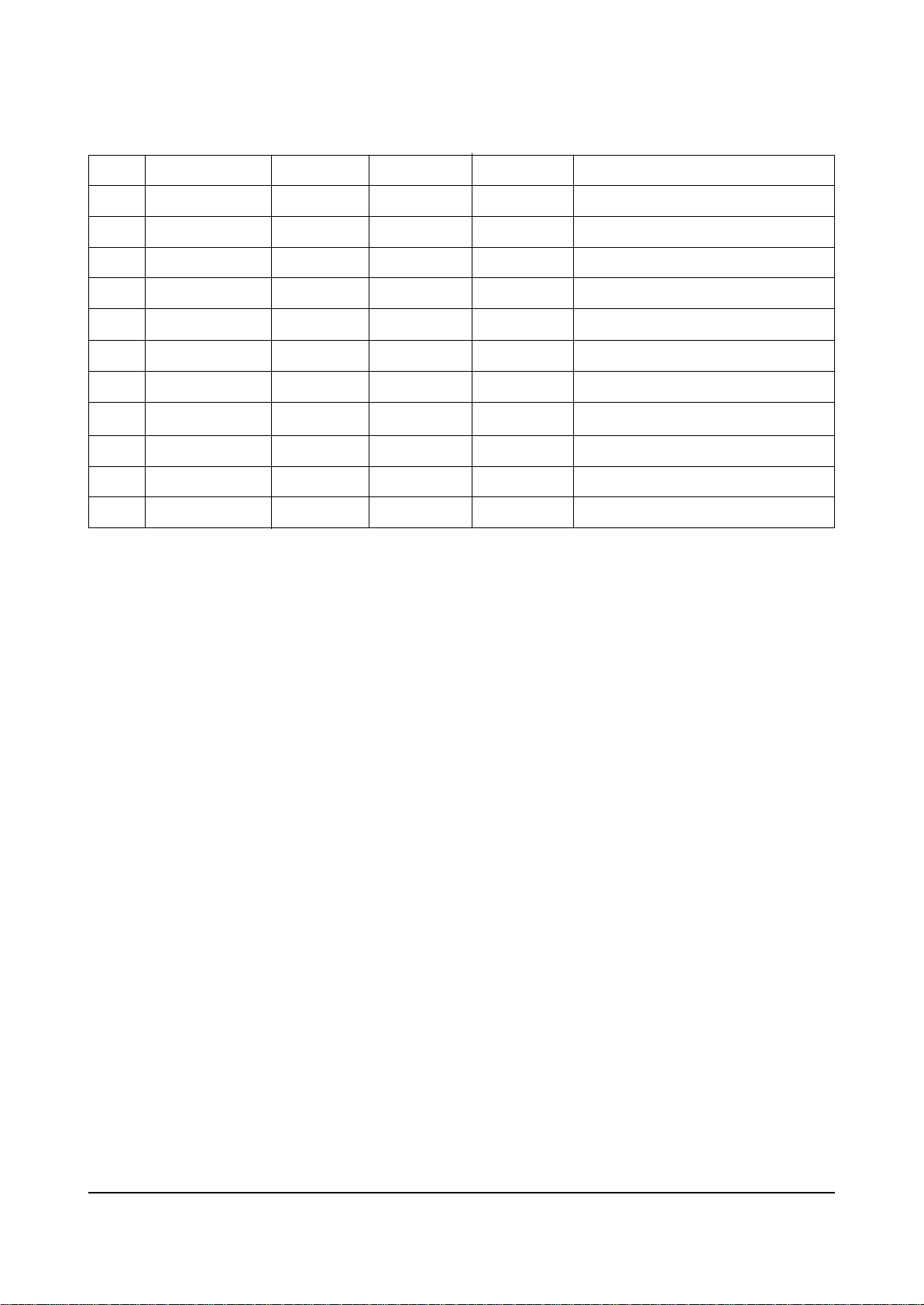

5) JaguarADC : PC

1

2

3

4

5

6

7

ITEM

R_GAIN

R_OFFSET

G_GAIN

G_OFFSET

B_GAIN

B_OFFSET

AUTOCOLOR

ADDRESS

0xf8

0xf9

0xfa

0xfb

0xfc

0xfd

MIN

0

0

0

0

0

0

MAX

255

255

255

255

255

255

DEFAULT

128

64

128

64

128

64

DESCRIPTION

R_GAIN Adjust

R_OFFSET Adjust

G_GAIN Adjust

G_OFFSET Adjust

B_GAIN Adjust

B_OFFSET Adjust

Jaguar ADC Autocolor

Alignment and Adjustments

Samsung Electronics 5-5

6) FLI2300 : RF, VIDEO, 480I

1

2

3

4

5

6

7

8

9

10

ITEM

CT

BR

SAT

LOW_FREQ

HIGH_FREQ

MULTI_MTN

Y_BR

CB_BR

CR_BR

NR

ADDRESS

0x302

0x303

0x304

0x16E

0x16F

0x170

0x34E

0x350

0x352

0x130

bit[6]

MIN

0

0

0

0

0

0

0

0

0

MAX

255

255

255

255

255

255

2046

2046

2046

1

DEFAULT

138

128

177

32

88

56

1023

1023

1023

1

DESCRIPTION

Contrast Adjust

Brightness Adjust

Saturation Adjust

Set motion threshold for low frequency

signals. Defines the lower limit of low

frequency motion, below which motion is

not detected

Contains motion threshold for high

frequency signals

Contains motion threshold for multiburst

signals

Contains the 2s complement brightness

control parameter for Y/G data

Contains the 2s complement brightness

control parameter for Cb/B data. Set to

0x000 for CbCr.

Contains the 2s complement brightness

control parameter for Cr/R data. Set to

0x000 for CbCr.

Noise reducer bypass control

0 = Noise reduction on

1 = Noise reduction off

1

2

3

4

ITEM

DYCOR

DYGAIN

DCCOR

DCGAIN

ADRESS

Ox04

Ox04

Ox05

Ox05

MIN

0

0

0

0

MAX

15

15

15

15

DEFAULT

1

10

2

10

DESCRIPTION

Y motion detection coning bit [7,4]

Y motion detection gain bit [3,0]

Y motion detection coning bit [3,0]

Y motion detection gain bit [3,0]

7) 3D_COMB : ALL

Alignment and Adjustments

5-6 Samsung Electronics

8) OPTION : ALL

1

2

3

4

5

6

7

8

9

10

11

ITEM

AUTOPOWER

EER_RESET

WBCONTROL

COLOR

DVCO

WBDEFSET

USERRESET

LAMPLIFE

LAMPCLEAR

MUTE_TIME

FAN_NUM

MIN

0

2

MAX

255

3

DEFAULT

off

on

on

off

700

3

DESCRIPTION

AUTO POWER ON/OFF Power ON/OFF

EEPROM RESET

White Balance Control

Color on/off

Digital VCD Adjust

White Balance Setting

User Reset

Lamp time display

Lamp time clear

Tuning mute time selection

FAN Number selection

Samsung Electronics 5-7

Alignment and Adjustment

5-2 Contents Failure Repair Methods

Remarks

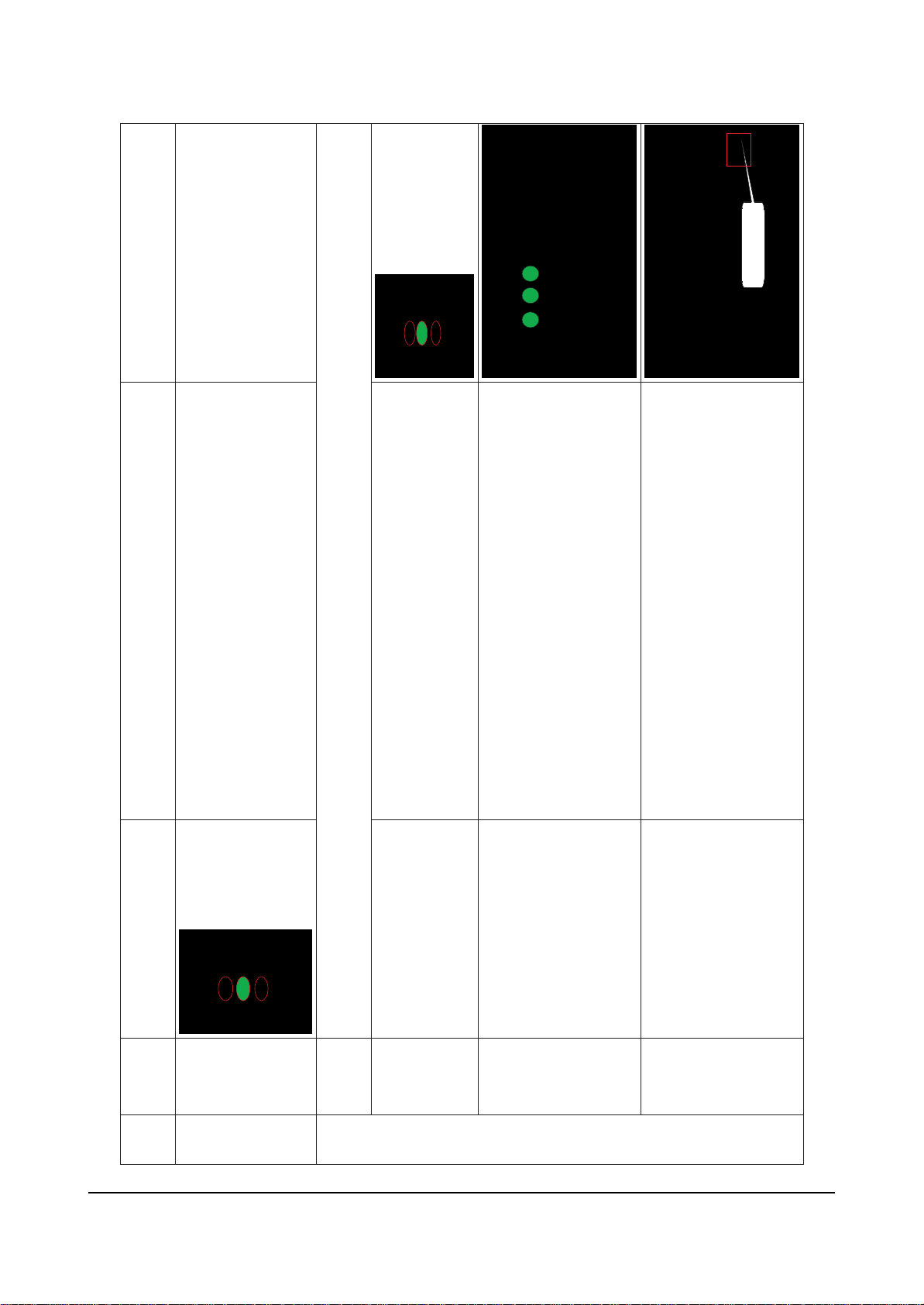

1. Flickering of the Lamp LED indicator

means that the lamp is about to be

turned on.

2. The ON state of the Lamp LED

indicator means that the lamp has

been turned on.

Description

Remarks

Inspection Items

sensor

Temperature

Cover lamp

1. When the power cord is plugged in and the power

switch on the right of set is pressed --------------- The

red LED indicator should be lit. (Domestic)

2.When the power cord is plugged in, the LED indicator

is not lit. (Overseas)

3.When the set is turned on via the remote control, the

Lamp LED indicator at the center is lit.

4.When the timer setting function is used, the Menu

Picture

Item

Normal

operation

[LED Status]

LED indicator at the top is lit.

1. Check whether or not the power cord is connected.

2. Check whether the power switch on the right of set has

been pressed.

Picture

When the

Failure Type

No.

1. Check whether the temperature sensor connector

attached to the engine has been inserted normally into

CN305 on the DIGITAL board.

2. Check whether the temperature sensor is normal when

3. Check the line filter fuse.

4. Check the connections of the ANALOG CN111 and

CN511 connectors.

5. Check the connection of the DIGITAL CN307 connector

and check whether LED indicator OP301 (one) is lit.

6.Check the connection of the DIGITAL CN303 connector

and check whether 5V power has been supplied to

pin #5.

Power Switch

Based on a 61" TV

light up.

does not

indicator

Domestic

Power LED

When the

both terminals have been short-circuited (connected).

Abnormal

or flickers.

LED indicat-

Temperature

1. Check that the fan operates when LED for timer,

standby or abnormal temperature blinks.

2. Check that the cover detection switch is inserted at

CN310 on the digital board when LED for timer,

standby or abnormal temperature blinks.

3. When LED for timer, standby or abnormal temperature

blinks, check that the lamp cover is properly assembled

and that the switch-pressing boss(inside) is not bent.

Timer+

standby/

temperature

at abnormal

LED blinking

abnormal

blinking at

Power/LED

temperature

Alignment and Adjustments

5-8 Samsung Electronics

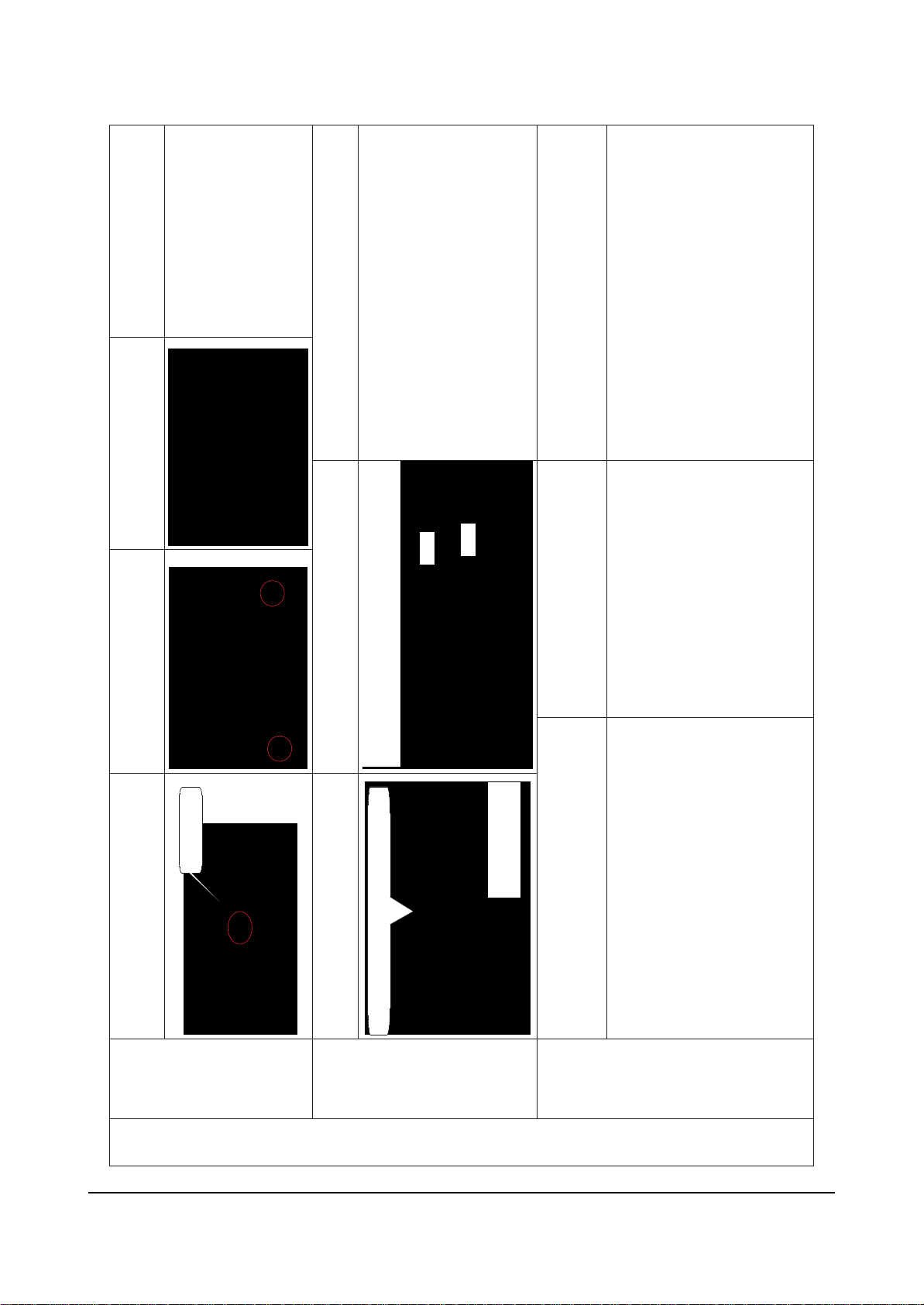

1

No.

Item

Picture

Description

Remarks

When the

Timer, Lamp,

and Abnormal

Temperature

LED indicators

flicker simulta-

neously.

Ballast CN2 terminal

Ballast CN1 terminal

*When measuring voltage,

make sure to measure the

voltage between the two

terminals.

1. If the 3 LED indicators flicker from the time the set is

turned on, it means:

1) The CN106 connector on the DMD board is not inserted

properly.

2) The MDR cable that connects the DIGITAL board to the

DMD board is not connected properly.

3) If the lamp does not turn on even after turning it on three

times, by powering off/on 15 second intervals:

! The B+ 380V power is not supplied to the ballast

(The cable is not connected properly between the power

and the ballast.)

@ The cable connected to the CN110 terminal on the

DMD board and the CN2 terminal on the ballast is short-

circuited or not connected.

# The lamp does not turn on because 5V has not been

supplied to blue pin #1 on the CN2 terminal of the

ballast.

$ 5V is supplied to the CN2 terminal on the ballast but the

lamp does not turn on because the ballast has a failure.

(If the lamp is replaced and 5V is supplied normally to

the CN2 terminal, suspect a ballast failure if the lamp still

does not turn on.)

% The ballast is normal but the lamp doest not turn on.

(When 5V is supplied to CN2 and 385V to CN1, but the

lamp does not turn on, try replacing the lamp. If it turns

on, that means it was a lamp failure.)

4) The color wheel engaged to the engine does not operate,

or the connector which indicates the operation of the

color wheel is not connected properly, and therefore

does not allow the lamp to turn on. The cause can be

determined when the set still does not turn on after

attempting to turn it on three times.

5) Another digital board or the DMD board has a failure.

Conclusively, if the three LED indicators flicker, first

check the above five items, then check the various

connector connections, and then suspect a failure of the

lamp or the ballast.

CN106

MDR cable

Color wheel

connector

Color wheel index connector

Lamp connector

Alignment and Adjustments

Samsung Electronics 5-9

1

2

No. Item

Picture Description

Remarks

The set is

normal

1) Means that the lamp is turned on normally.

* Description of LED indicator operations

! The Lamp LED indicator flickers while turning on the lamp.

@ The mechanism is designed in such a way that if three turning-on

trials (with 15 second intervals between each trial) fail, the set

should be powered off (reset) and then three turning-on trials

should be tried again.

Failure

Name

Failure if the LED indicator is normal but the screen is not displayed.

First

Check whether the External LED

indicator of the set is normal.

Only the Lamp LED indicator should be turned on.

Second

Third

Check whether the DIGITAL board

LED indicators inside the set are lit.

All of the three LED indicators should be turned on.

* You can observe those LED indicators through the cabinet holes

at the back of the set. All three LED indicators should be turned on.

Check whether the set

lamp is turned on.

When the lamp is turned off, replace it.

* When you turn on the set again after replacing the lamp,

- It should turn on within 30 seconds. (For 50 and 61 inch TVs)

*If more than one minute passes before it turns on, or if it does not

turn on, replace both the ballast within the engine and the lamp.

Check the lamp.

Alignment and Adjustments

5-10 Samsung Electronics

CN2

CN1

Fourth

[Lamp

replacement]

Remove the cover lamp screw as shown

in the figure below.

Remove the screws on both sides

of the lamp.

Pull the lamp out while holding its

knob, and then replace it with a

new one.

Lastly, assemble the cover lamp.

Check whether the new lamp

turns on.

Fifth

[Ballast

operation

check]

Cover lamp

The screen should be turned on.

Open the back cover of the set and short

the protection switch.

Check whether the power and the lamp enable

signal have been supplied to the ballast.

Repair plan

Press the switch to cause a short.

On the right side of

the back of the set.

1. Check whether 5V is supplied to the blue terminal of CN2

2. Check whether DC 380V is supplied to both end

terminals of CN1

1) If 5V is applied to the CN2 terminal of the ballast,

but the lamp does not turn on, replace the ballast.

2) When 5V is not supplied, replace first the engine.

If the lamp still does not work, replace the DMD

board attached to the engine.

* For repair methods of the DMD board, refer to

separate instructions.

Sixth

[The lamp is

normal,

but a blank

screen fail-

ure occurs.]

Check the signal supply procedure.

[Check whether the signals are supplied from the

analog board to the digital board]

Method for inspecting whether signals are

being supplied from the digital board to

the DMD board

DMD board inspection method

1) Check in which mode the screen does not display.

2) If the RF, VIDEO, DVD, or DTV mode screen

does not display, check the Analog CN511 termi-

nals, Digital CN309 connector connections, and

their signaling.

3) If the DVI or PC mode screen does not display,

replace and inspect the digital board.

4) If the screen does not display in any mode, check

whether the signals are being output from the

digital board.

Check the output of the IC314 terminal.

If the signal output state is normal, susp-

ect the DMD board.

* Refer to the Digital Board Description

Diagram.

1) Check whether +26V and -26V is being supplied to

the DMD board.

-> If the voltage is abnormal, replace the tantal cond-

enser (C116, C110: When failure occurs intermittently.)

If the problem continues after replacement, then rep-

lace the power drive IC (IC108).

2) If the DMD voltage is normal, replace the panel, or

reassemble the panel.

(Try to fix the four silver screws again.)

* Refer to the DMD Board Description Diagram.

2

Alignment and Adjustments

Samsung Electronics 5-11

CN2

CN1

Seventh

[DMD state

inspection

method]

Remove the heat sink attached to the DMD

board and follow the directions given below.

1) Replace the heat sink. Fix the DMD by tigh-

tening the screws again.

2) Check signaling for each part.

Horizontal raster failure occurs.

[Check whether the output of

the R NETWORK RA101~

RA104 terminals of the DMD

board are normal.]

Vertical line failure occurs.

* Check whether it occurs within

the regular wide range.

(Less than 26mm for 50-inch TV)

* Refer to the DMD Panel PIN Terminals

Characteristics Diagram.

* Refer to the DMD

Board Description Diagram

1) If it appears at regular intervals

of less than 26mm, check the

DMD fixing state.

→ Loosen the four silver screws

and then re-assemble them.

2) If the vertical lines do not occur

at regular intervals, or the inter-

vals are more than 26mm, or

irregular, replace IC117

(DDP1010).

Noise

failure

Check the noise state of the color wheel.

1) If the noise of color wheel is loud, replace

the engine or the color wheel.

2) When the color wheel is replaced, make sure

to adjust the delay value of 1.DDP1010 to

factory settings.

(Adjust to the position where the color red is

strongest.)

Fan noise

1) Check the revolving state of

the fan to inspect whether

the fan wire is caught on the

wings, then check the bear-

ing noise.

Ballast noise

1) Check whether there is noise from the ballast, if noise is too loud,

replace the ballast.

The color wheel is attached as shown in the

following figure. Loosen the screws which fix

the outer parts and then replace the color wheel.

50-inch: Two fans

61-inch: Three fans

For 50 inch

2

3

Alignment and Adjustments

5-12 Samsung Electronics

4

5

Screen image

adjustment

failure (Tilt)

Loosen the three screws as shown in the following figure and then adjust the

DMD board by turning it to the left, right, up, or down.

* For factory settings, set the POS-X & the POS-Y values of DDP1010 to the

center.(16/147)

1) Separate the digital board.

2) Loosen the three screws shown in the following figure and then perform the

image adjustment.

If the lower part of image is well aligned horizontally but the upper

part is not aligned horizontally (PC mode is best for viewing.)

1) To repair the upper distortion failure, separate the screen and put

an inlay into the buss of the cabinet back on the mirror fixing part.

Part where distortion occurs.

[Screen state]

Screen

color skip

failure

Failure state

1) Colors are mixed at the corners.

2) It checked-out okay while in the white pattern. (Lower part failure state)

Repair procedure

1) Loosen the screw of the part as shown in the following figure.

2) Move the mirror so that there is no skipped color and then fix the

mirror using U/V bond.

Displayed at the corners of the screen.

Loading...

Loading...