Page 1

CONFIDENTIAL

PDP-027-1(Module Format)

Issues:Nov.07.03

Version:1.0

50“ PDP

SERVICE MANUAL

MODEL: GTW-P50M603

PANEL: Samsung(VVES50HW-XD01--)

Page 2

CONTENTS

1. IMPORTANT SAFETY PRECAUTIONS …………..1-2

2. SPECIFICATION …………………………………2-10

3. F ACTOR Y & ELECTRONIC ADJUSTMENT……...3-7

4. BLOCK DIAGRAM ………………………………...4-4

5. TROUBLE SHOOTING GUIDES ……….…….….5-6

6. B.O.M. OF BOARD ASSEMBLY ………………....6-18

7. P.C. BOARD TOP VIEW ..…………………….…..7-9

8. ELECTRONIC MODULE LIST …………….……..8-1

9. EXPLODED VIEW ………………………….……..9-1

10.PACKAGING LIST ……………..…………..……10-1

Page 3

IMPORTANT SAFETY PRECAUTIONS VER1.0

1. Before returning an instrument to the customer, always make a safety check of the entire instrument,

including, but not limited to, the following items.

a. Be sure that no built-in protective devices are defective and/or have been defeated during servicing. (1)

Protective shields are provided on this chassis to protect both the technician and the customer. Correctly

replace all missing protective shields, including any removed for servicing convenience. (2) When reinstalling

the chassis and/or other assembly in the cabinet, be sure to put back in place all protective devices, including,

but not limited to, nonmetallic control knobs, insulating fish papers, adjustment and compartment

covers/shields, and isolation resistor/capacitor networks. Do not operate this instrument or permit it to be

operated without all protective devices correctly installed and functioning.

b. Be sure that there are no cabinet openings through which an adult or child might be able to insert their

fingers and contact a hazardous voltage, Such opening include, but are not limited to, (1) spacing between

the picture tube and the cabinet mask, (2) excessively wide cabinet ventilation slots, and (3) an improperly

fitted and/or incorrectly secured cabinet back cover.

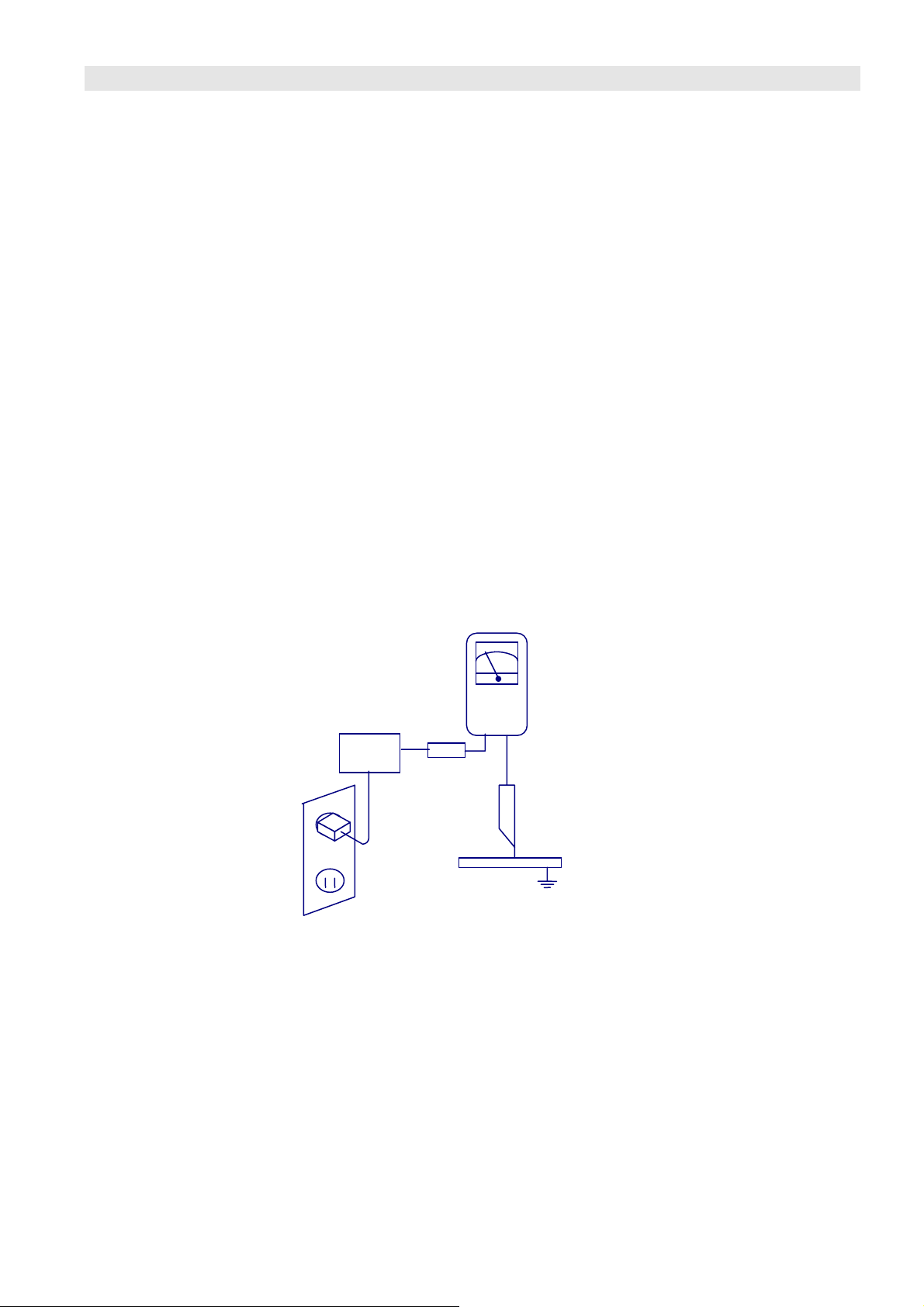

c. Leakage Current Hot Check—With the instrument completely reassembled, plug the AC line cord directly

into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a leakage current tester or a

metering system that complies with American National Standards Institutes (ANSI) C101.1 Leakage Current

for Appliances and Underwriters Laboratories (UL) 478. With the instrument AC switch first in the ON position

and then in the OFF position, measure from a known earth ground (metal water pipe, conduit, etc.) to all

exposed metal parts of the instrument (antennas, handle bracket, metal cabinet, screw heads, metallic

overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the

chassis. Any current measured must not exceed 3.5 milliamp. Reverse the instrument power cord plug in the

outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN INDICATE A

POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE INSTRUMENT

TO THE CUSTOMER.

AC Leakage T es t

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

3. WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2. Read and comply with all caution and safety-related notes on or inside the Monitor cabinet, on the Projection

Monitor chassis, or on the picture tube.

LEAKAGE

CURRENT

TESTER

+-

(READING

SHOULD NOT

BE ABOVE

3.5mA)

EARTH

GROUND

3. Design Alteration Warning—Do not alter or add to the mechanical or electrical design of this unit. Design

alterations and additions, including, but not limited to, circuit modifications and the addition of the items such

as auxiliary audio and/or video output connections might alter the safety characteristics of this Projection

Monitor and create a hazard to the user. Any design alterations or additions will void the manufacturer’s

warranty and will make you, the service, responsible for personal injury or property damage resulting

therefrom.

1-1

Page 4

IMPORTANT SAFETY PRECAUTIONS VER1.0

4. Hot Chassis Warning—a. Some Monitor chassis are electrically connected directly to one conductor of the

AC power cord and may be safely serviced without an isolation transformer only if the AC power plug is

inserted so that the chassis is connected to the ground side of the AC power source. To confirm that the AC

power plug is inserted correctly, with an AC voltmeter measure between the chassis and a known earth

ground. If a voltage reading in excess of 1.0V is obtained, remove and reinsert the AC power plug in opposite

polarity and again measure the voltage potential between the chassis and a known earth ground. b. Some

Monitor chassis normally have 85V AC (RMS.), between chassis and earth ground regardless of the AC plug

polarity. These chassis can be safely serviced only with an isolation transformer inserted in the power line

between the receiver and the AC power source, for both personnel and test equipment protection. c. Some

Projection Monitor chassis have a secondary ground systems in addition to the main chassis ground. This

secondary ground system is not isolated from the AC power line. The two ground system are electrically

separated by insulating material that must not be defeated or altered.

5. Observe original lead dress. Take extra care to assure correct lead dress in the following areas: a. near

sharp edges, b. near thermally hot parts—be sure that leads and components do not touch thermally hot

parts, c. the AC supply, d. high voltage, e. antenna wiring. Always inspect in all areas for pinched,

out-of-place, or frayed wiring. Do not change spacing between components, and between components and

the printed-circuit board. Check AC power cord for damage.

6. Components, parts, and/or wiring that appear to have overheated or are otherwise damaged should be

replaced with components, parts, or wiring that meet original specifications. Additionally, determine the

cause of overheating and/or damage and, if necessary, take corrective action to remove any potential safety

hazard.

7. PRODUCT SAFETY NOTICE—Many Monitor electrical and mechanical parts have special safety-related

characteristics some of which are often not evident from visual inspection, nor can the protection they give

necessarily be obtained by replacing them with components rated for higher voltage, wattage, etc. Parts that

have special safety characteristics are identified in this service data by shading with a mark on

schematics and by shading or a * mark in the parts list. Use of a substitute replacement part that does not

have the same safety characteristics as the recommended replacement part in this service data parts list

might create shock, fire, and/or other hazards.

1-2

Page 5

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

1. SCOPE:

These specifications describe all the characteristics of the 50-inch color monitor.

2. ELECTRICAL REQUIREMENTS:

2.1. Display panel: Specification

a. Screen size Diagonal 50 inch

b. Aspect ratio 16:9 wide

c. Number of pixels 1366 (Horizontal, RGB Trio) X 768 (Vertical) pixels

d. Pixel Pitch 0.81mm (H) X 0.81mm (V)

e. Luminance

f. Contrast Ratio

g. Chromatically

2.2. Power Source:

Typical 500cd/m

Typical 450:1 (1% white window)

x=0.260±0.03, y=0.275±0.03(color temperature HIGH )

at center block white pattern 100% (mosaic).

x=0.285±0.03, y=0.295±0.03(color temperature MID )

at center block white pattern 100% (mosaic).

x=0.335±0.03, y=0.343±0.03(color temperature LOW )

at center block white pattern 100% (mosaic).

x=0.313±0.03, y=0.329±0.03(color temperature 6500D )

at center block white pattern 100% (mosaic).

2

(1% white window)

a. Input volt age 100 ~ 240 Va c, 50 / 60 Hz

b. Input current 5A

c. Inrush current 60 A p-p/20ms Max.

d. Power consumption

e. Stand-by & DPMS 10 Watts Max. (at 110Vac)

2.3. Input Signal:

2.3.1 Connector Type:

2.3.2 Video/S-Video Signal:

a. Type Analog

b. Polarity Positive

c. Amplitude

d. Frequency

e. Input impedance 75 ohms

2.3.3 COMPONENT Signal:

470+10% Watts Max. (at 110Vac/color bar pattern)

RCA Jack for audio, video Y/C

and Y/PB/PR

B/CR

6 pin Din S-terminal

9 pin D-SUB

15 pin D-SUB

24 pin DVI

Video: 1Vp-p (with sync)

S-Video: Y=1Vp-p (with sy nc), C=0.286Vp-p

H: 15.734KHz V: 60Hz(NTSC)

H: 15.625KHz V: 50Hz(PAL)

a. Type Analog

b. Polarity Positive

c. Amplitude Y: 1Vp-p (with sync)

C

: 0.7Vp-p

B/PB

C

: 0.7Vp-p

R/PR

d. Frequency

Y/C

Y/P

B/CR

B/PR

: HDTV

H: 15.734KHz, V: 60Hz (NTSC)

H: 15.625KHz, V: 50Hz (PAL)

1. 31KHz/60Hz (480p)

2. 45KHz/60Hz (720p)

3. 33KHz/60Hz(1080i)

2-1

Page 6

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

2.3.4 RGB Signal:

a. Type TTL

b. Polarity Positive or Negative

c. Amplitude RGB: 0.7Vp-p

d. Frequency

2.3.5 DVI Signal:

H: support to 31K~91KHz

V: support to 50~85Hz

a. Type

b. Polarity

c. Frequency

d. HDCP Encryption

2.3.6 Audio Signal: Analog 500mV rms /more than 22Kohm

2.3.7 Pin Assignments For D-SUB Connector (In / Loop Out):

Pin Signal Assignment Pin Signal Assignment Pin Signal Assignment

1 RED 6 RED GND 11 GND

2 GREEN 7 GREEN GND 12 SDA

3 BLUE 8 BLUE GND 13 H-SYNC

4 GND 9 NC 14 V-SYNC

5 GND 10 GND 15 SCL

2.3.8 Pin Assignments For 24 Pin DVI Connector (Digital Only):

Pin Signal Assignment Pin Signal Assignment Pin Signal Assignment

1 TMDS Data 2- 9 TMDS Data 1- 17 TMDS Data 02 TMDS Data 2+ 10 TMDS Data 1+ 18 TMDS Data 0+

3 TMDS Data 2/4 Shield 11 TMDS Data 1/3 Shield 19 TMDS Data 0/5 Shield

4 TMDS Data 4- 12 TMDS Data 3- 20 TMDS Data 55 TMDS Data 4+ 13 TMDS Data 3+ 21 TMDS Data 5+

6 DDC Clock 14 +5V Power 22 TMDS Clock Shield

7 DDC Data 15 Ground (For +5V) 23 TMDS Clock +

8 No Connect 16 Hot Plug Detect 24 TMDS Clock -

Digital

Positive or Negative

H: support to 31K~68KHz

V: support to 50~85Hz

Enabled

2-2

Page 7

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

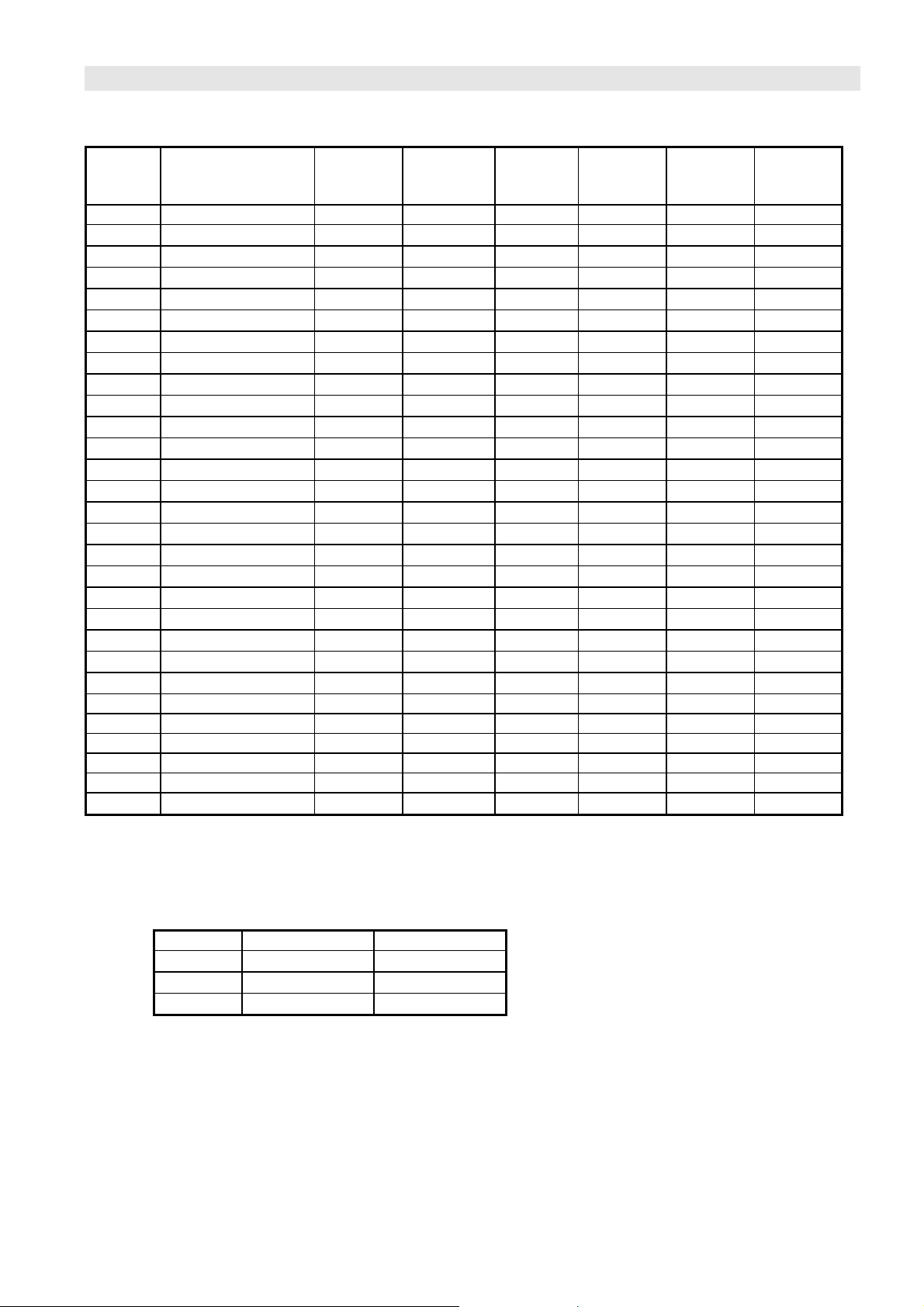

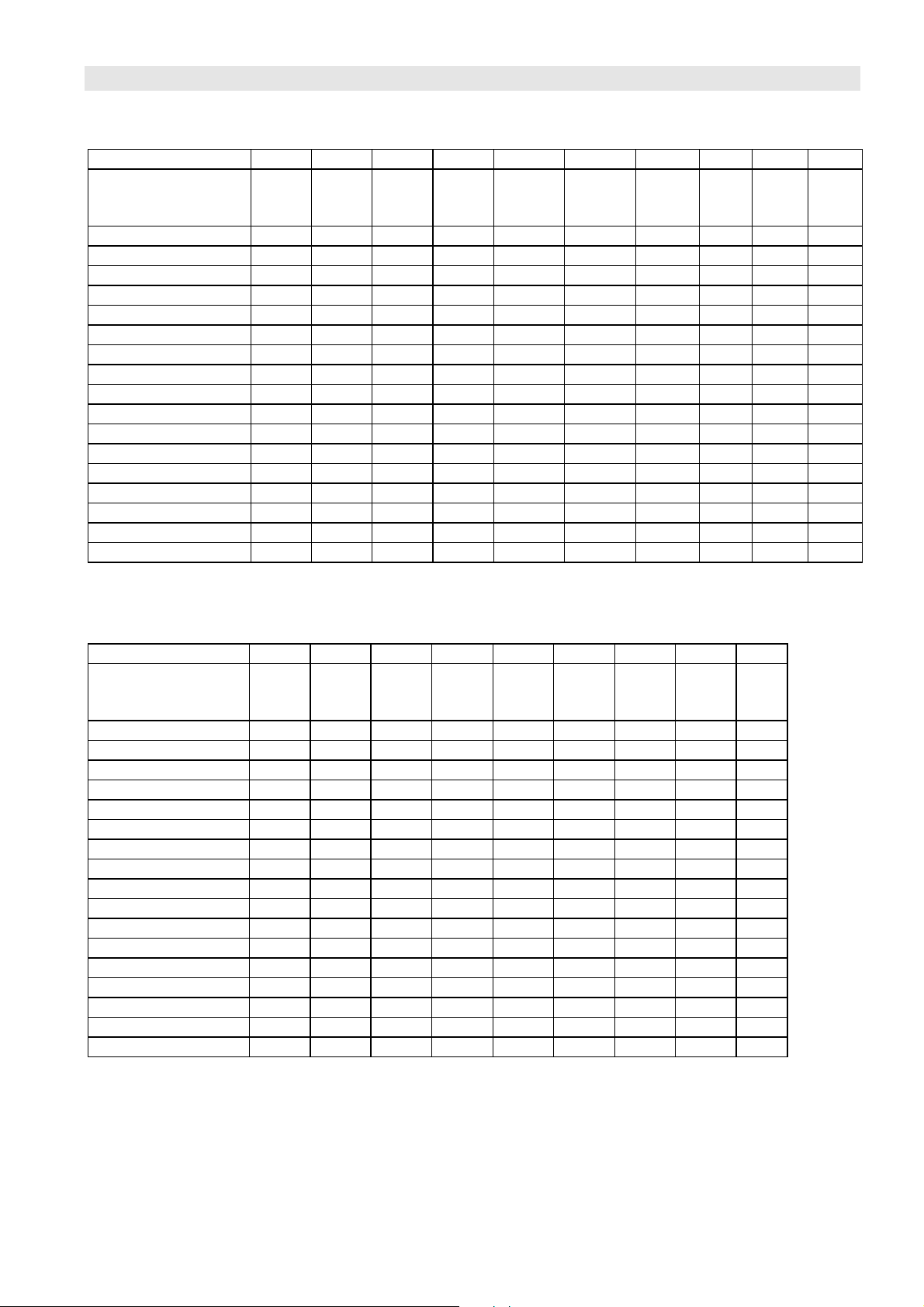

2.3.9 MODE LIST FOR RGB/DVI:

Mode No Resolution

(Hz) (K Hz) (Hz) (TTL) (TTL) (MHz)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15◎ 1280(SXGA)×1024

16◎ 1280(SXGA)×1024

18

19

20◎ 1280(HDTV)×720p

21◎ 1920(HDTV)×1080i

22

23

24 640 x 480 67 35.000 66.670 - - 30.240

25 832 x 624 75 49.730 74.550 - - 57.283

26 1152 x 870 75 68.680 75.060 - - 100.000

28 1360 x 768 60 47.368 59.960 - + 72.000

30 1280 x 960 60 60.000 60.000 + + 108.000

31◎

Note: 1. ◎: For DVI is not supported.

2. Mode 24~26 for Apple Macintosh computer.

640(VGA)×480

640(VGA)×480

640(VGA)×480

640(VGA)×480

800(SVGA)×600

800(SVGA)×600

800(SVGA)×600

800(SVGA)×600

800(SVGA)×600

1024(XGA)×768

1024(XGA)×768

1024(XGA)×768

1024(XGA)×768

1280(SXGA)×1024

720(DOS)×400

640(VGA)×480

640(VGA)×350

852(WGA)×480

1280 x 960 85 85.938 85.002 + + 148.500

Refresh

Rate

60 31.500 59.940 - - 25.175

72 37.900 72.810 - - 31.500

75 37.500 75.000 - - 31.500

85 43.300 85.010 - - 36.000

56 35.100 56.250 + + 36.000

60 37.900 60.317 + + 40.000

72 48.100 72.190 + + 50.000

75 46.900 75.000 + + 49.500

85 53.700 85.060 + + 56.250

60 48.400 60.010 - - 65.000

70 56.500 70.070 - - 75.000

75 60.000 75.030 + + 78.750

85 68.700 84.990 + + 94.500

60 63.980 60.020 + + 108.00

75 79.980 75.030 + + 135.00

85 91.150 85.020 + + 157.50

70 31.460 70.080 + - 28.322

50 31.500 50.000 - - 25.175

60 45.000 60.000 + + 74.250

60(i) 33.750 60.000 + + 74.250

70 31.500 70.000 - + 25.175

60 31.410 59.835 - - 30.000

Horizontal

Frequency

Vertical

Frequency

Vertical

Sync

Polarity

Horizontal

Sync

Polarity

Dot rate

2.3.10 Y/P

Mode No Resolution Refresh Rate

For Component:

B/PR

1

2

3

640 ×480p

1920 ×1080i

1280 ×720p

60

60

60

2-3

Page 8

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

2.4. Display Performance Requirements:

The data of display performance are measured based on the following

conditions unless otherwise specified.

a. Ambient temperature

b. Warm up period 30 minutes Min.

c. Line input voltage: 100 Vac ~ 240 Vac (50 / 60 Hz)

d. Viewing distance Distance from screen is 81 cm

e. Display mode Te s t with window white pattern mode if not specified.

f. Brightness condition Press recall bottom to set default brightness

2.4.1 Maximum Resolution: Support to 1280 x 1024

2.4.2 Horizontal Size (Standard) 1106.5±8 mm (for mode 1~31)

Vertical Size (Standard) 622.1±8 mm (for mode 1~31)

2.4.3 Horizontal Size (Max.) Mode 1~31Öover full-scan

Vertical Size (Max. ) Mode 1~31Ö over full-scan

2.4.4 Maximum Brightness Level: Ti ming Mode 1

a. 100% center block white

pattern (mosaic)

b. Raster background

2.5. Operation:

Main unit button

IR Remote Control

Power on/off

25±5 ℃

More than 25FL

(while pressing recall button to set default brightness)

Less than 0.4FL

(while pressing recall button to set default brightness)

Main power switch (power ON /OFF)

Power ON/OFF

Input Select (TV -> AV1 ->AV2[S] -> COMPONENT 1 ->

COMPONENT 2-> RGB -> DVI->TV run in cycle)

Menu key -,+

Adjustment -,+

MUTE

Display

Input Select (same as Main unit button)

Volume -,+

Wide:

TV/A V1/AV2[S]/COMPONENT 1/2

PANORAMA/4:3/16:9

(ZOOM1/ZOOM2/ZOOM3/OFF for 16:9 only)

Analog RGB input: 4:3/16:9

Menu -,+

Adjustment -,+

RECALL

PIP, SOURCE, SWAP, POSITION

USE FOR TV MODE:

V-CHIP/SET

FAV.CH, FAV.SET, QV, CCD, MTS, CH LOCK,

SLEEP TIMER,

Number Select, CH ▲▼

DIRECT KEY:

POWER ON, POWER OFF, RGB, TV, AV1, AV2,

COMPONENT1/2, DVI

input:

2-4

Page 9

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

2.5.1 Adjustable Items:

TV /A V1 /AV2[S] input

COMPONENT

input PICTURE:

Analog RGB input

DVI input

PICTURE:

Input Source, Brightness, Contrast, Color, Tint, Sharpness

Color Temperature, Clock Phase, Screen Wide, Zoom

SOUND:

Bass, Treble, Surround, BBE, Bass E xten sion, Volume,

INNER SPK, Audio Output

PIP:

Source, Position, Swap

POP:

Source, Screen Rate, Swap

TV:

Channel, Channel Status , MTS, CCD, V-CHIP, Ch Search,

Tuner Source, Background

OTHER:

OSD Timeout, OSD Brightness, OSD Background, Sleep,

OSD Language, Power Save (no function under this

input), Power On Sequence, Reset

Input Source, Brightness, Contrast, Color, Tint,

Sharpness, Color Temperature, Clock Phase, Screen

Wide, Zoom, Geometric Adjust

SOUND: (same as TV/AV1/ AV2[S]

PIP/POP: (no function under this input)

TV: (same as TV/AV1/AV2[S]

OTHER: (same as TV/AV1/AV2[S]

PICTURE:

Input Source, Brightness, Contrast, V-center, V-size,

H- position, H-width, Color Temperature, Clock Phase

SOUND: (same as TV/AV1/AV2[S]

PIP/POP: (no function under this input)

TV: (same as TV/AV1/AV2[S] input )

OTHER:

OSD Timeout, OSD Brightness, OSD Background, Sleep,

OSD Language, Power Save, Power On Sequence, Reset

PICTURE:

Input Source, Brightness, Contrast, V-center, V-size, Hposition, H-width, Color Temperature

SOUND: (same as TV/AV1/AV2[S]

PIP/POP; (no function under this input)

TV; (same as TV/AV1/AV2[S]

OTHER:

OSD Timeout, OSD Brightness, OSD Background, Sleep,

Power Save, Power On Sequence, Reset

input )

input)

input)

input)

input)

input)

3. DIMENSIONS: Without/Stand With/Stand

Width

Height

Depth

49.5”/1256mm

30.0” /762 mm

4.2”/107.5mm

49.5”/1256mm

31.9”/810mm

11.8”/300 mm

3.1. Package Dimensions:

Width 56.5”/1436 mm

Height 44.3”/1125 mm

Depth 18.5”/470 mm

3.2. Weight:

Net weight 103.6lbs/47 Kg (w/o stand) 108lbs/ 49Kgs (w/ stand)

Gross weight 132.24lbs/60 Kg

2-5

Page 10

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

4. ENVIRONMENT:

4.1. Operating:

Temperature

Relative humidity 20~80%

Pressure 800~1100hpa

4.2. Non-Operating:

Temperature

Relative humidity 20~90%

Pressure 700~1100hpa

Vibration X/Y/Z, 0.5G/10~55Hz(sweep), 10 minutes

4.3. Acoustics:

(IHF A-weighted 1meter) 40dB Max.

5. SOUND:

a. Residual hum (at volume min)

b. Practical max. Audio output (at 10% THD max.)

1.0vp-p 1K Hz input 5W +5W Max. /12 ohm

c. Sound distortion (at 250 mw 1K Hz) 1% Max.

d. Audio output (input at 1.4V

e. Max. hum (at volume max)

f. Sensitivity (at volume max. O/P 1W)

at 1KHz AV Input

g. Audio Fidelity (1KHz 0dB,corrected for emphasis characteristics)

WOOFER ON 60Hz

10KHz

BBE ON 60Hz

10KHz

WOOFER & BBE OFF 100Hz

10KHz

0~50℃ (32~122℉)

-20~60℃ (-4~140℉)

)

P-P

500μW Max.

≧1.0 V

P-P

1000μW Max.

150mV ±3dB

11dB ±3dB

4dB ±3dB

6dB ±3dB

8dB ±3dB

-1dB ±3dB

-1dB ±3dB

6. RF

6.1 RF Sensitivity (Peak)

VHF CH 2 ~ CH 13 30dB Max.

UHF CH 1 4 ~ CH 69 30dB Max.

CATV CH A-5 ~ CH W+29 30dB Max.

6.2 AFT Pull-In Range

VHF CH 2 ~ CH 13

UHF CH 14 ~ CH 69

CATV CH A- 5 ~ CH W+29

6.3 Picture IF Rejection

VHF CH 2 ~ CH 13 50dB Min.

UHF CH 14 ~ CH 69 50dB Min.

CATV CH A-5 ~ CH W+29 50dB Min.

6.4 Picture Image Rejection

VHF CH 2 ~ CH 13 40dB Min.

UHF CH 14 ~ CH 69 35dB Min.

CA TV

CH A-5 ~ CH W+29 35dB Min.

±0.6MHz Min.

±0.6MHz Min.

±0.6MHz Min.

2-6

Page 11

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

6.5 AGC Characteristics

AGC Figure Of Merit 50dB Min.

RF signal range in which video at PDP drops 6 dB from outpu t lev el obtained

with 100mV input.

6.6 RF AGC Cut In Level

6.7 FM/AM Rejection (100mV at SIF input) 14dB min

6.8 Noise Limits Sensitivity VHF 45dB max

7. Reliability Requirement:

The MTBF needs 20000hrs under operation 25±5℃(half luminosity, motion picture)

8. REGULATORY REQUIREMENTS:

8.1 Safety Requirement:

a. UL Safety of information technology equipment including

electrical business equipment

b. CSA

c. TUV

8.2 Emission Requirement:

The unit shall meet the EMI limits in all screen modes. For EMI testing, the unit must be failed

with the screen pattern consisting of scrolling capital “H” characters also the brightness

contrast will be adjusted to max. Level.

Safety of information technology equipment including

electrical business equipment

55dB ±2dB

UHF 49dB max

a. FCC class B part 15

8.3 Transit test

a. Drop Test 200mm max.

b. Vibration Test

1. Forward and backward

2. Right and left

3. Up and down

8.4 Power Management:

Mode H-sync V-sync Video Power dissipation

Normal Pulse Pulse Active Normal power

Stand-by No pulse No pulse No video Less than 10 watts

Power saving

This Plasma display is Energy star compliant when used with a computer equipped with DPMS.

Pulse No pulse

No pulse Pulse

Note: The power indicator LED color is green in normal state, yellow in stand-by and

power saving state.

30 minutes 1000 c.p.m

30 minutes 1000 c.p.m

30 minutes 1000 c.p.m

Blanked Less than 10 watts

2-7

Page 12

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

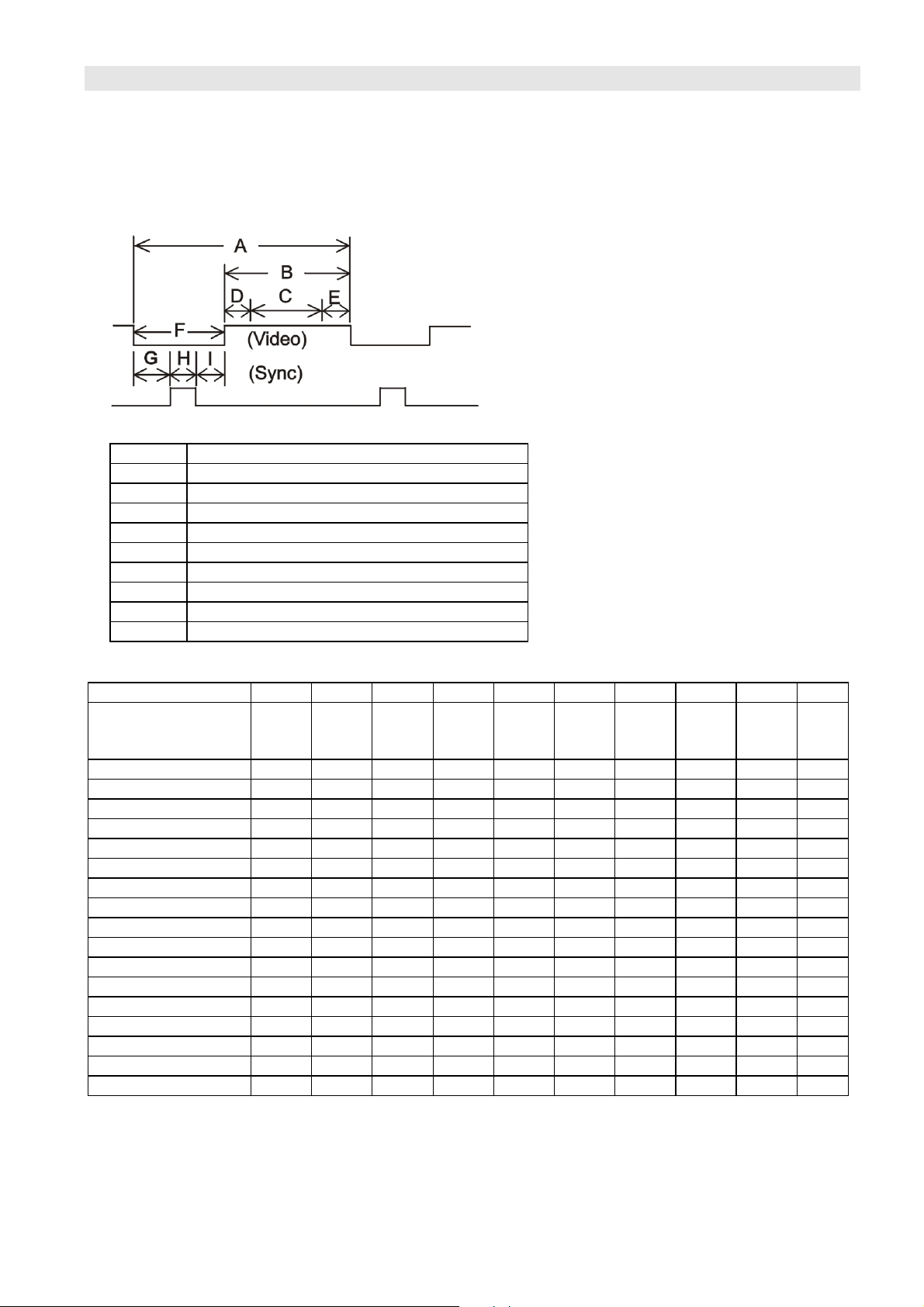

APPENDIX A :

Preset Timing Chart

Item Description:

A Total time

B Active display area including borders

C Active display area excluding borders

D Left/Top border

E Right/bottom border

F Blanking time

G Front porch

H Sync-width

I Back porch

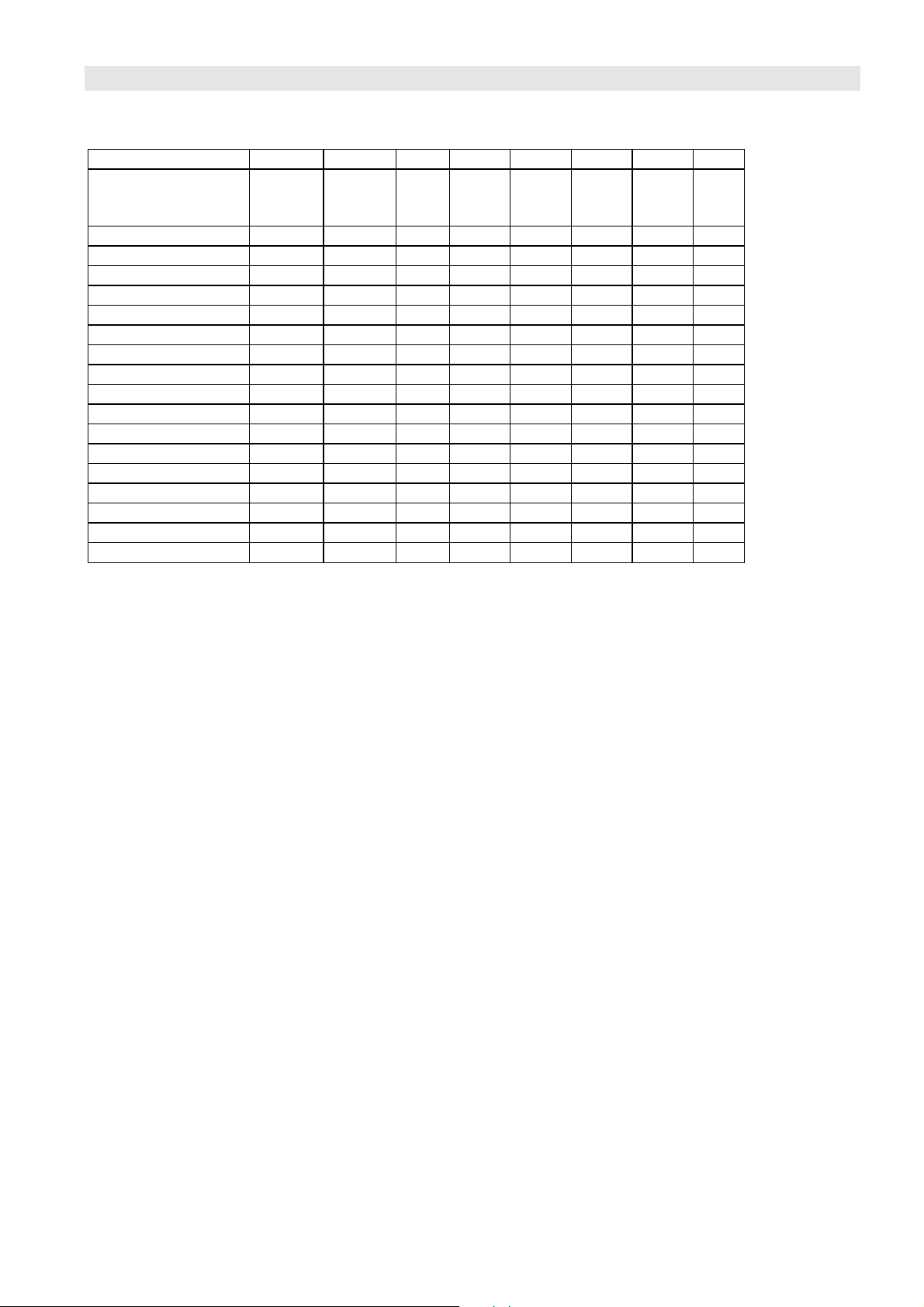

Mode No 1 2 3 4 5 6 7 8 9

Resolution

&

Refresh Rate

Pixel Clock 25.175 31.500 31.500 36.000 36.000 40.000 50.000 49.500 56.250 MHz

Horizontal visible 640 640 640 640 800 800 800 800 800 Dots

Horizontal total 800 832 840 832 1024 1056 1040 1056 1048 Dots

Horizontal front porch 16 24 16 56 24 40 56 16 32 Dots

Horizontal sync 96 40 64 56 72 128 120 80 64 Dots

Horizontal back porch 48 128 120 80 128 88 64 160 152 Dots

Horiz blanking time 160 192 200 192 224 256 240 256 248 Dots

Vertical visible 480 480 480 480 600 600 600 600 600 Lines

Vertical total 525 520 500 509 625 628 666 625 631 Lines

Vertical front porch 10 9 1 1 1 1 37 1 1 Lines

Vertical sync 2 3 3 3 2 4 6 3 3 Lines

Vertical back porch 33 28 16 25 22 23 23 21 27 Lines

Vertical blanking time 45 40 20 29 25 28 66 25 31 Lines

Horizontal frequency 31.469 37.861 37.500 43.269 35.156 37.879 48.077 46.875 53.674 KHz

Vertical frequency 59.940 72.809 75.000 85.008 56.250 60.317 72.188 75.000 85.061 Hz

Vertical sync polarity - - - - + + + + + TTL

Horiz sync polarity - - - - + + + + + TTL

640

480

60

640

480

72

640

480

75

640

480

85

800

600

56

800

600

60

800

600

72

800

600

75

800

600

85

Hz

2-8

Page 13

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

Mode No 10 11 12 13 14 15 16 18 19

Resolution

&

Refresh Rate

Pixel Clock 65.000 75.000 78.750 94.500 108.000 135.000 157.500 28.320 25.175 MHz

Horizontal visible 1024 1024 1024 1024 1280 1280 1280 720 640 Dots

Horizontal total 1344 1328 1312 1376 1688 1688 1728 900 800 Dots

Horizontal front porch 24 24 16 48 48 16 64 18 16 Dots

Horizontal sync 136 136 96 96 112 144 160 108 96 Dots

Horizontal back porch 160 144 176 208 248 248 224 54 48 Dots

Horiz blanking time 320 304 288 352 408 408 448 180 160 Dots

Vertical visible 768 768 768 768 1024 1024 1024 400 480 Lines

Vertical total 806 806 800 808 1066 1066 1072 449 629 Lines

Vertical front porch 3 3 1 1 1 1 1 12 62 Lines

Vertical sync 6 6 3 3 3 3 3 2 2 Lines

Vertical back porch 29 29 28 36 38 38 44 35 85 Lines

Vertical blanking time 38 38 32 40 42 42 48 49 149 Lines

Horizontal frequency 48.364 56.476 60.023 68.677 63.981 79.976 91.146 31.469 31.469 KHz

Vertical frequency 60.004 70.069 75.029 84.997 60.020 75.025 85.024 70.087 50.030 Hz

Vertic al sync polarity - - + + + + + + - TTL

Horiz sync polarity - - + + + + + - - TTL

1024

768

60

1024

768

70

1024

768

75

1024

768

85

1280

1024

60

1280

1024

75

1280

1024

85

720

400

70

640

480

50

Hz

Mode No 20 21 22 23 24 25 26 28

Resolution

&

Refresh Rate

Pixel Clock 74.250 74.250 25.175 30.000 30.240 57.283 100.000 72.000 MHz

Horizontal visible 1280 1920 640 852 640 832 1152 1360 Dots

Horizontal total 1650 2200 800 955 864 1152 1456 1520 Dots

Horizontal front porch 110 88 16 19 64 32 32 48 Dots

Horizontal sync 40 44 96 48 64 64 128 32 Dots

Horizontal back porch 220 148 48 36 96 224 144 80 Dots

Horiz blanking time 370 280 160 103 224 320 304 160 Dots

Vertical visible 720 540 350 480 480 624 870 768 Lines

Vertical total 750 562.5 449 525 525 667 915 790 Lines

Vertical front porch 5 3 37 10 3 1 3 2 Lines

Vertical sync 5 5 2 2 3 3 3 5 Lines

Vertical back porch 20 15 60 33 39 39 39 15 Lines

Vertical blanking time 30 23 99 45 45 43 45 22 Lines

Horizontal frequency 45.000 33.750 31.469 31.413 35.000 49.725 68.681 47.368 KHz

Vertical frequency 60.000 60.000 70.087 59.835 66.667 74.550 75.062 59.960 Hz

Vertical sync polarity + + - - - - - - TTL

Horiz sync polarity + + + - - - - + TTL

1280

720p

60

1920

1080i

60i

640

350

70

852

480

60

640

480

67

832

624

75

1152

870

75

1360

768

60

Hz

2-9

Page 14

SPECIFICATION FOR GTW-P50M603 PLASMA DISPLAY VER1.0

Mode No 30 31

Resolution

&

Refresh Rate

Pixel Clock 108.000 148.500 MHz

Horizontal visible 1280 1280 Dots

Horizontal total 1800 1728 Dots

Horizontal front porch 96 64 Dots

Horizontal sync 112 160 Dots

Horizontal back porch 312 224 Dots

Horiz blanking time 520 448 Dots

Vertical visible 960 960 Lines

Vertical total 1000 1011 Lines

Vertical front porch 1 1 Lines

Vertical sync 3 3 Lines

Vertical back porch 36 47 Lines

Vertical blanking time 40 51 Lines

Horizontal frequency 60.000 85.938 KHz

Vertical frequency 60.000 85.002 Hz

Vertical sync polarity + + TTL

Horiz sync polarity + + TTL

1280

960

60

1280

960

85

Hz

2-10

Page 15

Page 16

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

1. PANEAL voltage adjustment

POWER VOLTAGE ADJUST

VSD

VA

1. POWER ON

2. INPUT ALL WHITE PATTERN

3. ADJUST "Vs" VR MEASURE P805 PIN13 TO PIN10 VOLTAGE IS 158 ~ 172 V

4. ADJUST "Va" VR MEASURE P805 PIN1 TO PIN4 VOLTAGE IS 66 ~ 77 V

5. ADJUST "VSD" VR MEASURE P805 PIN1 TO PIN2 VOLTAGE IS 49 V

6. ADJUST "VSCAN" VR MEASURE P805 PIN7 TO PIN2 VOLTAGE IS 88 ~ 92 V

7. ADJUST "Vset" VR MEASURE P805 PIN7 TO PIN10 VOLTAGE IS 208 ~ 222 V

8. ADJUST "VE" VR MEASURE P805 PIN5 TO PIN2 VOLTAGE IS 183 ~ 197 V

3-1

Page 17

Page 18

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

2. Color Temperature Adjustment

1.1 Pre-setting Adjustment and Equipment Preparation for DVI Mode:

(1) Turn on the PDP and let it warm up for at least 30 minutes.

(2) Turn on the Color Analyzer (ie. Minolta, Model = CA-100) and reset the Color

Analyzer.

(3) Change the PDP input mode to DVI and press the “Recall” key on the remote

control to have the PDP set recalled back to default factory settings.

(4) Set up the Video Pattern Generator (ie. Chroma, Model = C2226) with the

following settings:

a. Timing: 640 x 480 @ 60Hz,

b. Make sure the Output signal is Digital (DVI)

Connect the PDP DVI input connector to the Chroma DVI output connector.

(5) Dark level and bright level center block definition:

A. Dark level center block definition:

Pattern set = Pattern name = 1-mosaic,

Color form = norm,

Background color = 0

Foreground color = 17

According to the C-2226’s user manual, appendix analog-color: Normal Pen

from Pen 17 = R: 102, G: 102, B: 102

102 (output amplifier)/1024 (total amplifier)=10%, therefore the 10% is the 10

IRE white output pattern.

B. Bright level center block definition:

Pattern set = Pattern name = 1-mosaic,

Color form = norm,

Background color = 0

Foreground color = 25

According to the C-2226’s user manual, appendix analog-color: Normal Pen

from Pen 25 = R: 614, G: 614, B: 614

614 (output amplifier)/1024 (total amplifier)=60%, therefore the 60% is the 60

IRE white output pattern.

(6) There are 3 different modes (DVI, RGB and Component) that have Color

Temperature settings. For each one of these 3 modes, there are 4 different Color

Temperatures (5400K, 6500D, 9300K and 13800K) that can be individually

adjusted. Each Color Temperature is adjusted through the dark level, bright level,

Gain and Bias values.

(7) Press the following key sequence to access the Factory Adjustment Menu:

Press and hold down the Left Arrow key for at least 5 seconds, then press and

hold down the Right Arrow key for at least 5 seconds followed by pressing the

FAV.SET key.

3-2

Page 19

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

From the Factory Adjustment Menu, choose the Color Temp. Adj option and the

following OSD will appear.

DVI (RGB, COM) 5400K (6500D, 9300K, 13800K)

x=335 y=343

GAIN BIAS

R G B R G B

X X X X X X

*Note: When adjusting the DVI and RGB color temperatures, please set the

PDP input source so that it matches the color temperature source being

adjusted (DVI color temp. to be adjusted with DVI source under DVI mode,

RGB color temp. with RGB source under RGB mode, COM color temp. with

Component source under Component1 mode).*

(8) Flatly place the Minolta Color Analyzer’s Photo Detector in contact with the center

of the PDP screen.

1.2 DVI Mode Color Temperature Adjustment Procedure:

(1) With the PDP’s DVI input connected to Chroma C-2226’s DVI output connector,

set the Chroma to send a dark level center block signal (10 IRE). Now press the

Factory Adjustment key sequence as stated in point (7) above. The DVI 5400K

Color Temperature setting menu will appear after choosing the Color Temperature

Adjustment option.

(2) Press the Left/Right Button to switch between the Bias (R, G, B) and Gain (R, G, B)

values. Use the Up/Down Buttons to change the Bias and Gain Values.

(3) 5400K dark level center block adjustment procedure:

A. Press the Left/Right key on the remote control to select G-BIAS and adjust

(using the up/down key) the G-Bias value until Y = 0.4±0.1 FL.

B. Press the Left/Right key on the remote control to select R-BIAS and adjust the

R-Bias value until x = 335±30

C. Press the Left/Right key on the remote control to select B-BIAS and adjust the

B-Bias value until y = 343±30

D. Repeat steps A, B and C until the following final values are obtained:

x = 335±30

y = 343±30

Y = 0.4±0.1 FL

(4) 5400K bright level center block adjustment procedure: (Please set the Chroma

C-2226 DVI bright level center block signal to 60 IRE)

A. Select G-GAIN and adjust the G-GAIN value until Y = 30±1 FL.

B. Select R-GAIN and adjust the R-GAIN value until x = 335±30

3-3

Page 20

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

C. Select B-GAIN and adjust the B-GAIN value until y = 343±30

D. Repeat steps A, B and C until the following final values are obtained:

x = 335±30

y = 343±30

Y = 30±1 FL

(5) Upon completion of Steps 3 and 4 above, press the FAV.SET key for the next

Color Temperature setting (5400→6500D→9300→13800).

For each color temperature setting, please repeat Steps 3 and 4 above but replace

the x and y settings with the following values:

a. 6500D: x = 313, y = 329 for both Dark and Bright Level Settings

b. 9300K: x = 285, y = 295 for both Dark and Bright Level Settings

c. 13800K: x = 260, y = 275 for both Dark and Bright Level Settings

For these 3 Color Temperatures (6500D, 9300K and 13800K), adjust the Dark and

Bright Levels to the following Y values:

a. Dark level Y = 0.4±0.1 FL

b. Bright level Y = 30±1 FL

(6) Once all 4 Color Temperatures have been adjusted, skip through the RGB and

Component Color Temperatures (using the FAV.SET key) and completely exit the

Factory Adjustment Menu.

2.1 Pre-setting Adjustment and Equipment Preparation for RGB Mode:

(1) Turn on the Color Analyzer (Minolta, Model = CA-100) and reset the Color

Analyzer.

(2) Switch the PDP input to RGB mode and press the “Recall” key on the remote

control to have the PDP set recalled back to default factory settings.

(3) Set up the Video Pattern Generator (Chroma, Model = C2226) with the following

settings:

A. Timing: 640 x 480 @ 60Hz,

B. Make sure the Output signal is Analog (RGB)

Connect the PDP RGB input connector to the Chroma C-2226 RGB output

connector.

(4) Dark level and bright level center block definition:

A. Dark level center block definition:

Pattern set = Pattern name = 1-mosaic

Color form = norm

Background color = 0

Foreground color = 17

According to the C-2226’s user manual, appendix analog-color: Normal Pen

from Pen 17 = R: 102, G: 102, B: 102

102 (output amplifier)/1024 (total amplifier)=10%, therefore the 10% is the 10

IRE white output pattern.

3-4

Page 21

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

B. Bright level center block definition:

Pattern set = Pattern name = 1-mosaic

Color form = norm

Background color = 0

Foreground color = 25

According to the C-2226’s user manual, appendix analog-color: Normal Pen

from Pen 25 = R: 614, G: 614, B: 614

614 (output amplifier)/1024 (total amplifier)=60%, therefore the 60% is the 60

IRE white output pattern.

(5) Flatly place the Minolta Color Analyzer’s Photo Detector in contact with the center

of the PDP screen.

2.2 RGB Mode Color Temperature Adjustment Procedure:

(1) With the PDP’s RGB input connected to Chroma C-2226’s RGB output connector, ,

set the Chroma C-2226 to a dark level center block signal (10 IRE). Enter the

Factory Adjustment Menu using the same Key sequence specified above and then

select the Color Temperature Adjustment option. Using the FAV.SET key skip

through all the DVI Color Temperatures until you reach the 5400K RGB Color

Temperature OSD.

(2) Press the Left/Right Button to switch between the Bias (R, G, B) and Gain (R, G, B)

values. Use the Up/Down Buttons to change the Bias and Gain Values.

(3) 5400K dark level center block adjustment procedure:

A. Select G-BIAS and adjust the G-Bias value until Y = 0.5±0.1 FL

B. Select R-BIAS and adjust the R-Bias value until x = 335±30

C. Select B-BIAS and adjust the B-Bias value until y = 343±30

D. Repeat steps A, B and C until the following final values are obtained:

x = 335±30

y = 343±30

Y = 0.5±0.1 FL

(4) 5400K bright level center block adjustment procedure: (Please set the Chroma

C-2226 RGB bright level center block signal to 60 IRE)

A. Select G-GAIN and adjust the G-GAIN value until Y = 30±1 FL

B. Select R-GAIN and adjust the R-GAIN value until x = 335±30

C. Select B-GAIN and adjust the B-GAIN value until y = 343±30

D. Repeat steps A, B and C until the following final values are obtained:

x = 335±30

y = 343±30

Y = 30±1 FL

(5) Upon completion of Steps 3 and 4 above, press the FAV.SET key for the next Color

Temperature setting (5400→6500D→9300→13800).

3-5

Page 22

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

For each color temperature setting, please repeat Steps 3 and 4 above but replace

the x and y settings with the following values:

a. 6500D: x = 313, y = 329 for both Dark and Bright Level Settings

b. 9300K: x = 285, y = 295 for both Dark and Bright Level Settings

c. 13800K: x = 260, y = 275 for both Dark and Bright Level Settings

For these 3 Color Temperatures (6500D, 9300K and 13800K), adjust the Dark and

Bright Levels to the following Y values:

a. Dark level Y = 0.5±0.1 FL

b. Bright level Y = 30±1 FL

(6) Once all 4 Color Temperatures have been adjusted, skip through the Component

Color Temperatures and completely exit the Factory Adjustment Menu.

3.1 Pre-setting Adjustment and Equipment Preparation for Component Mode:

(1) Turn on the Color Analyzer (Minolta, Model = CA-100) and reset the Color

Analyzer.

(2) Switch the PDP input to Component1 mode and press the “Recall” key on the

remote control to have the PDP set recalled back to default factory settings.

(3) Set up the Video Pattern Generator (ie. SENCORE VP-300 Multimedia Video

Generator) with the following settings:

A. Dark Level Center block definition:

a. Signal Type: Component

b. Format: 1080i

c. Pattern = WINDOW 1 14 IRE

B. Bright Level Center block definition:

a. Signal Type: Component

b. Format: 1080i

c. Pattern = WINDOW 2 60 IRE

(4) Connect the PDP Component1 input to the VP-300 Component output connector.

(5) Flatly place the Minolta Color Analyzer’s Photo Detector in contact with the center

of the PDP screen.

3.2 Component Mode Color Temperature Adjustment Procedure:

(1) Set the VP-300 to send a dark level center block signal (14 IRE). Enter the

Factory Adjustment Menu using the same Key sequence specified above and then

select the Color Temperature Adjustment option. Using the FAV.SET key skip

through all the DVI and RGB Color Temperatures until you reach the 5400K

Component Color Temperature OSD.

(2) Press the Left/Right Button to switch between the Bias (R, G, B) and Gain (R, G, B)

values. Use the Up/Down Buttons to change the Bias and Gain Values.

3-6

Page 23

FACTORY & ELECTRONIC ADJUSTMENT VER1.0

(3) 5400K dark level center block adjustment procedure:

A. Select G-BIAS and adjust the G-Bias value until Y = 1.0±0.1 FL.

B. Select R-BIAS and adjust the R-Bias value until x = 335±30

C. Select B-BIAS and adjust the B-Bias value until y = 343±30

D. Repeat steps A, B and C until the following final values are obtained:

x = 335±30

y = 343±30

Y = 1.0±0.1 FL

(4) 5400K bright level center block adjustment procedure: (Please set the VP-300

bright level center block signal to 60 IRE)

A. Select G-GAIN and adjust the G-GAIN value until Y = 45±1 FL

B. Select R-GAIN and adjust the R-GAIN value until x = 335±30

C. Select B-GAIN and adjust the B-GAIN value until y = 343±30

D. Repeat steps A, B and C until the following final values are obtained:

x = 335±30

y = 343±30

Y = 45±1 FL

(5) Upon completion of Steps 3 and 4 above, press the FAV.SET key for the next Color

Temperature setting (5400→6500D→9300→13800).

For each color temperature setting, please repeat Steps 3 and 4 above but replace

the x, y and Y values with the following values:

a. 6500D: x = 313, y = 329 for both Dark and Bright Level Settings

b. 9300K: x = 285, y = 295 for both Dark and Bright Level Settings

c. 13800K: x = 260, y = 275 for both Dark and Bright Level Settings

For these 3 Color Temperatures (6500D, 9300K and 13800K), adjust the Dark and

Bright Levels to the following Y values:

a. Dark level Y = 1.0±0.1 FL

b. Bright level Y = 45±1 FL

(6) Once all 4 Color Temperatures have been set you will automatically exit the Color

Temperature Adjustment. Once you exit the Color Temperature Adjustment

proceed on by completely exiting the Factory Adjustment Menu.

3-7

Page 24

BLOCK DIAGRAM VER1.0

Colum n Drive Board Column Drive Board

Column Drive Board

SCAN Drive Board

Y-Drive Board

LA2000

Pin[1:40]

Audio

Amplifier

Board Ass'y

Pin[1:40]

J1

(LVDS)

JP4

PinA[1:48]

JA2

Pin[1:10]

JA1

Pin[1:12]

Image Board

Ass'y

J14 Pin[1:6]

(5V,SB DET)

Pin[1:7]

J21

(24V,9V)

SA

Pin[1:13]

Speaker

Pin[1:9]

Main Power

X-Drive Board

Front

Button

Control

Board

Assy

Pin[1:6]

JA3

SCAN Drive Board

AV Module

Board(with

Tuner) Ass y

JP2 Pin[1: 48]

JP1

Pin[1:48]

Pin[1:48]

JP5

J15 Pin[1:4]

(9V)

Pin[1:3]

J25

(5V)

Logic Board

J12 Pin[1: 10]

(Audio Signal)

J11Pin[ 1: 12]

(Audio DC,Supply)

J5 Pin[1:6]

(Ke y)

AC Filter

AC IN

Line Filter Power

SW

Colum n Drive Board

Colum n Drive Board

4-1

Column Drive Board

Panel's Board Assembly

SAMPO Board Assembly

Page 25

BLOCK DIAGRAM VER1.0

Image Board Signal Block Diagram

SDRAM

(PAGE4)

TV

AV

S-VIDEO

TA8551CH

AV

SWITCH

IC1

(PAGE2)

VIDEO

Y

C

VIDEO

Y

C

Y1/CB/CR

Y1/PB/PR

MULTIPLEX

SWITCH

IC3

6830 MAIN

Video

Processor

U45

6830 SUB

Video

Porcessor

U46

YCBCR

YCBCR/YPBPR

YCBCR/YPBPR

(PAGE3)

(PAGE5)

SDRAM

(PAGE6)

YUV

MULTIPLEX

SWITCH

IC2

RGB IN

MULTIPLEX

SWITCH

U34

(PAGE7)

R,G,B

RGB OUT

AD

Converter

U29

(PAGE8)

SIL169 DVI

U32

(PAGE10)

SDRAM

(PAGE12)

SCALE IC

C711/C713

U23

(PAGE11)

LVDS

TRANSMITTER

(PAGE14)

Clock

Generator

9161A(PLL)

(PAGE13)

P

A

N

E

L

Y2/CB/CR

Y2/PB/PR

MULTIPLEX

SWITCH

IC7

(PAGE1)

TA1276

Color Space

Conveter

U43

CPU

U4

(PAGE9)

DVI IN

RS232

4-2

Page 26

Page 27

BLOCK DIAGRAM VER1.0

FROM A V

SELECTOR

ICR1

SRS SURROUND

PROCESSOR

PDP Sound Block Diagram

ICS1

LPF

Q1/Q2 AV_ OUTPUT

INPUT BUFFER

ICA3

FIXED/VARIBLE

OUTPUT

SELECTOR

ICA1 /ICA2

MUTE

Q8/Q9/Q11

MUTE

ICS2

MUTE

PAGE2

SUB_WOOFER

OUTPUT

IC1

BBE & SOUND

PROCESSOR

U1

BUFFE R

AMPLIFIER

PAGE1

IC2

M A IN PO WE R

AMP LIFIE R

4-3

INSIDE

SPEAKER

Page 28

Page 29

BLOCK DIAGRAM VER1.0

Tuner Board Signal Block Diagram

9V

TU201 RF

M O DUL E

TU201 PIF

MODULE

POWER BLOCK

7805

IC202

AUDIO OUT

7809 9V_T

IC201

NE555

IC241

2SC24825V

Q241

31V

UPC 1854ACT

FROM IMA G E

BO A RD CP U

MTS

IC203

JP2

SCL2

SDA2

TV_L OUT

TV_R OUT

VIDEO OUT

4-4

Page 30

Page 31

TROUBLE SHOOTING GUIDES VER1.0

No Power

SET POWER ON

Panel Main Power

Check

G

Power SW

Check

NG

Replace Main Power

Check

OK

NG

Replace Power SW

Check

OK

5-1

Page 32

TROUBLE SHOOTING GUIDES VER1.0

No Picture

No picture

AV Module Board (with

Tuner)

(DPWB11410-1GGTS)

Check

G

Image Board

(DPWB11400-1GGAS)

Check

G

NG

Replace

AV Module Board

(DPWB11410-1GGTS) Check

NG

Replace Image Board

(DPWB11400-1GGAS)

Check

(with Tuner)

OK

PDP Panel Module

(VVES50HW-XD01--)

Check

NG

Replace

PDP Panel Module

VVES50HW-XD01--)

(

Check

OK

OK

5-2

Page 33

TROUBLE SHOOTING GUIDES VER1.0

Vertical Line Fail

Vertical Line

Fail

X_XLT ,X_XCT ,X_XRT

X_XLB ,X_XCB ,X_XRB

Check

G

PDP Panel Module

Assembly

(VVES50HW-XD01--)

Check

NG

Replace

X_XLT ,X_XCT ,X_XRT

X_XLB ,X_XCB ,X_XRB

Check

OK

NG

Replace

PDP Panel Module Assembly

(

VVES50HW-XD01--) Check

5-3

OK

Page 34

TROUBLE SHOOTING GUIDES VER1.0

(

Horizontal Line Fail

Horizontal Line

Fail

X-Drive Board

(LJ92-00559A)

Check

G

Y-Drive Board

(LJ92-00560A)

Y-DRV-TOP

(LJ92-00561A) Check

Y-DRV-BOTTOM

(LJ92-00562A) Check

NG

Replace

X-Drive Board

(LJ92-00559A) Check

OK

NG

Replace

Y-Drive Board(LJ92-00560A)

Y-DRV-TOP

(LJ92-00561A) Check

Y-DRV-BOTTOM

G

LJ92-00562A) Check

PDP Panel Module

Assembly

(VVES50HW-XD01--)

Check

NG

Replace

PDP Panel Assembly

(VVES50HW-XD01--) Check

OK

5-4

OK

Page 35

TROUBLE SHOOTING GUIDES VER1.0

No Remote Control

SET POWER ON

Remote Control

Check

G

NG

Replace

Battery

Replace

(BRC-250CGATEWAY)

Check

OK

OK

Front Button Control Board

(DPWB11372-1G-K2)

Check

G

NG

Replace

Front Button Control Board

(DPWB11372-1G-K2)

Check

OK

Image Board

(DPWB11400-1GGAS)

Check

NG

Replace Image Board

(DPWB11400-1GGAS)

Check

OK

5-5

Page 36

TROUBLE SHOOTING GUIDES VER1.0

Front Button Fail

SET POWER ON

Front Button Control

Board

(DPWB11372-1G-K2)

NG

Check

Image Board

(DPWB11400-1GGAS)

Check

G

NG

Replace Front Button

Control Board

(DPWB11372-1G-K2)

Check

OK

Replace

Image Board

(DPWB11400-1GGAS)

Check

5-6

OK

Page 37

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

IMAGE BOARD ASS'Y DPWB11400-1GGAS

MODULE NAME PART NO.

AC MASTER POWER SWITCH B/D ASS'Y DPWB11398-1G---

7-1

Page 38

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

AUDIO AMPLIFIER BOARD ASS'Y DPWB11372-1GGSA

MODULE NAME PART NO.

FRONT BUTTON CONTROL BOARD ASS'Y DPWB11372-1G-K2

7-2

Page 39

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

AV MODULE BOARD (with Tuner) ASS'Y DPWB11410-1GGTS

MODULE NAME PART NO.

LOGIC BOARD ASS'Y LJ92-00598A

7-3

Page 40

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

Y DRIVE-TOP ASS'Y LJ92-00561A

MODULE NAME PART NO.

Y DRIVE-BOTTON ASS'Y LJ92-00562A

7-4

Page 41

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

Y-DRIVE BOARD ASS'Y LJ92-00560A

MODULE NAME PART NO.

X_XLB BOARD ASS'Y LJ92-00524B

7-5

Page 42

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

X_XCB BOARD ASS’Y LJ92-00525B

MODULE NAME PART NO.

X_XRB BOARD ASS’Y LJ92-00526C

7-6

Page 43

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

X_XLT BOARD ASS’Y LJ92-00527B

MODULE NAME PART NO.

X_XCT BOARD ASS’Y LJ92-00528B

MODULE NAME PART NO.

X_XRT BOARD ASS’Y LJ92-00529C

7-7

Page 44

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

X-DRIVE BOARD ASS'Y LJ92-00559A

MODULE NAME PART NO.

PANEL MAIN POWER SUPPLY ASS'Y LJ44-00044A

7-8

Page 45

P.C. BOARD TOP VIEW VER1.0

MODULE NAME PART NO.

EMI FILTER ASS'Y LJ92-00747A

MODULE NAME PART NO.

PDP PANEL MODULE ASS'Y VVES50HW-XD01- -

7-9

Page 46

ELECTRONIC MODULE LIST VER1.0

No. Module Supplier Supplier's Ass'y Part # Quantity Per Final

Assembly

1 Image Board Sampo DPWB11400-1GGAS 1

2 AC Master Power Switch Board Sampo DPWB11398-1G- - - 1

3 Audio Amplifier Board Sampo DPWB11372-1GGSA 1

4 Front Button Control Board Sampo DPWB11372-1G-K2 1

5 AV w/ Tuner Module Board Sampo DPWB11410-1GGTS 1

6 Logic Board Samsung LJ92-00598A 1

7 Y Driver-Top Samsung LJ92-00561A 1

8 Y Driver-Bottom Samsung LJ92-00562A 1

9 Y Drive Board Samsung LJ92-00560A 1

10 X_XLB Samsung LJ92-00524B 1

11 X_XCB Samsung LJ92-00525B 1

12 X_XRB Samsung LJ92-00526C 1

13 X_XLT Samsung LJ92-00527B 1

14 X_XCT Samsung LJ92-00528B 1

15 X_XRT Samsung LJ92-00529C 1

16 X Drive Board Samsung LJ92-00559A 1

17 Main Power Samsung LJ44-00044A 1

18 EMI Filter Samsung LJ92-00747A 1

19 Full Set PDP Panel Module Samsung VVES50HW-XD01- - 1

20 Glass Filter Sampo PGLS-0014-1- - - - 1

21 Speaker Sampo RSPK-L005-1CFJ- 2

22 Front Bezel Sampo DMSKP0128-1F- -D 1

23 Rear Cover Sampo GCABB0306-1P- -D 1

24 Plasma Stand Assembly Sampo DSTN-0021-1G- - - 2

8-1

Page 47

EXPLODED VIEW VER1.0

9-1

Page 48

Page 49

PACKAGING LIST VER1.0

10-1

Loading...

Loading...