Samsung DVE54M8750 User Manual

Dryer

User manual

DVE(G)54M8750*

DV8750M_DC68-03784A-05_EN.indd 1 3/29/2019 7:13:34 PM

Contents

Contents

Safety information 4

What you need to know about the safety instructions 4

Important safety symbols 4

CALIFORNIA PROPOSITION 65 WARNING 5

Important safety precautions 5

Warnings 7

Cautions 8

Installation requirements 10

Key installation requirements 10

Location considerations 10

Ducting requirements 11

Exhausting requirements 12

Gas requirements 13

Electrical requirements 14

Installation 16

What’s included 16

Step-by-step installation 18

Vent blockage test 24

Exhaust ducting guide 26

Switching the door position 26

Before you start 29

Sort and load 29

Functional prerequisite 29

Operations 30

Feature panel 30

Simple steps to start 33

Cycle overview 34

Drying guide 36

Special features 37

Samsung Smart Home 39

English2

DV8750M_DC68-03784A-05_EN.indd 2 3/29/2019 7:13:34 PM

Maintenance 41

Vent sensor 41

Cleaning 42

Troubleshooting 43

Checkpoints 43

Information codes 46

Specications 47

Fabric care chart 47

Protecting the environment 48

Specication sheet 49

Cycle chart 50

Contents

English 3

DV8750M_DC68-03784A-05_EN.indd 3 3/29/2019 7:13:34 PM

SAVE THESE INSTRUCTIONS

Safety information

Congratulations on your new Samsung dryer. This manual contains important information

on the installation, use and care of your appliance. Please take some time to read this

manual to take full advantage of your dryer’s many benets and features.

Safety information

What you need to know about the safety instructions

Please read this manual thoroughly to ensure that you know how to safely and efciently

operate the extensive features and functions of your new appliance. Please store the

manual in a safe location close to the appliance for future reference. Use this appliance

only for its intended purpose as described in this instruction manual.

Warnings and Important Safety Instructions in this manual do not cover all possible

conditions and situations that may occur. It is your responsibility to use common sense,

caution and care when installing, maintaining and operating your dryer.

Because the following operating instructions cover various models, the characteristics of

your dryer may differ slightly from those described in this manual and not all warning

signs may be applicable. If you have any questions or concerns, contact your nearest

service center or nd help and information online at www.samsung.com.

Important safety symbols

What the icons and signs in this user manual mean:

WARNING

Hazards or unsafe practices that may result in severe personal injury, death and/or

property damage.

CAUTION

Hazards or unsafe practices that may result in personal injury and/or property damage.

NOTE

Indicates that a risk of personal injury or material damage exists.

These warning signs are here to prevent injury to yourself and others.

Please follow them explicitly.

After reading this manual, store it in a safe place for future reference.

Read all instructions before using the appliance.

As with any equipment that uses electricity and moving parts, potential hazards exist.

To safely operate this appliance, familiarize yourself with its operation and exercise care

when using it.

English4

DV8750M_DC68-03784A-05_EN.indd 4 3/29/2019 7:13:35 PM

SAVE THESE INSTRUCTIONSSAVE THESE INSTRUCTIONS

CALIFORNIA PROPOSITION 65 WARNING

WARNING

Cancer and Reproductive Harm - www.P65Warnings.ca.gov.

WARNING - Risk of Fire

• Clothes dryer installation must be performed by a qualied installer.

• Install the clothes dryer according to the manufacturer’s instructions and local codes.

• Do not install a clothes dryer with exible plastic venting materials. If exible metal

(foil type) duct is installed, it must be of a specic type identied by the appliance

manufacturer as suitable for use with clothes dryers. Flexible venting materials are

known to collapse, be easily crushed, and trap lint. These conditions will obstruct

clothes dryer airow and increase the risk of re.

• To reduce the risk of severe injury or death, follow all installation instructions.

• Save these instructions.

Important safety precautions

WARNING

To reduce the risk of re, electric shock, or injury to persons when using your appliance,

follow basic precautions, including the following:

1. Read all instructions before using this appliance.

2. Do not dry articles that have been previously cleaned in, washed in, soaked in,

or spotted with gasoline, dry-cleaning solvents, or other ammable or explosive

substances, as they give off vapors that could ignite or explode.

3. Do not use the dryer to dry clothes which have traces of any ammable substance,

such as vegetable oil, cooking oil, machine oil, ammable chemicals, paint thinner, etc.,

or anything containing wax or chemicals, such as mops and cleaning cloths. Flammable

substances may cause the fabric to catch re by itself.

4. Do not store or use gasoline or other ammable vapors and liquids near this or any

other appliance.

5. Do not allow children to play on or in the appliance. Close supervision of children is

necessary when the appliance is used near children.

6. Before the appliance is removed from service or discarded, remove the door to the

drying compartment.

Safety information

English 5

DV8750M_DC68-03784A-05_EN.indd 5 3/29/2019 7:13:35 PM

SAVE THESE INSTRUCTIONS

Safety information

SAVE THESE INSTRUCTIONS

7. Do not reach into the appliance if the drum is moving.

Safety information

8. Do not install or store this appliance where it will be exposed to the weather.

9. Do not tamper with internal controls.

10. Do not repair or replace any part of the appliance or attempt any service unless

specically recommended in the user-maintenance instructions or in published userrepair instructions that you understand and have the skills to carry out.

11. Do not use fabric softeners or products to eliminate static unless recommended by the

manufacturer of the fabric softener or product.

12. Clean the lint screen before or after each load.

13. Do not use heat to dry articles containing foam rubber or similarly textured rubber-like

materials.

14. Keep area around the exhaust opening and adjacent surrounding areas free from the

accumulation of lint, dust, and dirt.

15. The interior of the appliance and exhaust duct should be cleaned periodically by

qualied service personnel.

16. Do not place items exposed to cooking oils in your dryer. Items contaminated with

cooking oils may contribute to a chemical reaction that could cause a load to catch re.

To reduce the risk of re due to contaminated loads, the nal part of a tumble dryer

cycle occurs without heat (cool down period). Avoid stopping a tumble dryer before the

end of the drying cycle unless all items are quickly removed and spread out so that the

heat is dissipated.

17. This appliance must be grounded. See “Electrical requirements” and ”Grounding” in

“Installation” section.

18. Do not allow children to play on or in the appliance. Close supervision of children is

necessary when the appliance is used near children.

19. Do not insert your hand under the dryer.

• This may result in injury.

20. Take care that children’s ngers are not caught in the door when closing it.

• This may result in injury.

21. The control board and inlet valve are intentionally not grounded and may present a

risk of electric shock only during servicing.

• Do not contact these parts while the appliance is energized.

English6

DV8750M_DC68-03784A-05_EN.indd 6 3/29/2019 7:13:35 PM

SAVE THESE INSTRUCTIONSSAVE THESE INSTRUCTIONS

WARNING - To reduce the risk of re or explosion:

• Do not dry items that have been previously cleaned, washed, soaked, or spotted with

gasoline, dry cleaning solvents, or other ammable or explosive substances. They

emit vapors that could ignite or explode. Any material that has been in contact with a

cleaning solvent or ammable liquids or solids should not be placed in the dryer until

all traces of these ammable liquids or solids and their fumes have been removed.

There are many highly ammable items used in homes, such as acetone, denatured

alcohol, gasoline, kerosene, some liquid household cleaners, some spot removers,

turpentine, waxes, and wax removers.

• Items containing foam rubber (may be labeled latex foam) or similarly textured

rubberlike materials must not be dried on a heat setting. Heated foam rubber

materials can, under certain circumstances, ignite spontaneously.

WARNING - What to do if you smell gas:

• Do not try to light any appliance.

• Do not turn on the appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Clear the room, building or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the re department.

• Installation and service must be performed by a qualied installer, service agency, or

the gas supplier.

Safety information

Warnings

WARNING

• Ensure pockets are free of small, irregularly shaped hard objects and foreign material,

i.e. coins, knives, pins, etc. These objects could damage your dryer.

• Gas leaks may occur in your system, resulting in a dangerous situation.

English 7

DV8750M_DC68-03784A-05_EN.indd 7 3/29/2019 7:13:35 PM

SAVE THESE INSTRUCTIONS

Safety information

SAVE THESE INSTRUCTIONS

Cautions

Safety information

CAUTION

• Do not allow children or pets to play on, in, or in front of the appliance. Close

supervision is necessary when the appliance is used near children and pets.

• Before discarding or removing your dryer from service, remove the door to the drying

compartment to prevent children or animals from becoming trapped inside.

• Do not reach into the appliance when the drum is moving.

• Do not install or store this appliance where it will be exposed to the weather.

• Do not tamper with the controls.

• Do not repair, replace, or attempt to service any part of the appliance unless

specically instructed to in the user-repair instructions and you have the

understanding and skills to carry out the procedure.

• Do not use fabric softeners or products to eliminate static unless the softener or

product is recommended for dryer use by the manufacturer of the fabric softener or

product.

• Clean the lint screen before or after each load.

• Keep the area around the exhaust opening and surrounding areas free from lint, dust,

and dirt.

• The interior of the dryer and exhaust duct should be cleaned periodically by qualied

service personnel.

• This appliance must be properly grounded. Never plug the power cord into a receptacle

that is not grounded adequately or not in accordance with local and national codes. See

the installation instructions for information about grounding this appliance.

• Do not sit on top of the dryer.

• Do not dry clothing with large buckles, buttons, or other heavy metal or solid objects.

• Gas leaks may not be detected by smell alone.

• Gas suppliers recommend you purchase and install a UL-approved gas detector.

• Install and use in accordance with the manufacturer’s instructions.

• Do not place items in your dryer that have been spotted or soaked with vegetable oil

or cooking oil. Even after being washed, these items may contain signicant amounts

of these oils.

English8

DV8750M_DC68-03784A-05_EN.indd 8 3/29/2019 7:13:35 PM

SAVE THESE INSTRUCTIONSSAVE THESE INSTRUCTIONS

• Residual oil on clothing can ignite spontaneoulsy. The potential for spontaneous

combustion increases when items containing vegetable oil or cooking oil are exposed

to heat. Heat sources such as your dryer can warm these items, allowing an oxidation

reaction in the oil to occur. Oxidation creates heat. If this heat cannot escape, the items

can become hot enough to catch re. Piling, stacking, or storing these kinds of items

may prevent heat from escaping and can create a re hazard.

• All washed and unwashed fabrics that contain vegetable oil or cooking oil can be

dangerous.

Washing these items in hot water with extra detergent will reduce, but not eliminate,

the hazard. Always use the Cool Down cycle for these items to reduce their

temperature. Never remove these items from the dryer hot or interrupt the drying

cycle until the items have run through the Cool Down cycle. Never pile or stack these

items when they are hot.

Safety information

English 9

DV8750M_DC68-03784A-05_EN.indd 9 3/29/2019 7:13:35 PM

Installation requirements

Read through the following instructions before installing the dryer, and keep this manual

for future reference.

WARNING

Certain internal parts are intentionally not grounded and may present a risk of electric

shock only during servicing.

Installation requirements

Service Personnel - Do not contact the following parts while the appliance is energized:

Control board and inlet valve.

Key installation requirements

• A grounded electrical outlet.

• A power cord for electric dryers (except

in Canada).

• Gas lines (for gas models) that must

meet national and local regulations.

Location considerations

• Adequate clearances between the dryer

and adjacent walls or other surfaces.

• Adequate air circulation for ventilation

and gas combustion.

• Away from water and weather.

WARNING

• Make sure to exhaust the dryer

outdoors to reduce the risk of re.

• Keep the dryer area clear of

combustible materials, gasoline, and

other ammable vapors and liquids.

• Do not install other fuel-burning

appliances around or in the same place

as the dryer.

• Place the dryer at least 18 in. (460 mm)

above the oor for garage installation.

• An exhaust system made of rigid metal

or exible stiff-walled metal exhaust

ducting.

WARNING

Remove the door from all discarded

appliances to prevent a child from

suffocating.

Alcove or closet installation

Minimum clearances between the dryer

and adjacent walls or other surfaces are:

2” in front, 17” on top, 1” on either side,

and 5.9 in. (150 mm) in the back.

The closet front must have two

unobstructed air openings for a combined

minimum total area of 72 in² with 3”

minimum clearance on the top and bottom.

A louvered door with equivalent space

clearance is acceptable.

English10

DV8750M_DC68-03784A-05_EN.indd 10 3/29/2019 7:13:36 PM

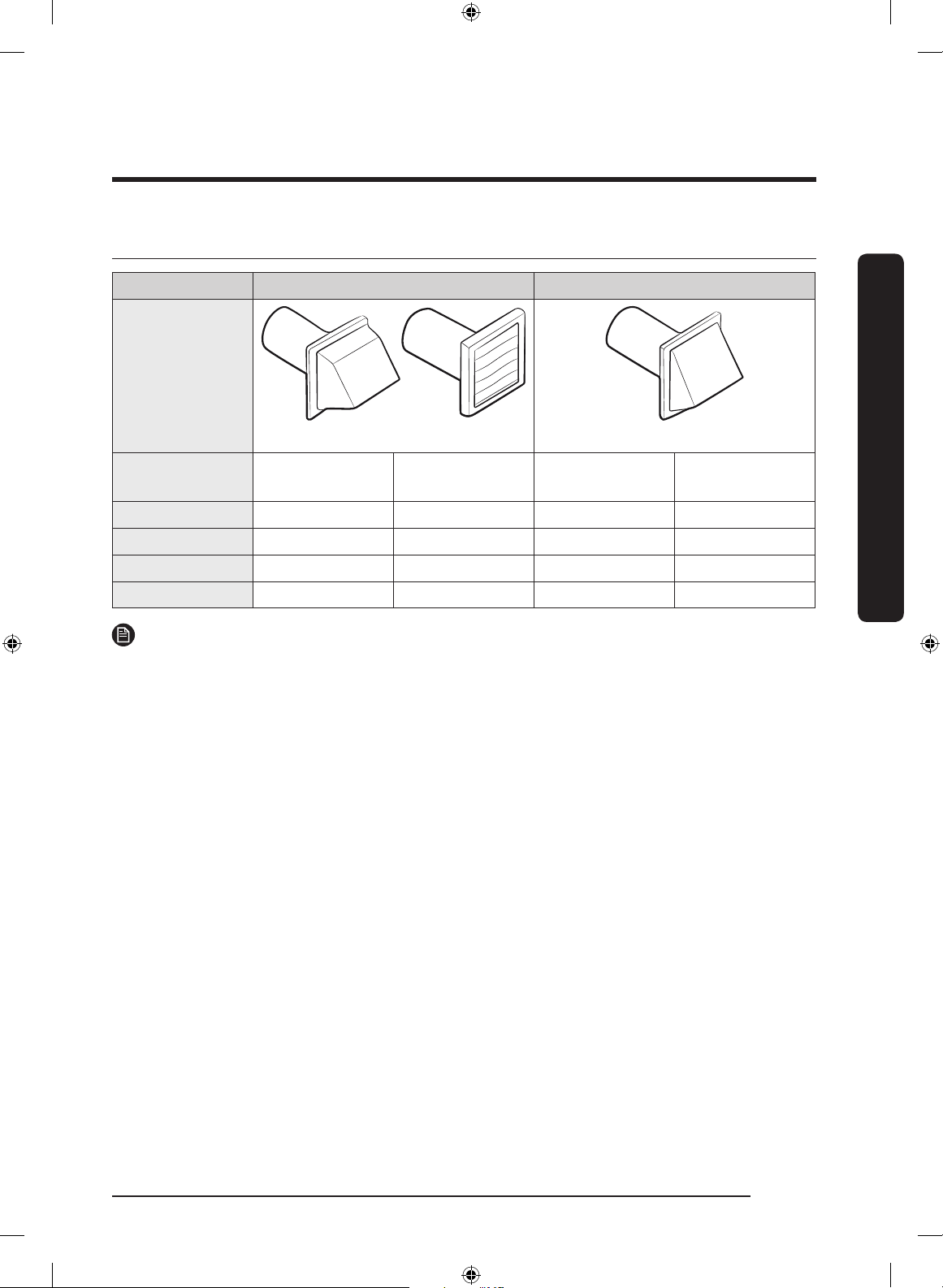

Ducting requirements

Weather hood

type

Recommended Use only for short-run installation

Installation requirements

No. of 90°

elbows

Rigid

4” (10.2 cm)

Metallic

exible*

2.5” (6.4 cm)

Rigid

Metallic

exible*

0 80 ft. (24.4 m) 41 ft. (12.4 m) 74 ft. (22.6 m) 33 ft. (10.1 m)

1 68 ft. (20.7 m) 37 ft. (11.2 m) 62 ft. (18.9 m) 29 ft. (8.8 m)

2 57 ft. (17.4 m) 33 ft. (10.1 m) 51 ft. (15.5 m) 25 ft. (7.6 m)

3 47 ft. (14.3 m) 29 ft. (8.8 m) 41 ft. (12.5 m) 21 ft. (6.5 m)

NOTE

* Use a 4-inch (10.2 cm) diameter rigid aluminum or galvanized steel duct.

If you integrate the dryer’s vent system with an existing exhaust system:

• Make sure the exhaust system meets all applicable local, state, and national regulations.

• Verify you are not using exible plastic duct.

• Make sure to check for and remove all lint buildup from inside the existing ducts.

• Conrm the duct is not kinked or crushed.

• Make sure the exhaust hood damper opens and closes freely.

Manometer measurements

The static pressure in any exhaust system must not exceed 0.83 inches of water column

or be less than 0. Note that these values are measured with the dryer running with a

manometer presented to the exhaust duct that connects to the dryer. The dryer tumbler

must be empty and lint lter clean.

English 11

DV8750M_DC68-03784A-05_EN.indd 11 3/29/2019 7:13:36 PM

Installation requirements

Exhausting requirements

The dryer must not be exhausted into a

chimney, a wall, a ceiling, an attic, a crawl

Installation requirements

space, or a concealed space of a building.

Exhausting the dryer to the outside will

prevent large amounts of lint and moisture

from being blown into the room.

In the United States and Canada

• All dryers must be exhausted to the

outside.

• The required exhaust duct is 4 inches

(10.2 cm) in diameter.

• See “Ducting requirements” in the

“Installation” section for the maximum

duct length and number of bends that

can be used.

• The total length of exible metal duct

must not exceed 7’ 10½” (2.4 m).

• Do not assemble the duct with screws

or other fasteners that extend into the

duct and catch lint.

• For the United States only: Use only

those foil-type exible ducts, if any,

specically identied for use with the

appliance by the manufacturer and that

comply with the Outline for Clothes

Dryer Transition Duct. Use Subject

2158A.

Outside the United States and Canada

• Refer to the local codes.

WARNING

• You must exhaust the dryer to the

outside to reduce the risk of re when

you install the dryer in an alcove or

closet.

• Do not use a plastic or non-metal

exible duct.

• If your existing ductwork is plastic, nonmetal, or combustible, replace it with

metal.

• Use only a metal exhaust duct that is

non-ammable to ensure containment

of exhaust air, heat, and lint.

English12

DV8750M_DC68-03784A-05_EN.indd 12 3/29/2019 7:13:37 PM

Gas requirements

WARNING

• Use only natural or LP (liquid propane)

gases.

• THE INSTALLATION MUST CONFORM WITH

LOCAL CODES, OR IN THE ABSENCE OF

LOCAL CODES, WITH THE NATIONAL FUEL

GAS CODE ANSI/Z223.1, LATEST REVISION

(FOR THE UNITED STATES), OR WITH THE

CAN /CGA-B149 INSTALLATION CODES (FOR

CANADA).

• Gas dryers are equipped with a burner

vent for use with natural gas. If you plan

to use your dryer with LP (liquid propane)

gas, it must be converted for safe and

proper performance by a qualied service

technician. (LNG models only)

You must check the burner of your model

and use the proper LP Kit accordingly. To

check the detail information of the burner,

open the door and check the rating label

location on the door frame.

- 20,000 BTU: DC98-04114A

- 22,000 BTU: LPKIT-3/XAA (DC99-00792A)

• A ⁄” (1.27 cm) gas supply line is

recommended and must be reduced to

connect to the ⁄” (1 cm) gas line on your

dryer. The National Fuel Gas Code requires

that an accessible, approved manual gas

shut-off valve be installed within 6” of your

dryer.

• Gas dryers installed in residential garages

must be raised 18 inches (46 cm) above the

oor.

• Additionally, a ⁄” (0.3 cm) N.P.T. (National

Pipe Thread) plugged tapping, accessible

for test gauge connection, must be installed

immediately upstream of your dryer’s gas

supply connection.

• Your dryer must be disconnected from the

gas supply pipe system during any pressure

testing of the system.

• Do not reuse old exible metal gas lines.

Flexible gas lines must be design certied

by the American Gas Association (CGA in

Canada).

NOTE

• Your dryer uses an automatic ignition

system to ignite the burner. There is no

constant burning pilot.

• Any pipe joint compound used must be

resistant to the action of any liqueed

petroleum gas.

• As a courtesy, most local gas utilities will

inspect a gas appliance installation.

Commonwealth of Massachusetts

installation instructions

Your dryer must be installed by a licensed

plumber or gas tter. A “T” handle manual gas

valve must be installed in the gas supply line to

your dryer. If a exible gas connector is used

to install your dryer, the connector can be no

longer than 3’ (36”).

WARNING

• Gas leaks may occur in your system,

creating a dangerous situation.

• Gas leaks may not be detected by smell

alone.

• Gas suppliers recommend you purchase and

install a UL-approved gas detector.

• Install and use in accordance with the

manufacturer’s instructions.

Installation requirements

English 13

DV8750M_DC68-03784A-05_EN.indd 13 3/29/2019 7:13:37 PM

Installation requirements

Electrical requirements

The wiring diagram is located on the plate

under the control panel or rear frame.

Installation requirements

WARNING

• Improperly connecting the equipment

grounding conductor can result in a

risk of electric shock. Check with a

qualied electrician or serviceman if

you are in doubt as to whether your

dryer is properly grounded. Do not

modify the plug provided with your

dryer – if it doesn’t t the outlet, have

a proper outlet installed by a qualied

electrician.

• To prevent unnecessary risk of re,

electrical shock, or personal injury, all

wiring and grounding must be done in

accordance with local codes, or in the

absence of local codes, in accordance

with the National Electrical Code, ANSI/

NFPA No. 70-Latest Revision (for the

U.S.) or the Canadian Electrical Code CSA

C22.1 – Latest Revisions and local codes

and ordinances. It is your responsibility

to provide adequate electrical service

for your dryer.

• All gas installations must be done in

accordance with the national Fuel Code

ANSI/Z2231 – Latest Revision (for the

U.S.) or CAN/CGA – B149 Installation

Codes – Latest Revision (for Canada)

and local codes and ordinances.

Grounding

This dryer must be grounded. In the event

of a malfunction or breakdown, the ground

will reduce the risk of electrical shock by

providing a path of least resistance for the

electrical current.

Gas models

WARNING

• Your dryer has a cord with an

equipment-grounding conductor and

a grounding plug. The plug must be

plugged into an appropriate outlet that

is properly installed and grounded in

accordance with all local codes and

ordinances.

• Do not modify the plug provided with

your dryer – if it doesn’t’t t the outlet,

have a proper outlet installed by a

qualied electrician.

• Do not connect the ground wire to

plastic plumbing lines, gas lines, or hot

water pipes.

Electric models

WARNING

• Your dryer has an optional cord with

an equipment-grounding conductor

and a grounding plug. This cord is sold

separately.

• The plug must be plugged into an

appropriate outlet that is properly

installed and grounded in accordance

with all local codes and ordinances.

• Do not modify the plug provided with

your dryer – if it doesn’t’t t the outlet,

have a proper outlet installed by a

qualied electrician.

English14

DV8750M_DC68-03784A-05_EN.indd 14 3/29/2019 7:13:37 PM

• If a power cord is not used and the

electric dryer is to be permanently

wired, the dryer must be connected to

a permanently grounded metal wiring

system, or an equipment grounding

conductor must be run with the circuit

conductors and connected to the

equipment grounding terminal or lead

on the dryer.

Electrical connections

Before operating or testing, follow all

grounding instructions in the “Grounding”

section. An individual branch (or separate)

circuit serving only your dryer is

recommended.

Do not use an extension cord.

Gas models – U.S. and Canada

A 120 volt, 60 Hz AC approved electrical

service with a 15-ampere fuse or circuit

breaker is required.

Electric models – U.S. only

Most U.S. dryers require a 120 / 240 volt,

60 Hz AC approved electrical service.

Some require 120 / 208 volt, 60 Hz

approved electrical service. The electric

service requirements can be found on

the data label located behind the door.

A 30-ampere fuse or circuit breaker on

both sides of the line is required.

• If a power cord is used, the cord

should be plugged into a 30-ampere

receptacle.

• The power cord is not provided with

U.S. electric model dryers. This cord is

sold separately.

WARNING

Risk of Electric Shock

When local codes allow, you can connect

the dryer’s electrical supply with a new

power supply cord kit, marked for use with

a dryer, that is U.L. listed and rated at a

minimum of 120 / 240 volts, 30-amperes

with three No. 10 copper wire conductors

terminated with closed loop terminals,

open-end spade lugs with turned up ends,

or with tinned leads.

• Do not reuse a power supply cord from

an old dryer. The power cord electric

supply wiring must be supported at the

dryer cabinet by a suitable UL-listed

strain relief.

• Grounding through the neutral

conductor is prohibited for (1) new

branch-circuit installations, (2) mobile

homes, (3) recreational vehicles, and

(4) areas where local codes prohibit

grounding through the neutral

conductor. (Use a 4-prong plug for a

4 wire receptacle, NEMA type 14-30R.)

Electric models – Canada Only

• A 120 / 240 volt, 60 Hz AC approved

electrical service fused through a

30-ampere fuse or circuit breaker on

both sides of the line is required.

• All Canadian models are shipped

with the power cord attached. The

power cord should be plugged into a

30-ampere receptacle.

NOTE

In Canada, you may not convert a dryer to

208 volts.

Installation requirements

English 15

DV8750M_DC68-03784A-05_EN.indd 15 3/29/2019 7:13:37 PM

Installation

This dryer must be installed by a qualied technician. The installer is responsible for

connecting the dryer to the main power while observing the relevant safety regulations of

your area.

What’s included

Make sure all the parts are included in the product package. If you have a problem with

the dryer or the accessories, contact a local Samsung service center or the retailer.

Installation

01

02

03

05

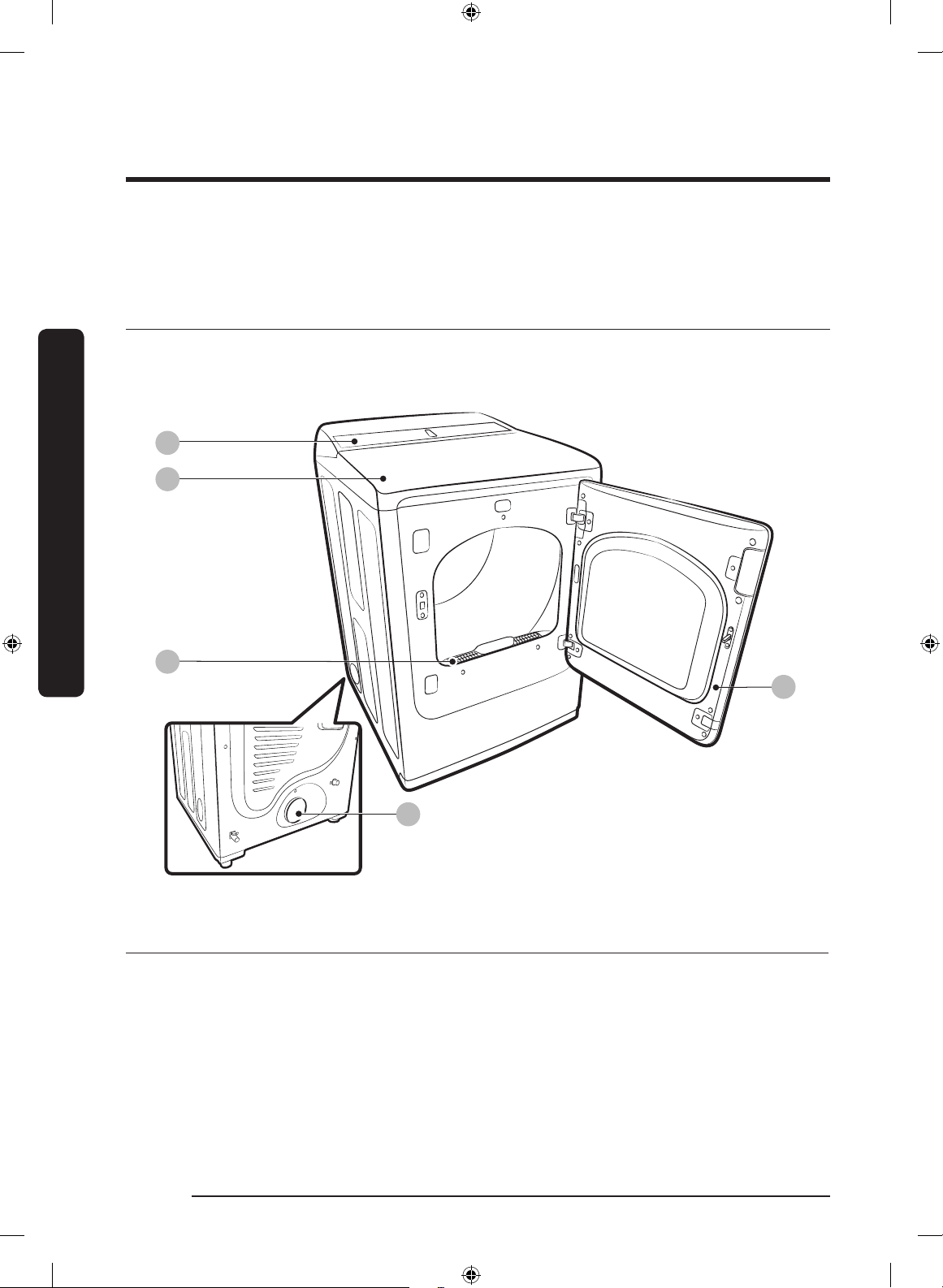

Dryer at a glance

01 Control panel 02 Worktop 03 Filter

04 Door 05 Exhaust duct

04

English16

DV8750M_DC68-03784A-05_EN.indd 16 3/29/2019 7:13:38 PM

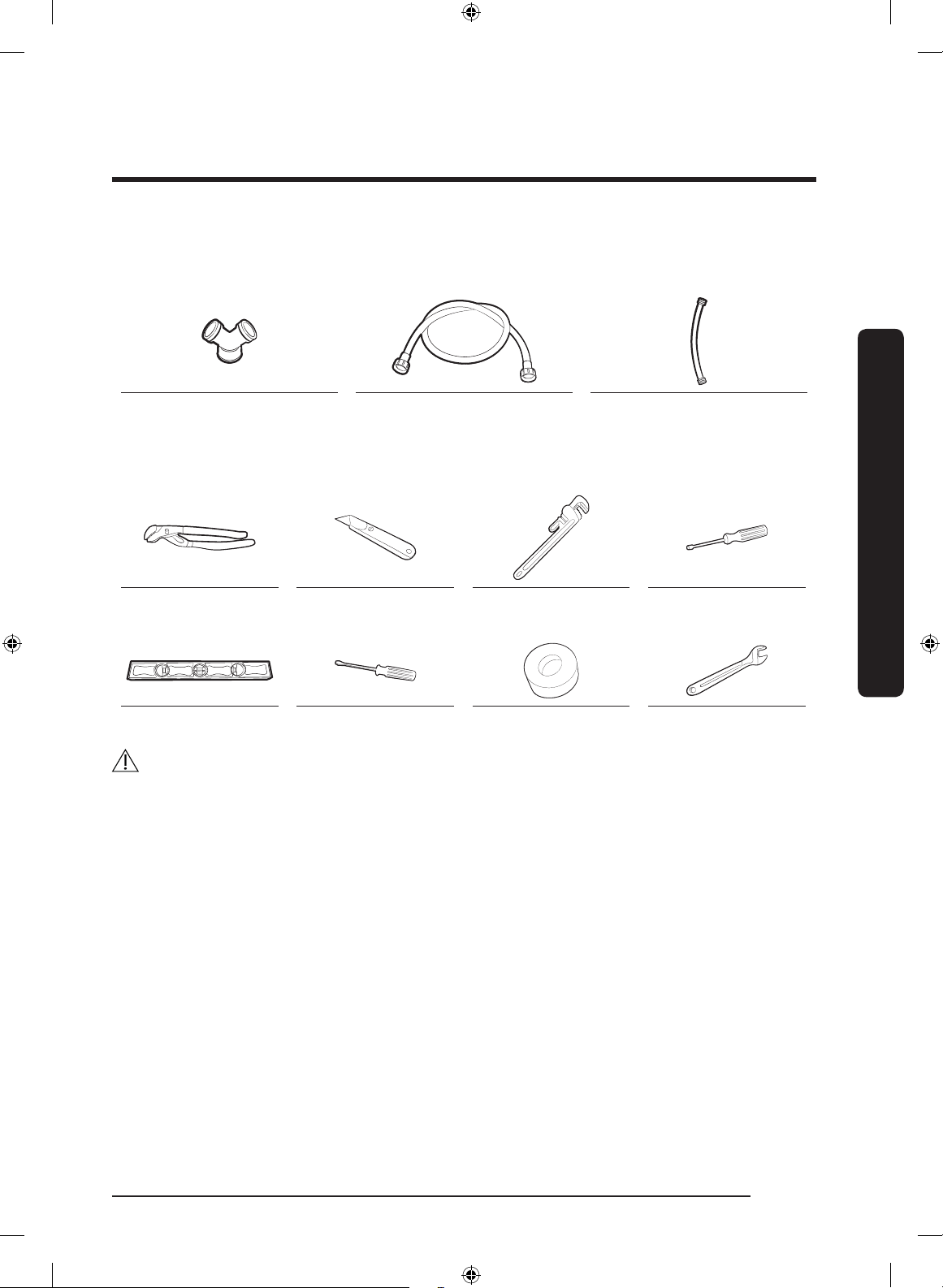

Accessories & tools

Provided accessories

Y connector Water hose (Canadian elec.

Short water hose

models only)

Required tools

Pliers Cutting knife Pipe wrench

Nut screwdriver

(gas models only)

Level Philips screwdriver Duct tape Wrench

WARNING

Packing materials can be dangerous to children. Keep all packing materials (plastic bags,

polystyrene, etc.) out of children’s reach.

Installation

English 17

DV8750M_DC68-03784A-05_EN.indd 17 3/29/2019 7:13:41 PM

Installation

Step-by-step installation

Make sure you have a qualied technician install the dryer. Step by step installation

instructions start below.

STEP 1 Install the exhaust system

1. Select a location and move the dryer to the site. For easy access, we recommend you

2. To change the door direction, see “Switching the door position”.

3. Install the exhaust system as instructed in the “Exhaust ducting guide” section.

Installation

Before installing your dryer, remove the packing in the duct.

• To move the dryer easily, lay two of the carton cushions from the packaging on the

• Secure room around the dryer to facilitate ducting and wiring.

install the dryer in the same location as your washer.

CAUTION

NOTE

oor. Tip the dryer on its side so it lies across both cushion-tops. Push the dryer so that

it is near its nal location, and then set the dryer upright.

STEP 2 Connect the gas line

First, read through the “Gas requirements” section, and follow these steps.

1. Remove the protective cap from the gas pipe.

2. Apply a LPG (Liqueed Petroleum Gas)-safe compound or 1.5 wraps of Teon tape to

all threaded connections.

3. Connect the gas supply to the dryer. An additional tting is required to connect the ⁄”

(1.9 cm) female thread end of a exible connector to the ⁄” (1 cm) male threaded end

on the dryer. Tighten up the tting over all threads.

4. Turn on the gas supply, and check for any leaks using a soap solution. If a leak is found,

tighten the connections and try again. DO NOT use an open ame to check for gas

leaks.

English18

DV8750M_DC68-03784A-05_EN.indd 18 3/29/2019 7:13:41 PM

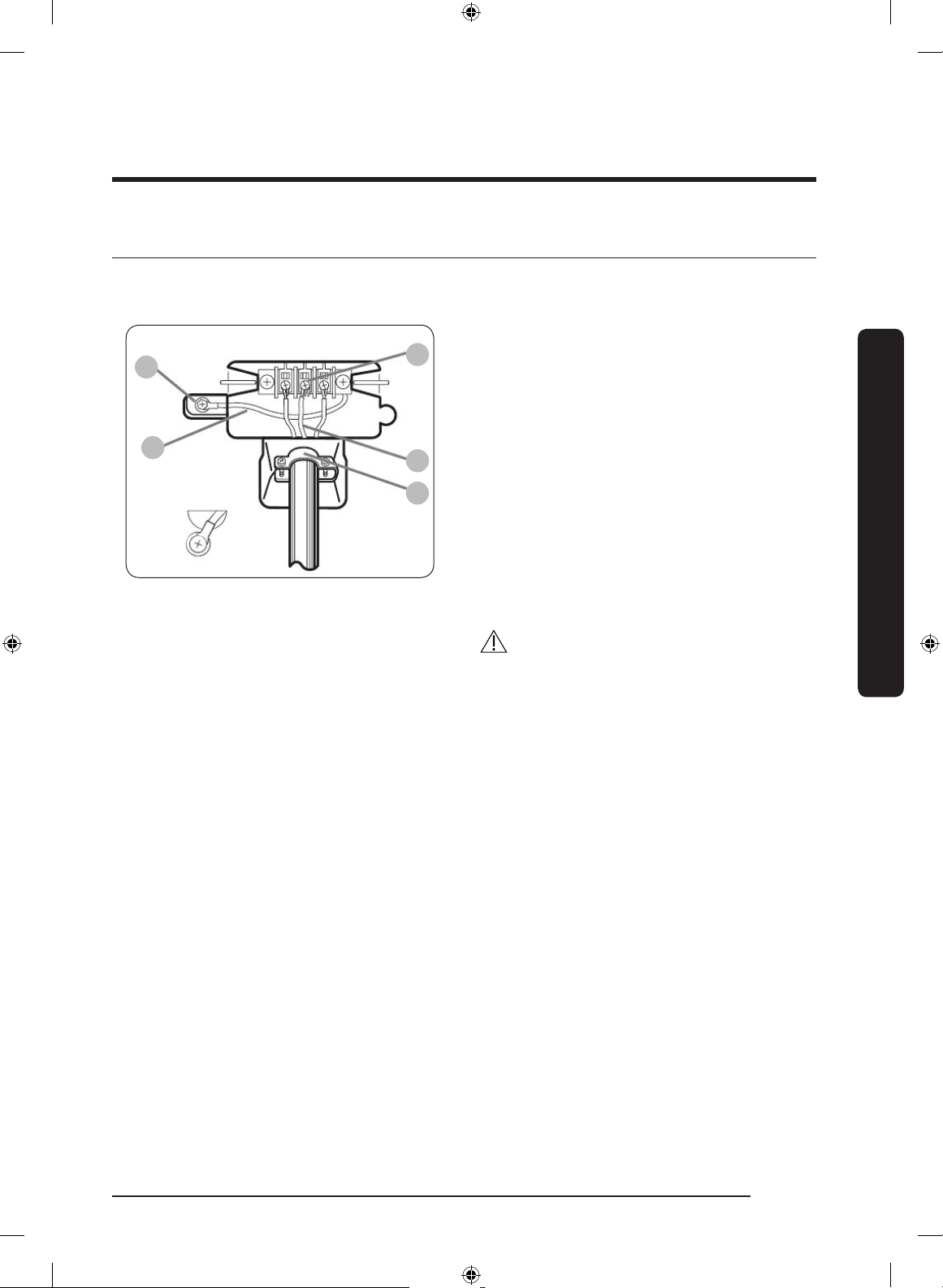

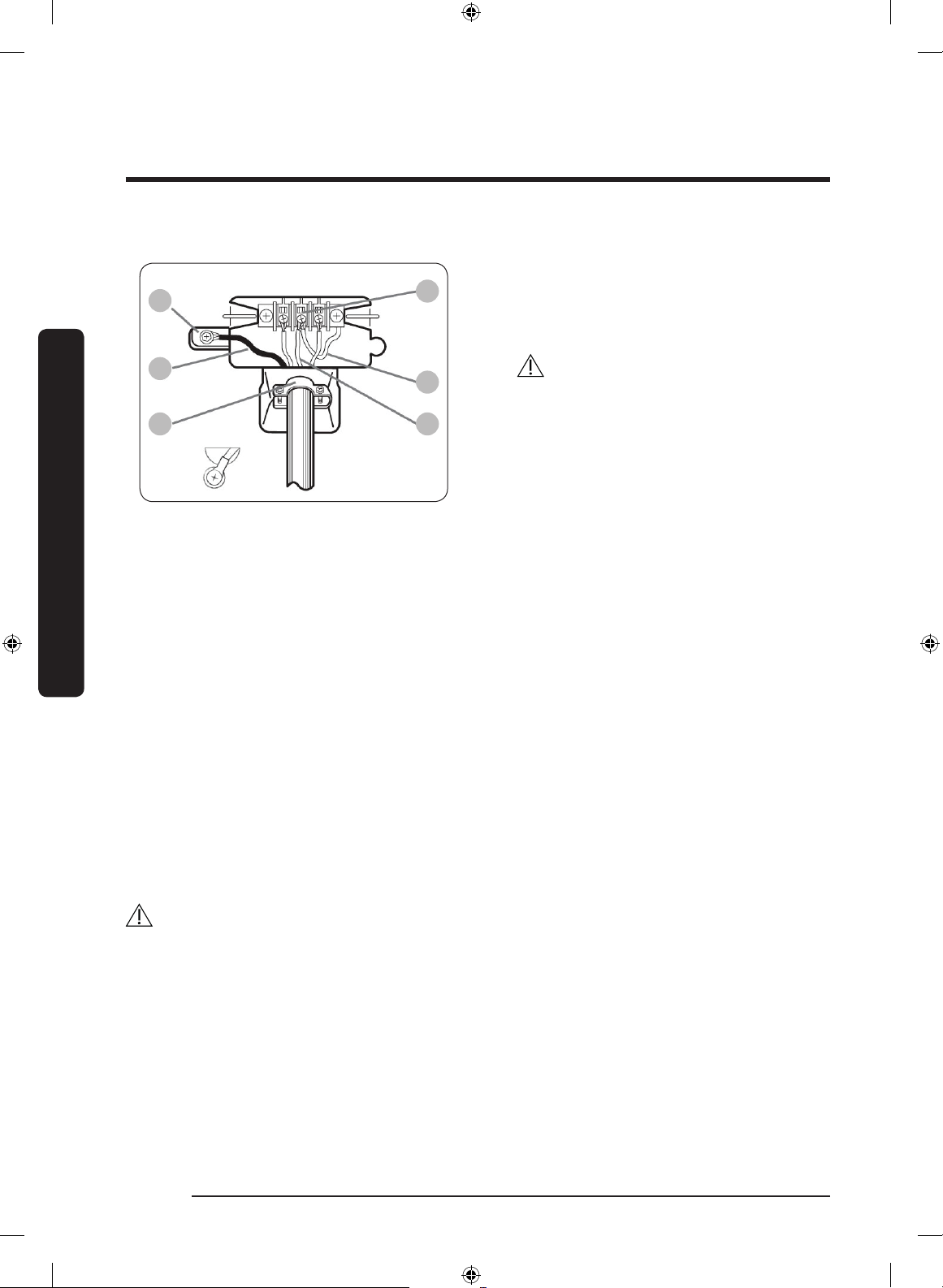

STEP 3 Connect the electrical wiring

A

B

E

C

D

First, read through the “Electrical requirements” section, and then follow these steps.

3-wire system

1. Loosen or remove the center terminal

block.

2. Connect the neutral wire (white or

center wire) of the power cable to the

center, silver-colored terminal screw of

the terminal block. Tighten the screws.

3. Connect the other wires to outer

terminal block screws. Tighten the

screws.

4. Tighten the strain relief screws.

5. Insert the terminal block cover into the

A. External ground connector

B. Neutral grounding wire (white)

C. Center silver-colored terminal block

screw

D. Neutral wire (white or center wire)

E. ¾” (1.9 cm) UL-listed strain relief

rear panel of the dryer. Then, secure the

cover with a hold-down screw.

CAUTION

• To convert from the 4-wire system

to 3-wire system, connect the ground

strap to the terminal block support to

ground the dryer frame to the neutral

conductor.

• Ring-type terminals are recommended.

If using strap terminals, make sure they

are tightened.

Installation

DV8750M_DC68-03784A-05_EN.indd 19 3/29/2019 7:13:42 PM

English 19

Installation

A

B

C

D

F

E

4-wire system

Installation

A. External ground connector

B. Green or bare copper wire of power

C. ¾” (1.9 cm) UL-listed strain relief

D. Center silver-colored terminal block

E. Neutral grounding wire (white)

F. Neutral wire (white or center wire)

cord

screw

1. Remove the external ground connector’s

screw, and connect the ground wire

(green or unwrapped) of the power cable

to the screw.

CAUTION

• To connect the ground wire to the

neutral position without through

contact A (cabinet ground), contact

a technician. This is not user

serviceable.

• Ring-type terminals are

recommended. If using strap

terminals, make sure they are

tightened.

2. Loosen or remove the screws from the

center terminal block.

3. Connect the neutral wire (white or

center wire) and ground wire (white) to

the center screw of the terminal block.

Tighten the screw.

4. Connect the other wires to the outer

terminal block screws. Tighten the

screws.

5. Tighten the strain relief screws.

6. Insert the tab of the terminal block cover

into the rear slot of the dryer. Secure the

cover with a hold-down screw.

WARNING

• All U.S. models are designed for a 3-wire system connection. The dryer frame is

grounded to the neutral conductor at the terminal block. A 4-wire system connection

is required for new or remodeled construction, mobile homes, or if local codes do not

permit grounding through neutral. If you use the 4-wire system, you cannot ground the

dryer frame to the neutral conductor at the terminal block.

• Remove the terminal block cover plate. Insert the power cord with a UL-listed strain

relief through the hole provided in the cabinet near the terminal block.

• A strain relief must be used. Do not loosen the nuts already installed on the terminal

block. Be sure they are tight. Use a ⁄” (1 cm) deep well socket.

English20

DV8750M_DC68-03784A-05_EN.indd 20 3/29/2019 7:13:42 PM

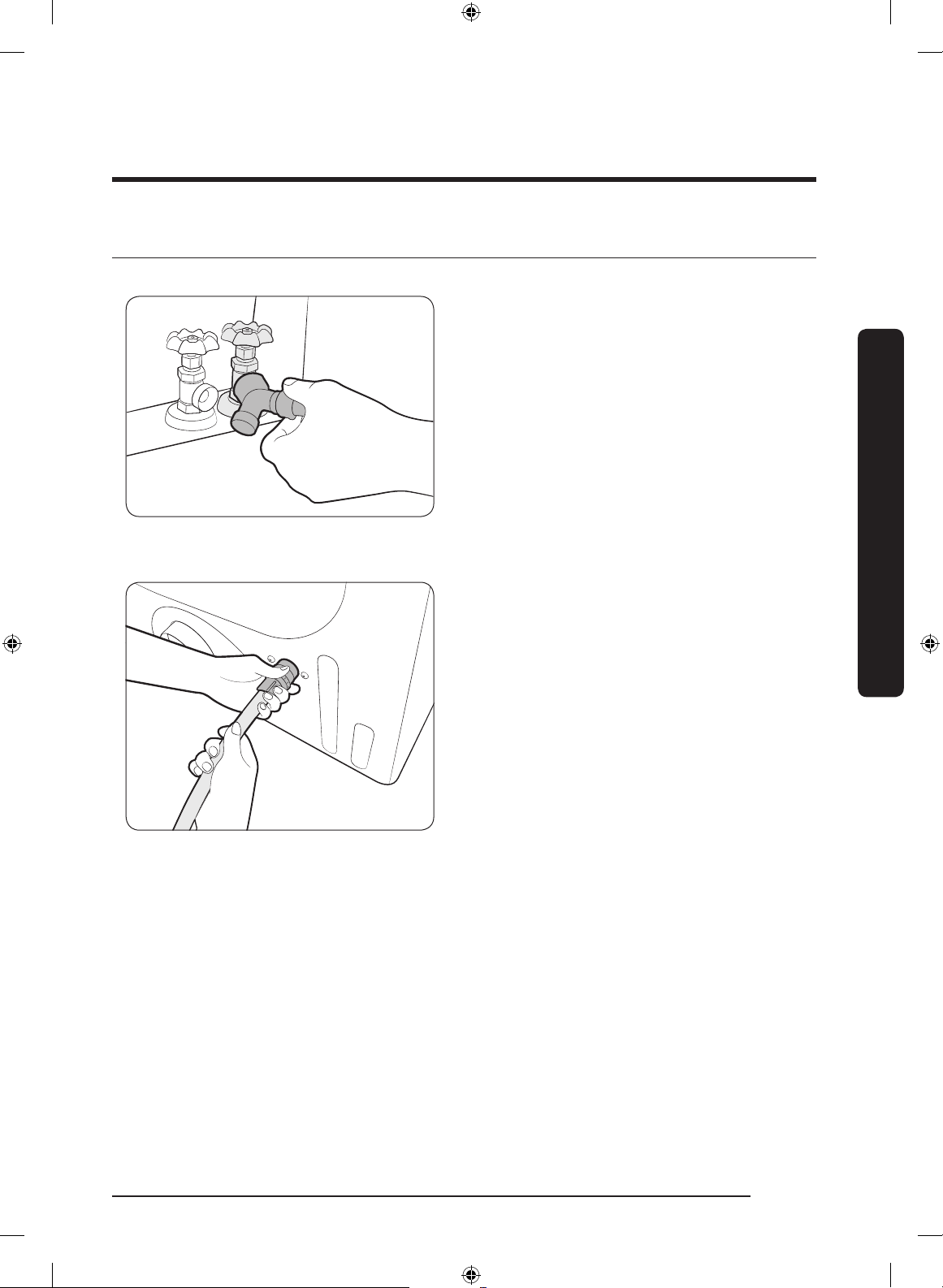

STEP 4 Connect the water hose (applicable models only)

The dryer must be connected to a cold water tap using the provided water hoses.

1. Close the cold water tap. If you have a

washer cold water hose attached to the

cold water faucet, unscrew and remove

the hose. Then, connect the female end

of the Y connector to the cold water

tap.

2. Connect the straight end of the water

hose to the Y connector.

3. Using pliers, tighten the coupling an

additional two-thirds turn. Do not

overtighten because the coupling may

be damaged.

4. Connect the angled end of the water

hose to the lling valve at the bottom

of the rear frame. Turn the coupling

manually until it is tight.

5. Using pliers, tighten the coupling an

additional two-thirds turn. Do not

overtighten because the coupling may

be damaged.

6. If you detached the cold water hose

from your washer, attach the hose

to the open end of the Y connector,

tighten the coupling until it is tight,

and then, using a pliers, tighten an

additional two-thirds turn.

7. Open the cold water tap, and then check

for any leaks.

Installation

If the Y connector cannot be directly connected to the cold water tap, use the short hose

as shown on the following page.

English 21

DV8750M_DC68-03784A-05_EN.indd 21 3/29/2019 7:13:43 PM

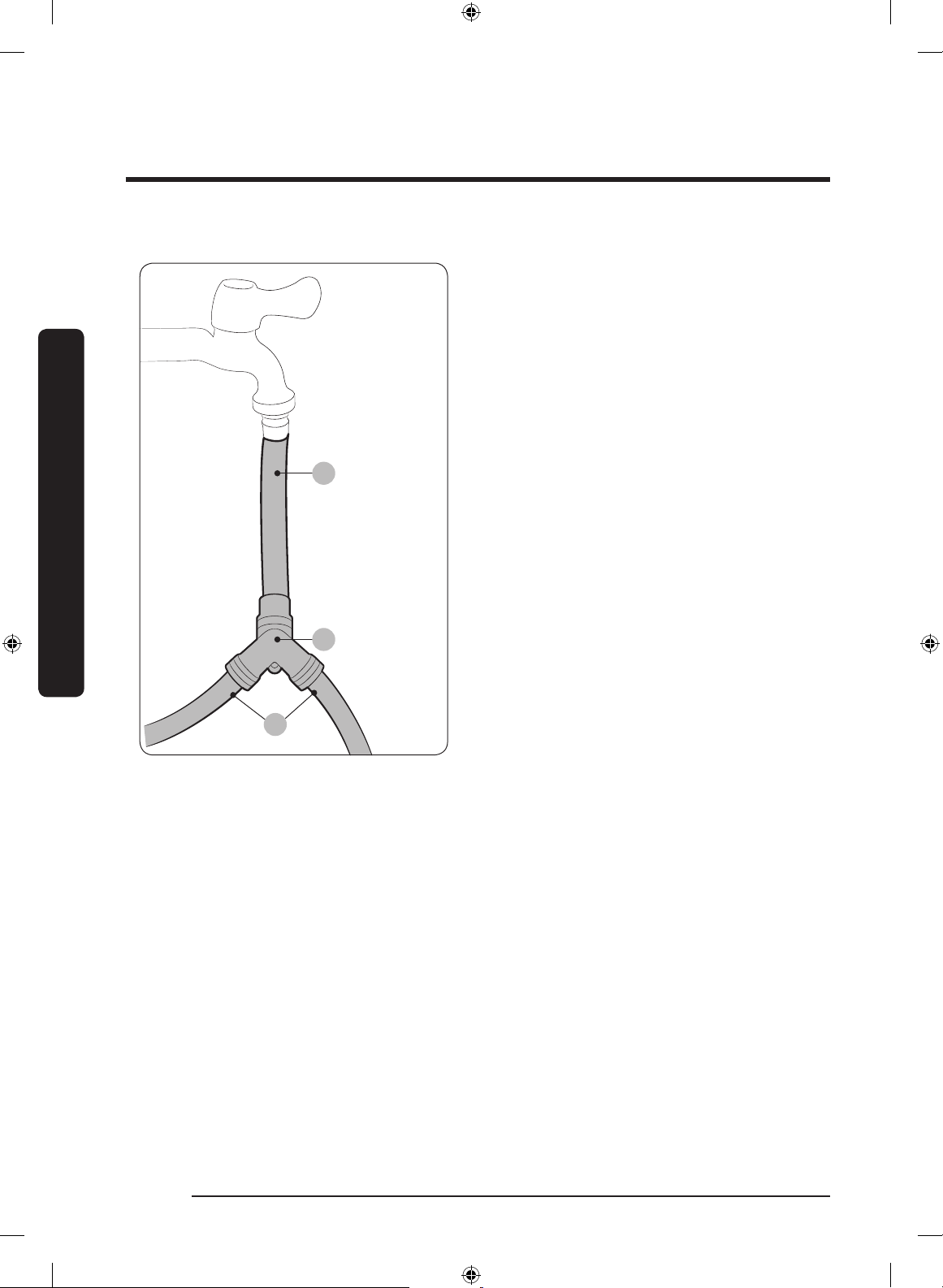

Installation

B

A

C

Using the short hose as an extension

Installation

1. Close the cold water tap. If you have

a washer cold water hose attached to

the cold water faucet, unscrew and

remove the hose. Then, connect the

short hose (B) to the cold water tap.

Turn the coupling manually until it is

tight.

2. Using pliers, tighten the coupling an

additional two-thirds turn. Do not

overtighten because the coupling may

be damaged.

3. Connect the Y connector (A) to the brass

male end of the short hose. Turn the

coupling manually until it is tight.

4. Using pliers, tighten the coupling an

additional two-thirds turn. Do not

overtighten because the coupling may

be damaged.

5. Connect the angled end of the water

hoses (C) to the lling valve at the

bottom of the rear frame. Turn the

coupling manually until it is tight.

6. Using pliers, tighten the coupling an

additional two-thirds turn. Do not

overtighten because the coupling may

be damaged.

7. If you detached the cold water hose

from your washer, attach the hose to

the free end of the Y connector, tighten

the coupling until it is tight, and then,

using a pliers, tighten an additional

two-thirds turn.

8. Open the cold water tap, and then check

for any leaks.

English22

DV8750M_DC68-03784A-05_EN.indd 22 3/29/2019 7:13:43 PM

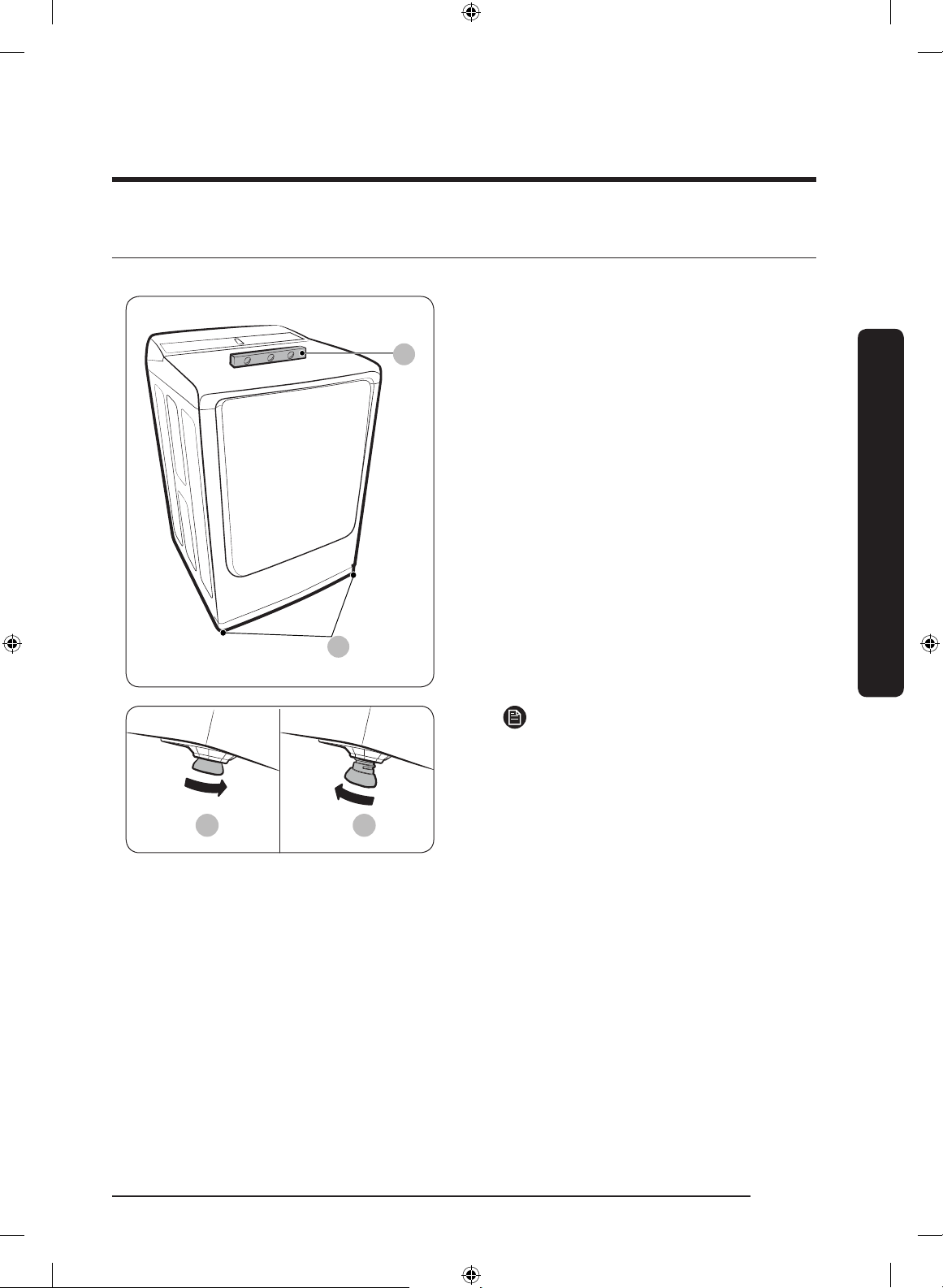

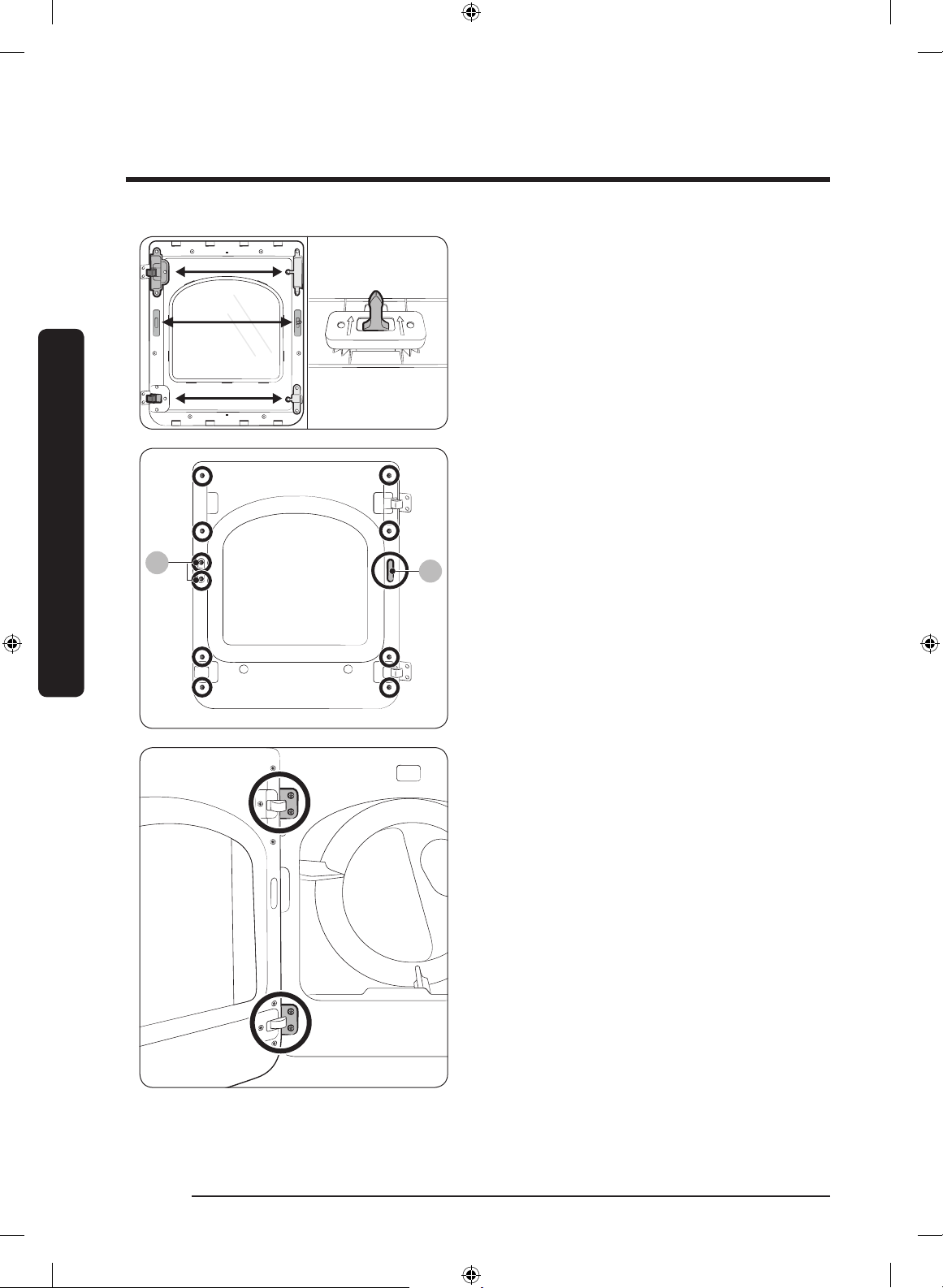

STEP 5 Level the dryer

A

B

A B

To ensure optimal performance, the dryer must be level.

1. Using a level (A), check if the dryer

is level side to side and then front to

back. If the dryer is not level, adjust the

leveling feet (B) at the bottom of the

dryer. Then, check if the dryer is level

again.

Installation

NOTE

• To set the dryer to the same height

as your washer, fully retract (A)

the leveling feet by turning them

counterclockwise, then loosen (B) the

feet by turning them clockwise. Once

the dryer is the same height as the

washer, follow the directions above

to level the dryer.

• Adjust the leveling feet only as much

as necessary to level the dryer.

Extending the leveling feet more

than necessary can cause the dryer

to vibrate.

English 23

DV8750M_DC68-03784A-05_EN.indd 23 3/29/2019 7:13:44 PM

Installation

STEP 6 Power on (Gas models)

Make sure all gas connections, the exhaust line, and all wiring is connected correctly. Then,

plug the power cord into a power source and check the dryer’s installation and operation

using the nal checklist in Step 7 below.

STEP 7 Final check

When installation is complete, conrm that:

• The dryer is plugged into an electrical outlet and grounded properly.

• The exhaust ductwork is connected and the joints are taped.

Installation

• You have used rigid or stiff-walled exible metal duct material, not plastic exible duct.

• The dryer is level and is sitting rmly on the oor.

• The dryer starts, runs, heats, and shuts off properly.

For gas models:

• The gas is supplied properly with no leaks.

The burner may not ignite initially due to air in the gas line. Allowing your dryer to

operate on a heat setting will purge the line. If the gas does not ignite within 5 minutes,

turn your dryer off and wait 5 minutes. Be sure the gas supply to your dryer has been

turned on. To conrm gas ignition, check the exhaust for heat.

CAUTION

Vent blockage test

After the dryer is installed, start the Vent Blockage Test to check if the duct system is

properly installed. The Vent Blockage Test automatically detects the status of duct and

reports any blockage or problems to the user. Proper ducting can reduce drying time and

save energy.

NOTE

The Vent Blockage Test must run at cool state. If the dryer warms up after the installation

check, run the AIR FLUFF cycle for several minutes to reduce its internal temperature.

Operation method

1. Make sure the drum is empty and close the door.

(If there are any clothes or other items in the drum, a correct test can not be made.)

2. Press the POWER button to turn the dryer on, then simultaneously press and hold the

BEDDING and Wrinkle Prevent buttons for 3 seconds.

When entering the Vent Blockage Test, “InS” appears in the display.

(If other procedures are started before entering the Vent Blockage Test, the dryer does

not enter the Vent Blockage Test.)

English24

DV8750M_DC68-03784A-05_EN.indd 24 3/29/2019 7:13:44 PM

3. The Vent Blockage Test starts immediately after pressing the START/PAUSE button.

During the test, the number indicator makes a circle in 6 steps clockwise.

The test takes about 2 minutes. Do not open the door during the test.

4. After 2 minutes, if the test has completed, the result is displayed and a tone is given.

If status of the duct system is normal, “0” appears and a completion sound is given.

If the duct system can not exhaust properly, “CLg” appears and an alarm sound is given.

In case of any other problem, an information code appears. Check the information

codes in this manual.

• To stop or cancel the Vent Blockage Test, press the POWER button to turn off your

dryer.

• During the test, if “dc” appears, make sure the door is closed. If “C1” is displayed,

make sure the drum has laundry inside.

• The result displays for about 5 minutes and then automatically turns off. You may

turn the result directly off by pressing the POWER button.

NOTE

• During or after the test, the internal drum is hot. Use caution to prevent burns.

The Vent Blockage Test is used to check for problems to the current duct system when

the dryer is installed for the rst time.

• If the test result displays “CLg” (the duct system is blocked ), refer to “Ducting

requirements” and “Exhaust ducting guide” section of this manual and take proper

measures for drying.

If the test is suspended, it could result in incorrect results. Follow the proper

procedures when testing the dryer.

• Even if the test result is normal (“0”), the duct system could be blocked slightly.

Properly install all duct work according to the installation instructions of this manual.

Installation

English 25

DV8750M_DC68-03784A-05_EN.indd 25 3/29/2019 7:13:44 PM

Installation

Exhaust ducting guide

Ducting

1. Make sure the dryer is installed properly so the air exhausts freely.

2. Use 4-inch rigid metal ducts. Tape all joints including the dryer connection.

3. To facilitate the exhaust, keep the ducts as straight as possible.

Cleaning

Installation

Clean all old ducts before installing the dryer, and make sure the vent ap opens and

closes freely. We recommend that you to clean the exhaust system annually or on a

regular basis.

• To prevent re, do not use plastic, thin-foil, or non-metal exible ducts of any kind.

• Do not use a poor exhaust system because it slows down the dryer’s performance.

• Do not use excessively long ducts that have multiple elbows.

• Do not use crushed or clogged venting or ducts.

Never use lint-trapping screws.

WARNING

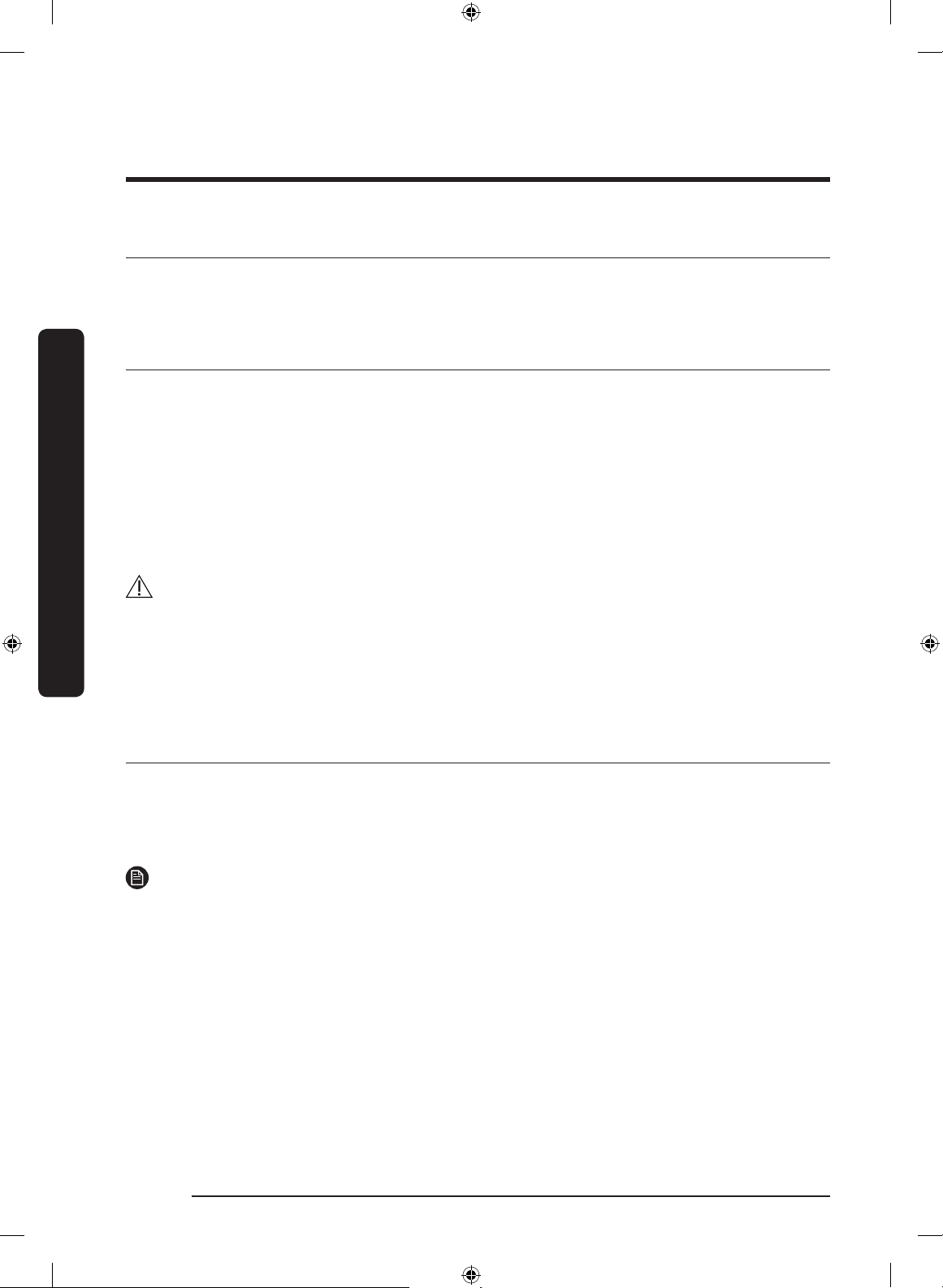

Switching the door position

To reverse the direction of the door, we

recommend that you contact a qualied

technician.

It is recommended to put a soft rug on the

oor to prevent scratches on the door.

1. Unplug the power cord of the dryer.

2. Remove the four hinge screws from

the door, and then remove the door by

lifting it up slightly.

English26

DV8750M_DC68-03784A-05_EN.indd 26 3/29/2019 7:13:45 PM

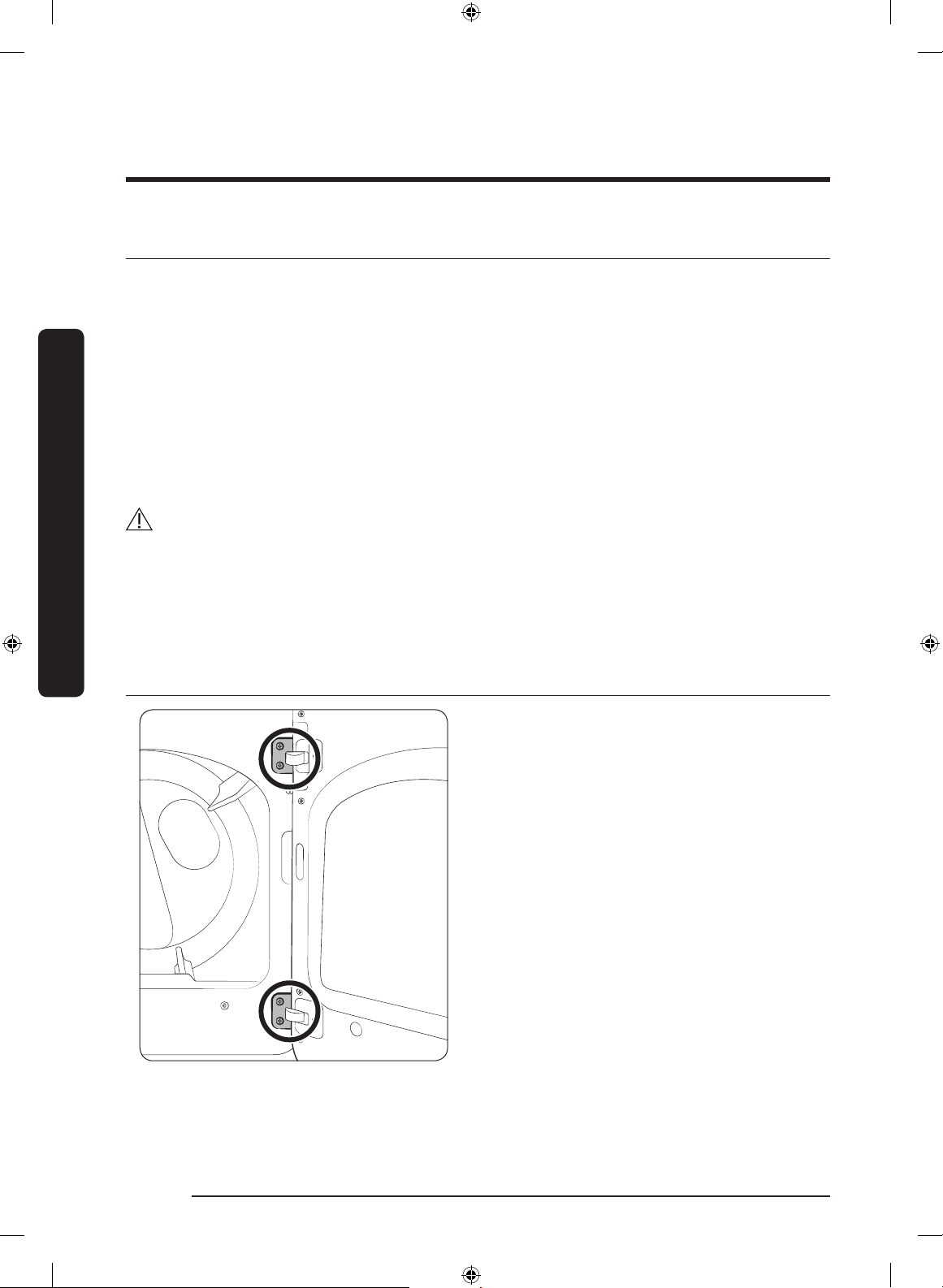

3. Remove the two screws from the lever

B

holder, and then remove the holder

cover.

4. Put the lever holder on the other side

as shown, and then tighten the screws.

Install the holder cover on the opposite

side as shown.

5. Use a at-head screwdriver to remove

the two hinge covers from the original

side. Install the hinge covers on the

opposite side as shown.

6. Locate and remove the 10 screws as

shown. Note that screw B (x2) is longer

than the others.

Installation

English 27

DV8750M_DC68-03784A-05_EN.indd 27 3/29/2019 7:13:46 PM

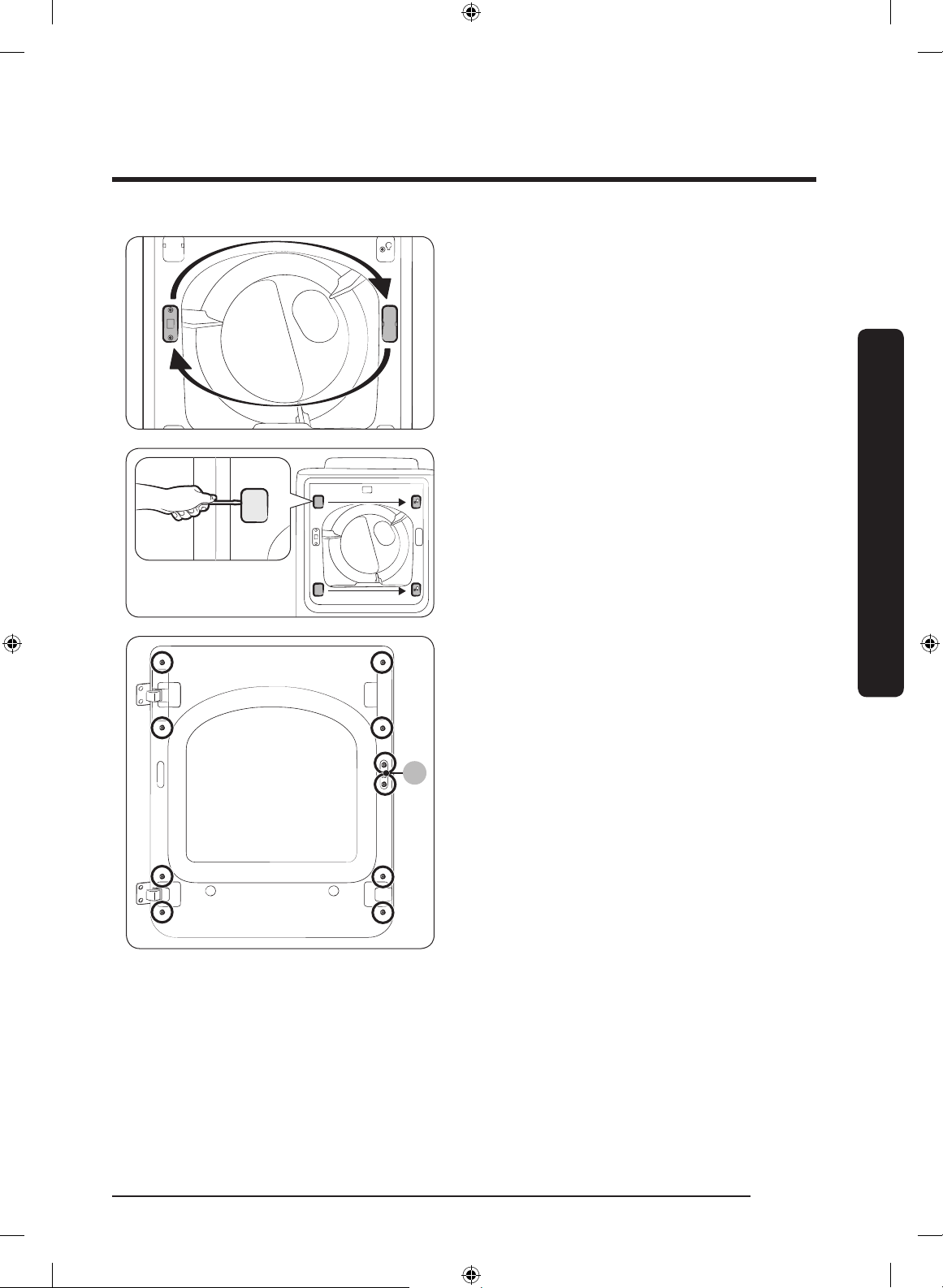

Installation

B

C

7. Remove the glass holder, and switch

the positions of:

a. the hinge cover and the door handle.

b. the hinge holder and the glass-guide

holder

8. Remove the door lever, and then move

it to the other side as shown.

Installation

9. Remove the hole cover (C), and then

insert and tighten the glass holder using

the removed 10 screws.

10. Install the hole cover on the opposite

side as shown.

11. Reinstall the door on the front frame,

and then carefully insert and tighten

the 4 hinge screws.

English28

DV8750M_DC68-03784A-05_EN.indd 28 3/29/2019 7:13:46 PM

Before you start

A

Here are a few things you should know before starting your dryer.

Sort and load

• Put one wash load in the dryer at a

time.

• Do not mix heavy and lightweight items

together.

• To improve drying efciency for one or

two items, add a dry towel to the load.

• For best results, untangle items before

inserting them into the dryer.

Functional prerequisite

Lint lter

• Overloading reduces the tumbling

action, resulting in uneven drying and

wrinkling.

• Unless recommended on the care label,

do not dry woolens or berglass items.

• Avoid drying unwashed items.

• Do not dry items soiled with oil, alcohol,

gasoline, etc.

Before you start

To prevent a risk of re, make sure to

clean the lint lter before or after every

load.

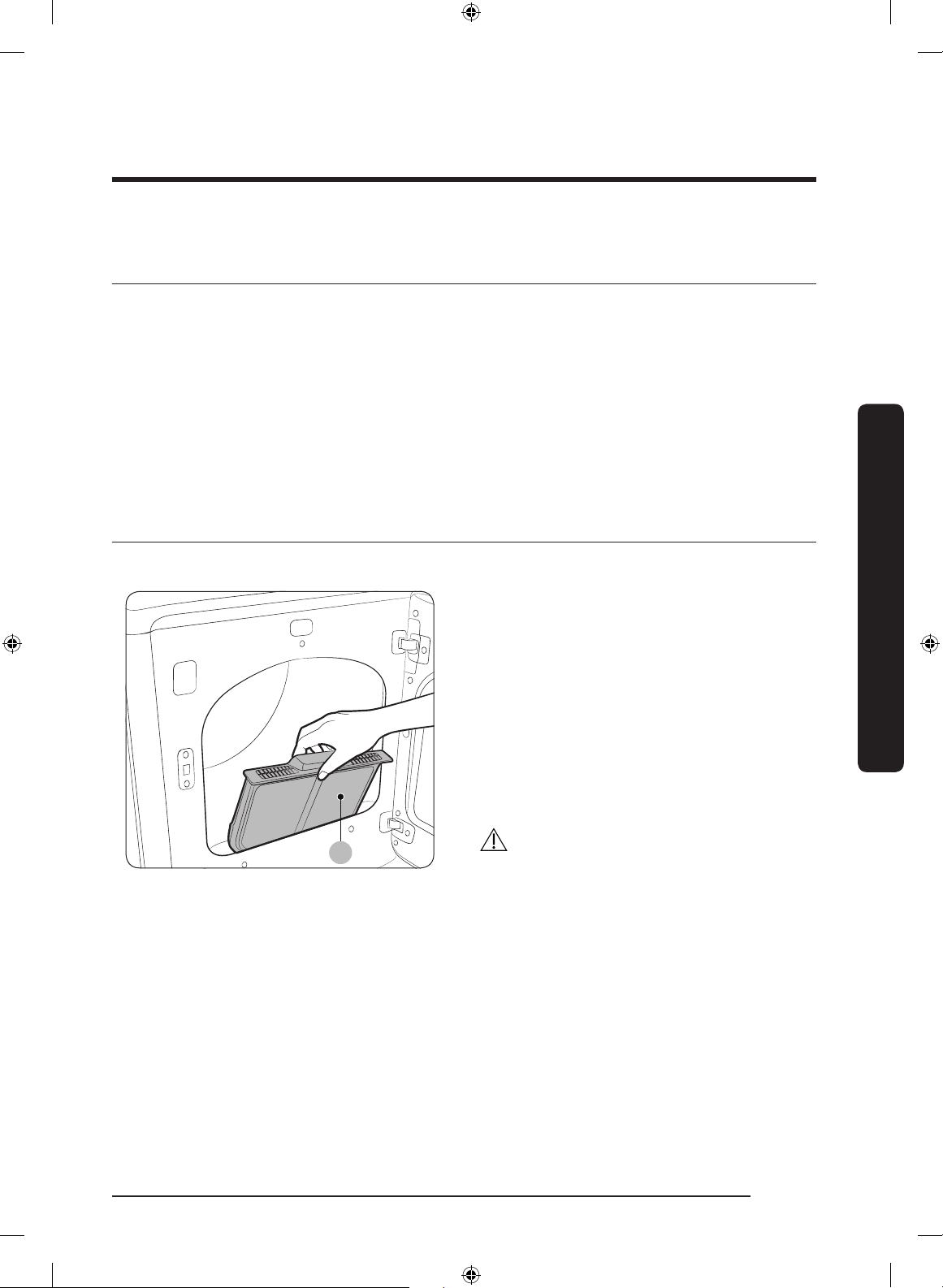

1. Turn off the dryer.

2. Open the door, and pull out the lint

lter (A) from inside the tumbler.

3. Remove the lint that has accumulated,

and then clean the lint lter.

4. Reinsert the lint lter, and then close

the door.

CAUTION

• Do not operate the dryer without the

lint lter in place.

• Do not use a damaged or broken lint

lter. This may reduce performance

and/or cause re.

English 29

DV8750M_DC68-03784A-05_EN.indd 29 3/29/2019 7:13:47 PM

Operations

01

03 04 05

13

14

02

09

12

08

07

06 10

11

WARNING

To reduce the risk of re, electric shock, or injury to persons, read the “Safety information“

before operating this appliance.

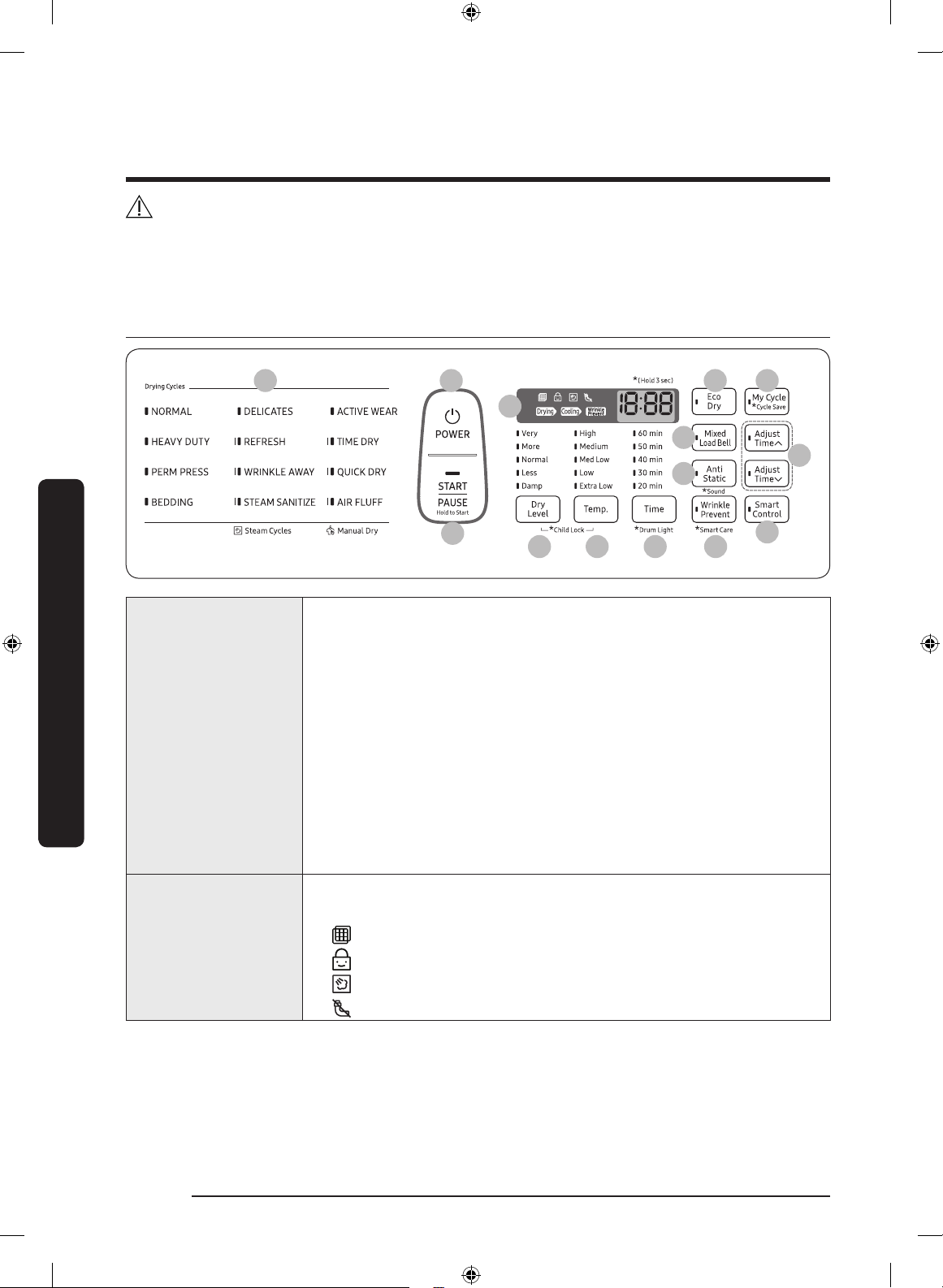

Feature panel

Operations

01 Cycle Selector

02 Digital Graphic

Display

Press to select a desired cycle in the left-most panel. When a

cycle is selected, the cycle indicator lights up.

• Sensor Dry cycles: The dryer senses the internal humidity

that will be applied to the drying time. This category includes:

NORMAL, HEAVY DUTY, PERM PRESS, BEDDING, DELICATES,

and ACTIVE WEAR.

• Steam Cycles: The dryer sprays water into the drum to

deodorize clothes and reduce static electricity and wrinkles.

This category includes REFRESH, WRINKLE AWAY, and STEAM

SANITIZE.

• Manual Dry cycles: The drying time is xed. This category

includes: TIME DRY, QUICK DRY, and AIR FLUFF.

Displays all cycle information, including the cycle time,

information code, and operating status.

•

Filter Check

Child Lock

•

• Steam

• Vent Sensor

English30

DV8750M_DC68-03784A-05_EN.indd 30 3/29/2019 7:13:48 PM

Loading...

Loading...