Samsung DVD-P241 Service Manual

Samsung Electronics 1-1

1. Precautions

1-1 Safety Precautions

1) Before returning an instrument to the customer,

always make a safety check of the entire instrument,

including, but not limited to, the following items:

(1) Be sure that no built-in protective devices are

defective or have been defeated during servicing.

(1)Protective shields are provided to protect both

the technician and the customer. Correctly replace

all missing protective shields, including any

removed for servicing convenience.

(2)When reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place

all protective devices, including, but not limited to,

nonmetallic control knobs, insulating fish papers,

adjustment and compartment covers/shields, and

isolation resistor/capacitor networks. Do not operate this instrument or permit it to be operated without all protective devices correctly installed and

functioning.

(2) Be sure that there are no cabinet openings through

which adults or children might be able to insert

their fingers and contact a hazardous voltage. Such

openings include, but are not limited to, excessively wide cabinet ventilation slots, and an improperly fitted and/or incorrectly secured cabinet back

cover.

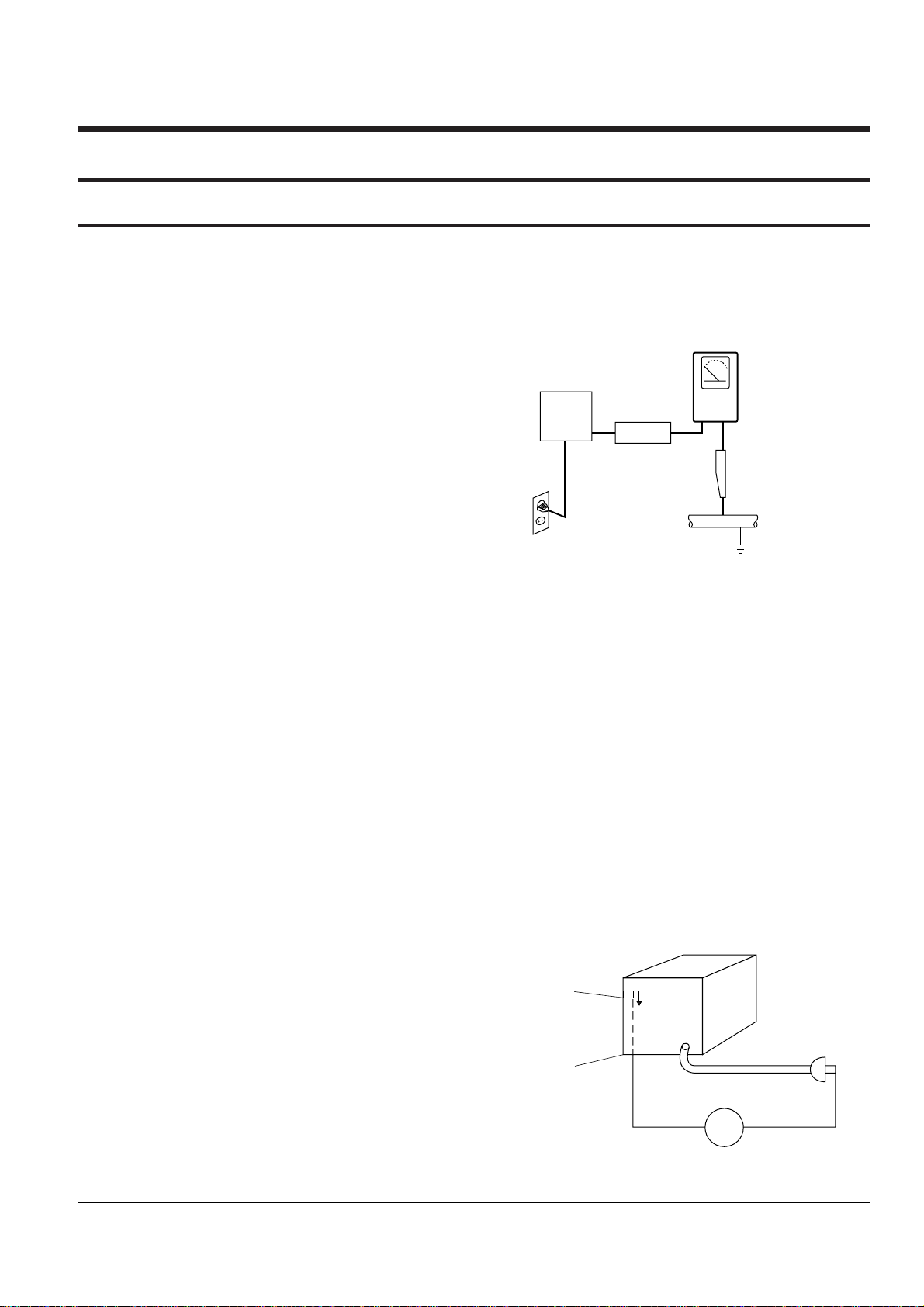

(3) Leakage Current Hot Check-With the instrument

completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a leakage

current tester or a metering system that complies

with American National Standards institute (ANSI)

C101.1 Leakage Current for Appliances and

Underwriters Laboratories (UL) 1270 (40.7). With

the instrument’s AC switch first in the ON position

and then in the OFF position, measure from a

known earth ground (metal water pipe, conduit,

etc.) to all exposed metal parts of the instrument

(antennas, handle brackets, metal cabinets, screwheads, metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5mA.

Reverse the instrument power cord plug in the outlet and repeat the test. See Fig. 1-1.

Any measurements not within the limits specified

herein indicate a potential shock hazard that must

be eliminated before returning the instrument to

the customer.

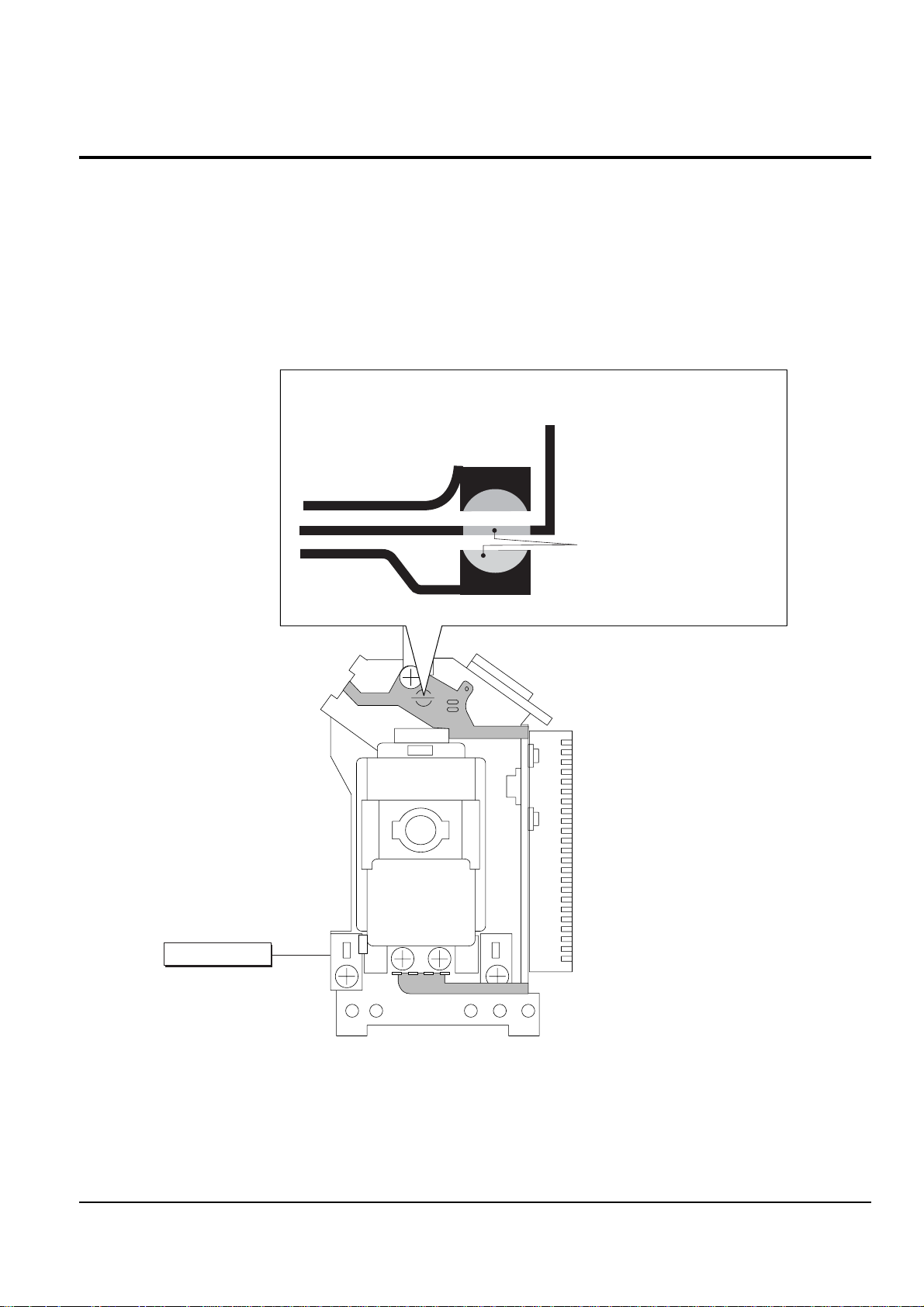

Fig. 1-1 AC Leakage Test

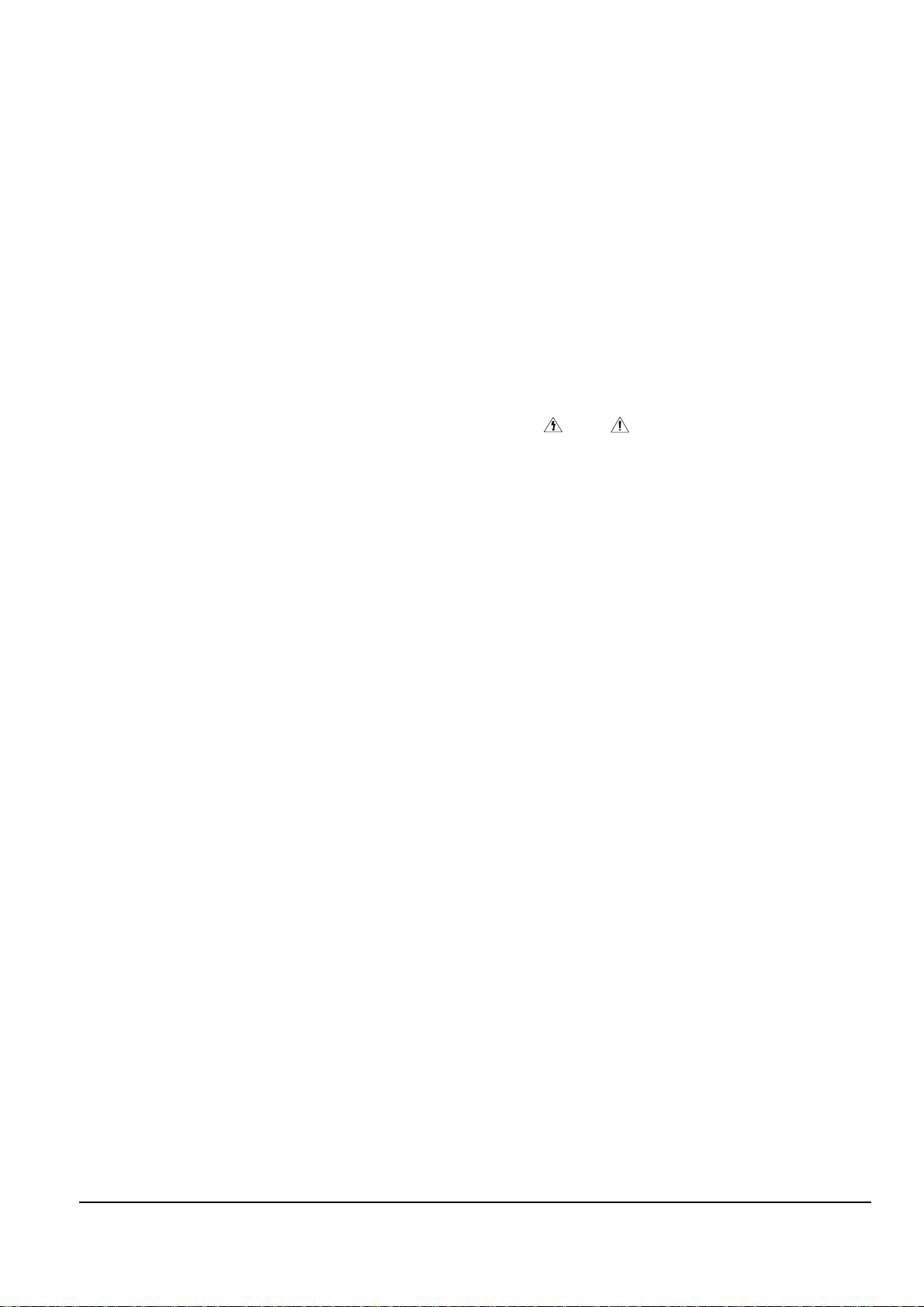

(4) Insulation Resistance Test Cold Check-(1) Unplug

the power supply cord and connect a jumper wire

between the two prongs of the plug. (2) Turn on the

power switch of the instrument. (3) Measure the

resistance with an ohmmeter between the

jumpered AC plug and all exposed metallic cabinet

parts on the instrument, such as screwheads,

antenna, control shafts, handle brackets, etc. When

an exposed metallic part has a return path to the

chassis, the reading should be between 1 and 5.2

megohm. When there is no return path to the chassis, the reading must be infinite. If the reading is

not within the limits specified, there is the possibility of a shock hazard, and the instrument must be

repaired and rechecked before it is returned to the

customer. See Fig. 1-2.

Fig. 1-2 Insulation Resistance Test

DEVICE

UNDER

TEST

(READING SHOULD

NOT BE ABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

TEST ALL

EXPOSED METER

SURFACES

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2-WIRE CORD

Antenna

Terminal

Exposed

Metal Part

ohm

ohmmeter

Precautions

1-2 Samsung Electronics

2) Read and comply with all caution and safety related notes on or inside the cabinet, or on the chassis.

3) Design Alteration Warning-Do not alter or add to

the mechanical or electrical design of this instrument. Design alterations and additions, including

but not limited to, circuit modifications and the

addition of items such as auxiliary audio output

connections, might alter the safety characteristics of

this instrument and create a hazard to the user. Any

design alterations or additions will make you, the

servicer, responsible for personal injury or property

damage resulting therefrom.

4) Observe original lead dress. Take extra care to

assure correct lead dress in the following areas:

(1) near sharp edges, (2) near thermally hot parts (be

sure that leads and components do not touch thermally hot parts), (3) the AC supply, (4) high voltage,

and (5) antenna wiring. Always inspect in all areas

for pinched, out-of-place, or frayed wiring, Do not

change spacing between a component and the

printed-circuit board. Check the AC power cord for

damage.

5) Components, parts, and/or wiring that appear to

have overheated or that are otherwise damaged

should be replaced with components, parts and/ or

wiring that meet original specifications.

Additionally, determine the cause of overheating

and/or damage and, if necessary, take corrective

action to remove any potential safety hazard.

6) Product Safety Notice-Some electrical and mechanical parts have special safety-related characteristics

which are often not evident from visual inspection,

nor can the protection they give necessarily be

obtained by replacing them with components rated

for higher voltage, wattage, etc. Parts that have special safety characteristics are identified by shading,

an ( )or a ( )on schematics and parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire and/or

other hazards. Product safety is under review continuously and new instructions are issued whenever appropriate.

Precautions

Samsung Electronics 1-3

1-2 Servicing Precautions

CAUTION : Before servicing units covered by this

service manual and its supplements, read and follow

the Safety Precautions section of this manual.

Note : If unforseen circumstances create conflict

between the following servicing precautions and any

of the safety precautions, always follow the safety precautions. Remember: Safety First.

1-2-1 General Servicing Precautions

(1) a. Always unplug the instrument’s AC power cord

from the AC power source before (1) re-moving

or reinstalling any component, circuit board,

module or any other instrument assembly, (2)

disconnecting any instrument electrical plug or

other electrical connection, (3) connecting a test

substitute in parallel with an electrolytic capacitor in the instrument.

b. Do not defeat any plug/socket B+ voltage inter-

locks with which instruments covered by this

service manual might be equipped.

c. Do not apply AC power to this instrument and

/or any of its electrical assemblies unless all

solid-state device heat sinks are correctly installed.

d. Always connect a test instrument’s ground lead

to the instrument chassis ground before connecting the test instrument positive lead. Always

remove the test instrument ground lead last.

Note : Refer to the Safety Precautions section ground

lead last.

(2) The service precautions are indicated or printed on

the cabinet, chassis or components. When servicing, follow the printed or indicated service precautions and service materials.

(3) The components used in the unit have a specified

flame resistance and dielectric strength.

When replacing components, use components

which have the same ratings. Components identified by shading, by( ) or by ( ) in the circuit diagram are important for safety or for the characteristics of the unit. Always replace them with the exact

replacement components.

(4) An insulation tube or tape is sometimes used and

some components are raised above the printed

wiring board for safety. The internal wiring is

sometimes clamped to prevent contact with heating components. Install such elements as they

were.

(5) After servicing, always check that the removed

screws, components, and wiring have been installed correctly and that the portion around the

serviced part has not been damaged and so on.

Further, check the insulation between the blades of

the attachment plug and accessible conductive

parts.

1-2-2 Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet

and turn the power ON. Connect the insulation resistance meter (500V) to the blades of the attachment

plug. The insulation resistance between each blade of

the attachment plug and accessible conductive

parts(see note) should be more than 1 Megohm.

Note : Accessible conductive parts include metal panels, input terminals, earphone jacks, etc.

Precautions

1-4 Samsung Electronics

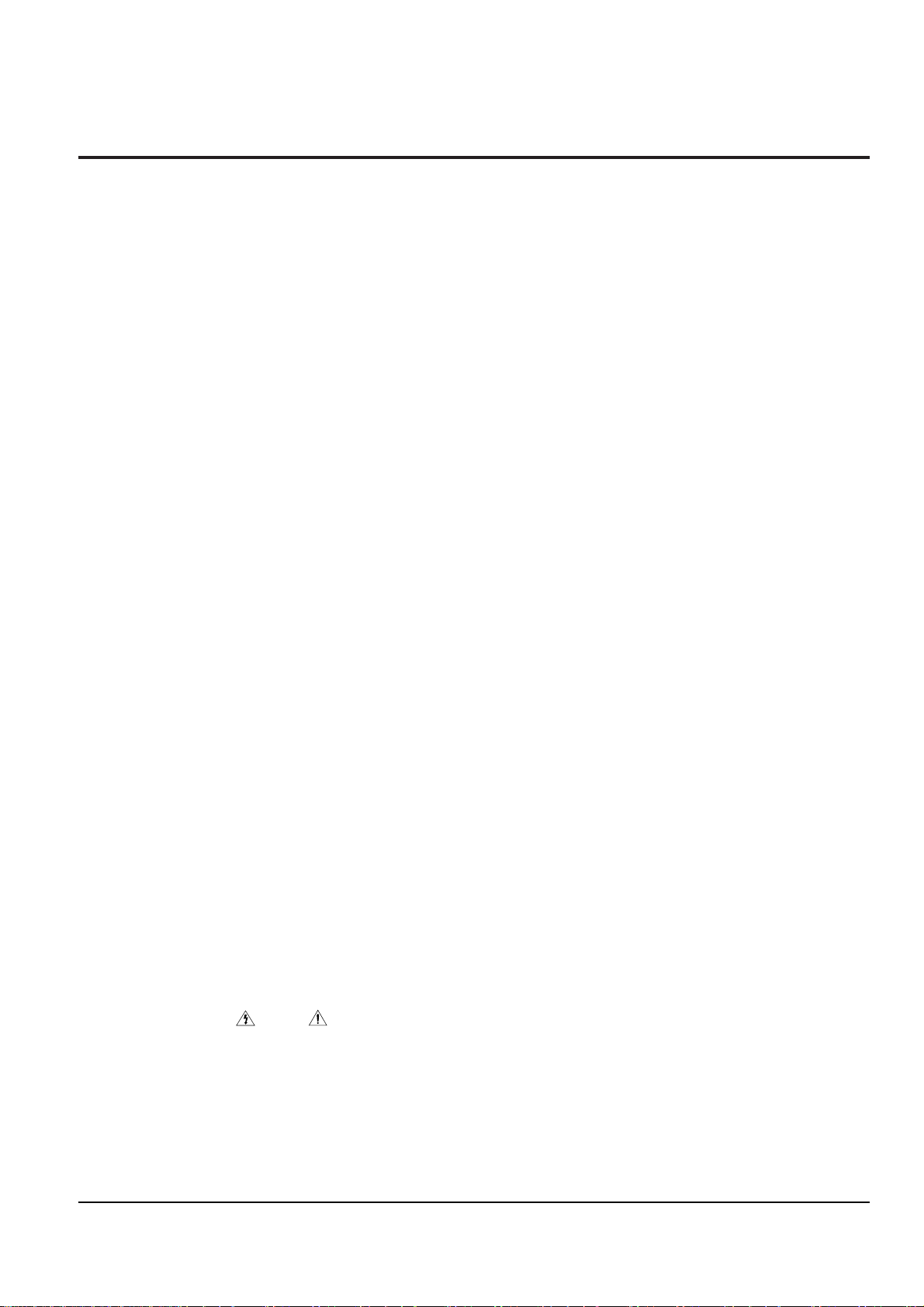

1-3 ESD Precautions

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity.

Such components commonly are called Electrostatically Sensitive Devices(ESD). Examples of typical ESD

devices are integrated circuits and some field-effect

transistors and semiconductor chip components. The

following techniques should be used to help reduce

the incidence of component damage caused by static

electricity.

(1) Immediately before handling any semiconductor

component or semiconductor-equipped assembly,

drain off any electrostatic charge on your body by

touching a known earth ground. Alternatively,

obtain and wear a commercially available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power to the unit under test.

(2) After removing an electrical assembly equipped

with ESD devices, place the assembly on a conductive surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

(3) Use only a grounded-tip soldering iron to solder or

unsolder ESD devices.

(4) Use only an anti-static solder removal devices.

Some solder removal devices not classified as

“anti-static” can generate electrical charges sufficient to damage ESD devices.

(5) Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESD devices.

(6) Do not remove a replacement ESD device from its

protective package until immediately before your

are ready to install it.(Most replacement ESD

devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive materials).

(7) Immediately before removing the protective ma-

terials from the leads of a replacement ESD device,

touch the protective material to the chassis or circuit assembly into which the device will be

installed.

CAUTION : Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

(8) Minimize bodily motions when handling unpack-

aged replacement ESD devices. (Otherwise harmless motion such as the brushing together of your

clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity sufficient

to damage an ESD device).

Precautions

Samsung Electronics 1-5

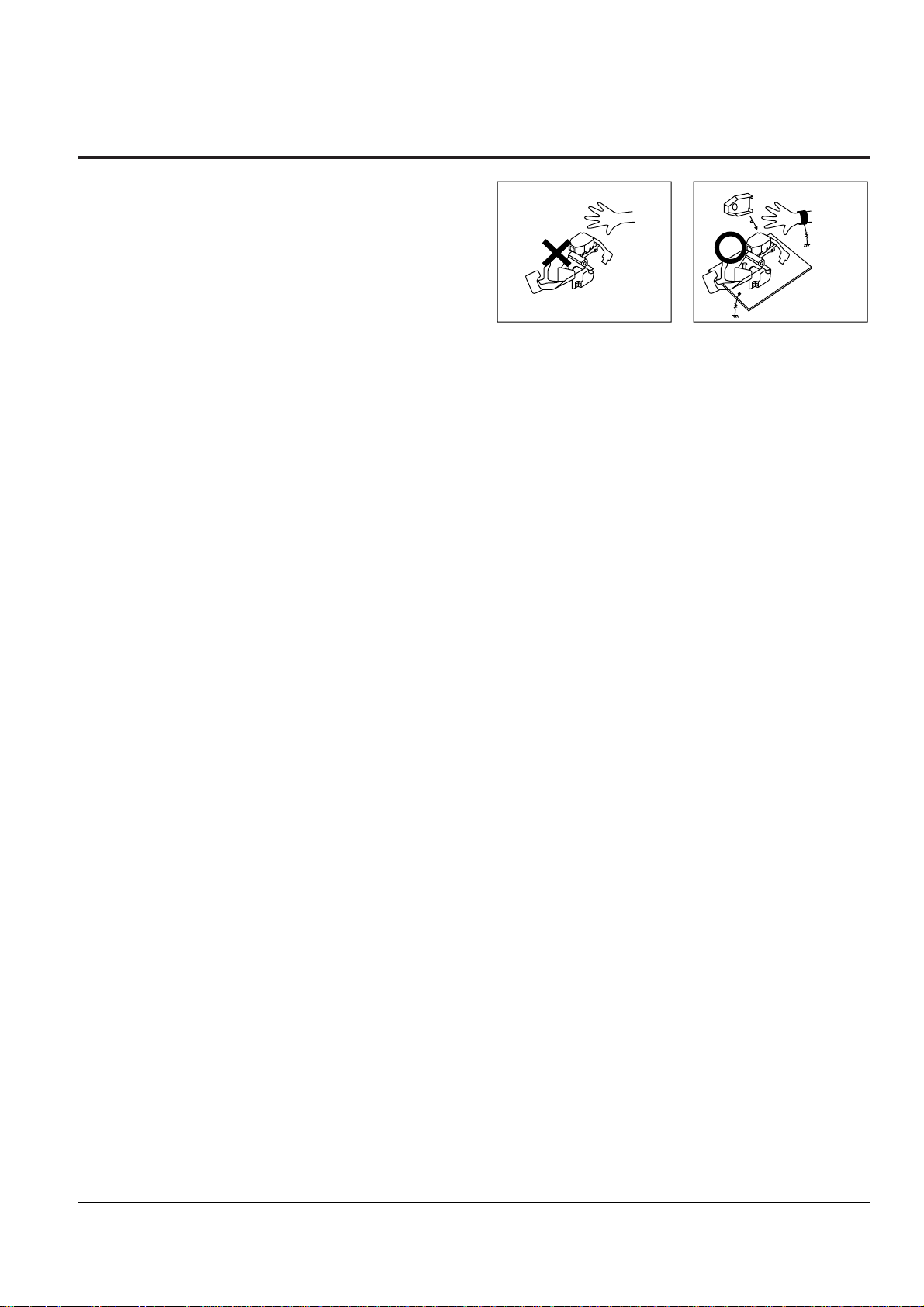

1-4 Handling the optical pick-up

The laser diode in the optical pick up may suffer electrostatic breakdown because of potential static electricity from clothing and your body.

The following method is recommended.

(1) Place a conductive sheet on the work bench (The

black sheet used for wrapping repair parts.)

(2) Place the set on the conductive sheet so that the

chassis is grounded to the sheet.

(3) Place your hands on the conductive sheet(This

gives them the same ground as the sheet.)

(4) Remove the optical pick up block

(5) Perform work on top of the conductive sheet. Be

careful not to let your clothes or any other static

sources to touch the unit.

◆ Be sure to put on a wrist strap grounded to the

sheet.

◆ Be sure to lay a conductive sheet made of copper

etc. Which is grounded to the table.

Fig.1-3

(6) Short the short terminal on the PCB, which is in-

side the Pick-Up ASS’Y, before replacing the PickUp. (The short terminal is shorted when the PickUp Ass’y is being lifted or moved.)

(7) After replacing the Pick-up, open the short termi-

nal on the PCB.

THE UNIT

WRIST-STRAP

FOR GROUNDING

1M

1M

CONDUCTIVE SHEET

Precautions

1-6 Samsung Electronics

1-5 Pick-up disassembly and reassembly

1-5-1 Disassembly

1) Remove the power cord.

2) Disassemble the Deck-Assy.

3) Make solder land 2 points short on Pick-up.

(See Fig. 1-4)

4) Disassemble the Pick-up.

1-5-2 Assembly

1) Replace the Pick-up.

2) Remove the soldering 2 points on Pick-up.

3) Reassemble the Deck-Assy.

PICK-UP ASS'Y

SOLDER LAND 2 POINTS SHORT

Note : If the assembly and disassembly are not done in correct sequence, the Pick-up may be damaged.

Fig. 1-4

DVD PLAYER

Chassis : Trino

DVD-P241

TRAINING

1. Precautions

2. Reference Information

3. Product Specification

4. Operating Instructions

5. Disassembly and Reassembly

6. Alignment and Adjustment

7. Circuit Operating Description

8. Troubleshooting

9. Block Diagram

10. Wiring Diagram

11. Schematic Diagrams

Manual

DVD PLAYER CONTENTS

TRAINING MANUAL DVD-P241

STANDBY/ON

EZ VIEW LOADING

ELECTRONICS

© Samsung Electronics Co., Ltd. DEC. 2003

Printed in Korea

AK82-00419A

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

international and/or domestic law.

Samsung Electronics 2-1

2. Reference Information

2-1 Introduction to DVD

2-1-1 The Definition of DVD

DVD is the next generation medium and is the acronym of the Digital Versatile Disc or thr Digital Video Disc,

which maximizes the saving density of the disk surface using the MPEG-2 compression technology to enable the

storage of 17G bytes of data on the same size CD.

1) 7 times the storage capacity of the conventional CD

◆ Minimized the track pitch and pit size to 1/2 of conventional CD.

◆ Uses red laser with short-wavelenght of 650nm (635nm).

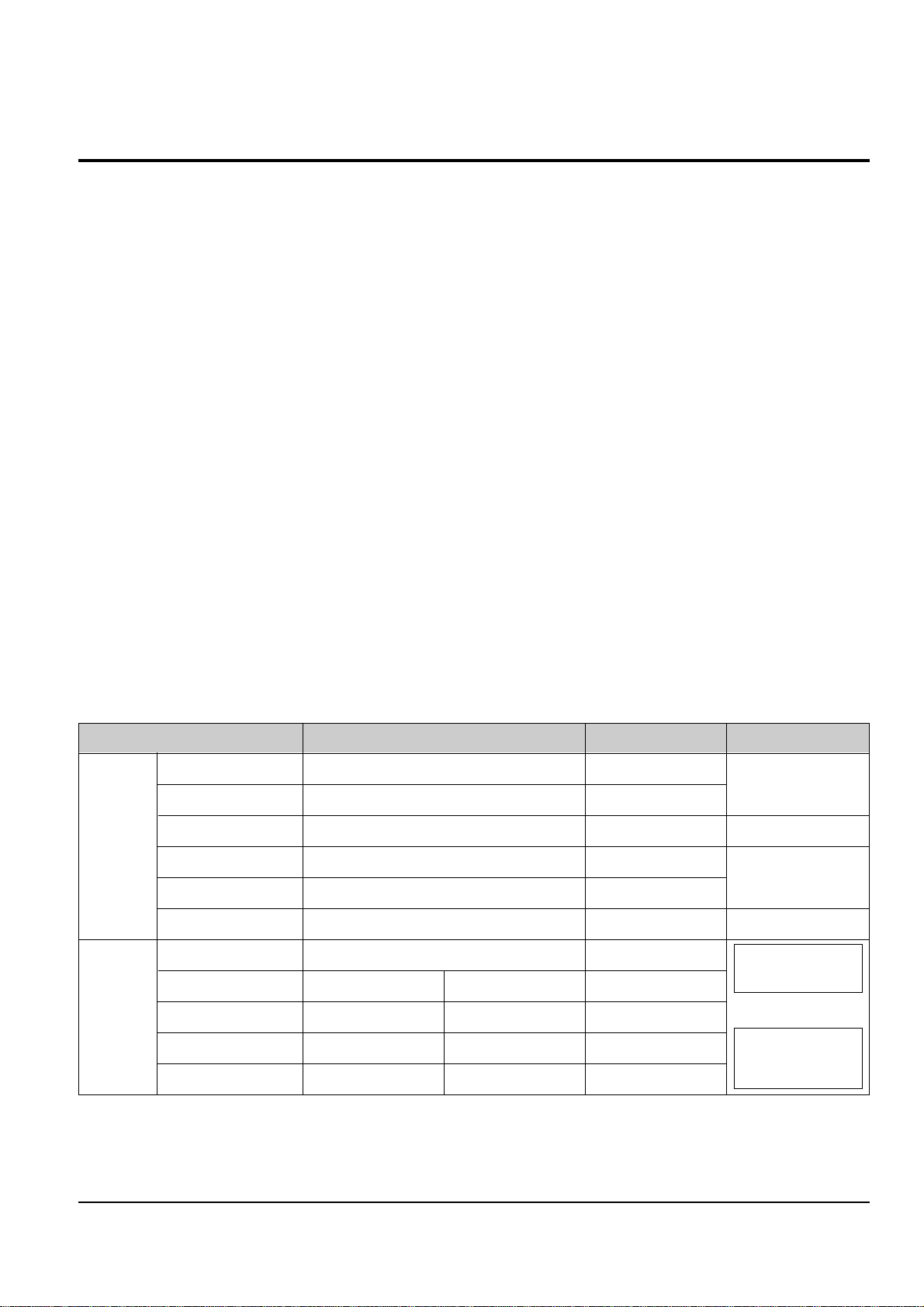

⌘ DVD Vs. CD-ROM

DVD

CD-ROM

Single-Layer Dual-Layer

Laser Wavelength 650nm (635nm) 780nm

Track Pitch 0.75um 1.6um

Disc Diameter 120mm

Disc Thickness 1.2 (0.6 x 2) mm 1.2mm

Linear Velocity 3.49m/s 3.84m/s 1.2 ~ 1.4m/s

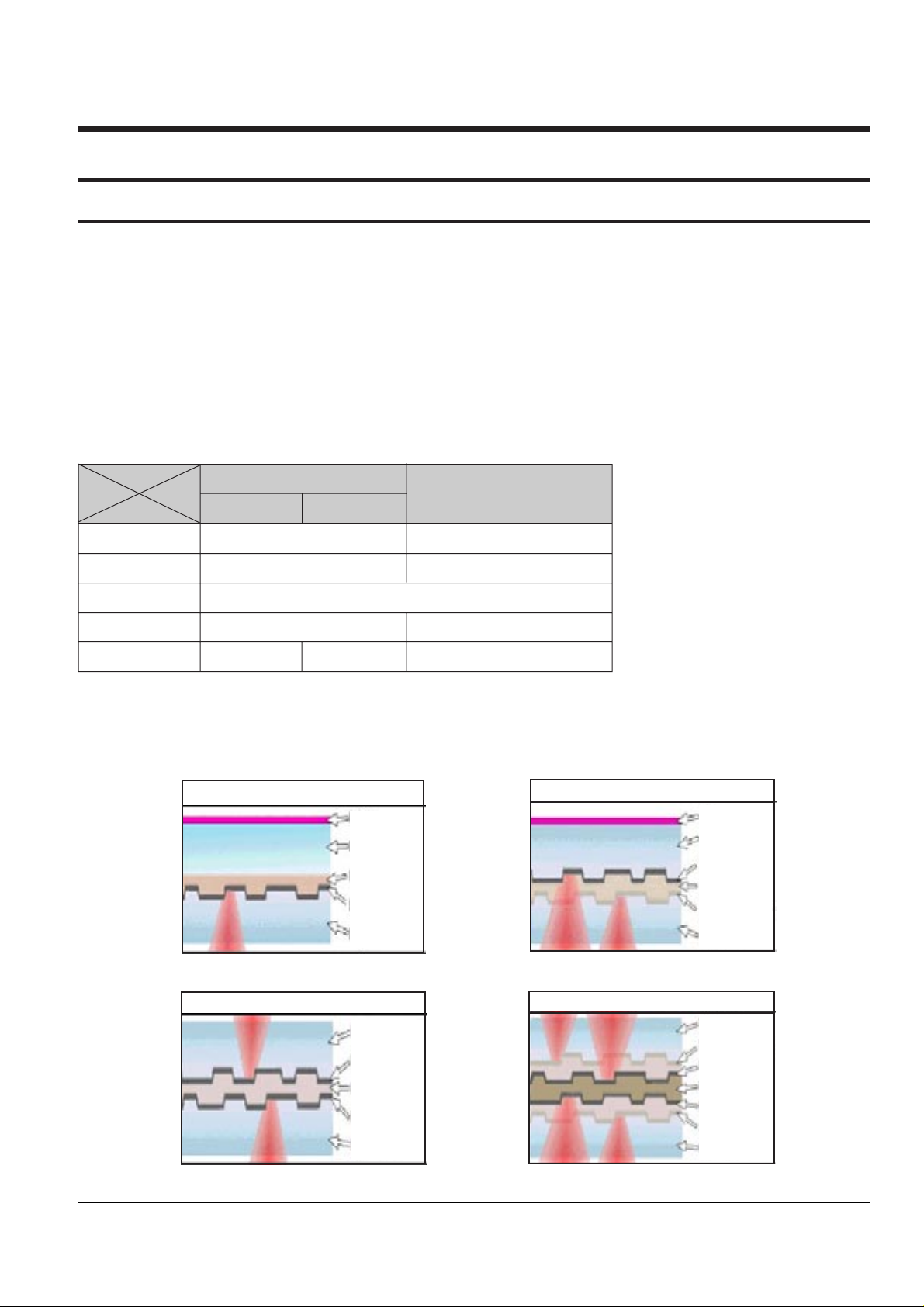

2) Disc Formats

DVD consists of two 0.6mm discs attached together, enabling access to the upper and lower side of the disk,

and 4 sides could be used at maximum.

Single Layer : 4.7GByte

Polycarbonate

Label

Bonding layer

Reflective layer

Polycarbonate

Label

Polycarbonate

Bonding layer

Reflective layer

Semi-reflective layer

Polycarbonate

Dual Layer : 8.5GByte

Bonding layer

Reflective layer

Reflective layer

Polycarbonate

Polycarbonate

Dual Side Single Layer : 9.5GByte

Polycarbonate

Bonding layer

Reflective layer

Reflective layer

Semi-reflective layer

Semi-reflective layer

Polycarbonate

Dual Side Dual Layer : 17GByte

Reference Information

2-2 Samsung Electronics

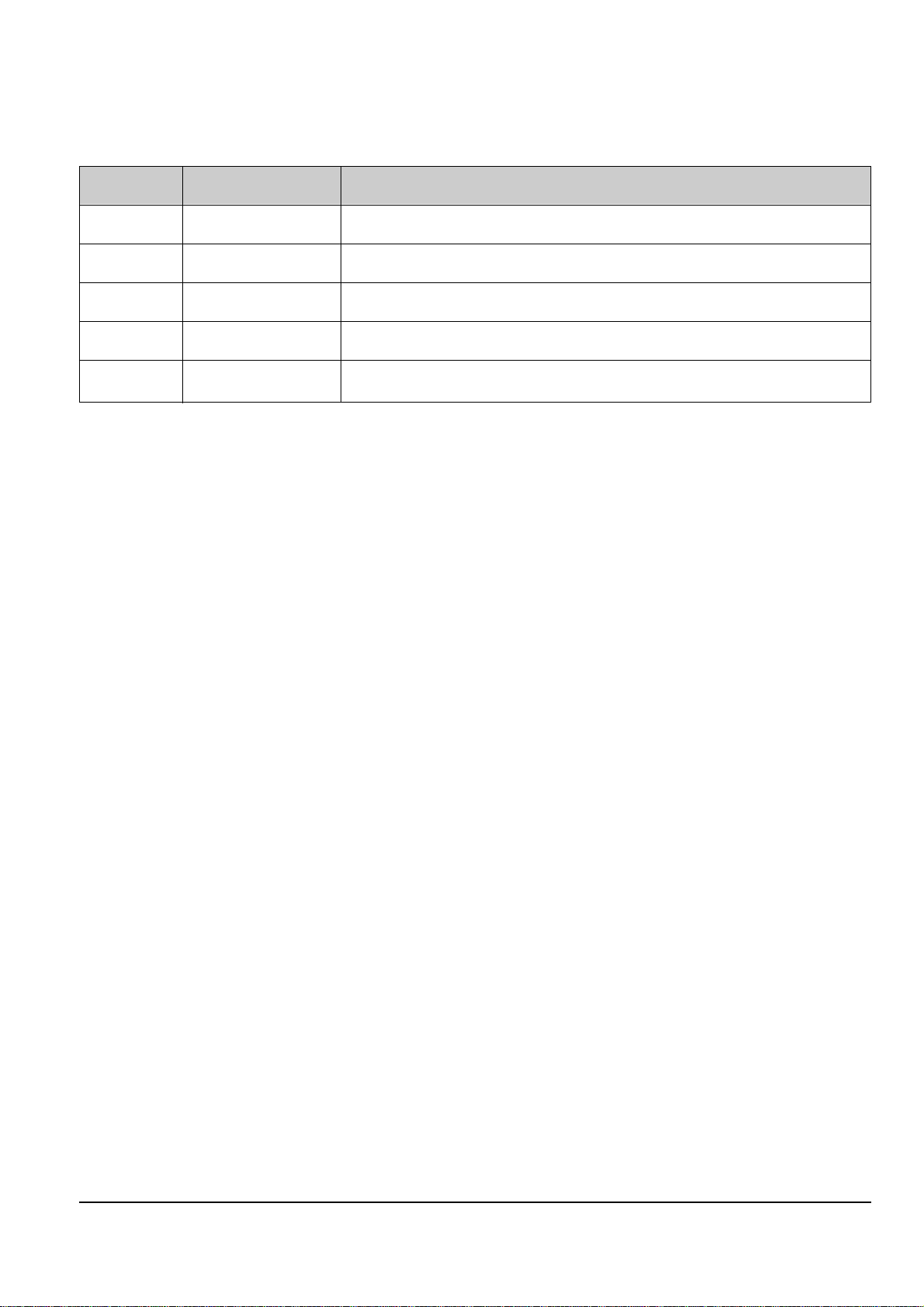

2-1-2 DVD Types

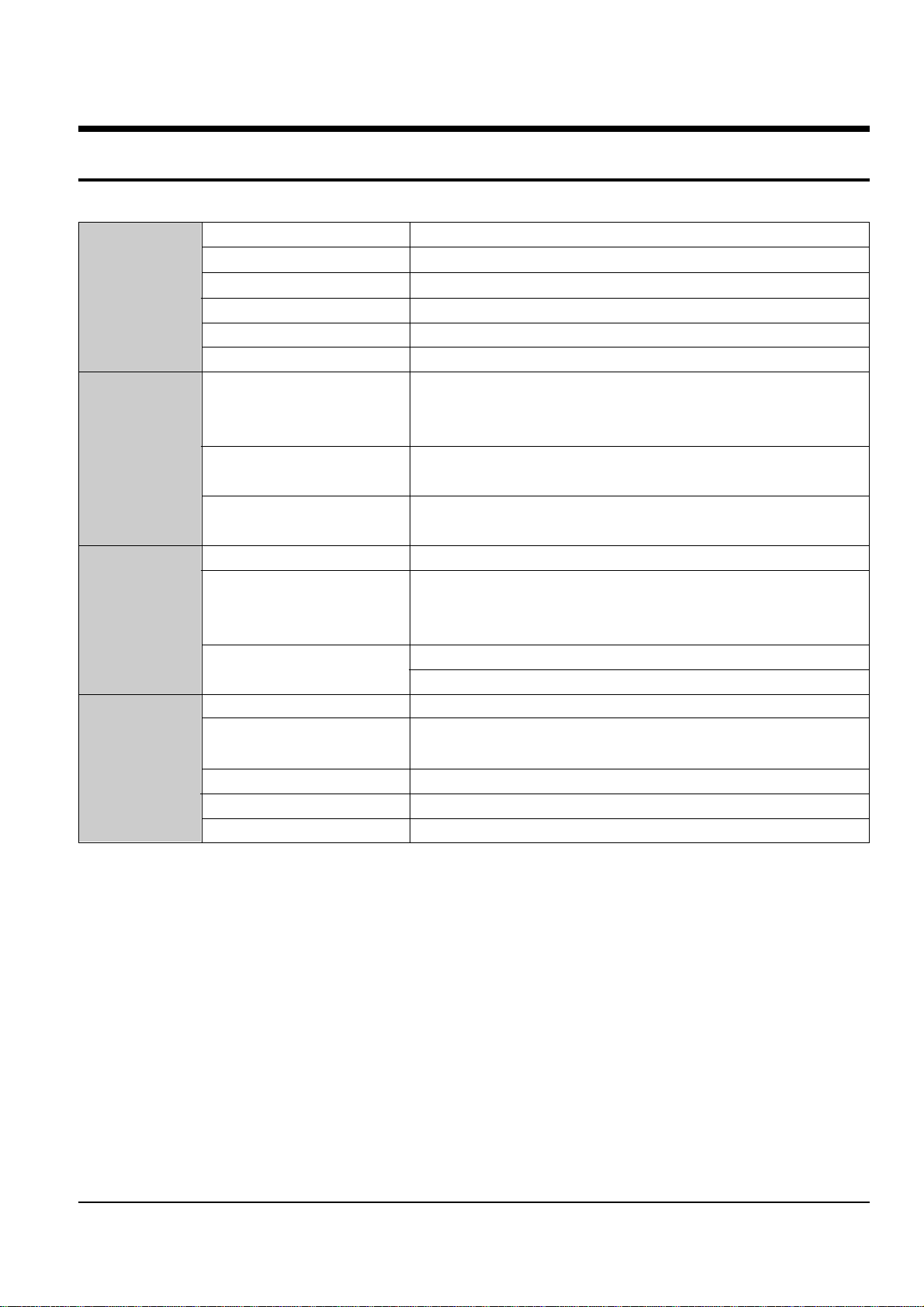

FORMAT TYPE APPLICATIONS

DVD-Video Playback Only High quality image and sound for movies and other video media.

DVD-ROM Read Only Multi-functional, multi-midia software that requires large storage capacity.

DVD-Audio Playback Only High quality sound that exceeds the CD, multi-channel Audio.

DVD-R 1 Time Recording Storage media for the computer.

DVD-RAM Rewritable Data access/storage media for the computer.

Reference Information

Samsung Electronics 2-3

2-2 DVD-Video Fromat

2-2-1 Main Features

1) Able to store up to 160 minutes of Movie by utilizing the MPEG-2 compression technology. ( Aver. 133min.)

2) Enables more than 500 lines of horizontal resolution. (Class corresponding to the Master Tapes used in

broadcasting stations)

3) Provides Dolby Digital 5.1ch Surround 3D sound, which enables theater quality sound (NTSC area).

◆ For PAL areas, 1 of either MPEG-2 Audio or Dolby Digital must be selected.

4) Multi-Language

◆ Able to store up to 8 languages of dubbing.

◆ Able to store up to 32 subtitle languages.

5) Milti-Aspect Ratio

3TV Mode alternatives ; 16:9 Wide Screen (DVD Basic)/4:3 Pan & Scan/Letter Box.

6) Multi-Story

Possible to implement Interactive Viewing which enables the user to select the scenario.

7) Multi-Angle

Able to view the camera angle you selected among the scenes recorded with multiple camera angles.

Note ; The above media features must have the DVD Title that contains the appropriate contents to function

properly.

2-2-2 Audio & Video Specifications

Classification DVD-Video Video-CD LD

Compression MPEG-2 MPEG-1

Analog

Pixel 720 x 480 352 x 240

VIDEO

Horizontal resolution Max. 500 Lines Max. 250 Lines Max.420 Lines

Compression rate 1/40 1/140

Analog

Transmission speed Max. 9.8Mbps (variable) 1.15Mbps (fixed)

TV aspect 16:9 / 4:3 4:3 4:3

Audio Max. 8 streams 2CH stereo

Recording type Dolby Digital Linear PCM MPEG-1 Layer 2

AUDIO Transmission rate 448Kbps/stream 6.144Mbps/stream 224Kbps

or

Channel 5.1CH/stream 8CH/stream 2CH

Sampling frequency 48KHz 16, 20, 24Bit/48, 96KHz 16Bit/44.1KHz

2 Analog CH.

2 Digital CH.

(16Bit/44.1KHz)

1 Analog CH.

1 Stream of Dolby Digital

2 Digital CH.

(16Bit/44.1KHz)

Reference Information

2-4 Samsung Electronics

2-2-3 Detailed Feature

As the storage capacity increases, the DVD-Video separates the main data and the additional data such as the

Multi-Function into different data areas, enabling the control of time-data ratio to provide the format that enables

the flexible Software development

◆ 1 Movie (3.5Mbps)

+ Subtitle (1 Language)

+ Surround Audio (1 Language)

= 160min storage (4.673Gbytes)

◆ 1 Movie (3.5Mbps)

+ Subtitle (4 Language)

+ Surround Audio (4 Language)

= 160min storage (4.680Gbytes)

◆ 1 Music Video (4Mbps)

+ 2ch High quality Audio (96kHz/24bit)

= 72min storage (4.648Gbytes)

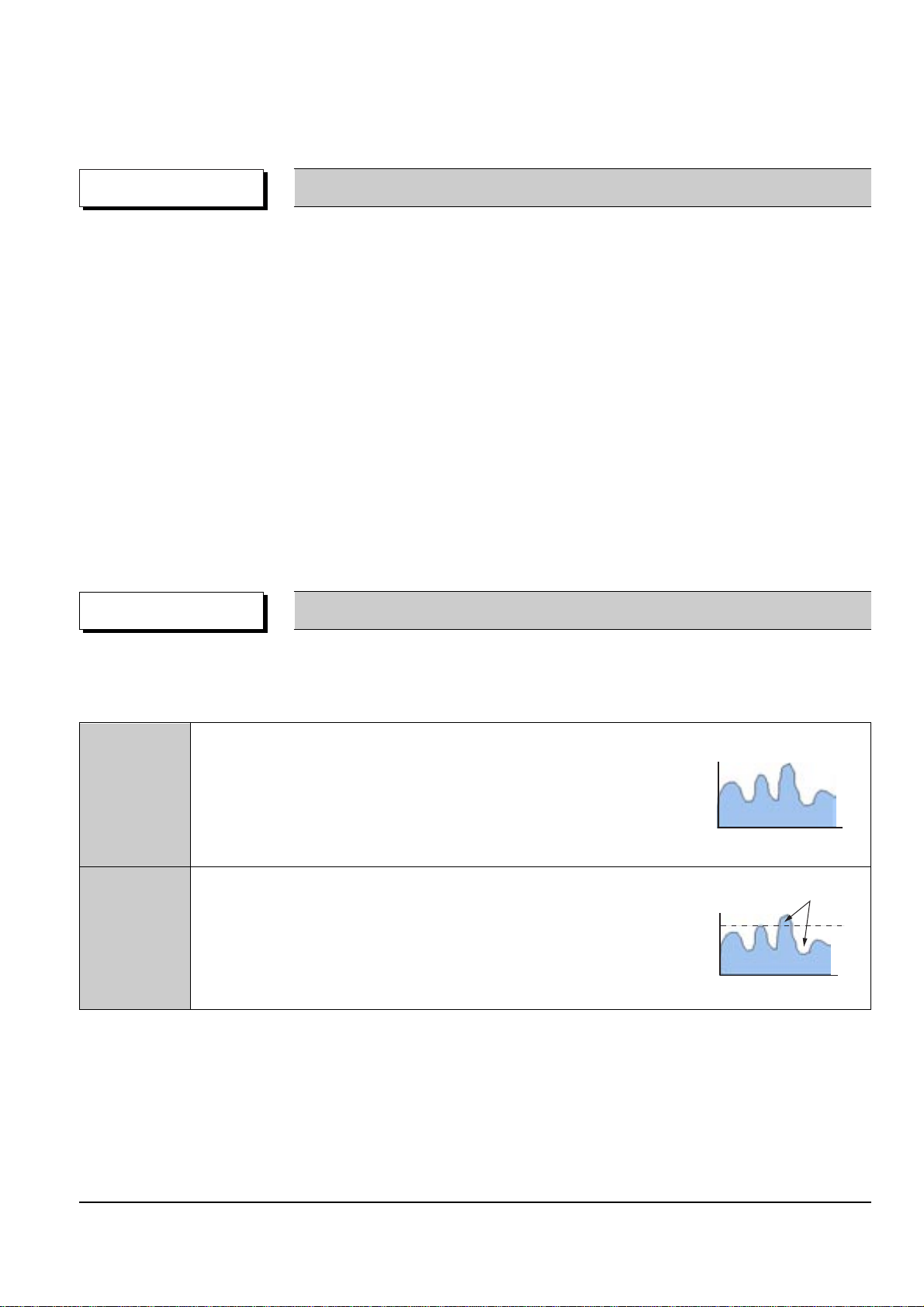

DVD-Video Feature 1 When Developing the DVD Software, various addition and modification is possible.

DVD-Video uses the variable compresion technology, the MPEG-2 to compress the moving image optimally, minimizing the Data loss to Provide a clear, natural screen while increasing the storage time.

DVD-Video Feature 2 Application of the MPEG-2 compression technology.

◆ MPEG-2 (Variable compression : Max. 1/40)

✓ Field unit compression.

DVD-Video

✓ Compression rate change according to the amount of Data.

✓ Differentiates the still image anf the moving image

compression rete, reducing Data loss and enables

efficient compression.

◆ MPEG-1 (Fixed compression : Max. 1/140)

✓ Frame unit compression.

Video-CD

✓ Compresses all data using the same ratio.

- Fast movements are jagged, and unnatural

Amount of data

Amount of data

Time

Loss area

Time

Reference Information

Samsung Electronics 2-5

DVD-Video can store the audio using the 5.1ch Dolby Digital compression or the advanced Liner PCM method,

providing the better-than-CD quality and theater like audio quality.

◆ Dolby Digital (AC-3)

✓ Unlike the traditional Dolby pro-Logic method, the Dolby Digital method separates all 5 main channels

(Front L/R, Center, Surround (Rear) L/R)and the Sub woofer to provide live surround audio.

✓ Using the Down Mix method, the conventional Dolby Pro-Logic and Stereo are all compatible.

✓ Each separated channels are played back at CD quality sound. (Frequency band: 20Hz ~ 20KHz)

◆ Linear PCM (Pulse Code Modulation)

✓ Provides the high quality Digital sound without the audio data compression.

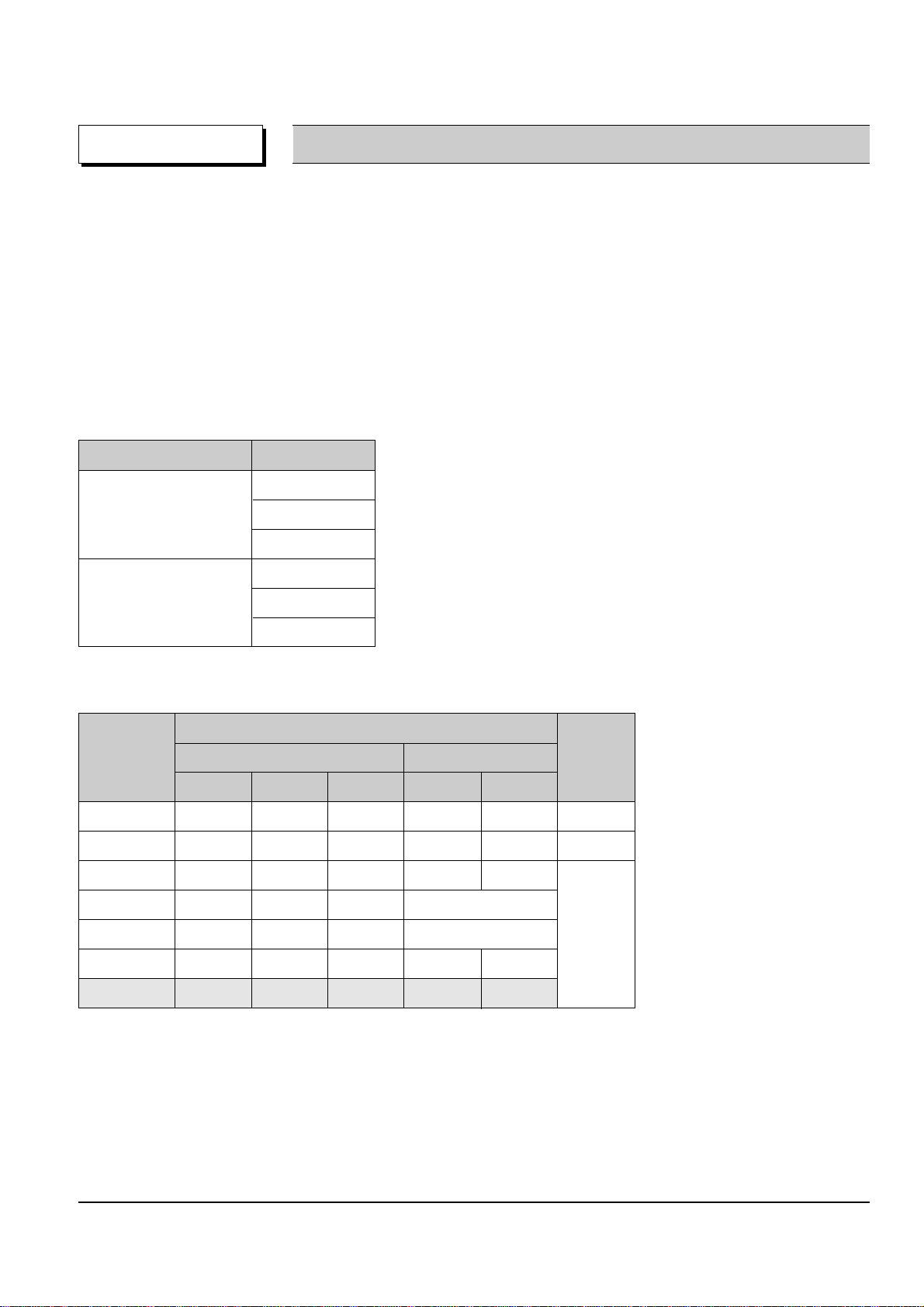

✓ Various Digital Recordings are possible as shown in the table to the right.

DVD-Video Feature 3 High quality surround audio.

Sampling Frequency Bit Rate

16bit

48KHz 20bit

24bit

16bit

96KHz 20bit

24bit

◆ Dolby Digital compatible Audio Mode

Audio Coding

Channel Format

Mode

Front Surround (Rear) Remark

LCRLR

1/0 O Mono

2/0 OO Stereo

3/0 OOO

2/1 OOMono

3/1 OOO Mono Surround

2/2 OOOO

3/2 OOOOO

Reference Information

2-6 Samsung Electronics

◆ Audio Dubbing - Max. 8 Languages

◆ Subtitle - Max. 32 Languages. Capable of storing, and selectiong.

◆ Linear PCM (Pulse Code Modulation)

DVD-Video Feature 4 Multi-Language

◆ Unlike the conventional VCD or LD, DVD-Video has the default of 16:9 Wide, and can be viewed using the

conventional 4:3 TV, enabling the expansion of viewer selection capabilities.

✓ 16 : 9 TV : Wide Mode (16:9 Wide Full Screen)

✓ 4 : 3 TV : Letter Box Mode, Pan & Scan Mode

DVD-Video Feature 5 Multi-Aspect

4:3 Pan & Scan

16:9 Wide

4:3 Letter Box

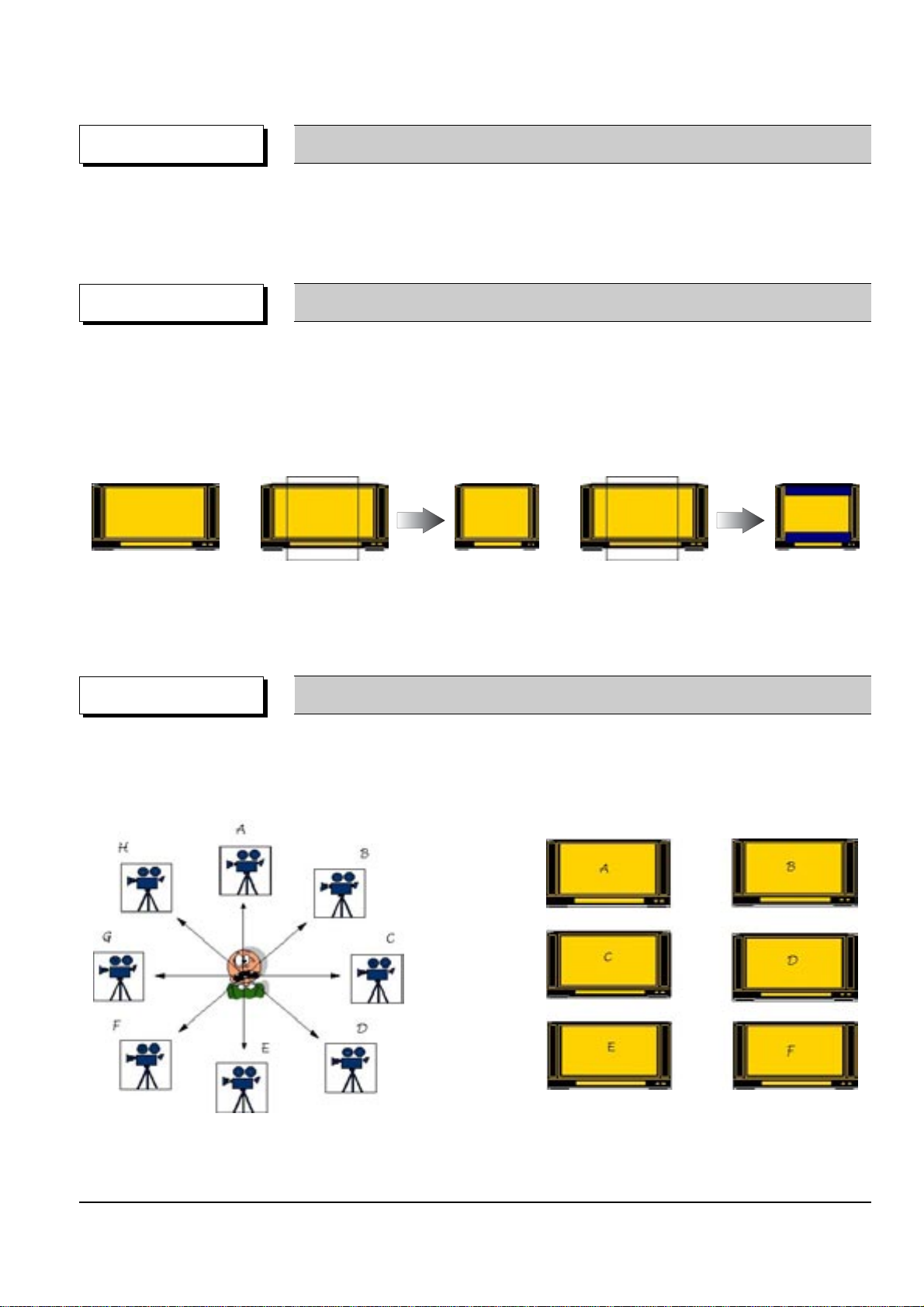

◆ Up to 9 angles of view may be stored, enabling the viewer to select a specific viewpoint at a given time.

--> Especially, for the Music Video and Sports Title, this provides a more lively image of the scene.

DVD-Video Feature 6 Multi-Angle

Note ; Only enable to be worked correctly by an appropriate data supported this function in Disc.

Note ; Only enable to be worked correctly by an appropriate data supported this function in Disc.

Reference Information

Samsung Electronics 2-7

◆ DVD-Video provides the enviroment suitable for the bi-directional Software develoment, providing multiple

scenarios. This feature enables the Multi-Story function.

DVD-Video Feature 7

Multi-Story

◆ For the titles that are not suitable for children viewing, Parental Locks are set, requesting user defined

passwords for viewing

◆ Parential Locks may be set on specific frames of the Title, enabling the player to skip those frames during

playback.

OPTION Parental Lock

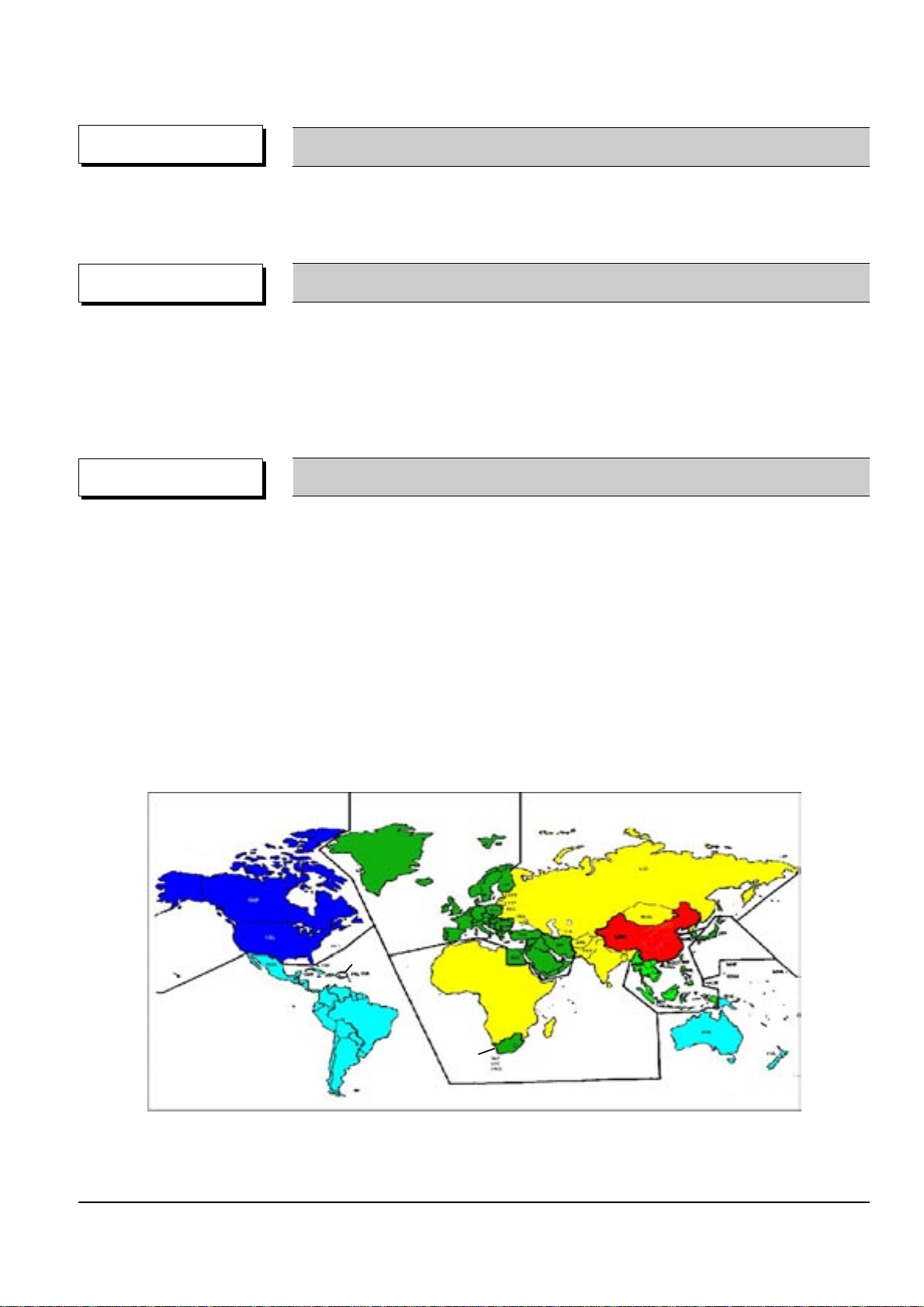

◆ Classify the world into 6 regions, and if the DVD Title and the Player’s “Reginal Code” do not agree, playback

is prohibited.

⌘ Regionnal Coding is optional for the Soft developers (Region 0 All Code), but the Hardware developers

must adopt the appropriate regionnal code for sale.

✓ Region 1 : The United States and its territories, Canada.

✓ Region 2 : Europe, Japan, Greenland, Egypt, South Africa, the Middle East.

✓ Region 3 : Taiwan, Hongkong, Korea, South East Asia.

✓ Region 4 : Mexico, South America, Australia, New Zealand.

✓ Region 5 : Russia, Eastern Europe, India, Africa.

✓ Region 6 : China.

✓ Region 0 : Worldwide (All Code)

COPYRIGHT Regional Code & Macrovision

◆ Adoptation of the Macrovision System disables the copying on to other media.

Œ

Œ

¨

¨

Œ

´

ˇ

ˆ

Ø

´

´

ˆ

Reference Information

2-8 Samsung Electronics

◆ The image quality of the DVD-Video may vary accoring to the quality of the Master and the Authoring Process

✓ The image quality of the DVD-Video varies according to the Digital Mastering Source such as the

conventional LD, VCD, or Original Film.

✓ Different Authoring Process are used accoring to the Software developers, and this may affect the

DVD image quality.

⌘ Authoring Process

Remark DVD-Video Authoring Process

Video/Audio

Master

Surround Audio

Master

Subtitle

Master

MPEG-2

Encoding

AC-3/MPEG Audio

Encoding

Cutting

Master

Disc

Production

Subtitle

Encoding

Authoring Process

Video/Audio

Subtitle

Multiplexing

bit stream

bit stream

bit stream

Samsung Electronics 3-1

3. Product Specification

Power Requirements AC120V, 60Hz

Power Consumption 10W

General

Weight 4.0Ibs

Dimensions W 16.9 in x D 8.1 in x H 1.7 in

Operating Temperature Range +41°F to 95°F

Operating Humidity Range 10% to 75%

DVD Reading Speed : 11.45ft/sec.

(Digital Versatile Disc) Approx. Play Time

(Single Sided, Single Layer Disc) : 135min.

Disc CD : 5” Reading Speed : 3.9 to 4.6ft/sec.

(Compact Disc) Maximum Play Time : 74min.

CD : 3

1/2”

Reading Speed : 3.9 to 4.6ft/sec.

(Compact Disc) Maximum Play Time : 20min.

Composite Video 1 channel ; 1.0Vp-p (75ohm load)

Component Video Y : 1.0Vp-p (75ohm load)

Video Output

Pr : 0.70Vp-p (75ohm load)

Pb : 0.70Vp-p (75ohm load)

S-Video Luminance Signal : 1.0Vp-p (75ohm load)

Chrominance Signal : 0.286Vp-p (75ohm load)

2 Channel L(1/L), R(2/R)

*Ferquency Response 48KHz Sampling : 4Hz to 22KHz

Audio Output

96KHz Sampling : 4Hz to 44KHz

*S/N Ratio 110dB

*Dynamic Range 100dB

*Total Harmonic Distortion 0.004%

* : Nominal specification

Product Specification

3-2 Samsung Electronics

MEMO

SETUP

General Features

This DVD player is capable of playing the following types of discs with the

corresponding logos:

Both the DVD player and the discs are coded by region. These regional codes must match in order for the

disc to play. If the codes do not match, the disc will not play.

The Region Number for this player is described on the rear panel of the player.

8 9

Play Region Number

Disc Type and Characteristics

5"

31/2"

Single-sided

240 min.

Double-sided

480 min.

Single-sided

80 min.

Double-sided

160 min.

Audio

+

Video

Audio

• CD is recorded as a

Digital Signal with better

audio quality, less

distortion and less

deterioration of audio

quality over time.

• DVD contains excellent

sound and video due to

Dolby Digital and MPEG-2

system.

• Various screen and audio

functions can be easily

selected through the on-

screen menu.

AUDIO-CD

5"

31/2"

74 min.

20 min.

Disc Types

(Logos)

Recording

Types

Disc Size

Max.

Playing Time

Characteristics

DVD

~

DIGITAL

SOUND

STEREO

NTSC

• Play Region Number • NTSC broadcast system

in U.S.A, Canada,

Korea, Japan, etc.

• Dolby Digital disc • Stereo disc

• Digital Audio disc

• DTS disc

• MP3 disc

Disc Markings

Excellent Sound

Dolby Digital, a technology developed by

Dolby Laboratories, provides crystal clear

sound reproduction.

Screen

Both regular and widescreen(16:9) pictures

can be viewed.

Slow Motion

An important scene can be viewed in slow

motion.

Programmed Play

You can program tracks to play in desired

order. (CD)

Parental Control

The parental control allows users to set the

level necessary to prohibit children from

viewing harmful movies such as those with

violence, adult subject matter, etc.

Various On-Screen Menu Functions

You can select various languages

(Audio/Subtitle) and screen angles while

enjoying movies.

Progressive Scan

Progressive scanning creates an improved

picture with double the scan lines of a

conventional interlaced picture.

EZ VIEW

Easy View can convert Letter Box images to

full screen viewing on your conventional TV.

Digital Photo Viewer (JPEG)

You can view Digital Photos on your TV.

Repeat

You can repeat a song or movie simply by

pressing the REPEAT button.

MP3

This unit can play discs created from MP3

files.

Instant Replay

This function is used to replay the previous

10 seconds of the movie from the current

position.

Instant Skip

This function skips playback ahead 10

seconds.

• Many DVD discs are encoded with copy protection. Because of this, you should only connect your

DVD player directly to your TV, not to a VCR. Connecting to a VCR results in a distorted picture from

copy-protected DVD

discs.

• This product incorporates copyright protection technology that is protected by methods claims of certain U.S.

patents and other intellectual property rights owned by Macrovision Corporation and other rights owners.

Use of this copyright protection technology must be authorized by Macrovision Corporation, and is intended

for home and other limited viewing uses only unless otherwise authorized by Macrovision Corporation.

Reverse engineering or disassembly is prohibited.

* Discs which cannot be played with this player.

• DVD-ROM • DVD-RAM

• CD-ROM • CDV

• CDI

• HD layer of super Audio CD

• CDGs play audio only, not graphics.

* Ability to play back may depend on recording

conditions.

• DVD-R, +R • CD-RW

• DVD+RW, -RW

* It may not play CD-R, CD-RW and DVD-R in all

cases due to the type of disc or condition of the

recording.

NOTE

COPY PROTECTION

Samsung Electronics 4-1

4. Operating Instructions

Operating Instructions

4-2 Samsung Electronics

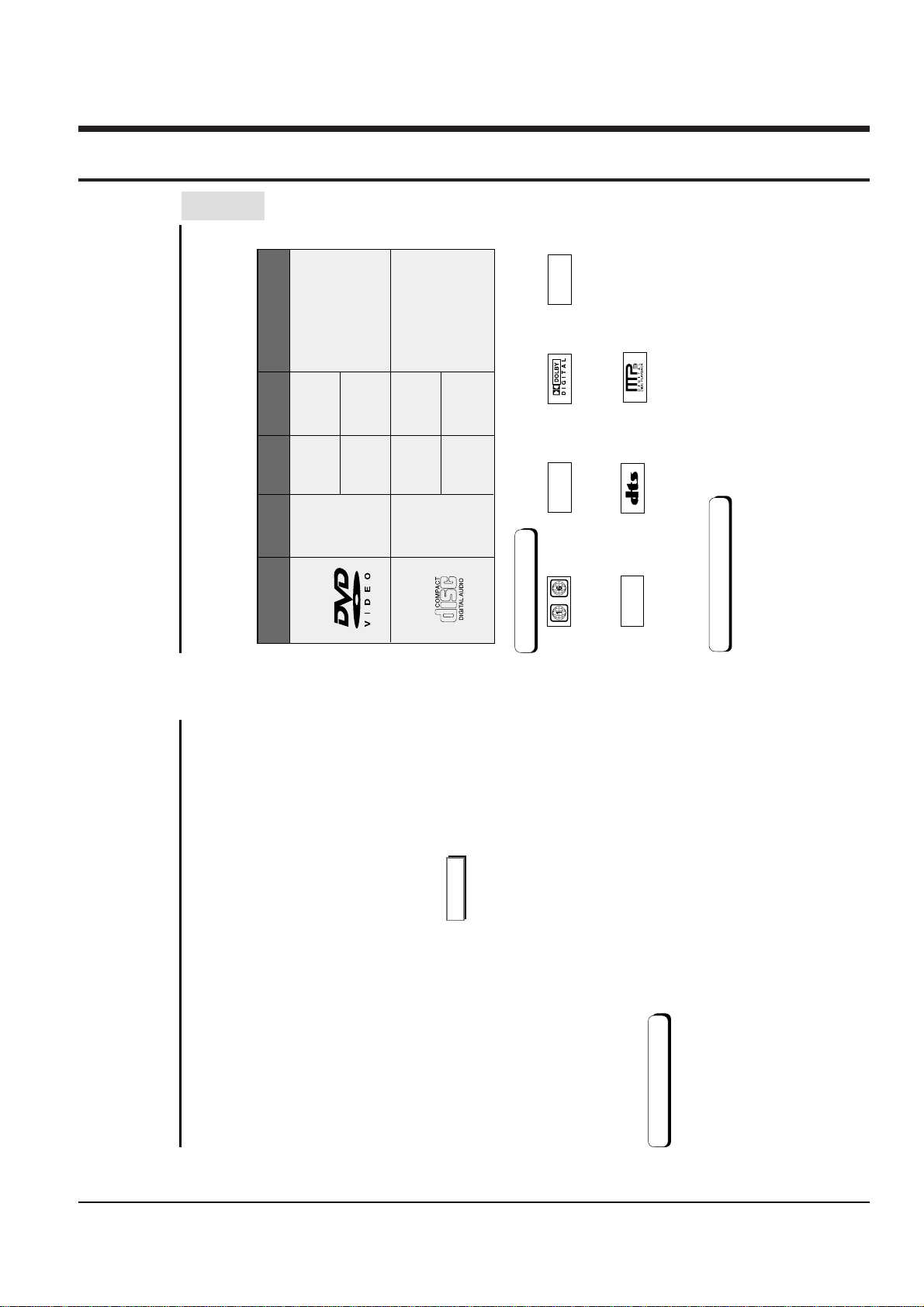

COAXIAL

AUD IO

V ID EO

R - AUDIO - L VIDEO S-VIDEO

Description-Rear Panel

SETUP

12345

If Progressive Scan is supported, follow the TV User’s Manual’s instructions regarding

Progressive Scan settings in the TV’s menu system.

• Consult your TV User’s Manual to find out if your TV supports Progressive Scan.

Rear Panel

• Easy View can convert Letter Box images to full

6. EZ VIEW

EZ VIEW LOADINGPLAY

Use to connect to an A/V Amplifier that contains a Dolby Digital or DTS decoder.

• Use either a coaxial digital cable to connect to a compatible Dolby Digital receiver.

1. DIGITALAUDIO OUT JACKS

screen viewing on your conventional TV.

2. ANALOG AUDIO OUT JACKS

• Press to open and close the disc tray.

7. OPEN/CLOSE ( )

8. PLAY

• Connect to the Audio input jacks of your television, audio/video receiver, or VCR.

• Use a video cable to connect to the Video input jack on your television.

3. VIDEO OUT JACK

• When playing the disc, the Play LED lights.

• When loading the disc, the Loading LED lights.

9. LOADING

Use the S-Video cable to connect this jack to the S-Video jack on your television for a higher picture quality.

• The Video Output in Setup Menu must be set to the 525i or S-Video.

•

• The Video Output in Setup Menu must be set to the S-Video.

4. S-VIDEO OUT JACK

• Place the disc here.

10. DISC TRAY

video. Along with S-Video, Component Video provides the best picture quality.

• Use these jacks if you have a TV with Component Video in jacks. These jacks provide Pr, Pb and Y

• If 525p Video Output is selected in Setup Menu, progressive scan mode will work.

5. COMPONENT VIDEO OUT JACKS

• If 525i Video Output is selected in Setup Menu, interlaced scan mode will work.

Important Note

• If 525P Video Output is selected in Setup Menu, Video and S-Video will not work.

(Red) (Green) (Yellow)

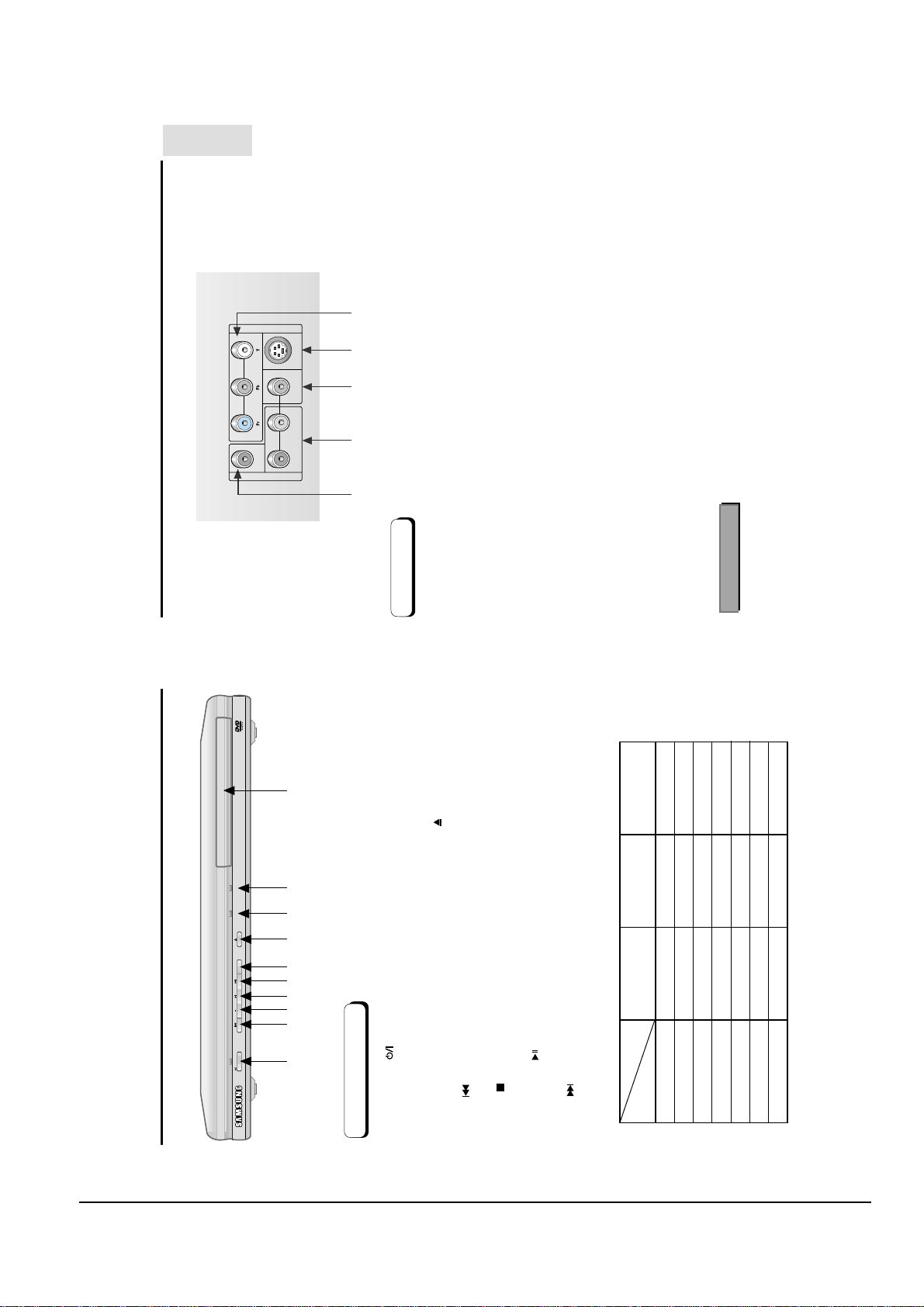

34 56 7 8 9 10

Power LED Play LED Loading LED

2

1

Power off/Standby O X X

no disc X X O

Stop X X O

Loading X X Blink

Play/Skip X O X

Search/Pause X Blink X

Front Panel Controls

1. STANDBY/ON ( )

2. SKIP ( )

Power LED lights. If you press the STANDBY/ON

button to turn on the player.

The LED goes out.

• When the player is plugged in, the

• Use to skip a scene or music.

• Stops disc play.

• Begin or pause disc play.

3. STOP ( )

4. PLAY/PAUSE ( )

• Use to skip a scene or music.

5. SKIP ( )

Error Blink Blink Blink

STANDBY/ON

Description-Front Panel

10 11

Operating Instructions

Samsung Electronics 4-3

SETUP

seconds of the movie from the current position.

• This function is used to replay the previous 10

• This function skips playback ahead 10 seconds.

• Begin/Pause disc play.

13. INSTANT REPLAY Button

14. INSTANT SKIP Button

• Displays the current disc mode.

15. PLAY/PAUSE Button ( )

16. INFO Button

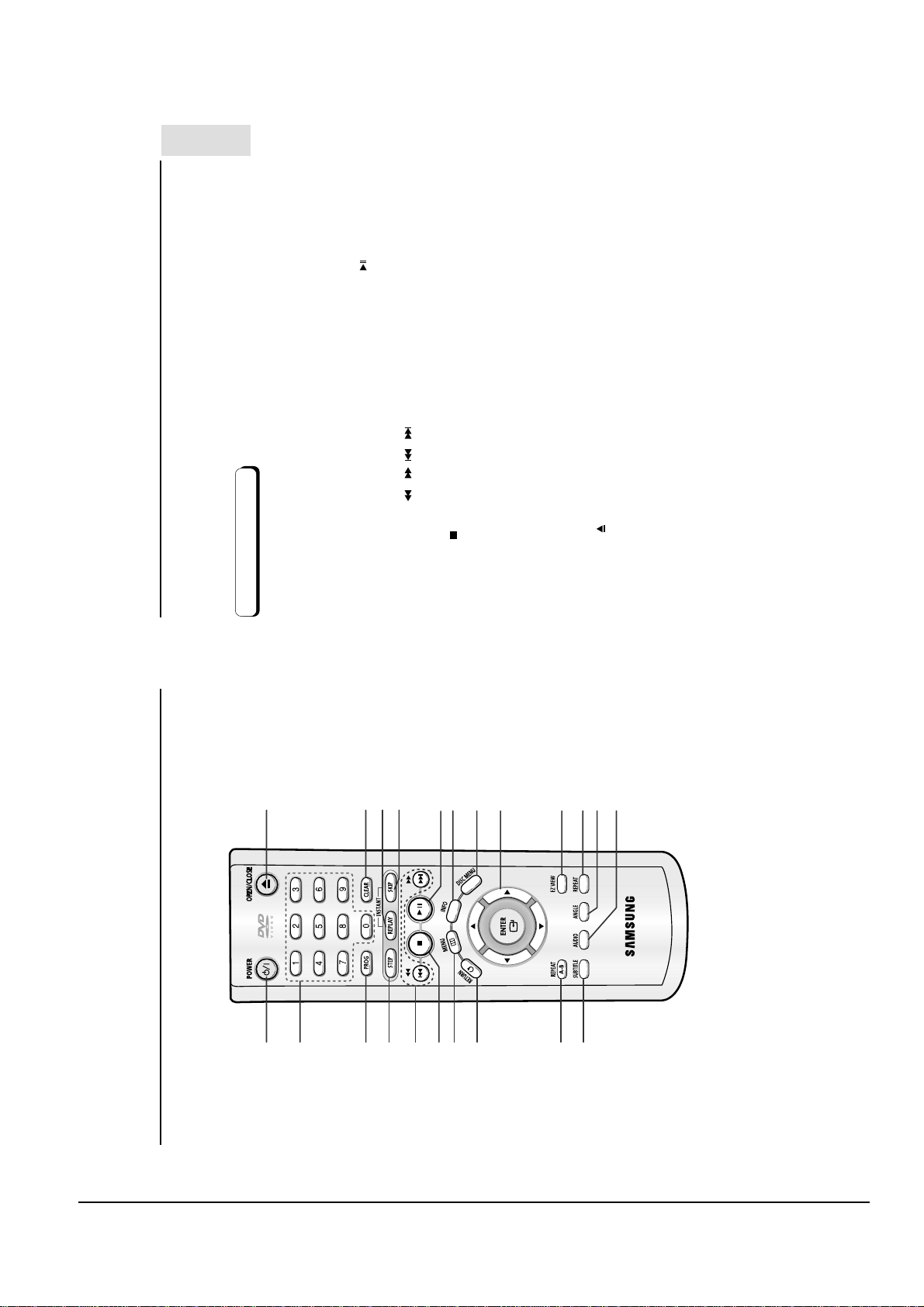

Tour of the Remote Control

DVD Function Buttons

• Turns the power on or off.

1. DVD POWER Button

• Allows you to program a specific order.

2. NUMBER Buttons

3. PROG Button

• Advances play one frame at a time.

• Allows you to search forward/backward through

4. STEP Button

5. SEARCH/SKIP buttons ( / , / )

121314

screen viewing on your conventional TV.

• Brings up the Disc menu.

• This button functions as a toggle switch.

• Easy View can convert Letter Box images to full

(UP/DOWN or LEFT/RIGHT Buttons)

17. DISC MENU Button

18. ENTER/DIRECTION Button

19. EZ VIEW Button

a disc. Use to skip the title, chapter or track.

6. STOP Button ( )

7. MENU Button

151617

• Brings up the DVD player’s setup menu.

• Returns to a previous menu.

8. RETURN Button

18

disc.

• Allows you to repeat play a title, chapter, track, or

20. REPEAT Button

• Use to mark a segment to repeat between Aand B.

9. REPEAT A-B Button

10. SUBTITLE Button

192021

21. ANGLE Button

11. OPEN/CLOSE ( ) button

a disc.

• Use to access various camera angles on a DVD.

• Use this button to access various audio functions on

22. AUDIO Button

screen.

• Use to remove menus or status displays from the

• To open and close the disc tray.

12. CLEAR Button

22

111

2

Tour of the Remote Control

3

4

5

678

9

10

12 13

Operating Instructions

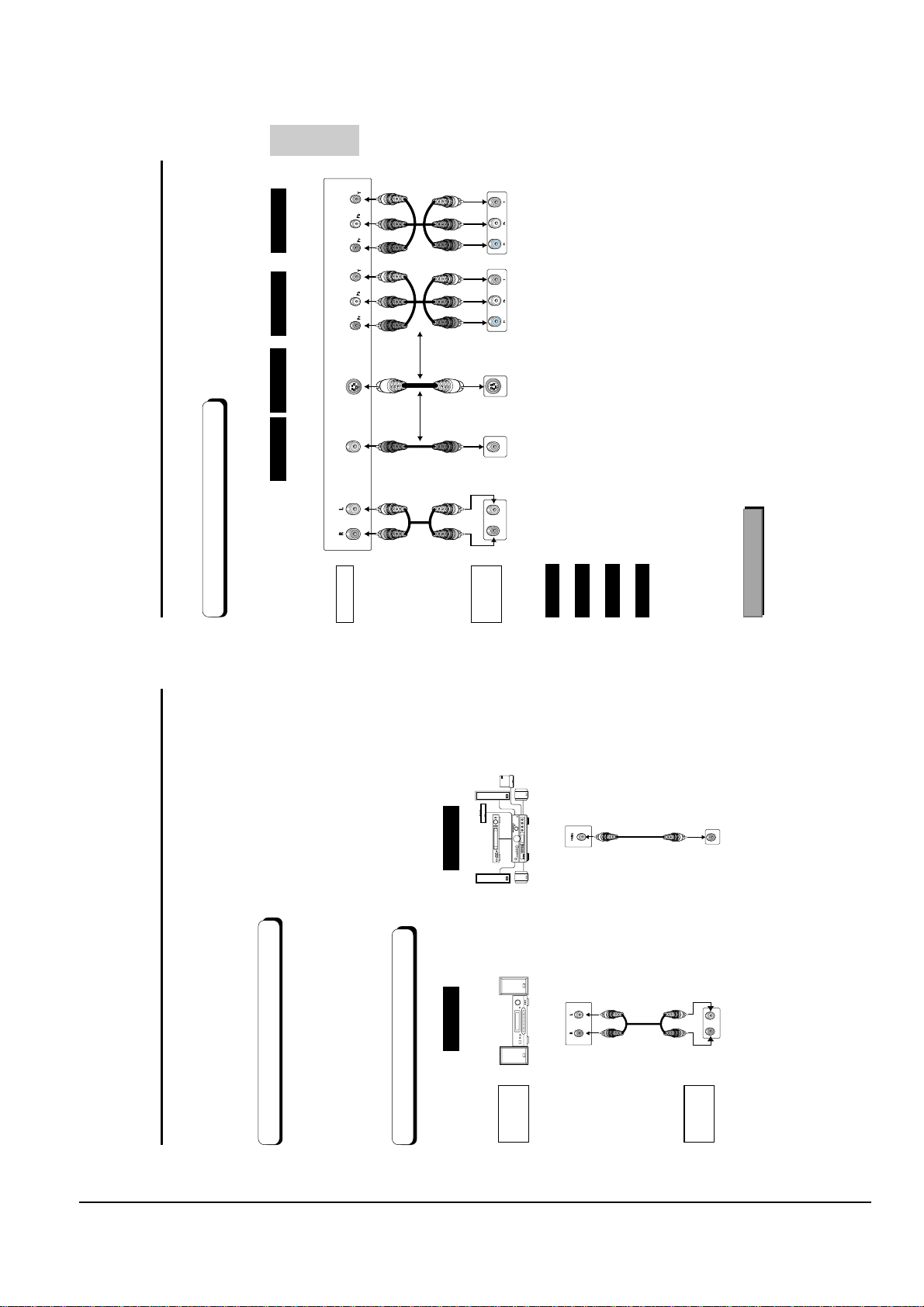

4-4 Samsung Electronics

R - AUDIO - L

VIDEO S-VIDEO

R - AUDIO - L

COAXIAL

CONNECTIONS

picture

Method 4

Optimum

Best

picture

Method 3

Better

picture

Method 2

Good

picture

Method 1

Video

S-Video

AV Cable

Cables

Cable

Component Video Jacks Component Video Jacks

S-Video Jack

OR OR

Video Output Jack

Basic Audio

Connection to a TV (For Video)

TV (Normal, Widescreen, Projection, etc..)

TV

DVD

Player

Audio Output Jacks

DVD Player + TV with Video Input Jack

(The Video Output in Setup Menu must be set to the S-Video or 525i.)

DVD Player + TV with S-Video Input Jack

Method 1

Dolby Digital Decoder

Digital Audio Input Jack

Video or S-Video on your TV. And then select 525p(480p) out of Video Output in Setup

Menu. Within 10 seconds, change the external input of TV to 525p(480p or Component)

(The Video Output in Setup Menu must be set to the S-Video.)

DVD Player + TV with Component Video Jacks

(The Video Output in Setup Menu must be set to the 525i.)

DVD Player + TV with Progressive Scan Jacks.

(The Video Output in Setup Menu must be set to the 525p.)

• If 525p Video Output is selected in Setup Menu, Video and S-Video will not work.

• Depending on your TV, your hookup for Method 4 may differ from the illustration.

Method 2

Method 3

Method 4

and then select "Yes" (See Page 44)

• If you want to convert Video Output to the Progressive Scan, you have to first connect

Important Note

Consult your TV User’s Manual to find out if your TV supports Progressive Scan.

If Progressive Scan is supported, follow the TV User’s Manual’s instructions regarding Progressive

Scan settings in the TV’s menu system.

Before Connecting the DVD Player

Choosing a Connection Choosing a Connection

The following shows examples of connections commonly used to connect the DVD player

with a TV and other components.

connecting for more information on those particular components.

you connect or disconnect any cables.

• Always turn off the DVD player, TV, and other components before

• Refer to the owner’s manual of the additional components you are

Method 1 Method 2

Connection to an Audio System

AUDIO

SYSTEM

2ch Amplifier

Audio Input Jacks

DVD

Player

Analog Audio Out Digital Audio Out

14 15

Operating Instructions

Samsung Electronics 4-5

BASIC

FUNCTIONS

Step Motion Play (Only DVD)

Press the STEP button on the remote during play.

7

(You can only perform step motion play in the forward direction.)

- Each time the button is pressed, a new frame will appear.

- No sound is heard during STEP mode.

- Press PLAY/PAUSE ( ) to resume normal play.

Slow Motion Play (Only DVD)

Press and hold the button to choose the play speed between 1/8, 1/4 and 1/2 of normal during

PAUSE or STEP mode.

- No sound is heard during slow mode.

- Press PLAY/PAUSE ( ) to resume normal play.

8

- Reverse slow motion play will not work.

RESUME function

When you stop disc play, the player remembers where you stopped, so when you press PLAY ( ) again,

it will pick up where you left off. (unless the disc is removed or the player is unplugged, or if you press the STOP

NOTE

( ) button twice.)

• If the player is left for 5 minutes in pause mode, it will stop.

(Automatic Power-Off Function)

saver will be activated. Press the PLAY ( ) button to resume normal play.

• If the player is left in the stop mode for more than 30 minutes, the power will automatically shut off.

• If the player is left in the stop mode for more than one minute without any user interaction, a screen

• This icon indicates an invalid button press.

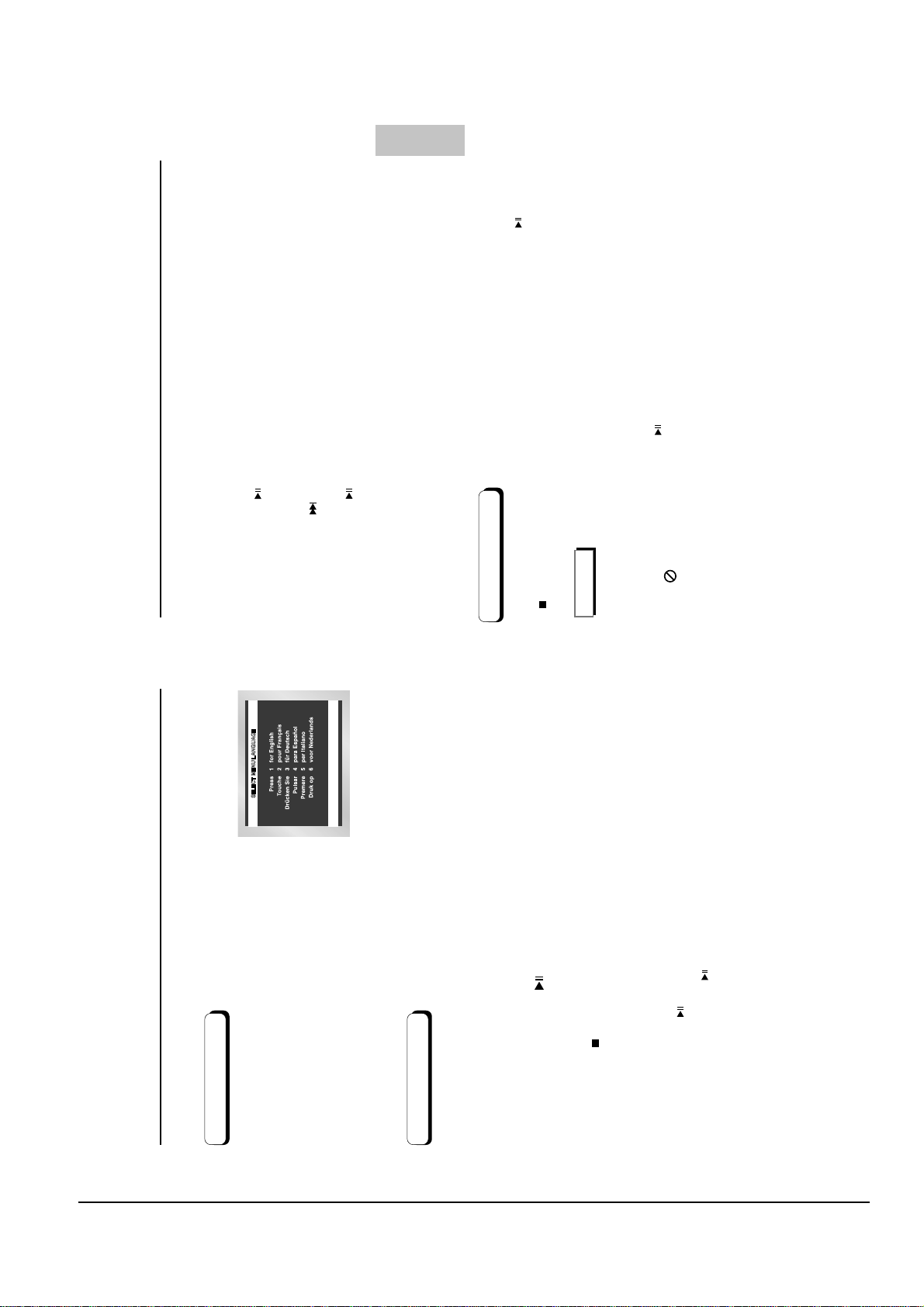

Play

Before Play

mode.

• Turn on your TV and press the TV/VIDEO button to select the video

• Turn on your Audio System and select AUX, CD or DVD.

Playing a Disc Playing a Disc

After plugging in the player, the first time you press the DVD

time.)

POWER button, this screen comes up :

If you want to select the language, press a NUMBER button.

(This screen will only appear when you plug in the player for the first

Press the OPEN/CLOSE button.

The STANDBY indicator light goes out and the tray opens.

Place a disc gently into the tray with the disc’s label

facing up.

Press the PLAY/PAUSE ( ) button or OPEN/CLOSE

button to close the disc tray.

Stopping Play

Press the STOP ( ) button during play.

Removing Disc

1

2

3

4

Press the OPEN/CLOSE button.

Pausing Play

Press the PLAY/PAUSE ( ) or STEP button on the remote during play.

- Screen stops, no sound.

- To resume, press PLAY/PAUSE ( ) button once again.

5

6

16 17

Operating Instructions

4-6 Samsung Electronics

DVD

Title

Time

Audio

Chapter

Subtitle

01020:00:13

ENG 5.1CH

Off

ENTER

CD

Track

Time

01

0:00:48

ENTER

Title

Chapter

Time

Audio

Subtitle

BASIC

FUNCTIONS

DVD

directly access a title, chapter or to start the playback from

the desired time.

During play, press the INFO button on the remote.

Use the UP/DOWN buttons to select the desired

1

item.

2

When Playing a DVD/CD

• You may use the number buttons of the remote control to

Use the LEFT/RIGHT buttons to make the desired

setup.

3

CD

Most DVD discs are recorded in chapters so that you

can quickly find a specific passage (similar to tracks

on an audio CD).

Allows playback of the film from a desired time.

To access the desired title when there is more than

one in the disc. For example, if there is more than one

movie on a DVD, each movie will be identified.

To make the screen disappear, press the INFO

button again.

You must enter the starting time as a reference.

4

Refers to the language of the film soundtrack.

In the example, the soundtrack is played in English

5.1CH. ADVD disc can have up to eight different

soundtracks.

Refers to the subtitle languages available in the disc.

You will be able to choose the subtitle languages or,

if you prefer, turn them off from the screen.

A DVD disc can have up to 32 different subtitles.

2X, 8X, 32X, 128X

2X, 4X, 8X

Searching through a Chapter or Track

Using the Search & Skip Functions Using the Display Function

During play, you can search quickly through a chapter or track or use the skip

function to jump to the next selection.

Press the SEARCH ( or ) button on the remote for more than 1 second.

DVD

button.

CD

If you want to search at a faster speed on the DVD or CD, press and hold the

Skipping Tracks

If you press the button, it moves to the beginning of the chapter.

One more press makes it move to the beginning of the previous chapter.

If you press the button, it moves to the beginning of the track. One more

During play, press the or button.

• When playing a DVD, if you press the button, it moves to the next chapter.

press makes it move to the beginning of the previous track.

• When playing a CD, if you press the button, it moves to next track.

18 19

Operating Instructions

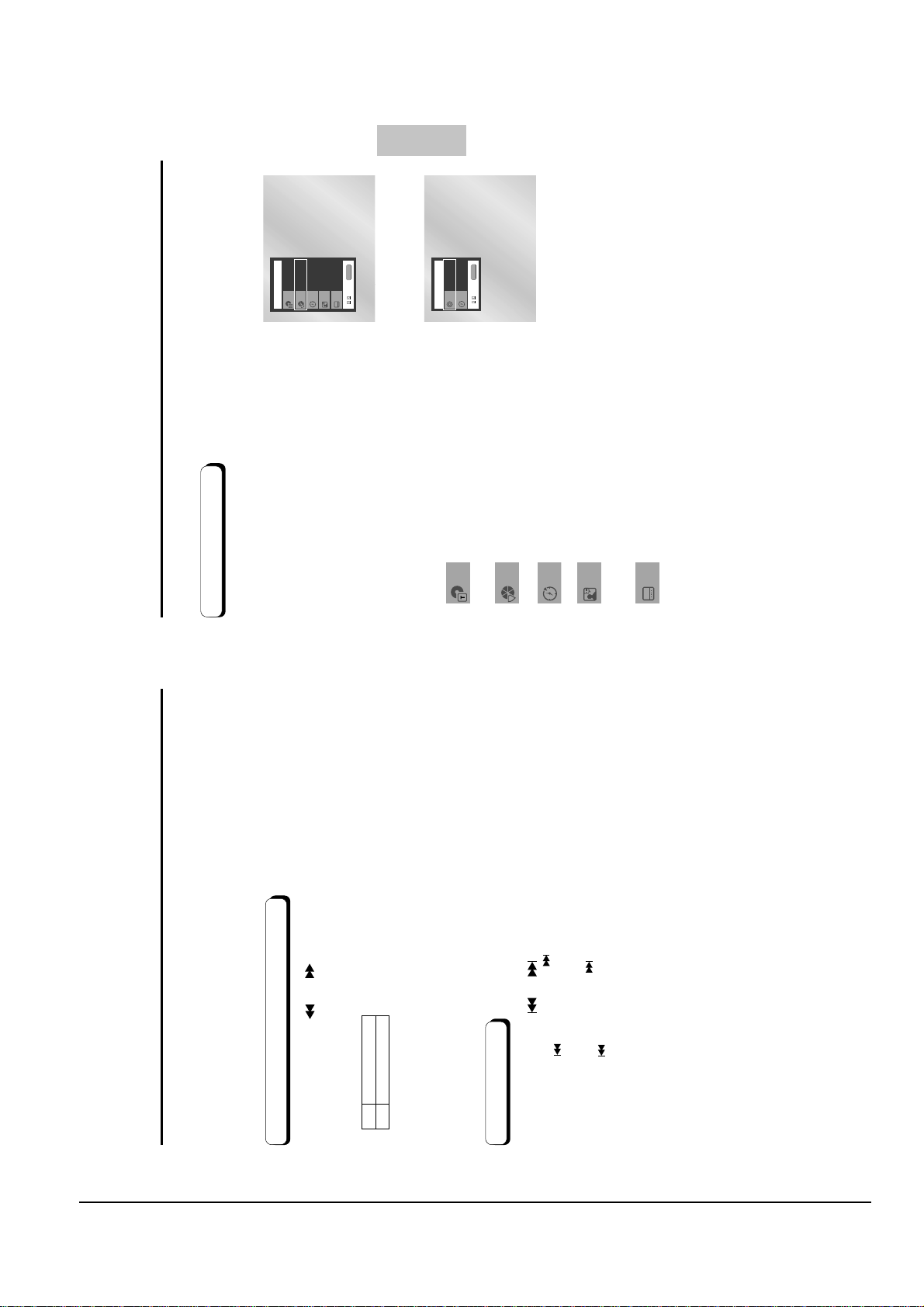

Samsung Electronics 4-7

BASIC

Setup

Press ENTER key

for Disc Menu

Title Menu

Function

Disc Menu

ENTER RETURN MENU

Setup

Disc Menu

Title Menu

Function

ENTER RETURN MENU

Press ENTER key

for Title Menu

Setup

Title Menu

Disc Menu

Function

Info

Zoom

Bookmark

Repeat

EZ View

ENTER RETURN MENU

FUNCTIONS

Using the Function Menu

- Info (See Page 19)

- Zoom (See Page 32)

- Bookmark (See Page 31)

Press the MENU button during playback.

Use the UP/DOWN buttons to highlight Function,

then press the RIGHT or ENTER button.

Function selection screen appears: Info, Zoom,

Using the Function Menu

1

2

Bookmark, Repeat and EZ View.

3

- Repeat (See Page 22)

- EZ View (See Page 24~25)

Use the UP/DOWN button to highlight one of the 5

functions. Then press the RIGHT or ENTER button

to access the function.

4

NOTE

• You can also directly select the parts of these functions using their respective buttons on the remote.

During the playback of a DVD disc, press the

MENU button on the remote.

Using the Disc Menu

Using the Disc and Title Menu

Select Disc Menu using the UP/DOWN buttons,

then press the RIGHT or ENTER button.

1

2

During the playback of a DVD disc, press the

MENU button on the remote.

Select Title Menu using the UP/DOWN buttons,

Using the Title Menu

1

then press the RIGHT or ENTER button.

2

NOTE

• Depending on the disc, the Title and Disc Menus may not work.

• Title Menu will only be displayed if there are at least two titles in the disc.

• You can also use the Disc Menu, using the DISC MENU button on the remote.

20 21

Operating Instructions

4-8 Samsung Electronics

Off 01 01 A - B

ENTER

T

Off 01 01 A - B

ENTER

D

T

PROGRAM

Random

PROGRAM 01

Track

05 06 07 08

09 10 11 12

13 14 15 16

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

- - - - - - - -

Program order

01 02 03 04

ENTER RETURN CLEAR

T

BASIC

FUNCTIONS

Random

PROGRAM

Program Play (CD)

Press the PROG button.

Use the LEFT/RIGHT buttons to select

PROGRAM. Press the ENTER button.

1

2

DVD

Use the LEFT/RIGHT/UP/DOWN buttons to

select the first track to add to the program.

Press the ENTER button. The selection

numbers appear in the Program Order box.

Press the PLAY/PAUSE ( ) button.

The disc will be played in programmed order.

3

4

CD

Random Play (CD)

Press the PROG button.

Use the LEFT/RIGHT buttons to select Random.

Press the ENTER button.

The disc will be played in random order.

1

2

NOTE

• Depending on the disc, the Program and Random Play functions may not work.

Random Play.

• PROGRAM/Random playback cannot be used if the disc contains more than two types of file extensions.

• This unit can support a maximum of 20 programmed order.

• While in playback mode, press the CLEAR button on the remote control to cancel Programmed Play or

REPEATA-B button

function starts. (A)

function ends. (B)

'REPEATA-B' button again.

Press the REPEAT button on the remote.

Repeat screen appears.

Select Chapter, Title or A-B using the

LEFT/RIGHT buttons.

• Chapter ( ) : repeats the chapter that is playing.

• Title ( ) : repeats the title that is playing.

• A-B : repeats a segment of the disc that you select.

Press ENTER.

To return to normal play, press REPEAT again,

then press the LEFT/RIGHT buttons to select Off

and press ENTER.

*

• Press the REPEATA-B button to select the point where the

When playing a DVD

Repeat Play Program Play & Random Play

Repeat the current track, chapter, title, a chosen section (A-B), or all of the disc.

1

2

3

4

• Press the REPEATA-B button to select the point where the

5 seconds has elapsed after point (A) has been set.

• To terminate the function, press the 'CLEAR' button or the

• A-B REPEAT does not allow you to set point (B) until at least

NOTE

• DVD repeats play by chapter or title, CD repeats play by disc or track.

• Depending on the disc, the Repeat function may not work.

22 23

Operating Instructions

Samsung Electronics 4-9

Adjusting the Aspect Ratio (EZ View)

ADVANCED

FUNCTIONS

Displays the content of the DVD title in 16:9 aspect ratio.

The black bars will appear at the top and bottom of the screen.

The left and right of the screen are cut off and displays the central

For 16:9 aspect ratio discs

• 4:3 Letter Box

portion of the 16:9 screen.

• 4:3 Pan Scan

• Screen Fit

If you are using a 4:3 TV

The top and bottom of the screen are cut off and the full screen

appears. The picture will look vertically stretched.

The top, bottom, left and right of the screen are cut off and the central

portion of the screen is enlarged.

• Zoom Fit

Displays the content of the DVD title in 4:3 aspect ratio.

The top and bottom of the screen are cut off and the full screen

For 4:3 aspect ratio discs

• Normal Screen

appears. The picture would look vertically stretched.

• Screen Fit

The top, bottom, left and right of the screen are cut off and the central

portion of the screen is enlarged.

• Zoom Fit

NOTE

• This function may behave differently depending on the type of disc.

Displays the content of the DVD title in 16:9 aspect ratio.

The top and bottom of the screen are cut off. When playing a

2.35:1 aspect ratio disc, the black bars at the top and bottom of the

screen will disappear. The picture will look vertically stretched.

(Depending on the type of disc, the black bars may not disappear

completely.)

The top, bottom, left and right of the screen are cut off and the central

Adjusting the Aspect Ratio (EZ View)

For 16:9 aspect ratio discs

• Wide Screen

setting in the initial setup menu.

• The screen size changes when the button is pressed repeatedly.

Press the EZ VIEW button.

To play back using aspect ratio (DVD)

correct aspect ratio in the initial setup (See page 44).

• The screen zoom mode operates differently depending on the screen

• To ensure correct operation of the EZ VIEW button, you should set the

If you are using a 16:9 TV

• Screen Fit

portion of the screen is enlarged.

• Zoom Fit

Displays the content of the DVD title in 16:9 aspect ratio.

The picture will look horizontally stretched.

The top and bottom of the screen are cut off and the full screen

appears. The picture will look vertically stretched.

The top, bottom, left and right of the screen are cut off and the central

portion of the screen is enlarged.

When a 4:3 DVD is viewed on a 16:9 TV, black bars will appear at

the left and right of the screen in order to prevent the picture from

For 4:3 aspect ratio discs

• Normal Wide

• Screen Fit

• Zoom Fit

looking horizontally stretched.

• Vertical Fit

24 25

Operating Instructions

4-10 Samsung Electronics

ENG

DOLBY DIGITAL 5.1CH

AUDIO

Stereo

AUDIO

ADVANCED

FUNCTIONS

Selecting the Audio Language

Using the AUDIO button

You can select a desired language quickly and easily with the AUDIO button.

DVD

Press the AUDIO button.

The Audio changes when the button is pressed

repeatedly.

- The audio languages are represented by abbreviations.

1

2

CD

Press the AUDIO button to select Stereo, Left

or Right. (On CD)

3

NOTE

• This function depends on what languages are encoded on the disc and may not work with all DVDs.

Refer to “Setting Up the Language Features” on page 41.

How to have the same audio language come up whenever you play a DVD;

• ADVD disc can contain up to 8 audio languages.

•

During play, press the PLAY/PAUSE ( ) button.

Press and hold the button to choose the play speed between 1/8, 1/4, and 1/2

of normal during PAUSE or STEP mode.

Press the REPEATA-B button to select the point where the function starts. (A)

When playing a DVD

Slow Repeat play

This feature allows you slowly to repeat scenes containing sports, dancing,

musical instruments being played etc. so you can study them more closely.

1

2

Press the REPEATA-B button to select the point where the function ends. (B)

3

4

NOTE

• The disc will play from Ato B repeatedly at the speed you chose.

• To terminate the function, press the 'CLEAR' button or the 'REPEATA-B' button again.

• A-B REPEAT does not allow you to set point (B) until at least 5 seconds has elapsed after point (A) has been set.

26 27

Loading...

Loading...