SAMSUNG DV4700V Service Manual

VIDEO-CD/LDP/CD PLAYER

1. Precaution

2. Specification and Comparison Charts

3. Disassembly and Reassembly

4. Exploded Views and Parts List

5. Alignment and Adjustment

6. Troubleshooting

7. Electric parts List

8. Block Diagrams

9. PCB Layout

10. Wiring Diagram

11. Schematic Diagrams

SERVICE

Manual

VIDEO-CD/LD/CD PLAYER

DV7720KV/DV7700KV/DV4720V/DV4700V

For deck assembly & reassembly refer to the Model DV530K/DV430(14739-0090-00)

issued previously.

CONTENTS

POWER

ON/STANDBY

SOUND

ONCE MORE REPEAT

KARAOKE

STANDARD

SURROUND

SELECTOR

VOLUMECONTROLMIC 1VOLUME

LOW KEY CONTROL HIGH

SCORE/

AUTO PAUSE

VOICE

CANCEL

VOICE

CHANGE

DIGITAL ECHO

PHONES

MIN MAX

MIN MAXMIN MAX

MIC 2

LAST MEMORY

OPEN/CLOSE

RETURN

PREVIOUS

DISC 1

162738495

10/0

DISC CHANGE

NTSC/PAL

DISC 2

SELECT

NEXT

SKIP/SEARCH

STOP

PLAY/PAUSE

POWER

ON/STANDBY

SOUND LAST MEMORY

OPEN/CLOSE

RETURN

PREVIOUS

DISC 1

162738495

10/0

DISC CHANGE

NTSC/PAL

DISC 2

SELECT

NEXT

SKIP/SEARCH

STOP

PLAY/PAUSE

POWER

ON/STANDBY

OPEN/CLOSE

PROGRAM

162738495

10/0

CLEAR

NTSC/PAL

SKIP/SEARCH

SOUND LAST MEMORY

PREV.

NEXT

PLAY/PAUSE

STOP

RETURNSELECT

POWER

ON/STANDBY

OPEN/CLOSE

PROGRAM

162738495

10/0

CLEAR

NTSC/PAL

SKIP/SEARCH

SOUND LAST MEMORY

PREV.

NEXT

PLAY/PAUSE

STOP

ONCE MORE REPEAT

KARAOKE

STANDARD

SURROUND

SELECTOR

VOLUMECONTROLMIC 1VOLUME

LOW KEY CONTROL HIGH

SCORE/

AUTO PAUSE

VOICE

CANCEL

VOICE

CHANGE

DIGITAL ECHO

PHONES

MIN MAX

MIN MAXMIN MAX

MIC 2

RETURNSELECT

•

Samsung Electronics Co., Ltd. Dec. 1996. Printed in Korea. AH68-20143A

Samsung Electronics

1-1

1. Precautions

1. Be sure that all of the built-in protective

devices are replaced.

2. When reinstalling the chassis and its

assemblies, be sure to restore all protective

devices, including control knobs and

compartment covers.

3. Make sure that there are no cabinet

openings through which people-particularly children--might insert fingers

and contact dangerous voltages. Such

openings include the spacing between the

picture tube and the cabinet mask,

excessively wide cabinet ventilation slots,

and improperly fitted back covers.

4. Design Alteration Warning:

Never alter or add to the mechanical or

electrical design of the unit. Example: Do

not add auxiliary audio or video

connectors. Such alterations might create

a safety hazard. Also, any design changes

or additions will void the manufacturer's

warranty.

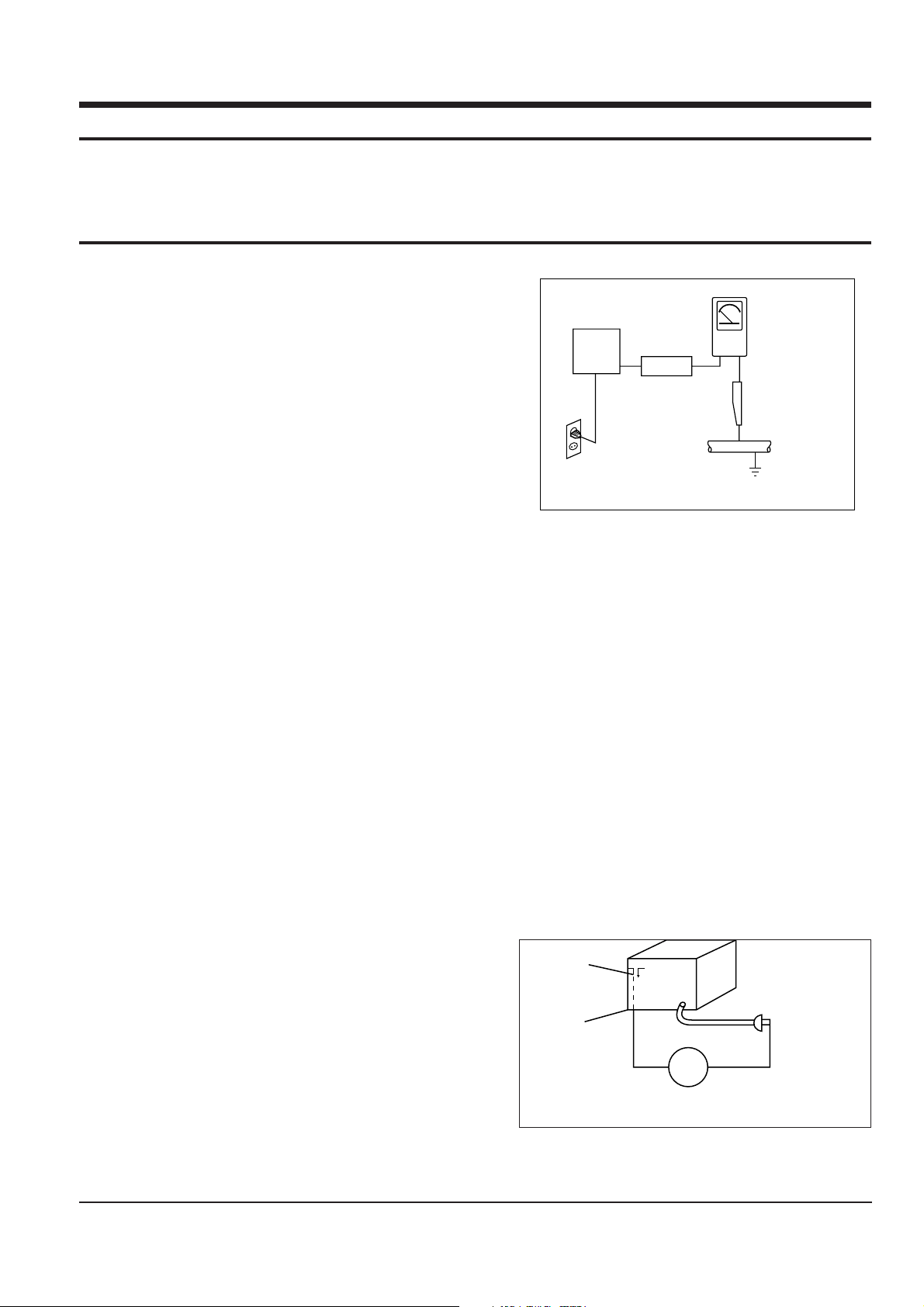

5. Leakage Current Hot Check (Figure 1-1):

Warning: Do not use an isolation

transformer during this test. Use a leakagecurrent tester or a metering system that

complies with American National Standards

Institute (ANSI C101.1,

Leakage Current for

Appliances), and Underwriters Laboratories

(UL Publication UL1410, 59.7).

With the unit completely reassembled, plug

the AC line cord directly into a 120V AC

outlet. With the unit's AC switch first in the

ON position and then OFF, measure the

current between a known earth ground

(metal water pipe, etc.) and all exposed

metal parts. Examples: Handle brackets,

metal cabinets, screwheads and control

shafts. The current measured should not

exceed 0.5 milliamp. Reverse the powerplug prongs in the AC outlet and repeat.

6. Insulation Resistance Cold Check:

(1) With the unit's AC plug disconnected

from the AC source, connect an electrical

jumper across the two AC prongs. (2) Set

the power switch to ON. (3) Measure the

resistance between the shorted AC plug and

any exposed metallic parts. Example:

Screwheads, antenna, control shafts or

handle brackets.

If any of the exposed metallic parts has a

return path to the chassis, the measured

resistance should be between 1 and 5.2

megohms. If there is no return path, the

measured resistance should be "infinite." If

the resistance is outside these limits, a shock

hazard might exist. See Figure 1-2

1-1 Safety Precautions

Follow these safety, servicing and ESD precautions to prevent damage and protect against potential hazards

such as electrical shock and X-rays.

Device

Under

Test

(Reading should

not be above

0.5mA)

Leakage

Currant

Tester

Earth

Ground

Test all

exposed metal

surfaces

Also test with

plug reversed

(using AC adapter

plug as required)

2-Wire Cord

Fig. 1-1 AC Leakage Test

Antenna

Terminal

Exposed

Metal Part

ohm

Ohmmeter

Fig. 1-2 Insulation Resistance Test

Samsung Electronics

1-2

1-1 Safety Precautions (Continued)

9. Product Safety Notice:

Some electrical and mechanical parts

have special safety-related characteristics

which might not be obvious from visual

inspection. These safety features and the

protection they give might be lost if the

replacement component differs from the

original--even if the replacement is rated

for higher voltage, wattage, etc.

10. Components that are critical for safety are

indicated in the circuit diagram by

shading, or . Use replacement

components that have the same ratings,

especially for flame resistance and

dielectric strength specifications. A

replacement part that does not have the

same safety characteristics as the original

might create shock, fire or other hazards.

7. Components, parts and wiring that appear

to have overheated or that are otherwise

damaged should be replaced with parts

that meet the original specifications.

Always determine the cause of damage or

overheating, and correct any potential

hazards.

8. Observe the original lead dress, especially

near the following areas: Antenna

wiring, sharp edges, and especially the

AC and high voltage power supplies.

Always inspect for pinched, out-of-place,

or frayed wiring. Do not change the

spacing between components and the

printed circuit board. Check the AC

power cord for damage. Make sure that

no wires or components touch thermally

hot parts.

5. Check the insulation between the blades of

the AC plug and accessible conductive parts

(examples: metal panels, input terminals

and earphone jacks).

6. Insulation Checking Procedure: Disconnect

the power cord from the AC source and

turn the power switch ON. Connect an

insulation resistance meter (500V) to the

blades of the AC plug.

The insulation resistance between each

blade of the AC plug and accessible

conductive parts (see above) should be

greater than 1 megohm.

7. Never defeat any of the B+ voltage

interlocks. Do not apply AC power to the

unit (or any of its assemblies) unless all

solid-state heat sinks are correctly installed.

8. Always connect a test instrument's ground

lead to the instrument chassis ground

before connecting the positive lead; always

remove the instrument's ground lead last.

Warning1: First read the "Safety Precautions" section of this manual. If some unforeseen circumstance creates a conflict

between the servicing and safety precautions, always follow the safety precautions.

1-2 Servicing Precautions

1. Servicing precautions are printed on the

cabinet. Follow them.

2. Always unplug the unit's AC power cord

from the AC power source before

attempting to: (a) Remove or reinstall any

component or assembly, (b) Disconnect an

electrical plug or connector, (c) Connect a

test component in parallel with an

electrolytic capacitor.

3. Some components are raised above the

printed circuit board for safety. An

insulation tube or tape is sometimes used.

The internal wiring may be clamped to

prevent contact with thermally hot

components. Reinstall all such elements to

their original position.

4. After servicing, always check that the

screws, components and wiring have been

correctly reinstalled. Make sure that the

portion around the serviced part has not

been damaged.

Precautions

Samsung Electronics

1-3

1-3 Precautions for Electrostatically Sensitive Devices (ESDs)

1. Some semiconductor ("solid state") devices

are easily damaged by static electricity.

Such components are called Electrostatically

Sensitive Devices (ESDs. Examples include

integrated circuits and some field-effect

transistors. The following techniques will

reduce the occurrence of component

damage caused by static electricity.

2. Immediately before handling any

semiconductor components or assemblies,

drain the electrostatic charge from your

body by touching a known earth ground.

Alternatively, wear a discharging

wrist-strap device. (Be sure to remove it

prior to applying power--this is an electric

shock precaution.)

3. After removing an ESD-equipped assembly,

place it on a conductive surface such as

aluminum foil to prevent accumulation of

electrostatic charge.

4. Do not use freon-propelled chemicals.

These can generate electrical charges that

damage ESDs.

5. Use only a grounded-tip soldering iron

when soldering or unsoldering ESDs.

6. Use only an anti-static solder removal

device. Many solder removal devices are

not rated as "anti-static" (these can

accumulate sufficient electrical charge to

damage ESDs).

7. Do not remove a replacement ESD from its

protective package until you are ready to

install it. Most replacement ESDs are

packaged with leads that are electrically

shorted together by conductive foam,

aluminum foil or other conductive

materials.

8. Immediately before removing the protective

material from the leads of a replacement

ESD, touch the protective material to the

chassis or circuit assembly into which the

device will be installed.

9. Minimize body motions when handling

unpackaged replacement ESDs. Motions

such as brushing clothes together, or lifting

a foot from a carpeted floor can generate

enough static electricity to damage an ESD.

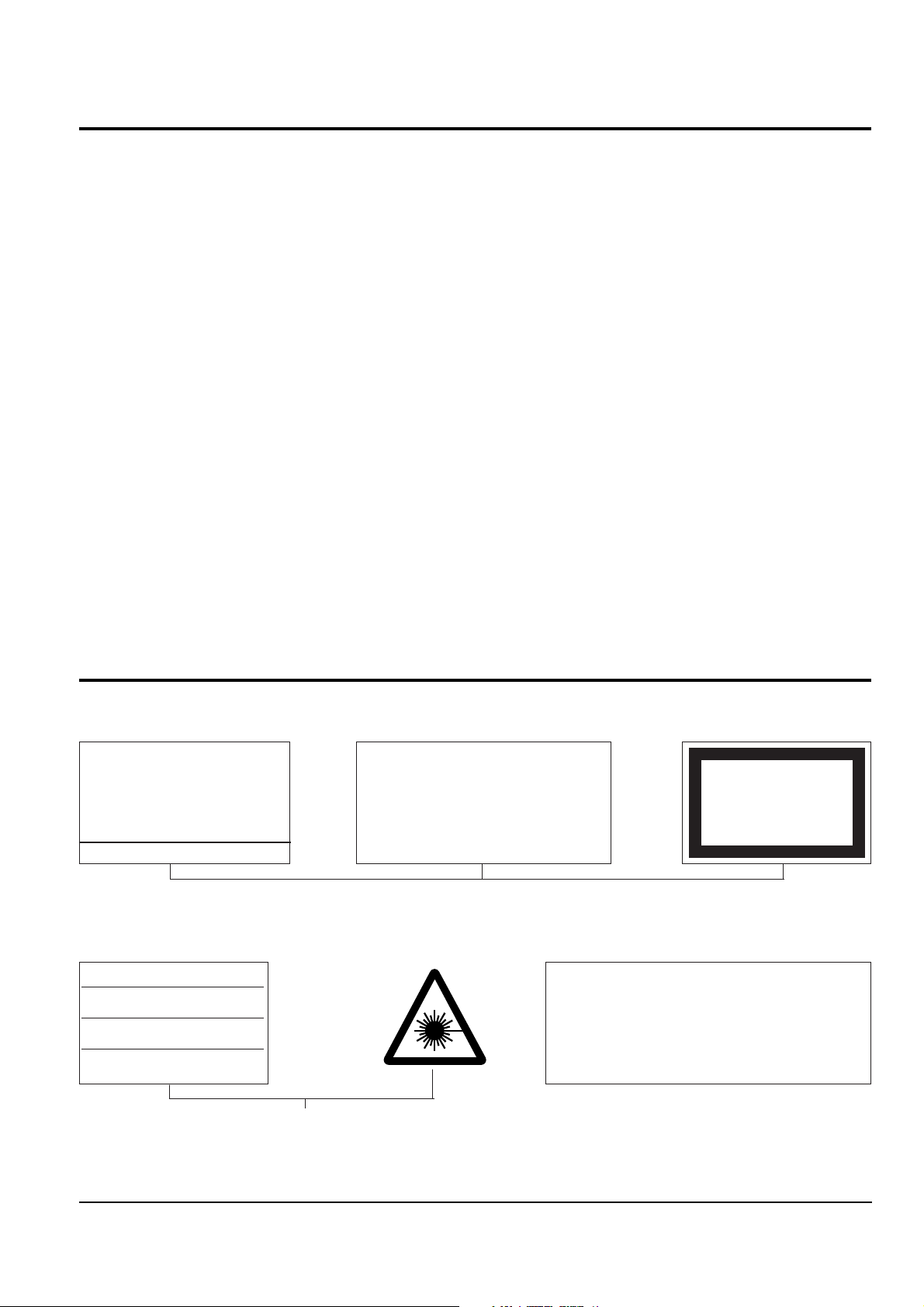

1-4 Special Precautions and Warning Labels for Laser Products

This Product Complies with

DHHS Rules 21CFR, Sub

chapter J.At date of Manufacture

CERTIFIED ONLY TO CANADIAN

ELECTRICAL CODE.

CERTIFIE EN VERTU DU CODE

CANADIAN DE LELETRICITE

SEULEMENT

CAUTION : INVISIBLE LASER RADIATION WHEN OPEN

AND INTERLOCKS DEFEATEO AVOIDEXPOSURE TO BEAM

ADVARSEL: USYNLIG LASERSTRÅLING VED ABNING

NÅR SIKKERHEDSAFBRYDERE ER UDE AF FUNKTION

UNDGA UDSAETTELSE FOR STRALING

VARO:AVATTAESSA JA SUOJALUKITUS OHITETTAESSA

OLET ALTTINA NAKYMATTÖMALLE LASERSATEILYLLE ALA

KATSO SATEESEEN!

VARNING:OSYNLIG LASERSTRÅLNING NAR DENNA DEL

AR OPPNAD OCH SPARREN AR URKOPPLAD BETRAKTA

EJSTRÅLEN!

UL : Manufactured for U.S.A. Market.

CSA : Manufactured for Canadian Market.

EU : Manufactured for European Market.

SCAN : Manufactured for Scandinavian

Market.

(UL)

(SCAN)

(CSA)

Fig. 1-3 Warning Labels (Location: Enclosure Block)

Fig. 1-4 Warning Labels (Location: Disc Clamper, Inner Side of Unit Door or Nearby Unit Chassis )

(EU)

CLASS 1

LASER PRODUCT

(EU)

Precautions

Samsung Electronics

1-4

1-4-1 Warnings

1. When servicing, do not approach the LASER

exit with the eye too closely. In case it is

necessary to confirm LASER beam emission,

be sure to observe from a distance of more

than 30 cm from the surface of the objective

lens on the optical pick-up block.

2. Do not attempt to handle the objective lens

when the DISC is not on the tray.

3. When servicing, do not approach the LASER

exit with the eye too closely. In case it is

necessary to confirm LASER beam emission,

be sure to observe from a distance of more

than 30 cm from the surface of the objective

lens on the optical pick-up block.

4. Do not attempt to handle the objective lens

when the DISC is not on the tray.

1-4-2 Laser Diode Specifications

Material: GaAs+ GaAlAs

Wavelength: 760-800 nm

Emission Duration: Continuous

Laser Output: 0.2 mw (measured at a

1.6 mm distance from the objective lens

surface on the optical pick-up block.)

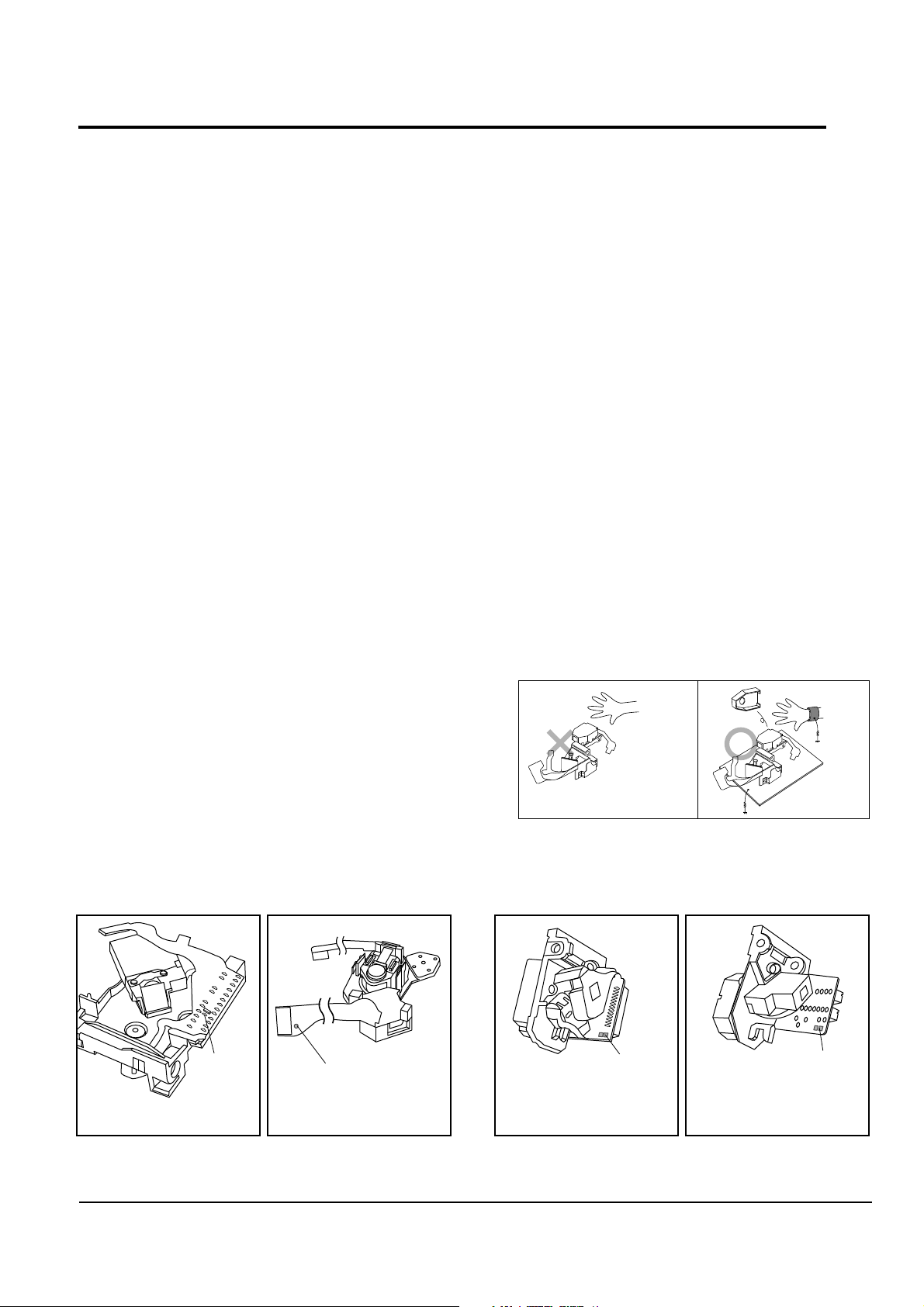

1-4-3 Handling the Optical Pick-up

1. Static electricity from clothing or the body

may cause electrostatic breakdown of the

laser diode in the Optical Pickup. Follow

this procedure:

2. Place a conductive sheet on the work bench

(i.e., the black sheet used for wrapping

repair parts.) Note: The surface of the work

bench should be covered by a copper

ground plane, which is grounded.

3. The repair technician must wear a wrist

strap which is grounded to the copper sheet.

4. To remove the Optical Pickup block:

Place the set on the conductive sheet, and

momentarily touch the conductive sheet

with both hands. (While working, do not

allow any electrostatic sources--such as

clothes--to touch the unit.

5. Ground the "Short Terminal" (located on the

PCB, inside the Pickup Assembly) before

replacing the Pickup. This terminal should

be shorted whenever the Pickup Assembly

is lifted or moved.

6. After replacing the Pickup, reopen the Short

Terminal. See diagrams below:

1-4 Special Precautions and Warning Labels for Laser Products (Continued)

THE UNIT

(1) WRIST-STRAP

FOR GROUNDING

Precautions

short

terminal

SOH91VI(LDP)

SOH91CI(CAR,walkman)

short terminal

1M

CONDUCTIVE SHEET

short

terminal

short

terminal

SOH-A1

(CMS-V10,CMS-V30)

1M

SOH94T4N

(CMS-V10,CMS-V30)

Samsung Electronics

2-1

2. Specifications and Comparision Charts

General • Power consumption : 33W

• Weight: 6.8kg

• Dimensions: 420(W)x388(D)x133.5(H) mm

• Operating temperature: +5°C~35°C (41°F~95°F)

Disc Compact Discs (CD) • Diameter: 5", 3"

• Thickness: 1.2mm

• Rotation direction (pick up side): counter clock wise

• Maximum playing time

– 5" disc: 74 min.

– 3" disc: 20 min.

VIDEO-CD (1.1 & 2.0 Version) • Diameter: 5"

• Thickness: 1.2mm

• Rotation direction (pick up side): counter clock wise

Video Characteristics • SIGNAL: NTSC/PAL/QUASI-PAL

• Video output

– Level: 1Vp-p normal, sync, negative, terminated.

– Impedance: 75Ω unbalanced

– Jack: RCA jack

AUDIO Characteristics • Output level

– During digital audio output: 200mVrms (1KHz, –20dB)

• Number of channels: 2

• Output jack: RCA jack

• Digital audio characteristics

Frequency response 20Hz~20KHz

S/N ratio 95dB

Dynamic range 90dB

Channel Separation 75dB

Total harmonic distortion 0.03% (at 1KHz - 0dB)

• AC3 output level : 0.5 Vp-p

(Designs and specifications are subject to change without notice.)

2-1 Specification

Samsung Electronics

2-2

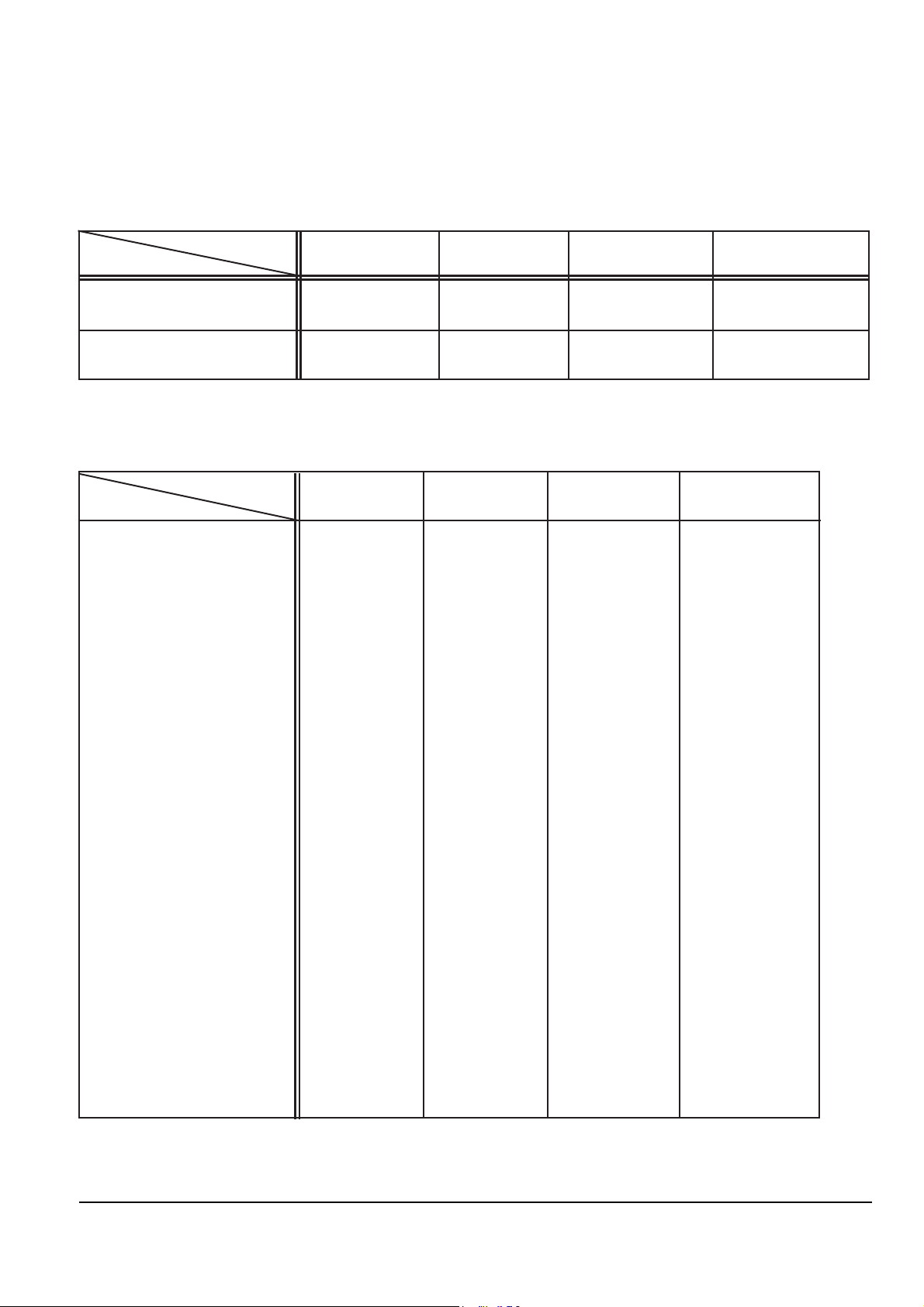

2-2 Comparision Charts

Specifications and Comparision Charts

MODEL DV7720KV DV4720V DV7700KV DV4700V

BLOCK

Karaoke use No use use No use

Tray 2CD 2CD 1CD 1CD

MODEL DV7720KV DV4720V DV7700KV DV4700V

BUTTON

Once more use no use use no use

Repeat use no use use no use

Karaoke/standard use no use use no use

Surround Selector use no use use no use

Score/Auto pause use no use use no use

Voice cancel use no use use no use

Voice change use no use use no use

Key control use no use use no use

MIC 1,2 volume use no use use no use

Digital Echo Volume use no use use no use

Head Phone Jack use no use use no use

MIC 1,2 Jack use no use use no use

Key Control Jack use no use use no use

Samsung Electronics

2-3

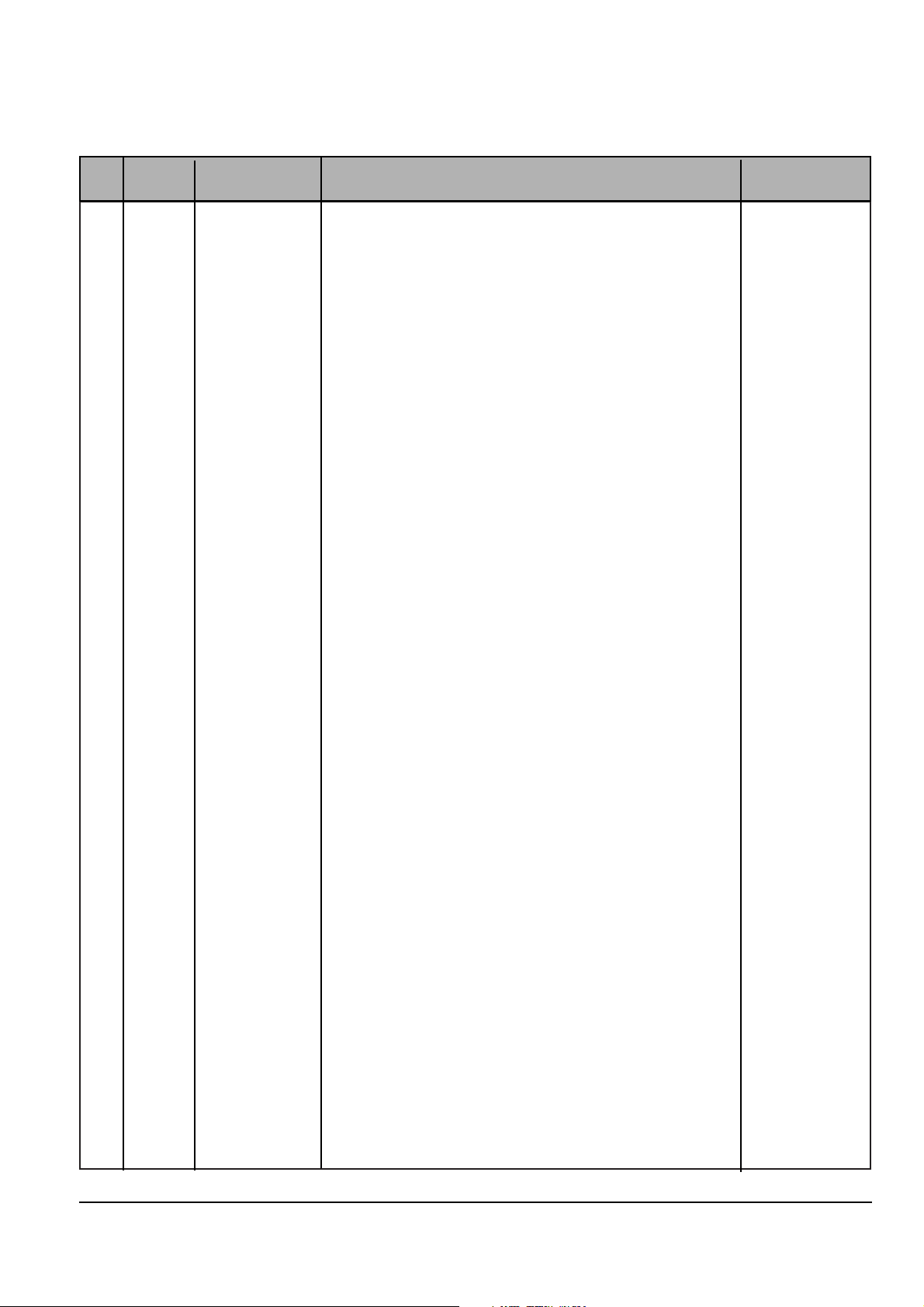

2-2-3 FMV specification ( PIN DESCRIPTION of CL680 MICOM)

Specifications and Comparision Charts

1 - NC NO CONNECTION 2 I /HINT CL680 INTERRUPT O

3 I MLATCH MAIN-TO-FMV MICOM COMMUCATION LATCH 4 - NC NO CONNECTION 5 O HSEL HOST ADDRESS/DATA SELECT 6 O HD-IN HOST SERIAL DATA OUTPUT 7 O HCK HOST CLOCK 8 I HRDY HOST DATA READY O

9 I HD-OUT HOST SERIAL DATA INPUT O

10 - NC NO CONNECTION 11 - NC NO CONNECTION 12 - NC NO CONNECTION 13 - NC NO CONNECTION 14 - NC NO CONNECTION 15 O AC3_CTL “AC3 CONTROL ( L:AC3 , H:MUTE)” 16 I SC SCORE TEST -> LOW:TEST MODE O

17 O LD “LD AUDIO CONTROL ( LD:H , CD,VCD:L )” 18 - NC NO CONNECTION 19 - NC NO CONNECTION 20 - NC NO CONNECTION 21 - NC NO CONNECTION 22 O MICMUTE MIC MUTE CONTROL -> LOW:MUTING 23 - VSS GROUND 24 - VDD VDD 25 - NC NO CONNECTION 26 - NC NO CONNECTION 27 O V.INT/EXT LD OR VCD VIDEO SELECTION -> LOW:LD 28 O /RESET680 CL680 RESET 29 I M_SENSE MIC INPUT SENSE -> HIGH:INPUTTING 30 - NC NO CONNECTION 31 O /RESET PCM1715 RESET 32 O CX LD AUDIO NOISE REDUCTION -> HIGH:ON 33 O SLATCH FMV-TO-MAIN MICOM COMMUCATION LATCH 34 O SDATA FMV-TO-MAIN MICOM COMMUCATION DATA 35 O MPX MPX ON SIGNAL -> HIGH:ON 36 O 1/L LEFT AUDIO CHANNEL SELECT O

37 O 2/R RIGHT AUDIO CHANNEL SELECT O

38 O D/A LD DIGITAL/ANALOG AUDIO SELECT -> LOW:ANALOG 39 O NT/PAL NTSC/PAL VIDEO SELECT -> HIGH:PAL 40 O KAR/NOR NORMAL OR KARAOKE SELECT -> LOW:NORMAL 41 O DAC-LATCH PCM1715 LATCH 42 I MDATA MAIN-TO-FMV MICOM COMMUNICATION DATA 43 I MCLK MAIN-TO-FMV MICOM COMMUNICATION CLOCK 44 O DATA “KS5514,TC9409,PCM1715 DATA” 45 O KLATCH TC9409 LATCH 46 O CLK “KS5514,PCM1715,TC9409 CLK” 47 - NC NO CONNECTION 48 O CSB KS5514 LATCH 49 - NC NO CONNECTION 50 I /RESET-I “MICOM,OSD RESET INPUT” 51 - VDD VDD -

PIN I/O NAME MEANING PULL-UP

NO

Samsung Electronics

2-4

PIN I/O NAME MEANING PULL-UP

NO

Specifications and Comparision Charts

53 - VSS GROUND 54 I 6MHz 6M RESONATOR INPUT 55 O 6MHz 6M RESONATOR OUTPUT 56 - VDD VDD 57 - NC NO CONNECTION 58 I LDP/CDP LDP/CDP OPTION ( LDP:H ,CDP:L) 59 I KEYCON KEYCON OPTION ( 7620:H ,5620:L ) O

60 - NC NO CONNECTION 61 I 1CD/2CD 1CD/2CD OPTION ( 1CD:H ,2CD:L ) O

62 I 4620 OPT 7620,5620 :H , 4620 :L O

63 I NTSC/PAL NTSC/PAL OPTION ( NTSC:H ,PAL:L ) O

64 I MIC_I/O MIC JACK INSERT CHECK -> HIGH:INSERT O

Samsung Electronics

2-5

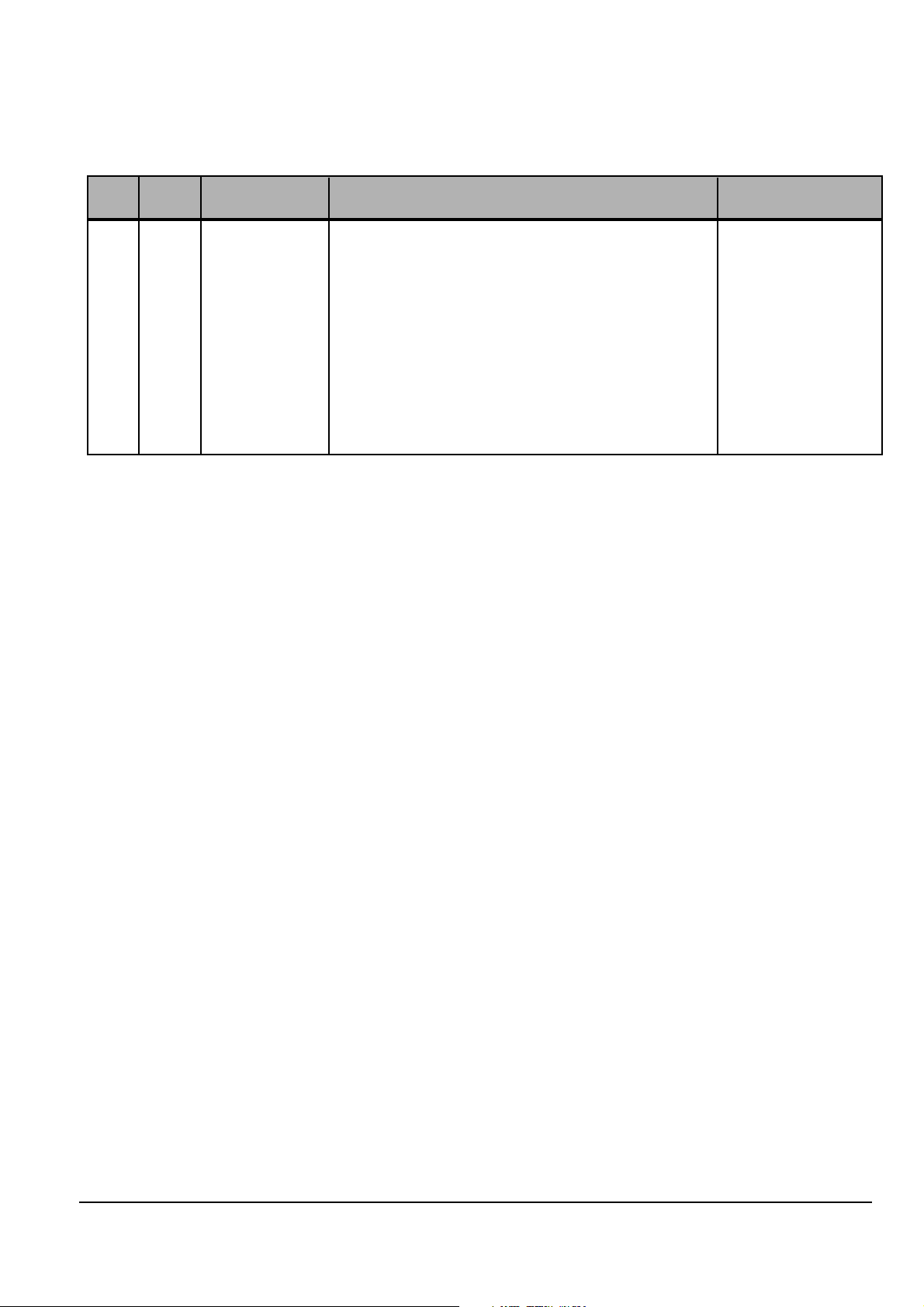

PIN PORT I/O MEANING PIN PORT I/O MEANING

NO NO NO NO

1 PORT5 O TX/RX 51 S16 O M

2 PWM $ 52 S17 O L

3 PORT2 I/O 9413 DATA0 I/O 53 S18 O P

4 PORT2 I/O 9413 DATA1 I/O 54 S19 O I

5 PORT2 I/O 9413 DATA2 I/O 55 S20 O K

6 PORT2 I/O 9413 DATA3 I/O 56 S21 O J

7 PORT2 I/O 9413 DATA4 I/O 57 S22 O H

8 PORT2 I/O 9413 DATA5 I/O 58 S23 O A

9 PORT2 I/O 9413 DATA6 I/O 59 S24 O B

10 PORT2 I/O 9413 DATA7 I/O 60 S25 O F

11 $ TEST 61 S26 O G

12 $ /RESET INPUT 62 S27 O C

13 $ XT1 63 S28 O E

14 $ XT2 64 S29 0 D

15 $ Vss1 65 S30 I KEYIN 0

16 $ CF1 66 S31 I KEYIN 1

17 $ CF2 67 PORT0 I KEYIN 2

18 $ Vdd1 68 PORT0 I CDSW

19 PORT8 I IRQ 69 PORT0 I LDSW

20 PORT8 I DVSP ACK 70 PORT0 I TRAY SW1

21 PORT8 I MODE SW3 71 PORT0 I TRAY SW2

22 PORT8 I MODE SW2 72 PORT0 I RRQ ; MLATCH

23 PORT8 I MODE SW1 73 PORT1 SO0 TXD ; MDATA

24 PORT8 I FL 74 PORT1 SI0 SUBQ

25 PORT8 I LOCK 75 PORT1 SCK0 SQCK

26 PORT8 I SENSE 76 PORT1 SO1 SDATA(SSP,DVSP,DSP,EXP.)

27 PORT7 INT VSYNC 77 PORT1 SI1 SRQ ; SUBLATCH

28 PORT7 INT SCOR 78 PORT1 SCK1 SCLK

29 PORT7 INT FG 79 PORT1 I RXD ; SUBDATA

30 PORT7 INT REMOCON 80 PORT1 I VCDCLK ; MCLK

31 S0 0 LED ; DISC1 81 PORT3 O MOTOR32 S1 O LED ; DISC2 82 PORT3 O MOTOR+

33 S2 O LED ; SHOWER LIGHTING 83 PORT3 O POWER ON

34 S3 O LED ; KARAOKE/STANDARD 84 PORT3 O MIC MUTE

35 S4 O LED ; AUTOPAUSE/SCORE 85 PORT3 O RESET OUT

36 S5 O LED ; VOICE CANCLE 86 PORT3 O SERVO LATCH

37 S6 O LED ; VOICE CHANGE 87 PORT3 O JUMP

38 S7 O GRID1 88 PORT3 O EXPANDER LATCH1

39 S8 O GRID2 89 $ Vss2

40 S9 O GRID3 90 $ Vdd2

41 S10 O GRID4 91 PORT4 O DSP LATCH

42 S11 O GRID5 92 PORT4 O DSP MUTE

43 S12 O GRID6 93 PORT4 O

44 S13 O GRID7 94 PORT4 O AUDIO FINAL MUTE(10/01)

45 S14 O GRID8 95 PORT4 O MTJ

46 S15 O GRID9 96 PORT4 O GENLOCK LATCH

47 $ VDDVPP 97 PORT4 O CLEAR SCAN

48 $ VP 98 PORT4 O SQ

49 O N 99 PORT5 O STB

50 O O 100 PORT5 O ATTN

2-2-4 Main Micom specification

Specifications and Comparision Charts

PIN N O 4(Q1) 5(Q2) 6(Q3) 7(Q4) 14(Q5) 13(Q6) 12(Q7) 11(Q8)

EXPANDER CLOSE DAC LD/CD,CDV CLV SCAN RF COR SP ON CL,CDV/CD OPEN

Samsung Electronics

2-6

KEY1(65) KEY2(66) KEY3(67)

S1,(49),N DISC1 DISC CHANGE

S2,(50),O DISC2 NTSC/PAL

S6,(54),1 SURROUND VOICE CANCEL VOICE CHANGE

S7,(55),K LAST MEMORY SOUND OPEN/CLOSE

S8,(56),J

SKIP,SEARCH, NEXT PLAY,PAUSE,SELECT STOP,RETURN

S10,(58),A 6 1 7

S11,(59),B 2 8 3

S12,(60),F KRAOKE/STANDARD SCORE

S13,(61),G REPEAT NATURAL KEY UP

S14,(62),C 5 4 9

S15,(63),E ONCE MORE KEY DOWN

S16,(64),D 10 POWER SKIP,SEARCH,BACK

2-2-5 Key Matrix

Specifications and Comparision Charts

Samsung Electronics

3-1

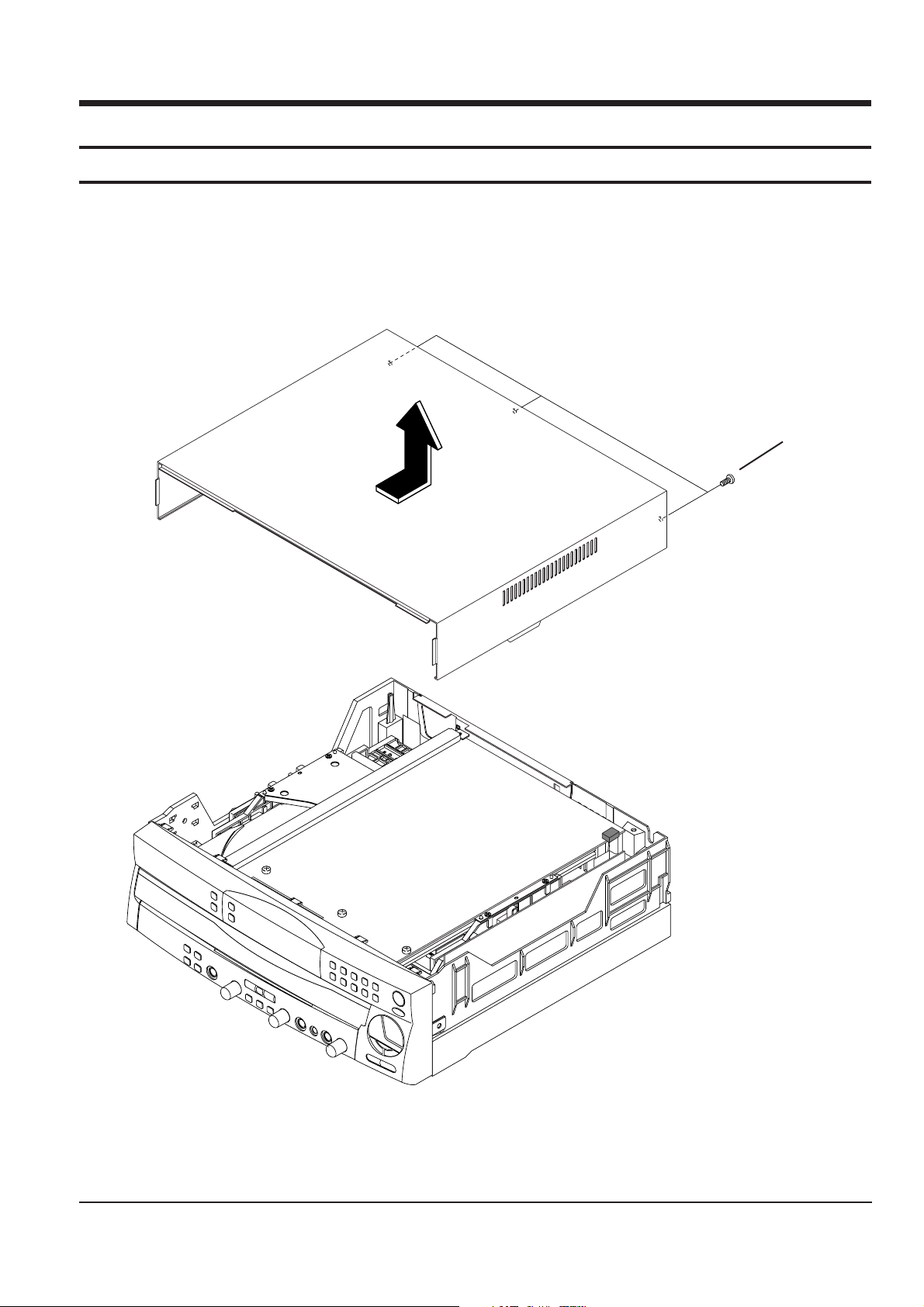

3. Disassembly

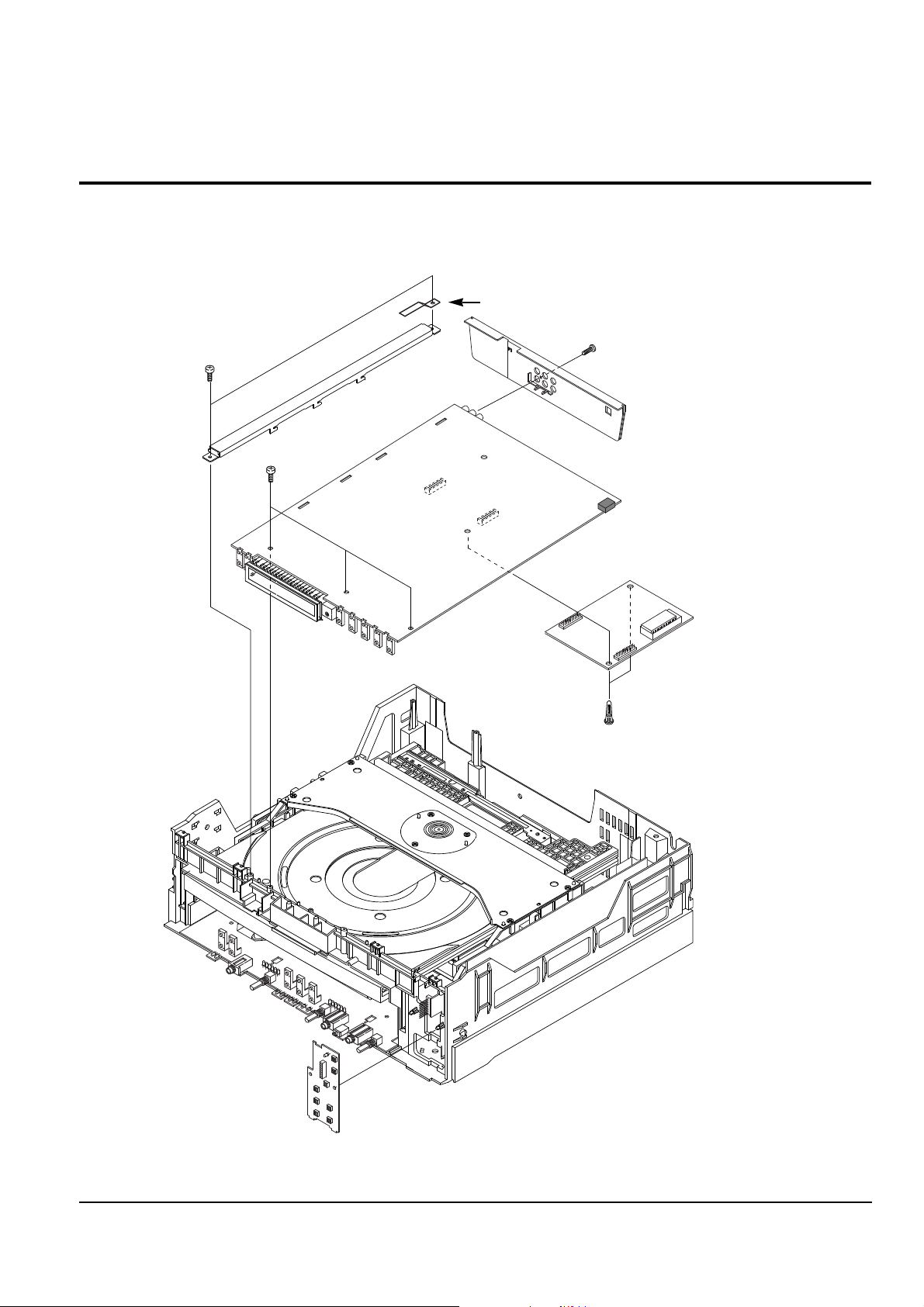

3-1 Disassembling the Top-Cabinet (Fig 1.)

1. Loosen 3 screws ! (3 x 10 black).

2. Push top 10mm backward horizontally, and separate it upward.

Figure 1.

1

!

Samsung Electronics

3-2

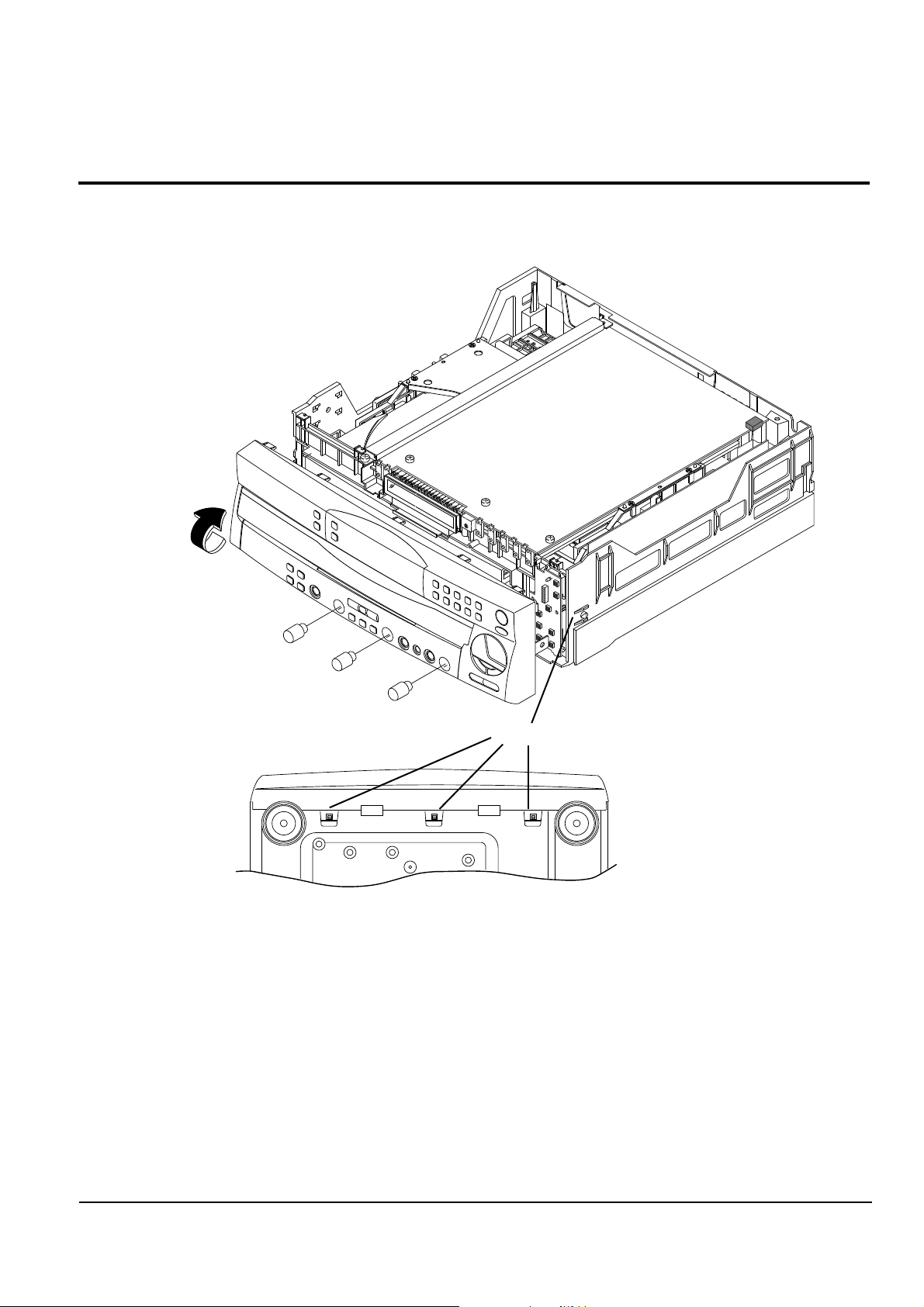

1

3-2 Disassembling the ass'y front (Fig. 2)

1. Separate ass'y front by pulling it horizontally using 3 knobs volume.

2. Loosen 5 hooks more or less(2 hooks on right and left side, and 3 hooks on the bottom)

3. Seperate ass'y front by turning it to the arrow direction.

Figure 2.

bottom view

knob volume

hook

Disassembly

3-3

1

Samsung Electronics

Figure 3.

3-3 Disassembling the Main PCB and VCD PCB (Fig-3)

1. Lossen 6 screws ( 5EA of 3 x 10 yellow, 1EA of 3 x10 black ).

2. After pull out the tray, turn the main PCB to the right side.

3. Separating flexible connected to PCB, and separate it by pulling the part connected 2EA of holder PCB.

4. Separate the BRACKET PCB and COVER REAR.

Cover Rear

Bracket PCB

Bracket PCB/G

Main PCB

Front PCB

Disassembly

Samsung Electronics

3-4

Figure 4.

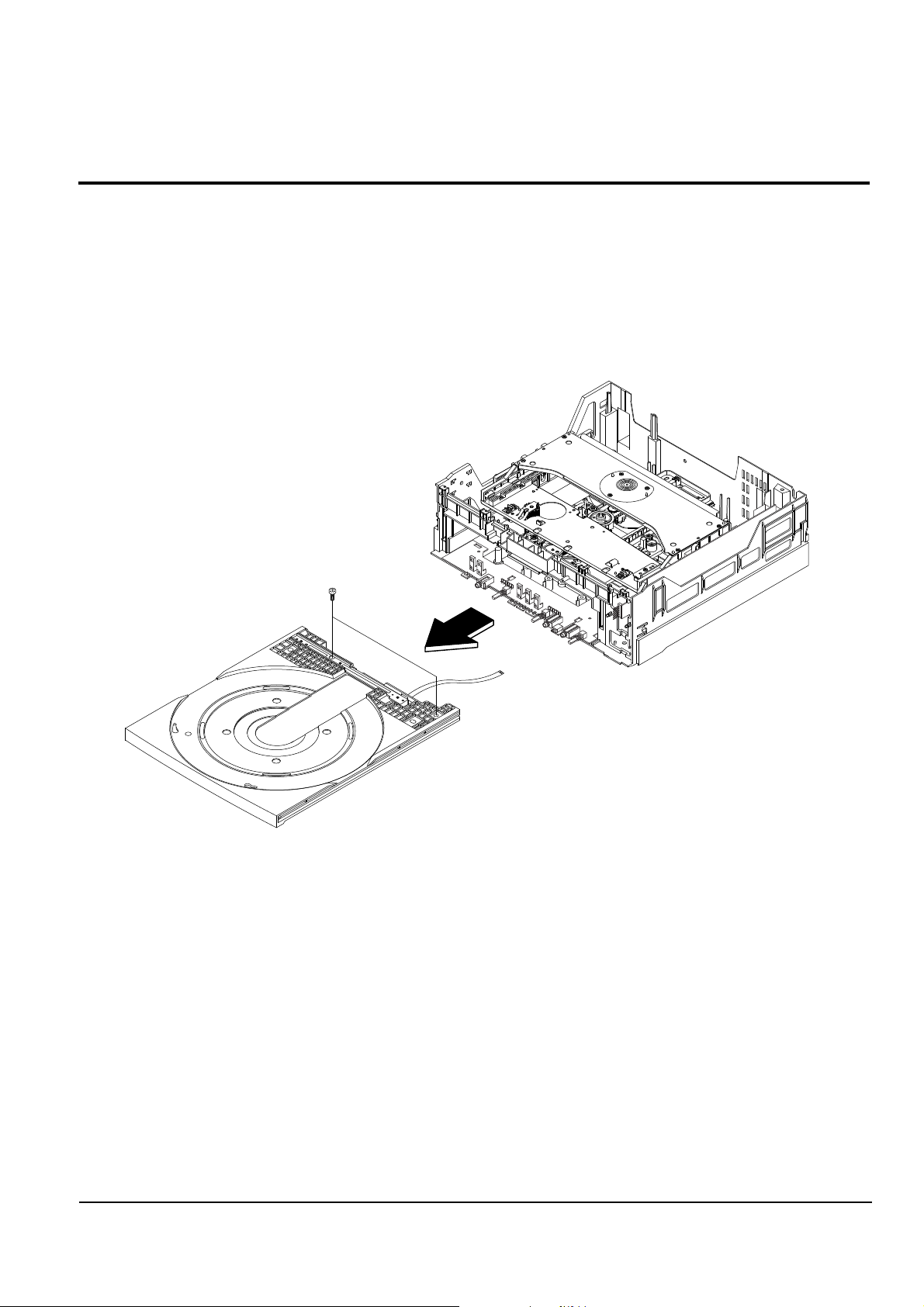

3-4 Disassembling the tray (Fig-4)

1. Lossen 2 screws (3 x 10 yellow) three turns, and fix them on the tray.

Do not separate them.

2. Pull out the try at the middle of set, and then Disconnect the flexible wire (6pin).

(Check the flexible wire connected to the set, when tray is not opened)

3. Pull out the tray to the arrow direction.

1

Tray

Flexible wire

Disassembly

Samsung Electronics

3-5

Figure 5.

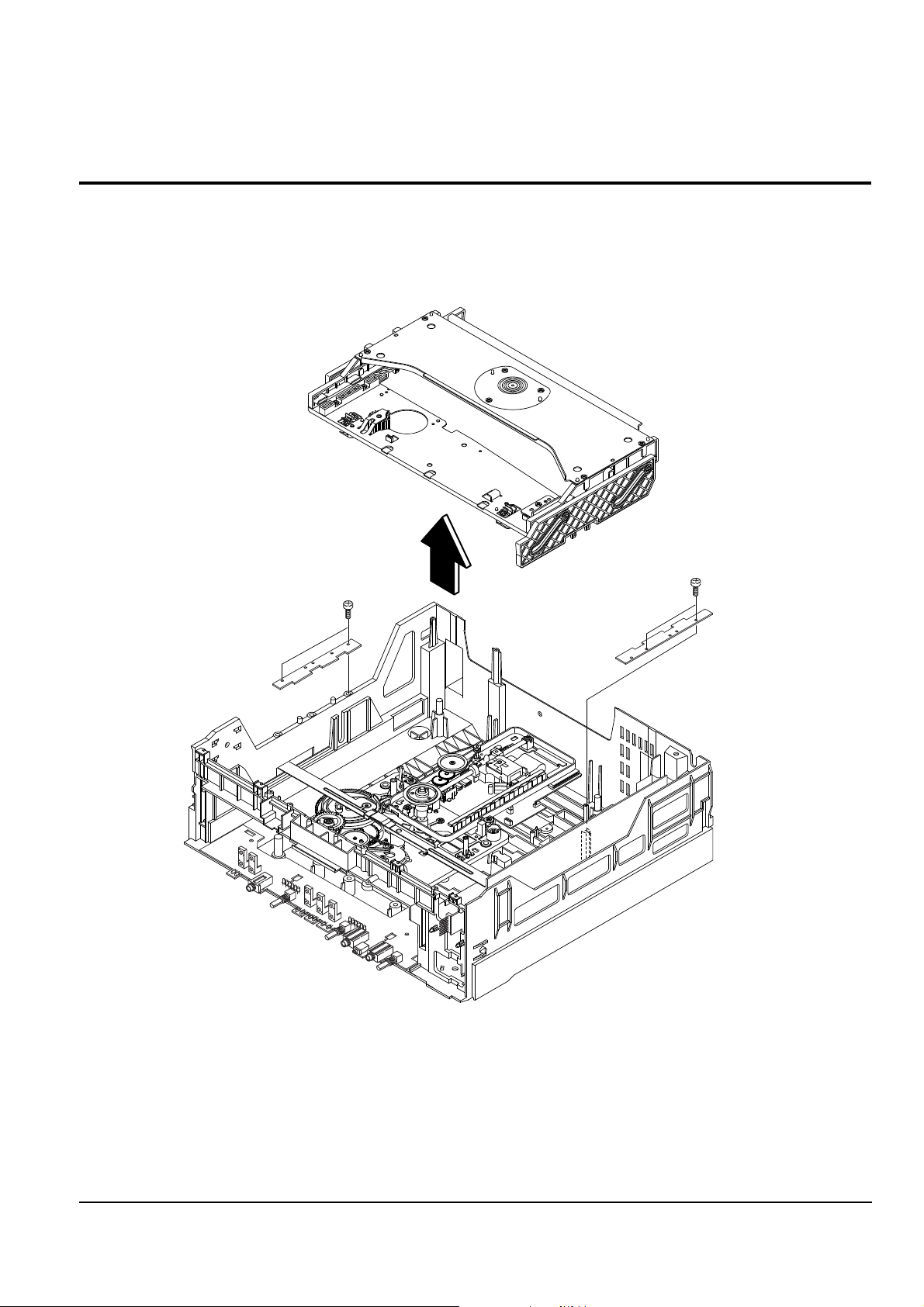

3-5 Disassembling the ass'y clamper (Fig-5)

1. Lossen 5 screws (3 x 10 yellow) , and separate 2 bracket horders.

2. Raise the ass'y clamper to the vertical direction, and separate it.

bracket holder

bracket holder

ass'y clamper

Disassembly

Samsung Electronics

3-6

Figure 6.

3-6 Disassembling the ass'y bracket lever (Fig-6)

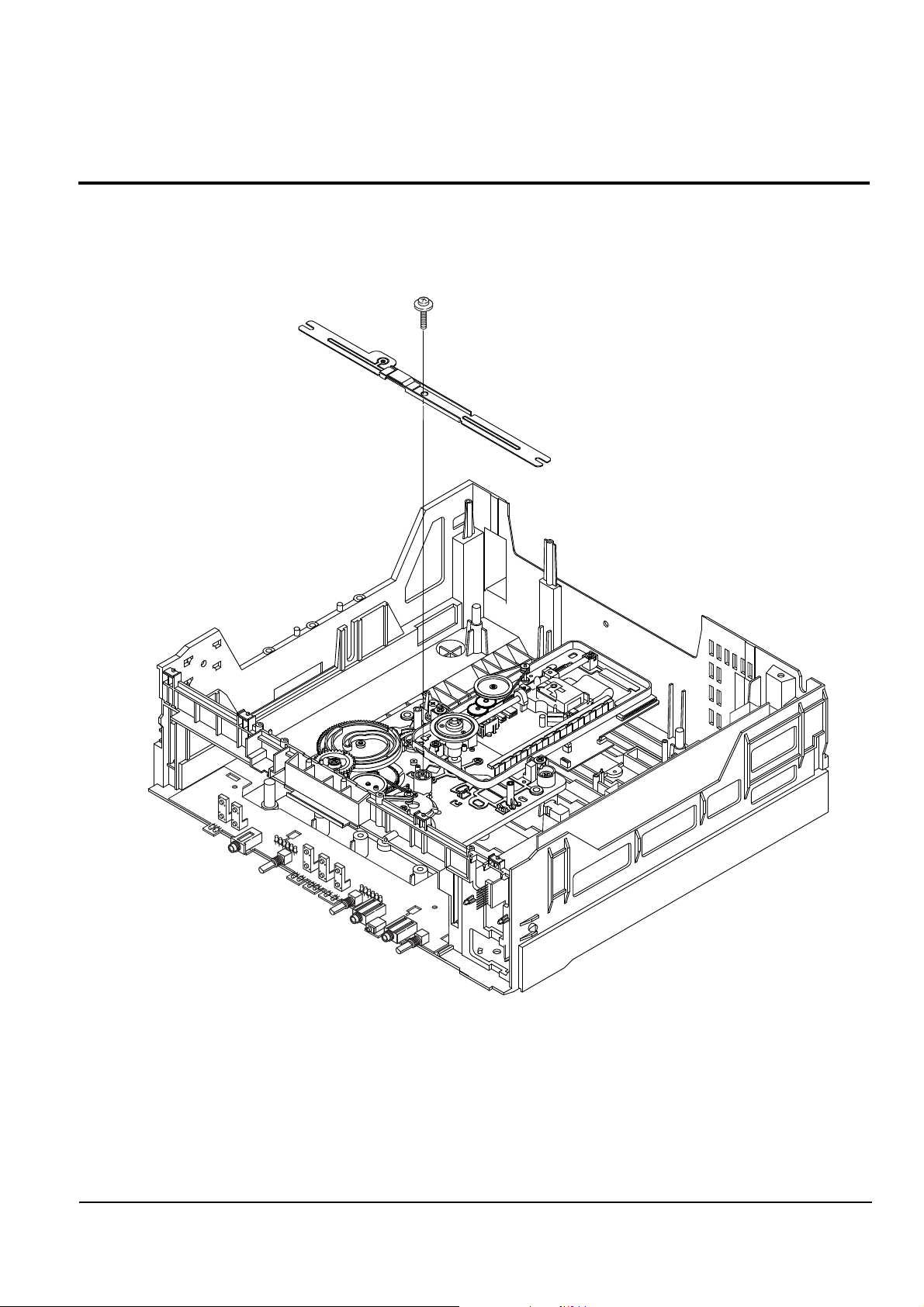

1. Lossen 1 screw (3 x 10 yellow).

2. separate the ass'y bracket lever.

bracket lever

Disassembly

Samsung Electronics

3-7

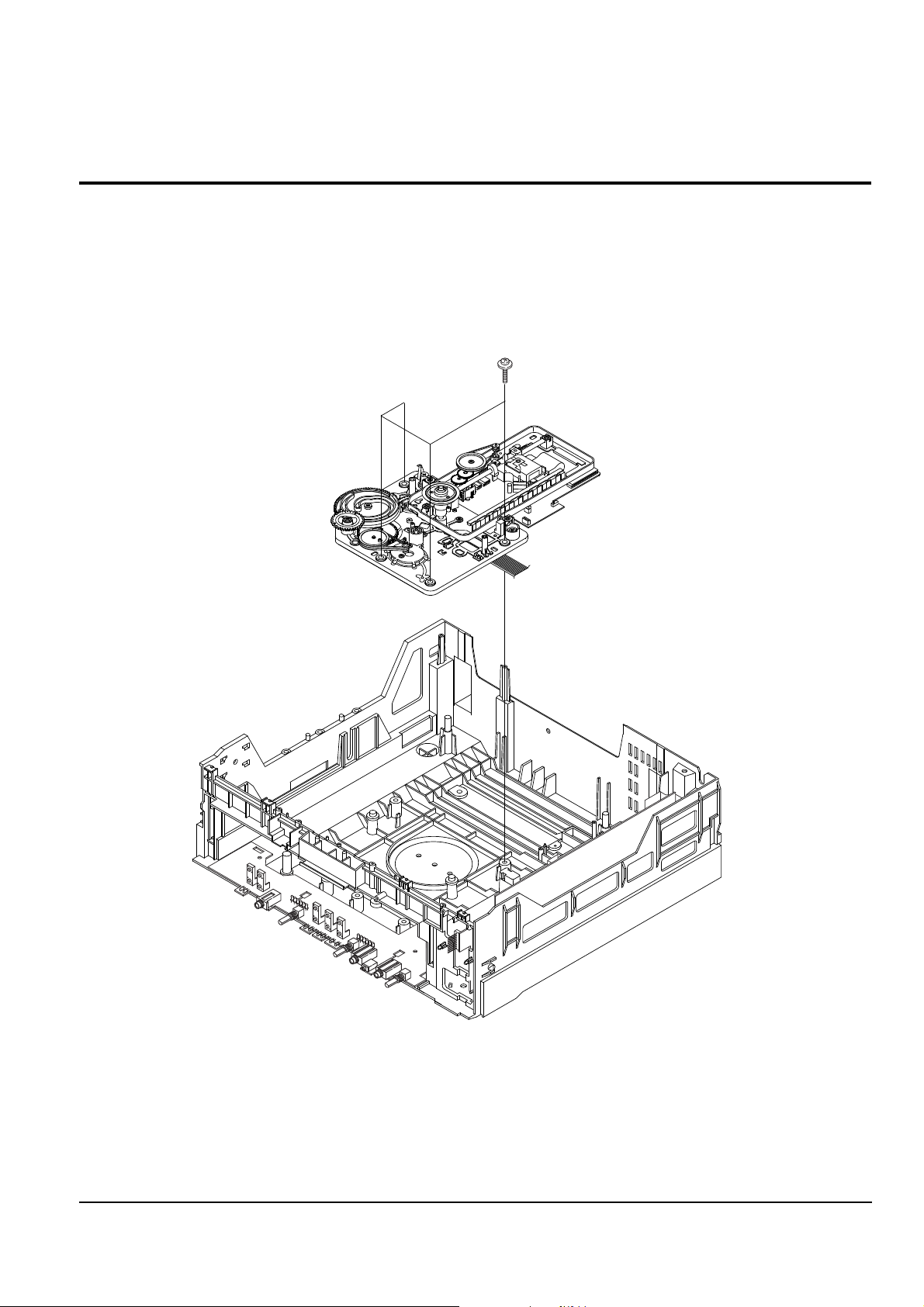

3-7. Disassembling the ass'y deck (Fig-7)

1. Lossen 4 screws (4 x 18yellow) .

2. Raise the deck to the vertical direction, and separate it.

Figure 7.

ass'y deck

Disassembly

Samsung Electronics

3-8

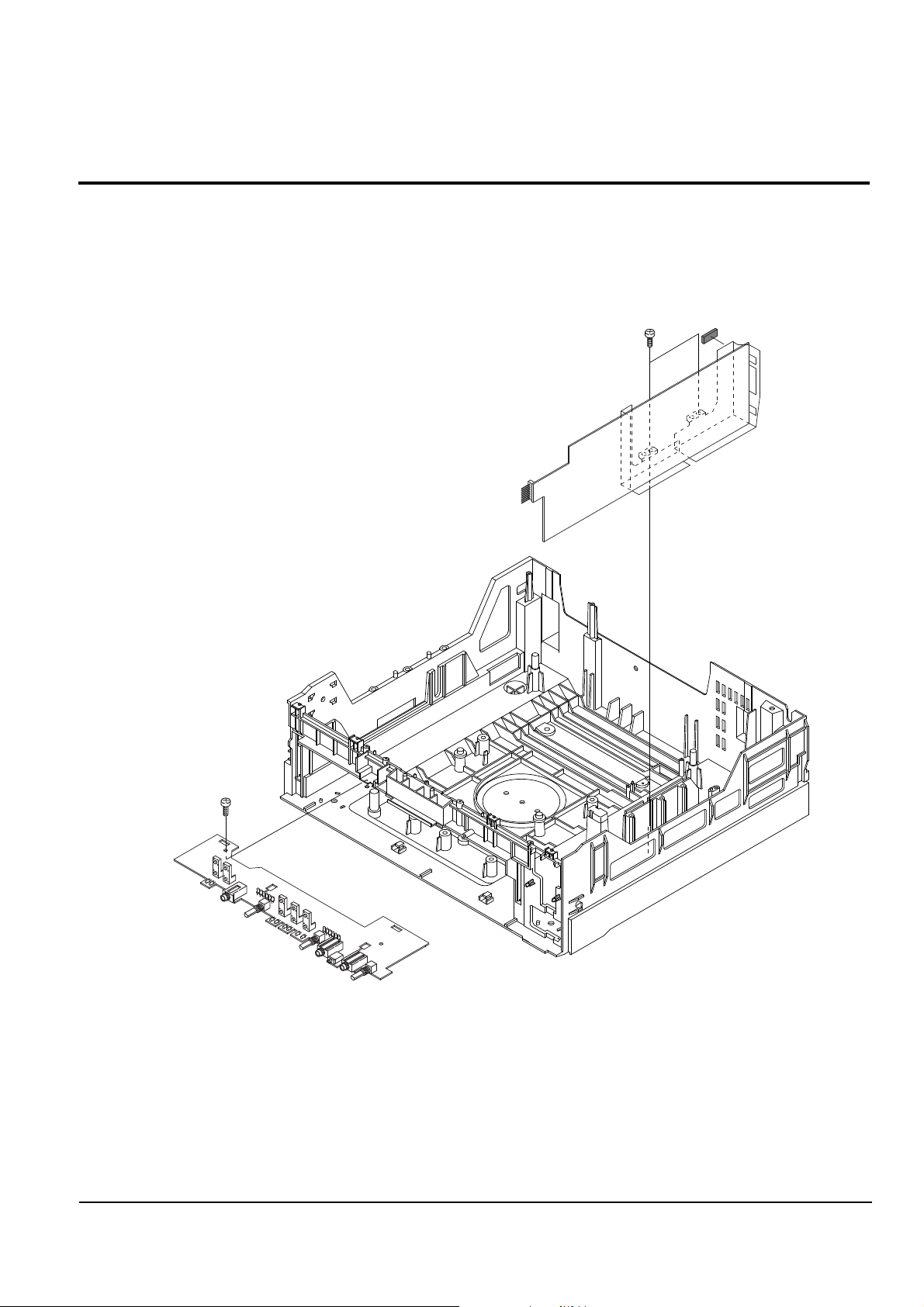

3-8. Disassembling the front PCB and power PCB (Fig-8)

1. Lossen 3 screws (3 x10 yellow).

2. Raise the power PCB to the vertical direction, and separate it.

3. Pull the front PCB 18mm forward horizontally, and raise to the vertical direction, and separate it.

Figure 8.

power PCB

front PCB

Disassembly

Samsung Electronics

5-1

5. Alignment and Adjustment

Before making adjustment

Adjustment to this unit is not required because adjustment is already

done during production procedure.

However if readjustment is required, be sure to proceed in the given.

MESUREMENT INSTRUMENT

1. OSCILLOSCOPE

2. MONITOR

3. FREQUENCY COUNTER

TEST DISC

1. LD ; STLD-¥ , STLD-¥–

2. CD ;YEDS-18, YEDS-43

ADJUSTMENT ITEM

1. REF(REFERENCE FREQUENCY) ADJUSTMENT.

2. TILT BALANCE ADJUSTMENT

3. TRACKING BALANCE ADJUSTMENT

4. LD FOCUS BALANCE ADJUSTMENT

5. CD FOCUS BALANCE ADJUSTMENT

6. RF GAIN ADJUSTMENT

7. TRACKING GAIN ADJUSTMENT

8. FOCUS GAIN ADJUSTMENT

9. VIDEO LEVEL ADJUSTMENT

10. PM ADJUSTMENT

Samsung Electronics

5-2

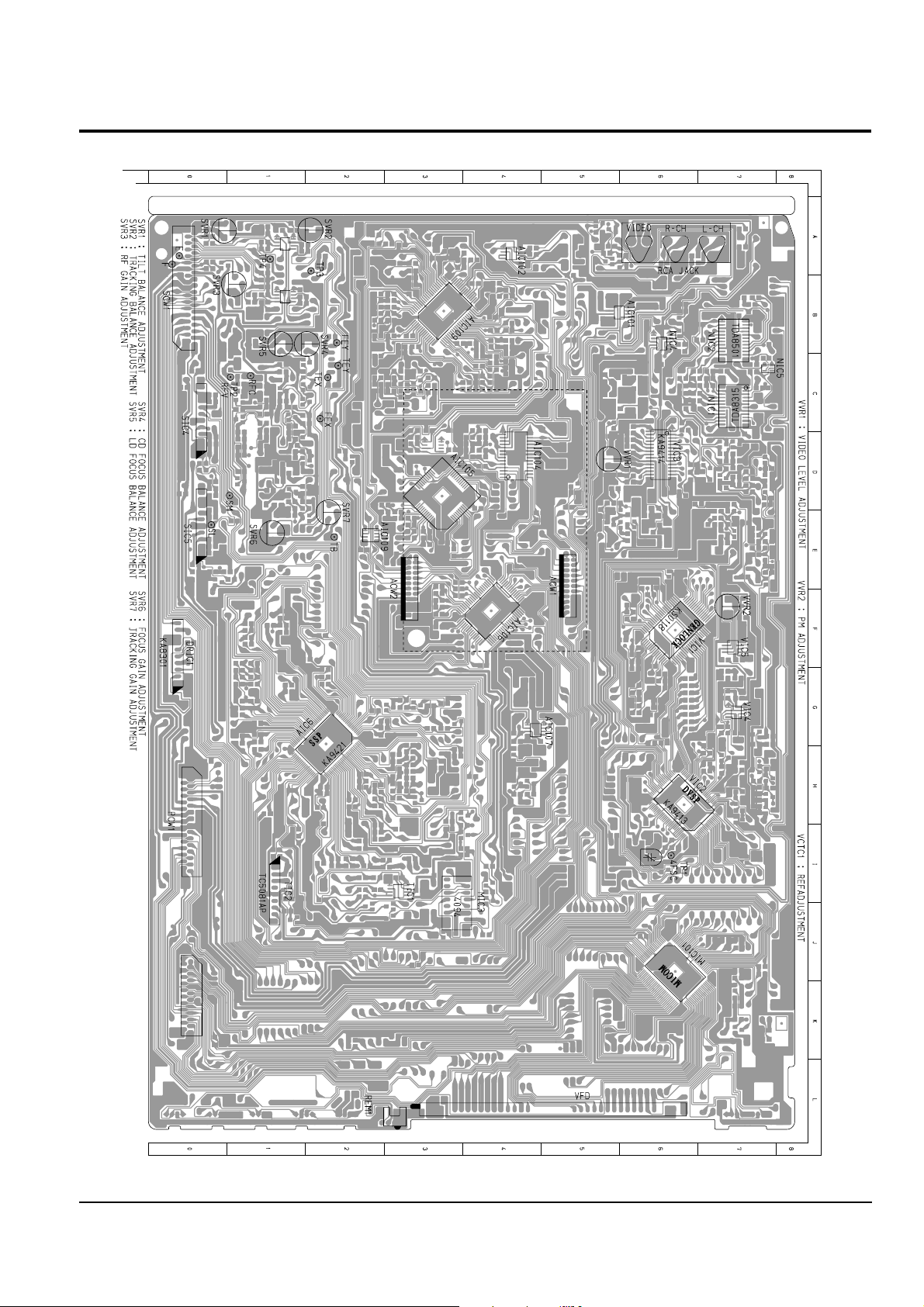

5-1 Adjustment Point Location

Alignment and Adjustment

Samsung Electronics

5-3

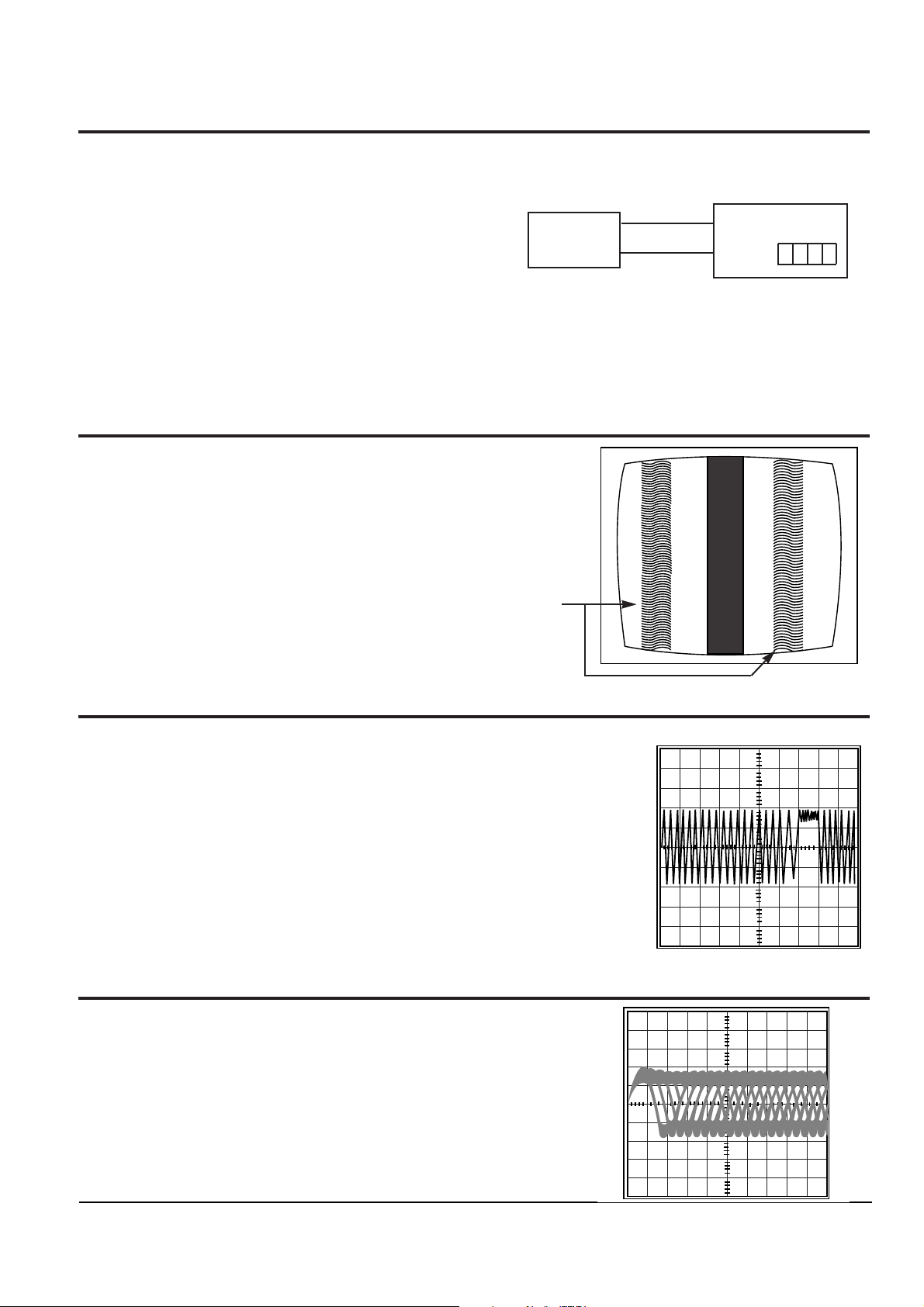

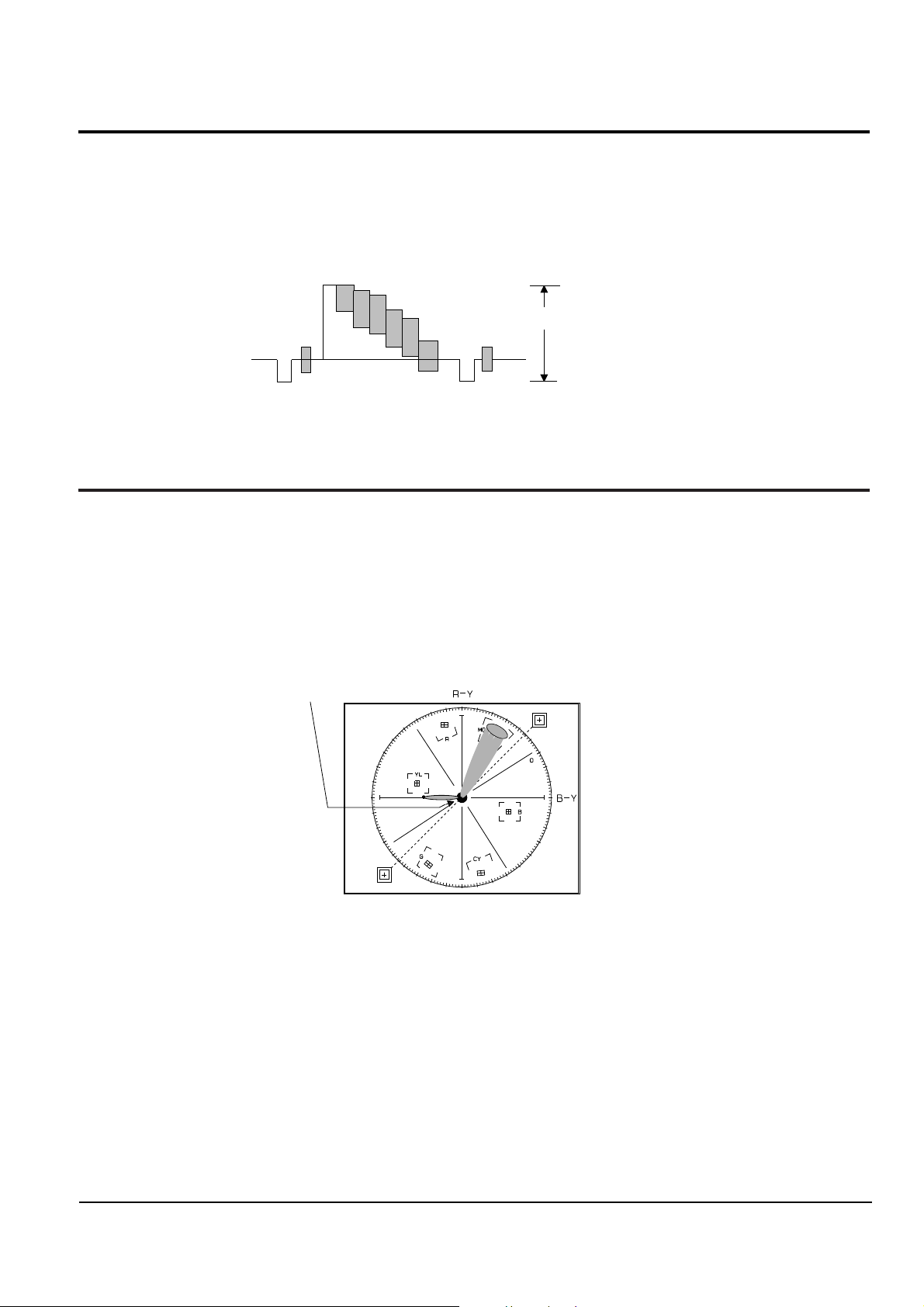

5-2 Reference Frequency Adjustment

5-3 Tilt Balance Adjustment

5-4Tracking Balance Adjustment

5-5 LD Focus Balance Adjustment

TP1(4fsc)

GND

IN

GND

1 .Turn power on and set the unit STOP mode.

2 .Adjust VCTC1 so that frequency counter reads

14.31818MHz ¡ 10Hz.

3 .Use 1:1 damping probe.

TP1(4fsc): pin2 of VIC2

1. Insert STLD -¥ , STLD -¥–LD Disc and press PLAY button.

2 .Set the vertical bar pattern at the STILL mode.

3 .Adjust SVR1 so that no cross talk noise.

1. Insert STLD-¥ , STLD-¥–LD Disc and press PLAY button.

2 .Set 1200 frame at the STILL mode.

3 .Adjust SVR2 so that the center of waveform at TB locates at 0V.

1. Insert STLD-¥ , STLD-¥–LD disc and press PLAY button.

2. Adjust SVR5 so that the waveform at TP2(RFV) is at the

maximum.

Main PCB

Counter

CROSS TALK

0V

0V

Alignment and Adjustment

Samsung Electronics

5-4

5-6 CD Focus Balance Adjustment

1. Insert YEDS-18,YEDS-43 disc and press PLAY button.

2. Adjust SVR4 so that the waveform at RFC is at the maximum.

0V

5-7 RF Gain Adjustment

1. Insert YEDS-18,YEDS-43 disc and press PLAY button.

2. Adjust SVR3 so that the waveform at RFC is 1Vp_p.

0V

1Vp-p

5-8 Tracking Gain Adjustment

1. Adjust SVR7 as shown in picture(one hour clockwise).

5-9 Focus Gain Adjustment

1. Adjust SVR6 as shown in picture(twohour clockwise).

Alignment and Adjustment

Samsung Electronics

5-5

5-10 Video Level Adjustment

1. Insert STLD-¥ , STLD-¥–LD disc and press PLAY button.

2 .Set the unit on chapter 8 at STILL mode.

3. Adjust VVR1 so that the waveform at video jack is 2Vp_p.

2Vp-p

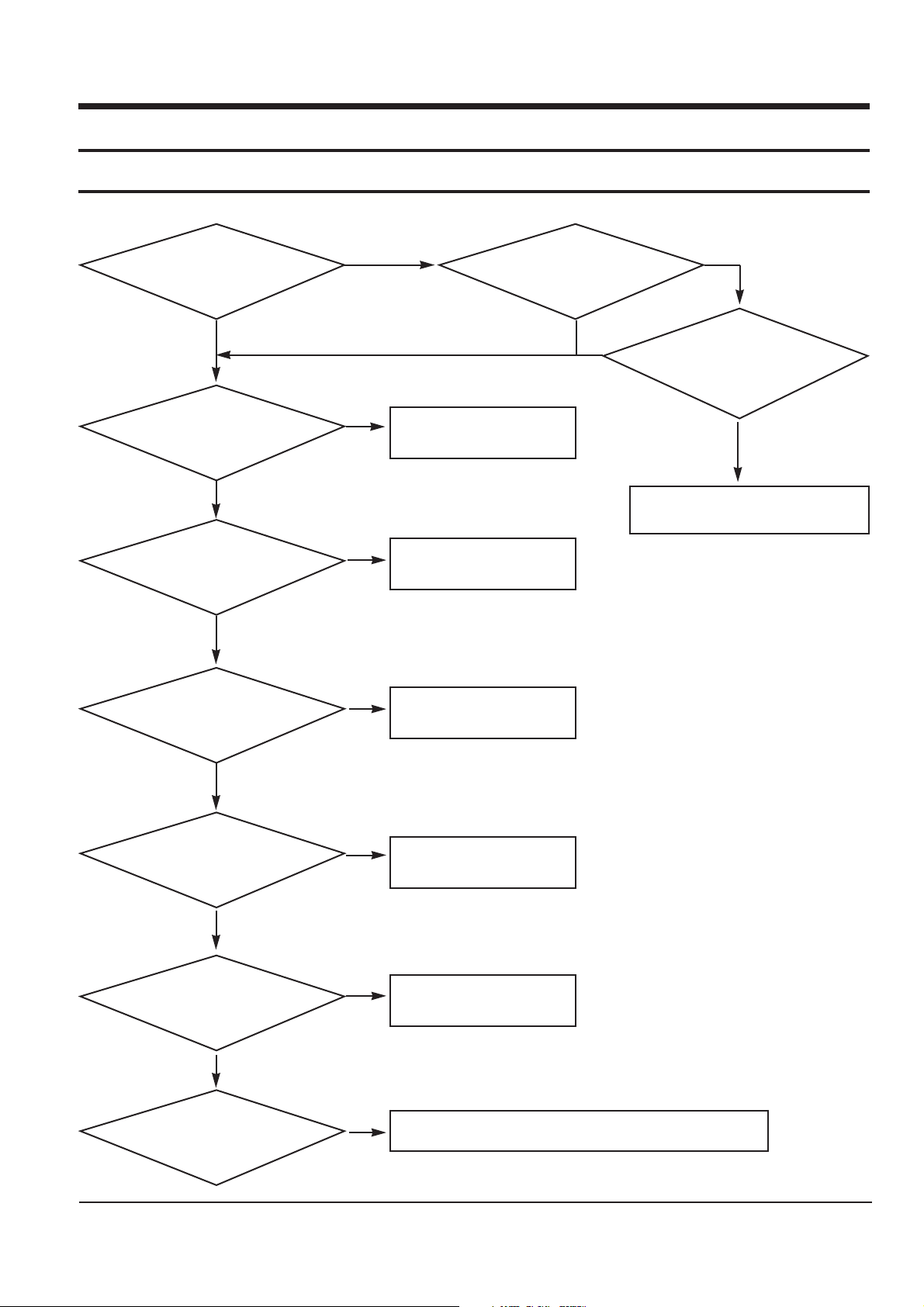

5-11 PM Adjustment

1. Insert STLD-¥ , STLD-¥–LD disc and press PLAY button.

2. Set the unit on chapter 7(STLD-¥ ), chapter 3(STLD-¥–) at STILL mode.

3. Adjust VVR2 so that the waveform of VECTORSCOPE is clear

It can be adjustable by observing pictures on screen.

Match the white luminance point with the black

luminance point

Alignment and Adjustment

Samsung Electronics

6-1

6. Troubleshooting

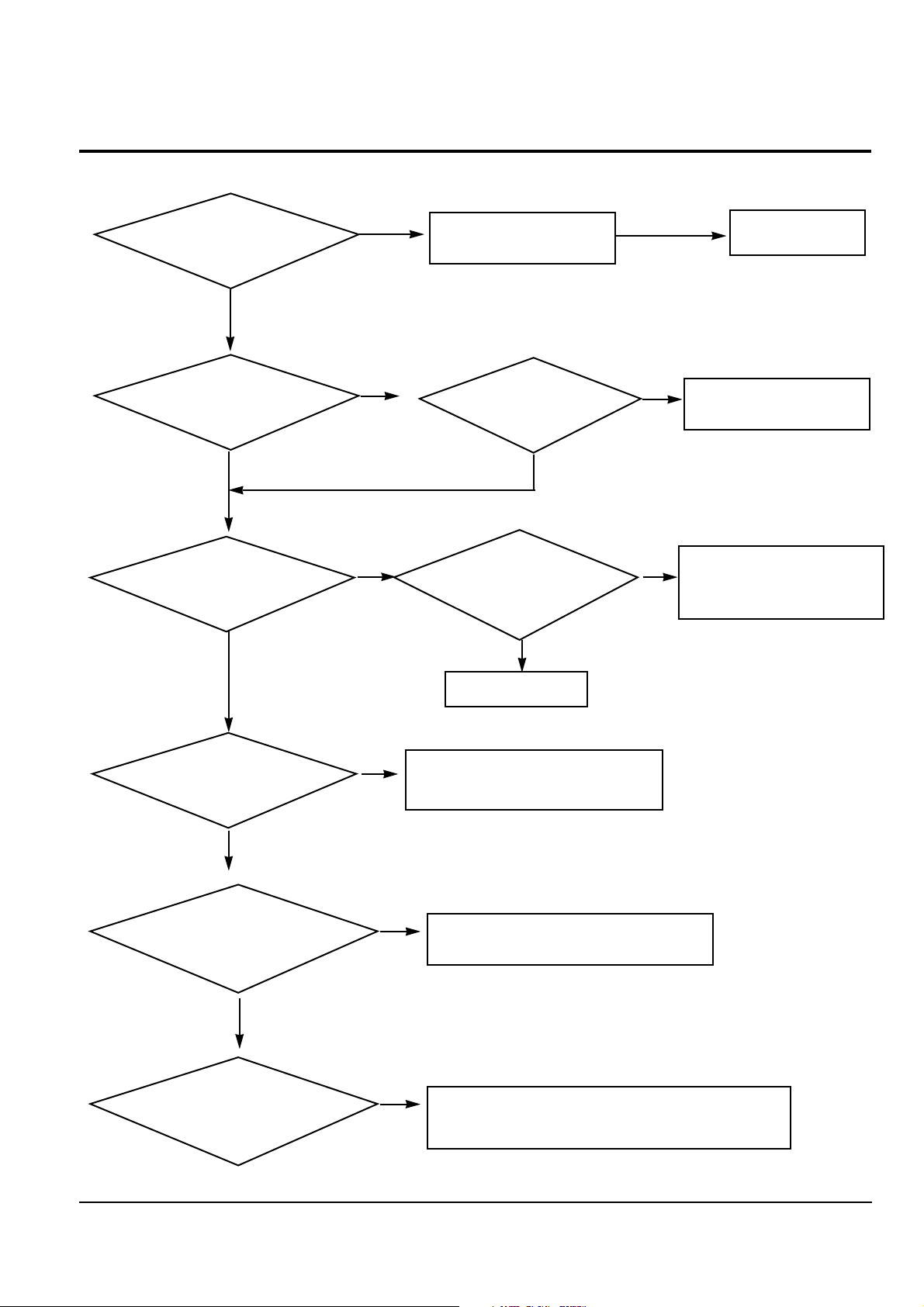

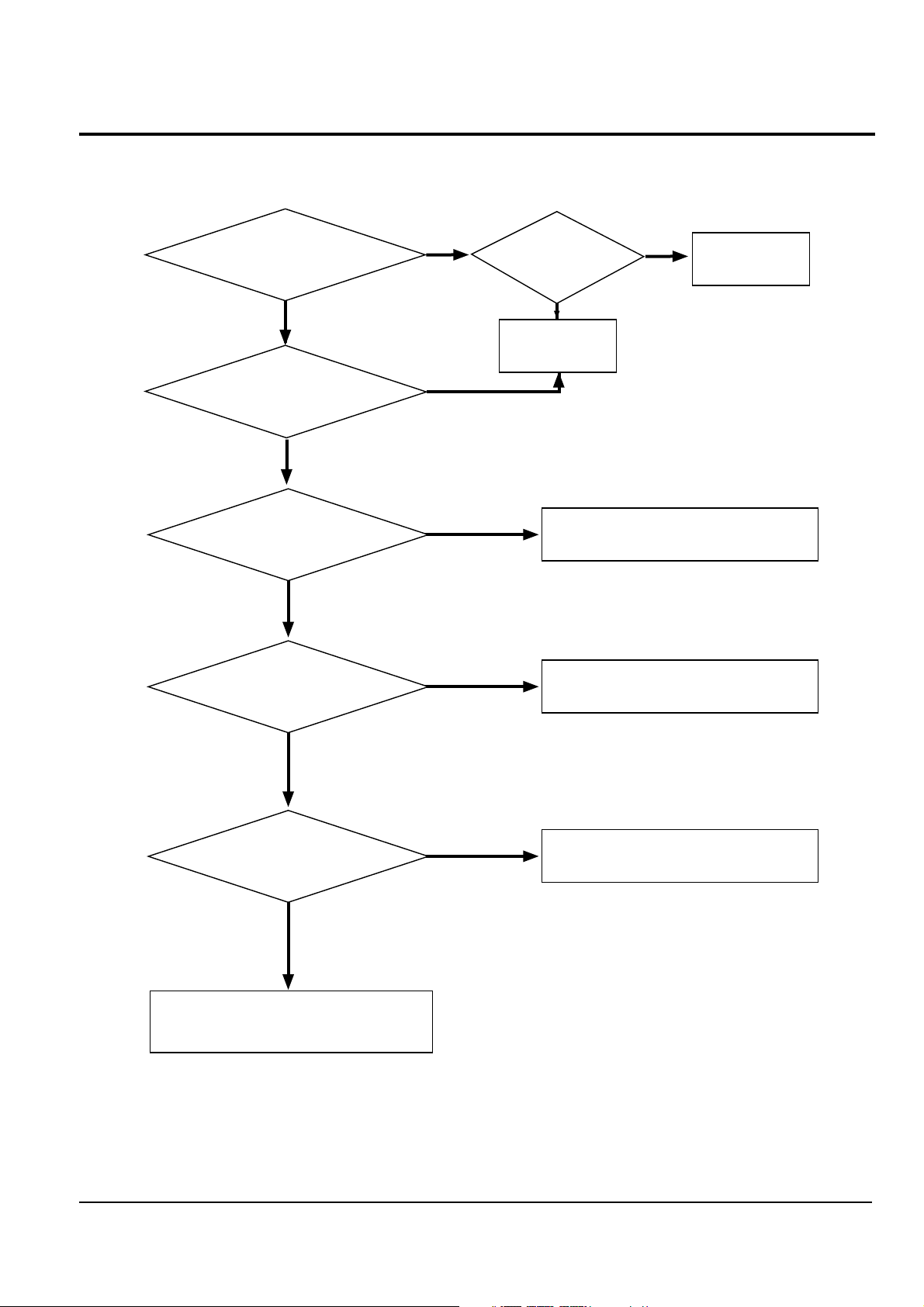

Check if PF1 is OK

Check if Power Trans

output is OK

Check for voltage

“8V”

Check for voltage

“-8V”

Check for voltage

“5V”

Check for voltage

“-5V”

Check for voltage Ever “5V”

Replace PF1

Replace PFT1,PIC1,PIC2,

PR4,PR75,PD1

Replace power PCB ASS’Y

Replace Power Trans

Replace PIC4

Replace PIC5

Replace PQ5,PQ6

Replace PQ3,PQ4

Replace PFET1,PIC1,PIC2,PR4,PR75,PD1

6-1 Power source problem

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

Samsung Electronics

6-2

6-2 Blue background not shown (LD,CD)

Check for 4fsc signal

at TP1

Check for Video signal

at pin 78 of VIC2

Check for video signal

at NC6

Check for video signal

at pin 7of NIC4

Check for video signal

at emitter of NQ1,NQ2

Check for micom

interface

Check for video signal

at base of VQ28

Replace VX1

Replace MIC101

Adjust VCTC1

Check for video signal at

base of VQ25, VQ19

,VQ20,VQ21

Replace VQ28

Replace NIC4

Check TV mode:NTSC or PAL

Check for connection of VCW1 on the FMV PCB

Replace NQ1,NQ2

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

NO

Troubleshooting

Check for video signal

at pin7 of VIC10 on the

FMV PCB

Check for connection of VCW1

on the FMV PCB

NO

Samsung Electronics

6-3

6-3 No disc error

More than 0.4V (2V generally)

0V

More than

0.3V

0V

Yes

No

Yes

Yes

Yes

Yes

No

No

Yes

No

No

No

NO DISC ERROR

Check for

signal at Pin 98 of SIC6

(during playing) : more

than 0.4V

Check for

signal at Pin 100 of SIC6

(during playing) : more

than 0.3V

Check for

voltage Pin 53 of SIC6

: from 5V to 0V

Replace MIC 1

Check if

pick-up goes up and

down when PLAY button

is pressed

Check if

pick-up emits

LASER beam

Replace SIC 6

See FOCUS

does not play

Check for

voltage at Pin 6

of SCW 1 : -5V

Check for change of voltage

at Pin 8 of SCW 1

when PLAY button is

pressed : 1.2V

2V

Replace pick-up

Replace SQI

5V

0V

100

4DSUM

53

FL

Troubleshooting

Samsung Electronics

6-4

6-4 No Video Signal

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

No

See "Blue - background not shown"

check for video

signal at PIN 70

of VIC 1

check for video

signal at emitter

of VQ1

check for DIGITAL

signal at PIN 48 THRUY

PIN 55 of VIC 2

check for V-sync signal

at PIN 39 of VIC 1

Replace VIC 1

Replace VQ1

Replace VIC3

check for IRQ signal

at PIN 90 of VIC 2

Replace VIC 2

check for HREF,PBHD

signal at

PIN 41,43 of VIC 2

See "LD DOES NOT PLAY"

Troubleshooting

Samsung Electronics

6-5

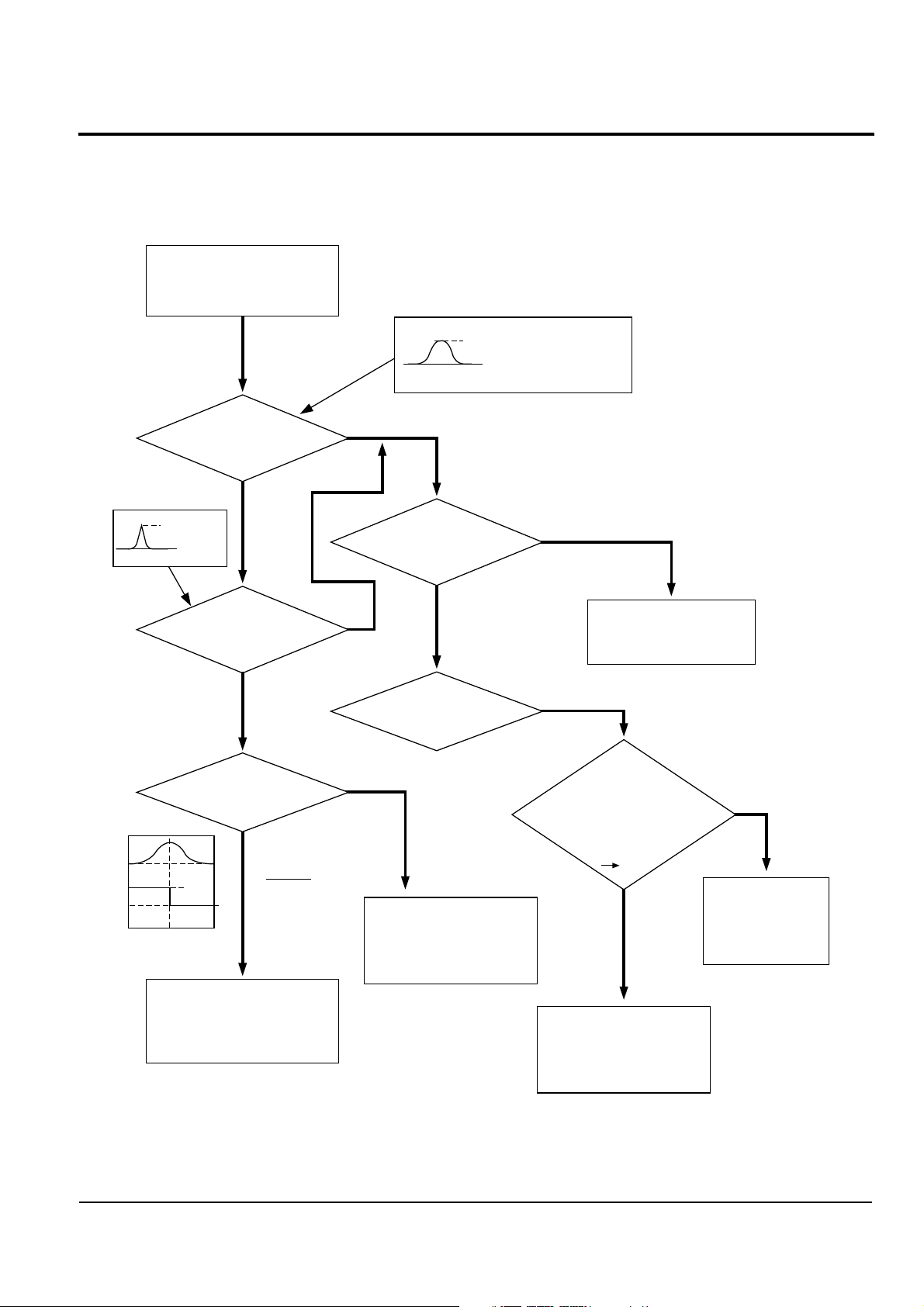

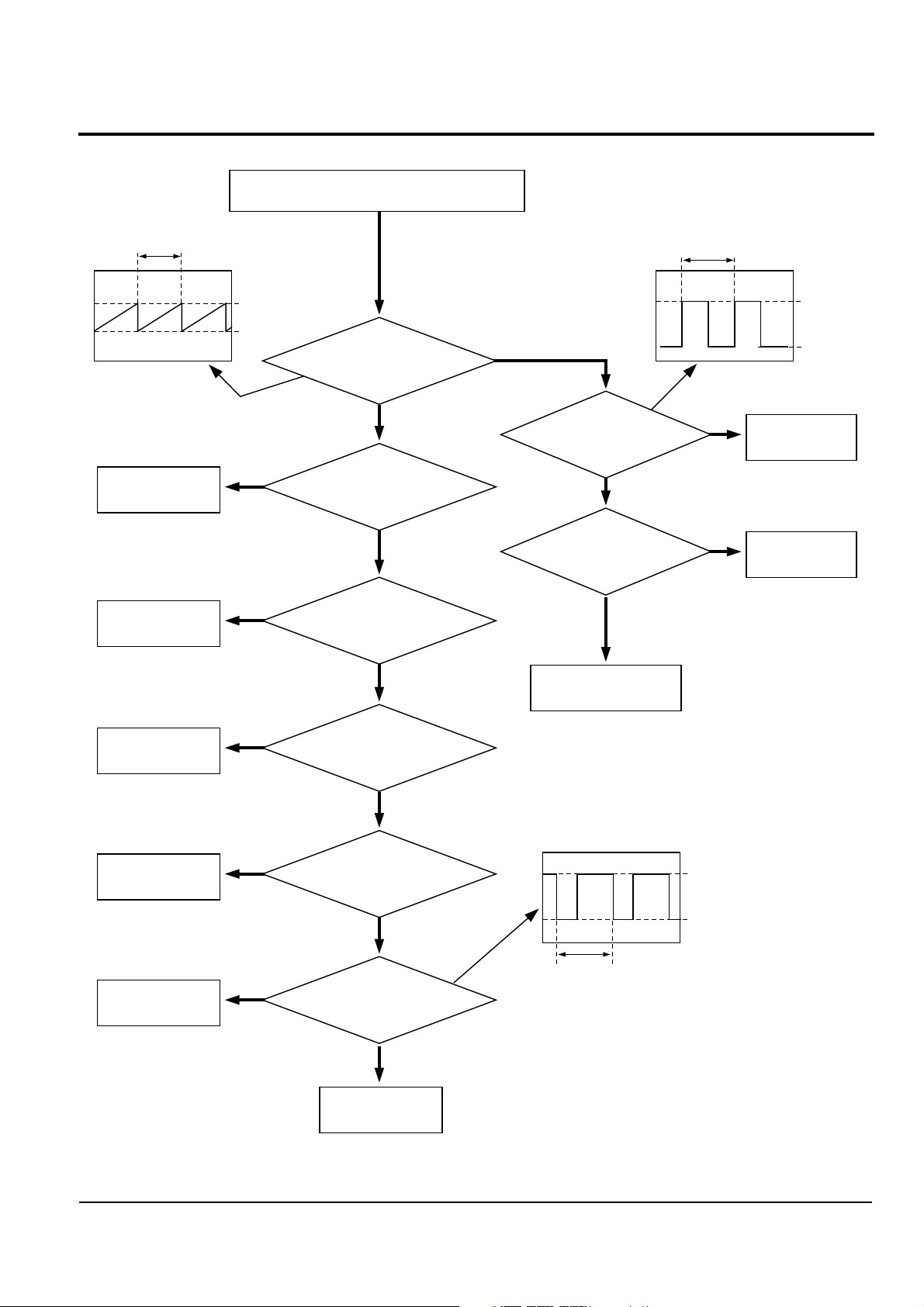

6-5 LD does not play

Yes

No

Yes

Yes

Yes

Yes

Yes

No

No

No

No

No

Yes

Yes

No

No

LD DOES NOT PLAY

Check for signal

at Pin 35 of

SIC6

Check for voltage

at Pin 31 of SIC6

: 2.5V

Check for signal

at Pin 23 of SIC6

: 2 ~ 3V

Check for signal

at Pin 27 of SIC6

: 1 ~ 2V

Check for signal

at Pin 32 of SIC6

: 2 ~ 3V

Check for signal

at Pin 46 of SIC6

DISC is

defective

Replace SIC6

Replace TIC2

Replace SIC6

Replace SIC6

Replace SIC6

Check for

frequency at Pin 45 of

SIC6 : 15.7KHz

Check for

frequency at Pin 42 of

SIC6 : 14.3MHz

Replace SIC6

Replace SIC6

Replace VIC2

5V

0V

15.7KHz

about 3V

2.5V

63.5µsec

5V

0V

63.5µsec

Troubleshooting

Samsung Electronics

6-6

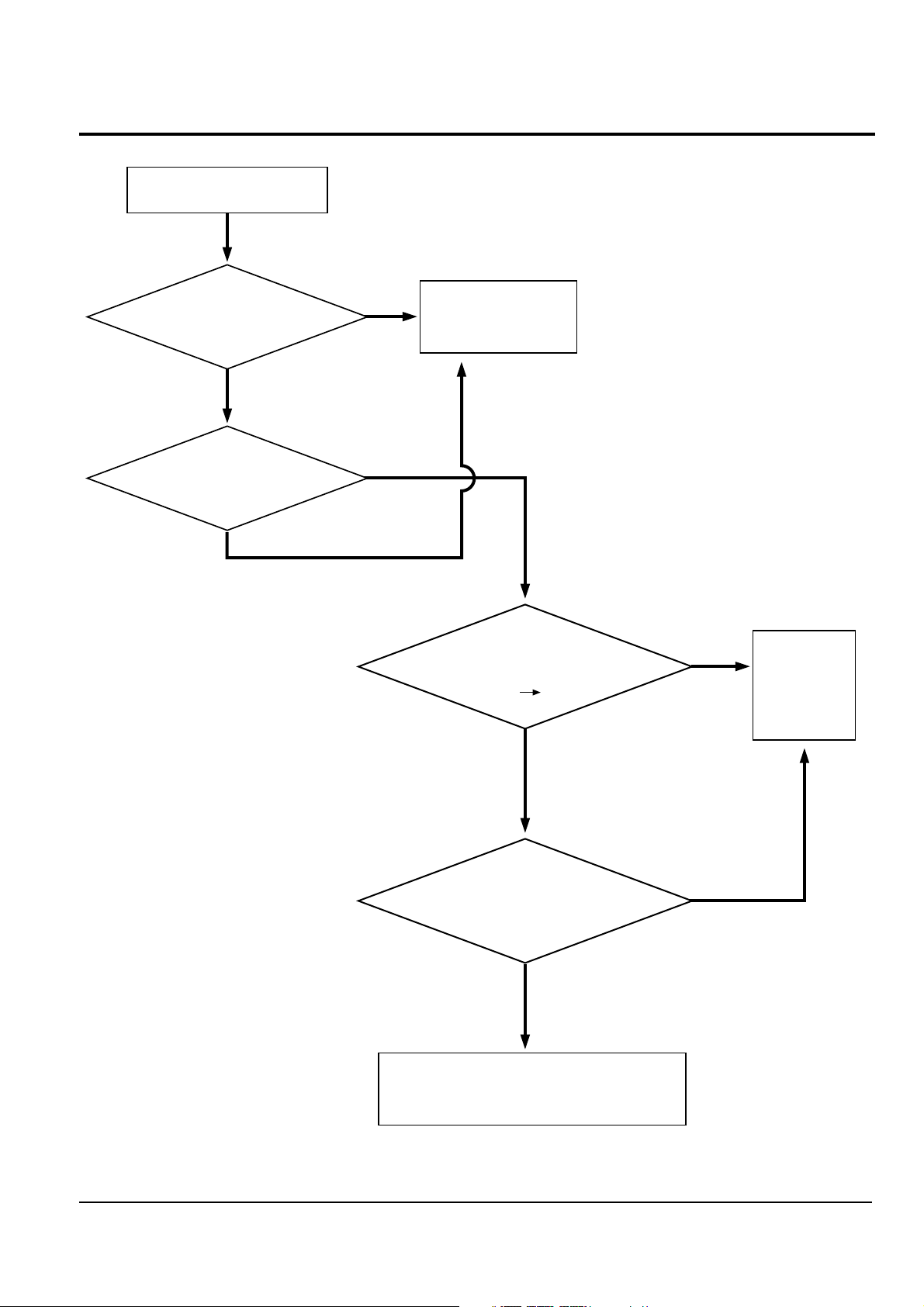

6-6 CD does not play

No

Yes

No

Yes

No

Yes

No

CD DOES NOT PLAY

Check for DIGITAL

sound of LD

Check if spindle

motor is O.K.

See "No Digital

Sound"

Check for change of

voltage at Pin 34 of SIC 6

when PLAY button is pressed

: 2V 3V

Check for voltage at

Pin 47, 46 of SIC 6

: 5V, 0V

See "SPINDLE MOTOR dose not work"

Replace

SIC 6

Troubleshooting

Loading...

Loading...