Page 1

COLOR MONITOR

DP14LS

DP14LT

DP15LS

DP15LT

Manual

SERVICE

COLOR MONITOR CONTENTS

1. Precautions

2. Product Specifications

3. Operating Instructions

4. Disassembly & Reassembly

5. Alignment & Adjustments

6. Troubleshooting

7. Exploded View & Parts List

8. Electrical Parts List

9. Block Diagram

10. Wiring Diagram

11 Schematic Diagrams

Page 2

Samsung Electronics Co., Ltd. April 1999

Printed in Korea

Code No.: BH68-00128A

Page 3

WARNINGS

1. For continued safety, do not attempt to modify the

circuit board.

2. Disconnect the AC power before servicing.

3. When the chassis is operating, semiconductor

heatsinks are potential shock hazards.

1-1-1 Servicing the High Voltage VR

and CRT :

WARNING:Damaged IC202 may cause excessive

x-ray emissions.

1. When servicing the high voltage system, remove

the static charge by connecting a 10 kohm resistor

in series with an insulated wire (such as a test

probe) between the chassis and the anode lead.

2. If the HV VR requires adjustment:

This monitor does not need to adjust high voltage,

high voltage step is saved at IC202, adjusting this

high voltage to 24.5±0.5 kV - 14Ó, 25.0±0.5 kV - 15Ó.

3. When troubleshooting a monitor with excessively

HV, avoid being unnecessarily close to the monitor.

Do not operate the monitor for longer than is

necessary to locate the cause of excessive voltage.

4. High voltage should always be kept at the rated

value, no higher. Only when high voltage is

excessive are X-rays capable of penetrating the shell

of the CRT, including the lead in glass material.

Operation at high voltages may also cause failure of

the CRT or high voltage circuitry.

5. When the HV regulator is operating properly, there

is no possibility of an X-ray problem. Make sure the

HV does not exceed its specified value and that it is

regulating correctly.

6. The CRT is especially designed to prohibit

X-ray emissions. To ensure continued X-ray

protection, replace the CRT only with one that is

the same or equivalent type as the original.

7. Handle the CRT only when wearing shatterproof

goggles and after completely discharging the high

voltage anode.

8. Do not lift the CRT by the neck.

1-1-2 Fire and Shock Hazard :

Before returning the monitor to the user, perform the

following safety checks:

1. Inspect each lead dress to make certain that the

leads are not pinched or that hardware is not

lodged between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as nonmetallic

control knobs, insulating materials, cabinet backs,

adjustment and compartment covers or shields,

isolation resistor-capacitor networks, mechanical

insulators, etc.

3. Leakage Current Hot Check (Figure 1-1):

WARNING: Do not use an isolation transformer during

this test.

Use a leakage current tester or a metering system

that complies with American National Standards

Institute (

ANSI C101.1, Leakage Current for

Appliances), and Underwriters Laboratories (UL

Publication UL1410, 59.7).

4. With the unit completely reassembled, plug the AC

line cord directly into a 120V AC outlet. With the

unitÕs AC switch first in the ON position and then

OFF, measure the current between a known earth

ground (metal water pipe, conduit, etc.) and all

exposed metal parts, including: metal cabinets,

screwheads and control shafts. The current

measured should not exceed 0.5 milliamp. Reverse

the power-plug prongs in the AC outlet and repeat

the test.

Figure 1-1. Leakage Current Test Circuit

1-1-4 Product Safety Notices

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection. The protection they give

may not be obtained by replacing them with

components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified by

on schematics and parts lists. A substitute

replacement that does not have the same safety

characteristics as the recommended replacement part

might create shock, fire and / or other hazards. Product

safety is under review continuously and new

instructions are issued whenever appropriate.

Components identified by on schematics and parts

lists must be sealed by a soldering iron after

replacement and adjustment.

DP14L*/DP15L* 1-1

1 Precautions

1-1 Safety Precautions

!

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOT BE ABOVE 0.5mA)

LEAKAGE

CURRENT

TESTER

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EARTH

GROUND

Page 4

1. Servicing precautions are printed on the cabinet,

and should be followed closely.

2. Always unplug the unitÕs AC power cord from the

AC power source before attempting to: (a) remove

or reinstall any component or assembly, (b)

disconnect PCB plugs or connectors, (c) connect all

test components in parallel with an electrolytic

capacitor.

3. Some components are raised above the printed

circuit board for safety. An insulation tube or tape

is sometimes used. The internal wiring is

sometimes clamped to prevent contact with

thermally hot components. Reinstall all such

elements to their original position.

4. After servicing, always check that the screws,

components and wiring have been correctly

reinstalled. Make sure that the area around the

serviced part has not been damaged.

1. Immediately before handling any semiconductor

components or assemblies, drain the electrostatic

charge from your body by touching a known earth

ground. Alternatively, wear a discharging wriststrap device. To avoid a shock hazard, be sure to

remove the wrist strap before applying power to

the monitor.

2. After removing an ESD-equipped assembly, place it

on a conductive surface such as aluminum foil to

prevent accumulation of an electrostatic charge.

3. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage

ESDs.

4. Use only a grounded-tip soldering iron to solder or

desolder ESDs.

5. Use only an anti-static solder removal device. Some

solder removal devices not classified as Òanti-staticÓ

can generate electrical charges sufficient to damage

ESDs.

5. Check the insulation between the blades of the AC

plug and accessible conductive parts (examples:

metal panels, input terminals and earphone jacks).

6. Insulation Checking Procedure: Disconnect the

power cord from the AC source and turn the power

switch ON. Connect an insulation resistance meter

(500 V) to the blades of the AC plug.

The insulation resistance between each blade of the

AC plug and accessible conductive parts (see

above) should be greater than 1 megohm.

7. Never defeat any of the +B voltage interlocks. Do

not apply AC power to the unit (or any of its

assemblies) unless all solid-state heat sinks are

correctly installed.

8. Always connect a test instrumentÕs ground lead to

the instrument chassis ground before connecting the

positive lead; always remove the instrumentÕs

ground lead last.

6. Do not remove a replacement ESD from its

protective package until you are ready to install it.

Most replacement ESDs are packaged with leads

that are electrically shorted together by conductive

foam, aluminum foil or other conductive materials.

7. Immediately before removing the protective

material from the leads of a replacement ESD,

touch the protective material to the chassis or

circuit assembly into which the device will be

installed.

Caution:

Be sure no power is applied to the

chassis or circuit and observe all

other safety precautions.

8. Minimize body motions when handling

unpackaged replacement ESDs. Motions such as

brushing clothes together, or lifting your foot from

a carpeted floor can generate enough static

electricity to damage an ESD.

9. Indicates ESDs on the Schematic Diagram in

this manual.

1 Precautions

1-2 DP14L*/DP15L*

1-3 Electrostatically Sensitive Devices (ESD) Precautions

Some semiconductor (solid state) devices can be easily damaged by static electricity. Such components are commonly

called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated circuits and some fieldeffect transistors. The following techniques will reduce the incidence of component damage caused by static electricity.

1-2 Servicing Precautions

WARNING1: First read the “Safety Precautions” section of this manual. If unforeseen circumstances

create conflict between the servicing precautions and safety precautions, always

follow the safety precautions.

WARNING2: An electrolytic capacitor installed with the wrong polarity might explode.

Page 5

DP14L*/DP15L* 2-1

2 Product Specifications

2-1 Specifications

Picture Tube: 14-Inch (36 cm); 13.2-Inch (33.5 cm) viewable, 90° Deflection,

15-Inch (38 cm); 13.8-Inch (35 cm) viewable, flat-face tube, 90° Deflection,

0.28 mm Dot pitch, Semi-tint, Non-glare, Antistatic silica coating, Invar shadow mask

Scanning Frequency Horizontal: 30 kHz to 55 kHz (Automatic) - 14” / 30 kHz to 61 kHz (Automatic) - 15”

Vertical: 50 Hz to 120 Hz (Automatic)

Display Colors Unlimited colors

Maximum Resolution Horizontal : 1024 Dots

Vertical : 768 Lines

Input Video Signal Analog, 0.7 Vp-p positive at 75 Ω, internally terminated

Input Sync Signal Separate Sync : TTL level positive/negative

Maximum Pixel Clock 14” : 65 MHz, 15” : 80 MHz

Active Display 14” 15”

Horizontal 255 mm ± 4 mm (4:3 ratio) 267 mm ± 4 mm (4:3 ratio)

Vertical 191 mm ± 4 mm 200 mm ± 4 mm

Input Voltage AC 90 to 264 Volts, 60 Hz/50 Hz ± 3 Hz

Power Consumption 75 Watt (Max.)

Dimensions 14” 15”

Unit (W x D x H) 13.70 x 14.65 x 14.49 Inches (348 x 372 x 368 mm) 14.25 x 15.12 x 15.12 Inches (362 x 384 x 384 mm)

Carton (W x D x H) 16.61 x 18.11 x 15.35 Inches (422 x 460 x 390 mm) 17.87 x 19.57 x 17.52 Inches (454 x 497 x 445 mm)

Weight (Net/Gross) 14” : 23.4 lbs (10.6 kg) / 26.9 lbs (12.2 kg)

15” : 26.5 lbs (12.0 kg) / 31.5 lbs (14.3 kg)

Environmental Considerations Operating Temperature : 32°F to 104°F (0°C to 40°C)

Humidity : 10 % to 80 %

Storage Temperature : -4°F to 113°F (-20°C to 45°C)

Humidity : 5 % to 95 %

• This above Models complies with SWEDAC (MPR II) recommendations for reduced electromagnetic fields.

• Designs and specifications are subject to change without prior notice.

Item Description

Page 6

2 Product Specifications

2-2 DP14L*/DP15L*

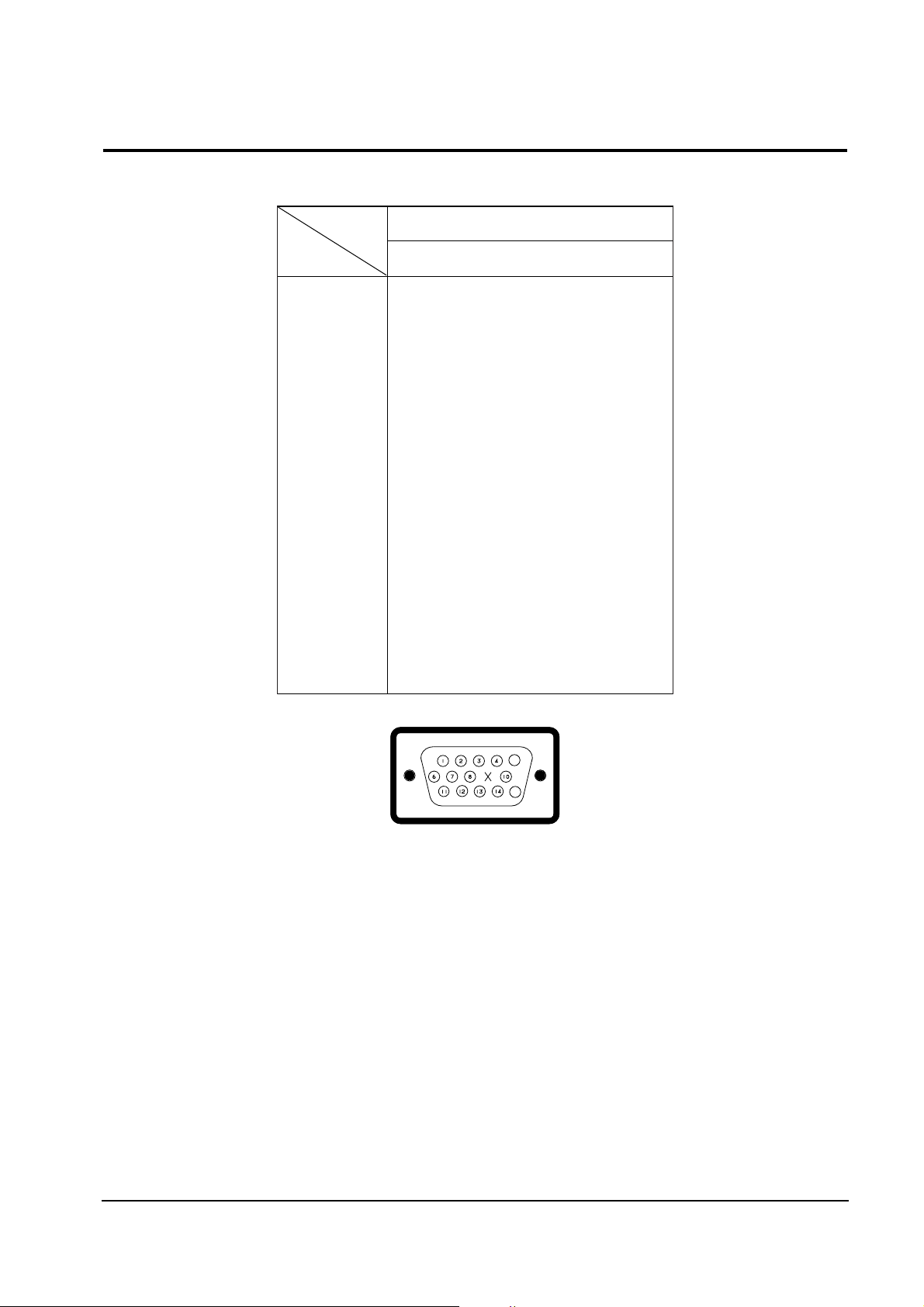

2-2 Pin Assignments

Sync

Type

Pin No.

15-Pin Signal Cable Connector (Figure 2-1)

Separate

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Red

Green

Blue

GND

DDC Return

GND-R

GND-G

GND-B

Reserved

GND-Sync/Self-raster

GND

DDC Data

H-Sync

V-Sync

DDC Clock

5

15

Figure 2-1. Male Type

Page 7

2 Product Specifications

DP14L*/DP15L* 2-3

fH (kHz)

A µsec

B µsec

C µsec

D µsec

E µsec

fV (Hz)

O msec

P msec

Q msec

R msec

S msec

Clock

Frequency

(MHz)

Polarity

H.Sync

V.Sync

Remark

IBM VESA

800/85 Hz

800 x 600

1024/60 Hz

1024 x 768

(14”)

1024/75 Hz

1024 x 768

(15”)

640/60 Hz

640 x 480

720/70 Hz

720 x 400

31.469

31.777

3.813

1.907

25.422

0.636

70.087

14.268

0.064

1.080

12.711

0.413

28.322

Negative

Positive

Separate

31.469

31.778

3.813

1.907

25.422

0.636

59.940

16.683

0.064

1.048

15.253

0.318

25.175

Negative

Negative

Separate

37.500

26.667

2.032

3.810

20.317

0.508

75.000

13.333

0.080

0.427

12.800

0.027

31.500

Negative

Negative

Separate

43.269

23.111

1.556

2.222

17.778

1.556

85.008

11.764

0.069

0.578

11.093

0.023

36.000

Negative

Negative

Separate

46.875

21.333

1.616

3.232

16.162

0.323

75.000

13.333

0.064

0.448

12.800

0.021

49.500

Positive

Positive

Separate

53.674

18.631

1.138

2.702

14.222

0.569

85.061

11.756

0.056

0.503

11.179

0.019

56.250

Positive

Positive

Separate

48.363

20.677

2.092

2.462

15.754

0.369

60.004

16.666

0.124

0.600

15.880

0.062

65.000

Negative

Negative

Separate

60.023

16.660

13.003

3.658

13.206

3.454

75.029

13.328

12.795

0.533

12.812

0.516

78.750

Positive

Positive

Separate

800/75 Hz

800 x 600

640/75 Hz

640 x 480

640/85 Hz

640 x 480

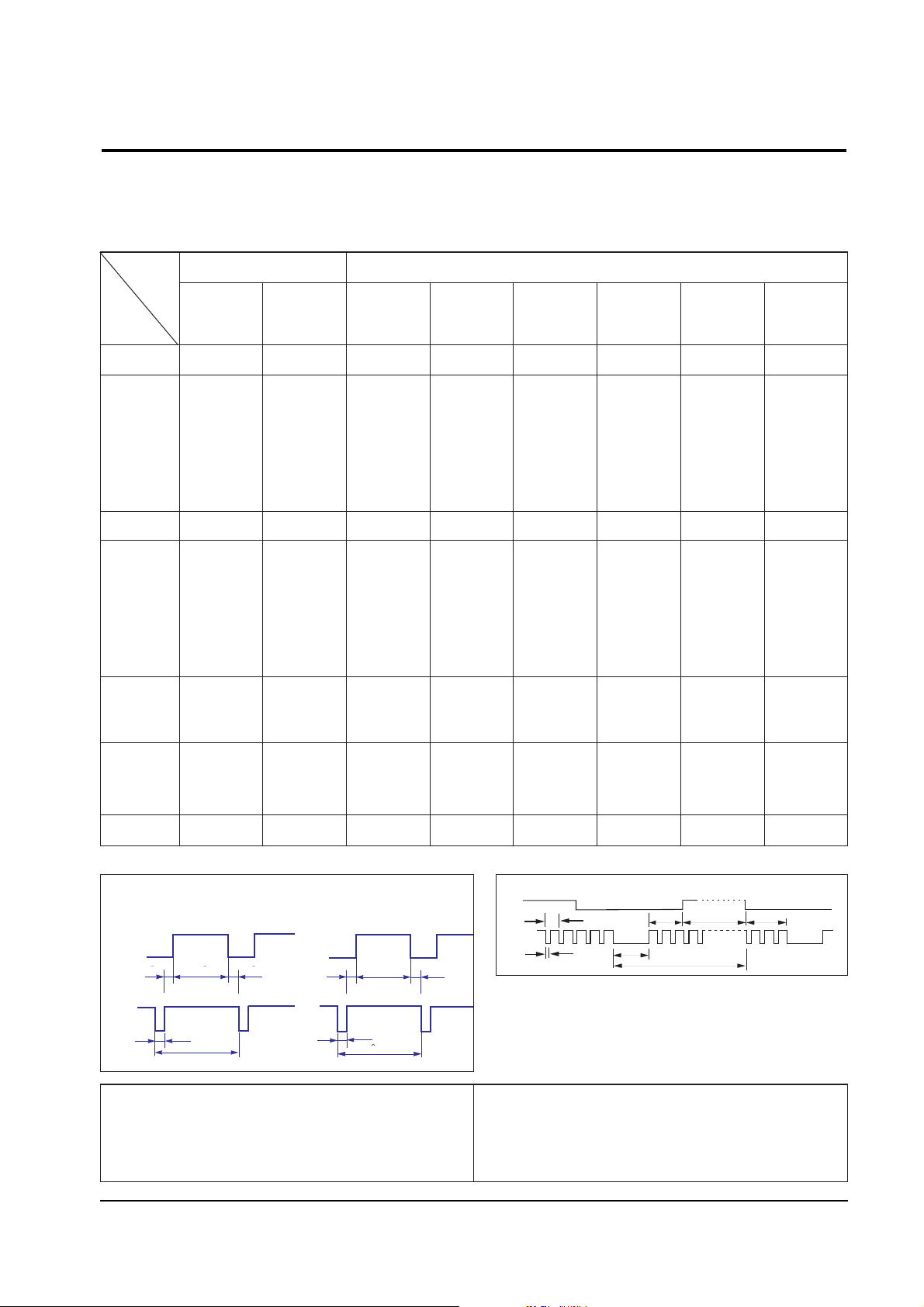

2-3 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard

for computer-generated video signals.

QRS

P

O

Video

Sync

Sync

Horizontal

Vertical

CDE

P

O

B

A

Video

Sync

Sync

Separate Sync

Table 2-1. Timing Chart

Mode

Timing

C D

A

O

E

B

P

Video

Sync

Sync

Video

Q R S

A : Line time total B : Horizontal sync width O : Frame time total P : Vertical sync width

C : Back porch D : Active time Q : Back porch R : Active time

E : Front porch S : Front porch

VIDEO

A

B

O

P

Q

R

S

Horizontal

Vertical

H/V Composite Sync

Page 8

Memo

2 Product Specifications

2-4 DP14L*/DP15L*

Page 9

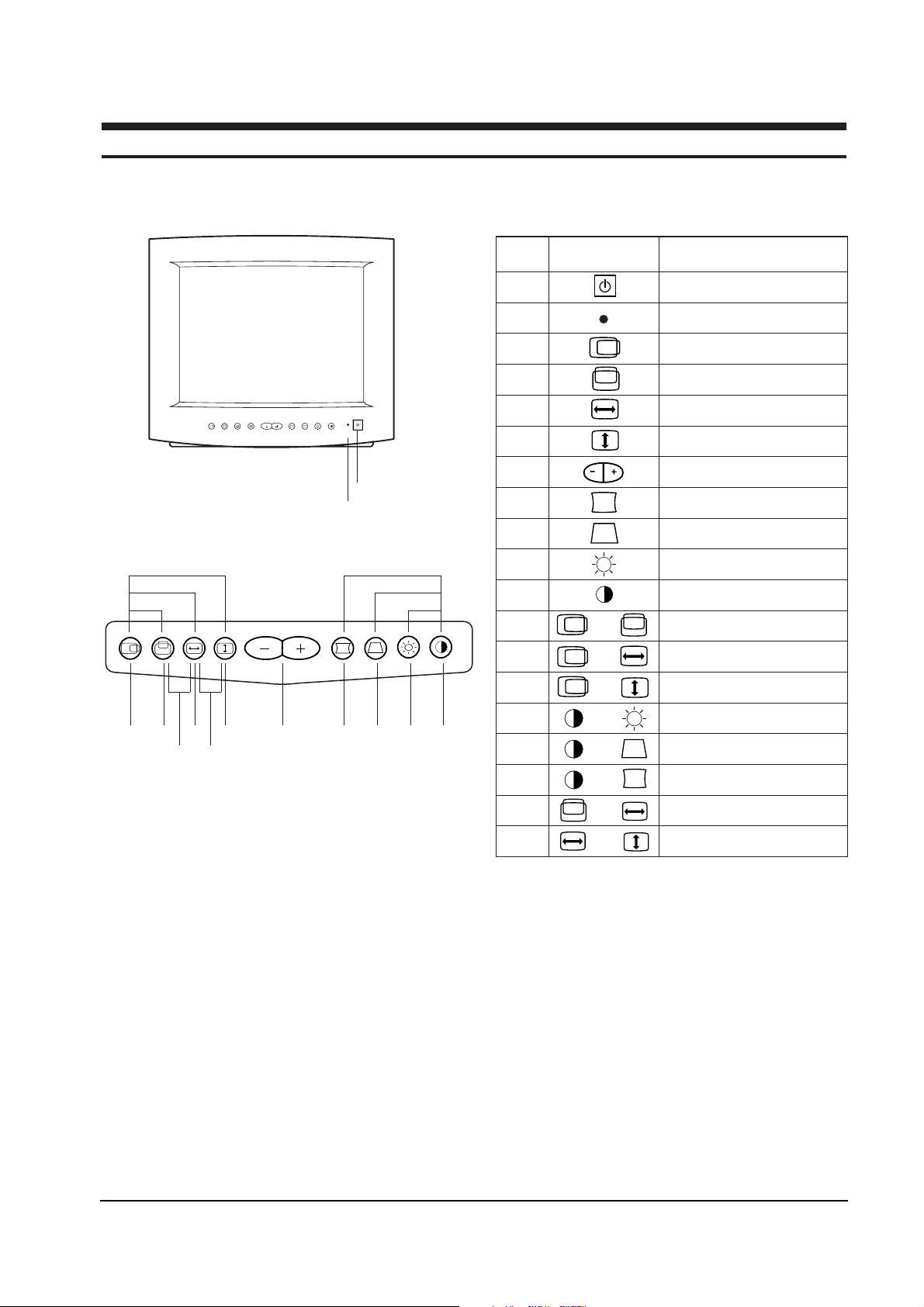

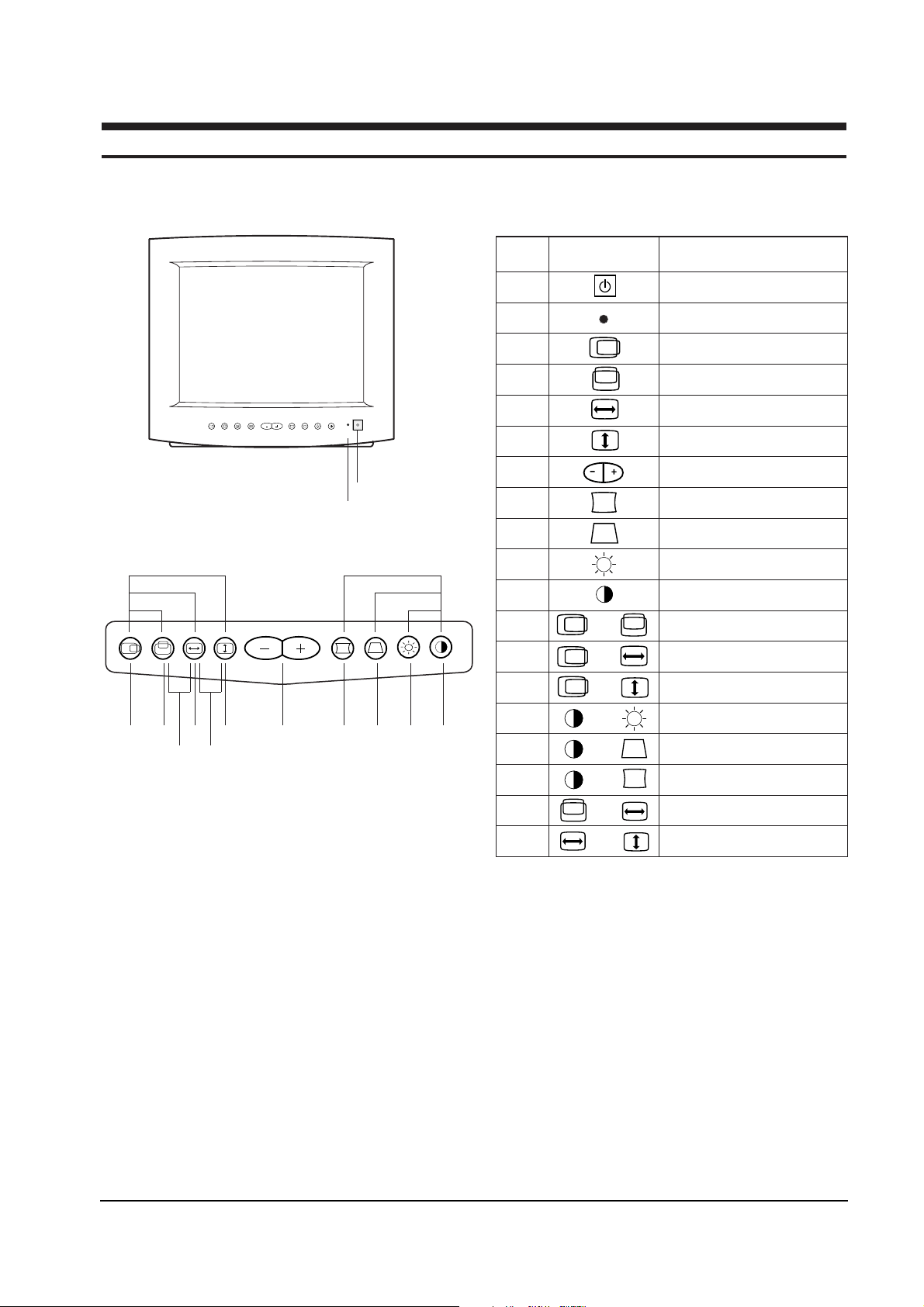

DP14L*/DP15L* 3-1

Location Symbol Description

1 Power Button

Power Indicator LED

Adjustment Buttons

Side Pincushion Button

Horizontal Position Button

Trapezoid Button

Brightness Control

Contrast Control

Parallelogram

V-Linearity

Pinbalance Button

Degauss

Recall

User Delete

Tilt (Option: 15”)

V-Moire

Vertical Size Button

Vertical Position Button

Horizontal Size Button

3

4

8

9

10

11

12

13

14

15

16

17

18

19

5

6

7

2

3

12

13

14 17

16

15

45186 7 8 9 10 11

1

2

19

Table 3-1. Front Panel Controls

Figure 3-1. Front Control Panel

+

+

+

+

+

+

+

+

3 Operating Instructions

3-1 Front View and Control

Page 10

Memo

3 Operating Instructions

3-2 DP14L*/DP15L*

Page 11

DP14L*/DP15L* 3-1

Location Symbol Description

1 Power Button

Power Indicator LED

Adjustment Buttons

Side Pincushion Button

Horizontal Position Button

Trapezoid Button

Brightness Control

Contrast Control

Parallelogram

V-Linearity

Pinbalance Button

Degauss

Recall

User Delete

Tilt (Option: 15”)

V-Moire

Vertical Size Button

Vertical Position Button

Horizontal Size Button

3

4

8

9

10

11

12

13

14

15

16

17

18

19

5

6

7

2

3

12

13

14 17

16

15

45186 7 8 9 10 11

1

2

19

Table 3-1. Front Panel Controls

Figure 3-1. Front Control Panel

+

+

+

+

+

+

+

+

3 Operating Instructions

3-1 Front View and Control

Page 12

Memo

3 Operating Instructions

3-2 DP14L*/DP15L*

Page 13

4-1-1 Cabinet Disassembly

1. With a pad beneath it, stand the monitor on its

front with the screen facing downward and

the base closest to you. Make sure nothing will

damage the screen.

2. Remove the Stand from the monitor.

(Refer to Stand manual)

3. Incline the monitor by lifting the rear of the

monitor.

4. Push the Opening jig each groove along the

top of the monitor till it makes a ÒttakÓ sound.

(2 grooves : Left and Right, Make sure each

snap is disengaged.)

5. Squeeze the hold-snap on bottom of the

monitor using your hand.

6. Insert the Opening jig into the groove then

release the hold-snap.

DP14L*/DP15L* 4-1

4 Disassembly and Reassembly

This section of the service manual describes the disassembly and reassembly procedures for the

DP14L*/DP15L* monitors.

WARNING: This monitor contains electrostatically sensitive devices. Use caution when handling

these components.

4-1 Disassembly

Cautions:1. Disconnect the monitor from the power source before disassembly.

2. To remove the Rear Cover, you must use the special opening jig tool.

Figure 1

Figure 2

Figure 3

Figure 4

Page 14

7. When the hold-snap release, lift the Rear

Cover slightly to make sure it doesnÕt reengage while you release the snap on the

other side.

8. In a similar manner, Release the hold-snap on

the opposite side.

9. Pull the Rear Cover up off the monitor.

10. Using pinch-nose pliers or ling-nose pliers,

acrefully disconnect the Anode Cap from the

CRT.

Warning: Do not touch the Anode contact

on the CRT (High Voltage may

remain).

Note : If the hold-snap on the bottom of the

Front Cover is broken, secure the

cabinet by applying a 4x16 screw in

the extra holes on each side of the

cabinet.

4-1-2 Removing the CRT Socket PCB

1. Complete all previous steps.

2. Disconnect the CRT and Main PCB ground

wires between the CRT Socket PCB and

Shield Cover. (DP14LS only)

3. Lift up the Video Spring and remove the CRT

Socket PCB from the CRT.

4. Disconnect all connectors on the CRT Socket

PCB.

5. Using a solder iron, disconnect Ground (G2)

on the back of the Video Shield and remove

the Shield Cap.

6. Remove the screw on the front of the Shield

Socket.

7. Desolder the 4 tabs on the CRT Socket PCB

and remove Shield.

8. Place the Video PCB on a flat, level surface

that is protected from static electricity.

4 Disassembly and Reassembly

4-2 DP14L*/DP15L*

Figure 5

Figure 6

Figure 7

Figure 8

Figure 9

Page 15

4-1-3 Removing the Main PCB

1. Complete all previous steps.

2. Disconnect the Degaussing Coil at GT601 and

GT602 on the Main PCB.

3. Disconnect all easily accessible ground wires

on the Main PCB and Bottom Chassis.

4. Disconnect the DY connector at the CN303

connector on the Main .

5. Using the jig, release the snaps (2) connecting

the Front Cover and Main PCB then lift up the

Bottom to separate the two Shield.

6. Remove the screws on the back and along

each side of the Bottom Chassis.

7. Carefully lift the Main PCB AssÕy and remove

the remaining ground wires.

8. Place the Main PCB AssÕy on a flat, level

surface that is protected from static electricity.

4-1-4 CRT Ass’y Disassembly

1. Complete all previous steps.

2. Straighten the Degaussing Coil Assembly

coated metal ties and lift the Coil AssÕy from

the CRT.

3. Remove the four corner screws and lift the

CRT up and away from the Front Cover

Assembly and place it on a padded surface.

Caution: Do not lift the CRT by the neck.

If you will be returning this CRT to

the monitor, be sure to place the CRT

face downward on a protective pad.

4 Disassembly and Reassembly

DP14L*/DP15L* 4-3

Figure 10

4-2 Reassembly

Reassembly procedures are in the reverse order of Disassembly procedures.

Page 16

Memo

4 Disassembly and Reassembly

4-4 DP14L*/DP15L*

Page 17

5-1-1 Before Making Adjustments

5-1-1 (a) ORIENTATION

When servicing, always face the monitor to the

east.

5-1-1 (b) MAGNETIC FIELDS

Whenever possible, use magnetic field isolation

equipment such as a Helmholtz field to surround

the monitor. If a Helmholtz field is not available,

frequently degauss the unit under test.

Caution: Other electrical equipment may cause

external magnetic fields which may

interfere with monitor performance.

Use an external degaussing coil to limit magnetic

build up on the monitor. If an external degaussing

coil is not available, use the internal degaussing

circuit. However, do not use the internal

degaussing circuit more than once per 30 minutes.

5-1-1 (c) WARM-UP TIME

The monitor must be on for 30 minutes before

starting alignment procedures. Warm-up time is

especially critical in Color Temperature and White

Balance adjustments.

5-1-1 (d) SIGNAL

Analog, 0.7 Vp-p positive at 75 ohm, internal

termination

Sync: Separate

(TTL level negative/positive)

5-1-1 (e) SCANNING FREQUENCY

Horizontal: 30 kHz to 55 kHz (automatic) 14Ó

30 kHz to 61 kHz (automatic) 15Ó

Vertical: 50 Hz to 120 Hz (automatic)

Unless otherwise specified, adjust at the 800 x 600

mode (H : 53.7 kHz, V: 85 Hz) -14Ó/15Ó signals.

Refer to Table on page 2-3.

5-1-1 (f) +B 13 V LINE CHECK

No beam

Contrast: Maximum

Brightness: Maximum

Check the DC 13 V ± 0.2 V at Cathode of D616

Point and GND.

5-1-1 (g) HIGH VOLTAGE CHECK

No beam

Contrast: Maximum

Brightness: Maximum

Check the high voltage to 24.5 ± 0.5 kV - 14Ó,

25 ± 0.5 kV - 15Ó at anode and GND.

5-1-1 (h) CENTER RASTER

Adjust VR501 so that the back raster comes to the

center when you apply a signal of

60 kHz/75 Hz - 15Ó .

5-1-1 (i) BRIGHTNESS AND CONTRAST

Unless otherwise specified, adjust brightness and

contrast buttons:

Brightness: Maximum

(press Å button until the LED is blink)

Contrast: Maximum

(press Å button until the LED is blink)

5-1-2 Required Equipment

The following equipment may be necessary for

adjustment procedures:

5-1-2 (a) DISPLAY CONTROL ADJUSTMENT

1. Non-metallic (Ð) screwdriver: 1.5 mm

Non-metallic (Ð) screwdriver: 3 mm

2. Philips (+) screwdriver: 1.5 mm

3. Non-metallic hexkey: 2.5 mm

4. Digital Multimeter (DMM), or

Digital Voltmeter (DVM)

DP14L*/DP15L* 5-1

5 Alignment and Adjustments

This section of the service manual explains how to make permanent adjustments to the monitor. Directions

are given for adjustments using the monitor Interface Board Ver. 2.0 and software (Softjig).

5-1 Adjustment Conditions

Caution: Changes made without the SoftJig are saved only to the user mode settings. As such, the

settings are not permanently stored and may be inadvertently deleted by the user.

Page 18

5. Signal generator, or

Computer with a video board that uses the

ET-4000 chipset (strongly recommended if

using Samsung DM 200 software) and that

displays: 800 x 600 @ 85 Hz, or 800 x 600

@ 75 Hz (minimum).

6. Personal computer

7. Required software: Softjig.exe from Samsung,

Samsung DM200, or DisplayMate for

Windows from Sonera Technologies

8. Interface Board Ver. 2.0 Code No.

BH81-90001K

9. Parallel communications cable (25-pin to

25-pin); Code No. BH81-90001H

10. Signal cable (15-pin to 15-pin cable with

additional 3-pin connector); Code No.

BH81-90001J

11. 5 V DC adapter, not supplied

Note: SoftJig Assembly (includes items 8, 9 and 10

Code No. BH81-90001L

5-1-2 (b) COLOR ADJUSTMENTS

1. All equipment listed in 5-1-2 (a), above

2. Color analyzer, or any luminance

measurement equipment

5-1-3 Connecting the SoftJig

Connect the monitor to the signal generator and/

or PC as illustrated in Figures 5-1 and 5-2.

Note: The signal cable connector which includes

the 3-wire cable must connect to the

monitor. If you use Setup 2 (PC only, no

signal generator) you can only make

adjustments to the signal timing available

on that computer system. To make

corrections to all factory timings requires

the use of an additional signal generator.

5-1-4 After Making Adjustments

After finishing all adjustments, test the monitor in

all directions. If, for example, the monitor does not

meet adjustment specifications when facing north,

reposition the monitor to face east and readjust.

This time, try for an adjustment closer to the ideal

setting within the tolerance range. Test the unit

again in all directions. If the monitor again fails to

meet specifications in every direction, contact

your Regional After Service Center for possible

CRT replacement.

5 Alignment and Adjustments

5-2 DP14L*/DP15L*

MONITOR

INTERFACE

BOARD VER. 2.0

PC

SIGNAL

GENERATOR

7 PIN MINI DIN

CONNECTOR

SIGNAL CABLE

5V DC

ADAPTOR

PARALLEL CABLE

Figure 5-1. Setup 1, With Signal Generator

MONITOR

INTERFACE

BOARD VER. 2.0

PC

7 PIN MINI DIN

CONNECTOR

SIGNAL CABLE

PARALLEL CABLE

D-SUB

CONNECTOR

5V DC

ADAPTOR

Figure 5-2. Setup 2, Without Signal Generator

Page 19

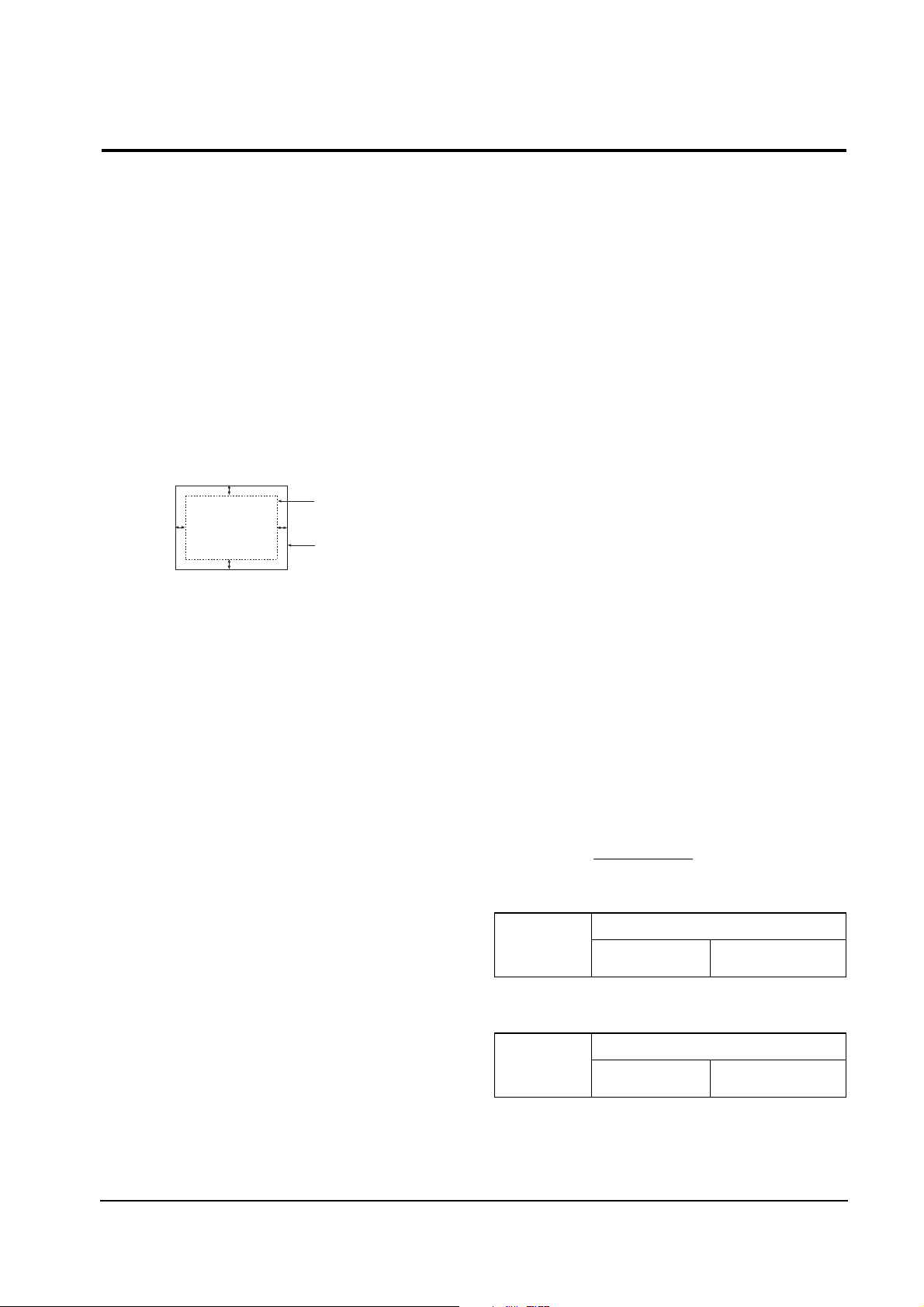

5-2-1 Centering

Centering means to position the center point of

the display in the middle of the display area.

Horizontal size and position and vertical size and

position control the centering of the display.

Adjust the horizontal size and vertical size to their

optimal settings: 267 mm (H) x 200 mm (V) for

15Ó, 255 mm (H) x 191 mm (V) for 14Ó

Adjust the horizontal position and vertical

position to within 4.0 mm of the center point of

the screen.

l A - B l ² 5.0 mm.

l C - D l ² 5.0 mm.

5-2-1 (a) HORIZONTAL MINIMUM SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 53.7 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

PROCEDURE

Horizontal minimum size can be adjusted as

follows using Softjig.

1. Display the timing 800 x 600/85 Hz.

2. Adjust horizontal size to minimum size using

H_SIZE.

3. Adjust horizontal minimum size to 250 mm

(15Ó) or 242 mm (14Ó) using H_SIZE MIN.

4. Adjust horizontal size to 267 mm (15Ó) or

255 mm (14Ó) using H_SIZE.

5. Press the ALL MODE SAVE horizontal

minimum size for each timing is saved

automatically.

If horizontal minimum size range cannot meet the

spec, horiontal maximum size of 640 x 480/75 Hz

including 800 x 600/60 Hz, 56 Hz, may be

saturated or cannot overscan the bezel.

5-2-1 (b) VERTICAL SIZE ADJUSTMENT

CONDITIONS

Scanning frequency: 53.7 kHz/85 Hz

Display image: Crosshatch pattern

Brightness: Maximum

Contrast: Maximum

Adjust the vertical size of the display pattern to

200 mm (15Ó) and 191 mm (14Ó).

(Tolerance: ± 3 mm.)

5-2-1 (c) HORIZONTAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 53.7 kHz/85 Hz

Display image: Crosshatch pattern

PROCEDURE

Center the test pattern on the raster.

5-2-1 (d) VERTICAL POSITION ADJUSTMENT

CONDITIONS

Scanning frequency: 53.7 kHz/85 Hz

Display image: Crosshatch pattern

Center the test pattern on the raster.

5-2-2 Linearity

Linearity affects the symmetry of images as they

appear on the screen. Unless each row or column

of blocks in a crosshatch pattern is of equal size,

or within the tolerances shown in Tables 5-1 and

5-2, an image appears distorted, elongated or

squashed.

The formular of linearity (%)

Table 5-1. Standard Modes Linearity: 800 x 600/85Hz

Table 5-2. Other Modes Linearity: VGA, SVGA, XGA,

MAC, etc.

5 Alignment and Adjustments

DP14L*/DP15L* 5-3

5-2 Display Control Adjustments

C

A

DISPLAY AREA

EDGE OF BEZEL

B

D

Figure 5-3. Centering

Supported Timing Mode

Each block (14 %)

Difference between

adjacent blocks (5 %)

Standard Timing Modes

Each block (10 %)

Difference between

adjacent blocks (4 %)

2 x (Max – Min)

= x 100

Max + Min

Page 20

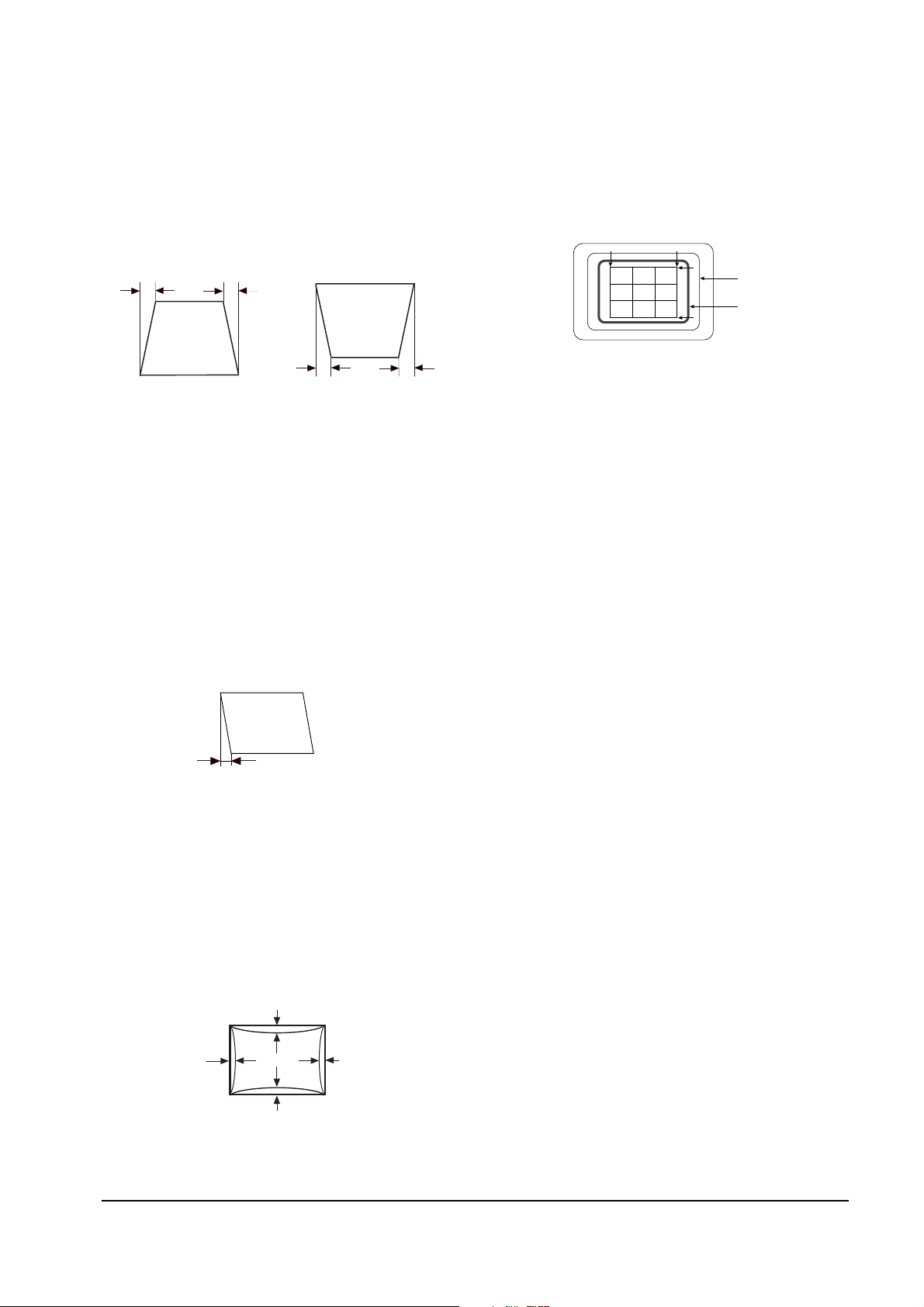

5-2-3 Trapezoid Adjustment

CONDITIONS

Scanning frequency: 53.7 kHz/85 Hz

Display image: Crosshatch pattern

Make the the test pattern rectangular.

Figure 5-4. Trapezoid

5-2-4 Parallelogram Adjustment

CONDITIONS

Scanning frequency: 53.7 kHz/85 Hz (14Ó/15Ó)

Display image: Crosshatch pattern

To activate the Parallelogram Adjustment

function, push both the Horizontal Position and

Vertical Position buttons and hold them in for

longer than 3 seconds, or until the power indicator

LED changes from green to blink and back to

green.

Use the Increase (+) and Decrease (Ð) buttons to

correct the display shape.

Figure 5-5. Parallelogram

5-2-5 Side Pincushion Adjustment

CONDITIONS

Scanning frequency: 53.7 kHz/85 Hz (14Ó/15Ó)

Display image: Crosshatch pattern

After pushing the Side Pincushion button once,

push the Increase (+) and Decrease (Ð) buttons to

straighten the sides of the test pattern.

5-2-6 CRT Tilt Adjustment ( Option)

TILT ADJUSTMENT (DP15L* With Tilt)

Push the V-Posi and H-Size simultaneously until

Led blinks and back on again. Push the Increase

(+) and Decrease (Ð) buttons to correct the Tilt.

5-2-7 Vertical Linearity Adjustment

To activate the vertical linearity adjustment, push

both the horizontal position and horizontal size

buttons and hold then in for longer than 3

seconds, or until the power indicator LED changes

from green to blink and back to green.

Use the Increase (+) and Decrease (Ð) buttons to

correct the display shape.

5-2-8 Pin Balance Adjustments

To activate the pin balacne function, push both the

horizontal position and vertical Size buttons and

hold then in for longer than 3 seconds, or until the

power indicator LED changes from green to blink

and back to green.

Use the Increase (+) and Decrease (Ð) buttons to

correct the display shape.

5-2-9 Degauss

Push the contrast and brightness buttons

simultaneously. The degaussing circuit can

effectively function only once per 30 minutes. If

available, use an external degaussing coil during

servicing.

5-2-10 Delete User Mode Data

To delete the picture data from the user modes,

push the contrast button and side pincushion

button for 5 or more seconds simultaneously.

5-2-11 Recall

To delete the picture data from current user mode,

push the contrast button and trapzoid button for 5

or more seconds simultaneoulsy.

5 Alignment and Adjustments

5-4 DP14L*/DP15L*

2.2 mm 2.2 mm

| C1 |, | C2 | ≤ 2.0 mm, | D1 |, | D2 | ≤ 2.2 mm.

Figure 5-6. Pincushion

A

B

C

D

FRONT BEZEL

BACK RASTER

Figure 5-7. CRT Tilt Adjustment

2.2 mm 2.2 mm

C2

D2

D1

C1

2.2 mm

Page 21

Before making adjustments, check that the video

signals are as follows:

Video : Analog, 0.7 Vp-p (at 75 ½ termination)

Sync : Separate TTL level

Unless otherwise specified, use 800 x 600 mode

signal (53.7 kHz/85 Hz) for adjustments.

5-3-1 Color Coordinates (Temperature)

Color temperature is a measurement of the

radiant energy transmitted by a color. For

computer monitors, the color temperature refers

to the radiant energy transmitted by white. Color

coordinates are the X and Y coordinates on the

chromaticity diagram of wavelengths for the

visible spectrum.

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 53.7 kHz/85 Hz

Display image: White flat field at

center of display area

Luminance: Maximum

PROCEDURE

Using the directions in sections 5-3-2 through

5-3-5, adjust the Color Coordinates for 9300K to

x = 0.283 ± 0.02 and y = 0.298 ± 0.02

5-3-2 Back Raster Color Adjustment

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 53.7 kHz/85 Hz

Display image: Back raster pattern

Brightness: Maximum

Contrast: Maximum

PROCEDURE

1. Adjust the Screen VR on the FBT so that the

brightness of the Back Raster is 0.3 to 0.5 ft-L

(typically 0.4 ft-L).

2. Adjust the G_CUT to center.

3. Adjust the B_CUT to set the ÒyÓ coordinate to

0.298 ± 0.02.

4. Adjust the R_CUT to set the ÒxÓ coordinate to

0.283 ± 0.02.

Note: If the above adjustments cannot be done to

each coordinate, adjust G_CUT to increase

or decrease the green cutoff and repeat

procedures 3 and 4.

5-3-3 Video Gain Adjustment

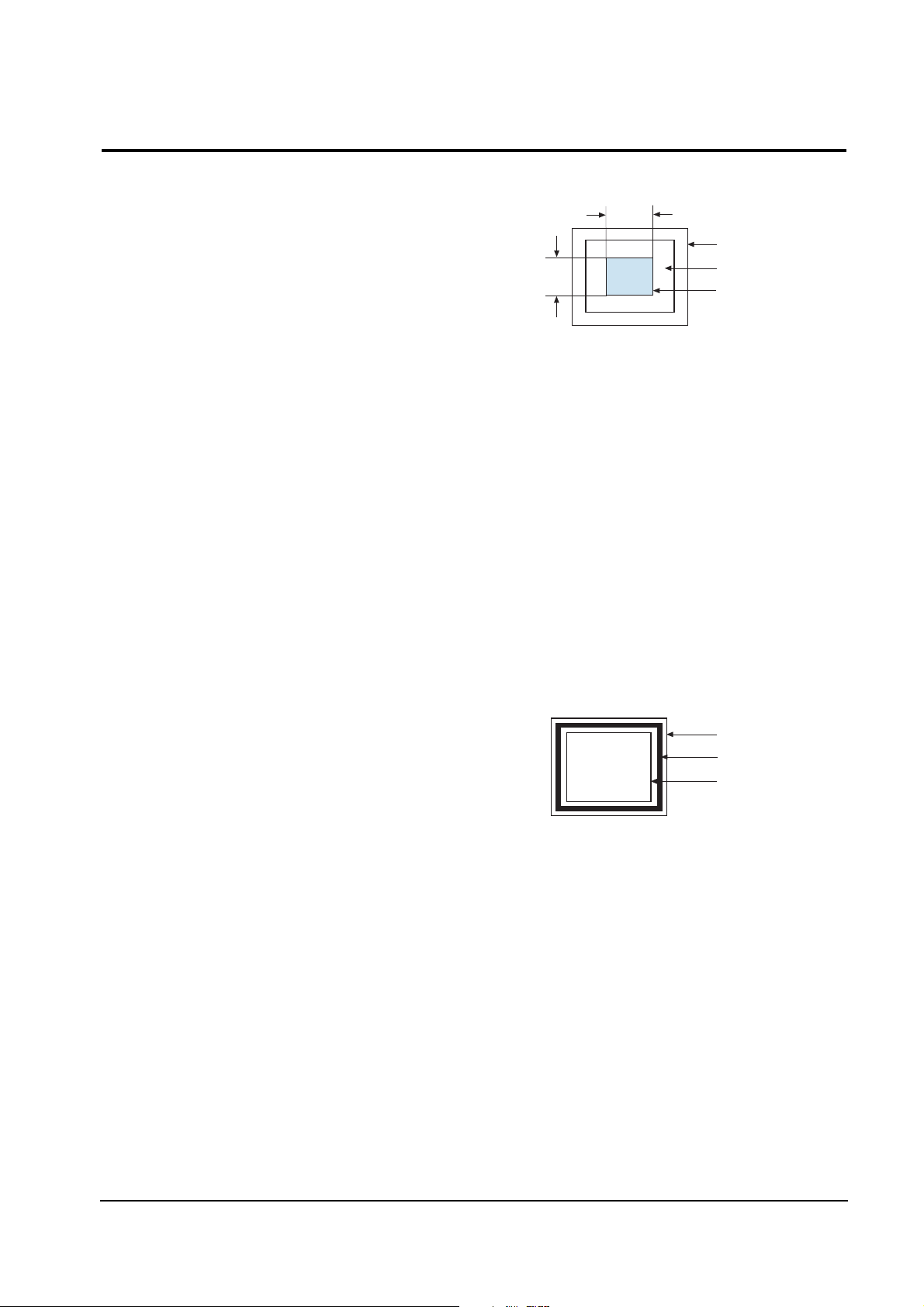

Figure 5-8. Green Box Pattern

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 53.7 kHz/85 Hz

Display image: Green box pattern

within range for which

the ABL circuit is not

active (1/3 to 1/2H and

1/3 to 1/2V).

Brightness: Maximum

Contrast: Maximum

PROCEDURE

1. Adjust G-Gain so that the brightness of the

green gain is 40 ± 1 ft-L

(typically 40 ft-L).

5-3-4 White Balance Adjustment

Figure 5-9. Full White Pattern

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 53.7 kHz/85 Hz

Display image: Full white pattern

Brightness: Maximum

Contrast: Maximum

PROCEDURE

1. Display the full white pattern.

2. Adjust R-Gain and B-Gain so that the video is

white.

(x = 0.283 ± 0.02 and y = 0.298 ± 0.02)

5 Alignment and Adjustments

DP14L*/DP15L* 5-5

5-3 Color Adjustments

1/3H-1/2H

1/3V-1/2V

FRONT BEZEL OPENING

BACK RASTER

GREEN WINDOW

FRONT BEZEL OPENING

BACK RASTER

WHITE WINDOW

Page 22

5-3-5 White Balance Fine Adjustment

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 53.7 kHz/85 Hz

Display image: Full white pattern

X-Y coordinates: x = 0.283 ± 0.02

y = 0.298 ± 0.02

PROCEDURE

1. Adjust the Contrast control so that the

brightness of the video is about 5 ft-L.

2. Check whether the white coordinates of the

video meet the specification above. If they do

not, adjust them so that they do.

3. Adjust the Contrast to maximum luminance.

4. Check whether the white coordinates still

meet the specification above. If they do not,

adjust them so that they do.

5-3-6 ABL Point Adjustment

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 53.7 kHz/85 Hz

Display image: Full white pattern

Brightness: Maximum

Contrast: Maximum

PROCEDURE

Adjust ABL so that the brightness level is

35 ± 1 ft-L.

5-3-7 Focus Adjustment

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 53.7 kHz/85 Hz

Display image: ÒHÓ character pattern

Brightness: Maximum

Contrast: Maximum

PROCEDURE

1. Adjust the Focus VR on the FBT to display the

sharpest image possible.

2. Use Locktite to seal the Focus VR in position.

5-3-8 Luminance Uniformity Check

CONDITIONS

Measurement instrument: Color analyzer

Scanning frequency: 53.7 kHz/85 Hz

Display image: White flat field

Brightness: Cut off point at 30 ft-L

PROCEDURE

Measure luminance at nine points on the display

screen: top left corner, top center, top right corner,

center row left side, center, center row right side,

bottom left corner, bottom center, and bottom

right corner.

5-3-9 Color Purity Adjustment

Color purity is the absence of undesired color.

Conspicuous mislanding (unexpected color in a

uniform field) within the display area shall not be

visible at a distance of 50 cm from the CRT

surface.

CONDITIONS

Orientation: Monitor facing east

Scanning frequency: 53.7 kHz/85 Hz

Display image: White flat field

Luminance: Cutoff point at the center

of the display area

Caution: Color purity adjustments should only

be attempted by qualified personnel.

PROCEDURE

For trained and experienced service technicians

only.

Use the following procedure to correct minor

color purity problems:

1. Make sure the display is not affected by

external magnetic fields. Use an external

degaussing coil to neutralize magnetic fields

which may be affecting color purity.

2. Very carefully break the glue seal between the

2-pole purity convergence magnets (PCM), the

band and the spacer .

3. Make sure the spacing between the PCM

assembly and the CRT stem is

22.5 mm ± 1 mm.

4. Display a red pattern over the entire display

area.

5. Adjust the Purity Magnet Rings on the PCM

assembly to display a pure green pattern.

(Optimal setting: x = x = 0.283 ± 0.02,

y = 0.298 ± 0.02)

6. Repeat steps 4 and 5 using a red pattern and

then again, using a blue pattern.

Table 5-3. Color Purity Tolerances

(For 9300K white color adjustment:

x = 0.283 ± 0.02, y = 0.298 ± 0.02)

7. When you have the PCMs properly adjusted,

carefully gule them together with Locktite to

prevent their movement during shipping.

5 Alignment and Adjustments

5-6 DP14L*/DP15L*

Red: x = 0.625 ± 0.015 y = 0.340 ± 0.015

Green: x = 0.310 ± 0.015 y = 0.592 ± 0.015

Blue: x = 0.150 ± 0.015 y = 0.063 ± 0.015

Page 23

DP14L*/DP15L* 6-1

6 Troubleshooting

6-1 General Troubleshooting

Notes: 1. If a picture does not appear, fully rotate the brightness and contrast controls clockwise and reinspect.

2. Check the following circuits.

• No raster appears: Power circuit, Horizontal output circuit, H/V control circuit, and H/V output circuit.

• High voltage develops but no raster appears: Video output circuits.

• High voltage does not develop: Horizontal output circuits.

6-1-1 No Picture

Check signal cable connection, H/V Sync input.

Check Timing mode (14”: 30~55kHz, 15”: 30~61kHz).

Check Cont,

Bright

key (all Max) and Screen VR (G2).

Check key components of secondary part. :

D406, D407, D408, D515, Q402, Q410, Q504, Rectifier

diodes (D608 ~ D612), IC101 (Vcc~GND)

Check key components of primary part. :

D601 ~ D607, FH601, IC601, TH602

Check SW601 (Power key)

Refer to 6-2-16 No Video.

Refer to 6-2-1 No Power.

Refer to 6-2-3 No Raster and 6-2-12 High Voltage Failure.

Refer to 6-2-17 Micom Failure.

Refer to 6-2-13 I2C Failure.

Page 24

6 Troubleshooting

6-2 DP14L*/DP15L*

6-1-2 Shut Down

Check X-ray protection circuit. :

D502, D503, R510

Check key components of secondary part. :

D406, D407, D408, D515, IC101 (Vcc ~ GND)

Q402, Q504, Rectifier diodes

Check and replace IC601.

Refer to 6-2-1 No Power.

Refer to 6-2-3 No Raster and 6-2-12 High Voltage Failure.

Refer to 6-2-17 Micom Failure.

Refer to 6-2-13 I2C Failure.

Page 25

6 Troubleshooting

DP14L*/DP15L* 6-3

6-1-3 No Video or Missing Colors

Are 0.7Vp-p video input on

CN202_2 R, G, B?

Check signal cable and generator.

Yes

No

Are proper waveform on

SK103’s R, G, B cathode?

Refer to 6-2-16 No Video.

Yes

No

Is G2 and heater voltage OK?

Check and replace SK103 and

some parts around it.

Yes

No

Change CRT and replace it.

Check white balance adjustment.

WAVEFORMS

22

19

19

46.4 V (SK103, G)

CH1 P-P = 46.4 V CH1 RMS = 38.16 V

22

1.016 V (CN202_2, #2,4,6)

CH1 P-P = 1.016 V CH1 RMS = 174.4 mV

WAVEFORMS

17

35.2 V (SK103, G1)

CH1 P-P = 35.2 V CH1 RMS = 80.84 V

25

4.96 V (IC201, #30)

CH1 P-P = 4.96 V CH1 RMS = 350 mV

Check signal cable connection, H/V Sync input.

Check Timing mode (14”: 30~55kHz, 15”: 30~61kHz).

Check Cont, Brit key (all Max) and Screen VR (G2).

6-1-4 Visible Retrace

Is G2 voltage (Screen VR) OK?

Adjust Screen VR to 0.4~0.6F/L (back

raster) at cont, bright all max.

Yes

No

Is V_sync input on Q301 base?

Check V_sync input line.

Yes

No

Is proper G1 pulse on SK103’s

G1 pin?

Check C306, C506, D504

Q301, Q501 and around parts.

Yes

No

Check and replace CRT.

25

17

Page 26

6 Troubleshooting

6-4 DP14L*/DP15L*

6-1-5 Unsynchronized image

Are H/V sync input on IC201’s

Pins 30 and 31?

Check the connection of signal cable.

Refer to 6-2-12 High Voltage Failure.

Yes

Check H/V sync input line.

No

6-1-6 Misconvergence

Spec in?

(Center : 0.3 mm, Cornor : 0.4 mm)

Readjust Misconvergence.

Done

Yes

Change CRT and readjust

Miconvergence and color.

No

Refer to 6-2-17 Micom

Failure.

No

Are H/V sync input on IC401’s

Pins 1 and 2?

Yes

Check and replace IC401.

Yes

Check H/V sync input line.

No

Check and replace IC201.

No

WAVEFORMS

24

26

25

27

24

5.28 V (IC201, #31)

CH1 P-P = 5.28 V CH1 RMS = 1.218 V

25

4.96 V (IC201, #30)

CH1 P-P = 4.96 V CH1 RMS = 350 mV

26

5.48 V (IC401, #1)

CH1 P-P = 5.48 V CH1 RMS = 1.362 V

27

4.48 V (IC401, #2)

CH1 P-P = 4.48 V CH1 RMS = 284 mV

Page 27

6 Troubleshooting

DP14L*/DP15L* 6-5

6-1-7 Poor Focus

Improved Focus?

Aging monitor and check focus

change for 1~2 hours.

Check Focus lead from FBT to

CRT Socket.

Adjust Focus VR.

No

Yes

Are the CRT Socket and

connection OK?

Replace and connect it.

Check and replace CRT.

Yes

Yes

No

6-1-8 Purity Failure

Degaussing

Is purity OK?

Done

No

Yes

IS degaussing circuit OK?

Refer to 6-2-20 Degaussing Failure.

Yes

No

Check if there is strong

electric or magnetic fields near

user’s circumstance?

Recommend free electric or

magnetic field.

No

Yes

Change CRT and readjust

misconvergence and color.

Page 28

6 Troubleshooting

6-6 DP14L*/DP15L*

6-2 Detail Repair Section

Notes: 1. If a picture does not appear

check first • if AC power cord is plugged or not,

• if signal cable is connected or not,

• if signal generator (PC) is operated well or not (DPMS mode)

• if the Timing mode is out of spec or not (14”: 30~55 kHz, 15”: 30~61 kHz)

Does recitfied voltages of

secondary part appear on C620,

C622, C623, C624, C630?

Refer to 6-2-3 No Raster and

6-2-12 High Voltage Failure.

Check and replace D406, D407, D408,

IC101, Q402, Q410, Q504

Yes

Are D608 ~ D612 OK?

Replace it.

Check and Replace

IC601, T601.

Check and replace D602, D603, D607,

IC601, T602.

No

No

Does rectified voltage

(1.4 x AC input) of primary part

appear on C607?

Check and replace

D601~D607, FH601, TH602.

Yes

Yes

No

Is IC601’s Pin 1 OK?

No

Yes

Yes

Is IC601’s Pin 5 OK?

NoYes

Does rectified voltage

(1.4 x AC input) of primary

part appear on C617?

No

6-2-1 No Power

Check and replace IC601, T601.

Check and replace T601 and

around parts.

WAVEFORMS

1

2

1

410 V (IC601, #1)

CH1 P-P = 410 V CH1 RMS = 332.8 V

2

8.40 V (IC601, #5)

CH1 P-P = 8.40 V CH1 RMS = 4.680 V

Desolder IC601’s Pin 1.

No

Page 29

6 Troubleshooting

DP14L*/DP15L* 6-7

Is LED blinking? (1 sec toggle)

Check and replace

OP201.

Make sure that there is No H/V sync

from signal generator. (Signal cable

should be connected)

Yes

Are there 0V on IC201’s Pin 5 (sus)

and 0V on IC201’s Pin 6 (off)?

Check and replace IC201.

Check and replace IC201.

No

Is OP201 OK?

Yes

No

No

Yes

+6.3 V line Off?

Check and replace Q603, Q604.

No

+12 V Off?

Check and replace Q605 ~ Q608.

No

Yes

Yes

Done

6-2-2 DPMS Failure

6-2-2 (a) Off Mode (No H/V sync)

Page 30

6 Troubleshooting

6-8 DP14L*/DP15L*

6-2-2 (b) Suspend Mode (H sync: OK, V sync: No)

Is LED blinking? (0.5 sec toggle)

Check and replace

OP201.

Make sure that H sync is OK and V sync is

not. (Signal cable should be connected)

Yes

Are there 0V on IC201’s Pin 5 (sus)

and 5V on IC201’s Pin 6 (off)?

Check and replace IC201.

Check and replace IC201.

No

Is OP201 OK?

Yes

No

No

Yes

+12 V Off?

Check and replace Q605 ~ Q608.

No

Yes

Done

6-2-2 (c) Stand-by Mode (H sync: No, V sync: OK)

Is LED blinking? (0.5 sec toggle)

Check and replace

OP201.

Make sure that H sync is not and V sync is

OK. (Signal cable should be connected)

Yes

Are there 5V on IC201’s Pin 5 (sus)

and 0V on IC201’s Pin 6 (off)?

Check and replace IC201.

Check and replace IC201.

No

Is OP201 OK?

Yes

No

No

Yes

Is high voltage On?

Refer to 6-2-3 No Raster and

6-2-12 High Voltage Failure.

No

Yes

Video Mute?

Refer to 6-2-16 No Video and

6-2-13 I2C Failure.

No

Yes

Done

Page 31

6 Troubleshooting

DP14L*/DP15L* 6-9

6-2-3 No Raster : No Raster means (Power: OK, High Voltage: No)

Is 12 V on C628?

Check and replace

Q602, Q605, Q606,

IC101, IC401.

Yes

Check signal cable and pattern.

No

Is 0 V on IC201’s Pin 5 (sus)?

Yes

No

Check and replace

IC201.

Are H/V sync on IC201’s

Pins 30 and 31?

Yes

No

Is 53 V on C507?

Refer to 6-2-1 No Power.

No

Yes

Does oscillation waveform

appear on IC401’s Pin 6?

Check and replace IC401.

No

Yes

WAVEFORMS

3

Does horizontal output waveform

appear on IC401’s Pin 26?

Check and replace Q401, Q402, Q504,

T401, T501.

No

Yes

4

Is Q402 OK?

Replace it.

No

Yes

Is Q504 OK?

Replace it.

Check and replace D407, D408,

D409, D515.

Check and replace C506, D503, D504,

D505, IC401, Q401, T401 , T501,

CRT.

No

Yes

Operating?

Yes

3

5.12 V (IC401, #6)

CH1 P-P = 5.12 V CH1 RMS = 4.256 V

4

4.60 V (IC401, #26)

CH1 P-P = 4.60 V CH1 RMS = 3.054 V

Page 32

6 Troubleshooting

6-10 DP14L*/DP15L*

6-2-4 S-correction Failure

6-2-5 H-Linearity Failure

Are S1 and S2 OK at IC201’s

Pins 9 and 10?

Replace Q405, Q407.

Symptoms: Poor Horizontal linearity

– Corner: wide, Center: narrow or

– Corner: narrow, Center: wide

No

Are Q406 and Q408 OK?

Replace it.

Check and replace C431, C433, C434,

D412, D413, Q405, Q407.

Check and replace IC201.

Yes

Are Q405 and Q407 OK?

No

Yes

No

Yes

31 ~ 35 35 ~ 40 40 ~ 49 49 ~ 61

S1 0 V 0 V 5 V 5 V

S2 0 V 5 V 0 V 5 V

Table 6-1.

* As CRT vendor and inch, there are differential items like C431, C433, C434, L401, R231, R441.

If you want to change a PCB board to another one that is for different CRT and inch, you have to change

differential items at schematic diagram.

Are code nomber and polarity

of L401 right?

Check and replace it.

No

Yes

Are C427, D409, R423 OK?

Check and replace it.

Refer to 6-2-4 S-correction Failure.

No

Yes

Page 33

6 Troubleshooting

DP14L*/DP15L* 6-11

6-2-6 Invariable H_Size

Does the PWM duty of IC201’s Pin

22 vary, pressing H_Size button?

Check and replace

Q409.

Yes

Is paravola waveform on

IC401’s Pin 24?

Replace IC401.

Replace IC201.

No

Is Q409 OK?

No

No

No

Yes

Are D414, Q411 and Q412 OK?

Replace it.

No

Yes

Check and replace Q409, Q410, L402.

WAVEFORMS

8

8

1.12 V (IC401, #24)

CH1 P-P = 1.12 V CH1 RMS = 3.094 V

Does PWM duty of IC201’s

Pin 22 vary with different timings?

(Low freq. : narrow duty

High freq. : wide duty)

Check and replace IC201 and some

parts around it.

Check if R441 are right

as CRT differential items?

Adjust horizontal minimum size with

softjig. (Refer to 5-2-1)

No

Does the FBT B+ voltage on T501’s

Pin 2 vary with different timings?

Refer to 6-2-12 High Voltage Failure.

Yes

No

Yes

6-2-7 Abnormal H_Size

Page 34

6 Troubleshooting

6-12 DP14L*/DP15L*

6-2-8 S_Pin, Trap, Para, V_Lin, Pin_Bal Failure

Is IC401’s Pin 24 OK?

Yes

Check and replace IC401.

No

Does the PWM duty of

IC201’s Pin 21 vary, pressing tilt

and + or – key?

Check and replace IC201, IC302.

No

No

Does the output voltage of

IC302’s Pin 1 vary, pressing tilt and

+ or – key?

Check and replace IC302, +13 V

and –12 V line.

Check and replace CRT.

Yes

Refer to 6-2-13 I2C Failure.

No

Key check (6-2-19)

6-2-9 Tilt Failure

Check tilt connector. (CN303)

Key check (6-2-19)

WAVEFORMS

8

8

1.12 V (IC401, #24)

CH1 P-P = 1.12 V CH1 RMS = 3.094 V

Page 35

6 Troubleshooting

DP14L*/DP15L* 6-13

6-2-10 Vertical Deflection Failure

Are +13 V, –12 V line OK?

Is V_out waveform on IC401’s

Pin 23?

Yes

Check and replace D608, D609,

IC301, IC302.

No

Symptoms: – One horizontal line

– Rainbow color, No Video

Check and replace

R307, R308, IC401.

No

Is V_deflection waveform on

IC301’s Pin 6?

Check and replace IC301, R305, R306,

and some parts around it.

Check and replace IC401.

Yes

Is 8 V on IC401’s Pin 21?

No

Yes

No

Yes

Refer to 6-2-13 I2C Failure.

10

9

6-2-11 Invariable V_Size or V_Position

Key check (6-2-18)

Refer to 6-2-13 I2C Failure.

Does V_Out (IC401’s Pin 23) vary,

pressing V_Size or V_Posi key?

Check and replace IC301 and some

parts around it.

No

Yes

WAVEFORMS

10

50.8 V (IC301, #6)

CH1 P-P = 50.8 V CH1 RMS = 7.04 V

9

3.16 V (IC401, #23)

CH1 P-P = 3.16 V CH1 RMS = 3.686 V

9

WAVEFORMS

9

3.16 V (IC401, #23)

CH1 P-P = 3.16 V CH1 RMS = 3.686 V

Page 36

6 Troubleshooting

6-14 DP14L*/DP15L*

6-2-12 High Voltage Failure

Is Q504’s drain waveform ok?

Check and replace it.

No

Check and replace AFC input line

from T501 to IC401’s Pin 12. :

C408, R406.

Yes

Are D515, L501, Q504 ok?

No

Yes

Check and replace it.

Are D403, D408, D409, Q402

and Q411, Q412 ok?

No

Yes

Is 53 V on C623?

Refer to 6-2-1 No Power.

No

Yes

WAVEFORMS

13

Are D502, D503, R509, R510 ok?

Check and replace it.

No

Yes

Does B_Out duty of IC401’s

Pin 28 vary with different

H_frequency and image load

(Full White or No Video)?

Check and replace Q502, Q503,

IC401, T501 and REG_IN line to

IC401’s Pin 15.

No

Yes

Check and replace Q502, Q503,

IC401, T501.

12

14.0 V (IC401, #28)

CH1 P-P = 14.0 V CH1 RMS = 7.34 V

13

136 V (Q504, Drain)

CH1 P-P = 136 V CH1 RMS = 78.3 V

Symptoms 1: – No Power

– No Raster

– Unstable operation (Fixed FBT B+ voltage with different H_frequency,

Over 31 kHz: whistle sound, Narrow H_Size, Unsynchronized image, 31 kHz: OK)

12

Page 37

6 Troubleshooting

DP14L*/DP15L* 6-15

Are C417, C504, D502, D503, R509

and R510 ok?

Yes

Check and replace it.

No

Symptoms 2: – X-ray protection

– One vertical line and then high voltage shut down.

Check and replace D407, D408,

D414, Q402, Q504, IC401.

Check and replace IC201.

Is 5 V on IC401’s Pin 32 and

IC203’s Pin 8?

Check and replace it.

No

Yes

Is there data communication on

IC401’s Pins 30 and 31?

No

Yes

Is there data communication

on IC401’s Pins 30 and 31 during

I2C function? (H/V Posi, V_Size,

S_Pin, Trap, Cont, Bright)

Check I2C data and clock line.

Check and replace I2C devices.

(IC201, IC203, IC401)

No

Yes

Done

14

14

6-2-13 I2C Failure

– Almost data (Horizontal drive duty, FBT B+ duty, display image data, color data) is transferred

from IC201 to IC203 and IC401 through I2C data line during power on.

– After user adjusts display image data, contrast and brightness data, these are saved to IC203.

Key check (6-2-18)

WAVEFORMS

14

5.92 V (IC203, #5, 6)

CH1 P-P = 5.92 V CH1 RMS = 3.812 V

CH1 : IC401’s Pin 31

CH2 : IC401’s Pin 30

Page 38

6 Troubleshooting

6-16 DP14L*/DP15L*

No

Does full white luminance vary,

adjusting ABL step with Softjig?

Yes

Does the voltage of

IC101’s Pin 8 vary between full

white and No Video?

Yes

No

Does the PWM duty of

IC201’s Pin 25 vary adjusting

ABL step?

Yes

No

Display the full white pattern.

Check and replace IC101.

Does T501’s Pin 8

voltage vary between full white

and No Video?

Yes

No

Check and replace D506, IC101.

Are 12 V line, R523, R523 ok?

No

Yes

Replace it.

Check and replace T501 and CRT.

Check and replace IC201 and

around parts.

Check connections between

CN105 and CN202.

6-2-14 ABL Failure

Symptoms : – Full white luminance is too bright. (ABL minium is over 35 F/L)

– Full white luminance is too dark. (ABL maximum is under 35 F/L)

– The luminance of full white and No Video are almost same.

F/W: 4.1~4.3V

No Video: 5.3~6.0V

F/W: 1.5~3.0V

No Video: 5.5~7.0V

Page 39

6 Troubleshooting

DP14L*/DP15L* 6-17

Does IC101’s output

(Pins 18, 21 and 23) vary, pressing

cont, bright key?

Replace IC101.

Yes

Yes

No

Does IC103’s output

(Pins 1, 2 and 3) vary, pressing

cont, bright key?

Replace IC103.

Yes

No

Check and replace Q101R, Q101G,

Q101B, Q102R, Q102G, Q102B,

Q103R, Q103G, Q103B.

Refer to 6-2-18 Key Check.

(Contrast, Brightness)

I2C check (6-2-13)

6-2-15 Invariable Contrast, Brightness Control

15

16

WAVEFORMS

15

3.16 V (IC101, #21)

CH1 P-P = 3.16 V CH1 RMS = 1.008 V

16

43.2 V (IC103, #3)

CH1 P-P = 43.2 V CH1 RMS = 63.56 V

Page 40

6 Troubleshooting

6-18 DP14L*/DP15L*

6-2-16 No Video

Is heater voltage (5.9~6.3V) on

SK103’s heater Pin?

Replace it.

No

Check and replace Q604, R622.

Yes

Are D612, Q603 and R618 ok?

No

Yes

Check and replace

Q603, R618, R619.

Is 0V on Q604’s collector?

No

Yes

Check and replace

IC201.

Is 5V on IC201’s Pin 6

No

Yes

Replace IC101.

Refer to 6-2-1

No Power.

Opening BD102, is it

short between IC101’s Vcc and

ground?

No

Yes

Check signal cable connection.

Check Cont,

Bright

key (All max).

Is G1 voltage OK at

SK103’s G1 Pin?

Check and replace C119, D504, D505,

Q501, R515, R516, R517, SK102.

Check CN103’s connection (G2).

No

Yes

WAVEFORMS

17

Desoldering SK101 and C118,

is G2 voltage ok?

Check and replace SK101, C118

and then T501.

No

Yes

Is 12 V on IC101’s Pins 1 and 7?

No

Check and replace

IC201 and around it.

Is clamp signal on IC101’s

Pin 12?

No

Is IC101’s output on Pins 18,

21 and 23?

No

Yes

17

35.2 V (SK103, G1)

CH1 P-P = 35.2 V CH1 RMS = 80.84 V

15

18

Page 41

6 Troubleshooting

DP14L*/DP15L* 6-19

Check and replace

IC201 and around it.

Is clamp signal on IC101’s

Pin 12?

No

Is IC101’s output on Pins 18,

21 and 23?

No

15

18

Refer to 6-2-15 ABL Failure.

YesYes

Check 70 V line.

Is 70 V on IC103’s Pin 4?

No

Is IC103’s output on Pins 1,

2 and 3?

No

16

Replace IC103.

YesYes

Check again cont, bright key.

6.3 V line, G1, G2 line.

Is it ok?

Are there waveforms on SK103’s

R, G, B?

Yes

Disconnect Video PCB from CRT neck.

YesNo

Replace IC101.

6-2-16 No Video Continued

Are ther waveforms on

SK103’s R, G, B?

Check and replace SK103 and CRT.

No

Yes

Check and replace Q101R, Q101G,

Q101B, Q102R, Q102G, Q102B,

D103R, D103G, D103B and

PCB pattern.

19

WAVEFORMS

15

3.16 V (IC101, #21)

CH1 P-P = 3.16 V CH1 RMS = 1.008 V

16

43.2 V (IC103, #3)

CH1 P-P = 43.2 V CH1 RMS = 63.56 V

18

5.60 V (IC101, #12)

CH1 P-P = 5.60 V CH1 RMS = 4.908 V

19

46.4 V (SK103, G)

CH1 P-P = 46.4 V CH1 RMS = 38.16 V

Page 42

6 Troubleshooting

6-20 DP14L*/DP15L*

Check if timing is out of spec or not.

Key check (all key) : Refer to 6-2-19.

Check the connection of signal cable. If signal cable is disconnected, self raster (No Video, Bright Raster) appears.

If there is no H/V sync, monitor is operated as DPMS mode.

If out of sepc, monitor is operated as stand-by mode. (No Video, LED: 0.5 sec toggle)

14”: Horizontal 30 ~ 55 kHz, Vertical 50 ~ 120 Hz

15”: Horizontal 30 ~ 61 kHz, Vertical 50 ~ 120 Hz

Check H/V sync from PC or signal

generator.

Are oscillation (8 MHz) on

IC202’s Pins 13 and 14?

Check and replace C203, C204, X201.

Yes

No

6-2-17 Micom Failure

Refer to 6-2-1

No Power.

Is 13 V on C624?

No

Is 5V on IC201’s Pins 11 and 34?

No

Cceck and replace

IC201, R226.

When disconnecting signal

cable: Is 0V on IC201’s Pin 19?

When connecting signal cable:

Is 5V on IC202’s Pin 13?

No

Are H/V sync input on

IC201’s Pins 30 and 31?

Yes

20

Check reset part.

Are IC202 ok?

Replace it.

Yes

No

Check and replace IC602.

YesYes

24 25

WAVEFORMS

20

4.92 V (IC201, #14)

CH1 P-P = 4.92 V CH1 RMS = 2.912 V

Page 43

6 Troubleshooting

DP14L*/DP15L* 6-21

Cceck and replace

IC201, R226

Signal cable.

When disconnecting signal

cable: Is 0V on IC201’s Pin 19?

When connecting signal cable:

Is 5V on IC201’s Pin 19?

No

Are H/V sync input on

IC201’s Pins 30 and 31?

Yes

24 25

6-2-17 Micom Failure Continued

Check signal cable.

Sus (Pin 5) : 5 V,

Off (Pin 6) : 5 V?

Refer to 6-2-13 I2C Failure.

Replace LED.

Yes

LED is ok?

No

Check PCB pattern to

IC401’s

Pins 1 and 2.

Replace IC201.

Are H/V sync input from

IC201 on IC401’s

Pins 1 and 2?

Yes

Yes

Yes

Check D202, D203.

Check PCB pattern to Pins 30 and 31.

Yes

Yes

WAVEFORMS

24

5.28 V (IC201, #31)

CH1 P-P = 5.28 V CH1 RMS = 1.218 V

25

4.96 V (IC201, #30)

CH1 P-P = 4.96 V CH1 RMS = 350 mV

26

5.48 V (IC401, #1)

CH1 P-P = 5.48 V CH1 RMS = 1.362 V

27

4.48 V (IC401, #2)

CH1 P-P = 4.48 V CH1 RMS = 284 mV

26 27

Yes

No

Yes

Page 44

CH1 of Picture Pin 21

Pressed RMS voltage

0.7 ~ 0.9 V

0.7 ~ 0.9 VCH2 of Picture Pin 21

Keyout

Normal

5 V

0 VKeyin

6 Troubleshooting

6-22 DP14L*/DP15L*

6-2-18 Key Check

1) Key Map

R206 R207 R208 R209

SW204

(V-Size)

SW203

(H-Size)

SW202

(V-Posi)

SW201

(H-Posi)

SW208

(Cont)

SW207

(Brit)

SW206

(Trap)

SW209

(Up)

SW210

(Down)

SW205

(S-Pin)

Keyout3

(#5)

Keyout2

(#4)

Keyout1

(#3)

Keyin4

(#39)

Keyin3

(#40)

Keyin2

(#42)

Keyin1

(#1)

2) Voltage Check of Keyin and Keyout

– Press the key what you want to check.

– At that moment, the voltage of keyin and keyout that is connected with together should be changed as follows.

3) LED Check

– Pressing key, LED should be blinked.

4) How to Repair?

– If only one key has a key problem, replace that key.

– But if some keys that are connected with same keyin or keyout line have problems,

check and replace PCB pattern and IC201.

WAVEFORMS

21

5.52 V (IC201, Keyout)

CH1 P-P = 5.52 V CH1 RMS = 3.696 V

21

5.44 V (IC201, Keyin)

CH1 P-P = 5.44 V CH1 RMS = 1.436 V

Page 45

6 Troubleshooting

DP14L*/DP15L* 6-23

6-2-19 User Control Failure

When pressing keys,

does LED blink?

Check knob function and space

at front cover.

Refer to 6-2-18 Key Check.

Refer to 6-2-18 Key Check.

Yes

No

When pressing cont and brit

key simultaneously, does the

voltage of IC201’s Pin 4 vary from

0 V to 5 V for 2~3 seconds?

Refer to 6-2-18 Key Check.

Check if degaussing coil is connected

with GT601, GT602.

Check and replace D616, Q601,

R603, RL601.

No

Yes

Check and replace degaussing coil.

6-2-20 Degaussing Failure

Page 46

6 Troubleshooting

6-24 DP14L*/DP15L*

6-2-21 Horizontal Blank Failure

6-2-23 Spot at Center During Power Off

6-2-22 Whistle Sound

Check trans coil (L401, T501, T601, CRT)

Is H_Blank waveform on

Q510’s collector?

Check CN105 and CN202.

Check and replace IC101.

Check and replace C501, C502,

C503, R504.

No

Yes

Are Q504 and D515 ok?

Replace it.

Yes

No

Symptoms: – Dark image and if shifting image to left or right side, image is rolled.

– Raster left or right side is rolled.

Does G1 voltage vary from

–60~80 Vrms to –200 Vrms during

power off time? (After falling

down to –200V, G1 voltage is

slowly increased to 0V).

Check and replace CRT.

No

Yes

32

31

Are 12 V line and Q501 ok?

Replace it.

Check and replace C506, D504, R515,

R516, R517.

Yes

No

WAVEFORMS

31

5.36 V (Q510, Collector)

CH1 P-P = 5.36 V CH1 RMS = 4.210 V

WAVEFORMS

32

158 V (CN105, G1)

CH1 P-P = 158 V CH1 RMS = 151.1 V

Page 47

7 Exploded View and Parts List

7-1 DP14L*

DP14L*/DP15L* 7-1

Page 48

7 Exploded View & Parts List

7-2 DP14L*/DP15L*

7-2 DP15L*

Page 49

DP14L*/DP15L* 7-3

7-1-1 Front Cover & CRT Ass’y (DP14L*)

Page 50

7-1-2 Chassis & Stand Ass’y (DP14L*)

7 Exploded View & Parts List

7-4 DP14L*/DP15L*

Page 51

7-1-3 Rear Cover Ass’y (DP14L*)

7 Exploded View & Parts List

DP14L*/DP15L* 7-5

Page 52

7 Exploded View & Parts List

7-6 DP14L*/DP15L*

7-2-1 Front Cover & CRT Ass’y (DP15L*)

Page 53

7-2-2 Chassis & Stand Ass’y (DP15L*)

7 Exploded View & Parts List

DP14L*/DP15L* 7-7

Page 54

7-2-3 Rear Cover Ass’y (DP15L*)

7 Exploded View & Parts List

7-8 DP14L*/DP15L*

Page 55

8 Electrical Parts List

8-1 Main PCB Parts

BD402 3301-000011 CORE-FERRITE BEAD AA,3.5x1.0x5.7mm,1500

BD403 3301-000012 CORE-FERRITE BEAD AA,3.5x1x9mm,1000,3000

BD406 3301-000011 CORE-FERRITE BEAD AA,3.5x1.0x5.7mm,1500

BD501 3301-000012 CORE-FERRITE BEAD AA,3.5x1x9mm,1000,3000

BD502 3301-000012 CORE-FERRITE BEAD AA,3.5x1x9mm,1000,3000

BD601 3301-000012 CORE-FERRITE BEAD AA,3.5x1x9mm,1000,3000

BD602 3301-000012 CORE-FERRITE BEAD AA,3.5x1x9mm,1000,3000

BD603 3301-000011 CORE-FERRITE BEAD AA,3.5x1.0x5.7mm,1500

BD604 3301-000011 CORE-FERRITE BEAD AA,3.5x1.0x5.7mm,1500

C201 2401-000050 C-AL 10uF,20%,16V,GP,TP,5x11,2.5

C203 2201-000483 C-CERAMIC,DISC 33pF,5%,50V,CH,TP,5x3,5

C204 2201-000483 C-CERAMIC,DISC 33pF,5%,50V,CH,TP,5x3,5

C208 2201-000146 C-CERAMIC,DISC 100pF,5%,50V,SL,TP,5x3,5

C209 2201-000017 C-CERAMIC,DISC 1nF,10%,50V,Y5P,TP,4x3.5

C210 2401-000050 C-AL 10uF,20%,16V,GP,TP,5x11,2.5

C211 2401-000050 C-AL 10uF,20%,16V,GP,TP,5x11,2.5

C212 2401-000050 C-AL 10uF,20%,16V,GP,TP,5x11,2.5

C213 2201-000144 C-CERAMIC,DISC 100pF,5%,50V,CH,TP,8x3,5

C214 2202-002009 C-CERAMIC,MLC-AXIAL 100nF,+80-20%,50V,Y5

C301 2401-000849 C-AL 220uF,20%,35V,GP,TP,10x12.5,5

C302 2305-000237 C-FILM,MPEF 1uF,5%,63V,TP,7.5x15.5mm,5mm

C303 2202-002008 C-CERAMIC,MLC-AXIAL 10nF,+80-20%,50V,Y5V

C304 2301-000519 C-FILM,PEF 3.3nF,5%,100V,TP,5.8x3x12.5,5

C305 2401-000603 C-AL 1uF,20%,50V,GP,TP,5x11,5

C306 2301-001027 C-FILM,PEF 15nF,10%,250V,TP,9.5x12x4.5,5

C309 2401-000050 C-AL 10uF,20%,16V,GP,TP,5x11,2.5

C310 2201-000558 C-CERAMIC,DISC 470pF,10%,50V,Y5P,TP,5x3

C401 2301-000016 C-FILM,PEF 22nF,5%,100V,TP,7.2x4.5x9.0mm

C402 2201-000573 C-CERAMIC,DISC 47pF,5%,50V,CH,TP,6.5x3.0

C403 2301-000016 C-FILM,PEF 22nF,5%,100V,TP,7.2x4.5x9.0mm

C404 2202-002021 C-CERAMIC,MLC-RADIAL 1nF,5%,50V,NPO,TP,5

C405 2401-002075 C-AL 4.7uF,20%,50V,GP,TP,5x11,5

C406 2301-000174 C-FILM,PEF 15nF,5%,100V,TP,7.2x4.0x7.5mm

C407 2401-000603 C-AL 1uF,20%,50V,GP,TP,5x11,5

C408 2301-000004 C-FILM,PEF 2.2nF,5%,100V,TP,5.5X10X2.9,5

C409 2202-002009 C-CERAMIC,MLC-AXIAL 100nF,+80-20%,50V,Y5

C410 2401-000031 C-AL 47uF,20%,16V,GP,TP,5x11,5

C412 2301-000016 C-FILM,PEF 22nF,5%,100V,TP,7.2x4.5x9.0mm

C413 2201-000471 C-CERAMIC,DISC .33NF,10%,50V,Y5P,TP,4X3M

C414 2201-000863 C-CERAMIC,DISC 680pF,10%,50V,Y5P,TP,5x3

C415 2401-000042 C-AL 100uF,20%,16V,GP,TP,6.3x7,5

C416 2401-000042 C-AL 100uF,20%,16V,GP,TP,6.3x7,5

C417 2202-002009 C-CERAMIC,MLC-AXIAL 100nF,+80-20%,50V,Y5

C418 2301-000168 C-FILM,PEF 150nF,5%,100V,TP,11.5x19mm,7

C419 2305-000412 C-FILM,MPEF 470nF,5%,63V,TP,5mm

!

DP14L*/DP15L* 8-1

Loc. No. Code No. Description Specification Remarks

Page 56

C420 2401-001509 C-AL 47uF,20%,16V,GP,TP,5x7,2.5mm

C421 2401-001515 C-AL 47uF,20%,16V,WT,TP,6.3x11,5

C422 2401-000603 C-AL 1uF,20%,50V,GP,TP,5x11,5

C423 2301-000004 C-FILM,PEF 2.2nF,5%,100V,TP,5.5X10X2.9,5

C424 2401-000887 C-AL 220uF,20%,63V,GP,TP,10x20,5

C425 2301-000005 C-FILM,PEF 33nF,5%,100V,TP,5.8x12.5x3,5

C426 2301-001207 C-FILM,PPF 5.2nF,5%,2.5KV,BK,29x21.5x13

C427 2201-000291 C-CERAMIC,DISC 1nF,10%,500V,Y5P,TP,8.5x5

C428 2401-000028 C-AL 10uF,20%,50V,GP,TP,5x11,5

C429 2401-000028 C-AL 10uF,20%,50V,GP,TP,5x11,5

C430 2401-000603 C-AL 1uF,20%,50V,GP,TP,5x11,5

C431 2301-001125 C-FILM,MPPF 600nF,5%,250V,TP,26x20x11.5

C432 2401-000603 C-AL 1uF,20%,50V,GP,TP,5x11,5

C433 2306-000164 C-FILM,MPPF 220nF,5%,250V,TP,19x22x10,7

C434 2306-000007 C-FILM,MPPF 470nF,5%,250V,BK,26x18.5x10

C435 2201-000471 C-CERAMIC,DISC .33NF,10%,50V,Y5P,TP,4X3M

C437 2301-000004 C-FILM,PEF 2.2nF,5%,100V,TP,5.5X10X2.9,5

C438 2401-001012 C-AL 3.3UF,20%,50V,BP,TP,16X25,7.5

C439 2303-001029 C-FILM,PPF 5.2nF,5%,630V,TP,19x7x13,7.5

C440 2201-000326 C-CERAMIC,DISC 2.2nF,10%,50V,Y5P,TP,6.5x

C501 2201-000017 C-CERAMIC,DISC 1nF,10%,50V,Y5P,TP,4x3.5

C502 2201-000471 C-CERAMIC,DISC .33NF,10%,50V,Y5P,TP,4X3M

C503 2201-000017 C-CERAMIC,DISC 1nF,10%,50V,Y5P,TP,4x3.5

C504 2401-000059 C-AL 220nF,20%,50V,GP,5x11,5

C506 2401-002267 C-AL 2.2uF,20%,250V,GP,TP,8x11.5,5

C507 2401-003448 C-AL 150UF,20%,100V,GP,TP,10X20MM,5

C508 2201-000409 C-CERAMIC,DISC 270pF,10%,500V,Y5P,TP,6x4

C509 2306-000007 C-FILM,MPPF 470nF,5%,250V,BK,26x18.5x10

C510 2301-000168 C-FILM,PEF 150nF,5%,100V,TP,11.5x19mm,7

C511 2401-000603 C-AL 1uF,20%,50V,GP,TP,5x11,5

C512 2301-000174 C-FILM,PEF 15nF,5%,100V,TP,7.2x4.0x7.5mm

C513 2401-000010 C-AL 220uF,20%,16V,GP,6.3x11mm,2

C601 2301-001195 C-FILM,MPPF 150nF,10%,275VAC,BK,26x16.5x

C602 2301-001195 C-FILM,MPPF 150nF,10%,275VAC,BK,26x16.5xq

C603 2201-000023 C-CERAMIC,DISC 2.2nF,20%,125V,Y5U,TP,11x

C604 2201-000023 C-CERAMIC,DISC 2.2nF,20%,125V,Y5U,TP,11x

C606 2202-002009 C-CERAMIC,MLC-AXIAL 100nF,+80-20%,50V,Y5

C607 2401-003119 C-AL 150uF,20%,400V,GP,BK,25.4x30,1

C608 2401-000966 C-AL 22uF,20%,50V,GP,TP,5x11,5

C609 2301-000284 C-FILM,PEF 47nF,5%,100V,TP,8.5x12.5mm,5m

C610 2201-000019 C-CERAMIC,DISC 10nF,+80-20%,500V,Y5V,TP

C611 2201-000012 C-CERAMIC,DISC 220pF,10%,1KV,Y5P,TP,6x5

C612 2401-001551 C-AL 47uF,20%,35V,GP,TP,6.3x11,5

C613 2401-000603 C-AL 1uF,20%,50V,GP,TP,5x11,5

C614 2301-000010 C-FILM,PEF 100nF,5%,100V,TP,11.5x12.5mm

C615 2401-002299 C-AL 4.7uF,20%,50V,GP,TP,5x7,5

C618 2201-000023 C-CERAMIC,DISC 2.2nF,20%,125V,Y5U,TP,11x

!!!!!!!

!

8 Electrical Parts List

8-2 DP14L*/DP15L*

Loc. No. Code No. Description Specification Remarks

Page 57

Loc. No. Code No. Description Specification Remarks

C619 2201-000023 C-CERAMIC,DISC 2.2nF,20%,125V,Y5U,TP,11x

C620 2401-000039 C-AL 1000uF,20%,16V,GP,TP,10x16,5

C621 2201-000469 C-CERAMIC,DISC 330pF,10%,500V,Y5P,TP,6x4

C622 2401-001551 C-AL 47uF,20%,35V,GP,TP,6.3x11,5

C623 2401-000058 C-AL 220UF,20%,100V,GP,TP,10X20MM,5

C624 2401-000039 C-AL 1000uF,20%,16V,GP,TP,10x16,5

C626 2401-000039 C-AL 1000uF,20%,16V,GP,TP,10x16,5

C628 2401-000042 C-AL 100uF,20%,16V,GP,TP,6.3x7,5

C629 2401-000031 C-AL 47uF,20%,16V,GP,TP,5x11,5

C630 2401-000039 C-AL 1000uF,20%,16V,GP,TP,10x16,5

C631 2201-000291 C-CERAMIC,DISC 1nF,10%,500V,Y5P,TP,8.5x5

CN201 3711-003873 CONNECTOR-HEADER BOX,7P,1R,2mm,STRAIGHT

CN202 3711-003845 CONNECTOR-HEADER BOX,11P,1R,2mm,STRAIGHT

CN303 3711-000197 CONNECTOR-HEADER 1WALL,3P,1R,2.5mm,STRAI

CN502 BH71-40300A PIN-HINGE BRASS,D2.36,SN,HEAT/SINK

CN503 BH71-40300A PIN-HINGE BRASS,D2.36,SN,HEAT/SINK

CN601 3721-001028 PLUG-AC POWER 3P,NI

D201 0403-000005 DIODE-ZENER UZ5.1B,4.8-5.4V,500mW,DO-35

D202 0403-000005 DIODE-ZENER UZ5.1B,4.8-5.4V,500mW,DO-35

D203 0403-000005 DIODE-ZENER UZ5.1B,4.8-5.4V,500mW,DO-35

D204 0403-000005 DIODE-ZENER UZ5.1B,4.8-5.4V,500mW,DO-35

D205 0403-000005 DIODE-ZENER UZ5.1B,4.8-5.4V,500mW,DO-35

D301 0402-000274 DIODE-RECTIFIER UF4004,400V,1A,DO-41,TP

D401 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D404 0402-000128 DIODE-RECTIFIER 1N4002GP,100V,1A,DO-41,T

D405 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D406 0402-001252 DIODE-RECTIFIER DG3L,1500V,3A,DG3,BK

D407 0402-001257 DIODE-RECTIFIER DTV32F,1500V,15A,TO-220A

D408 0402-001118 DIODE-RECTIFIER UF1G,400V,1.2A,DO-204AL

D409 0402-000007 DIODE-RECTIFIER 1N4937GP,600V,1A,DO-41,T

D410 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D411 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D412 0402-000006 DIODE-RECTIFIER 1N4007GP,1000V,1A,DO-41

D413 0402-000006 DIODE-RECTIFIER 1N4007GP,1000V,1A,DO-41

D414 0402-001112 DIODE-RECTIFIER MDV04-600,600V,4A,DO-201

D501 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D502 0403-001247 DIODE-ZENER UZ24BH,24V,24.2-25.7V,500mW

D503 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D504 0402-000546 DIODE-RECTIFIER TVR10G,400V,1.0A,DO-41,T

D505 0401-000006 DIODE-SWITCHING BAV21,250V,250mA,DO-35,T

D506 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D507 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D508 0403-000007 DIODE-ZENER UZ6.2BM,6.2V,6.0-6.4V,500mW

D515 0402-001118 DIODE-RECTIFIER UF1G,400V,1.2A,DO-204AL

D5V 0403-000005 DIODE-ZENER UZ5.1B,4.8-5.4V,500mW,DO-35

D601 0402-000103 DIODE-BRIDGE D2SBA60,600V,1.5A,SIP-4,ST

!!!

8 Electrical Parts List

DP14L*/DP15L* 8-3

Page 58

D602 0402-000012 DIODE-RECTIFIER UF4007,1KV,1A,DO-41,TP

D603 0402-000546 DIODE-RECTIFIER TVR10G,400V,1.0A,DO-41,T

D604 0402-000012 DIODE-RECTIFIER UF4007,1KV,1A,DO-41,TP

D605 0402-000546 DIODE-RECTIFIER TVR10G,400V,1.0A,DO-41,T

D606 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D607 0403-000361 DIODE-ZENER UZ6.2BSB,6.2V,5.99-6.24V,500

D608 0402-000546 DIODE-RECTIFIER TVR10G,400V,1.0A,DO-41,T

D609 0402-001118 DIODE-RECTIFIER UF1G,400V,1.2A,DO-204AL

D610 0402-000012 DIODE-RECTIFIER UF4007,1KV,1A,DO-41,TP

D611 0402-000005 DIODE-RECTIFIER 31DF4,400V,3A,DO-201AD,B

D612 0402-000546 DIODE-RECTIFIER TVR10G,400V,1.0A,DO-41,T

D613 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D614 0403-000007 DIODE-ZENER UZ6.2BM,6.2V,6.0-6.4V,500mW

D615 0403-000007 DIODE-ZENER UZ6.2BM,6.2V,6.0-6.4V,500mW

D616 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

D617 0401-000005 DIODE-SWITCHING 1N4148,75V,200MA,DO-35,T

FH601 3602-000001 FUSE-CLIP 30mohm

FUSE 3601-000004 FUSE-FERRULE 250V,3.15A,SB,CERAMIC,5x20m

GT301 BH71-40300A PIN-HINGE BRASS,D2.36,SN,HEAT/SINK

GT302 BH71-40300A PIN-HINGE BRASS,D2.36,SN,HEAT/SINK

GT601 BH71-40300A PIN-HINGE BRASS,D2.36,SN,HEAT/SINK