Page 1

46

Ⅵ. TROUBLESHOOTING & MAINTENANCE

When using the adaptor, the

power does not turn ON.

If using the battery, the

power doesn’t turns ON.

Poor soldering of Power

diode.(Power PCB D10)

Resolding the Diode

전원 Diode 납땜 불량

Replace the Fuse

(Power PCB F2)

See 6-1.POWER Error

Disconnected FUSE.

(Broken FUSE)

Replace the Battery CapPoor contacts of Battery Cap

Verify if disconnected

between Battery spring

and Power Board.

When using the battery,the

power does not turn ON.

See 6-2. SUB PCB Error

See 6-1. POWER Error

Check the LED FPCB

LED is illuminated.

The letter does not appear

on TN LCD

See 6-4. CAMERA Mode

Error

Check the booting by mode.

Poor booting in CAMERA

Mode

See 6-3.MAIN PCB Error

Booting does not operate.

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

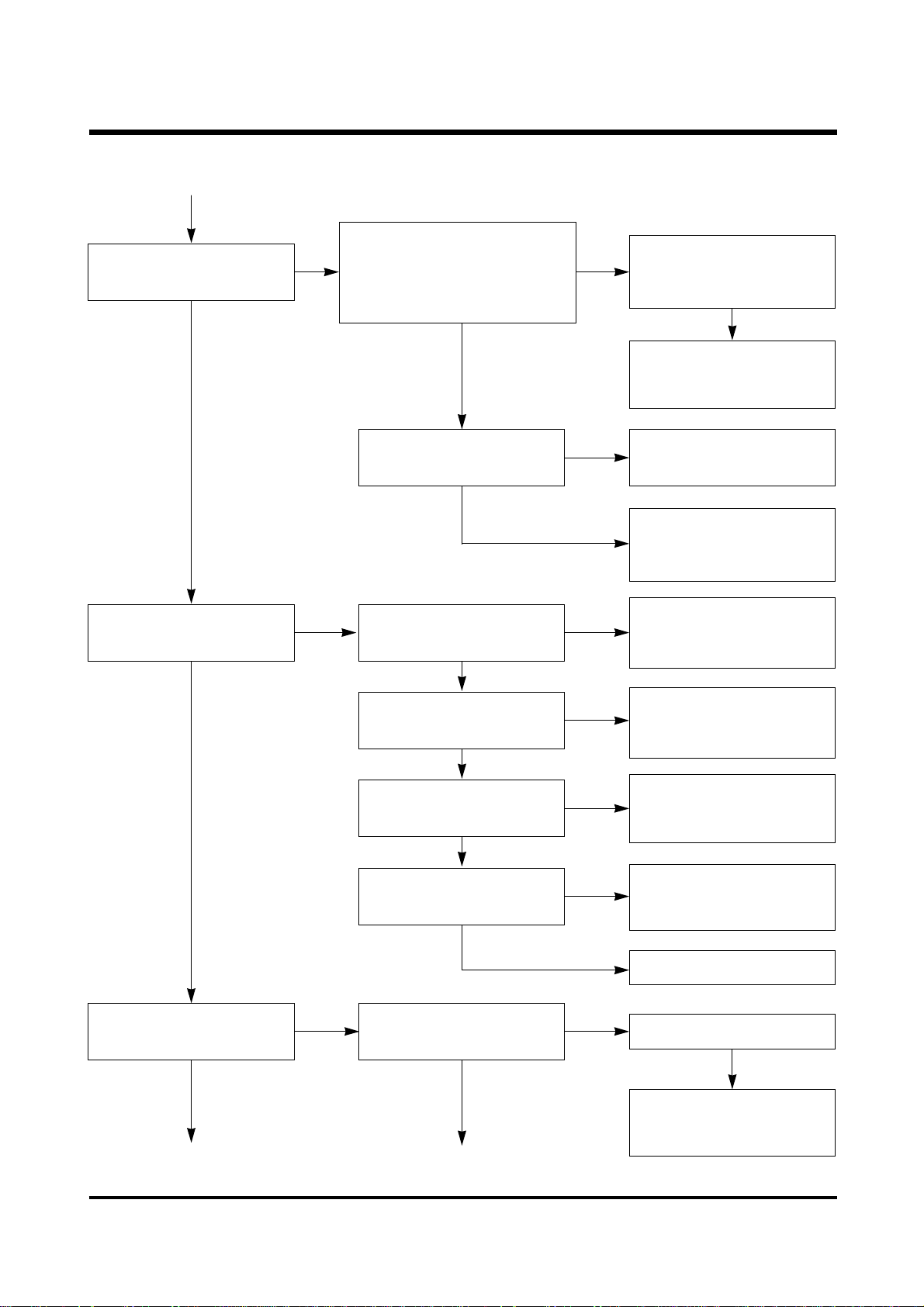

Page 2

47

Ⅵ. TROUBLESHOOTING & MAINTENANCE

KEY IN Error See 6-2. KEY IN Error

YES

Image display Error TFT LCD Output Error

TV Monitor output Error

See 6-5. LCD Error

See 6-6. TV Output Error

See 6-7. Image Error

YES

Moving Image display Error

YES

See 6-9. Replay Error

Replay Error

YES

See 6-10. CARD ErrorCARD related Error

YES

See 6-11. Strobo Error

Strobo luminescent Error

YES

See 6-12. Barrel Error

See 6-13. Software

Installing Error

See 6-14. USB Error

See 6-15. SERIAL Error

Lens drive

(Zoom,Shutter,AF)Error

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

Photographing Error

Though the shutter pressed,

it will not photograph

Image recording Error

See 6-2. KEY IN Error

See 6-8. Card Recording

Error

YES

NO

YES

PC Interface Error

Program Installation Error

Serial Interface Error

YES

NO

NO

YES

YES

YES

YES

USB Interface Error

Page 3

48

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Check for overcurrent with

VCC connected

Check if C4,C18,C51,C52,C103

damaged and shorted.

Lift Pin 5 of U3 and check

for overcurrent with power

on.

Lift L9 and check for

overcurrent with power on.

Replace damaged TALTAL

Replace U1

Replace U3

Replace

Q8

Replace

C50

Replace

Q7

Replace

Q9

Replace

U2

Replace

Q1

Replace

Q2

Detach D9 (from a board)

and check for overcurrent

with

Detach C50 and check for

overcurrent with power on.

Detach Q7 and check for

overcurrent with power on.

Detach Q9 and check for

overcurrent with power on.

Detach Q1 and check for

overcurrent with power on.

Detach Q2 and check for

overcurrent with power on.

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

6-1. POWER Error

Lift pin 20,37,47 of U1 and

check for overcurrent with

power on.

Page 4

49

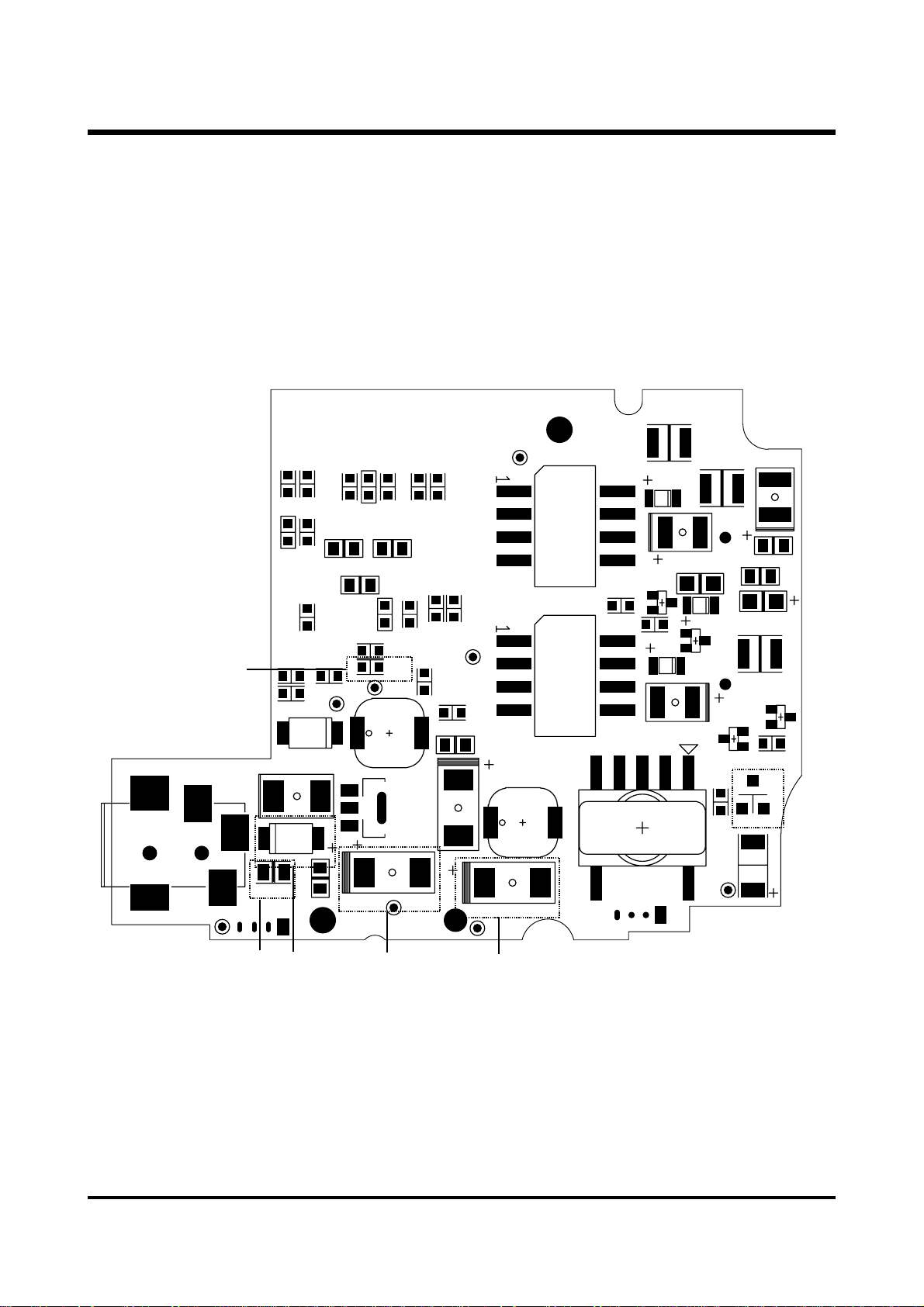

Ⅵ. TROUBLESHOOTING & MAINTENANCE

C4

Q9

Q1

J2

R210

R203

C16

C35

Q9

C15

L7

C27

R208

L3

L1

C46

Q2

C201

C11

J4

D4

D6

D1

C10

C34

D12

Q102

R201

D7

C2

D3

R51

Q1

C26

L6

C18

Q6

C4

C18

Q2

R41

Q8

C37

R44

R35

C38

C47

R52

C14

C31

R37

C40

R39

R46

R43

C39

VR1

D9

R17

R42

U3

C13

R27

R31

C30

R30

R49

R15

C33

R13

R24

R48

C32

C12

C23

L9

R10

C29

R8

C17

R7

R22

U1

R4

C9

R12

R18

C25

C103

L12

C103

J3

D9

L9

Page 5

50

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Replace C44

YES

Replace Q3

YES

NO

NO

NONO

NO

NO

NO

NO

NO

Connect R26 with

VCC(F2,C52) and check for

overcurrent with power on.

Connect R25 with

VCC(F2,C52) and check for

overcurrent with power on.

Check C44

for short.

Check if

D8

damaged.

Detach Q2 and check if there is

short between Collector & Base,

Collector & Emiter, Emiter & Base

Detach D4, D6, D7 and check

the board for short.

Detach C19

and check the

board for short

Replace

C19

Detach Q3 and check

if short between

Collector & Base,

Collector & Emiter,

Emiter & Base

Replace

U1

Replace C44

Replace

Q2

YES

YES YES

YES

YES

NO

Solder D4 and then check the

board for short

Detach C16

and check the

board for short

Replace

C16

YES

YES

NO

Detach C15

and check the

board for short

Replace

C15

Check Pin

11,13,15 of J2

YES

NO

Solder D6 and then check the

board for short

Detach C27

and check the

board for short

Replace

C27

YES

YES

NO

Detach C26

and check the

board for short

Replace

C26

Check Pin

13,15,17 of J2

YES

NO

Detach L5 and

check the

board for short

Replace

C20

YES

NO

Check Pin 3,5

of J2 for short

Replace

U1

YES

NO

After touch up J2

connector and check

the board for short

Replace

U1

YES

Page 6

51

Ⅵ. TROUBLESHOOTING & MAINTENANCE

BAT-

R26

J5

L11

F2

R2

C1

R16

R14

R21

D8

C51

R6

R5

C22

C28

R9

3.3V

Q3

D10

R23

C52

C24

L4

T2

R209

Q203

R207

U2

C6

D5

C19

C3

ZD1

Q202

D2

LCD_BL

R28

C41

R25

R26

T-WAE

7V_TP

R29

C36

R38

L8

C44

R32

R34

LCD_TP

R40

R36

CCD_TP

R33

T1

C45

L10

C50

LCD_7V

L5

R50

C8

Q204

Q201

C101

C20

C21

C5

L2

R206

Q7

Q7

F2

C51

C52 C50

Page 7

52

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Solder D7 and then check the

board for short

Detach C35

and check the

board for short

Replace

C35

Detach Q2 and check if short

between Collector & Base,

Collector & Emiter, Emiter & Base

Connect R31 with VCC(F2,C52)

and check for overcurrent with

power on.

Replace

Q1

YES

Detach D1,D3 and

check the board for

short

Detach C5 and check the

board for short

Replace

C5

YES

Solder D1 and check

the board for short

YES

Solder D3 and check

the board for short

Check C10,11 broken and

short

Check Pin 23,25,27 of J2

YES

Check

C2,C3,C201,R207,208,209,

Q202,Q203 parts and if

short in cold soldered.

Replace

abnormal

parts and

remove

short

Replace

abnormal

parts and

remove

short

Remove

short

Detach L2 and check the

board for short

Replace

C6

YES

Detach Pin 27,29 of J2.

Replace

U1

YES

YES

After touch up connector

and check the board for

Replace

U1

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

Detach C34

and check the

board for short

Replace

C34

Check Pin

4,6,8 of J2

YES

YES

Check Pin

16,18,20 of J2

YES

YES

YES

YES

YES

YES

Page 8

53

Ⅵ. TROUBLESHOOTING & MAINTENANCE

3.3V is input at

V2 Test Port

When mounting battery or

DC adaptor, the voltage is

changed from L to H in the

output end(#3) of

Reset IC(U1)

If pin #9 and #10 of

connector J1 being short

more than 0.5 seconds,

Beep(Buzzer-1) sound

occurred.

Short at V2 T.P and G1 T.P

terminals

Visual check if the parts

are soldered properly.

Y : Replace SUB board

N : Replace and check the

part

Replace SUB board

Replace J2 connector parts

Replace Reset IC(U1)

Resolder Reset IC(U1)

Replace Oscillator(Y1)

Replace Buzzer

Resolder CPU(U2)Pin #38

Resolder J1 Pin #9, #10

Resolder R3,D1,C10

Resolder CPU(U2) Pin #49

Resolder BZ+, BZ- L/W

Resolder R2

Resolder and check CPU(U2)

Pin #70, #71 Oscillator(Y1)

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO NO

NO

NO

NO

YES

YES

YES

6-2. SUB PCB Error

Good soldering of J2

connector PIN #4, #6

Good soldering Reset IC(U1)

CPU(U2) #38 Pin is

changed from H to L level.

Oscillating wave form is

measured at CPU(U2)Pin

#70 and #71

Oscillating wave of about

100ms is output to

CPU(U2)Pin #49 (f=4kHz)

Page 9

54

Ⅵ. TROUBLESHOOTING & MAINTENANCE

“boot”display goes on and

off(2Hz) in Status LCD

“boot”display disappears

within 5 seconds

During booting, green LED

next to finder goes on and

off

LCD driving power is normal.

T.P terminal of T1 :about 3.0V

T.P terminal of T2:about 2.0V

T.P terminal of T3:about 1.0V

“Err”is displayed in

Status LCD

Connector(J2)Pin #14 is

measured as “H”

Connector(J2)Pin #18 is

measured as “H”

Connector(J2)Pin #10 is

measured as “L”

Connector(J2)Pin #15 is

changed to “L”to “H”after

25ms

3.3V power supplied at

ASL+ terminal

Check if 3.3V output at

CPU(U2) Pin #25 and then

resolder it

Resolder R10/R5/R7/R9

Resolder

CPU(U2)#26/#27/#28

Resolder CPU(U2) Pin #10

~#24, clean and check it

Check of the contacts of

mode dial distorted

clean the mode dial pattern

Resolder CPU(U2) Pin #47

Resolder connector(J2) Pin

#14

Resolder CPU(U2)Pin #75

Resolder connector(J2)Pin

#18

Resolder CPU(U2)Pin #53

Resolder connector(J2)Pin

#10

Resolder CPU(U2)Pin #50

Resolder connector(J2)Pin

#15

Resolder SUB PCB

(Jump wire) or Resolder

SUB PCB Ass’y

See 5-3. Main PCB repair

Resolder LED FPCB

YES

YES

YES

YES

NO NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

NO

Page 10

55

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Cst5

280V

U1

J2

#14->H

#18->H

#10->L

#15->25ms

L->H

V2 Test point

G1 Test point

U2

#25=3.3V

#38 H->L

#70,71

#49 100ms

#58=About 3V

T1 = 3.0V

T2 = 2.0V

T3 = 1.0V

ASL=3.3V

T6=

8kHz

STL=

4kHz

STL=

4kHz

#49 =

#70,71 =

Page 11

56

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Oscillating wave form is

measured in the end T.P of

T6

Resolder CPU(U2)Pin #39 to

#41 and connector(J2)Pin

#7/#9/#11

Oscillating wave output in

AFL-terminal(f=4Hz)

Resolder CPU(U2)Pin #35

Resolder R4/R6

See 5-3. Repairing

Main PCB

Resolder AF LED(LED FPCB)

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

Battery Half mark goes on

and off(2Hz)

The voltage of about 3V is

measured in CPU(U2)Pin

#58

Resolder CPU(U2) Pin

: #58/#65/#64

Resolder connector (J2)Pin

#2. Resolder C6/C7

Whill charging flash,

red LED next to finder

goes on and off(8Hz)

Oscillating wave is output

in STL-terminal (f=8Hz)

Resolder CPU(U2) #34 Pin

Resolder R11/R18

See 5-3. Repairing

Main PCB

Resolder STB LED(LED FPCB)

NO

If controlling button and

mode dial, it operates

KEY recognition Buzzer

sound is generated.

After about 2 minutes,“E10”

will be displayed in Status

LCD

Resolder CPU(U2) Pin

: #54 to #57 Pin

: #77 to #80 Pin

Resolder U3/U4/U5/U6

Resolder CPU(U2) Pin

: #39 to #41,48 Pin

Resolder connector (J2) Pin

: #7/#9/#11/#13 Pin

Replace KEY FPCB Ass’y

NO

NO

Page 12

57

Ⅵ. TROUBLESHOOTING & MAINTENANCE

1. Check Buzzer sound

2. Check Mode Dial conversion

3. Check if the current 600mA (If error occurred, See Merr 8)

Mode Dial→MACRO→

CAMERA→PLAY→MACRO

Menu Key→Right→Left

→Down→Up→Menu Key

Status(Erase)Key

“ON”, “OFF”

Enter Key “ON”, “OFF”

LCD Key “ON”, “OFF”

Zoom Key operation

T ↔ W 2 times

1. check TV Monitor

2. Remove video cable

3.Check TFT-LCD screen

Start

Mode Dial → PLAY

Power Switch “ON”

1. Check buzzer sound(if error occurred, See Merr 1)

2. Check of the current being 500mA(If error occurred, See Merr 2)

1. Check if Zoom operation Checking current being 800mA.

(if error occurred, See Merr 9)

1. Check TFT-LCD User I/F (If error occurred, See Merr 10)

1. Check TFT-LCD backlight control terminal

(If error occurred, See Merr 11)

Setting in TFT-LCD or TN-LCD

1. Check SUB↔HOST micom communication

(TN-LCD “BOOT”display continuously →

See

Merr 3)

2. Check HOST↔ZORAN micom communication

(Green LED ON continuously →

See

Merr 4)

3. Check ZORAN Card related I/F (“Card ERROR”display →

See

Merr 5)

4. Check Video ZORAN related (No image on TV monitor →

See

Merr 6)

5. Check TFT-LCD I/F related (No image on TFT-LCD →

See

Merr 7)

6-3. MAIN PCB ERROR

Fill-in flash mode setup

Page 13

58

Ⅵ. TROUBLESHOOTING & MAINTENANCE

1. check of shutter button operated on the 1st stage and the current being 1.0A

(If Error occurred, → See Merr 12)

2. check of shutter button operated on the 2nd stage and the current being 1.1A

(If Error occurred,→ See Merr 13)

3. Check of strobo operated and illuminated (If Error occurred,→ SeeMerr 14)

4. Check for photo Sensor Circuit and photo sensor open/close.

(If Error occurred,→ See Merr 15)

Mode Dial→MACRO→

shutter button 1st stage→

2nd stage→Photographing

(with photo sensor)

Shutter button 1st stage→

2nd stage→Photographing

(With photo sensor open)

Mode Dial→PLAY

Check screen TFT-LCD

Mode Dial→PLAY

Check TFT-LCD screen

When inserting and

removing CF Card 2 Times,

check “Card Error”

Power switch→“OFF”

End

1. Check Card recognition, if “card Error”displayed

(If error occurred, See Merr 5)

1. Check PR circuit, If TN LCD is extinguished 3 seconds of Power OFF

(If error occurred, See Merr 16)

Page 14

59

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Check the mounting status

of CP 8,9,10

Check the mounting status

of CP11,Rp1,and RP2

Check if Pin J2 #4, 6,and

other pins being short.

check of Pin J3 #2 and

other pins being short.

UP3 #3=3.3V? CP11-1=3.3V?

Buzzer sound can not be

heard.

Check the SUB PCB

power,VCC3-KA is 3.3V?

Battery check power,

BAT-CHK is 2.7V?

MAIN Power,

+3.3VCC(MAIN)=3.3V?

MERR1

YES YES

NO NO

Check if Pin J3 #20, 22, 24

and other pins being short.

Check if pin J3 #20, 22, 24

and other pins being short.

Check if J3 pin #19, 21, 23

and other pins being short.

UP3 #2=5.6V? UP4 #3=5.6V? UP4 #2=3.3V?

Page 15

60

Ⅵ. TROUBLESHOOTING & MAINTENANCE

J3

UP4

#2=3.3V

#3=5.6V

RP1,2

CP8,9,10

CP11=3.3V

UP3

#2=5.6V

#3=3.3V

Page 16

61

Ⅵ. TROUBLESHOOTING & MAINTENANCE

The current will be over 5oomA

in Play Mode, When turn”ON”.

There is abnormal in

Zoom or Focus drive.

Check if U16 #34 to #40

being short

MERR2

There is abnormal in Focus.

NO

Check if J4 pin 2, 4, and other

pins being short.

Check if U16 #52 to 55, 42,

and 57 being short.

Check if J4 64, 66, 68, 70 and

other pins being short.

Check if J4 pin 6, 8, 10, 12

and other pins being short.

Check if J4 1, 3 and other

pins being short.

YES

Page 17

62

Ⅵ. TROUBLESHOOTING & MAINTENANCE

U16 short check

#34~40

#52~55

#42,57

J1

Page 18

63

Ⅵ. TROUBLESHOOTING & MAINTENANCE

“boot”continues to be

displayed in TN-LCD.

SUB ↔ Hist micom

communication error check

Check if “Mreset”signal of

TP being output when turn

on.

Check if Xrst1 signal of TP

being output.

Check if U18, 19, 21 parts

being short(XHCS of TP)

Check if SL1, SO1, SCK1,

KEY_BR signal line being

short

Check if U1 pin 144 and

other pins being short.

Check if RA33 and RA32

signal line being short.

Check if U16 pin 27 to 30

and other pins being

short(signal line A8~A10)

Check if J2 pin 7, 9, 11, 13

being short.

Check if U1 pin 130, 131,

134 to 137, 139, 140, and

other pins being short.

Check if U16 pin 11 to 13,

and 65 being short.

Check if U16

pin

40, 41,

43,61and other pins being

short (singnal line XHRD,

XHWR, XHAS, XHIRQ).

Check if U1 pin 145 to

147, 127, 139, 140, and

other pins being short.

Check the

EEPROM

soldering status.

If “boot”continues

to be displayed

in TN-LCD

Check the soldering status

of U4, RA10, U1, pin #204

and 205.

MERR3,4

See 6-10, Card Error.

MERR5

See 6-6, TV Output Error

MERR6

See 6-5, LCD Image Error

MERR7

YES

NO

Page 19

64

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Check the RTC circuit.

VDD3-RTC voltage > 1.8V?

Remove card and check if

“boot”completed.

Remove card after 1 minute,

check if “boot”completed.

See 6-10. Card Error.

Check for TFT-LCD

image

Check for TV output

screen.

See error 6-6. TV output

Error.

See 6-5. image Error.

Check if SAMSUNG logo seen

with green LED flickered.

Check if U20, U16 PIN #15

and other parts being short.

Check the Diode(DP1)

polarity and resistor(R70),

BTP1 value check.

Check if VCC3-HOST is 3.3V

at the point DP1-Anode

Check if green LED being Off.

YES

YES

NO

NO

NO

NO

End

YES

YES

YES

YES

YES

NO

Resoldering

and replace.

Page 20

65

Ⅵ. TROUBLESHOOTING & MAINTENANCE

RA32

RA33

U16 short check

#11~13,15, 27~30

#40,41,43,61,65

J1

RTC >1.8V

U20 #15

Short check

U4

RA10

Page 21

66

Ⅵ. TROUBLESHOOTING & MAINTENANCE

k

U1 Short check

#145~147,127,139,140,144

U18,19,21

R70

DP1 Anode=3.3V

J2 Short chec

#7, 9, 11, 13

Page 22

67

Ⅵ. TROUBLESHOOTING & MAINTENANCE

See 6-4. CAMERA Mode

Error

MERR8

Check if the current being

800mA during Zoom Key

operation

MERR9

Check if J4 #2,4,64,66,68,

70, pin and other pins

being short.

Check if RA34, U16 #36 to

39 being short (EN0~EN3)

Check if U16 #34, 35 being

short (ZIN0, ZIN1)

See 6-2. SUB PCB error.

MERR10

TFT-LCD “ON-OFF”

does not work.

MERR11

Check if J3 #28, J2 #16,

and other pins being short.

Check if the current being

1.0A instantaneously in the

1st stage of shutter button.

MERR12

Focus motor control signal

line error.

See MERR2.

Check if the current being

1.0A instantaneously in the

2nd stage of shutter button.

MERR13

Error occurred in shutter

control signal AE-METER

control signal line.

Check if J4 #5, 7, 9, 11,

and other pins being short.

Check if U1-208, U16-62, U16

48 to 51, and other pins

being short.

PR circuit check.

MERR16

TN-LCD turns off after 3

seconds in power OFF.

Check for QM1, 2, DM1,

RM1, 2 parts and short.

Check if U16 #31, 32, R49

and other pins being short.

Check for PR FPCB.

Check the strobo operation.

MERR14, 15

Check if J3 #20 to 24 and

other pins being short.

See 6-11.STROBO Error.

Check if U16 #44, 64, 76 to 80

and other pins being short.

D50 polarity check.

photo circuit check.

Page 23

68

Ⅵ. TROUBLESHOOTING & MAINTENANCE

MERR13

U1 Short check

#208

MERR11

J3 Short check

#28

MERR14,15

J3 Short check

#20~24

MERR16

R49 Check

MERR9

J4 Short check

#2,4,64,66,68,70

MERR13

J4 Short check

#5,7,9,11

MERR11

J3 Short check

#16

Page 24

69

Ⅵ. TROUBLESHOOTING & MAINTENANCE

MERR16 Check

QM1,2DM1,RM1,2

MERR14,15

D50 Check

MERR9

U16 Short check

#36~39

MERR13

U16 Short check

#2, 48~51

MERR14,15

U16 Short check

#44,64,76~80

MERR16

U16 Short check

#31,32

RA34

Page 25

70

Ⅵ. TROUBLESHOOTING & MAINTENANCE

When changing CAMERA

mode, the current goes to 0

instantaneously or system

is halted.

Check if being short between

CCD shield and other parts.

Lens body tube distortion or

damage.

Replace lens.

YES

YES

YES

YES

Focus motor sounded creaking

See 6-12. Lens Error.

YES

‘E05’message displayed

YES

Encoder contact distortion

YES

YES

YES

YES

Check the soldering of UM1

Check X1 pulse in CCD board.

Ckeck if IR14 and BD6

soldered.

Check IR14(CCLK)

Output,18MHz?

Check the voltage of IL3, IL4 are 3.3V

Check soldering state of surrounding

parts of X1 in CCD board.

Replace CCD board.

Check if connected between

JM3-FPCB and check

soldered state IJ1(CCD

board),J4(MAIN board).

NO

See 6-7 Image Error

Lens does not come out.

Zoom motor is not

initialized.

(Slants to one side,

NO

NO

NO

NO

NO

NO

NO

NO

6-4. CAMERA Mode Error

Encoder contact joint error

See 6-12. Lens Error.

Replace lens.

See 6-12. Lens Error.

YES

YES

YES

Page 26

71

Ⅵ. TROUBLESHOOTING & MAINTENANCE

IR14

BD6

IJ1

JM3

UM1

IL4

Page 27

72

Ⅵ. TROUBLESHOOTING & MAINTENANCE

See 6-9. Replay Error

See 6-3. MAIN Board Error

LCD Image Error

See the image on TV

Is the image of LCD equal

with TV screen?

Is the image good in PLAY

mode?

See 6-3. Main Board Error

See 6-7. Image Error

Resolder RL23,RL24,RL51

UL1,U1#178~180,#142 in

Main board.

Resolder UL1, JL1

U1#118~126 PIN,

and LCD circuits

See 6-1. POWER Error

YES YES

YES

NO

TV output, OK?

YES

NO

Test LCD by changing with

another. OK?

Replace LCD pannel

YES

NO

Back Light dose not turn on.

Check the connection of

BACK LIGHT connector

See 6-1. POWER Error

YES

NO

Image on LCD is white.

Check the powers of LCD

part (CL7:+5V, RL67:+15V,

DL1 CATHOD:-10V)

Check the below signals in

Main board

RL23:19KHz

RL24:73.8KHz

RL51:13.6MHz CLK

YES

YES

YES

NO

NO

NO

LCD image comes out but

not clear.

Resolder UL1#50~#60,

JL1,U1#118~#126,R41,R42,

R44~R47,R59,R60 in Main

board OK?

Replace the Main board

Replace the Main board.

NO

NO

NO

NO

NO

6-5. LCD Error

Is the image good in

CAMERA mode?

See 6-6. TV Output Error

Page 28

73

Ⅵ. TROUBLESHOOTING & MAINTENANCE

UL1 #50~#60

U1 #118~#126

RL23,24,50

RL51

U1 #178~#180

R41,42

R60

R44~47

JL1

CL7

RL67

DL1

MAIN PCB (TOP)

MAIN PCB (BOT)

Page 29

74

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Image on LCD is good, but not

good on TV screen.

Image is displayed on TV Check soldering of L50 Resolder L50

YES

YES

NO

Is the image quality equal

to LCD?

NO

NO

Check the connection JACK

board

Reconnect JACK board

YES

NO

When video jack inserted,

check the U16 #47 change

‘H’to ‘L’

resolder Q3,Q4,R19. Steel

not working, replace Q3, Q4.

YES

NO

Check video output of U1 #164 Resolder U1 #164

YES

NO

U1 error Replace Main board

YES

Is the image good in PLAY

mode?

Check the connection JACK

board

Resolder the JACK board

including J5.

Reconnect JACK board.

Check the video filter

(L50 surroundings)

NO

Resolder R37, U1 #164

NO

Replace Main board

NO

Resloder the video filter

(L50,,R81,C90~C92,J5)

See 6-7. Image Error

YES

YES

YES

YES

YES

NO

NO

See 6-3. Main PCB Error

6-6. TV Output Error

See 6-9. Replay Error

Is the image good in

CAMERA mode?

Page 30

75

Ⅵ. TROUBLESHOOTING & MAINTENANCE

U1 #164

R37

C91

C92

C90

L50

R81

Page 31

76

Ⅵ. TROUBLESHOOTING & MAINTENANCE

YES

NO

Resolder IJ1, UM3 and its

surroundings

Playback image of normally

captured is good. But,

image of camera mode has

error.

Check connection between

boards

Check EEPROM data, OK? Rewrite EEPROM data

NO

Check lens operation, OK? See 6-12. Lens error

NO

CCD board change test,

OK?

Resolder U1 #182~#191, J4

See 6-3. Main Board Error

NO NO

Check the CCLK(BD6)

signal. (18MHz)

Resolder IJ1, X1, IU3, IR14, in

CCD board and J4, U1 #197

in Main board

Resolder IL3, IL4.

See 6-1. POWER Error

Check power IL3, IL4 are +5V

Replace CCD board

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

Check the signal in CAMERA

mode

HD(IR32):9.8KHz

VD(IR33):30Hz

Resolder IJ1, IU3 in CCD

board and J4 R103, R104, U1

#194~ #197 in Main board

Check CCD output in CCD board

Resolder IU3 and its

surroundings

NO

Replace CCD board

YES

YES

Preview image is not clear

Replace CCD board

Resolder IU3 and its

surroundings, IU2 and its

surroundings, IJ1

YES

Captured image has error

As press shutter, system

halted

YES

6-7. Image Error

YES

Replace CCD board

Resolder IU3 and its

surroundings

Replace CCD board

Page 32

77

Ⅵ. TROUBLESHOOTING & MAINTENANCE

R103,104

U1 #194~197

J4

MAIN PCB (TOP)

CCD PCB (BOT)

CCD PCB (TOP)

IL4

JM1

IR14

UM3

X1

Page 33

78

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Mechanical Shutter does

not operate when press

the shutter button.

Check if connected between

JM2 CONNECTOR and

FPCB in CCD PCB ASS’Y.

Resolder JM2 or reconnect

CONNECTOR.

YES YES

NO

Resolder UM3.

YES

NO

YES

NO

See 6-10. Card error

NO

6-8. Card Recording Error

Resolder #5,7,9,11 pins of

J1.

Check if #5,7,9,11 pins of

J1 soldered in CCD PCB

ASS’Y.

Check if UM3 soldered in

CCD PCB ASS’Y.

Replace BARREL ASS’Y,

CCD PCB ASS’Y, MAIN PCB

ASS’Y one by one and

check for operation.

See MERR 13.

YES

Page 34

79

Ⅵ. TROUBLESHOOTING & MAINTENANCE

JM2

X1

J4

U16

J1

MAIN PCB (TOP)

CCD PCB (BOT)

CCD PCB (TOP)

MAIN PCB (BOT)

UM3

Page 35

80

Ⅵ. TROUBLESHOOTING & MAINTENANCE

NO

YES

The picture will not replay.

If waiting for 1 minute, the

picture appears.

Green LED goes on and off

continuously.

Image photographed in TIFF

See 6-10. CARD Error

YES

Replayed picture goes off in

the way of replaying.

YES

Moving image mark is

displayed in the upper lift

corner of picture and

replayed if pressing Enter

button.

YES YES

YES

NO

YES

Dark photographing

environment.

Brightness of image itself

too low

CCD I/F Error

COACH Processor Error

Picture photographed in

Moving image.

All of replayed picture have

abnormal colors.

YES

AWB Error

MAIN PCB U1 part Error

Picture Size Setting Error

MAIN PCB U16 part Error

NO

NO

NO

NO

NO

NO

6-9. Replay Error

Replayed picture appears

small.

Replace MAIN PCB Ass’y

Compression Error

MAIN PCB U1 part Error

Replace MAIN PCB Ass’y

For other errors

Page 36

81

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Card is not

recognized.

Ckeck J1 Connector

being short.

Check the buffer

U9 and U10

being short.

Check U15 NOT

Gate being short.

Check the

resistors

RA4,RA5, and

RA35 being short.

When pressing the shutter

in Macro mode, “No Card”

is displayed.

And “Error Pos=1”is

displayed.

“Bad Format”is displayed.

Use the formatted card.

Otherwise, “Error Pos=2”is

displayed.

Card compatibility error.

After formating card,Use that.

Use the recommended card.

Remove the card and

then insert it.

Check U16 #3,

NO. 46 being

short.

SEE Card Error(Merr5).

NO

YES

NO

NO

YES

6-10. CARD Error

Check U14 NOT

Gate being short.

Check U30 OR

Gate being short.

Check R55 Gate

being short.

Check U1 Card

I/F being short.

Otherwise, “Error Pos=4”is

displayed.

When pressing the shutter

in Macro mode, “No Card”

is displayed.

When pressing the shutter

in Macro mode, “Error

Pos=2”is displayed.

NO

Page 37

82

Ⅵ. TROUBLESHOOTING & MAINTENANCE

U30

U1

R55

U13

U14

U15

R35

U9

U16

RA4

RA5

Page 38

83

Ⅵ. TROUBLESHOOTING & MAINTENANCE

NO NO

NO

NO

NO NO

NO

YES

YES

YES

YES

YES

YES

YES

Bad Charging

Is it charged during Power

On?

Flash Emitting Error

Is it luminescent in low

brightness?

“H”Supply at Qst9 Base(OSC)

“H”Supply at Qst8 Base(NEC)

Is it charged?

When Cst5 charged at

about 280V, is NEst1

illuminated?

Charging circuit and

detector of STROBO are

normal.

Check if OSC, NEC, and

NES signal lines are

connected from Main PCB to

SUB PCB normally.

Is about 200V voltage output

at Qst6 Collector?

Is “H”output at Qst6 Gate

when supplying “H”at

Rst11”

Check charging circuit

Check Qst9, Qst1, Rst4,

Qst2, Cst1, Qst3, Tat1, Rst1,

Dst1, and Dst2 for normal.

Check if not soldered, cold

soldered, and parts

damaged.

Check if IGBT being broken.

Check if Qst6 Parts being

broken. Check Rst6 for

normal.

Check TRIG Control Circuit.

Check Rst11,Rst12,Qst4,Qst5,

Rst5, Rst10,Rst13, and Ust1

for normal. Check if not

soldered, cold soldered or

parts damaged.

6-11. STROBO Error

Check charging circuit

Check Rst2, NEst1, Rst3,

Qst7, Rst9, Qst8, and Cst2

for normal.

Check if not soldered, cold

soldered, and parts

damaged.

When NEst1 illuminated,is

about 0.7V output at NES

terminal?

Page 39

84

Ⅵ. TROUBLESHOOTING & MAINTENANCE

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

Abnormal Flash Emitting.

The intensity of illumination

is different in the same

conditions.

Check Photo Sensor circuit.

Is the waveform of PWM

output in S1?

Dose the Analog

voltage(different according

to Zoom position) appear at

#3 of Uef1 in S1?

Flash Emitting circuit of

STROBO is normal. Check if

TRIG and TRIG OFF signal

lines are connected from

Main PCB to SUB PCB

properly.

Check if the Photo Sensor,

Main Capacitor, and XETube are soldered and J2

connector is connected.

Check if Qef5, and #44 of

U16 are connected.

When supplying “H”to

Rst11, is Qst6 Collector set

to “L”?

Check TRIG Circuit.

Check Cst3, Cst4, Rst7, Rst8,

Tst2, XE-Tube, Lead

Wire for normal. Check if not

soldered, cold soldered or

parts damaged.

Abnormal Flash Emitting.

Always Full/Low

luminescence.

Check if Qef1, Qef5, Ref3,

Ref4, Ref5, Cef5,and Cef6

are not soldered, cold

soldered, and parts

damaged.

Page 40

85

Ⅵ. TROUBLESHOOTING & MAINTENANCE

REF2

DEF2

QEF3

QEF2

UEF1

QEF4

REF1

MAIN PCB (BOT)

SUB PCB

Qst6

B

C

G

NEst1

Rst11

Cst5

280V

C

Qst9

BE

J2

Page 41

86

Ⅵ. TROUBLESHOOTING & MAINTENANCE

NO

YES

When setting FA-START

terminal to “H”, is #1 of

Uef1 set to “L”?

NO

YES

When luminescent

photographing in the range

of about 20cm, is FA-END

rerminal set to “L”within

100us?

Check if Uef1, Ref2, Def2,

and photo Sensor are not

soldered, cold soldered, and

parts damaged.

Check if Qef4 is not

soldered, cold soldered, and

parts damaged.

Check if Ref1, Qef3, and

Qef2 are not soldered, cold

soldered, and parts

damaged.

Page 42

87

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Zoom does not operate.

AF does not operate.

During operation of ZOOM

Key, buzzer does not ring.

See 6-2. (KEY IN error)

YES YES

NO

NO

Check if DC Motor being

supplied with power in

Barrel Ass’y.

Resolder DC Motor.

YES

NO

Check if UM1 being soldered

in CCD PCB Ass’y.

YES

NO

YES

NO

YES

Check if UM2 is soldered in

CCD PCB Ass’y.

Resolder UM2.

YES

YES

NO

NO

NO

Resolder U16.

Replace Barrel Ass’y, CCD

PCB Ass’y, MAIN PCB Ass’y

one by one and check for

each operation.

YES

NO

6-12. LENS Error

Check if J1 being soldered

in CCD PCB Ass’y.

Check if J4 being soldered

in MAIN PCB Ass’y.

Check if U16 being soldered

in MAIN PCB Ass’y.

Resolder UM1.

Resolder J1.

Resolder J4.

YES

Check if JM1 Connector and

FPCB are connected in CCD

PCB Ass’y.

Resolder JM1 or reconnect

the connector.

Page 43

88

Ⅵ. TROUBLESHOOTING & MAINTENANCE

NO

Shutter does not operate.

Check if J1 being soldered

in CCD PCB Ass’y.

Resolder J1.

YES

NO

YES

NO

YES

YES

See 6-8.(Card Recording Error)

Check if J4 being soldered

in MAIN PCB Ass’y.

Check if U16 being soldered

in MAIN PCB Ass’y.

Resolder J4.

Resolder U16.

Replace Barrel Ass’y, CCD

PCB Ass’y, Main PCB Ass’y

one by one and check for

each operation.

Page 44

89

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Is there installation CD in

CD-Rom Drive?

Installation of Serial

TWAIN/ Serial

Direct/USB Direct.

Insert CD.

YES

YES

Is Autorun screen displayed?

Click the program to install.

Installation is completed.

Execute “SAMSUNG.EXE”

from CD-ROM Drive root

directory.

Open Window Explorer,

select the program folder to

install from CD-ROM Drive

directory, and click

“setup.exe”in that folder.

YES

NO

NO NO

6-13. Program Installation Error

1) Installation of Serial TWAIN/Serial Direct/USB Direct

Page 45

90

Ⅵ. TROUBLESHOOTING & MAINTENANCE

Is there USB port in PC? UPrepare PC with USB port.

After PC rebooting,

install again.

NO

NO

NO

NO

NO

YES

(Add New Hardware

Wizard) appears.

Check if there is

“Samsung Digimax

210SE Camera”i n

Controller→System→

DeviceManager→Imaging

Device.

Is there (Unknown

device) in Controller

P→System→Device

Manager?

Remove (Unknown

device), perform PC

rebooting and then

install again.

NO NO

YES

NO

Is the driver to

install designated

with CD-ROM drive?

Check if there is ? mark on

“Samsung Digimax 210SE

Camera”in Controller

→System→Device

Manager→Imaging Device

Driver has been

already installed.

NO

YES

Check if Window OS being 98 or later Install Window 98 or later.

YES

YES

YES

Is the mode of camera set to PC mode?

Change the mode of camera to PC mode.

Does the camera turn on? Turn “ON”the camera.

YES

Is there installation

CD in CD-ROM drive?

Insert the installation

CD into CD-ROM drive.

NO

NO

YES

YES

YES

YES

NO

Necessary files are

copied automatically.

Installation is

completed.

Select “Samsung Digimax

210SE Camera”in

Control Panel→System→

Device Manager→Imaging

Device and then press

「Remove」button

Is there 「Samsung

TechwinD210SE.inf」in

「Windows/inf/other」

folder?

Remove

(SamsungTechwinD210

SE.inf)

After PC

rebooting, install

again.

NO

YES

YES

Are the Camera and PC connected

with USB cable?

Connect the camera and PC

using USB cable.

2) Installation of USB TWAIN

YES

YES

Is the driver to

install selected as

D210SE.inf?

Page 46

91

Ⅵ. TROUBLESHOOTING & MAINTENANCE

6-14. USB Error

Check lf the both edges of MAIN PCB R8 being 12MHz.

Check if J1 being soldered or short in JACK PCB.

Check if being soldered L1 through L4 in JACK PCB.

Check #2, #4 and #6 of J2 being soldered in JACK PCB.

Connecting USB cable with PC, make sure that R51 and

Q10

Check #2, #4 and #6 of J5 being soldered in MAIN PCB.

Check R3, R5, C2 and C5 for capacity and connection in

MAIN PCB.

Check if #238 and #239 of U1 being short from the

surrounding terminal in MAIN PCB.

Page 47

92

Ⅵ. TROUBLESHOOTING & MAINTENANCE

R8

J1

R3,5

C2

Q10

R51

C5

J5

Page 48

93

Ⅵ. TROUBLESHOOTING & MAINTENANCE

6-15. SERIAL Error

Check if the both edges of MAIN PCB R8 being 12MHz.

Check #1 and #3 of J5 being soldered in MAIN PCB

Check U3, U5, U31 and the surreonding R(9,10,12, 13, 14,

65, 110, 11, 112, 113) and C(5, 6, 25, 29, 30, 32, 131) for

capacity and connection in MAIN PCB.

Check if #224 and #245 of U1 being short in MAIN PCB.

J1

J2

L1~L4

Loading...

Loading...