SAMSUNG CL29K5MQ2X-XAX Service Manual

COLOR TELEVISION RECEIVER

Chassis : K16A(N)_Rhumba

Model : CL29K5MQ2X/XAX

COLOR TELEVISION RECEIVER FEATURES

■■

Turbo Plus

■

DNIe jr.

■■

Low Stand-By Power Wattage

■

SOUND Equalizer

SERVICE

Manual

CL-29K5MQ

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© Samsung Electronics Co., Ltd. Feb. 2006

Printed in Korea

AA82-03347A

Table of Contents

Chapter 1 Precaution

■ 1-1 Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

■ 1-2 Servicing Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

■ 1-3 Static Electricity Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

■ 1-4 Installation Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2 Product Specification

■ 2-1 Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

■ 2-2 Key Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

■ 2-3 Specifications Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

■ 2-4 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Chapter 3 Alignment & Adjustment

■ 3-1 Service Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

■ 3-2 How to Access Service Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

■ 3-3 Factory Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

■ 3-4 Service Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

■ 3-5 Software Upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

■ 3-6 Replacements & Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Chapter 4 Exploded View & Part List

■ 4-1 CL29K5MQ2X/XAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Chapter 5 Electrical Part List

■ 5-1 CL29K5MQ2X/XAX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Chapter 6 Troubleshooting

■ 6-1 Checkpoints by Error Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

■ 6-2 Troubleshooting Procedures by Error Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

■ 6-3 Troubleshooting Procedures by ASS'Y . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Chapter 7 Block Diagram

■ 7-1 Overall Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

■ 7-2 Partial Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter 8 Wiring Diagram

■ 8-1 Overall Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

■ 8-2 Pin Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Chapter 9 PCB Diagram

■ 9-1 Main Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

■ 9-2 PIP Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

■ 9-3 CRT Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Chapter 10 Schematic Diagram

■ 10-1 Power & Deflection Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

■ 10-2 IF & UOC(Chroma_Micom) Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

■ 10-3 PIP & CRT Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-3

■ 10-4 AV & Sound Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Chapter 11 Operation Instruction & Installation

■ 11-1 Product Features and Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

Chapter 12 Disassembly & Reassembly

■ 12-1 Overhaul Disassembly & Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

Chapter 13 Circuit Description

■ 13-1 Overall Block Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

■ 13-2 Partial Block Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-2

Chapter 14 Reference Information

■ 14-1 Other issues related to other products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-1

■ 14-2 Technical Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-2

1. Make sure all protective devices are properly installed

including non-metallic handles and compartment covers

when installing or re-installing the chassis or chassis

assemblies.

2. Make sure that no gaps exist between the cabinets for

children to insert their fingers in to prevent children from

receiving electric shocks. Gaps mentioned above include

ventilation holes of a too great magnitude between the

vaccum tube and the cabinet mask, and the improper

installation of the rear cabinet.

Errors may occur when the resistance is below 1.0 ㏁ or

over 5.2 ㏁.

In these cases, make sure that the device is repaired

before sending it back to the customer.

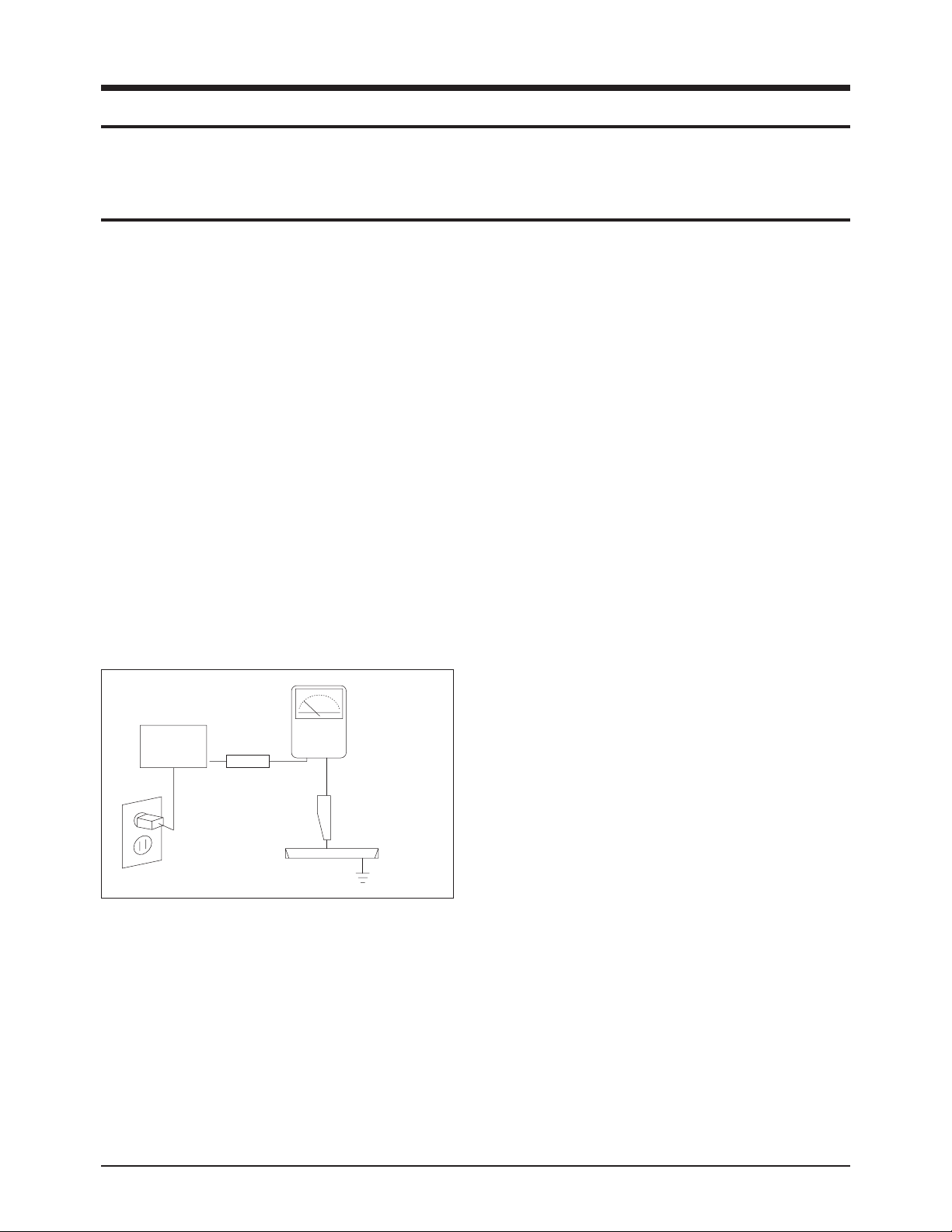

3. Check for Electricity Leakage (Figure 1-1)

Warning: Do not use an insulated transformer for checking the leakage. Use only those current leakage testers

or mirroring systems that comply with ANSIC 101.1 and

the Underwriter Laboratory's specifications (UL1410,

59.7).

Fig. 1-1 AC Leakage Test

4. A high voltage is maintained within the specified limits

using safety parts, calibration and tolerances. When

voltage exceeds the specified limits, check each special

part.

5. Warning for Engineering Changes:

Never make any changes or additions to the circuit

design or the internal part for this product.

Ex: Do not add any audio or video accessory

connectors. This might cause physical damage.

Furthermore, any changes or additions to the original

design/engineering will invalidate the warranty.

6. Warning - Hot Chassis:

Some TV chassis are directly connected to one end of

the AC power cord for electrical reasons.

Without insulated transformers, the product can only be

repaired safely when the chassis is connected to the

earthed end of the AC power source.

To make sure the AC power cord is properly connected,

follow the instructions below. Use the voltmeter to

measure the voltage between the chassis and the

earthed ground. If the measurement is over 1.0V, unplug

the AC power cord and change the polarity before reinserting it. Measure the voltage between the chassis

and the ground again.

7. Some TV chassis are shipped with an additional

secondary grounding system. The secondary system is

adjacent to the AC power line. These two grounding

systems are separated in the circuit using an

unbreakable/unchangeable insulation material.

8. When any parts, material or wiring appear overheated or

damaged, replace them with new regular ones

immediately. When any damage or overheating is

detected, correct this immediately and make a regular

check of possible errors.

9. Check for the original shape of the lead, especially that

of the antenna wiring, any sharp edges, the AC power

and the high voltage power. Carefully check if the wiring

is too tight, incorrectly placed or loose. Never change the

space between the part and the printed circuit board.

Check the AC power cord for possible damages. Keep

the part or the lead away from any heat-emitting

materials.

Precaution

Samsung Electronics 1-1

To avoid possible damages or electric shocks or exposure to radiation, follow the instructions below with regard to safety,

installation, service and ESD.

1. Precaution

1-1 Safety Precautions

(READING SHOULD

DEVICE

UNDER

TEST

EXPOSED METAL

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

SURFACES

LEAKAGE

CURRENT

TESTER

NOT BE ABOVE

0.5mA)

EARTH

GROUND

10. Safety Indication:

Some electrical circuits or device related materials

require special attention to their safety features, which

cannot be viewed by the naked eye. If an original part is

replaced with another irregular one, the safety or

protective features will be lost even if the new one has a

higher voltage or more watts.

Critical safety parts should be bracketed with ( ).

Use only regular parts for replacements (in particular,

flame resistance and dielectric strength specifications).

Irregular parts or materials may cause electric shock or

fire.

Precaution

1-2 Samsung Electronics

!

1. The service instructions are printed on the cabinet, and

should be followed by any service personnel.

2. Make sure to unplug the AC power cord from the power

source before starting any repairs.

(a) Remove or re-install parts or assemblies.

(b) Disconnect the electric plug or connector, if any.

(c) Connect the test part in parallel with the electrolytic

capacitor.

3. Some parts are placed at a higher position than the

printed board. Insulated tubes or tapes are used for this

purpose. The internal wiring is clamped using buckles to

avoid contact with heat emitting parts. These parts are

installed back to their original position.

4. After the repair, make sure to check if the screws, parts

or cables are properly installed. Make sure no damage is

caused to the repaired part and its surroundings.

5. Check for insulation between the blade of the AC plug

and that of any conductive materials (i.e. the metal

panel, input terminal, earphone jack, etc).

6. Insulation Check Process: Unplug the power cord from

the AC source and turn the switch on. Connect the insulating resistance meter (500v) to the AC plug blade.

The insulating resistance between the blade of the AC

plug and that of the conductive material should be more

than 1 ㏁.

7. Any B+ interlock should not be damaged.

If the metal heat sink is not properly installed, no

connection to the AC power should be made.

8. Make sure the grounding lead of the tester is connected

to the chassis ground before connecting to the positive

lead. The ground lead of the tester should be removed

last.

9. Beware of risks of any current leakage coming into

contact with the high-capacity capacitor.

10. The sharp edges of the metal material may cause

physical damage, so ensure wearing protective gloves

during the repair.

Precaution

Samsung Electronics 1-3

Warning 1: First carefully read the "Safety Instruction" in this service manual.

When there is a conflict between the service and the safety instructions, follow the safety instruction at all times.

Warning 2: Any electrolytic capacitor with the wrong polarity will explode.

1-2 Servicing Precautions

1-3 Static Electricity Precautions

1. Some semi-conductive ("solid state") devices are

vulnerable to static electricity. These devices are known

as ESD. ESD includes the integrated circuit and the field

effect transistor. To avoid any materials damage from

electrostatic shock, follow the instructions described

below.

2. Remove any static electricity from your body by

connecting the earth ground before handling any

semi-conductive parts or ass'ys. Alternatively, wear a

dischargeable wrist-belt.

(Make sure to remove any static electricity before

connecting the power source - this is a safety instruction

for avoiding electric shock)

3. Remove the ESD ass'y and place it on a conductive

surface such as aluminum foil to prevent accumulating

static electricity.

4. Do not use any Freon-based chemicals.

Such chemicals will generate static electricity that

causes damage to the ESD.

5. Use only grounded-tip irons for soldering purposes.

6. Use only anti-static solder removal devices.

Most solder removal devices do not support an

anti-static feature. A solder removal device without an

anti-static feature can store enough static electricity to

cause damage to the ESD.

7. Do not remove the ESD from the protective box until the

replacement is ready. Most ESD replacements are

covered with lead, which will cause a short to the entire

unit due to the conductive foam, aluminum foil or other

conductive materials.

8. Remove the protective material from the ESD

replacement lead immediately after connecting it to the

chassis or circuit ass'y.

9. Take extreme caution in handling any uncovered ESD

replacements. Actions such as brushing clothes or lifting

your leg from the carpet floor can generate enough static

electricity to damage the ESD.

Precaution

1-4 Samsung Electronics

CAUTION

These servicing instructions are for use by

qualified service personnel only.

To reduce the risk of electric shock do not

perform any servicing other than that contained in the

operating instructions unless you are qualified to do so.

Precaution

Samsung Electronics 1-5

1-4 Installation Precautions

1. For safety reasons, more than two people are required

for carrying the product.

2. Keep the power cord away from any heat emitting

devices, as a melted covering may cause fire or electric

shock.

3. Do not place the product in areas with poor ventilation

such as a bookshelf or closet. The increased internal

temperature may cause fire.

4. Bend the external antenna cable when connecting it to

the product. This is a measure to protect it from being

exposed to moisture. Otherwise, it may cause a fire or

electric shock.

5. Make sure to turn the power off and unplug the power

cord from the outlet before repositioning the product.

Also check the antenna cable or the external connectors

if they are fully unplugged. Damage to the cord may

cause fire or electric shock.

6. Keep the antenna far away from any high-voltage cables

and install it firmly. Contact with the high-voltage cable or

the antenna falling over may cause fire or electric shock.

7. Check the basics of the screen test.

- Image position/size, Tilt adjustment

1-6 Samsung Electronics

MEMO

Product Specification

Samsung Electronics 2-1

2. Product Specification

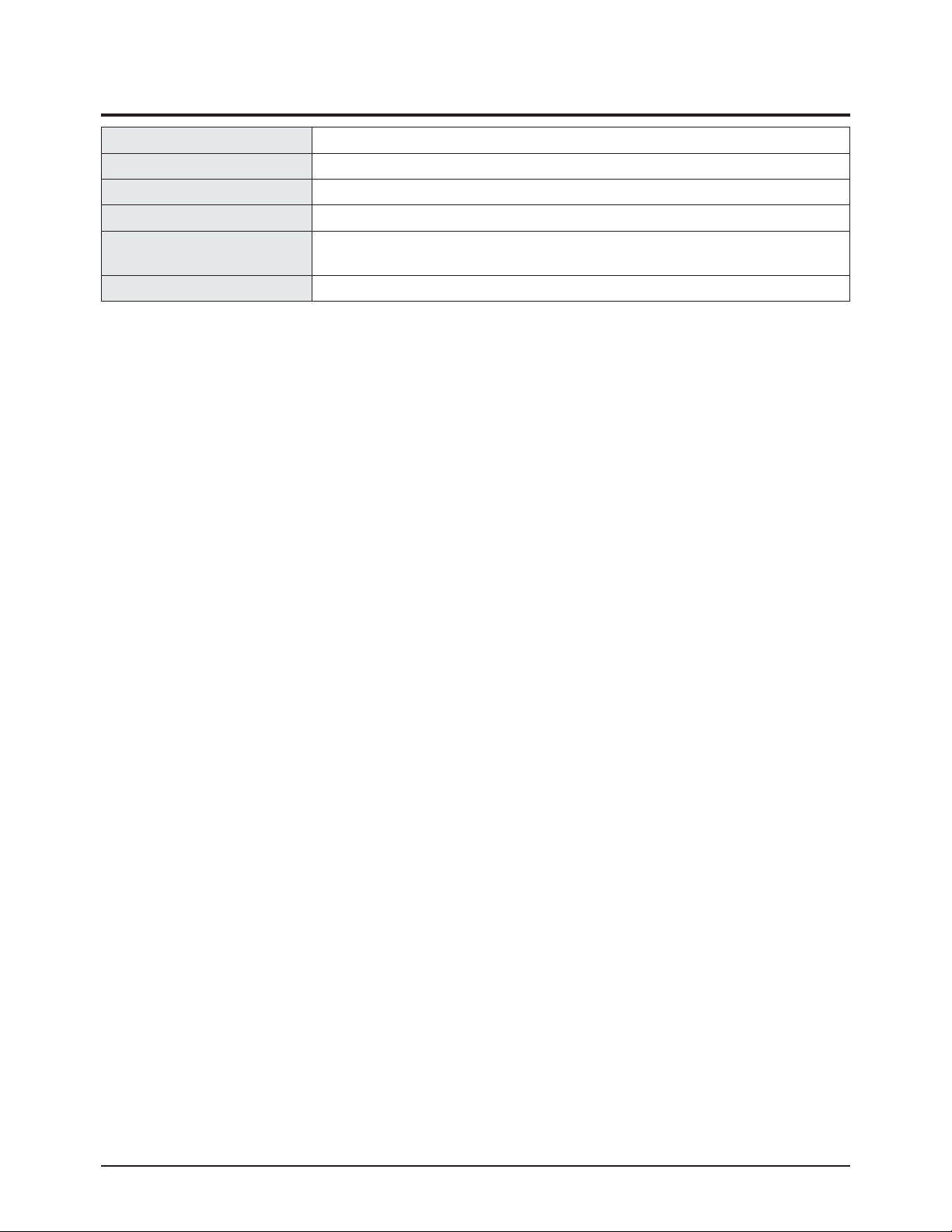

2-1 Product Features

Block Specfication Core Parts Remark

CRT 29" FLATAK CRT GREEN CRT

RF Part 1TUNER F/S TUNER TDQ-6F/13F2S

Power

WORLD WIDE INPUT VOLTAGE RANGE

STD-BY : 5W UNDER

STR-W6750F

Video

- MULTI SYSTEM(NT/PAL)

- 1H Comb Filter

TDA12005PQ,

TDA12015PQ

Audio

- Output : 5W/10W/15W X2

- BTSC/SAP STEREO : PSEUDO STEREO, TURBO PLUS

TDA12005PQ,

TDA12015PQ,

TDA7297SA

Cabinet - 29" CABINET

Other

- BASIC MODEL : CL29M21FQ2XXAX

- UOC3 with a built-in MSP

- TURBO → TURBO PLUS

■ Core Parts Functions

- TDA12005PQ : Video/Sound Processing and MICOM (NTSC)

- TDA12015PQ : Tri-noma

- STR-W6750F : SMPS Power STR

- TDA7297SA(or 7266) : 5W ~ 15W Sound Output BTLAMP

- 24C16 : 16K EEPROM

- LA78040 : Vertical Deflection AMP

- C5936 : H-OUT S/W TR

- TDA-6F/13F2S : F/S PALTuner

- TDA6108AJF : R/G/B Drive AMPIC

Product Specification

2-2 Samsung Electronics

2-2 Key Features

Model CL29K5MQ

Voltage AC100-240V

Frequency of Operation 50/60 Hz

Power Consumption 110 Watts

Dimensions (mm/inches)

766 X 558 X 586/

30.16 X 21.97 X 23.07

Weight (Kg/ lbs) 41/90.39

■ Hardware Configuration

- 1 Chip : UOC3 TDA12005PQ(CHROMA, IF+Deflection, MICOM, MSP)

- Tuner : TDA-6F/13F2S

- SOUND AMP: TDA7297SA(ZIP, 15P, -, DUAL, 32dB, PLASTIC, 20V, 30W)

- SMPS Controller : STR-W6750F(6P, TO-3P-F7L)

- Vertical AMP : LA78045(TO220, 7P, 15V)

- Flyback Trans : FOK14B001(11P, 27KV)

- CRT : A51QDX993X(A) (AK, 1H Single Focus)

■ Software Configuration

- MCU : 80C51-controller core

- Data Capture for US Closed Caption

- 0.4883s machine cycle

■ Picture

- Enhance : DNIe Jr.(Digital Natural Image Engine)

- System : NTSC3.58

- Interlaced(60Hz)

- AKB(Auto Kinetic Bais)

- Comb Filter : 1H Comb Filter

- 4:3/Zoom

■ Sound

- BTSC/SAP-STEREO

- Output : 5/10/15W X 2CH

- Auto Stereo, Sound Equalizer, Auto Mute, Auto Volume Limit, PSEUDO STEREO, TURBO PLUS

■ Feature

- Composite (RCAA/V, DVD), S-Video(Y/C)

- Picture Size : Zoom/4:3

- Auto Serch

- Sleep Timer : 180 Min

- Clock Setting

- Blue Screen, Melody On-Off, Picture Mode Select

■ In/Out Terminals

- Rear : 2RCA/DVD/S-VHS

- Front or Side A/V Input(Side A/V Preferability)

■ Remocon

- Universal Interface TM75

■ Power Consumption : 105W

Product Specification

Samsung Electronics 2-3

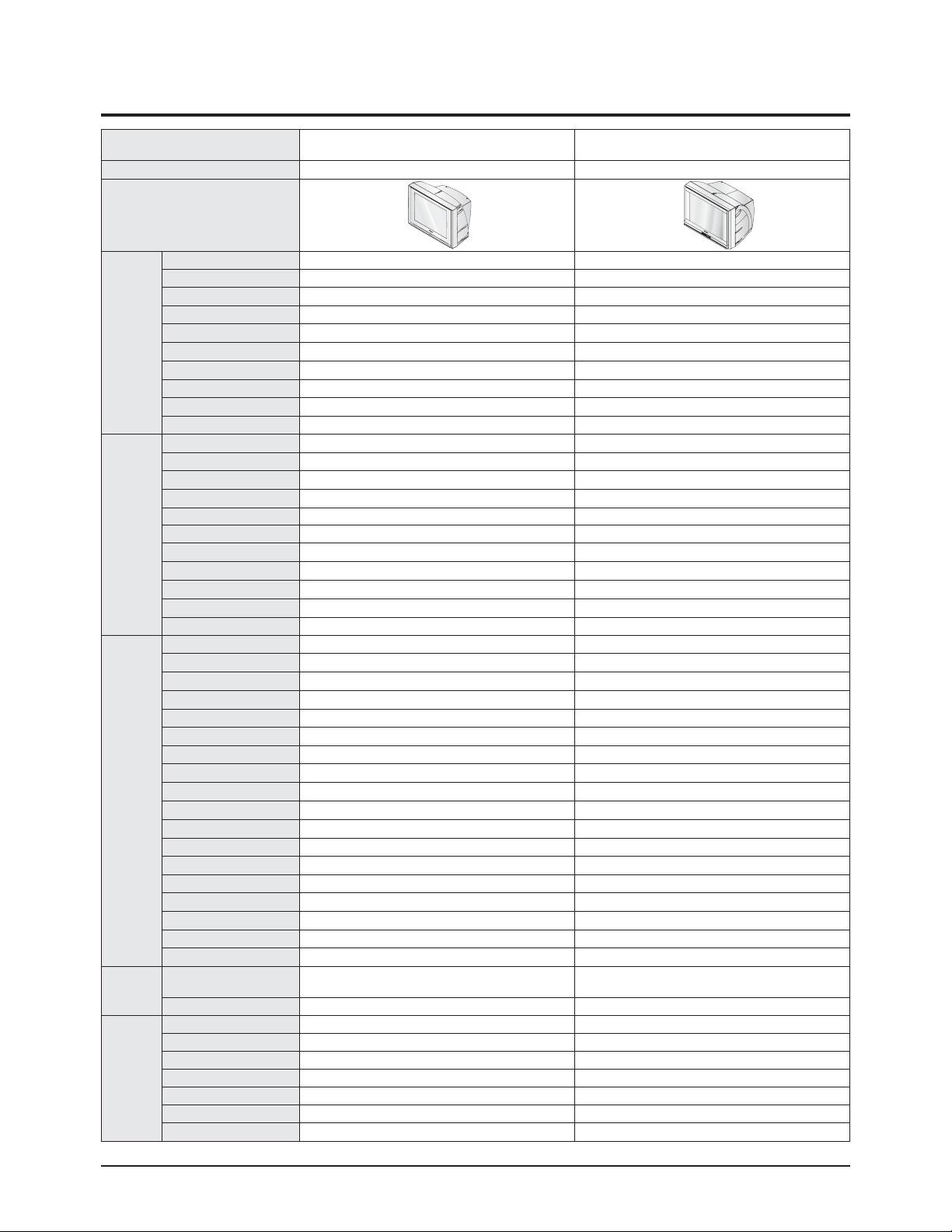

2-3 Specifications Analysis

Model CL29M21PQ CL29K5MQ

Chassis KS7A K16A

Design

Picture

Screen Size 29" 29"

Pure Flat CRT

○ ○

DNIe Jr.

○ ○

Comb Filter 1H 1H

Velocity Modulation

× ×

Video Noise Reduction

○ ○

Auto Kinetic Bias

○ ○

Color Tone Control

○ ○

Tilt Control

× ×

Picture Mode 4 Mode 4 Mode

Sound

MTS/SAP

○ ○

Output Power(RMS) 15W x 2 15W x 2

Tweeter

× ×

BBE

× ×

Surround Surround Surround

Sound Mode 5 Mode 5 Mode

Graphic Equalizer

× ×

Sub-Woofer Speaker

× ×

Auto Volume Leveler

○ ○

Melody On/Off

○ ○

Turbo Sound

○ ○

Convenience

PIP 2T (Optional)

×

Plug & Play

○ ○

Zoom Mode

○ ○

OSD Demo

○ ○

OSD Language E/F/S E/F/S

Previous Channel

○ ○

Closed Caption

○ ○

On/Off Timer

○ ○

Sleep Timer

○ ○

Auto Power Off

○ ○

Clock

○ ○

Channel Scan

× ×

Self-diagnostic System

○ ○

Remote Control TM76 TM75

Remote Surf

○ ○

Channel Labelling

○ ○

Blue Screen

○ ○

Rack

× ×

Voltage

Voltage

AC100-240V

AC120V (Mexico)

AC100-240V

Stand-by under 3W under 5W

Jacks

RF Input R1 R1

A/V Input S1/R2 S1/R2

Monitor Output R1 R1

S-VHS Input R1 R1

Headphone S1 S1

DVD Input

○ ○

PC Input(VGA)

× ×

Product Specification

2-4 Samsung Electronics

2-4 Accessories

Accessories Item Item code Remark

SuppliedAccessories

Remote Control

AAAAlkaline Battery (2)

AA59-00316B

4301-000121

Samsung Service center

Owner's Instructions AA68-03671H

Warranty Card BN68-00797A

Accessories that can be purchased

additionally

Video Cable /

Audio Cable

-

Internal shopping mallAntenna Cable -

Component Cable -

Alignment & Adjustment

Samsung Electronics 3-1

3. Alignment & Adjustment

3-1 Service Instruction

1. General Adjustment :

In general, a color TV can provide ideal visual quality by adjusting the basic settings such as the vertical size, horizontal size,

focus, etc.

Display a black and white picture on the screen to check if the picture is clearly displayed.

If there are some 'spotted' points on the screen when displaying a black and white picture, degauss the screen using the

degauss coil. If the spotted points remain, re-adjust the purity and the convergence.

This completes the basic performance examination.

Notice.

■ These adjustments and the check list are only applied to K16A chassis-applied models.

■ Only use 230V for the measurement set. It is recommended using an insulation transformer when supplying power to

the set so as to prevent shock to the set or to yourself.

■ These adjustment specifications have been created on the basis of the domestic K16A chassis-applied remote control

model. Some of the contents may be changed subject to the sales location and the product specifications.

※When replacing the Module Service Instruction

1. When replacing the MAIN Board : Tilt adjustment, Focus adjustment, Screen voltage, W/B adjustment are all required. Since

the settings including the Channel information, Deflection, etc. are saved to the EEPROM,

recogfigure these settings when replacing the MAIN Board.

The notation of the software information : T-RHMNSA-1000 refer to "GREEN2 BASIC MODEL EUROPE. ver.1000"

Since the settings including the Channel information, Deflection, etc. are

saved to the EEPROM, recogfigure these settings when replacing the MAIN Board.

2. When replacing the CRT Ass'y : No adjustments required

3. When replacing the front panel Master Power switch : No adjustments required

4. When replacing the Side AV Ass'y : No adjustments required

5. When replacing the PIP Module : No adjustments required

6. When replacing the Control Ass'y : No adjustments required

7. When replacing the PFC Ass'y : No adjustments required

1. To enter Service Mode, press the keys on the remote control according to the following sequence. (in Stand-by status)

Mute → 1 → 8 → 2 → Power On

※ When failing to enter Service Mode, repeat the procedure above.

2. The initial screen of Service Mode.

3. Functions of the Keys within Service Mode.

Alignment & Adjustment

3-2 Samsung Electronics

3-2 How to Access Service Mode

MENU Show all menus

▲ / ▼

Move the cursor to select an item.

◀ / ▶

Adjust the selected configuration value

Option1 XX XX XX XX XX

Option2

Deflection

Video Adjust1

Video Adjust2

Video Adjust3

Video Adjust4

Video Adjust5

YC Delay

Others

Bus Stop Off

CHECKSUM 0000

G2 Adjust

RESET

T-RHMNSA-XXXX 20XX/XX/XX

Alignment & Adjustment

Samsung Electronics 3-3

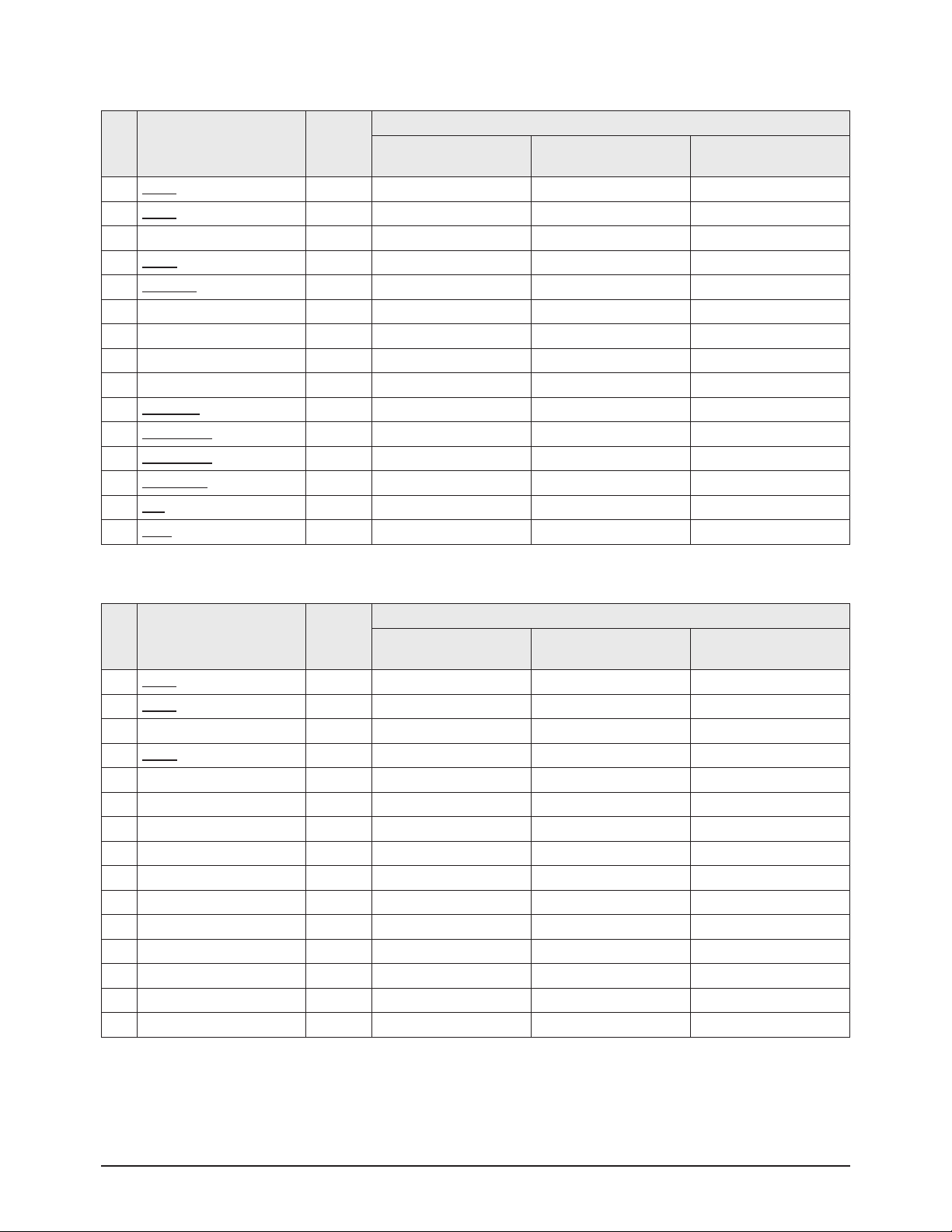

3-3 Factory Data

1. Option1

2. Option2

★ The underlined are items applied during the service adjustment. None of the others should be adjusted.

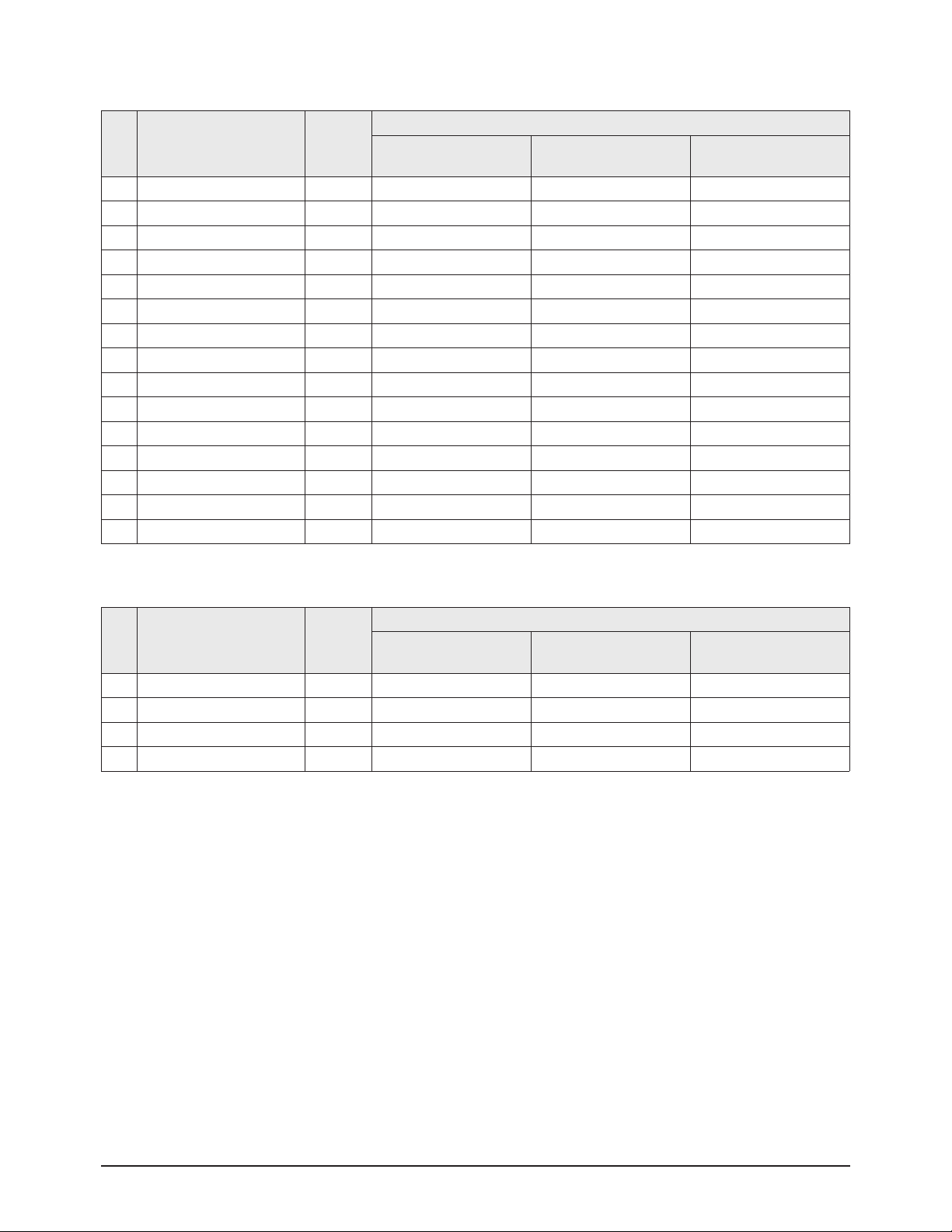

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 System Var. CL CL CL

2 Video Mute Var. 400msec 400msec 400msec

3 A

V Jack

Var. 2RCA+S+DVD 2RCA+S+DVD 2RCA+S+DVD

4 Sound Var. Stereo Stereo Stereo

5 Volume Curve Var. Large Large Large

6 Initial Lang. Var. Engilsh Engilsh Engilsh

7 T

ilt

Var. Off Off On

8 DNIe Jr Var. Off On On

9 PIP Var. Off Off 2-Tuner

10 Auto Power On Var. Off Off Off

11 Caption Var. On On On

12 Vchip Var. Off Off Off

13 Child Look Va r. Off Off Off

14 Plug Play Var. On On On

15 StandBy LED Var. Off Off Off

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 X-Ray Protect Var. Off Off Off

2 High Deviation Var. Off Off Off

3 V-Guard Var. On On On

4 ACS Var. Off Off Off

5 CRT Var. 4:3 Zoom 4:3 Zoom 4:3 Zoom

6 LNA Va r. Off Off On

7 Hotel Mode Var. Off Off Off

8 Philippines Var. Off Off Off

Alignment & Adjustment

3-4 Samsung Electronics

3. Deflection(NTSC 60Hz)

4. Deflection(PAL N 50Hz)

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 V Amp Var. 47 47 47

2 V Shift Var. 24 24 24

3 H EW Var. 48 48 48

4 H Shift Var. 49 49 49

5 V Linearity Var. 30 30 30

6 V S-Correction Fixed 32 32 32

7 V Slope Fixed 30 30 30

8 V Scroll Fixed 25 25 25

9 V Zoom Fixed 48 48 48

10 H Parabola Var. 45 45 45

11 Upper Corner Var. 51 51 51

12 Lower Corner Var. 54 54 54

13 H Trapezium Va r. 22 22 22

14 Bow Var. 26 26 26

15 Angle Var. 29 29 29

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 V

Amp

Var. 0 0 0

2 V Shift Var. 0 0 0

3 H EW Var. 0 0 0

4 H Shift Var. -6 -6 -6

5 V Linearity Fixed 0 0 0

6 V S-Correction Fixed 0 0 0

7 V Slope Fixed 0 0 0

8 V Scroll Fixed 0 0 0

9 V Zoom Fixed 0 0 0

10 H Parabola Fixed 0 0 0

11 Upper Corner Fixed 0 0 0

12 Lower Corner Fixed 0 0 0

13 H Trapezium Fixed 0 0 0

14 Bow Fixed 0 0 0

15 Angle Fixed 0 0 0

Alignment & Adjustment

Samsung Electronics 3-5

Alignment & Adjustment

3-6 Samsung Electronics

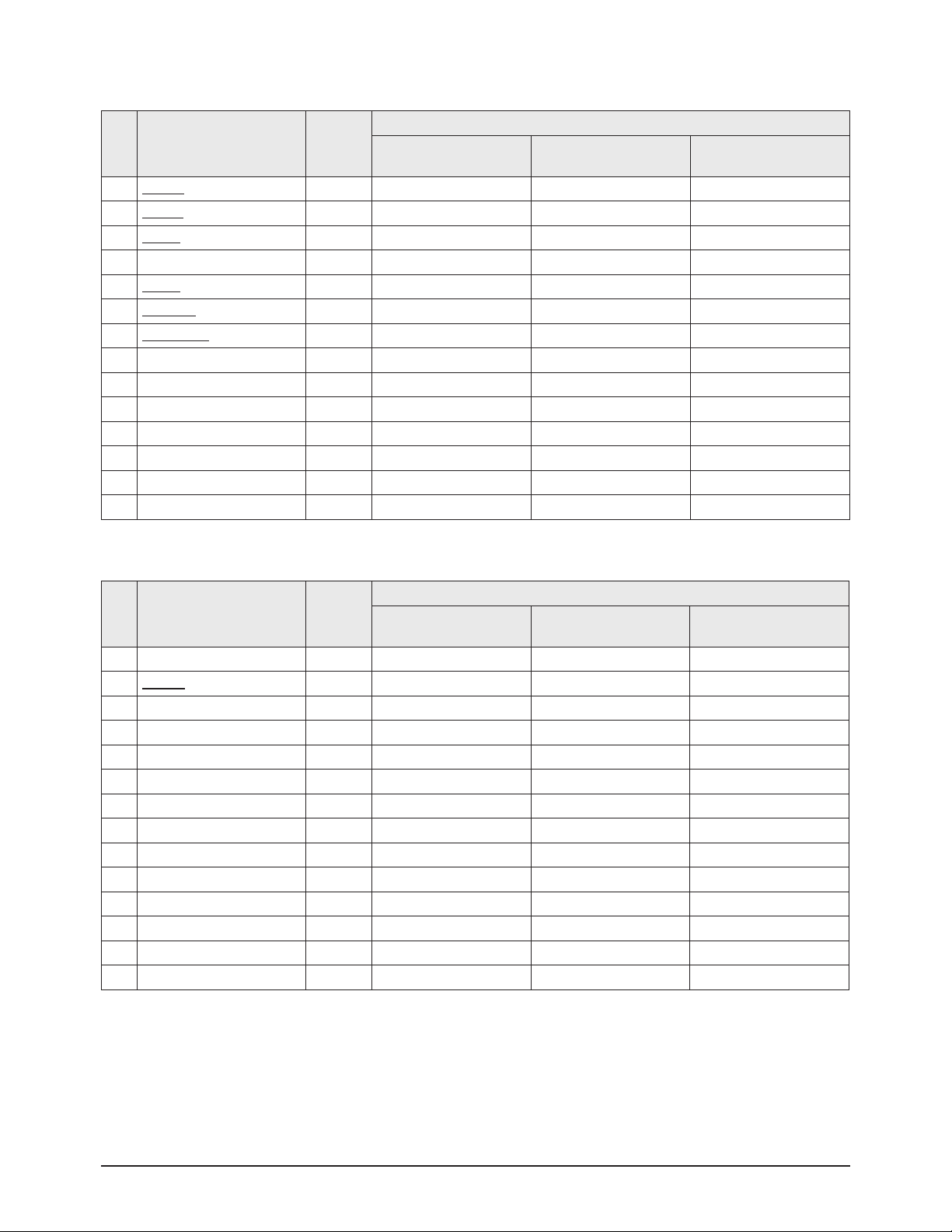

5. Video Adjust1

6. Video Adjust2

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 R Cutoff Var. 20 20 20

2 B Cutof

f

Var. 49 49 49

3 R Drive Va r. 29 29 29

4 G Drive Fixed 15 15 15

5 B Drive Var. 21 21 21

6 Sub Bright Va r. 17 17 17

7 Sub Contrast Var. 7 7 7

8 PAL/SECAM Sub Color Fixed 23 23 23

9 NTSC Sub Color Fixed 21 21 21

10 NTSC Sub Tint Fixed 15 15 15

11 YUV Sub Tint Fixed 32 32 32

12 AKB Option Fixed 0 0 0

13 Peaking CFO & Delay Mode Fixed 1 1 1

14 Sub Sharpness-RF Fixed 10 10 10

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 Melody Volume Fixed 25 25 25

2 RF AGC Var. 24 24 24

3 IF AGC Speed Fixed 1 1 1

4 VM Mode Fixed 0 0 0

5 VM Gain Fixed 0 0 0

6 VM Delay Fixed 0 0 0

7 Blue Stretch Fixed 0 0 0

8 G2 Adjust Bright Fixed 48 48 48

9 Soft Clipping Level Fixed 1 1 1

10 Peak White Limit Fixed 8 8 8

11 Cathode Drive Level Fixed 4 4 4

12 IF Demodulator Fixed 30 30 30

13 Fast Filter IF PLL Fixed 0 0 0

14 FOAB Fixed 3 3 3

Alignment & Adjustment

Samsung Electronics 3-7

7. Video Adjust3

8. Video Adjust4

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 PIP Contrast Fixed 10 10 10

2 PIP Bright Fixed 4 4 4

3 PIP Tint Fixed 3 3 3

4 PIP Color Fixed 8 8 8

5 PIP YC Delay Fixed 12 12 12

6 PIP PAL V.Pos Fixed 1 1 1

7 PIP NTSC V. Pos Fixed 1 1 1

8 PIP H. Pos Fixed 2 2 2

9 PIP R Cutoff Fixed 7 7 7

10 PIP G Cutoff Fixed 6 6 6

11 PIP B Cutoff Fixed 7 7 7

12 PIP R Drive Fixed 139 139 139

13 PIP G Drive Fixed 152 152 152

14 PIP B Drive Fixed 142 142 142

15 PIP AGC Mode Fixed 3 3 3

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 IF Preset Value 1 Fixed 32 32 32

2 IF Preset Value 2 Fixed 32 32 32

3 IF PLL Osc Preset Value Fixed 0 0 0

4 Preset Gain R Fixed 20 20 20

5 Preset Gain G Fixed 20 20 20

6 Preset Gain B Fixed 20 20 20

7 Turbo Center Frequency Fixed 0 0 0

8 DCXO Caps/NICAM Center Fixed 59 59 59

9 DCXO Scaning Control Gain Fixed 3 3 3

10 Component H-Shift Offset Fixed -4 -4 -4

Alignment & Adjustment

3-8 Samsung Electronics

10. YC Delay

9. Video Adjust5

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 System I Output Signal AMP Fixed 0 0 0

2 Bypass of Chroma Base Band Fixed 1 1 1

3 Fixed Beam Current Fixed 0 0 0

4 Fixed Beam Current 1 Fixed 0 0 0

5 IF Sensitivity Fixed 0 0 0

6 Forced Digital Interface Fixed 0 0 0

7 Enable Digital Interface Fixed 0 0 0

8 Sync Performance Trick Mode Fixed 0 0 0

9 Vertical Overscan Fixed 0 0 0

10 Beam Current Limiting Fixed 0 0 0

11 Comb filter Fixed 0 0 0

12 De Interlace Fixed 0 0 0

13 Chroma Trap Mode Fixed 0 0 0

14 Black Current Measure Line Fixed 0 0 0

15 EHT Tracking Mode Fixed 1 1 1

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 PAL Delay Fixed 8 8 8

2 NTSC Delay Fixed 8 8 8

3 PALAV Delay Fixed 8 8 8

4 NTSC AV Delay Fixed 8 8 8

Alignment & Adjustment

Samsung Electronics 3-9

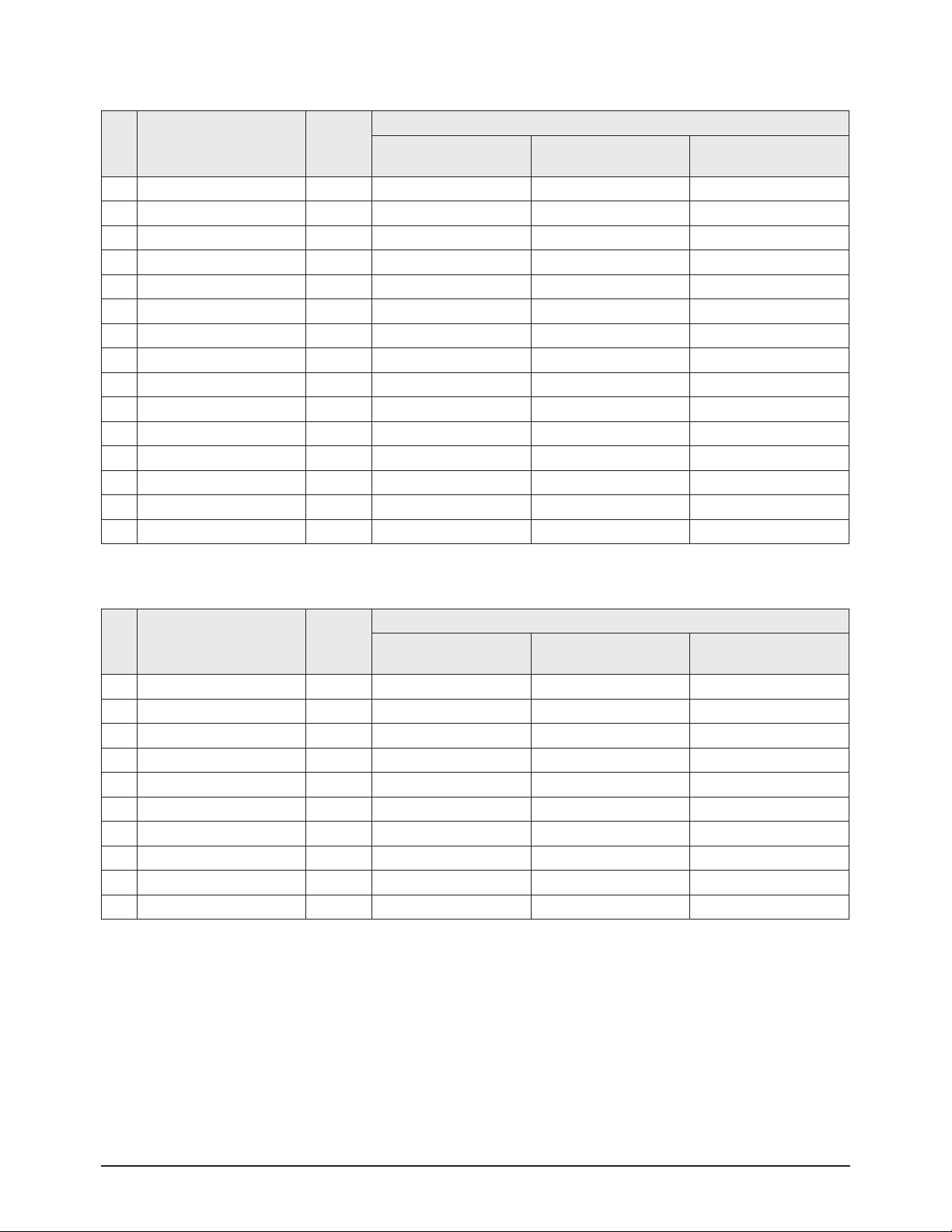

11. Others

12. Bus Stop : Off

13. Checksum : 0000

14. G2 Adjust : Screen Adjust OK/NG/Obove

15. Reset

No Item Var./Fixed

Model

CL29M16MQ CL29M2MQ

CL29M21FQ

CL29T21FQ

1 Service Blanking Fixed 0 0 0

2 High Current Level Fixed 1 1 1

3 Black Area Fixed 2 2 2

4 Black Stretch Fixed 2 2 2

5 OSD Brightness Fixed 10 10 10

6 PWL Active Fixed 1 1 1

7 Bypass Peaking Delay Fixed 0 0 0

8 Ratio Pre. & After Shoot Fixed 2 2 2

9 Ratio Posi. & Nega Peaks Fixed 1 1 1

10 Dynamic Skin Fixed 0 0 0

11 Gamma & White Stretch Fixed 1 1 1

12 Video Depandent Coring Fixed 2 2 2

13 PAL/NTSC Ident Sensitivity Fixed 1 1 1

14 Comb Filter Diode Clamp Fixed 1 1 1

15 DC Transfer Ratio Fixed 1 1 1

Item DATA

MICOM(UOC3)

Version NO.

T-RHMNSA-****

2005/**/**

T-RHMNSA-****

2005/**/**

T-RHMNSA-****

2005/**/**

White Balance

(NTSC/PAL N-M)

275/275/40ft

265/265/2.0ft

275/275/40ft

265/265/2.0ft

275/275/40ft

265/265/2.0ft

Alignment & Adjustment

3-10 Samsung Electronics

3-4 Service Adjustment

3-4-1 Adjusting the Picture Size

■ Since the K16A chassis includes a deflection adjustment of the Factory Data, adjustments must be performed according to the

following procedures when replacing the Main Board.

1. Display the Lion pattern.

2. Press "Power Off → Mute → 1 → 8 → 2 → Power On"

using the remote control and enter Factory Mode.

3. Enter Deflection Mode. 4. Adjust the V-AMP, V-SHIFT, H-AMP and H-SHIFT items so

that the width becomes 5 and the height becomes 4.

Alignment & Adjustment

Samsung Electronics 3-11

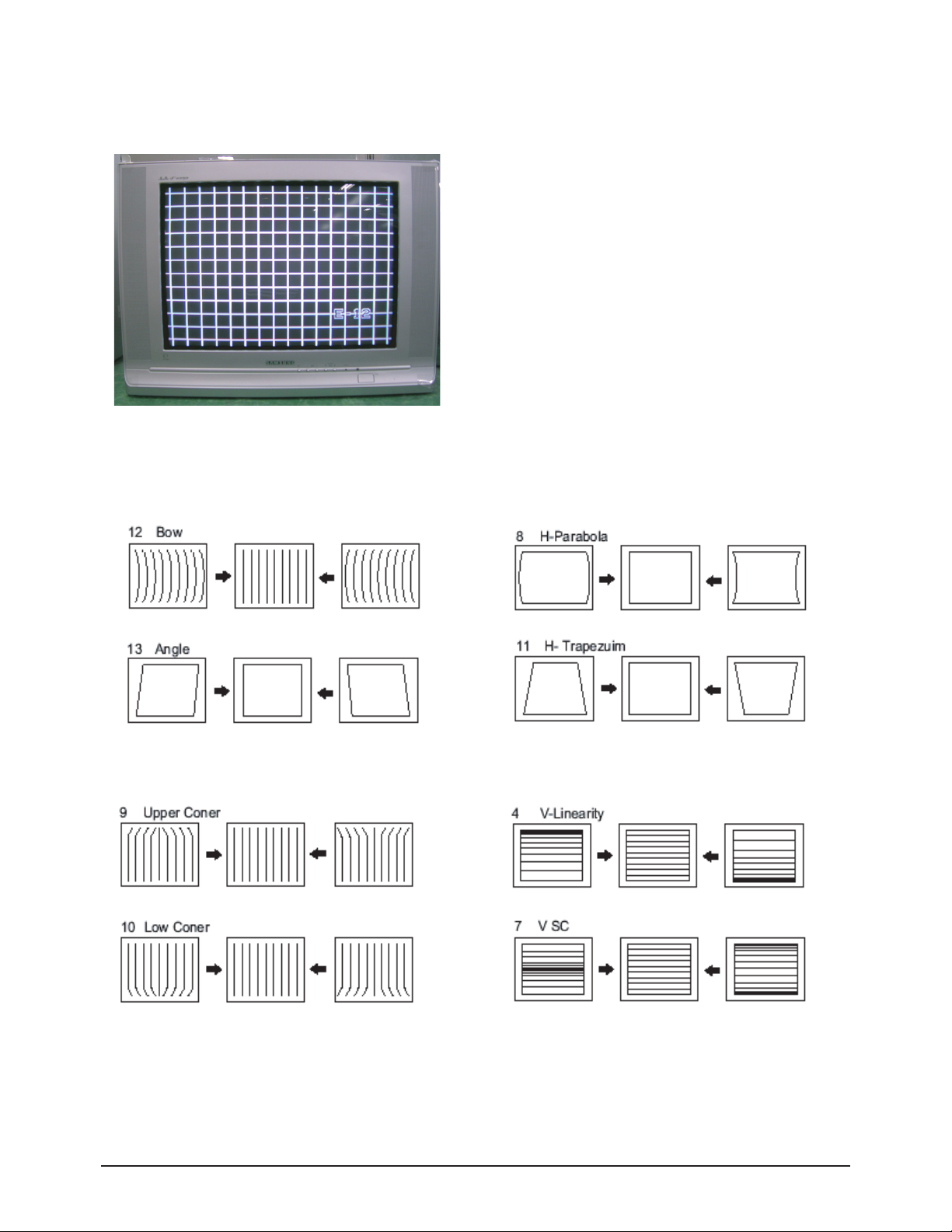

3-4-2 Adjusting the Picture Straight Lines

1. Display the Cross Hatch pattern.

2. Adjust settings other than V-AMP, V-SHIFT, H-AMP and H-SHIFT so that straight lines are displayed without curves.

7. When the adjustments are complete, display the Lion pattern and check that the picture size has not been changed.

If there is no change, finish the adjustments.

3. Adjust BOW and the Angle settings so that the center line

becomes a straight line.

4. Adjust the H-Parabola and H-Trapezium settings so that

the left and right lines become straight.

5. Adjust the Upper Corner and the Low Corner settings so that

the end of the lines become straight.

6. Adjust the V-Linearity and V-SC settings so that the

intervals of the horizontal lines become uniform.

Loading...

Loading...