Samsung cea455 series Service Manual

c8

SAMSUNG

r

/'

'-

-:.z.

:::JO;

--t

(

SERVICE MANUAL

EGA COLOR MONITOR

CEA455*

""

I

.......

~

nil

l:I

L-----1

..

.

~

Ir

I

\

"\

CONTENTS

• SPECIFICATION

.........................................................................

2

• IMPORTANT SERVICE SAFETY PRECAUTION

...............................................

3

• THEORY OF OPERATION

................................................................

5

1.

VIDEO

2.

HORIZONTAL & VERTICAL DEFLECTION

3.

POWER SUPPLY

• DISASSEMBLY INSTRUCTION

............................................................

11

• ALIGNMENT INSTRUCTION

..............................................................

12

• TRUOBLESHOOTING GUIDE

.............................................................

16

• WIRING DIAGRAM AND

PARTS

LIST

......................................................

21

• EXPLODED VIEW

.......................................................................

29

• EXPLODED VIEW

PARTS

LIST

...........................................................

31

• ELECTRICAL

PARTS

LIST

................................................................

33

• SCHEMATIC DIAGRAM AND

WAVE

FORM

.................................................

48

• SEMICONDUCTOR LEAD IDENTIFiCATION

.................................................

50

-1-

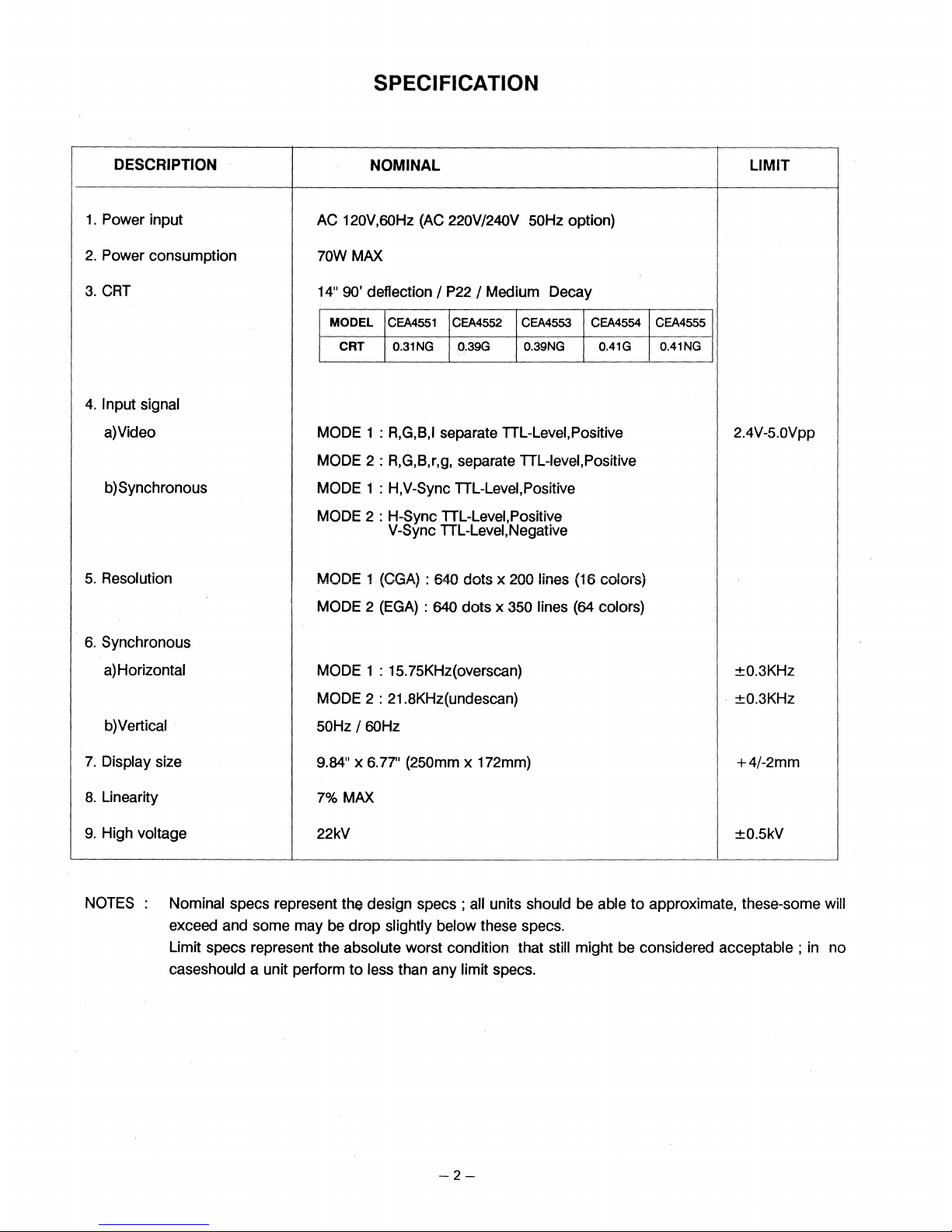

DESCRIPTION

1.

Power input

2.

Power consumption

3.

CRT

4.

Input signal

a)Video

b)

Synchronous

5.

Resolution

6.

Synchronous

a)

Horizontal

b)Vertical

7.

Display size

8.

Linearity

9.

High voltage

SPECIFICATION

NOMINAL

AC 120V,60Hz (AC 220V/240V 50Hz option)

70W MAX

14" 90' deflection / P22 / Medium Decay

MODEL CEA4551 CEA4552 CEA4553 CEA4554 CEA4555

CRT

O.31NG

O.39G

O.39NG

0.41G 0.41NG

MODE 1 : R,G,B,I separate TIL-Level,Positive

MODE 2 : R,G,B,r,g, separate TIL-level,Positive

MODE 1 : H,V-Sync TIL-Level,Positive

MODE

2:

H-Sync TIL-Level,Positive

V-Sync TIL-Level,Negative

MODE 1 (eGA) : 640

dots

x 200 lines (16 COIOiS)

MODE 2 (EGA) : 640

dots

x 350 lines (64 colors)

MODE 1 : 15.75KHz(overscan)

MODE 2 : 21.8KHz(undescan)

50Hz / 60Hz

9.84" x 6.77" (250mm x 172mm)

7%

MAX

22kV

LIMIT

2.4V-5.0Vpp

±O.3KHz

±O.3KHz

+4/-2mm

±O.5kV

NOTES

Nominal specs represent the design

specs;

all units should be able

to

approximate, these-some will

exceed and some may be

drop

slightly below these specs.

Limit specs represent the absolute worst condition that still might be considered

acceptable;

in no

caseshould a unit perform

to

less than any limit specs.

-2-

IMPORTANT SERVICE SAFETY PRECAUTIONS

Service work should

be

perf~rmed

only by qualified

service

technicians who

are

thoroughly familiar with

all

of

the following safety checks

and

servicing guidelines:

WARNING

1.

For continued

safety,

do not attempt to modify

the circuit.

2.

Disconnect the AC power before

serviCing.

3.

Semiconductor

heat

sinks

are

potential shock

hazards when the chassis

is

operating.

SERVICING THE HIGH VOLTAGE SYSTEM

AND

PICTURE TUBE

When

servicing the high voltage

system,

remove

the static charge by connecting a 10kohm

resis-

tor

in

series

with

an

insulated wire (such

as

a

test probe) between the chassis

and

the anode

lead.

(The

AC line cord should

be

disconnected

from the

AC outlet.)

1.

The

picture tube

in

this display monitor employs

integral implosion protection.

2.

Replace

with a tube of the

same

type

and

number for continued

safety.

3.

Do not lift the picture tube by the

neck.

4.

Handle the picture tube only when wearing shatter proof goggles

and

after discharging the high

voltage anode completely.

X-RADIATION AND HIGH VOLTAGE LIMITS

1.

Be

sure

all

service personnel

are

aware of the

procedures

and

instructions covering X-radia-

tion.

The

only potential source of

X-ray

in

a

current solidstate display monitor

is

the

tube.

However,the picture tube does

not

emit

measurable

X-ray

radiation

if

the high voltage

is

as

specified

in

the "high voltage

check"

instruction.

It

is

only when high voltage

is

excessive that

X-radiation

is

capable of penetrating the

shell

of

the picture

tube,

including the

lead

in

glass

material.

The

important precaution

is

to

keep

the high voltage below the maximum

level

specified.

2.

It

is

essential that servicemen

have

available

at

all

times

an

accurate high voltage

meter.

The

calibration of this meter should

be

checked

periodically.

3.

High voltage should always

be

kept

at

the

rated

value-no higher. Operation

at

high voltages

may

cause a failure of the picture tube or high voltage

circuitry and,also under certain conditions,may

produce radiation

in

excess of desirable

levels.

4.

When

the high voltage regulator

is

operating

properly there is no possibility of

an

X-radiation

problem.

'

Everytime a color chassis

is

serviced,the bright-

ness

should

be

tested while monitoring the high

. voltage with a meter to

be

certain that the high

voltage does not exceed the specified

value

and

. that it

is

regulating correctly.

5.

Do not

use

a picture tube other than that

specified

or

make unrecommended circuit

modifications to the high voltage circuitry.

6.

When

trobleshooting or taking test

measure-

ments on a display monitor with excessively high

voltage, avoid being unnecessarily close to the

display monitor.

Do

not operate the display

monitor longer than

is

necessary to locate the

cause of excessive voltage.

-3-

BEFORE RETURNING THE DISPLAY MONITOR

Fire and Shock Hazard

Before returning the display monitor

to

the

user,perform the following safety checks:

1.

Inspect

all

lead

dress to make certain that the

leads

are

not pinched or that the leads

are

not

lodged between the chassis

and

other

metal

parts

in

the display monitor.

2.

Inspect

all

protective devices such as nonmetallic control knobs, insulating materials,

cabinet backs, adjustment and compartment

covers or shields,isolation resistor-capacitor networks, mechanical insulators,etc.

3.

To

be

sure that no shock hazard exists,check

for

leakage current

in

the following manner:

• Plug the

AC

line cord directly into a 120volt

AC

outlet.

(Do

not

use

an

isolation transformer for

this test)

• Using two clips

leads,

connect

1.5

kohm,

10

watt

resistor

paralleled by a 1.5uF capacitor

in

series

with

all

exposed metal cabinet parts

and

a known

earth ground such

as

electrical conduit or

electrical ground connected to earth ground.

•

Use a SSVM

or

YOM

with

1000

ohms per-volt

or higher sensitivity to measure the

AC

voltage

drop across the resistor.

(See

Figure

1.)

• Connect the resistor

to

all

exposed metal parts

having a return path

to

the chassis(metal cabinet,

screw

heads,

knobs

and

shafts,escutcheon,etc.)

and

measure the

AC

voltage drop across the

resistor.

• Any reading of

O.3volt

RMS

(this corresponds to

0.5milliamp.AC) or more

is

excessive and

indicates a potential shock hazard which must

be corrected before returning the display monitor

to the

user.

SAFETY NOTICE

Many electrical

and

mechanical parts which

have

special characteristics

in

this chassis often

pass

unnoticed and the protection afforded by them

can not necessarily

be

obtained by using

replacement components rated for higher voltage,

wattage,

etc.

Replacement parts that

have

these special safety

characteristics are identified

in

this manual,and

its supplement; electrical components having

such features are identified by a !

in

the Parts

List and

Schematic Diagrams.

Before replacing any of these components,read

the Parts List

in

this manual carefully.

The

use

of substitute replacement parts that do not

have

the same safety characteristics

as

specified

in

the Parts List may create shock,

fire,

or other

hazards.

-4-

AC

VOLllETER

1500

n

TO

EXPOSED

METAL

PARTS

TO

KNJWEN

EARTH

GROUND

FIG. 1 LEAKAGE

CURRENT

TEST

CIRCUIT

THEORY OF OPERATION

GENERAL

CEA4551

is

a high resolution color display using a

0.31

dot pitch

NON-GLARE

CRT.

(CEA4552 ; 0.39

glare

CRT,CEA4553 ; 0.39

non-glare

CRT,

CEA4554

;

0.41

glare

CRT , CEA4555 ; 0.41

non-glare

CRT)

It

uses

R,

G,

B,

I or

R,

r,

G,

g,

B, b TTL

input Video

Signals

and

separate

TTL

sync signals.lt

can

operate

in

16

colors

640

by

200

overscan mode or 64colors

640

by

350

underscan mode. This two mode

Is

automatically switched by the polarity of vertical

frequency.

VIDEO

I. Video

Drive Circuit

The

video signals

are

applied to

CUSTOM

IC

(IC1

01).

The

output signals of

IC101

are

applied

to

IC103

which

is

an

open-collector Hex-buffer.

The

output signal

level

of

IC103

(R,r,G,g,B,b)

are

controlled by the

BRIGHTNESS

VR

and

SUB-BRIGHTNESS

VR

(VR110)

and the secon-

dary signals

(r,

g,

b)

are controlled by the

CONTRAST

VA.

The

output signals of

IC103

are

to combine

blanking signals

(H,

V blanking).

Primary signals

(R,

G,

B)

and

secondary signals

(r,

g,

b)

are mixed through

R121

and

D116,R123

and

D117,R125

and

D115

respectively

in

mode

2.Then

the signals

are

applied to the

base

of

pre-amp

transistors(0103,0104,0105).

The

output signals of

IC101

in

MODE 1 and

MODE

2 are selected by the

MODE

signal from

pin no.8 of

IC101

(SL205).

2.

VIDEO

(R,

G,

B)

OUTPUT

The

R,G,B

drive system

is

utilized

in

the video

output circuit of this unit.

In

the case of

RED

signal,the combined color

and blanking signals

are

amplfied sufficiently by

the cascode transistor

(0109, 0110)

The

cut-off levels of the picture tube

are

con-

trolled by the

bias

VRs

(VR103,VR1

04,VR1

05)

between 85Vdc and

145Vdc.

These

DC

voltages are taken from pin no.8 of

FBT

(T

403)

and

pin no.14 of

POWER

TRANS

(T601).

The

color signals

and

blanking signals of 0103,

0104

and

0105

are

supplied

to

the

base

of

0110, 0112, 0114.

The

screen grid,

G2,

is

common

in

the

case

of

RED,GREEN

and

BLUE

CATHODE

respectively.

The

drive control

VRs

(VR101,

VR102)

control

the

base

current of 0110, 0114 for white balance

adjustment.

FIG. 2 SYNC

INTERFACE

CIRCUIT

-5-

VERTICAL

AND

HORIZONTAL DEFLECTION CIR-

CUIT

1.

SYNC

INTERFACE CIRCUIT

In

MODE 1 (CGA

MODE),

the polarity of horizon-

tal

and

vertical sync

are

both positive but

in

MODE

2(EGA

MODE)

the polarity of horizontal

sync

is

positive

and

the vertical sync

is

negative.

If the

HN

sync signal

is

applied

in

MODE

1,

then the output voltage

level

from

pin

nO.8

of

IC102

(EX-OR

gate)

is

OV

and the output voltage

level

from pin

no.

3 of

IC102

is positive.

If the

HN

sync signal

is

applied

in

MODE

2,then

the output voltage

level

from pin

no.

8 of

IC102

is

3.2V

and

the output polarity from pin

nO.3

of

IC102

is

negative.

According to the polarity of vertical sync,

MODE 1 and

MODE 2 are

selected automat-

ically.

Vertical

Deflection Circuit

Vertical

circuit

is

composed of

IC102

(74HCTlS86),

IC301

(LA7830).

IC401

(lA7851),

IC402

(MC14053BCP)

and

its

relative circuits.

The

vertical sync signal from

IC102

which polarity

IS

positive or negative is applied to pin no.19 of

IC401.

Pin

no.19 of

1C401

is

connected to the vertical

oscillation circuit.

The

frequency of oscillator

is

controlled by

the

volt-

age

of pin

18

which

can

varied by the

V-HOLD

VR(VR306).

The

output circuit of

1C301

Is

controlled by

V-SIZE

VR(VR

307)

to vary the vertical

size

of the raster,

that

is

related both

MODE 1 and

MODE

2.

But

V-SIZE

of

MODE 1 Is

only controlled by

CGA

V-SIZE

VR(VR402).

Horizontal OSCillator, AFC and Drive Circuit

The

horizontal sync signal with positive polarity

is

applied to pin 1 of

1C401.The

output from the fly-

back transformer

(T403)

is connectored pin 4 of

1C401

as

part of the automatic frequency circuit

(AFC).

H-CENTER

VR(VR407)

determines the posi-

tion of picture

in

MODE 1 and

MODE

2 but

CGA

H-CENTER

VR(VR403)

controls the position of

CGA

picture only.

The

horizontal oscillation frequency

is,

-6-

obtained from pin

12

of

1C401

and

it

is

fed

to the

next

horizontal drive circuit.

The

pulse-switching

mode of the drive

and

output stage

is a reverse

polarity type

and

that's done when the drive transistor

0401

is

on

and

the output transistor 0402

is

off.

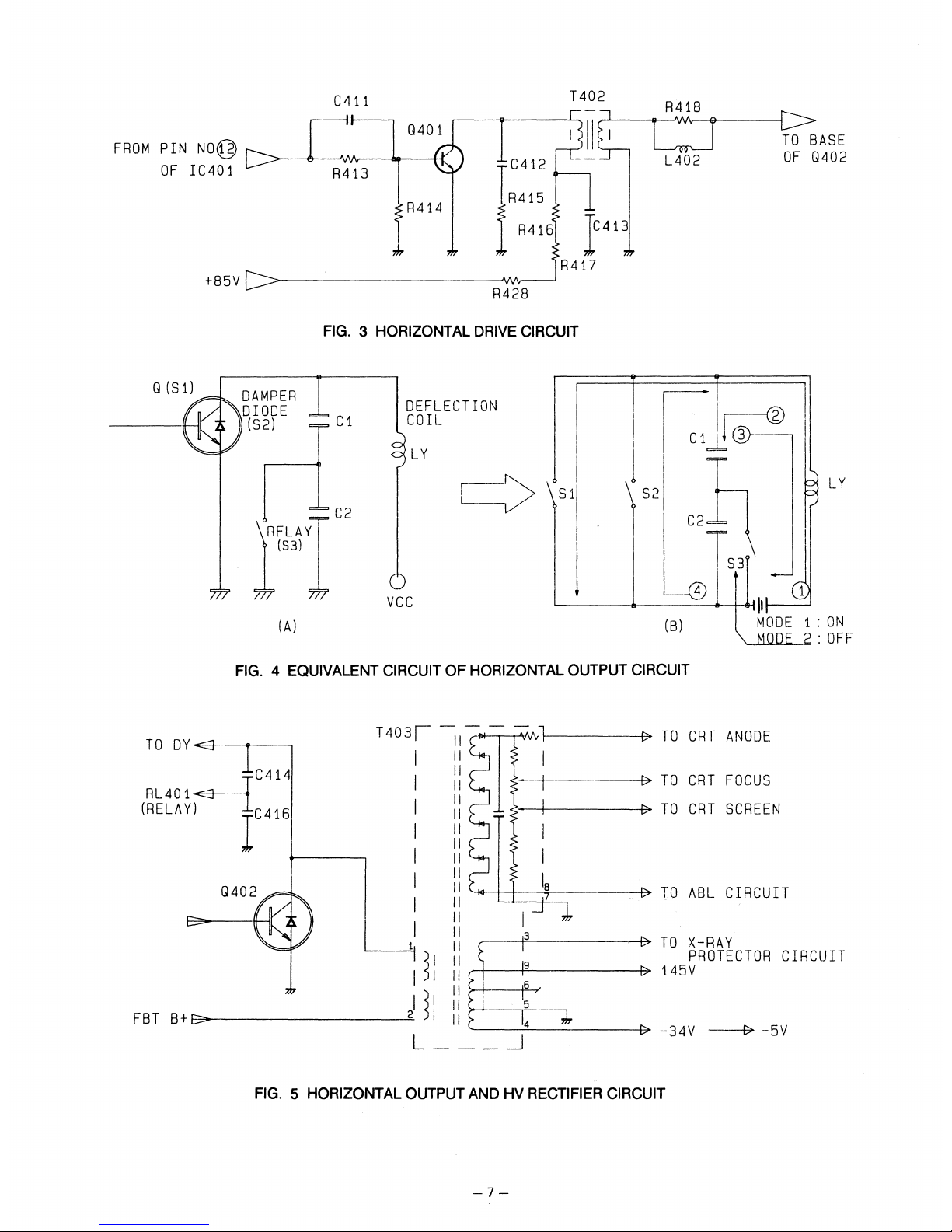

HORIZONTAL

OUTPUT

AND HV RECTIFIER

Horizontal drive voltage which developed at pin

12

of the deflection processor

(IC401)

is

amplified

through the horizontal drive stage (0401)

and

coupled to the

base

of the horizontal output cicuit

via

the horizontal drive transformer(T401).

Refering

to

Fig.3,

the horizontal circuit generates the horizon-

tal scan and high voltage to

be

applied to the picture

tube.

The

function of the horizontal output stage

(0402)

is

to

serve

as

a switch for the horizontal

output circuit.

Refter

to

Fig.4.

During the horizontal scanning period, 0 operates

(S1

is closed,

S2

is opened)

and

the current

is

applied

in

one direction through the horizontal coils

of

the deflection yoke

(ly)

and the capacitor

(MODE

1

:Cl,

MODE

2:C1,C2).

During retrace time, 0 become

to

operate(S1

is

opened,

S2

is

closed)

and

the current

is

applied

In

the opposite direction

through the damper diode

(D),

the horizontal coils of the deflection yoke (ly)

and

the capacitor

Cl,

C2.

The

high voltage required to

be

applied to the anode

of the picture tube

is

generated by boosting the

pulse from the collector of 0402 through

T302

during

the flyback(retrace) period

and

applying this boosted

pulse to a serious of rectifiers.

Refering

to

Fig.5,

high

voltage regulation

is

accomplished internally

in T 403.

HIGH VOLTAGE SHUT-DOWN

SYSTEM

The

shut-down circuit prevents the high voltage from

rising above a presence

level.

Under norminal operat-

ing conditions, this circuit

is

inactive. Operation of

the protector circuit depends upon

an

AFC

pulse,

which apears at pin 3 of the horizontal output

traformer

(T403).

It monitors

an

AFC

pulses sub-

jected to rectification by

D406.

Since it

is

in

propor-

tion to the voltage of that

AFC

pulse,

if the incoming

high voltage increases

and

exceeds its limit, the

AFC

pulse voltage aiso

inceases.

As a result,

there

is

a

larger voltage produced

to

R422

so that its potential

will eventually

be

higher than the voltage( +

8.2V}

of

FROM

PIN

NO@

OF

IC401

+B5V

Q

(S

1)

C411

T402

R418

-II

;::J...-L-

j

----tt--iWv---j.--.--C>

tl

~

TO

BASE

L402

OF

Q402

R428

FIG. 3 HORIZONTAL DRIVE CIRCUIT

o=b

C1

DEFLECTION

COIL

LY

\RELAYI

C2

1.IS31

C=:>

vec

(A)

(B)

MODE

1:

ON

MODE

2:

OFF

FIG. 4 EQUIVALENT CIRCUIT

OF

HORIZONTAL OUTPUT CIRCUIT

TO

DY

~I--~---,

C414

RL401---=-J

(RELAY~C416

I

T403l11

(~lrl~---~f>

TO

CRT

ANODE

I

II~

I

II

Iii:

!

+II-----&[)

TO

CRT

FOCUS

+.

-----&[)

TO

CRT

SCREEN

I

II

I

I

II

,

II

I

I

::

18

~-+-l---'l----~

TO

AB

L C I

RCU

IT

I

II

I

II

II

1

II

L--~

<I

II

I

51

II

(

3

I

19

1

6

/

~

---,;;0

~

-v

TO

X-RAY

PROTECTOR

CIRCUIT

145V

I < I

::

FBT

B+

F::b

__

---------Ei.

2

51

II

5

1

4

*

....

L

___

.-J

L-

-34V

~

-5V

FIG. 5 HORIZONTAL OUTPUT AND

HV

RECTIFIER CIRCUIT

-7-

the Zener diode(ZD401) turning it

ON.

With

0401

turned

ON,

the X-ray protector of

1C401

operates to

stop the horizontal oscillation,shutting down the

resultant high voltage.

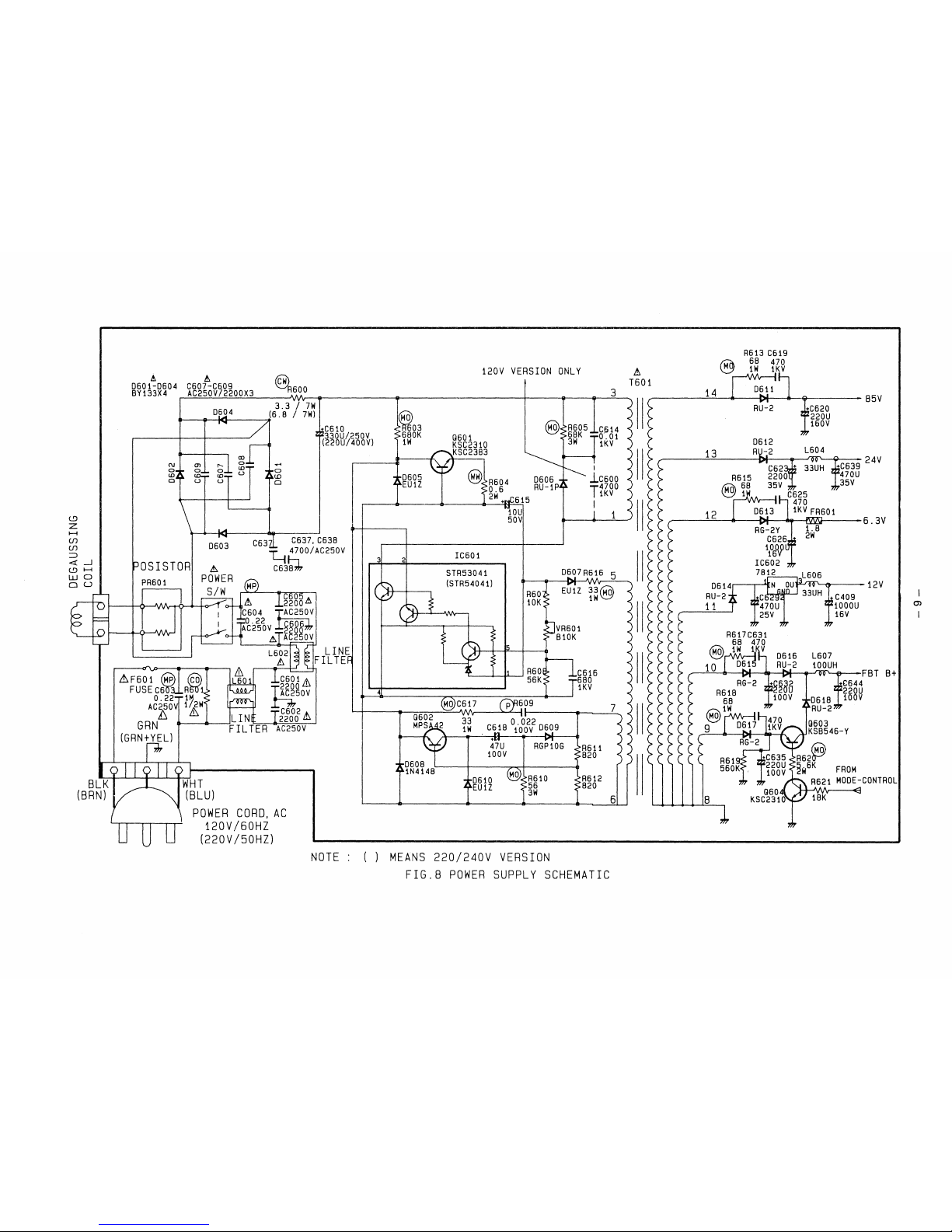

POWER SUPPLY

The

AC

voltage

is

full-wave rectified by the rectified-

smoother circuit and then changed to

DC

voltage

by smoothing capacitor

C610.

When

the power

is

turn

on,

a small current flows into the

base

of output

transistor (included

in

1C601)

via the start-up resistor

(R603).

As

a result, the collector current flows

through the primary windings (pin 1

and

pin 3 of

the power transformer

T601)

and then it produces

an

electromagnetic force.Therefore some voltage

is

induced between pin 6 and pin 7 (driving winding)

of the power tranormer. The induced voltage

is

positively feedback to the base of the output transistor (included

in

1C601)

to increase the

base

current

of this transistor.

As

a result of this base current,

the

collector current of that transistor

is

increased.

The

above operation occurs instaneously to impress

suffiecient base current. The

small signal transis-

tor(0601) protects

1C601

from the surge current

and

0602

is

trigger transistor.

The

FBT

B +

is

selected

by the

MODE

detecting circuit.

In

CGA

MODE,

the

FBT

B + voltage comes from pin

10

of

T60

1 but

in

EGA

MODE

the

FBT

B + comes from pin

11

of

T601

by auto mode sensing circuit. Here the mode sensing

circuit let 0604 and 0603 operate.

FROM

PIN@

OF

T403

(AFC

PULSE)

0406

R423

ZD401

0401

AC

INPUT LINE FILTER

(L60

1.

L602)

IC401

f R422

R438

FIG.6

HIGH

VOLTAGE

SHUT

DOWN

SYSTEM

CIRCUIT

RECTIFIER

IC

(1C60

1)

POWER

TRANS

(T60

11

T601

14

DC

85V

13

DC

24V

l-----DC

6.3V

l-----DC

12V

\----DC

54V

(MODE

1)

9

l----DC

65V

(MODE

2)

FIG. 7 POWER

SUPPLY

BLOCK

DIAGRAM

-8-

(..')

Z

H

U1

U1

::l

<!-.l

(..') H

wo

au

(

\D

~

~

A

t,

0601-0604

C607-C609

BYI33X4 AC250V/2200X3

@

R600

3.3 / 7W

oPJl4

(6.8 / 7W)

.......-

__

........

G---/~

+C610

IF330U//250V

(220U 400V)

!MOl

.¥603

"?680K

IW

A613 C619

r.:;;,.

68

470

6

IW

~K';

14 1

0611

1

II

,..---~2--+--1>

.....

+--+--1(----

85V

AU':2

z~C620

i"220U

@ R605

C.614

IT

160V

G601

~3~KI

~Kel

0612

KSC2383

~

.

V1

24V

120V

VERSION

ONLY

L!.

T601

3

KSC2310

II

13 RU-2

L604

0605

~~

~

0606

~

-LC600 A615

2200

470U

l..'::..rL)

-............-............

I

~

C62:~.

33UH

!1

C639

~~EU1Z

~

A604

4700

(

r.AiiI

68 35V 35V

.-

__

-----t!>-------<l>-g-W-'~t:t=6'_i15

RU

- I P

;>.

T I K V

II

~

6

1

0

~A

-11-,

C

~~5

~IOU

1 1

>-

12

0613

lIKV.!.e,601

50V

Ij-----=-~ ~ ~

r">----=-='---<!>--A-i'G>t:.:.-

2Y

---..--f!

~lofJ1..

8~--

6 . 3 V

...

0603

C6371

C637. C638

J~

4700/AC250V

C63~

POSISTOR

PR601

v J

~

POWER

eo..

S / w

r'~~~P)<---_"","",,,,,--

~Ut,

J:~~88L!;

1---t--Q---'VII'r-t-Q-"""'t--'cY

I

<> <>

I

..1g

60 4 ~ 2 5 0 V

I I

TAh~tv

1.~~8f,1

V<>H

Al.TAC250V

'-----

L

602lliJd

LI

N:~

56K

680

>-

>- >-

FO~~6U

~

2 W

II

~ t ~

lC6

106

2

,

o6..tl7R616

5

>- >- >-

7812

L606

.-----f/"--_-t:>t--:--W'v~Q---"--.,)

>- >-

>-

o6Ij4.--.-...1

....

N

.QU,90

12V

R6qj

EUIZ

~~@

)

>-

(>

? RU-2

~&.fU---l

33UH

C409

10K

)

II

>-

? ? 11 q

Z

470U z

~IOOOU

) >->- >-

~,.----=-=---

25

V 16 V

~

)

>->-?

,

~VR601

>->-? R617C631

810K

<

>- >- >-

>-

68

470

)11

~ >-~ ( @~~

0616

L607

) ~ >-

>-

~

10 1

'b~~'l

R~-2

100UH

<

~

..99~:r-FBT

B+

3 2

le601

STR53041

I:::A

(STR54041)

~cJJ~

~

5

t:,.

l'

FILTEr

r---4~\.P--:::-U"""---:-~--'

&

r----<T.~

FUSE

C603.

R%OI

AC250V

.1.F601

(i.1p)

rcm

,lqjj

I~:6&

,----+-¥-1--,

R60(n1616

L..-:t-----------'

lKV

R618RG-

2

z~~~So I ~~~~d

0.22

1M

i~

AC250V

I/jW

~

~

L!.>

ILIN~

T~~~02Lt.

GRN

FIL

TER

AC250V

(GRNl!Ll

<

11911

)~----.....,

~----~~~~M=~~IC~~~~7.---~C0R~160~9------~---7~

[3p

G602

33

C618

0.022

0609

MPS 2 IW

...

100V-",

47U

RGPIOG

100V

0608

,

IN4148

R611

820

68

100V

0618

100V

IW

~

RU-2

~

~:Jt~h

~~g§46-Y

~

R~,J

'¥'

rMOI

A61

0<

I~C635

R62F

560K'

rI5g~

~~6K

FROM

II

BLKI

~

WHT

(BRN)

V

'\

(BLU)

,0610

~,R610

• EUIZ

56

3W

R612

820

",

,IT

k..

R621

MODE-CONTROL

G60

"L1

"""

u U u

POWER

CORD,

AC

120V/60HZ

(220V 150HZ)

NOTE

6

8 KSC2310

18K

~-=--Jr

( )

MEANS

220/240V

VERSION

FIG.S

POWER

SUPPLY

SCHEMATIC

en

I

~

o

I

V

I

IDEO

NPUT

H

V

-SYNC-

-SYNC-

AC

-INPUT

-~

-

h

-~

l

f-r>

r-c-

VIDEO-INTERFACE

IC-BUFFER

TF1-BUFFER

VIDEO

OUPUT

Q103

Q110-Q109

R~B

III

IC101

IC103

III

Q104

Q112-Q111

III

Q105

Q114-Q113

\U

CONTRAST

~

YBRIGHTNES

Q101

Q102

VIDEO-BOARD

L.....-

V-SIZE

V·-HOLD

SYNC-INTERFACE

.~.

~.

V-SYNC

IC

VERT.OSC.

VERT.OUTPUT

DY

IC102

H-SYNC

V I H

401

HOR.OSC.

IC301

<}-

i

H-JoSI

1 &

~

MODE-CONTROL

MODE-SELECT

S/W

HOR.DRIVE

SPCT

H-WIDTH

CGA

(OV)

IC402

Q401

T401

T402

VR305

fr-

EGA

(3.

5V)

Q302 Q303

H-LIN.

cd

C~A

CkEGA

H-POSI

V-SIZE

H-HOLD

HOR.OUTPUT

Q402

FBT

RELAY-DRIVE

RELAY

T403

r-

Q403 Q404

RL401

IDC

65V

(EGA)

r

I

IDC

54 V (CGA)

f---i>DC

90V

f---i>DC

24V

LINE-FILTER

---i>

RECTIFIER

f-------i:>

POWER-SWITCHING ~ SMPS-TRANS

f---i>DC

12V

L601

L602

0601-0604 IC601

T601

DC

6.3V

MAIN-BOARD

OJ

r

o

(")

"

c

»

C)

:D

»

s:

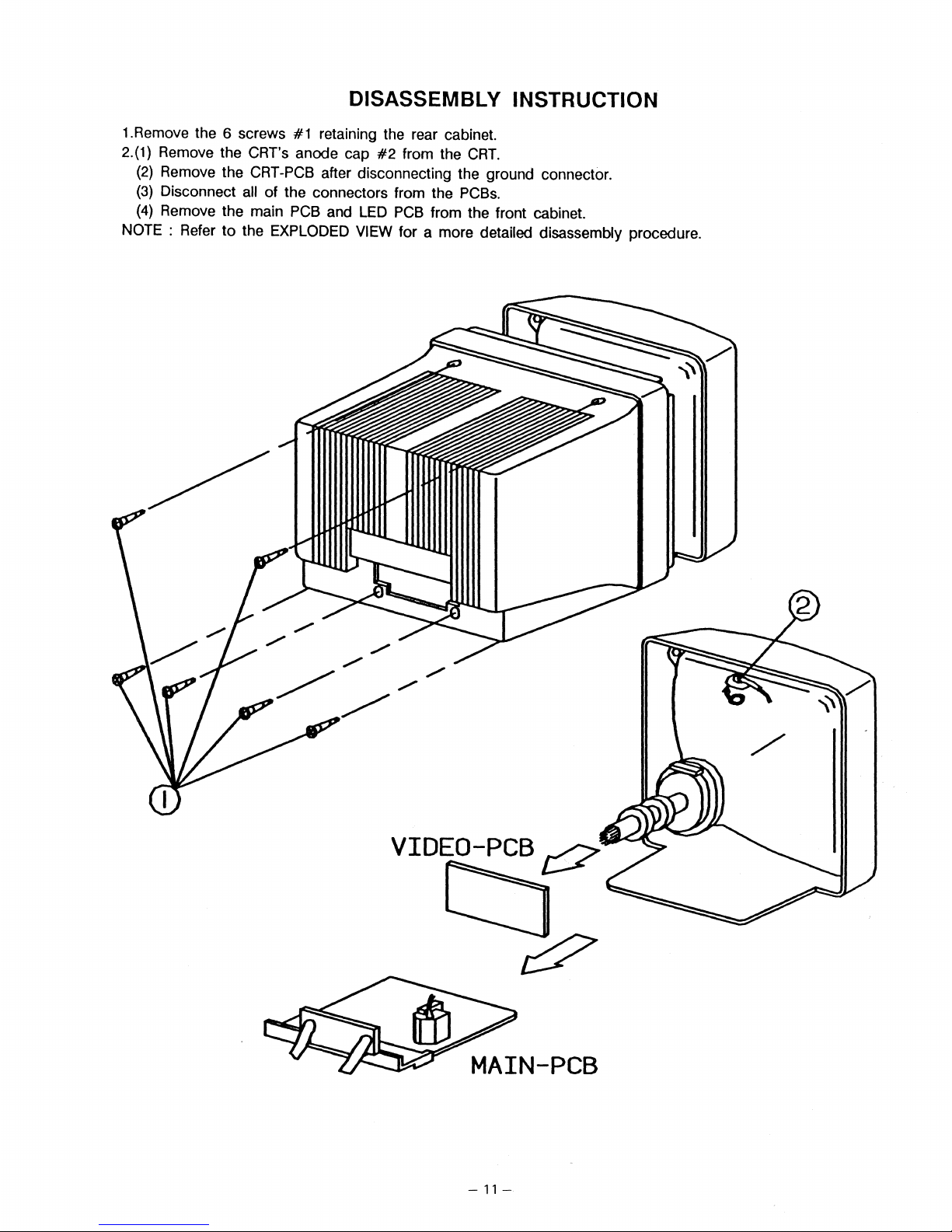

DISASSEMBLY INSTRUCTION

1.Remove the 6 screws #1 retaining

the

rear cabinet.

2.(1)

Remove

the CRT's anode cap

#2

from the

CRT.

(2)

Remove

the

CRT-PCB

after disconnecting the ground connector.

(3)

Disconnect

all

of the connectors from the

PCBs.

(4)

Remove

the main

PCB

and

LED

PCB

from the front cabinet.

NOTE : Refer

to

the

EXPLODED

VIEW

for a more detailed disassembly procedure.

-

11

-

NO

1

2

3

4

5

6

7

8

9

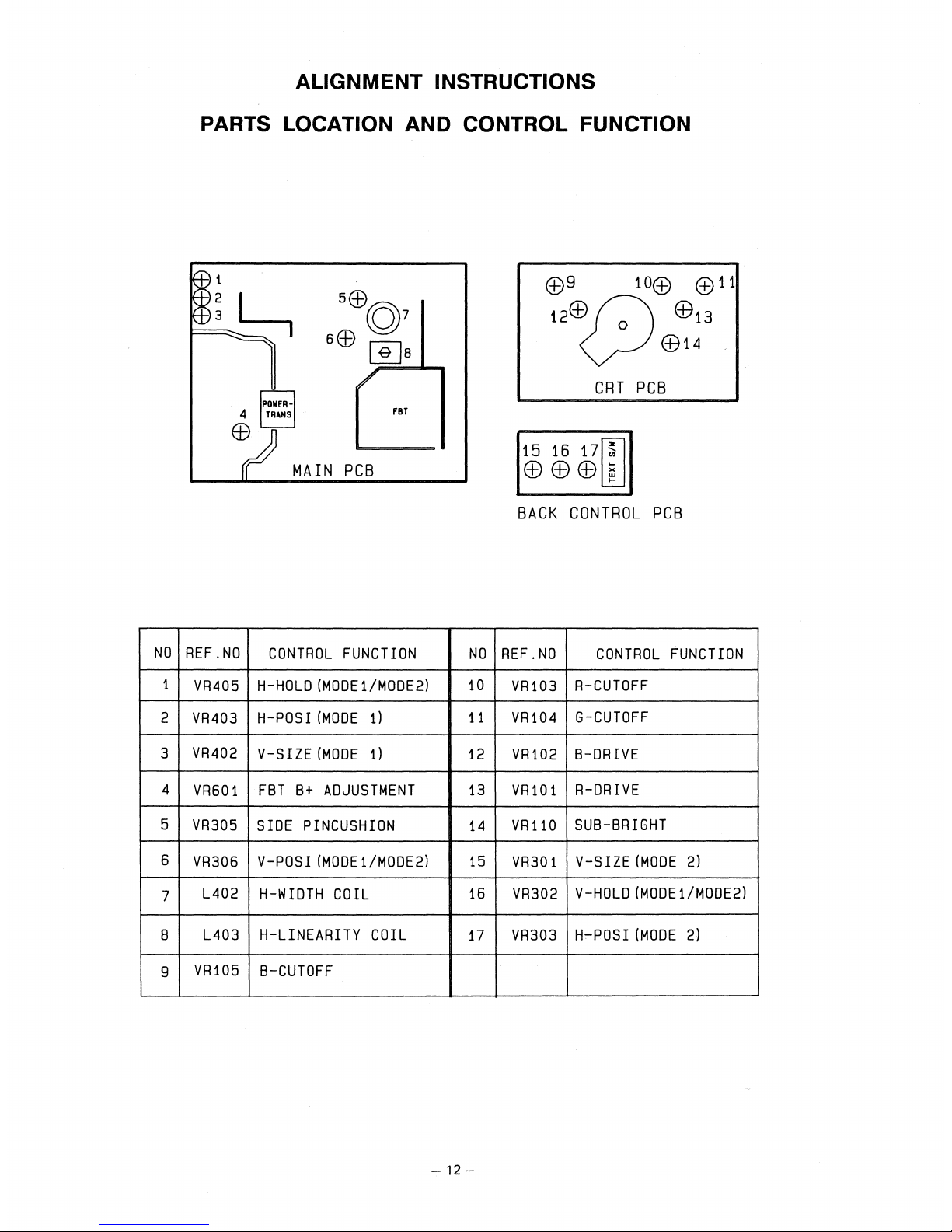

ALIGNMENT INSTRUCTIONS

PARTS LOCATION

AND CONTROL FUNCTION

1

2

3

REF.NO

VR405

VR403

VR402

VR601

VR305

VR306

L402

L403

VR105

FBT

PCB

CONTROL

FUNCTION

H-HOLD(MODE1/MODE2)

H-POSI

(MODE

1)

V-SIZE

(MODE

1)

FBT

B+

ADJUSTMENT

SIDE

PINCUSHION

V-POSI

(MODE1/MODE2)

H-WIDTH

COIL

H-LINEARITY

COIL

B-CUTOFF

NO

10

11

12

13

14

15

16

17

-

12-

CRT

PCB

151617151

EBEBEBE

>-

BACK

CONTROL

PCB

REF.NO

CONTROL

FUNCTION

VR103

R-CUTOFF

VR104

G-CUTOFF

VR102

B-DRIVE

VR101

R-DRIVE

VR

110

SUB-BRIGHT

VR301

V-SIZE

(MODE

2)

VR302

V-HOLD

(MODE1/MODE2)

VR303

H:-POSI

(MODE

2)

ALIGNMENT PROCEDURE ( UNIT FACING

EAST)

Power supply voltage is 120VAC

160Hz

or

220VAC (240VAC)

150Hz

(OPTION)

1.

POWER

SUPPLY

OUTPUT

VOLTAGE

(FBT

B + )

Connect a

DVM

to the anode of

D615

(GT

pin

is

standing)

and

adjust the voltage to

54V

using

VR601.

CONDITION:

1).

NO

SIGNAL

2).CONTRAST,

BRIGHTNESS

is

MINIMUM

(0

BEAM)

2.

MAIN

PCB

ADJUSTMENT

Unless special comment, adjust the

EXT

VR

at

the mechanical center paint.

2-1)

H-RASTER

CENTERING

Turn the

SCREEN

VR

so

that background

raster

can

be

seen

and control the H-CEN-

TER

S/W

(SW401)

so

that the background

raster

is

on

the center of

CRT.

This must

be

done

in

EGA

MODE

(MODE

2 I

21.8KHz).

2-2)

H-HOLD

ADJUSTMENT

(a)

Disconnect the signal cable

(b)

Connect the frequency counter

at

the

H-DY

WIRE

(RED

wire) and adjust the frequency

in

range of 15.700KHz +

I-50Hz

using

CGNEGA

H-HOLD

VR

(VR405).

* Frequency of

EGA

(MODE

2/21.8KHz)

is

ad-

justed automatically.

2-3)

V-HOLD

ADJUSTMENT

(a)

Disconnect the signal cable.

(b)

Connect the frequency counter at R304(side

of

IC301)

and adjust the frequency

in

the

range of 56Hz

+

1-1

Hz using V-HOLD

VR(VR306).

* If the vertical frequency from

PC

is

50Hz,adjust

the vertical frequency at 46Hz

+

1-1

Hz.

2-4)

H-LINEARITY

ADJUSTMENT

(a)

Connect the signal cable.

(b)

Adjust

L403

to the optimum linearity

in

MODE

1 and

MODE

2 linearity pattern.

-13-

2-5)

H-POSITION

(a)

Adjust

H-CENTER

VR

(VR407)

to the center

of the picture when the signal of

MODE

2

is

applied.

(b)

Change mode

to

CGA MODE (MODE

1/15.75KHz) and adjust H-CENTER

VR

using

CGA

H-POSI

VR(VR403}.

2-6)

SIDE

PINCUSHION

Adjust the side pincushion to the optimum

side pincushion using

VR305.

2-7)

H-WIDTH

a)

Adjust the

H-WIDTH

using width coil

(L402)

so

that

H-WIDTH

is

adjusted

in

the range

250

+ 4/-2MM

in

MODE

2 .

b)

Check the

H-WIDTH

of

MODE

1.

*

H-WIDTH

of

MODE 1 is

adjusted

in

the range

250

+ I-4MM automatically.

2-8)

V-POSITION

Adjust the center of vertical using

v-pas

I

VR(VR306).

*

The

V-POSI

VR

(VR306)

can control vertical

center of

MODE

1,MODE 2 together.

2-9)

V-SIZE

a)

Adjust

V-SIZE

using

V-SIZE

VR

(VR

307)

so

that vertical size

is

172MM

in

MODE

2.

b)

Change to

MODE

2 and adjust vertical

size

to

172MM,

equal

to

MODE

2 vertical

size,

using

CGA

V-SIZE(VR402).

2-10)

FOCUS

ADJUSTMENT

Adjust the focus control to the optimum

position.

2-11)

BLACK

AND

WHITE

TRACKING

a)

Turn the screen control fully clockwise. Turn

the red,green and blue bias controls

mechanical centers.

Set

the brightness con-

trol

and

the

red

and blue drive controls at

the center positions.

b)

Turn the

SW301

to the left.

c)

Rotate the screen control counterclockwise

until a raster (either the

red,

green or blue)

appears dimply on the screen.

Notes:

Adjust

VR104

and

VR105

if

red

is

appears.

Adjust

VR103

and

VR105

if green

is

appears.

Adjust

VR103

and

VR104

if blue

is

appears.

d)

Return the

SW301

to its original position.

e)

Operate the computer

in

such a way that

the entire screen

is

R,

G,

B white.

f)

Rotate the

RED

and

BLUE

drive controls

until the raster

is

white.

g)

Set

the brightness control at its maximum

position and adjust the sub-brightness con-

trol until a reading of

20

+ /-2F/L appears.

h)

Turn the brightness control

in

either direc-

tion to check that the picture maintains a

good white balance.

i)

Repeat

steps

(a)

thru

(h)

for readjustment.

Horizontal:12 Lines

Min.

Vertical:16 Lines

Min.

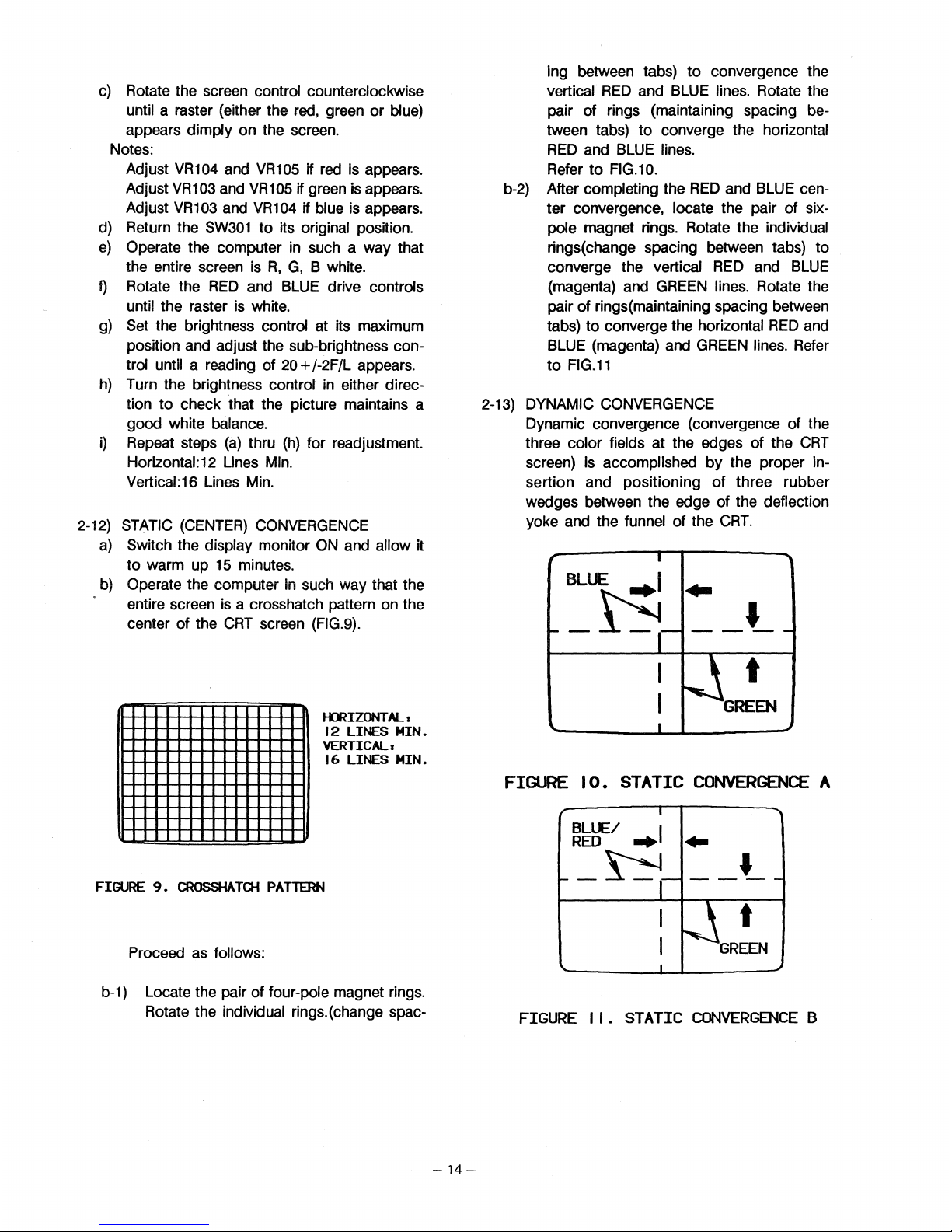

2-12)

STATIC

(CENTER)

CONVERGENCE

a)

Switch the display monitor

ON

and allow it

to warm up

15

minutes.

b)

Operate the computer

in

such way that the

entire screen

is

a crosshatch pattern

on

the

center of the

CRT

screen

(FIG.9).

KlRIZONTAL.

12

LINES

MIN.

VERTICAL

I

16

LINES

MIN.

FIGURE

9.

CROSSHA

Ta-t

PATTERN

Proceed

as

follows:

b-1)

Locate the pair of four-pole magnet rings.

Rotate the individual rings.(change spac-

-

14-

ing between tabs) to convergence the

vertical

RED

and

BLUE

lines. Rotate the

pair of rings (maintaining spacing be-

tween tabs) to converge the horizontal

RED

and

BLUE

lines.

Refer to

FIG.l0.

b-2)

After completing the

RED

and

BLUE

cen-

ter convergence, locate the pair of

sixpole magnet rings. Rotate the individual

rings(change spacing between tabs) to

converge the vertical

RED

and

BLUE

(magenta) and

GREEN

lines. Rotate the

pair of rings(maintaining spacing between

tabs) to converge the horizontal

RED

and

BLUE

(magenta)

and

GREEN

lines.

Refer

to

FIG.11

2-13)

DYNAMIC

CONVERGENCE

Dynamic convergence (convergence of the

three color fields at the edges of the

CRT

screen)

is

accomplished by the proper insertion and positioning of three rubber

wedges between the edge of the deflection

yoke

and

the funnel of the

CRT.

FIGURE

10.

STATIC

CONVERGENCE

A

BLlE/

I

RED

..

....

•

---

-~

t

GREEN

FIGURE

I

I.

STATIC

CONVERGENCE

B

Loading...

Loading...