Samsung CE935 Alignment and Adjustments

Samsung Electronics

5. Alignment and Adjustments

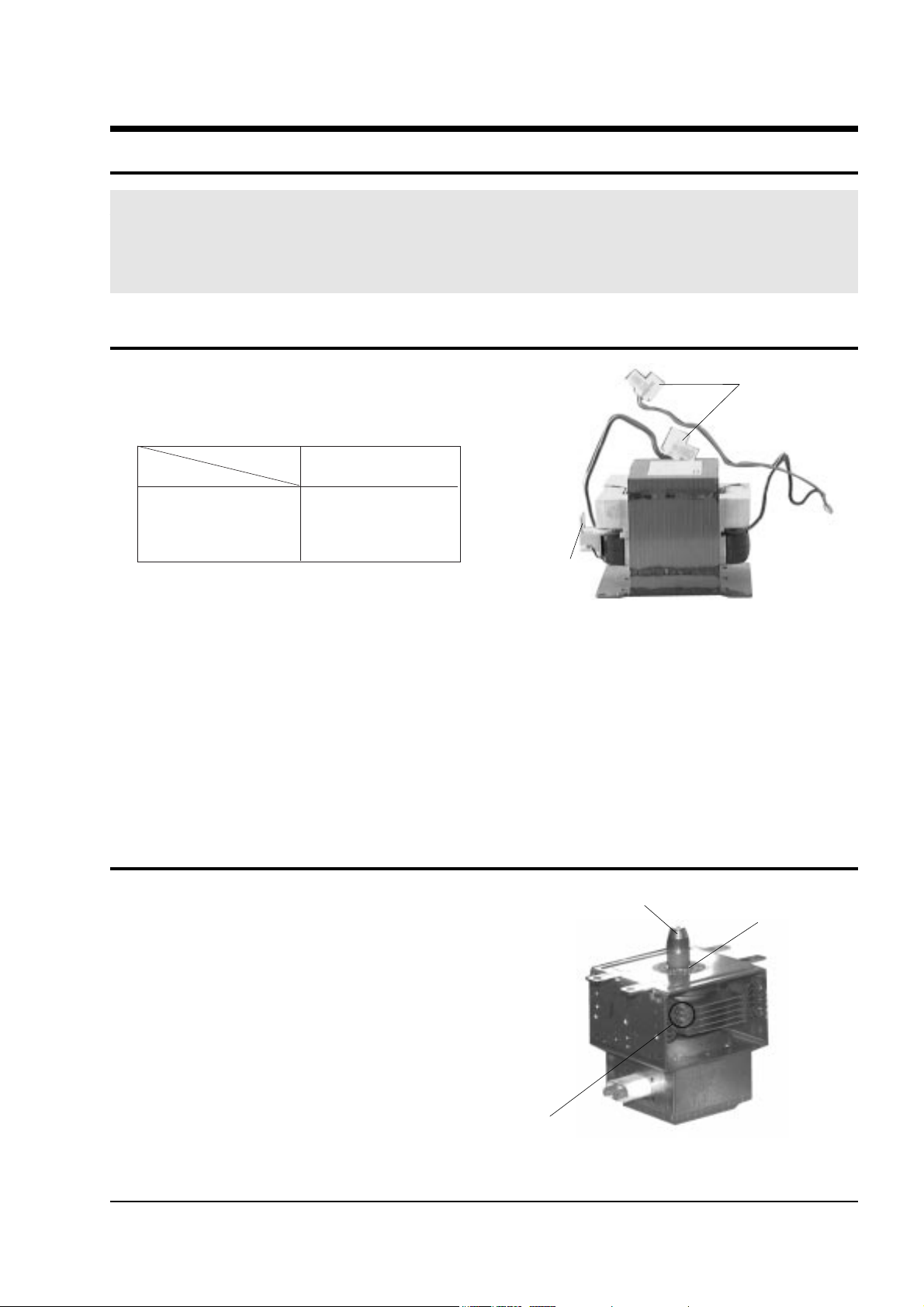

5-1 High Voltage Transformer

5-2 Magnetron

5-1

1. Remove connectors from the transformer terminals

and check continuity.

2. Normal resistance readings are as follows:

(Room temperature = 20ûC)

1. Continuity checks can indicate only an open

filament or a shorted magnetron. To diagnose an

open filament or shorted magnetron :

2. Isolate the magnetron from the circuit by

disconnecting its leads.

3. A continuity check across the magnetron filament

terminals should indicate one ohm or less.

4. A continuity check between each filament terminal

and magnetron case should read open.

PRECAUTION

1. High voltage is present at the high voltage terminals during any cook cycle.

2. It is neither necessary nor advisable to attempt measurement of the high voltage.

3. Before touching any oven components or wiring, always unplug the oven from its power source and discharge the high voltage

capacitor.

Filament Terminals

Primary

Terminals

MODEL

SHV-945EG1

Secondary 103.0Ω ¡ 10%

Filament Shows Continuity

Primary 1.6Ω ¡ 10%

Cooling Fins

Gasket Plate

Magnetron Antenna

Samsung Electronics

5-3 High Voltage Capacitor

5-4 High Voltage Diode

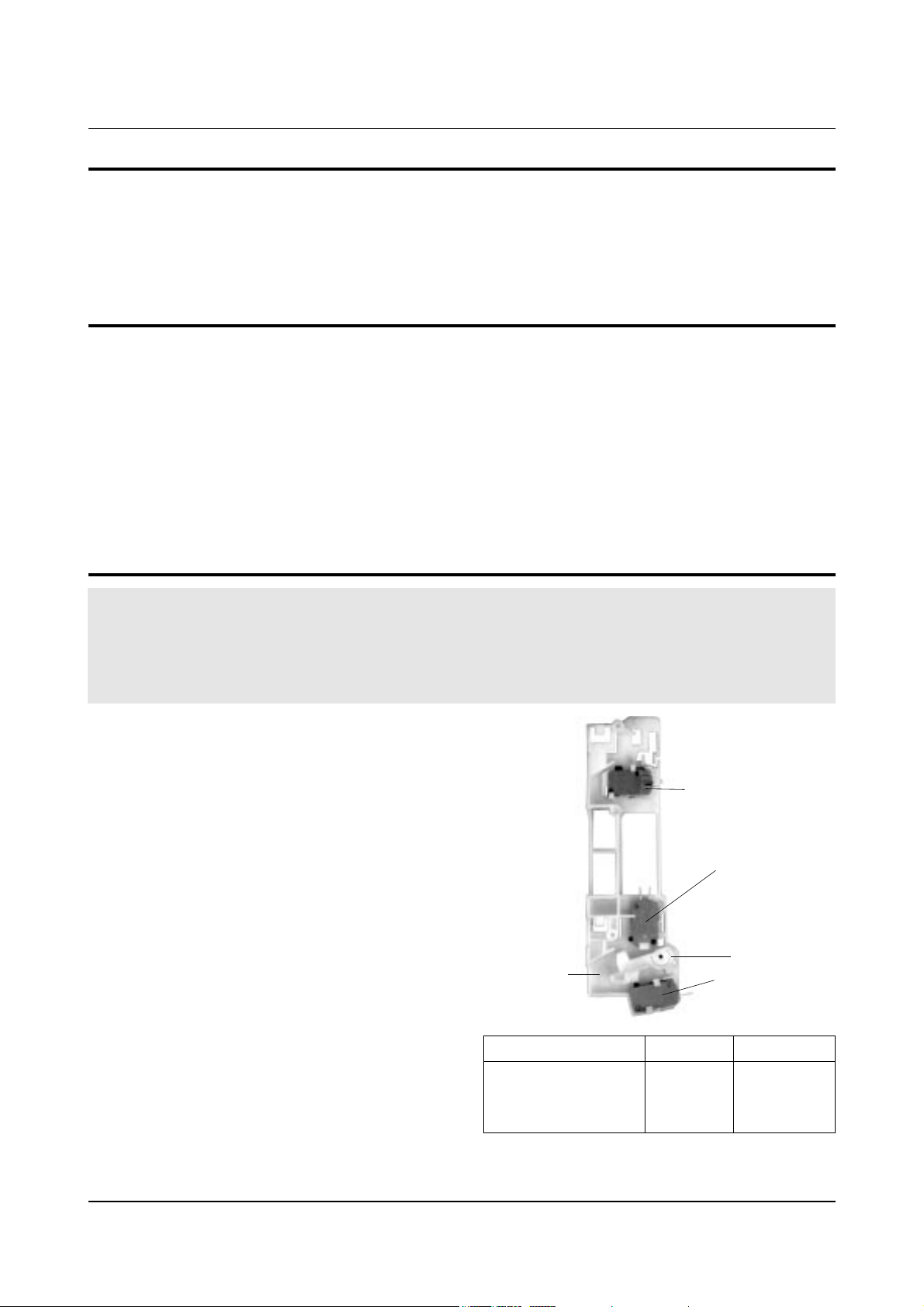

5-5 Adjustment of Primary Switch, Secondary Switch and Monitor Switch

5-2

1. Check continuity of the capacitor with the meter set at the highest resistance scale.

2. Once the capacitor is charged, a normal capacitor shows continuity for a short time, and then indicates 9MΩ.

3. A shorted capacitor will show continuous continuity.

4. An open capacitor will show constant 9MΩ.

5. Resistance between each terminal and chassis should read infinite.

1. Isolate the diode from the circuit by disconnecting its leads.

2. With the ohm-meter set at the highest resistance scale, measure across the diode terminals. Reverse the

meter leads and read the resistance. A meter with 6V, 9V or higher voltage batteries should be used to

check the front-to back resistance of the diode (otherwise an infinite resistance may be read in both

directions). The resistance of a normal diode will be infinite in one direction and several hundred KΩ in

the other direction.

1. When mounting Primary switch and Interlock

Monitor switch to Latch Body, consult the

figure.

2. No specific adjustment during installation of

Primary switch and Monitor switch to the latch

body is necessary.

3. When mounting the Latch Body to the oven

assembly, adjust the Latch Body by moving it so

that the oven door will not have any play in it.

Check for play in the door by pulling the door

assembly. Make sure that the latch keys move

smoothly after adjustment is completed.

Completely tighten the screws holding the Latch

Body to the oven assembly.

4. Reconnect to Monitor switch and check the

continuity of the monitor circuit and all latch

switches again by following the components test

procedures.

5. Confirm that the gap between the switch

housing and the switch actuator is no more than

0.5mm when door is closed.

Precaution

For continued protection against radiation hazard, replace parts in accordance with the wiring diagram and be sure to use the

correct part number for the following switches: Primary and secondary switche, and the interlock monitor switch (replace all

together). Then follow the adjustment procedures below. After repair and adjustment, be sure to check the continuity of all

interlock switches and the interlock monitor switch.

Alignment and Adjustments

Door Open Door Closed

Primary switch ∞ 0

Monitor switch (COM-NC) 0 ∞

Secondary switch

∞

0

Primary Interlock Switch

Lever Switch

Body Latch

Secondary Switch

Interlock Monitor

Switch

Loading...

Loading...