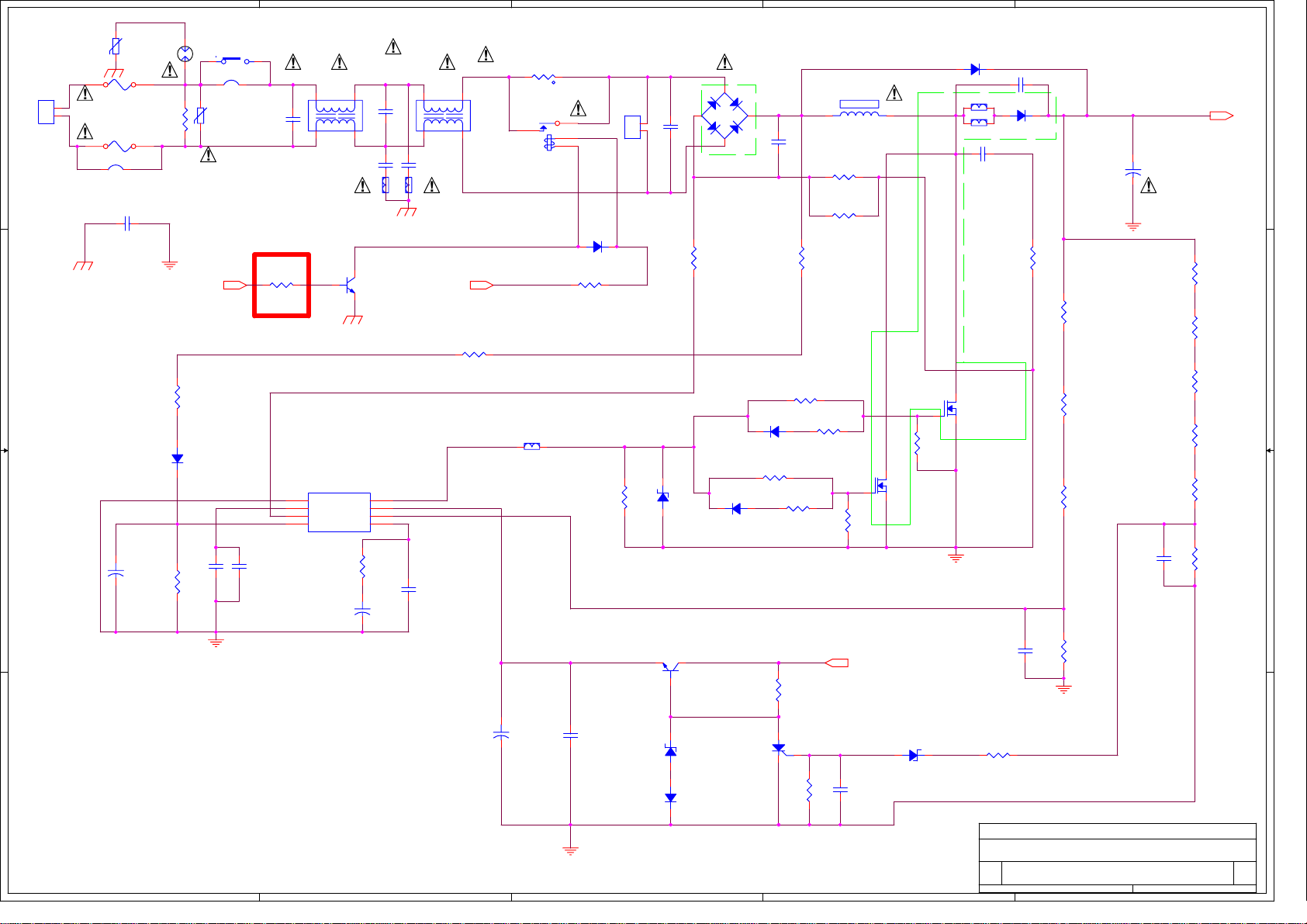

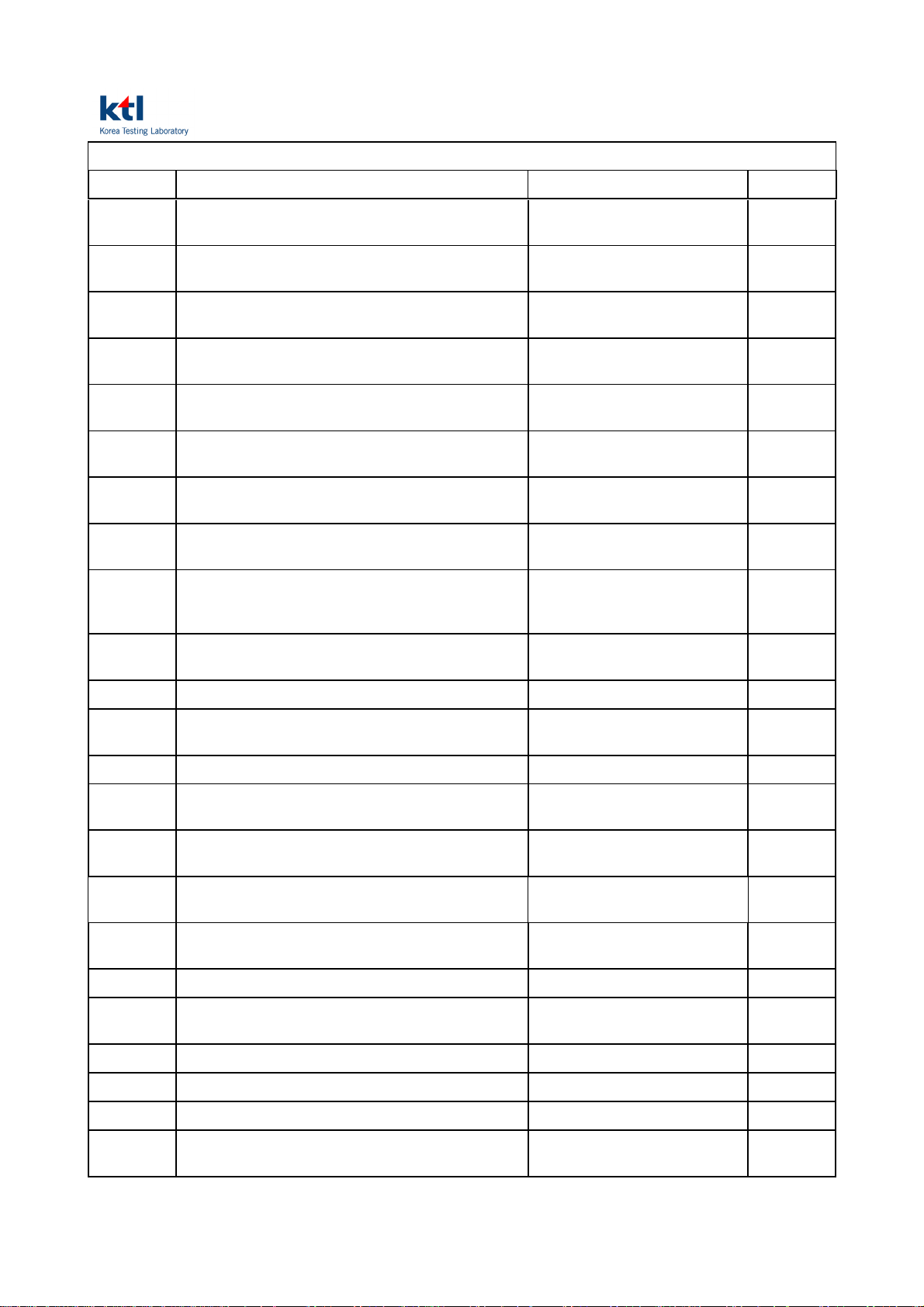

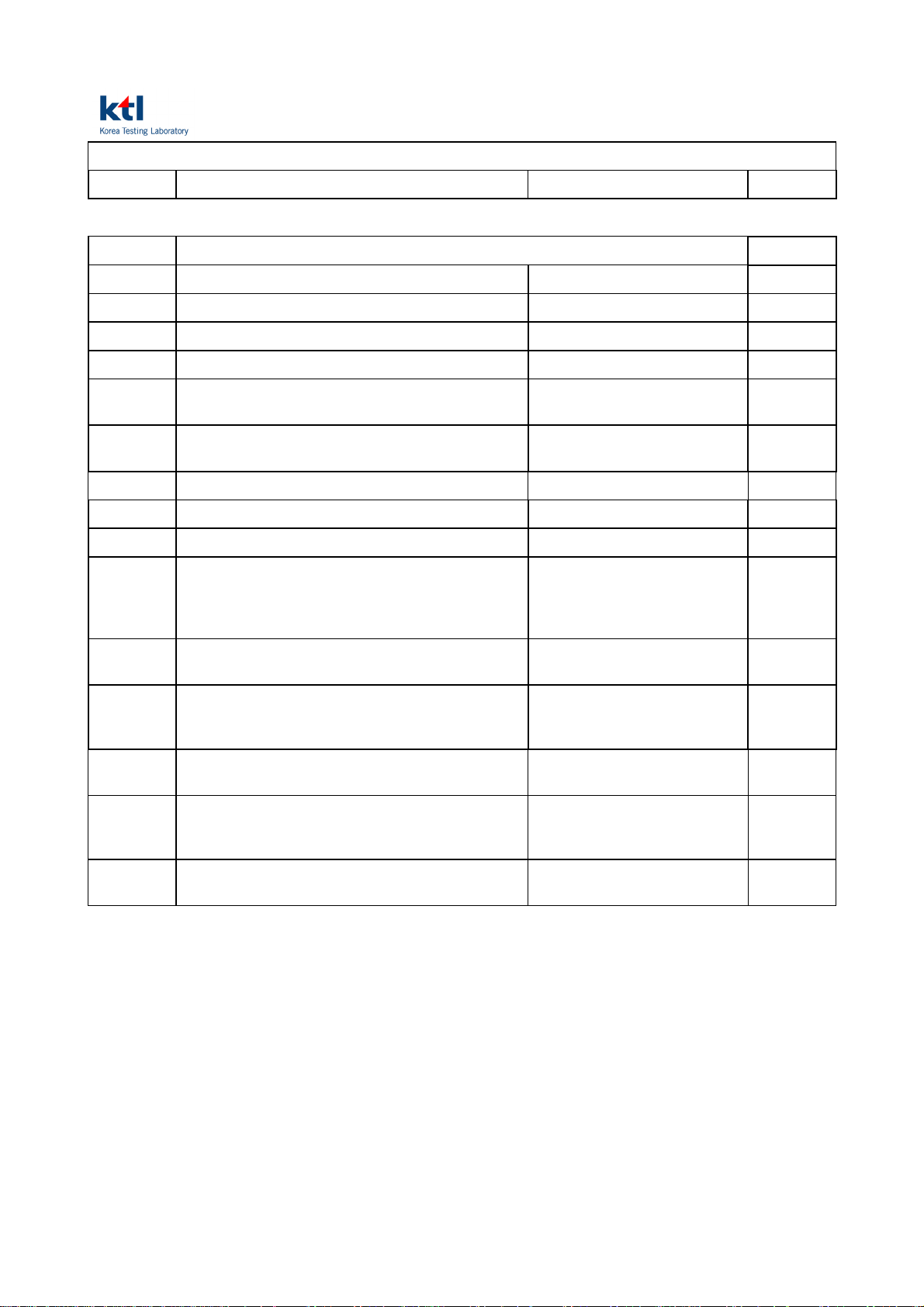

Samsung BN44-00167A Schematic

5

SX801

RX801

RA-452MS-V7

!

RP818

560KRF 3216

BAV70 (SOT-23)

CP803

SW1NC

1 2

J812,J811

1 2

JUMPER 15mm

VX801

14N751

!

ON/OFF

DP806

NC

CX801

0.68uF275V

RS813

1KRF 2012

CP813

MY/50V/102/J

!

1

2

3

4

LX801

CV940120S

1

4

400VAC 471M

2

ICP801

GND

ICOM

ISEN

VIN

ICE1PCS02

RP807

10KRF 2012

CP804

50V 1uF

VX802

14N751

!

FS801

T6.3AH250V

1

L

2

N

D D

PD801S

YW396-03AB

C C

B B

!

FS802

1 2

J813,J814

JUMPER 15mm

MSR 1/2W 560KR

NC

CY813

NC

+

CP802

50V 0.22uF

RP806

47KRF 3216

!

CY821

GATE

VCC

VSEN

VCOM

23

!

31

QS803

KTN2222

CX803

0.47uF275V

LING BEAD

8

7

6

5

+

4

!

!

LX802

CV940120S

1

4

CY822

400VAC 471M

LING BEAD

!

560KRF 3216

CP805

334K 2012

23

STB 6.5V

RP802

3

!

NT801

5D15

1 2

t

REL801

10A250V

3

BP802

3550

4

1

2

!

DS805

1N4937

RS814

JUMPER

RP808

100KRF 2012

1

L

2

N

CN811

YW396-03AV

ZDP801

24V(SOT-323)

CX802

0.47uF275V

!

BD801

GSIB15A60

3

HS801

2

DP805

100*9*23

1

CX804

0.1uF275V

DP804

BAV70(SOT-323)

RP809

100RF 2012

-+

4

RP804

220RF 2012

BAV70(SOT-323)

RP810

100RF 2012

RP825

10RF 2012

RP801

MPR5W 0.1R

RP803

RP819

560KRF 3216

RP826

10RF 2012

10KRF 2012

NC

RP812

LP801

EER4042

1

2

!

HS802

100*20*30

23

QP802

FQA13N50CF

BP803

3550

BP804

3550

1

MUR460L

23

DP801

QP801

FQA13N50CF

RP811

10KRF 2012

CP810

NC

DP802

YG963S6R,LSL9R860PF2

CP801

1KV 101K

RP805

2W 47R

CP809

450V220uF(35*30)

RP817

560KRF 3216

RP816

560KRF 3216

RP815

560KRF 3216

1

+

!

CP811

104K 2012

PFC 385V

RP820

330KRF 2012

RP821

330KRF 2012

RP822

330KRF 2012

RP823

330KRF 2012

RP824

220KRF 2012

RP828

22KRF 2012

QP803

C1008-Y TO-92

1

3

2

CP806

+

50V 47uF

A A

5

4

CP807

104K 2012

ZDP807

ZN16B(AXIAL)

DP807

BAV70(SOT-323)

3

SCP801

MCR100-6

RP813

3.3KRF 2012

RP829

100KRF 2012

VCC PFC

CP812

104K 2012

ZDP803

6.2V(AXIAL)

2

CP808

222K 2012

RP827

0RJ 2012

Thursday, July 12, 2007

Title

PFC

Size Document Number Rev

<Doc>

A3

Date: Sheet

22KRF 2012

2006. 06.07

RP814

12

1

of

5

4

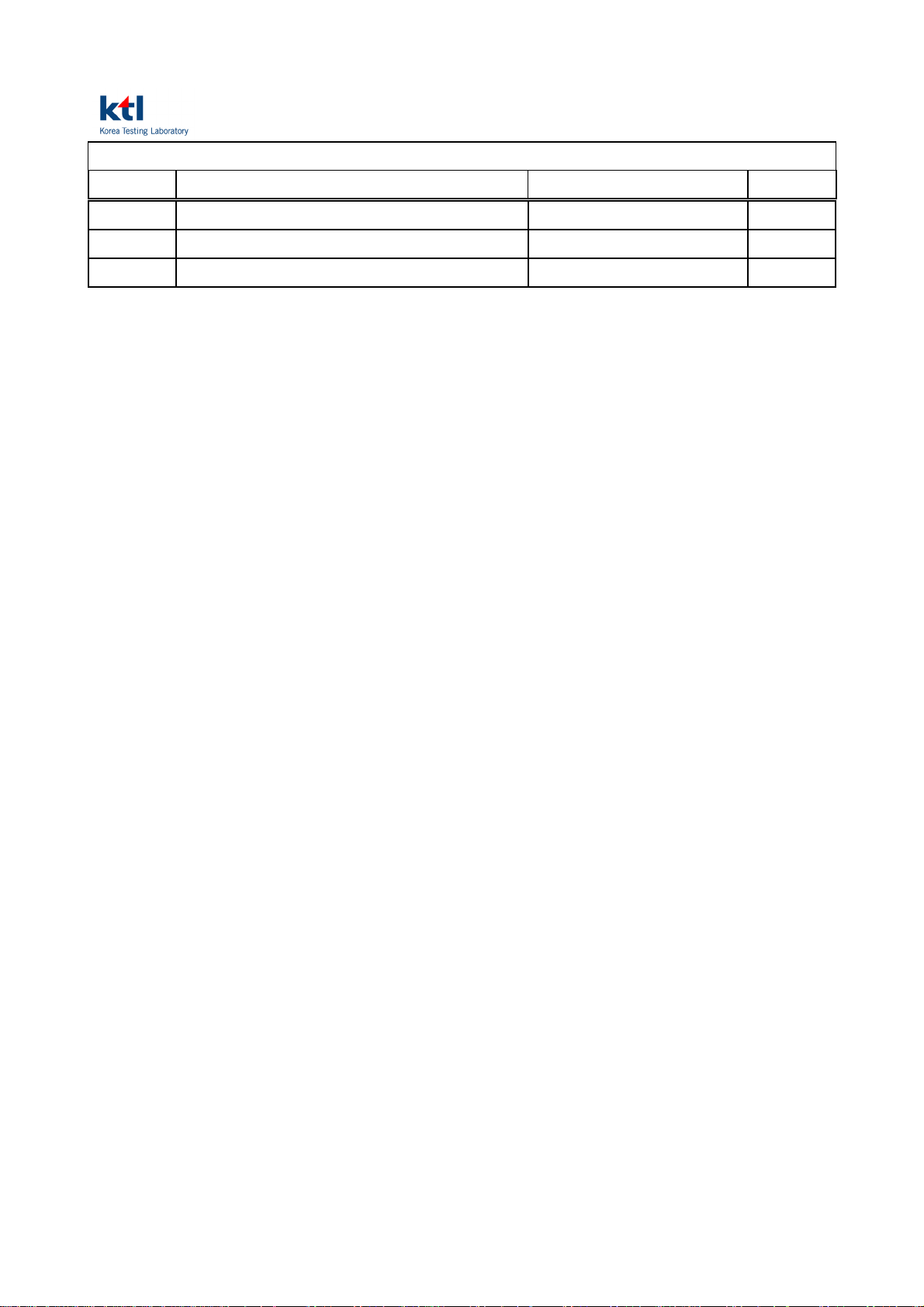

HOT

COL

D

3

2

STB5.2V

1

RM820

100R 1W

ZDM801

CM804

50V 47uF

CS810

1KV 10pF

CM802

1KV 101K

DM801

UF4007

BP801

3550

ZDS801

24V(SOT-323)

1 2

DM810

1N4148(AXIAL)

RM821

75RF 2012

RM802

47KRF 2012

CS805

472K 2012

CM818

1KV 68pF

CS802

50V 10uF

CS808

104K 2012

1 2

BM801

3550

1

2

3 4

FSDM0565REWDTU

ICM801

CM815

104K 2012

+

ZDS802

15V(AXIAL)

QS801

C2331

TO-92

HS803

40*20*30

DRAIN

GND

VCC FB

ZDM805

24V(AXIAL)

NC

SS

CS801

1KV 471K

DS801

UF4007

DS802

1N4937

DS803

1N4937

CS804

50V 47uF

RS804

47KRF 2012

100KRF 2012

6

5

CM803

104K 2012

CM816

223K 2012

1 2

4

+

RS805

15V(SOT-323)

RM819

3.9KRF 2012

DM809

NC

RM818

3KRF 3216

ZDM802

2W 220KR

1 2

RS801

TM801

EER2828

DM808

SS26

1

!

2

5

7

6

7

!

4

!

TCED1108

4

!

7 14

5 8,9,10

3

2

!

4

!

1

2 3

!

CY811

400VAC 471M

!

CY812

400VAC 152M

PFC385V

D D

876

5

D2

N.C

VCC

CS803

50V 1uF

QM801

C1008-Y

TO-92

3

CM805

50V 10uF

123

CM801

1KV 222K

RM801

2W 100KR

RM804

2W 100KR

TDM801

P6KE160A

2

+

DM802

1N4148(AXIAL)

5

GND2

SSFBCS

D1

4

+

RS803

SR37 1W 2.2R

1

16V(AXIAL)

+

ICS801

ICE3B0365J

C C

PFC VCC

PFC 385V

B B

RM817

560KRF 3216

RM816

1MRF 3216

RM815

1MRF 3216

A A

ICM804

KA431

20KRF 2012

2 3

RM814

RM803

2.2KRF 2012

1

+

CM814

50V 47uF

9

11

TS801

EE2020

PCS801

TCED1108

PCS802

11,12,13

L1

INDUCTOR

PCM801

TCED1108

PCI801

TCED1108

LING BEAD

CS809

1KV 101K

DS804

SB2100

CS806

10V1000uF

1

23

1

23

HS804

80*15*30

MBRF10H100CT

1

23

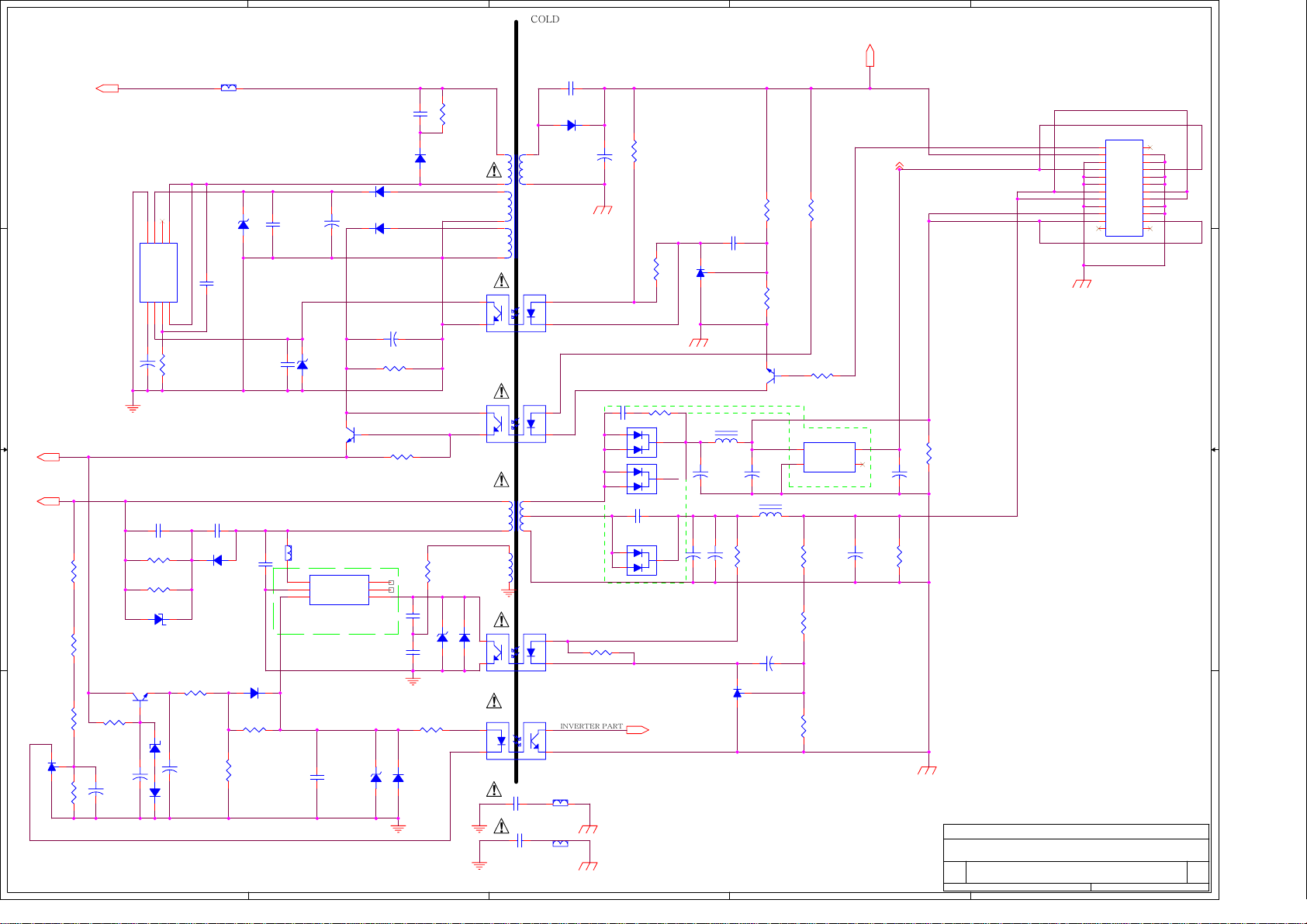

INVERTER PART

4

BM803

3550

+

CM806

1KV 102K

DM804

RM806

3.3KRF 2012

3

RS806

220RF 2012

DM805

1

3

NC

1

3

DM803

MBRF10H150CT

CM810

1KV 221K

1

3

RS807

4.7KRF 2012

RM812

2W 12R

2

2

2

CM811

10V 1000uF

UVLO

RS808

2.2KRF 2012

CS807

63V 104

1

ICS802

2 3

KA431

KTN2222AS (CHIP)

LM802

4.7uH

+

CM807

25V 1000uF(12.5*25)

+

+

CM817

10V 1000uF

ICM803

KA431

QS802

RM805

330RF 2012

1

2 3

1

3

+

CM808

25V 1000uF

LM801

4.7uH

+

RS810

2KRF 2012

RS812

2

4.7KRF 2012

1 2

IN OUT

3 4

GND CTR

KIA278R12

RM807

2KF 2012

RM808

330RF 2012

CM813

50V 0.22uF

RM809

2KRF 2012

RS811

1KRF 2012

ICM802

25V 220uF

+

CM812

10V 1000uF

2

STB 5.2V 0.4A

12V D

+

CM809

POWER ON/OFF

AUDIO 12V/ 1.2A

Main_5.4V/4.0A

SYSTEM_13V/2.0A

RM811

1W 2.2KR

RM810

2W 220R

Thursday, July 12, 2007

SIP400B

Title

STB+MULTI

Size Document Number Rev

Date: Sheet

Custom

<Doc>

CN801

12

34

56

78

910

11 12

13 14

15 16

17 18

19 20

21 22

23 24

SMW200-24C

1

22

of

12VDC

ON/OFF

VDDA

UVLO

PWM

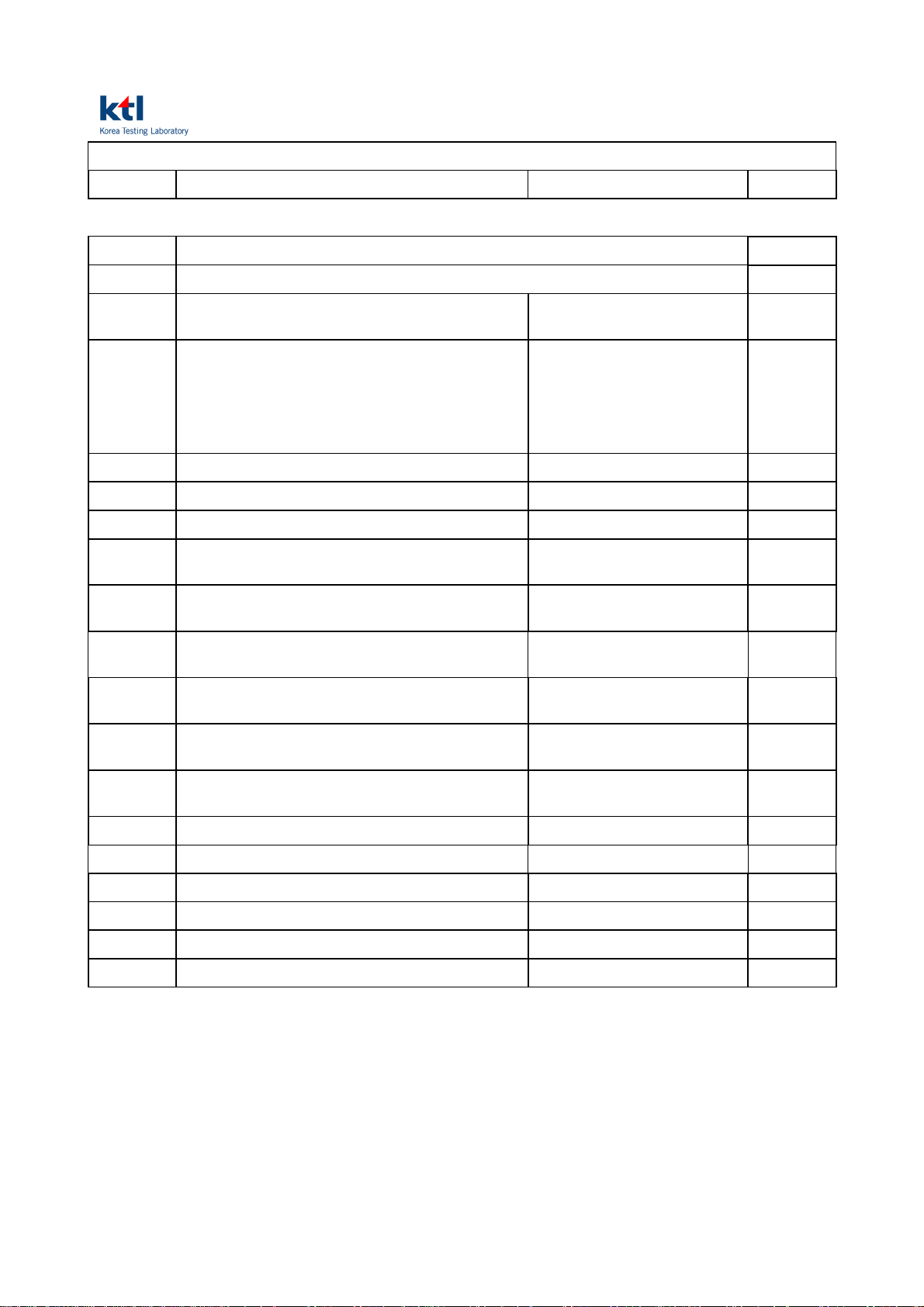

CI844

47u/50V/AL

12Vdc

+

RI891

100R/F

PWM

RI802 120KR/F

RI801 120KR/F

RI841 10KR/F

CI803

0.1u/50V

RI815

10KR/F

CI838

1u/25V

1u/25V

CI843

RI803

27KR/F

RI892

10KR/F

KTN2222AS

QI810

RI808

24KR/F

RI862 1KR/F

RI865 1KR/F

RI853

100R/F

QI815

KTN2222AS

RI848

100R/F

ICI801 LX1691A

1

GND

2

AOUT

3

BOUT

4

DD_CLK

5

DIM_MODE

6

BRITE_OUT

7

BRITE_R

8 9

BRITE_IN ENABLE

RI804

20KR/F

RI852

10KR/F

1

QI805

DTC144EKA

CI809

0.1u/50V

QI813

KTN2222AS

QI814

KTN2907AS

RI842

10KR/F

PFC385V

DI809

!

BAV70

DI814

CI823

NC

RI830

4.7KR/F

RI819

1KR/F

DI804

BAV70

RI863

1KR/F

RI836

0R/J

RI864

5.6KR/F

DI808

BAV70

CI830

NC

NC

DI812

RI846

120R/F

NC

RI824

1.5KR/F

RI845

120R/F

QI807

KTN2907AS

RI823

1KR/F

2

RI811

NC

CI808

CI833

1u/25V

5

QI812

KTN2222AS

QI811

KTN2907AS

5V

VDDA

CI834

1u/25V

CI802

0.1u/50V

CI807

CI811

22n/50V

1u/25V

RI866

220KR/F

RI860

220KR/F

VR801

15KR/20%

CI835

1u/25V

RI832

1M/F

RI847

QI806

470KR/F

KTN2222AS

RI838 1KR/F QI801

RI839 1KR/F

RI818

100R/F

QI816

KTN2222AS

16

VDDP

15

VDDA

14

OP_SNS

13

VIN_SNS

12

I_SNS

11

EA_OUT

10

I_R

RI810

NC

RI812

10KR/F

RI813

10KR/F

QI804

2

3

1u/25V

2

3

1

DTC144EKA

10

9

7

8

TI802

FULSE TRANS MAIN TRANS

EE1614

RI816

NC

QI803

KTN2222AS

RI851

1M/F

DI811

BAV70

QI809

KTN2907AS

RI856

33KR/F

1

RI858

470KR/F

A

ICI803A

KIA358

FI801

250Vac/T3.15A

RI806

4R7/F

RI844

10KR/F

RI817

4R7/F

RI840

10KR/F

84

+

-

3.3n/50V

3

2

CI828

ZDI802

CI840

ZN15V

4.7n/50V

ZDI803

ZN15V

CI826 NC

RI887 44R/G/(2W MOR)

RI888 44R/G/(2W MOR)

CI837

CI832

NC

NC

CI827

1n/50V/J

DI801

MUR460L

FQPF13N50C

DI810

MUR460L

CI839

4.7n/50V

RI857

100KR/F

DI807

BAV70

1

1

QI802

FQPF13N50C

CI829

1u/25V

!

3

DI813

31GF6

2

2

DI802

31GF6

3

CI806

1u/400V/MP

2

TI801

UU32.5

-

6

7

+

8 4

CI814

2.2uF/10V

5

0.1u/50V

CI815

ICI802B

KIA358

RI826

470KR/F

RI820

1M/F

RI849

1M/F

RI827

1M/F

RI867 150R/F/3216

RI869 150R/F/3216

RI868 150R/F/3216

61

RI871 150R/F/3216

RI873 150R/F/3216

RI872 150R/F/3216

RI874 150R/F/3216

RI870 150R/F/3216

5

4

RI882 150R/F/3216

RI875 150R/F/3216

RI881 150R/F/3216

RI880 150R/F/3216

3

RI876 150R/F/3216

RI877 150R/F/3216

RI879 150R/F/3216

RI878 150R/F/3216

CI842

0.1u/50V

RI837

10KR/F

RI854

100KR/F

CI819

3.3n/50V

CI822

3.3n/50V

CI824

27p/6kV(10mm)

CI813

2.2n/50V

CI825

2.2n/50V

CI820

27p/6kV(10mm)

5V

84

1

RI809

0R/J

RI814

0R/J

ICI802A

KIA358

3

+

2

-

CI816

0.1u/50V

RI843

NC

RI861

NC

1

PR_2

FB

LD

PR_3

PR_2

PR_3

PR_2

2

CNI801

35002WS-02L

CNI802

1

2

35002WS-02L

PR_2

PR_3

PR_2

PR_2

FB

LD

PR_3

RI834

RI833

100KR/F

5.6KR/F

DI805

BAV99

BAV70DI806

DI803

BAV99

RI829

1M/F

RI805

NC

RI825

1M/F

CI818

1u/25V

CI821

1u/25V

RI828

1M/F

CI817

0.1u/50V

CI845

1n/50V

RI835

100KR/F

RI831

5.6KR/F

5V

QI808

5V

RI822

100KR/F

RI855

180KR/F

RI859

56KR/F

6

5

ICI803B

KIA358

-

+

ZDI805

N6.2V

8 4

KTC4375

213

RI807

4.7KR/F

CI804

ZDI801

1u/25V

ZN5.6V

7

RI850

0R/J

PWM

A

RI821

30KR/F

RI890

27KR/F

DIM

CI831

1u/25V

12Vdc

12VDC

ON/OFF

12VDC

DIM

FB

LD

CI812

1u/25V

1

2

3

4

5

1

2

3

4

5

CNI803

SMW200-05

CNI806

SMW200-05

Inverter On/Off

Dim

NC

GND

DET_5V

VCC_12V

FB

GND

NC

LD

SIP400B REV1.1 (R.C)

Title

Size Document Number Rev

Custom

Date: Sheet

11Tuesday, March 27, 2007

0.2

of

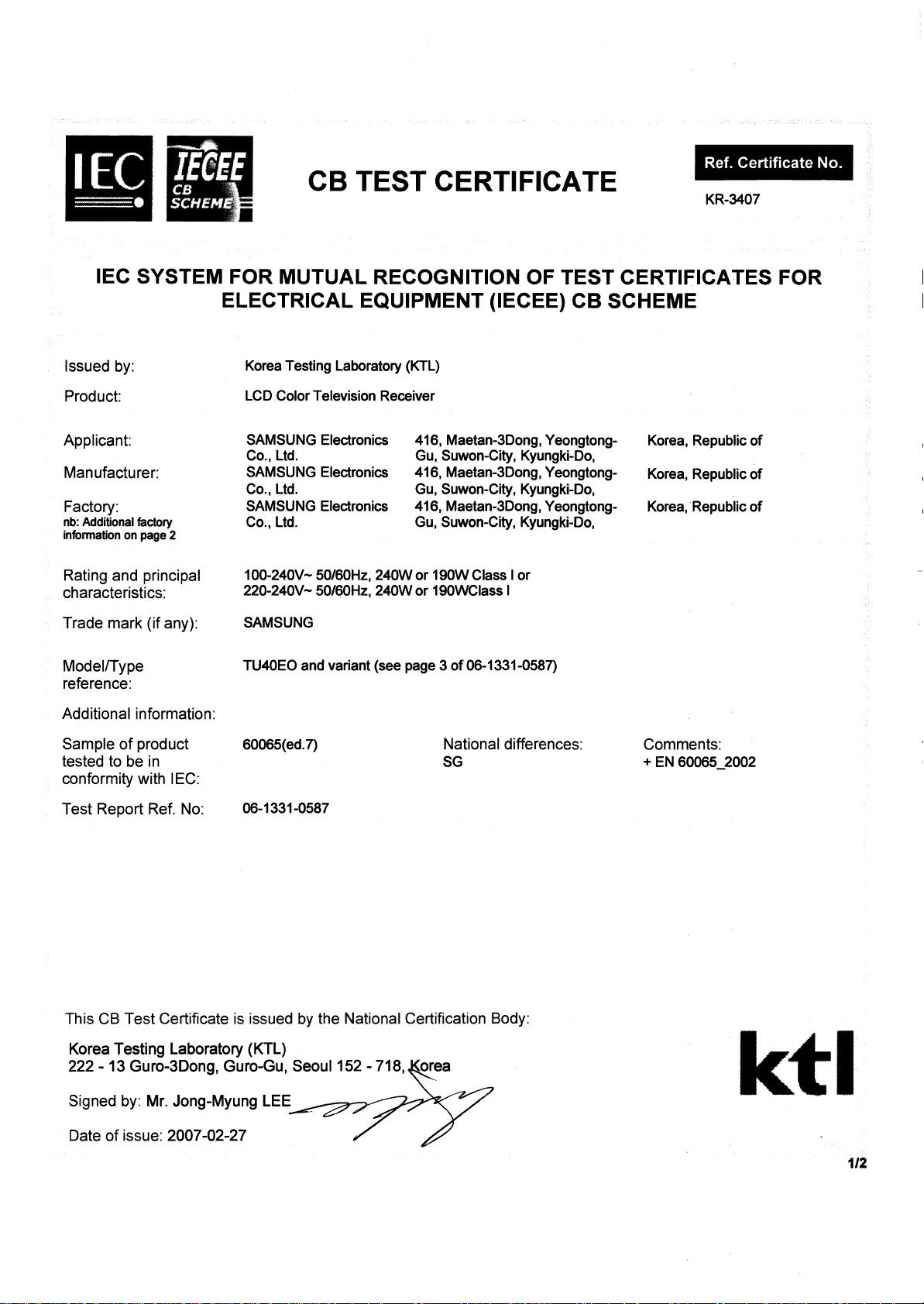

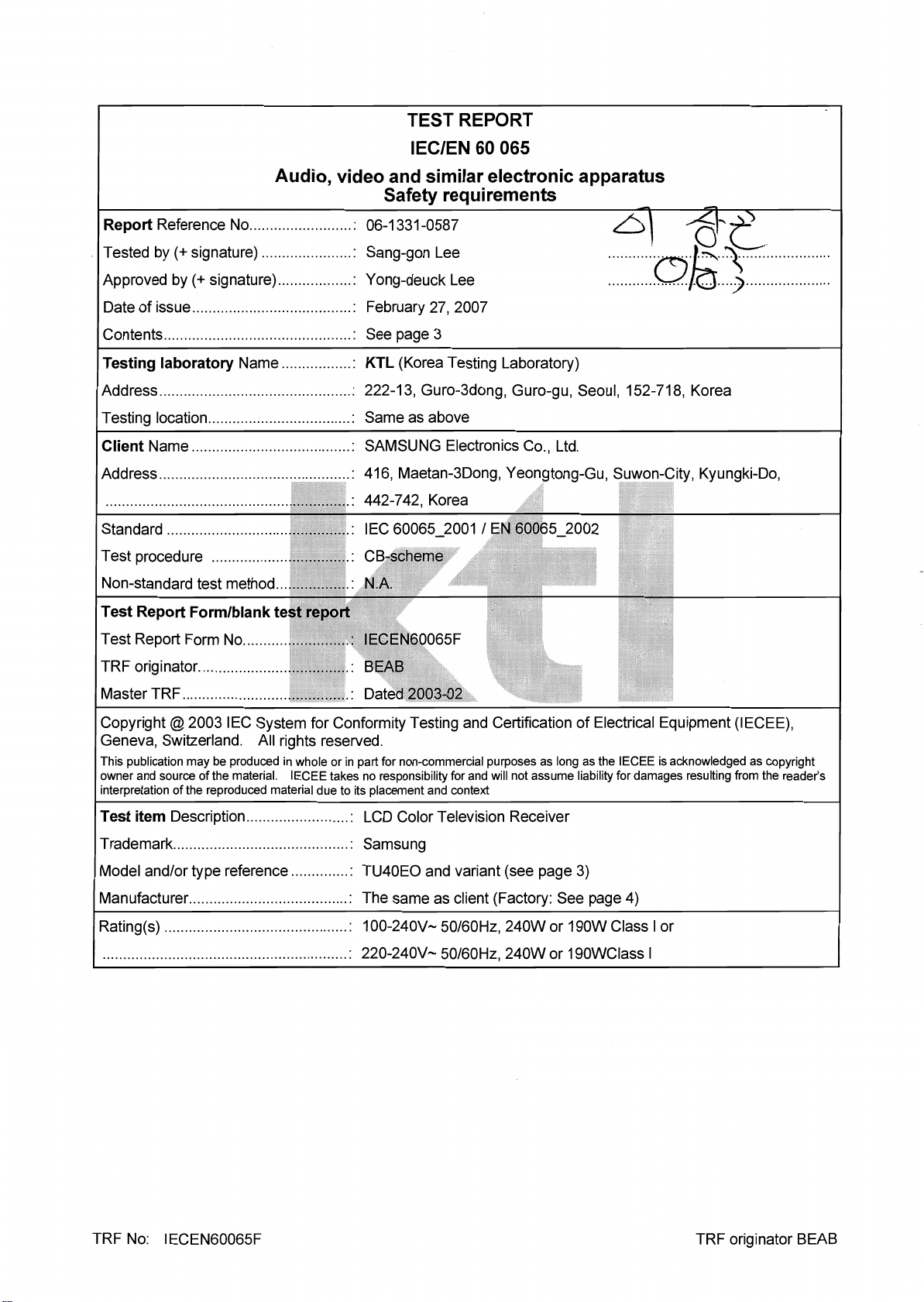

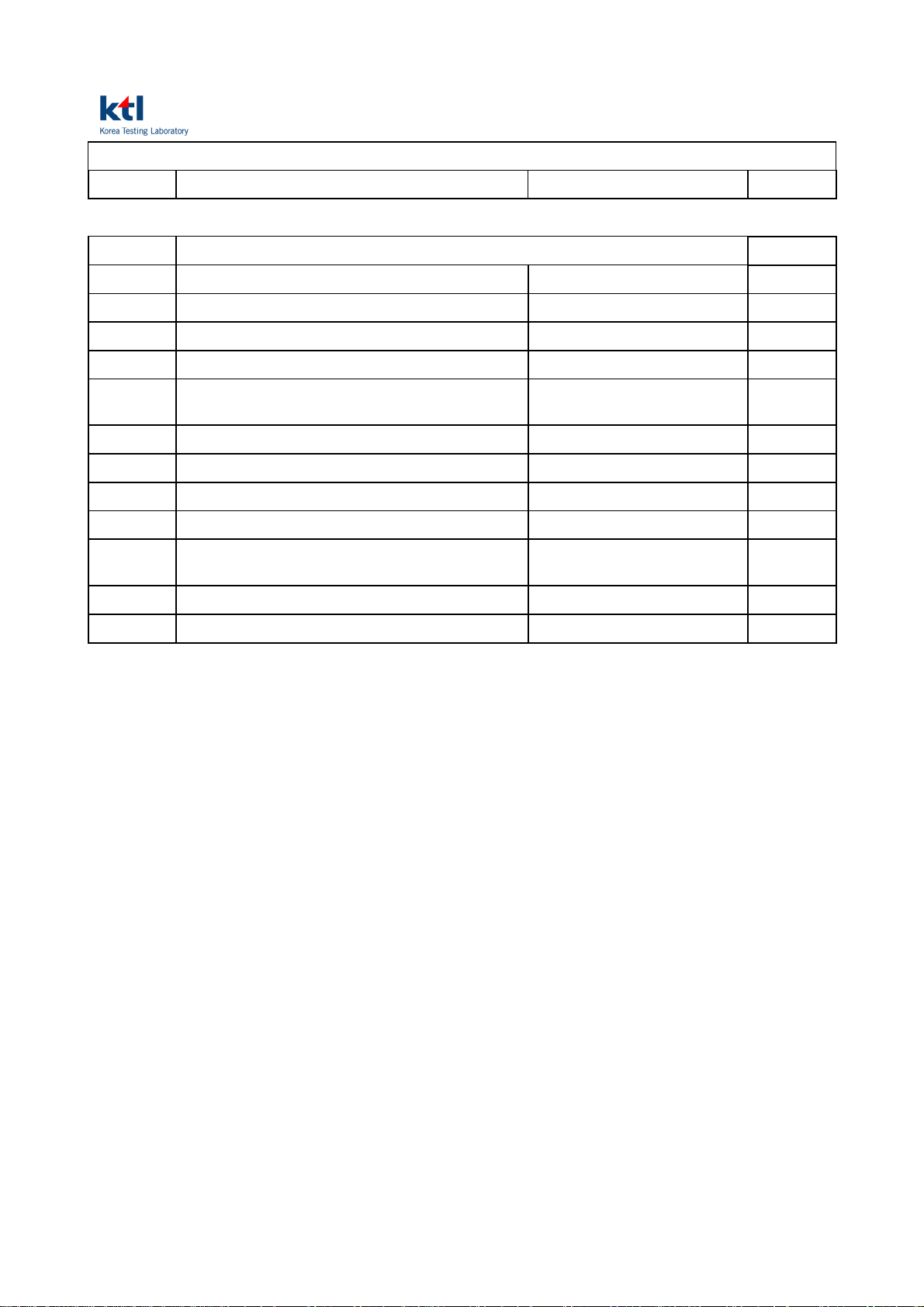

CB TEST CERTIFICATE

KR-3407

IEC SYSTEM FOR MUTUAL RECOGNITION OF TEST CERTIFICATES FOR

ELECTRICAL EQUIPMENT (IECEE) CB SCHEME

Issued by:

Product:

Applicant:

Manufacturer:

Factory:

nb: Additional factory

information on

page

2

Rating and principal

characteristics:

Trade mark (if any):

Modelrrype

reference:

Additional information:

Sample of product

tested to be in

conformity with IEC:

Test Report Ref. No:

Korea Testing Laboratory (KTL)

LCD Color Television Receiver

SAMSUNG Electronics 416, Maetan3Dong, Yeongtong- Korea, Republic of

Co., Ltd. Gu, Suwon-City, Kyungki-Do,

SAMSUNG Electronics 416, Maetan3Dong. Yeongtong- Korea, Republic of

Co., Ltd. Gu, Suwon-Ci, Kyungki-Do,

SAMSUNG Electronics 416, Maetan3Dong, Yeongtong- Korea, Republic of

Co., Ltd. Gu, Suwon-City, Kyungki-Do,

100-240V- 50160Hz. 240W or 190W Class I or

220-240V- 50160Hz. 240W or 19OWClass

SAMSUNG

TU4OEO and variant (see page 3 of 06-1331-0587)

60065(ed.7)

06-1331-0587

National differences: Comments:

SG

I

+

EN 60065-2002

This CB Test Certificate is issued by the National Certification Body:

Korea Testing Laboratory (KTL)

222

-

13 Guro-3Dong, Guro-Gu, Seoul

152 - 718,

orea

&.

Signed by: Mr. Jong-Myung LEE

Date of issue:

2007-02-27

Page 2 of 48 Ref. No. : 06-1331-0587

Test case verdicts

Test case does not apply to the test object.................. : N(.A.)

Test item does meet the requirement .......................... : P(ass)

Test item does not meet the requirement .................... : F(ail)

Testing

Date of receipt of test item .......................................... :

Date(s) of performance of test………………………:

December 12, 2006

December 12, 2006 – February 26, 2007

General remarks

This report is not valid as a CB Test Report unless signed by an approved CB Testing Laboratory and

appended to a CB Test Certificate issued by a NCB, in accordance with IECEE 02.

This report shall not be reproduced except in full without the written approval of the testing laboratory.

The test results presented in this report relate only to the item(s) tested.

"(see appended table)" refers to a table appended to the report.

“(see remark #)” refers to a remark appended to the report.

“(see Annex #) refers to an annex appended to the report.

Throughout this report a comma (point) is used as the decimal separator.

Summary of Testing and Conclusions

The sample(s) tested complies with the requirements of IEC/EN 60065:2002. Compliance with European

Special National Conditions, Annex ZB, and A – Deviations, Annex ZC, is recorded at the end of this report.

TRF No: IECEN60065F TRF originator BEAB

Page 3 of 48 Ref. No. : 06-1331-0587

Items covered

1. Model number covered by the scope of this test report is as follows;

The products differences in the following respects: Minor differences in the external design as well as in

the low voltage secondary circuits, with no importance from safety point of view.

As the differences from TU40EO, listed below.

Alternative models type : xx40yy or

1)2) 3)4) 5)6) 7)8)9)10)11) 5)6) 7)8)9)10)11)

xx40yyyyy

or

xx-40yyyyy

Models designation can be explaned by follows.

40: Screen size

1)2)

: Project name (can be TU,BP,JA, BD)

3)4)

: Marketing region (can be EO, UO, SO, JO, KO, CO)

5)6)

: Marketing region (can be LN, LT, LTN, LS, LTP, LW, LNR, LE, LA, SE)

7)

: Cabinet design for project (can be M, R, S)

8)9)

: Cabinet design (can be any 2 numeric characters)

10)11)

: Function (can be any 2, 3, 4 or 5 alphanumeric characters or blank)

2. We tested TU40EO as a basic model for the most severe test conditions.

3. These products, TU40EO series, are intended to use of internal SMPS power boards as follows.

1) Model no. of internal SMPS power board: IP-231135A

- Manufacturer: Samsung Electro-Mechanics Co., Ltd.

- Rating: 100-240Vac, 50/60Hz, 4.0A Cl.l

- Output: 0.5A/ +5.2V, 4.0A/+5.4V, 1.2A/+12.0V, 2.0A/+13.0V, (CNI801-CNI802) 100mA/2100Vac

- Applied Standard: IEC 60065:2001 / EN 60065:2002

- Approved by: NEMKO AS

- Report and Certification No. : 78822 / NO41914

2) Model No. of internal SMPS power board: SIP400B

- Manufacturer: Hansol LCD Inc.

- Rating: 100-240Vac, 50/60Hz, 4.0A Cl.l

- Output: STB DC 5.2Vdc/0.3A, DC 5.4V/3.5A, DC 12V/1.0A, DC 13V/1.5A,

Inverter 1500Vrms/72mArms

- Applied Standard: IEC 60065:2001 / EN 60065:2002

- Approved by: DEMKO

- Report and Certification No. : E301536-C06T003-1 / DK-10597

4. These models, TU40EO series, have two input rated voltage according to marketing area. There is no

difference except for marking of rated voltage.

5. Marking of power consumption might be different according to adopted LCD panel.

- The model series with marking of 240W power consumption: xx40TU, xx40yyMyy or xx-40yyMyy

- The model series with marking of 190W power consumption: Others models

TRF No: IECEN60065F TRF originator BEAB

Page 4 of 48 Ref. No. : 06-1331-0587

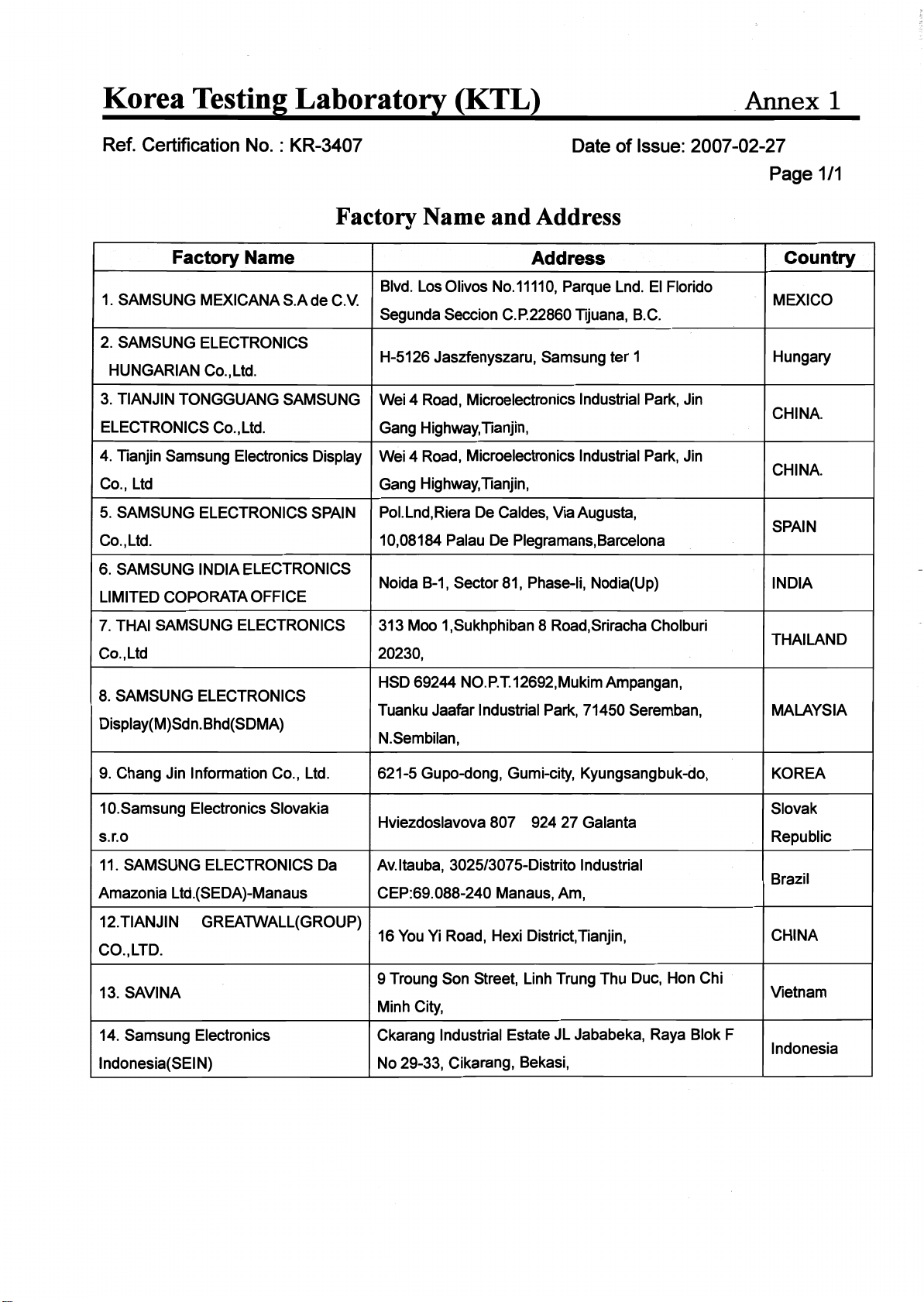

Manufacturer and factory

1. The same as manufacturer

2. SAMSUNG MEXICANA S.A de C.V.

Blvd. Los Olivos No.11110, Parque Lnd. El Florido

Segunda Seccion C.P.22860 Tijuana, B.C.MEXICO.

3. SAMSUNG ELECTRONICS HUNGARIAN Co., Ltd.

H-5126 Jaszfenyszaru, Samsung ter 1 Hungary.

4. TIANJIN TONGGUANG SAMSUNG ELECTRONICS Co., Ltd.

Wei 4 Road, Microelectronics Industrial Park, Jin

Gang Highway,Tianjin, People’s Republic Of CHINA.

5. Tianjin Samsung Electronics Display Co., Ltd

Wei 4 Road, Microelectronics Industrial Park, Jin

Gang Highway,Tianjin, People’s Republic Of CHINA

6. SAMSUNG ELECTRONICS SPAIN Co., Ltd.

Pol.Lnd,Riera De Caldes, Via Augusta,

10,08184 Palau De Plegramans,Barcelona,SPAIN.

7. SAMSUNG INDIA ELECTRONICS LIMITED COPORATA OFFICE

Noida B-1, Sector 81, Phase-Ii, Nodia(Up) INDIA.

8. THAI SAMSUNG ELECTRONICS Co., Ltd.

313 Moo 1,Sukhphiban 8 Road,Sriracha Cholburi 20230,THAILAND..

9. SAMSUNG ELECTRONICS Display(M)Sdn.Bhd(SDMA)

HSD 69244 NO.P.T.12692,Mukim Ampangan,

Tuanku Jaafar Industrial Park, 71450 Seremban, N.Sembilan, Malaysia

10. Chang Jin Information Co., Ltd.

621-5 Gupo-dong, Gumi-city, Kyungsangbuk-do, Korea.

11. Samsung Electronics Slovakia s.r.o

Hviezdoslavova 807

924 27 Galanta,Slovak Republic.

12. SAMSUNG ELECTRONICS Da Amazonia Ltd.(SEDA)-Manaus

Av.Itauba, 3025/3075-Distrito Industrial

CEP:69.088-240 Manaus, Am, Brazil

13. TIANJIN GREATWALL(GROUP) CO., LTD.

16 You Yi Road, Hexi District,Tianjin, China.

14. SAVINA

9 Troung Son Street, Linh Trung Thu Duc, Hon Chi Minh City, Vietnam

15. Samsung Electronics Indonesia(SEIN)

Ckarang Industrial Estate JL Jababeka, Raya Blok F No 29-33, Cikarang, Bekasi, Indonesia

Contents

1. Test report :page 1 to 45

2. EN60065:1998 Annex ZB+ZC: Page 46 and 47 of 48

3. National deviation for Singapore: Page 48 of 48

4. ATTACHMENT 1 : Photo

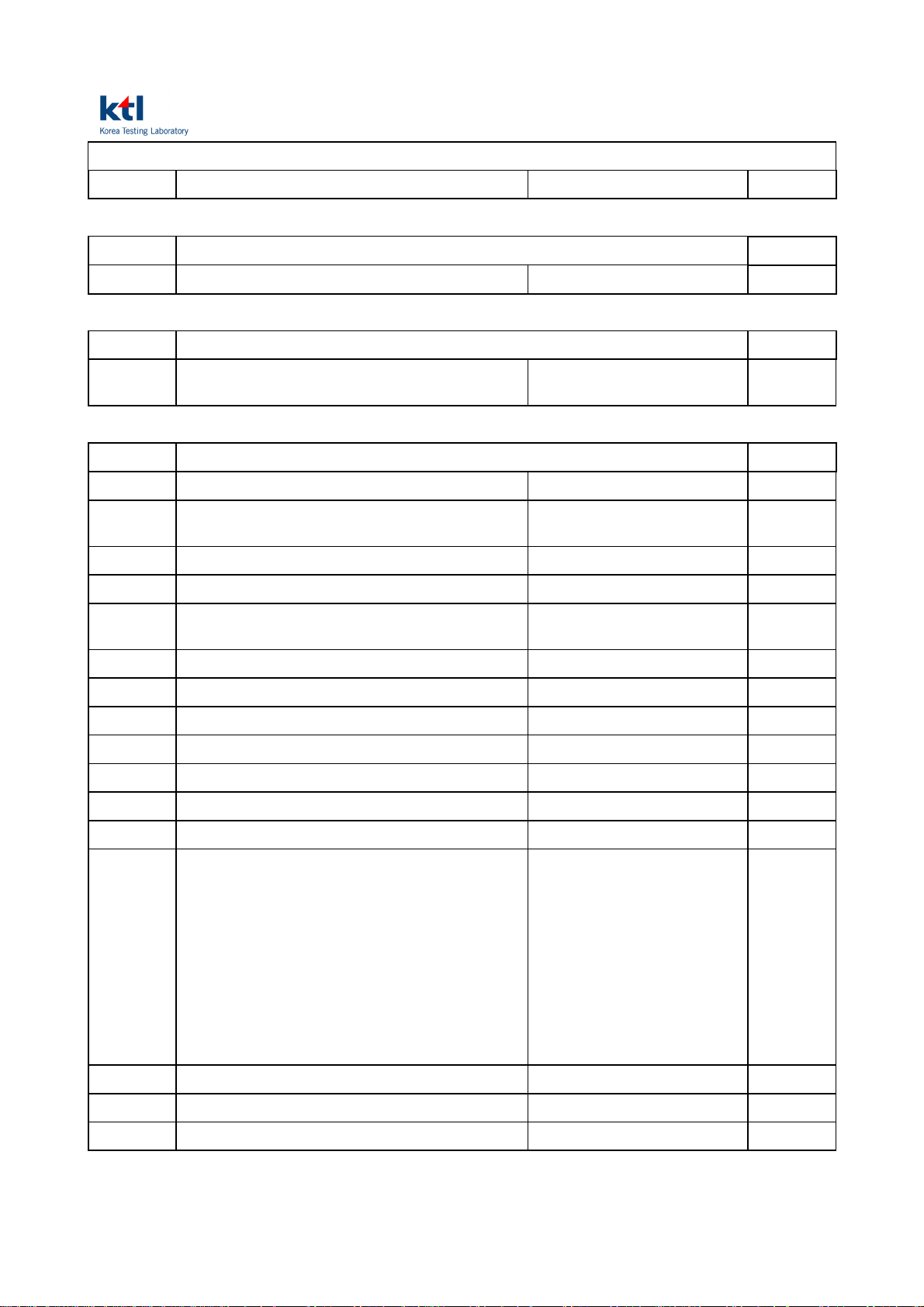

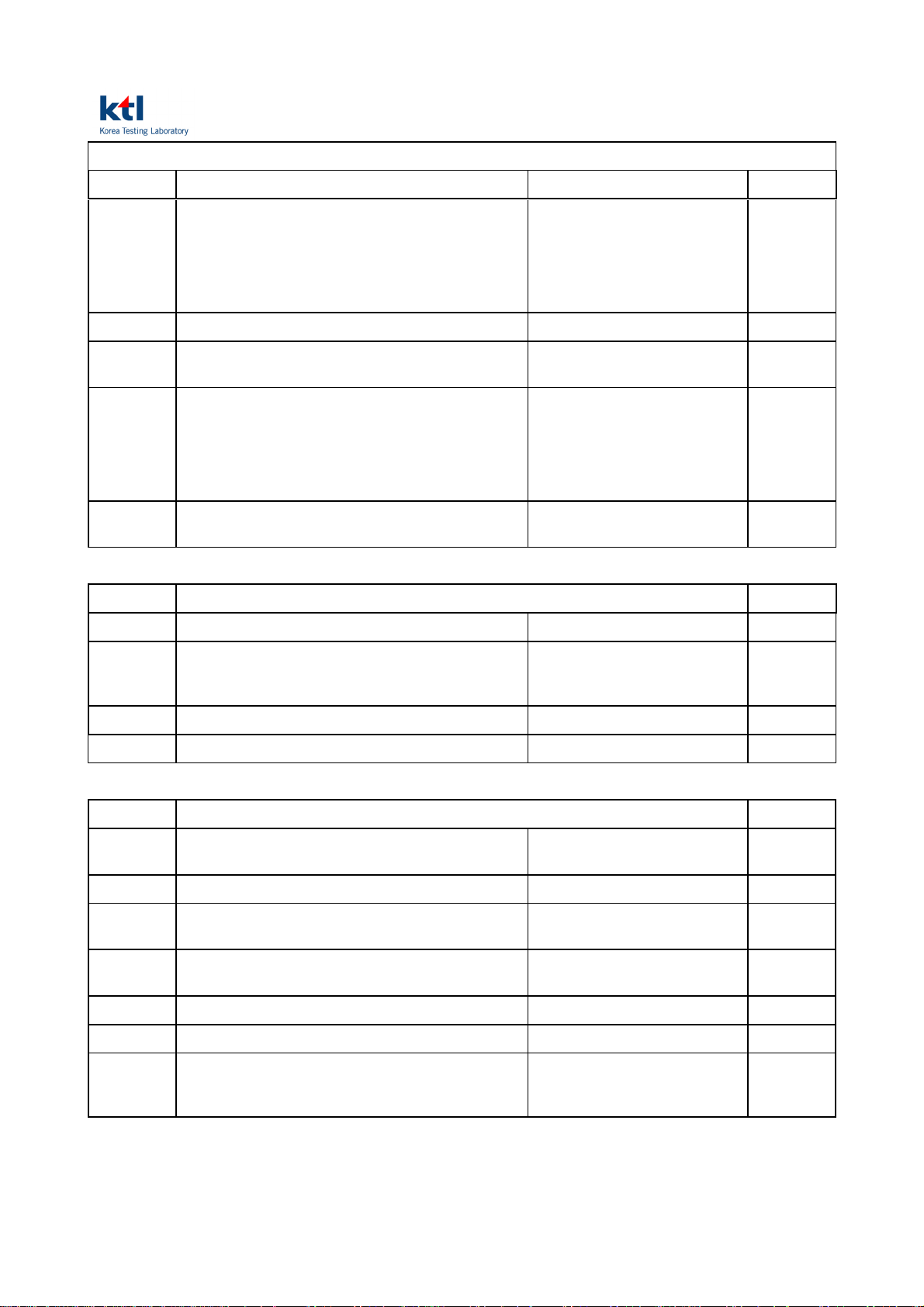

5. ATTACHEMNT 2 : Circuit diagrams

TRF No: IECEN60065F TRF originator BEAB

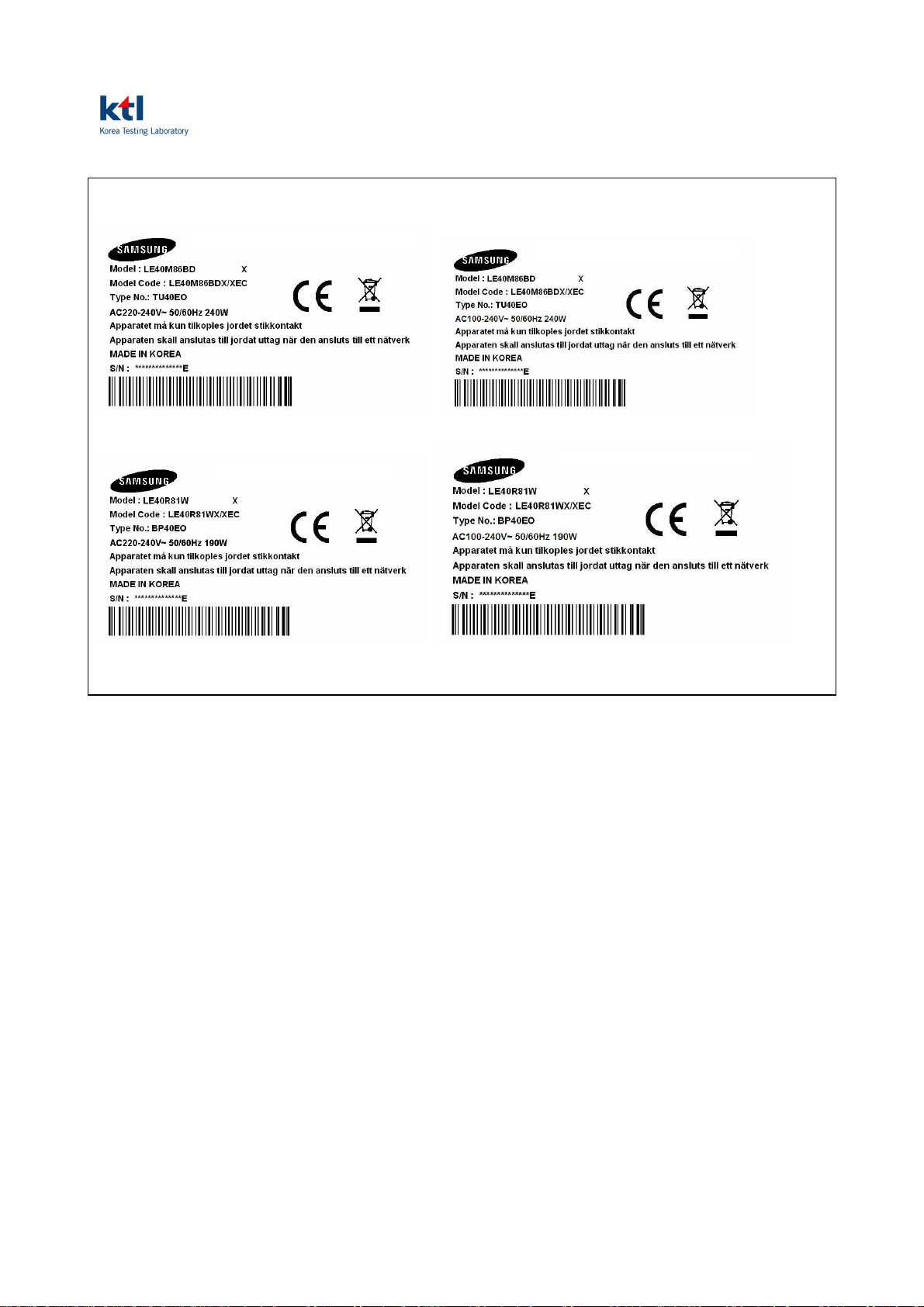

Copy of marking plate

Page 5 of 48 Ref. No. : 06-1331-0587

TRF No: IECEN60065F TRF originator BEAB

Page 6 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

3 GENERAL REQUIREMENTS

Safety class of the apparatus ................................. : Class 1 P

4 GENERAL CONDITIONS OF TESTS

4.1.4 Ventilation instructions require the use of the test

No N

box

5 MARKING

Comprehensible and easily discernible Rear Enclosure P

Permanent durability against water and petroleum

P

spirit

5.1 Identification, maker, model ................................... : Samsung TU40EO P

Class II symbol if applicable Class l Equipment P

Rated supply voltage and symbol .......................... : AC 100-240V~ or

AC 220- 240V~

Frequency if safety dependant 50/60Hz P

Rated current or power consumption .................... : 240W or 190W P

5.2 Earth terminal Mains inlet with earth terminal P

Hazardous live terminals No live terminal N

Supply output terminals (other than mains) No supply output N

5.3 Use of triangle with exclamation mark In circuit diagram P

P

5.4 Instructions for use By English P

5.4.1 Mains powered equipment not exposed to dripping

or splashing. Warning concerning objects filled

with liquid, etc.

In user’s manual

“Do not place a water

containing vessel on this

P

apparatus, as this can result in

a risk or fire or electric shock.

Do not expose this apparatus

to rain or place it near water

(near a bathtub, washbowl,

kitchen sink or laundry tub, in a

wet basement, or near a

swimming pool etc.)

Hazardous live terminals, instructions for wiring No live terminal N

Instructions for replacing lithium battery No battery N

Instructions for modem if fitted No modem used N

TRF No: IECEN60065F TRF originator BEAB

Page 7 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

Class I earth connection warning In user’s manual

P

“Use only a properly grounded

plug ad receptacle. An

improper ground may cause

electric shock or equipment

damage.”

Instructions for multimedia system connection In user’s manual P

Special stability warning for fixed installation The apparatus is tested to the

N

stability requirements of 19.1-3

5.4.2 Disconnect device: plug/coupler or all-pole mains

switch location, accessibility and markings

In user’s manual

“To disconnect the apparatus

P

from the mains, the plug must

be pulled out from the mains

socket, therefore the mains

plug shall be readily operable”

Instructions for permanently connected equipment No permanently connected

N

equipment

6 HAZARDOUS RADIATION

6.1 Ionizing radiation < 36 pA/kg (0,5 mR/h) No ionizing radiation N

6.1

EN 60065

European Council Directive 96/29/Euratom of 13

May 1996 10cm from outer surface of apparatus

N

<1µSv/h (0,1mR/h)

6.2 Laser radiation, emission limits to IEC 60825-1 .... : No laser system N

Emission limits under fault conditions .................... : N

7 HEATING UNDER NORMAL OPERATING CONDITIONS

7.1 Temperature rises not exceeding specified values,

(see appended table) P

no operation of fuse links

7.1.1 Temperature rise of accessible parts (see appended table) P

7.1.2 Temperature rise of parts providing electrical

(see appended table) P

insulation

7.1.3 Temperature rise of parts acting as a support or as

(see appended table) P

a mechanical barrier

7.1.4 Temperature rise of windings (see appended table) P

7.1.5 Parts not subject to a limit under 7.1.1 to 7.1.4 (see appended table) P

7.2 Softening temperature of insulating material

supporting parts conductively connected to the

mains carrying a current > 0,2 A at least 150

o

(see appended table) N

C

TRF No: IECEN60065F TRF originator BEAB

Page 8 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

8 CONSTRUCTIONAL REQUIREMENTS WITH REGARD TO THE PROTECTION

AGAINST ELECTRIC SHOCK

8.1 Conductive parts covered by lacquer, paper,

Considered as bare P

untreated textile oxide films and beads etc.

considered to be bare

8.2 No shock hazard when changing voltage setting

No voltage setting device N

device, fuse-links or handling drawers etc.

8.3 Insulation of hazardous live parts not provided by

No hygroscopic materials N

hygroscopic material

8.4 No risk of electric shock following the removal of a

No shock hazard P

cover which can be removed by hand

8.5 Class I equipment P

Basic insulation between hazardous live parts and

P

earthed accessible parts

Resistors bridging basic insulation complying with

P

14.2.1 a)

8.6 Class II equipment and Class II constructions

within Class I equipment

Class ll construction within

class l equipment

P

(Evaluated by CB test report of

SMPS board)

Reinforced or double insulation between

hazardous live parts and accessible parts

(Evaluated by CB test report of

SMPS board)

P

Components bridging reinforced or double

insulation complying with 14.1 a) or 14.3

Basic and supplementary insulation each being

bridged by a capacitor complying with 14.2.1 a)

Reinforced or double insulation being bridged with

(Evaluated by CB test report of

P

SMPS board)

(Evaluated by CB test report of

P

SMPS board)

N

2 capacitors in series complying with 14.2.1 a)

Reinforced or double insulation being bridged with

a single capacitor complying with 14.2.1 b)

Basic insulation bridged by components complying

(Evaluated by CB test report of

P

SMPS board)

N

with 14.3.4.3

8.7 Basic insulation between parts at 35 V to 71 V

N

(peak) a.c. or 60 V to 120 V d.c. and accessible

parts

Reinforced or double insulation between circuits

N

operating at voltages between 35 V and 71 V

(peak) a.c. or between 60 V and 120 V d.c. and

hazardous live parts at higher voltage

Separation by Class II isolating transformer N

Separation by Class I transformer N

Separation by earthed conductive part N

TRF No: IECEN60065F TRF originator BEAB

Page 9 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

8.8 Basic or supplementary insulation > 0,4 mm (mm)

P

................................................................................. :

Reinforced insulation > 0,4 mm (mm) ................... : (Evaluated by CB test report of

P

SMPS board)

Thin sheet insulation (Evaluated by CB test report of

P

SMPS board)

Basic or supplementary insulation, at least two

N

layers, each meeting 10.3

Basic or supplementary insulation, three layers

N

any two of which meet 10.3

Reinforced insulation, two layers each of which

N

meet 10.3

Reinforced insulation, three layers any two which

N

meet 10.3

8.9 Adequate insulation between internal hazardous

live conductors and accessible parts

Adequate insulation between internal hazardous

Provided double or reinforce

P

insulation

Dressed away from live parts P

live parts and conductors connected to accessible

parts

8.10 Double insulation between conductors connected

Class l equipment N

to the mains and accessible parts

8.11 Detaching of wires P

No undue reduction of creepages or clearance

Yes P

distances if wires become detached

Vibration test carried out ........................................ : No N

8.12 Adequate cross-sectional area of internal wiring to

No socket outlets N

mains socket-outlets

8.13 Adequate fastening of windows, lenses, lamp

N

covers etc. (pull test 20 N for 10 s)

8.14 Adequate fastening of covers (pull test 50 N for

N

10 s)

8.15 No risk of damage to the insulation of internal

wiring due to hot parts or sharp edges

Wires are dressed away from

hot parts or sharp edge

P

8.16 Only special supply equipment can be used No special supply equipment N

8.17 Insulated winding wire without additional

interleaved insulation

(Evaluated by CB test report of

SMPS board)

P

8.18 Endurance test as required by 8.17 N

8.19 Disconnection from the mains P

8.19.1 Disconnect device Type : Mains Plug P

All-pole switch or circuit breaker with >3mm

N

contact separation

TRF No: IECEN60065F TRF originator BEAB

Page 10 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

8.19.2 Mains switch ON indication N

8.20 Switch not fitted in the mains cord No switch N

8.21 Bridging components comply with clause 14 N

TRF No: IECEN60065F TRF originator BEAB

Page 11 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

9 ELECTRIC SHOCK HAZARD UNDER NORMAL OPERATING CONDITIONS

9.1 Testing on the outside

9.1.1 For voltages >1000 V ac or >1500 V dc complies

< 1000 V ac and < 1500 V dc P

with clause 13.3.1 for basic insulation

9.1.1.1 Touch current measured from terminal devices

using the network in annex D ................................. :

<IP-231135A>

U

: 0.78V

1

U2: 0.19V

P

<SIP400B>

U

U

: 0.91V

1

: 0.22V

2

Discharge not exceeding 45 μC P

Energy of discharge not exceeding 350 mJ N

9.1.1.2 Test with test finger and test probe P

9.1.2 No hazardous live shafts of knobs, handles or

No live shafts N

levers

9.1.3 Ventilation holes and other holes tested by means

of 4 mm x 100 mm test pin

9.1.4 Terminal devices tested with 1 mm x 20 mm test

Width of ventilation less than in

P

4 mm

No hazard P

pin (10 N); test probe D of IEC 61032

Terminal devices tested with 1 mm x 100 mm

No hazard P

straight wire (1 N); test probe D of IEC 61032

9.1.5 Pre-set controls tested with 2.5 mm x 100 mm test

No preset controls N

pin (10 N); test probe C of IEC 61032

9.1.6 No shock hazard due to stored charge on

withdrawal of the mains plug; voltage (V) after 2 s :

Apparatus on and stand-by

mode : Max 40V

P

If C is not greater than 0,1 μF no test needed N

9.1.7 Enclosure sufficiently resistant to external force No damaged, No hazard. P

Test probe 11 of IEC 61032 for 10 s (50 N) P

Test hook of fig. 4 for 10 s (20 N) P

30 mm diameter test tool for 5 s (100 or 250 N) ... : N

9.2 No hazard after removing a cover by hand N

TRF No: IECEN60065F TRF originator BEAB

Page 12 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

10 INSULATION REQUIREMENTS

10.1 Insulation resistance (MΩ) at least 2 MΩ min. after

> 100Mohm P

surge test for basic and 4 MΩ min. for reinforced

insulation ................................................................. :

10.2 Humidity treatment 48 h or 120 h .......................... : 120 h, 93%, 40(oC) P

10.3 Insulation resistance and dielectric strength (see appended table) P

11 FAULT CONDITIONS

11.1 No shock hazard under fault condition P

11.2 Heating under fault condition P

No hazard from softening solder P

11.2.1 Measurement of temperature rises (see appended table) P

11.2.2 Temperature rise of accessible parts (see appended table) P

11.2.3 Temperature rise of parts, other than windings,

(see appended table) P

providing electrical insulation

Temperature rise of printed circuit boards (PCB)

exceeding the limits of table 3 by max. 100 K for

Not exceeding the limit of table

2

N

max. 5 min

a) Temperature rise of printed circuit boards (PCB)

N

to 20.1.3, exceeding the limits of table 3 by not

more than 100 K for an area not greater than

2 cm²

b) Temperature rise of printed circuit boards (PCB)

N

to 20.1.3 up to 300 K for an area not greater than

2 cm² for a maximum of 5 min

Meets all the special conditions if conductors on

N

printed circuit boards are interrupted

Class I protective earthing maintained (see appended table) P

11.2.4 Temperature rise of parts acting as a support or

(see appended table) P

mechanical barrier

11.2.5 Temperature rise of windings (see appended table) P

11.2.6 Temperature rise of parts not subject to the limits

(see appended table) P

of 11.2.1 to 11.2.5

TRF No: IECEN60065F TRF originator BEAB

Page 13 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

12 MECHANICAL STRENGTH

12.1.1 Bump test where mass >7 kg P

12.1.2 Vibration test N

12.1.3 Impact hammer test 0.5J P

Steel ball test 2J P

12.1.4 Drop test for portable apparatus where mass < 7

Not portable apparatus N

kg

12.1.5 Thermoplastic enclosures strain relief test 7h, 80 (oC) P

12.2 Fixing of knobs, push buttons, keys and levers 100 N P

12.3 Remote controls with hazardous live parts No remote control with live N

12.4 Drawers (pull test 50 N, 10 s) No drawers N

12.5 Antenna coaxial sockets providing isolation Antenna socket outlets was

N

mounted on secondary circuits

12.6 Telescoping or rod antennas construction No such a device N

12.6.1 Telescoping or rod antennas securement N

TRF No: IECEN60065F TRF originator BEAB

Page 14 of 48 Ref. No. : 06-1331-0587

IEC / EN 60065

Clause Requirement – Test Result - Remark Verdict

13 CLEARANCE AND CREEPAGE DISTANCES

13.1 Clearances in accordance with 13.3 (see appended table) P

Creepage distances in accordance with 13.4 (see appended table) P

13.2 Determination of operating voltage (see appended table) P

13.3 Clearances (see appended table) P

13.3.2 Circuits conductively connected to the mains

(see appended table) P

comply with table 8 and, where applicable, table 9

13.3.3 Circuits not conductively connected to the mains

N

comply with table 10

13.4 Creepage distances (see appended table) P

Creepage distances greater than table 11 minima (see appended table) P

13.5 Printed boards N

13.5.1 Clearances and creepage distances between

None N

conductors on printed circuit boards, one of which

may be conductively connected to the mains, as in

fig. 10

13.5.2 Type B coated printed circuit boards complying

None N

with IEC 60664-3 (basic insulation only)

13.6 Conductive parts along uncemented joints

None N

clearances and creepage distances comply with

13.3 and 13.4

Conductive parts along reliably cemented joints

comply with 8.8

13.7 Enclosed, enveloped or hermetically sealed parts:

(Evaluated by CB test report of

P

SMPS board)

None N

not conductively connected to the mains:

clearances and creepage distances as in table 12

13.8 Parts filled with insulating compound, meeting the

None N

requirements of 8.8

TRF No: IECEN60065F TRF originator BEAB

Loading...

Loading...