Samsung AVMWH032CA0, AVMWH072CA0, AVMWH040CA0, AVMWH052CA0, AVMWC020CA0 Installation Manual

...

E§§HNIKA

INSTALLATION MANUAL

MANUAL DE INSTALACIÓN

MANUEL D’INSTALLATION

MANUALE D’INSTALLZIONE

MANUAL DE INSTALAÇÃO

INSTALLATIONS-HANDBUCH

E°XEIPI¢IO E°KATA™TA™H™

азлнкмдсаь ий млнДзйЗдЦ

System Air Conditioner

Aire acondicionado sistemático

Climatiseur numérique multifonctionnel

Sistema Aria Condizionata

Sistema Ar Condicionado

Klimaanlage System

™‡ЫЩЛМ· ∫ПИМ·ЩИЫМФ‡

лЛТЪВПМ˚И ЗУБ‰Ы¯М˚И дУМ‰ЛˆЛУМВ

E S F I P D G R DB98-05180A(2)

A VMWH020CA0

A VMWH032CA0

A VMWH040CA0

A VMWH052CA0

A VMWH072CA0

A VMWH020EA(B)0

A VMWH026EA(B)0

A VMWH035EA(B)0

A VMWH052EA(B)0

A VMWH070EA(B)0

Heat pump

A VMWC020CA0

A VMWC032CA0

A VMWC040CA0

A VMWC052CA0

A VMWC072CA0

A VMWC020EA(B)0

A VMWC026EA(B)0

A VMWC035EA(B)0

A VMWC052EA(B)0

A VMWC070EA(B)0

Cooling only

ENGLISH

ESPAÑOL

FRANÇAIS

ITALIANO

PORTUGUÊS

DEUTSCH

RUSSIAN

■ Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

OO

OO

PPPPTTTTIIIIOOOONNNNAAAALL

LL

AA

AA

CCCCCCCCEEEESSSSSSSSOOOORRRRIIIIEEEESS

SS

Chapter

Contents

E-2

■ Preparation for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

■ Deciding on Where to Install the Indoor Unit . . . . . . . . . . . . . . . . . 5

■ Fixing the Installation Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

■ Electronic Expansion Valve Kit Installation . . . . . . . . . . . . . . . . . . . 9

■ Connecting the Refrigerant Pipe . . . . . . . . . . . . . . . . . . . . . . . . . 12

■ Cutting / Flaring the Pipes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

■ Performing Leak Test & Insulation . . . . . . . . . . . . . . . . . . . . . . . . 14

■ Drain Hose Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

■ Connecting the Connection Cord . . . . . . . . . . . . . . . . . . . . . . . . . 16

■ Assigning Address to Indoor Unit . . . . . . . . . . . . . . . . . . . . . . . . . 17

■ Additional Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

■ Bio-pure Filter Installation (optional) . . . . . . . . . . . . . . . . . . . . . . . 19

■ Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

WW

WW

AAAALLLLLL

LL

--

--

MMMMOOOOUUUUNNNNTTTTEEEEDD

DD

TT

TT

YYYYPPPPEE

EE

II

II

NNNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONN

NN

Chapter

■ Preparation for Installation . . . . . . . . . . . . . . . . 4

■ Deciding on Where to Install the Indoor Unit . . . 5

■ Fixing the Installation Plate . . . . . . . . . . . . . . . . 8

■ Electronic Expansion Valve Kit Installation . . . . 9

■ Connecting the Refrigerant Pipe . . . . . . . . . . . 12

■ Cutting / Flaring the Pipes . . . . . . . . . . . . . . . . 13

■ Performing Leak Test & Insulation . . . . . . . . . 14

■ Drain Hose Installation . . . . . . . . . . . . . . . . . . 15

■ Connecting the Connection Cord . . . . . . . . . . 16

■ Assigning Address to Indoor Unit . . . . . . . . . . 17

■ Additional Functions . . . . . . . . . . . . . . . . . . . . 18

■ Bio-pure Filter Installation (optional) . . . . . . . . 19

■ Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 20

WW

WW

AAAALLLLLL

LL

--

--

MMMMOOOOUUUUNNNNTTTTEEEEDD

DD

TT

TT

YYYYPPPPEE

EE

II

II

NNNNSSSSTTTTAAAALLLLLLLLAAAATTTTIIIIOOOONN

NN

Chapter

E-3

ENGLISH

Preparation for Installation

When deciding on the location of the air conditioner with the owner,

the following restrictions must be taken into account.

General

Do NOT install the air conditioner in a location where it will come into

contact with the following elements:

◆

Combustible gases

◆

Saline air

◆

Machine oil

◆

Sulphide gas

◆

Special environmental conditions

If you must install the unit in such conditions, first consult your dealer.

E-4

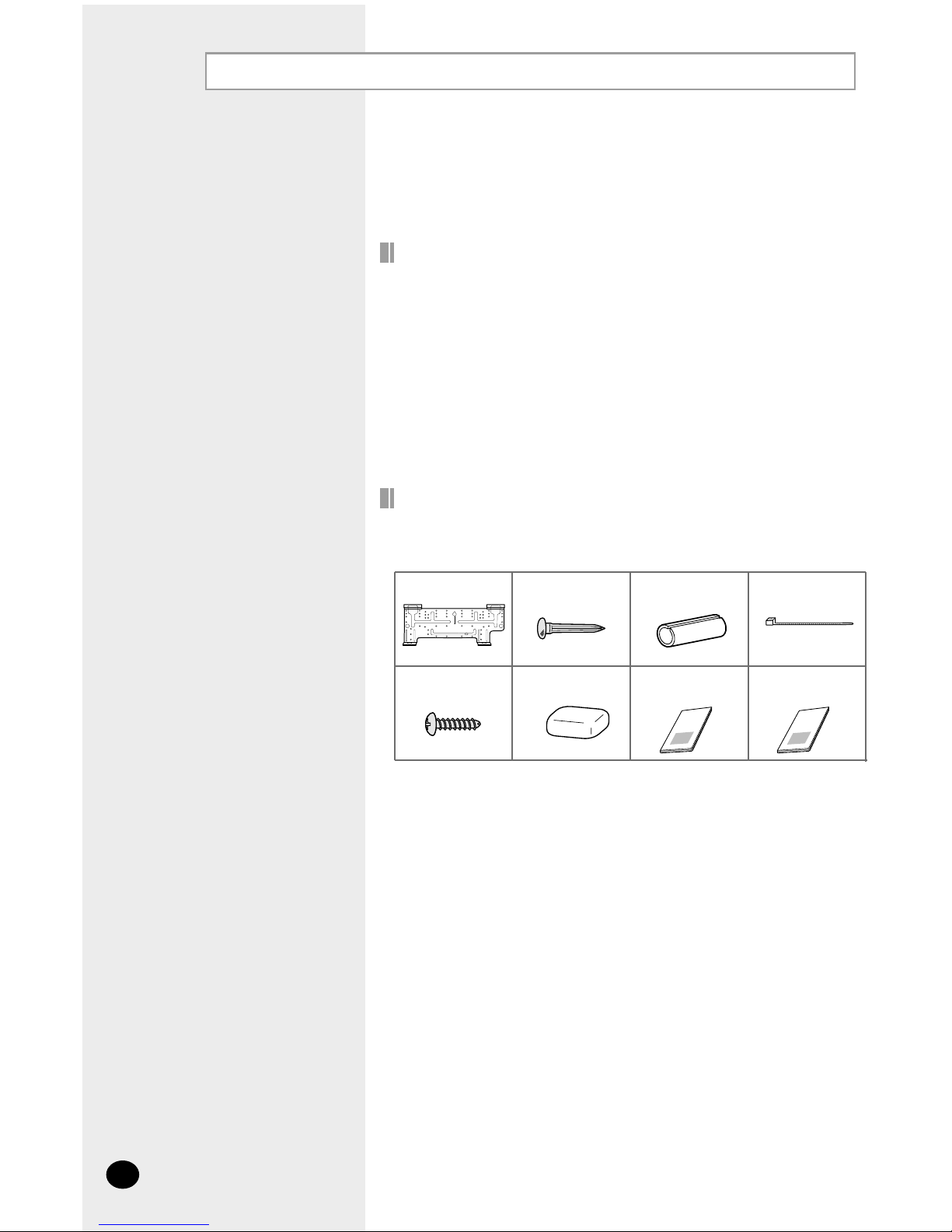

Accessories

◆ The following accessories are supplied with the indoor unit.

The quantities are indicated in parentheses.

Installation plate (1) Insulation refrigerant

pipe (1)

Cement nail (6)

Cable tie (4)

Tapped screw (6) Putty (1) Owner’s instructions

(1)

Installation manual

(1)

O

W

N

E

R

’

S

I

N

S

T

R

U

C

T

I

O

N

S

S

p

l

u

t

-

t

y

p

e

R

o

o

m

A

i

r

C

o

n

d

i

t

i

o

n

e

r

O

W

N

E

R

’

S

I

N

S

T

R

U

C

T

I

O

N

S

S

p

l

u

t

-

t

y

p

e

R

o

o

m

A

i

r

C

o

n

d

i

t

i

o

n

e

r

Deciding on Where to Install the Indoor Unit

Indoor Unit

◆

There must be no obstacles near the air inlet and outlet.

◆

Install the indoor unit on a wall that can support its weight.

◆

Maintain sufficient clearance around the indoor unit.

◆

Make sure that the water dripping from the drain hose runs away correctly

and safely.

◆

The indoor unit must be installed in this way, that they are out of public

access. (Not touchable by the users)

E-5

ENGLISH

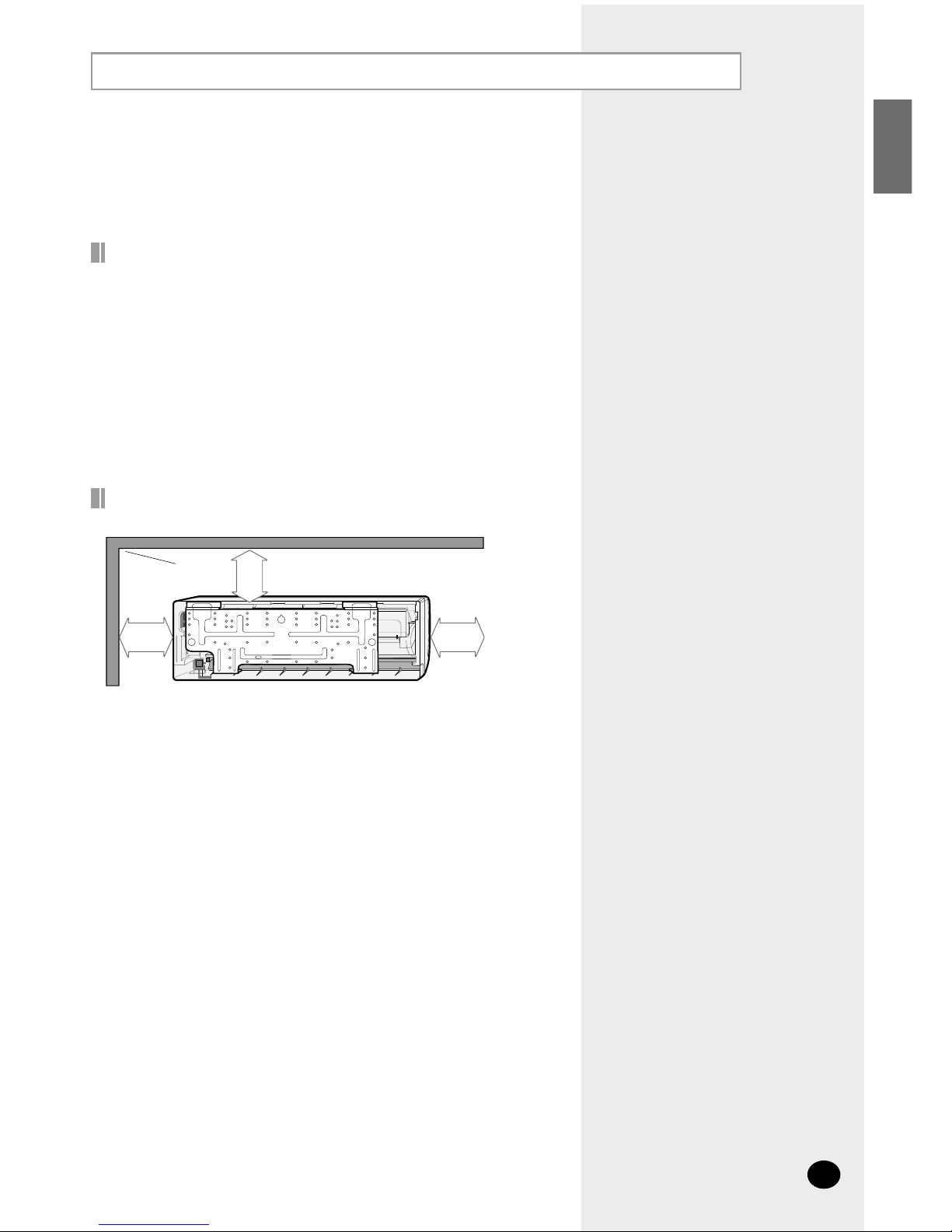

Space Requirements for Indoor Unit

125mm

or more

125mm

or more

30mm

or more

E-6

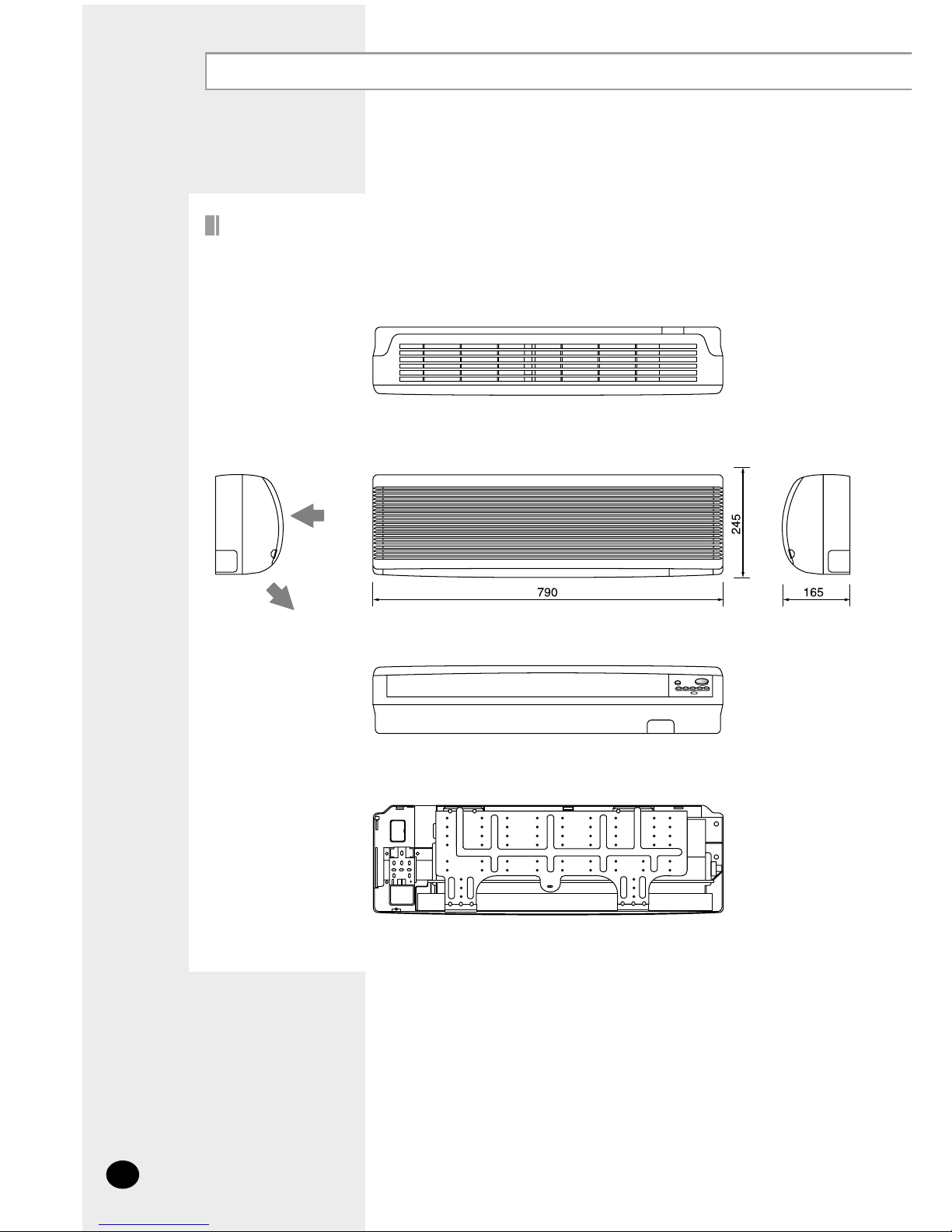

Deciding on Where to Install the Indoor Unit (cont.)

Drawing of the indoor unit

✴✴

020/026/032/035/040

✴✴

Unit : mm

Air In

Front view

Rear view

Air out

E-7

ENGLISH

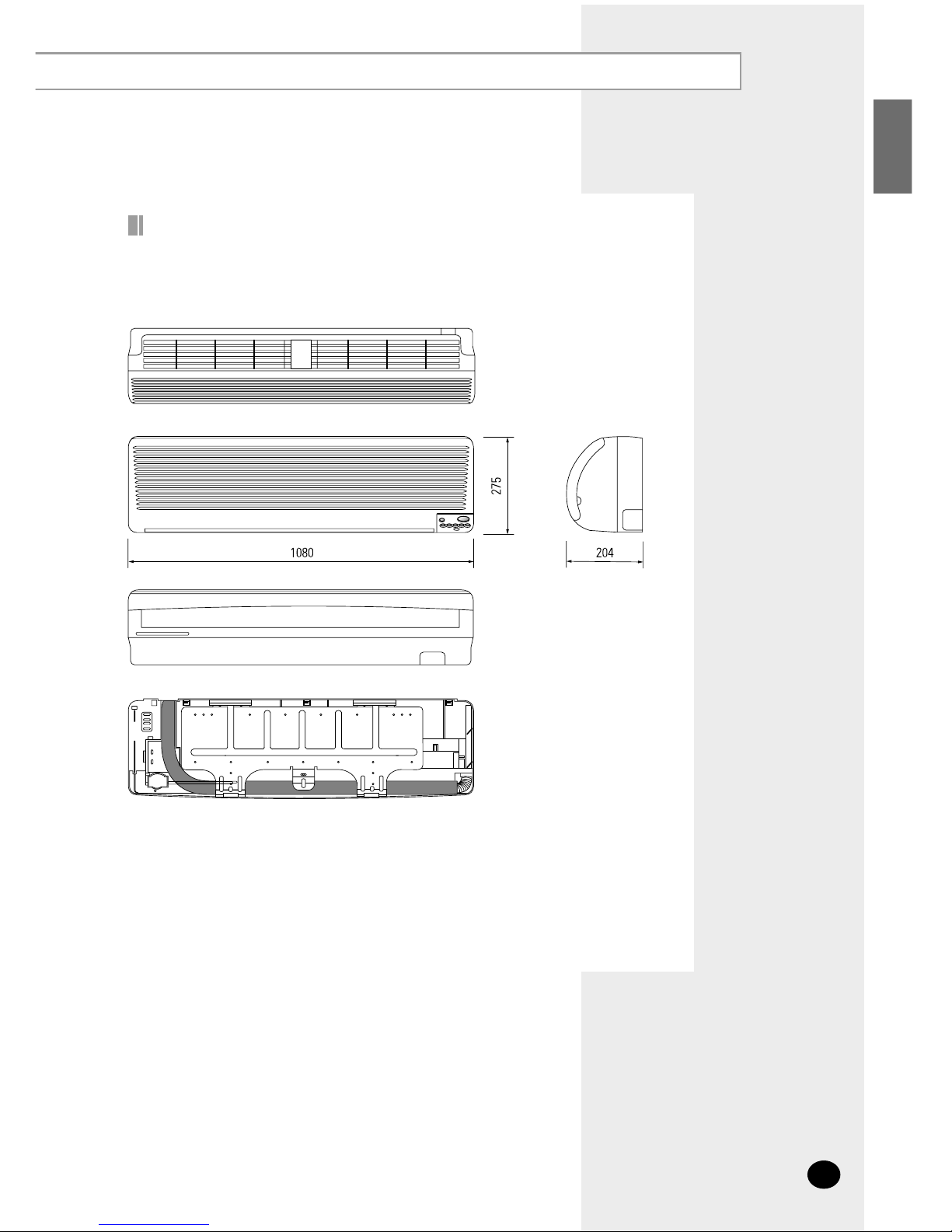

✴✴

052/070/072

✴✴

Drawing of the indoor unit

Front view

Rear view

Unit : mm

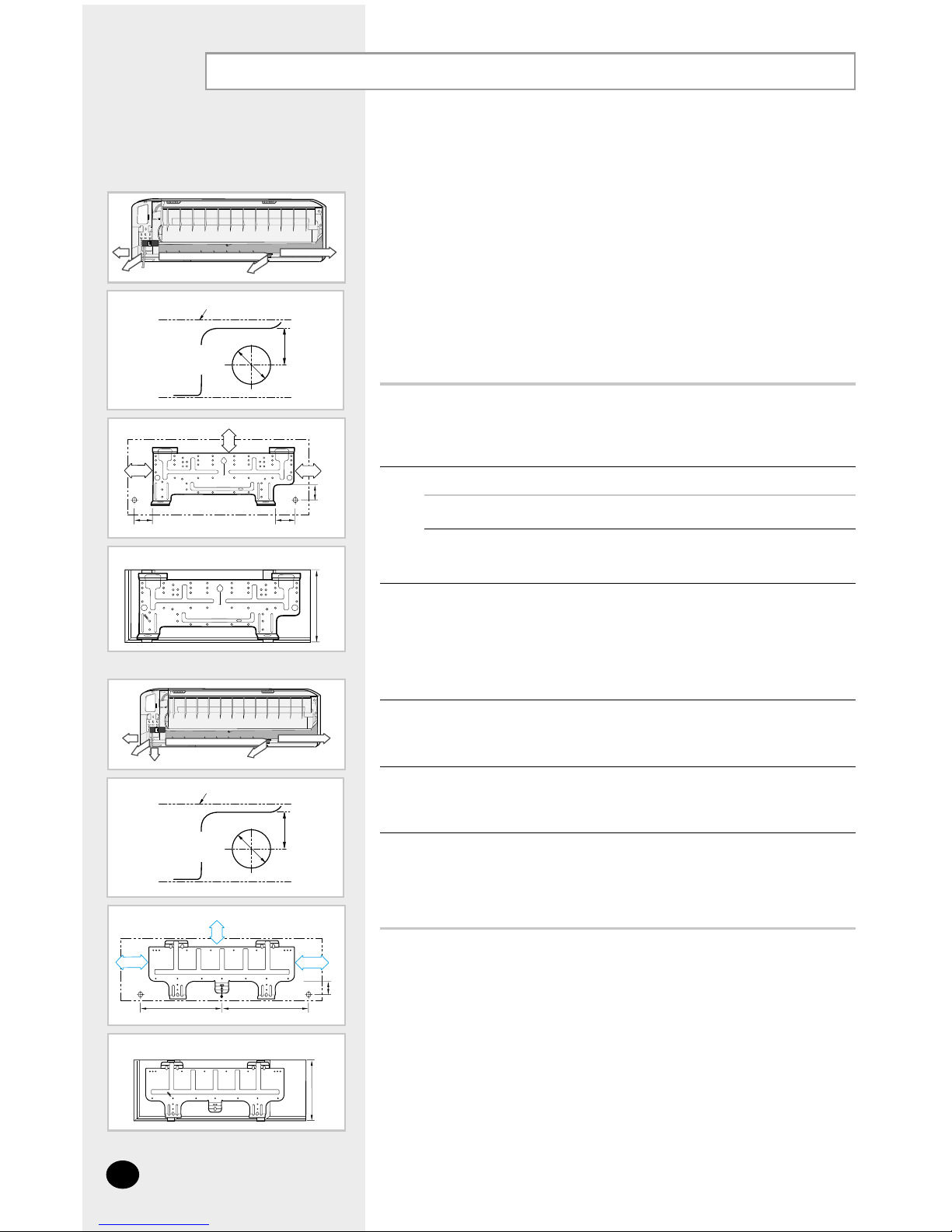

Fixing the Installation Plate

E-8

60

30

252

275

14090

410~730

Before fixing the installation plate to a wall or window frame, you

must determine the position of the 65 mm hole through which the

cable, piping and hose pass to connect the indoor unit up to the

outdoor unit. When facing the air conditioner in position on the wall,

the piping and cable can be connected from the:

◆ Right

◆ Left

◆ Underside;

✴✴

052/070/072

✴✴

◆ Rear (right or left)

1 Determine the position of the pipe and drain hose hole using the right

figure and drill the hole with an inner diameter of 65 mm so that it slants

slightly downwards.

2 If you are fixing the indoor unit to a... Then follow Steps...

Wall 3.

Window frame 4 to 6.

3 Fix the installation plate to the wall in a manner appropriate to the weight

of the indoor unit.

➢ If you are mounting the plate on a concrete wall with anchor

bolts, the anchor bolts must not project by more than 20 mm.

4 Determine the positions of the wooden uprights to be attached to the

window frame.

5 Attach the wooden uprights to the window frame in a manner appropriate

to the weight of the indoor unit.

6 Using tapped screws, attach the installation plate to the wooden uprights,

as illustrated in the last figure opposite.

✴✴

020/026/032/035/040

✴✴

30mm

Installation plate

Pipe hole

(

Ø

65mm)

(Unit : mm)

(Unit : mm)

60

45

255

325

415512

410~730

✴✴

052/070/072

✴✴

45mm

Installation plate

Pipe hole

(

Ø

65mm)

(Unit : mm)

(Unit : mm)

Electronic Expansion Valve Kit Installation

1

Decide an installation place that can support the electronic expansion

valve kit.

2

Connect the “IN” refrigerant pipe to the outdoor unit.

3

Connect the “OUT” refrigerant pipe to each indoor unit(A, B and C).

◆

The liquid and gas pipes should not be crossed when piping connection.

4

Insulate the connection piping. Ajoint part of pipe needs double

thickness of insulation.

5

The expansion valve has to be installed that the user has no access

to it. (built-in type)

Nylon band

Electronic

Expansion

valve

body

E-9

ENGLISH

Connection of refrigerant piping & Insulation

Electronic Expansion Valve Kit Installation (cont.)

E-10

Wiring & Assigning address

1

Connect the AC power cable and communication cable from the outdoor

unit to terminal, then connect the cable to another electronic expansion

valve kit.

Room A

Room B

Outdoor

unit

Another

distributor kit

Room C

2

Connect the AC power cable and communication cable to each indoor

unit (A, B and C).

3

Align the SW51, SW52 and SW53’s addresses with A, B and C indoor

units’.

SW51

SW52

SW53

A

B

C

CN63(Y ellow)

CN62(Blue)

CN61(White)

Switch No.

Appropriate indoor unit

(Electronic expansion valve)

Connector No.

◆

The numbers which is displayed on left are the status of indoor unit checking

status through communication with same outdoor unit.

(If it indicates 1, 3 and 7, that means the ADDRESS of indoor unit is

set to 1, 3 and 7.)

◆

The numbers which is displayed on right indicate the ADDRESS of SW51,

SW52 and SW53 in sequential. (If it indicates 0, 1 and 2, that means the

SW51 is set to 0, the SW52 is set to 1, and the SW53 is set to 2.)

◆

If the communication error occurs in distributor, the Er↔C0 message will be

shown on the display alternatively.

E-11

ENGLISH

Function of Display

◆

If you press a KEY on the PCB, the display will show you a step of appropriate

electronic expansion valve.

KEY function

K1

K2

K3

K4

Step of electronic expansion valve A

Step of electronic expansion valve B

Step of electronic expansion valve C

-

19

(19 x 10 =

190 STEP)

-

KEY No.

Meaning

Example

E-12

Connecting the Refrigerant Pipe

◆

If the pipes must be shortened refer to page 13.

NNNNoooottttee

ee

Outer Diameter Torque (kgf•cm)

6.35 mm (1/4") 144~176

9.52 mm (3/8") 333~407

12.70 mm (1/2") 504~616

15.88 mm (5/8") 630~770

19.05 mm (3/4") 990~1210

22.23 mm (7/8") 990~1210

4 Cut off any excess foam insulation.

5 If necessary, bend the pipe round, along the bottom of the indoor unit and

out through the appropriate hole, taking care to ensure that:

◆ The piping does not jut out from the rear of the indoor unit

◆ The bending radius is 100 mm or more

6

It would be necessary to double the insulation thickness(10mm or

more) to prevent condensation even on the insulator when if the

installed area is warm and humid.

There are two refrigerant pipes of different diameters:

◆ A smaller one for the liquid refrigerant

◆ A larger one for the gas refrigerant

A short length of piping is already fitted to the air conditioner. You

must extend this piping using assembly piping (optionally supplied).

The connection procedure for the refrigerant piping varies according

to the exit position of the piping from the indoor unit, as seen when

facing the air conditioner in position on the wall:

◆ Right (A)

◆ Left (B)

◆ Underside (C) ; ✴✴052/070/072✴✴

◆ Rear

1 With a knife, cut out the appropriate knock-out piece on the rear of the

indoor unit (unless you are connecting directly from the rear).

2 Smooth the cut edges.

3 Remove the protection caps on the pipes and connect the assembly piping

to each pipe, tightening the nuts, first manually and then with a wrench,

applying the following torque.

A

B

C

Cutting / Flaring the Pipes

E-13

ENGLISH

Outer Diameter Torque (kgf•cm)

6.35 mm (1/4") 144~176

9.52 mm (3/8") 333~407

12.70 mm (1/2") 504~616

15.88 mm (5/8") 630~770

19.05 mm (3/4") 990~1210

22.23 mm (7/8") 990~1210

Make sure that you have the required tools available (pipe cutter, reamer,

flaring tool and pipe holder).

1

If you wish to shorten the pipes, cut it with a pipe cutter, taking care to

ensure that the cut edge remains at a 90° angle with the side of the pipe.

Refer to the illustrations below for examples of edges cut correctly and

incorrectly.

2

To prevent any gas from leaking out, remove all burrs at the cut edge of the

pipe, using a reamer.

3

Slide a flare nut on to the pipe and modify the flare.

4

Check that the flaring is correct, referring to the illustrations below for

examples of incorrect flaring.

5

Align the pipes and tighten the flare nuts first manually and then with

a wrench, applying the following torque.

6

Outer Diameter (D) Depth (A)

6.35 mm (1/4") 1.3mm

9.52 mm (3/8") 1.8mm

12.70 mm (1/2") 2.0mm

15.88 mm (5/8") 2.2mm

19.05 mm (3/4") 2.2mm

22.23 mm (7/8") 2.2mm

90

O

Oblique Rough Burr

Inclined Damaged Surface Cracked Uneven Thickness

◆

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

In case of welding the pipe, you must weld with nitrogen

gas blowing.

Performing Leak Test & Insulation

To check for gas leaks on the indoor unit, check the connection part

of each refrigerant pipe by using a leak detector.

Once you have checked that there are no leaks in the system,

you can insulate the piping and hose.

To avoid condensation problems, place T13.0 or thicker Acrylonitrile

Butadien Rubber separately around each refrigerant pipe.

1

Wind insulating tape around the pipes.

2

Finish wrapping insulating tape around the rest of the pipes leading to the

outdoor unit.

3

◆

Always make the seam of pipes face upwards.

NNNNoooottttee

ee

Leak Test

Insulation

Insulation

Be sure to overlap

the insulation

Indoor Unit

CCCCAAAAUUUUTTTTIIIIOOOONN

NN

Must fit tightly against

body without any gap.

No gap

NBR(T13.0 or thicker)

E-14

Drain Hose Installation

E-15

ENGLISH

To install the drain hose, proceed as follows.

1 If necessary, connect the 2-metre extension to the drain hose.

2 If you are using the extension, insulate the inside part of the extension

drain hose with a shield.

3 Pass the drain hose under the refrigerant piping, taking care to keep the

drain hose tight.

4 Pass the drain hose through the hole in the wall, making sure that it is

sloping downwards, as shown in the illustrations above.

Care must be taken when installing the drain hose for the indoor unit to ensure that any condensation

water is correctly drained outside. When passing the drain hose through the 65 mm hole drilled in the

wall, check that none of the following situations occur.

The hose must

NOT slope

upwards.

The end of the drain

hose must NOT be

placed in water.

Do NOT bend the

hose in different directions.

Keep a clearance of

at least 5 cm between

the end of the hose

and the ground.

Do NOT place the

end of the drain hose

in a hollow.

5 cm

less

Ditch

Shield

Drain hose

Extension drain hose

Connecting the Connection Cord

Wiring Diagram

The indoor unit is powered from the outdoor unit via the connection cord.

Remove the screw on the electrical component box and remove the cover

plate.

1

Route the connection cord through the side of the indoor unit and connect

the cable to terminals; refer to the figure below.

2

Route the other end of the cable to the outdoor unit through the ceiling &

the hole on the wall.

3

Reassemble the electrical component box cover, carefully tightening the

screw.

4

Indoor Unit

Outdoor Unit

PowerCommunication

Next Indoor unit(Power)

Next Indoor unit

(Communication)

E-16

Assigning Address to Indoor Unit

Before installing the indoor unit, assign an address to the indoor unit

according to the air conditioning system plan.

1

The address of the indoor unit is assigned by adjusting MAIN(SW02) and

RMC(SW01) rotary switches.

2

The MAIN address is for communication between the indoor unit and the outdoor

unit. Therefore, you must set it to operate the air conditioner properly.

3

It is required to set the RMC address if you install the wired remote controller

and/or the centralized controller.

4

If you install optional accessories such as the wired remote controller, centralized

controller, etc. see an appropriate installation manual.

5

If an optional accessory is not installed, you do not have to set the RMC

address. However, adjust K1 and K2 switches of the SW03 DIP switch to

"ON" position in this case.

6

Set the MAIN address by adjusting the rotary switch(SW02) from 0 to F. Each

indoor unit connected to the same outdoor unit must have different address.

i. e. If an indoor unit does not have an optional accessory and its MAIN address

is "4"

7

E-17

ENGLISH

K1 K2 K3 K4

K5 K6 K7 K8

K9

K10

K11

K12

SW03 SW04

SW05

SW01 RMC SW02 MAIN

K1 K2 K3 K4

K5 K6 K7 K8

K9

K10

K11

K12

SW03

SW04

SW05

SW01 RMC

SW02 MAIN

Additional Functions

E-18

Compensation for lost temperature in heating operation

◆ Reduces the difference between an actual room temperature and a sensed

temperature by the air conditioner when heating.

Adjusting filter cleaning cycle

◆ You can adjust the cycle for filter sign indicator.

K5 K6 K7 K8

SW04

K5 K6 K7 K8

SW04

K5 2°C compensation 5°C compensation

Switch No.

Switch ON Switch OFF

Control of electronic expansion valve at the indoor unit off

◆ When an indoor unit off makes refrigerant noise, set K11 to OFF position to

reduce the noise. However, if a distributor kit is installed, K11 must be at ON

position.

K9 K10

K1 1 K12

SW05

K11

Electronic expansion valve

step 80

Electronic expansion valve

step 0 (Sub cool control)

Switch No.

Switch ON Switch OFF

K6 1000 hours 2000 hours

Switch No.

Switch ON Switch OFF

Bio-pure Filter Installation (optional)

E-19

ENGLISH

The air conditioner can be fitted with a Bio-Pure or deodorizing filter to remove

minute dust particles or odours. The service life of the filter is approximately

three months depending on the time during which the air conditioner is used.

Bio-pure filter

Deodorizing filter

Deodorizing

filter

1

Bio-pure filter

1

Accessories

Insert the filter in the filter holder and press the three tabs until you hear

a click.

2

1

Open the front grille by pulling on the tabs on the lower right and left side

of the indoor unit.

3

Take out the existing filter and replace it with the new one.

4

Do not remove the packing from a bio-pure filter until you wish

to use the filter, as it will lose its properties.

NNNNoooottttee

ee

Remove the vinyl packing from the filter.

Troubleshooting

E-20

Displayed on appropriate indoor

unit which is operating

Displayed on appropriate indoor

unit which is operating

Displayed on appropriate indoor

unit which is operating

Displayed on appropriate indoor

unit which is operating

Displayed on outdoor unit

1. Error of indoor unit: Displayed

on the indoor unit regardless

of operation

2. Error of outdoor unit:

Displayed on the indoor unit

which is operating

Power reset

Error of temperature sensor in indoor unit

(OPEN/SHORT)

Error of heat exchanger sensor in indoor unit

Error of heat exchanger OUT sensor in indoor unit

Error of outlet temperature sensor in indoor unit

(OPEN/SHORT): For heat pump models only

Error of mixed operation

Error of indoor fan motor:

Below 450RPM for 15 minutes

Error of outdoor temperature sensor

Error of COND sensor

Error of DISCHARGE sensor

1. No communication for 2 minutes between

indoor unit and outdoor unit (communication error for more than 2 minutes)

2. Indoor unit receiving the communication

error from outdoor unit

3. Outdoor unit tracking 3 minute error

4. When sending the communication error

from outdoor unit due to the mismatching

of the communication numbers and

installed numbers after completion of

tracking (communication error for more

than 2 minutes)

XXX

XXX

XXXX

X

X

X

XXX

X

X

X

X

XX

X

X

● On Flickering X Off

Detection of errors

◆ If an error occurs during the operation, an LED flickers and the operation is stopped except the LED.

◆ If you re-operate the air conditioner, it operates normally at first, then detect an error again.

LED Display

Operating

Indicators

Abnormal conditions

Green Red

LED Display on the indoor unit

E-21

ENGLISH

LED Display

● On Flickering X Off

◆

If you turn off the air conditioner when the LED is flickering, the LED is also turned off.

◆

If you re-operate the air conditioner, it operates normally at first, then detects an error again.

Displayed on appropriate indoor

unit which is operating

Displayed on outdoor unit

Displayed on appropriate indoor

unit which is operating

Displayed on outdoor unit

Self-diagnostic error

(including the indoor unit not detected)

1.

Error of electronic expansion valve close

2.

Error of electronic expansion valve open

3. Breakaway of EVA OUT sensor

4. Breakaway of EVA IN sensor

5. Breakaway of COND MID sensor

6.

2nd detection of refrigerant completely leak

7.

2nd detection of high temperature COND

8.

2nd detection of high temperature DISCHARGE

9. COMP DOWN due to 2nd detection of

low pressure switch

10. Error of reverse phase

1 1.

Compressor down due to 6th detection of

freezing

12.

Self-diagnosis of condensation sensor (G8, G9)

13.

Compressor down due to condensation

ratio control

Error of float switch

Error of setting option switches for optional accessories

EEPROM error

EEPROM option error

X X

XX

XX

XXX

XX

X

Operating

Indicators

Abnormal conditions

Green Red

E-22

Troubleshooting (cont.)

Explanation

Display

Error of communication between the outdoor unit and the wired

remote controller

Error of communication between the indoor unit and the wired

remote controller

Breakaway of indoor unit eva sensor

Breakaway of indoor unit eva out sensor

Open error of electronic expansion valve

Close error of electronic expansion valve

Breakaway of eva mid and eva out sensors in indoor unit

Error of float switch

OPEN/SHORT error of room sensor in indoor unit

OPEN/SHORT error of eva in sensor in indoor unit

OPEN/SHORT error of eva out sensor in indoor unit

EEPROM error

EEPROM option error

Error of fan starting

Error of outdoor unit

Communication

errors

Displays related to

indoor unit

(x : 0~F)

For the details, refer to

the installation manual

of the outdoor unit.

Remark

The order of priority : EA→ Eb → Cx → dx → bx → Ax → Fx → ox → qx → rx → sx → tx → Ux → vx →Eo

- In case that the same error displays from multi-indoor units, the one having the faster address

has the priority.

x

x

x

x

x

x

x

x

x

x

x

x

Wired remote controller

◆ If an error occurs, is displayed on the wired remote controller.

◆ If you would like to see an error code, press the Test button.

■ Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

OO

OO

PPPPTTTTIIIIOOOONNNNAAAALL

LL

AA

AA

CCCCCCCCEEEESSSSSSSSOOOORRRRIIIIEEEESS

SS

Chapter

E-23

ENGLISH

Parts List

E-24

Wired remote

controller

1

Cable-tie2Cable clamp

5

M4x16 tapped

screw

7

Indoor unit power

drawing cable

1

Wired Remote Controller Accessories

Centralized

controller

1

Cable-tie2Cable clamp

5

M4x16 tapped

screw

7

Centralized Controller Accessories

Transmitter

1

Transmitter

power cable

1

Transmitter

communication cable

1

T ransmitter Accessories

Owner’s

instructions

1

Installation

manual

1

Function

controller

1

Cable-tie2Cable clamp

6

M4x16 tapped

screw

7

Function Controller Accessories

Owner’s

instructions

1

Installation

manual

1

Owner’s

instructions

1

Installation

manual

1

Installation

manual

1

Wireless

remote controller

1

Battery

2

Remote

control holder

1

STS 2S-2x10

tapped screw

2

Owner’s

instructions

1

Installation

manual

1

Wireless Remote Controller Accessories

Memo

E-25

ENGLISH

ELECTRONICS

THIS AIR CONDITIONER IS MANUFACTURED BY:

ESTE AIRE ACONDICIONADO HA SIDO FABRICADO POR:

CE CLIMATISEUR EST FABRIQUE PAR:

QUESTO CONDIZIONATORE D’ARIA È PRODOTTO DA:

ESTE APARELHO DE AR CONDICIONADO É FABRICADO POR:

DIESE KLIMAANLAGE IST FABRIZIERT VON:

AYTH H ™Y™KEYH KATA™KEYA™THKE A¶O:

щнйн дйзСасайзЦк абЙйнйЗгЦз оакейв:

Printed in Korea

Loading...

Loading...