SAMSUNG AS18A1UE Service Manual

ROOM AIR CONDITIONER

AS180UE

AS181UE

AS18A1UD

AS18A1UE

AS-2408BR

SERVICE

Manual

CONTENTSAIR CONDITIONER

1. Pre c a u t i o n s

2. Product Specifications

3. Operating Instructions and

I n s t a l l a t i o n

4. Disassembly and Reassembly

5. Tro u b l e s h o o t i n g

6. Exploded Views and Parts List

7. Block Diagrams

8. PCB Diagrams

9. Wiring Diagrams

10. Schematic Diagrams

© Samsung Electronics Co., Ltd. FEB. 1999.

Printed in Korea.

Code No. DB81-10161A(3)

1. Precautions

1) Remove power cable from power outlet.

Remove power cable from an outlet prior to disassembly for

repair.

When the power cable is removed wait for at least 1 minute

and measure the voltage between the + and - terminal of the

large capacity electrolyti capacitor using a tester. Make sure

that the voltage is less than DC 10V, then starts repairing.

2) Warning about electrical shock

If you cannot avoid checking the circuits with power not

disconnected pay special attention not to touch live parts to

avoid electric shock.

3) Use proper parts

Use genuine parts of a model if parts need to be replaced.

(It is recommended that parts are replaced rather than

repaired, to avoid electrical contact. Customers should

refrain from repairing parts themselves as this can be

extremely dangerous.)

4) Use proper tools

Use proper tools for repair and be familiarized with

handling test equipment.

Using worn out tools may result in problems such as

intermittent contact, etc.

dangerous

5) Lead wire or power cable damaged

Check if lead wire or power cord is damaged prior to repair,

and replace if damaged.

6) Avoid tapping a power cord

Tapping a power cable or using an extension cord from a

power outlet is dangerous and should be avoided. It may

result is malfunctioning or fire.

7) Checking insulation

Be sure to check insulation resistance when assembly is

completed. (Check insulation resistance between the power

cord plug and ground terminal using an ohm meter and

check if it is greater than 30MΩ prior to applying the power.)

8) Check grounding

Check grounding status and fix it if not sufficient.

9) Check installation condition

Check installation condition and fix insufficient conditions.

If it is still not satisfactory find another area for installation.

10) Child care

It is recommended to have children stay away the units

when the repair is being done to avoid accidents.

Cleaning

No

inter connection

Brilliantly

Clean the unit and the area arount it.

Let the customer know that the unit has been repaired.

Samsung Electronics

1-1

M E M O

1-2

Samsung Electronics

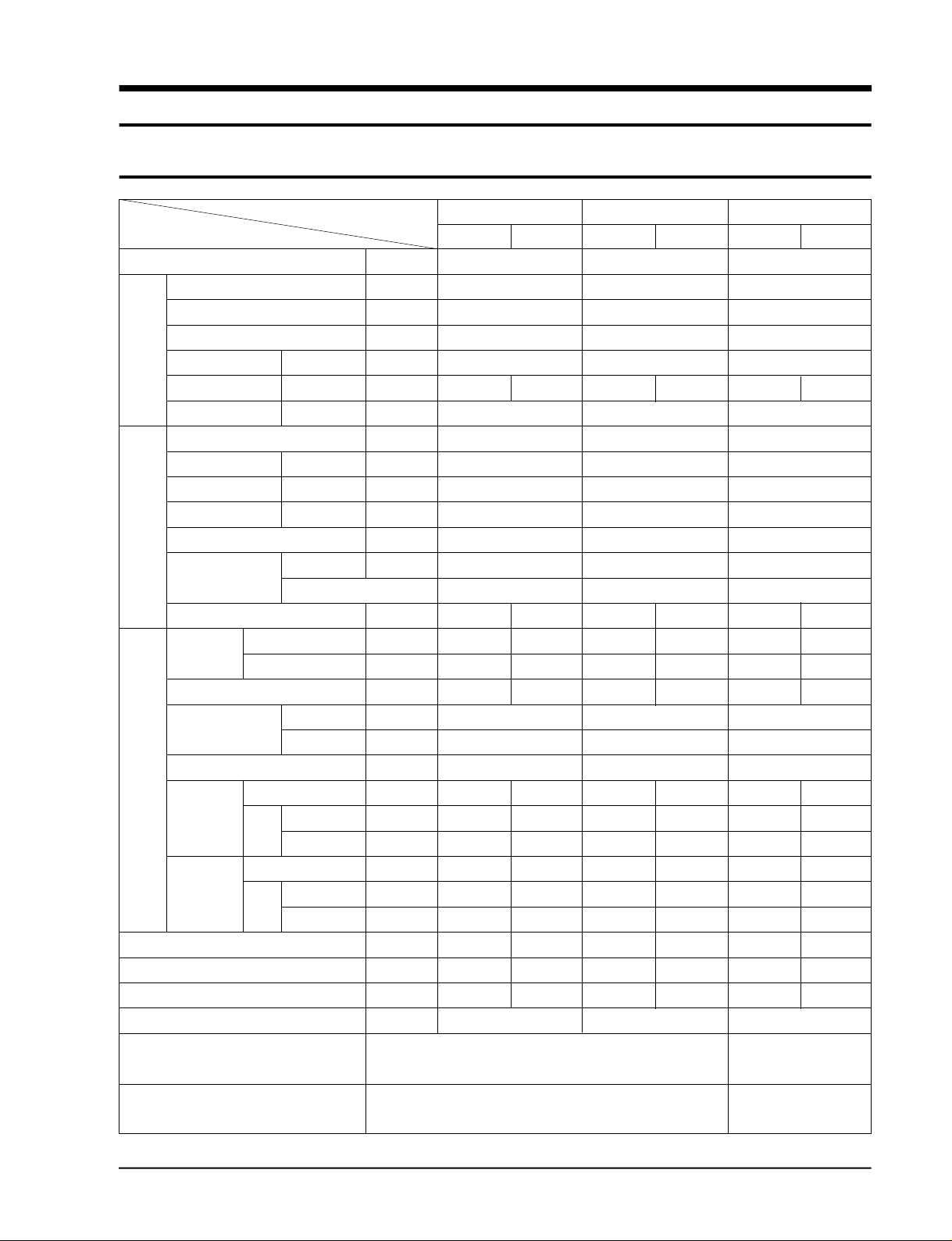

2. Product Specifications

2-1 AS180UE/AS181UE/AS18A1UE/AS18A1UD/AS-2408BR

I t e m

Ty p e C o o l i n g B T U / h

D e h u m i d i t y i n g l/ h

P e rf o rm a n c e

P o w e r

E l e c t r i c a l

C h a r a c t e r i st i c s

P ro d u c t

Maximum operation Condition

“*” : Tailand Only

Low temp. heating B T U / h

Air volume C o o l i n g m3/ m i n

N o i s e C o o l i n g d B

E n e rgy efficiency ratio C o o l i n g B T U / h . W

Power V- H z

Power Consumption C o o l i n g W

Operating Curre n t C o o l i n g A

Power factor C o o l i n g %

S t a rting curre n t A

Power cable L e n g t h m

Number of core wire

Fuse capacity A

Outer Width x Height m m

dimension x Depth i n c h

We i g h t k g

Coolant pipe L i q u i d OD(mm) x L(m)

C o o l a n t OD(mm) x L(m)

Drain hose ID(mm)x L(m)

C o m p ressor Ty p e

M o t o r Ty p e

Rated input W

Blower Ty p e

M o t o r Ty p e

Rated input W

Heat exchanger

Coolant control unit

F reezer oil capacity c c

Coolant to charg e ( R - 2 2 ) g

Cooling test Condition

M o d e l

A S 1 8 0 U E / A S 1 8 1 U E / A S 1 8 A 1 U E

Indoor unit Outdoor unit

Wa l l - m o u n t i n g

1 7 , 5 0 0 ( * 1 7 , 0 0 0 )

1 . 6

-

1 3 . 8

4 5 5 5

9 . 7 ( * 9 . 4 )

1-220 / 240-50

1 8 0 0

8 . 0

93.8 (at 240V)

4 0

6 . 2

3G x 2.5mm2/ A re a

3 . 1 5 1 0 5 0 x 2 9 8 x 1 8 0 7 8 7 x 6 2 0 x 3 2 0

4 1 . 3 4 x 1 1 . 7 3 x 7 . 0 9 3 0 . 9 8 x 2 4 . 4 x 1 2 . 6

1 3 4 6

ø6.35 x 5

ø12.7 x 5

ø17 x 2

- R o t a ry

- -

- 1 8 5 5

C ro s s - f a n P ro p e l l e r

R e s i n S t e e l

3 0 6 0

2Row 12Step 2Row 24Step

C A P I L L A RY TUBE

6 0 0

1 , 5 8 0

INDOOR UNIT : DB 27°C W B 1 9 ° C

OUTDOOR UNIT : DB35°C W B 2 4 ° C

INDOOR UNIT : DB 32°C W B 2 3 ° C

OUTDOOR UNIT : DB 43°C W B 2 6 ° C

AS18A1UD

Indoor unit Outdoor unit

Wa l l - m o u n t i n g

17,000 (5,000W)

4 5 5 5

1-200 / 220-50

3G x 2.5mm2/ A re a

3 . 1 5 1 0 5 0 x 2 9 8 x 1 8 0 7 8 7 x 6 2 0 x 3 2 0

4 1 . 3 4 x 1 1 . 7 3 x 7 . 0 9 3 0 . 9 8 x 2 4 . 4 x 1 2 . 6

1 3 4 6

- R o t a ry

- -

- 1 8 5 5

C ro s s - f a n P ro p e l l e r

R e s i n S t e e l

3 0 6 0

2Row 12Step 2Row 24Step

1 . 6

-

1 3 . 8

9 . 2

1 8 5 0

9 . 3

90.9 (at 220V)

4 0

6 . 2

ø6.35 x 5

ø12.7 x 5

ø17 x 2

C A P I L L A RY TUBE

1 , 1 8 0

AS-2408BR

Indoor unit Outdoor unit

Wa l l - m o u n t i n g

4 6 5 6

1 - 2 2 0 - 6 0

3G, AW G 1 4

3 . 1 5 1 0 5 0 x 2 9 8 x 1 8 0 7 8 7 x 6 2 0 x 3 2 0

4 1 . 3 4 x 1 1 . 7 3 x 7 . 0 9 3 0 . 9 8 x 2 4 . 4 x 1 2 . 6

1 3 4 6

ø6.35 x 5

ø15.8 x 5

- R o t a ry

- -

- 2 1 5 7

C ro s s - f a n P ro p e l l e r

R e s i n S t e e l

3 0 6 0

2Row 12Step 2Row 24Step

6 0 0

INDOOR UNIT : DB 27°C W B 1 9 . 5 ° C

OUTDOOR UNIT : DB35°C W B 2 4 ° C

INDOOR UNIT : DB 32°C W B 2 2 . 5 ° C

OUTDOOR UNIT: DB 43°C W B 2 5 . 5 ° C

2 2 , 0 0 0

2 . 8

-

1 4 . 3

1 0 . 5

2 1 0 0

1 0 . 0

9 5 . 4

5 0

6 . 2

ø17 x 2

C A P I L L A RY TUBE

6 0 0

1 , 6 5 0

Samsung Electronics

2-1

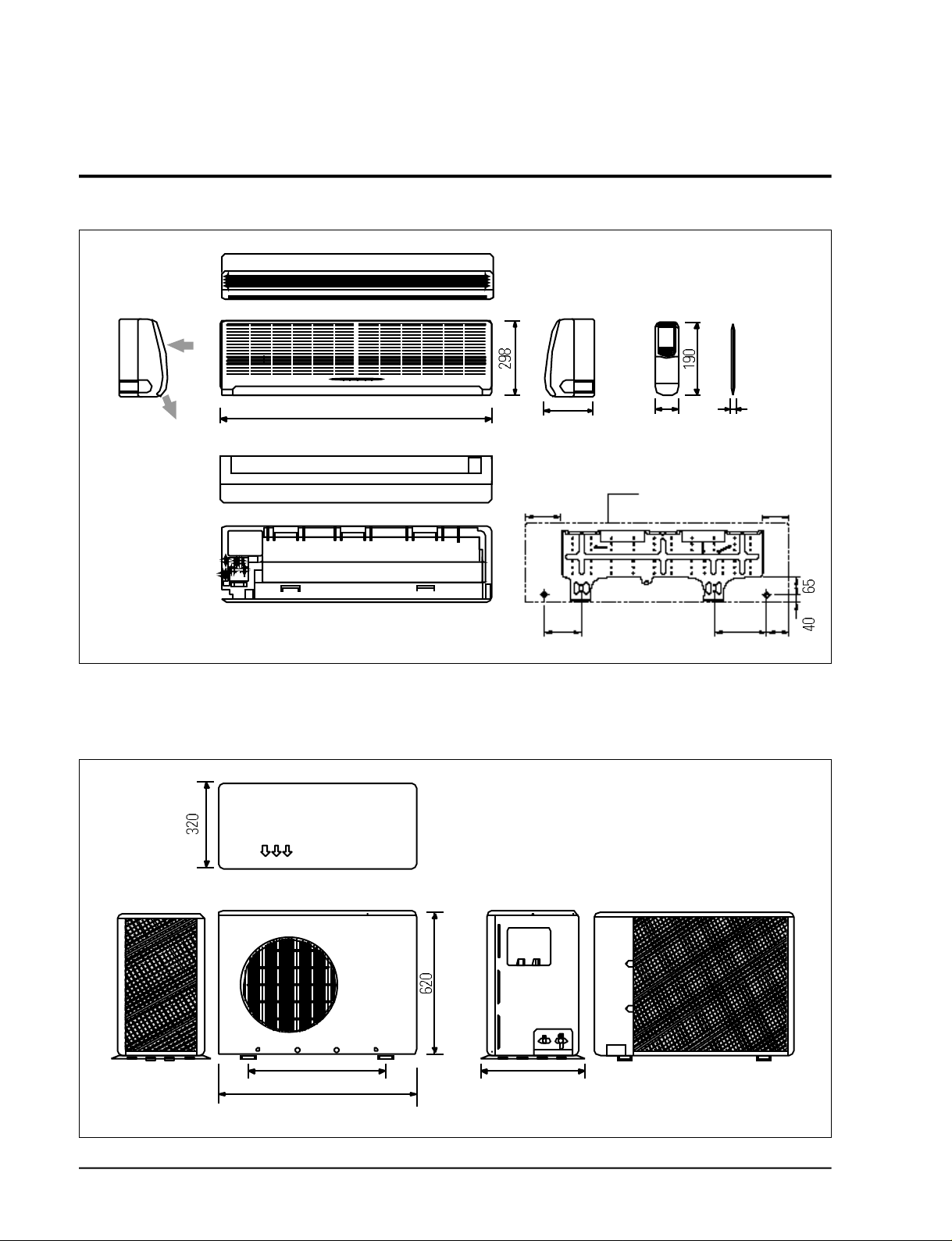

2-2 Dimensions

2-2-1 Indoor Unit

Air out

(Front view)

Air

in

(Rear view)

1050

unit : mm

(Remote control unit)

180 63

21

(Installation plate)

outer edge of

250 145

260 200 100

indoor unit

2-2-1 Outdoor Unit

2-2

(Front view) (Rear view)

582 340

787

Samsung Electronics

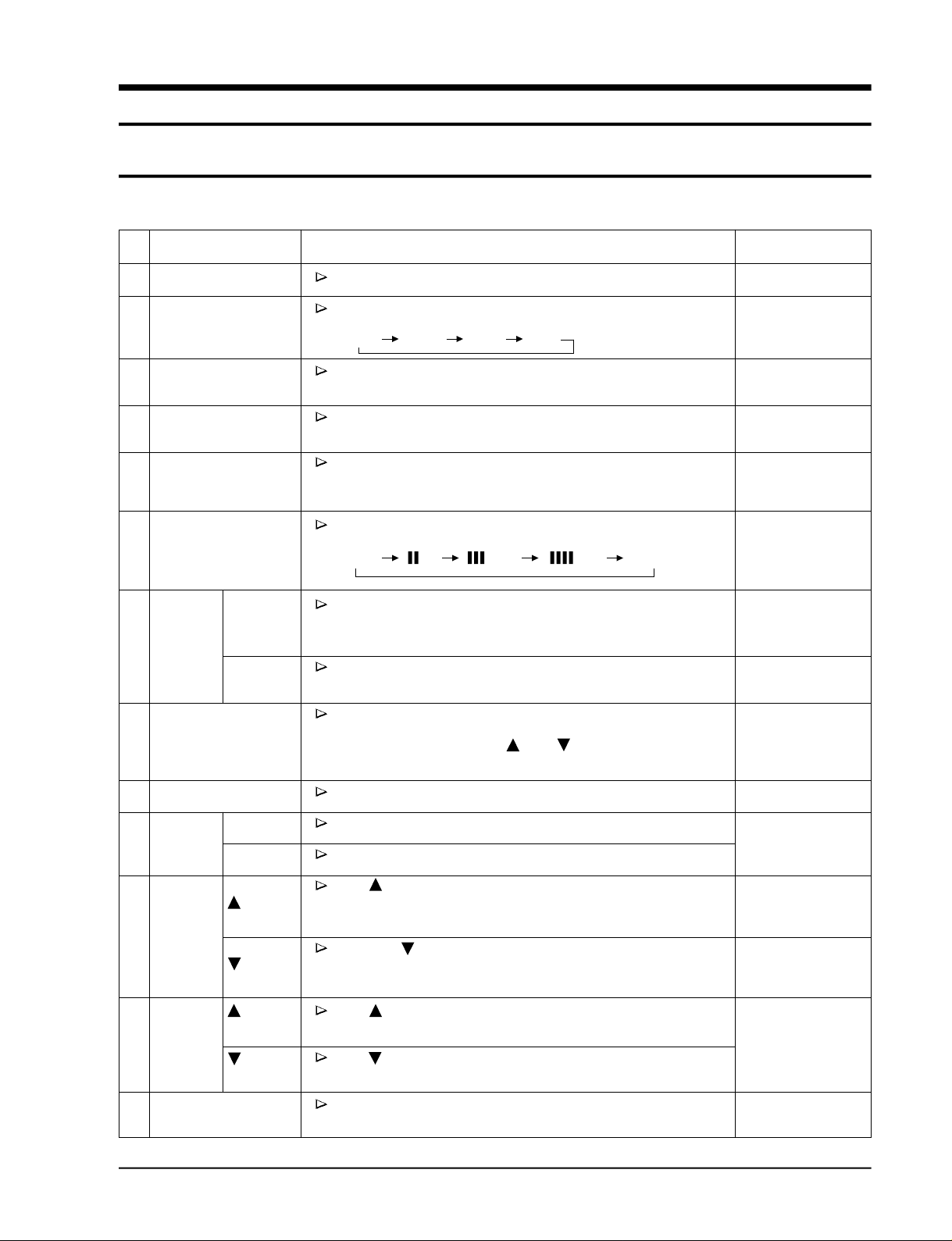

3. Operating Instructions and Installation

3-1 Operating Instructions

3-1-1 Name & Function of Key in remote controller

NO

NAMED OF KEY

1

2

3

4

5

6

7

FAN SPEED

SWING

ON/OFF

MODE

TURBO

MILD

Q. TIMER

SET

AUTO

Use this button to start and stop air conditioner.

Each time you press this button,

MODE is changed in the following order.

"AUTO" "COOL" "DRY" "FAN"

Use this button to provide heavy duty cooling

for 30 minutes.

Use this button to provide pleasant cooling

for 3 hours.

Set up the reserve or cancel the timer on and timer off quickly.

Each time you press this button,

FAN SPEED is changed in the following order.

"AUTO" " (L)" " (ME)" " (HI)" NATURAL

Adjusts air flow vertically.

Each time you press this button,

BLADE-H rotates by 8° (Changable range 50°).

Each time you press this button,

BLADE-H rotates within 35° and stop.

FUNCTION OF KEY

ONE SHOT KEY

ONE SHOT KEY

OR

CONTINUOUS KEY

ONE SHOT KEY

ONE SHOT KEY

ONE SHOT KEY

OR

CONTINUOUS KEY

ONE SHOT KEY

OR

CONTINUOUS KEY

ONE SHOT KEY

OR

CONTINUOUS KEY

ONE SHOT KEY

10

12

11

13

8

9

TIME

TIMER/CANCEL

TIMER

TIME

TEMP

SLEEP

ON

OFF

(UP)

(DOWN)

(UP)

(DOWN)

Without regard to ON/OFF condition in remote controller,

use this button to set current time.

Adjust the current time using TIME button.

(Data can be transmitted after setting up the time)

Use this button to reserve or cancel the timer on and timer off.

Set up the time that operation start.

Set up the time that operation stop.

If the TIME button is pressed once, the time increase by one

minute during the time set mode, and ten minutes during the

timer set mode.

If the TIME button is pressed once, the time decrease by one

minute during the time set mode, and ten minutes during the

timer set mode.

If the button is pressed once,

the setting temperature is increased by 1°C.

If the button is pressed once,

the setting temperature is decreased by 1°C.

Use this button for sleep operation.

(The SLEEP mode can be selected at COOL mode.

ONE SHOT KEY

ONE SHOT KEY

ONE SHOT KEY

ONE SHOT KEY

OR

CONTINUOUS KEY

ONE SHOT KEY

OR

CONTINUOUS KEY

ONE SHOT KEY

OR

CONTINUOUS KEY

ONE SHOT KEY

Samsung Electronics

3-1

Operating Instructions and Installation

3-1-2 Main controller function.

1. A U TO MODE: In this mode, operation

mode (COOL) is selected automatically by

the room temperature of initial operation.

Operation Type

Cool Operation (Set Temp:24°C + ∆T)

∆T= -1°, -2°C, 0°C, +1°C, +2°C

∆T is controlled by setting temperature

up/down key of remote contro l l e r

2. C O O L MODE: The unit operates accord i n g

to the diff e rence between the setting and

room temperature .

The setting temperature range is

1 8 ° C t h rough 30°C.

3. D RY MODE: The unit is operated at comp ressor on state re g a rdless of room tempera t u re for an initial 30 minutes of dehumidification operation, and the indoor fan motor

is automatically operated due to the tempera t u re diff e rence between the room temperat u re and set temperature .

The compressor is automatically contro l l e d

due to the temperature diff e rence between

room temperature and set temperature after

operation of 30 minutes.

* Set temperature: 18°C~30°C

* Protective function: Low temperature

release. (Prevention against fre e z e )

4. TURBO MODE: This mode is available only

in A U TO, COOL m o d e .

When this button is pressed at first, the air

conditioner is operated “powerful” state for

30 minutes re g a rdless of the set temperat u re, room temperature .

When this button is pressed again, or when

the operating time is 30 minutes, turbo

operation mode is canceled and returned to

the previous mode.

5 . MILD MODE: This mode is available only

in A U TO, COOL m o d e .

When this button is pressed at first, the air

conditioner is operated in its current state

for 3 hours.

The setting temperature is automatically

raised by 3°C.

When this button is pressed again or when

the operating time is 3 hours, mild operation mode is canceled and returned to the

p revious mode.

6 . S L E E P MODE: Sleep mode is available only

in COOL m o d e .

The operation will stop after 6 hours.

* In COOL mode : The setting temperature

is automatically raised by 1°C each 1hour

When the temperature has been raised by

total of 2°C, that temperature is maint a i n e d .

7. FAN SPEED: Manual (3 step), Auto (4 step),

N a t u r a l

Fan speed automatically varies depending

on both the diff e rence between setting and

the room temperature .

8 . C O M P U L S O RY O P E R ATION:

For operating the air conditioner without

the remote contro l l e r.

The operating is the same function that

A U TO MODE in the remote contro l l e r.

* Set temperature: 22°C

3-2

Samsung Electronics

Operating Instructions and Installation

9 . SWING: BLADE-H is rotated vertically by

the stepping motor.

* Memory louve: When ON/OFF button is

p ressed at stop state, the BLADE-H re t u r n s

to its original location which is operating

state before stop.

* Swing auto: The BLADE-H can ro t a t e

within about 35° in the original position set

by the SWING SET button.

* Swing set: Press the SWING SET button,

then the blade rotates vertically by 8°

The BLADE-H location is dispalyed on

REMOTE CONTROL. (total 7 steps)

1 0 . Q.TIMER: Q. timer (quick timer) allows

reservation or cancel the timer on and timer

o ff quickly.

When Q.timer button is pressed at operating state, LCD displays the polling state

s e q u e n t i a l l y.

The LCD also displays the time re m a i n i n g .

1 2 . SELF TEST

* Interruption of electric power and Power

o n .

* Abnormal condition of the room sensor.

* Indoor unit fan motor lock.

* Abnormal condition of the indoor unit's

heat exchanger sensor.

1 3 . TIME SHORTENING: If the "Time short"

connector pin is shorted on the main P. C. B,

the compressor's three minutes delay function is cancelled, and each operation time is

shortened to one fiftieth of its original time.

1 4 . BUZZER SOUND: Whenever the ON/OFF

button is pressed or whenever change

occurs to the condition which is set up or

select, the compulsory operation mode,

buzzer is sounded "beep".

11 . TIMER: The air conditioner is turned

ON/OFF at a specified time using TIMER

O N / O F F.

* Timer LED lights on.

Samsung Electronics

3-3

3-2 Installation

3-2-1 Selecting Area for Installation

Select an area for installation that is suitable

to the customer's needs.

3-2-1(a) Indoor Unit

1 . Make sure that you install the indoor unit in

an area providing good ventilation. It must

not be blocked by an obstacle affecting the

airflow near the air inlet and the air outlet.

2 . Make sure that you install the indoor unit in

an area allowing good air handling and

endurance of vibration of the indoor unit.

3. Make sure that you install the indoor unit in

an area where there is no source of heat or

vapor nearby.

4 . Make sure that you install the indoor unit in

an area from which hot or cool air is spre a d

evenly in a ro o m .

5 . Make sure that you install the indoor unit in

an area away from TVs, audio units, cordless phones, fluorescent lighting fixture s

and other electrical appliances (at least 1

m e t e r ) .

6 . Make sure that you install the indoor unit in

an area which provides easy pipe connection with the outdoor unit, and easy

drainage for condensed water.

7. Make sure that you install the indoor unit in

an area which is large enough to accomodate the measurements shown in figure on

the next page.

3-2-1(b) Outdoor Unit

1 . Make sure that you install the outdoor unit

in area not exposed to the rain or direct sun

l i g h t .

(Install a separate sunblind if exposed to

d i rect sun light.)

2 . Make sure that you install the outdoor unit

in area allowing good air moment, not

amplifying noise or vibration, especially to

avoid disturbing neighbours.

(Fix the unit firmly if it is mounted in a

high place.)

3 . Make sure that you install the outdoor unit

in area providing good ventilation and

which is not dusty. It must not be blocked

by any obstacle affecting the airflow near

the air inlet and the air outlet.

4 . Make sure that you install the outdoor unit

in area free from animals or plants.

5 . Make sure that you install the outdoor unit

in area not blocking the traff i c .

6. Make sure that you install the outdoor unit

in area easy to drain condensed water fro m

the indoor unit.

7. Make sure that you install the outdoor unit

in area which provides easy connection

within the maximum allowable length of a

coolant pipe (10 meters).

Note

1. Add 10 grams of refrigerant (R-22) for

every 1 meter if the pipe length exceeds

the standard pipe length of 5 meters.

2. Maintain a height between the indoor and

outdoor units of less than 3 meters.

8 . Make sure that you install the outdoor unit

in an area which is large enough to accommodate the measurements

shown in figure on the next page.

3-2-1(c) Remote Control Unit

1 . Make sure that you install the remote con-

t rol unit in an area free from obstacles such

as curtains etc, which may block signals

f rom the remote control unit.

2. Make sure that you install the remote cont rol unit in an area not exposed to

d i rect sunlight, and where there is no sourc e

of heat.

3. Make sure that you install the remote cont rol unit in an area away from TVs, audio

units, cordless phones, fluorescent lighting

f i x t u res and other electrical appliances (at

least 1 meter).

Caution :

It is harmful to the air conditioner if it is used in the following environments: greasy areas (including areas near machines),

salty areas such as coast areas, areas where sulfuric gas is present such as hot spring areas. Contact your dealer for advice.

3-4

Samsung Electronics

Operating Instructions and

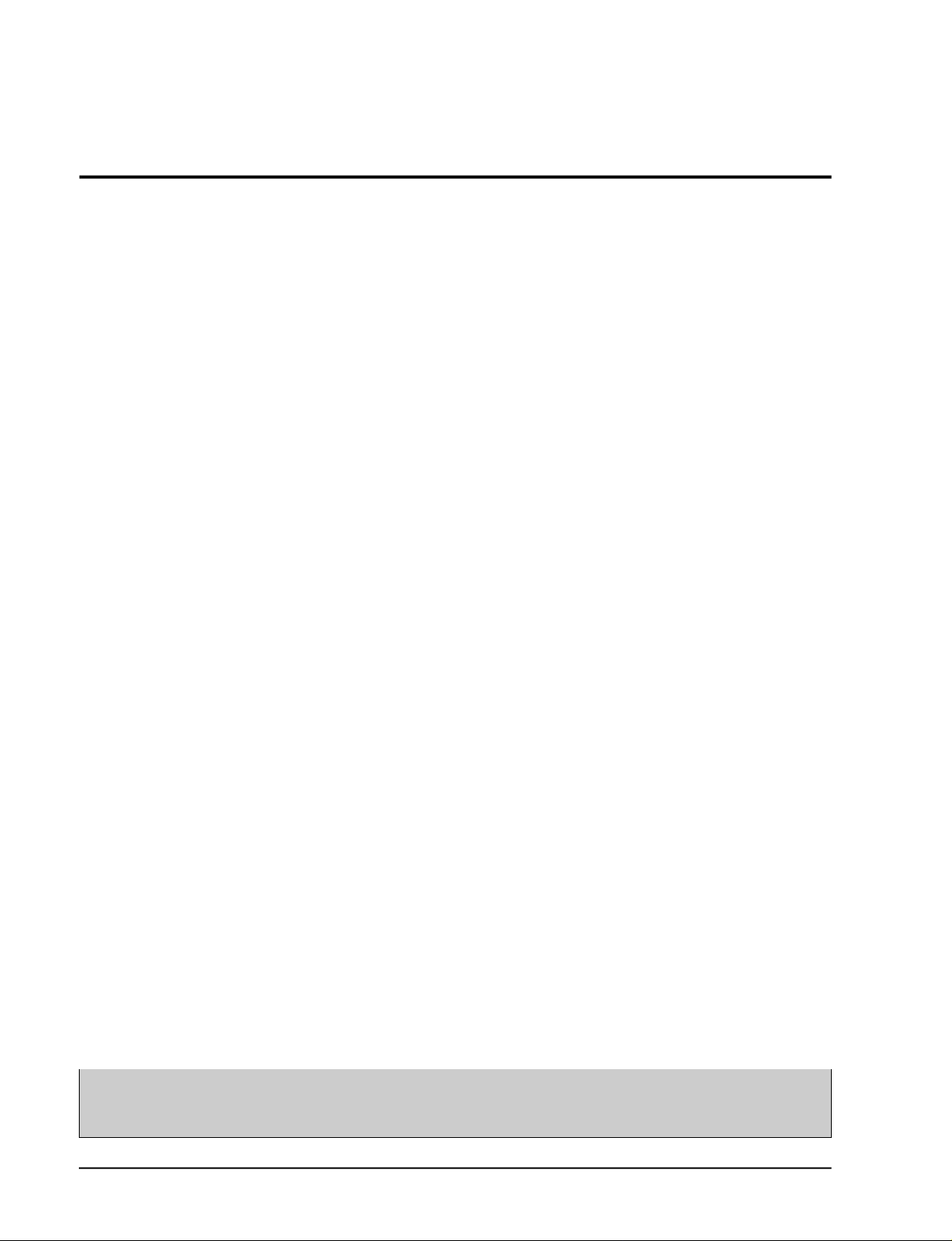

3-2-2 Installation diagram of indoor unit and outdoor unit

GAS LEAK TEST Slope of drain hose * Piping may be laid to the rear, left, right or down.

Avoid up

Indoor unit check

points

slopes

Right

Left

Outdoor unit

check points

* Check for gas leak from the flare nut

connections with leak detector.

5 6

250mm

m i n i m u m

4

Rear

Down

Insulation of pipe connection area

* Perform gas leakage test first, and insulate the pipe

connection area.

Use an insulation tube for insulation as shown in figure.

The insulation

tube shall be

properly finished

not to allow

any gap.

Left rear

350mm or more

Vinyl tape

(purchase locally)

Remote control

Remote control holder

Hole dimension of bolts for the outdoor unit

Insulation

tube

Coolant adjustment pro c e d u re

C l a s s

C o n n e c t i o n

pipe lengh

A i r- p u rg e

m e t h o d

C o o l a n t

a d j u s t m e n t

u n n e c e s s a ry

5m max

Refer to the

detailed

a i r- p u rg e

p ro c e d u re .

Add 10g of

c o o l a n t

5 ~ 1 0 m

<R-22> for

e v e ry 1m.

(Refer to

the detailed

c o o l a n t

c h a rg e

p ro c e d u re . )

Samsung Electronics

Air purg e

m e t h o d

P u rge air

using

a vacuum

pump or an

a d d i t i o n a l

c o o l a n t

c y l i n d e r.

R e f r i g e r a n t

q u a n t i t y

See table

r i g h t .

Add 10g of

c o o l a n t

<R-22> for

e v e ry 1m.

(Refer to

the detailed

c o o l a n t

c h a rg e

p ro c e d u re . )

10

Fix firmly if installed in an area affected by typhoons.

582

Coolant adjustment pro c e d u re

Outer diameter Fixing torque Final torque

ø6.35mm 160 200

ø12.7mm 500 550

ø15.8mm 700 750

Tighten the flare nut by hand first, and tighten firmly with a spanner

ø12

kg .cmAt installation At installation

3-5

Operating Instructions and Installation

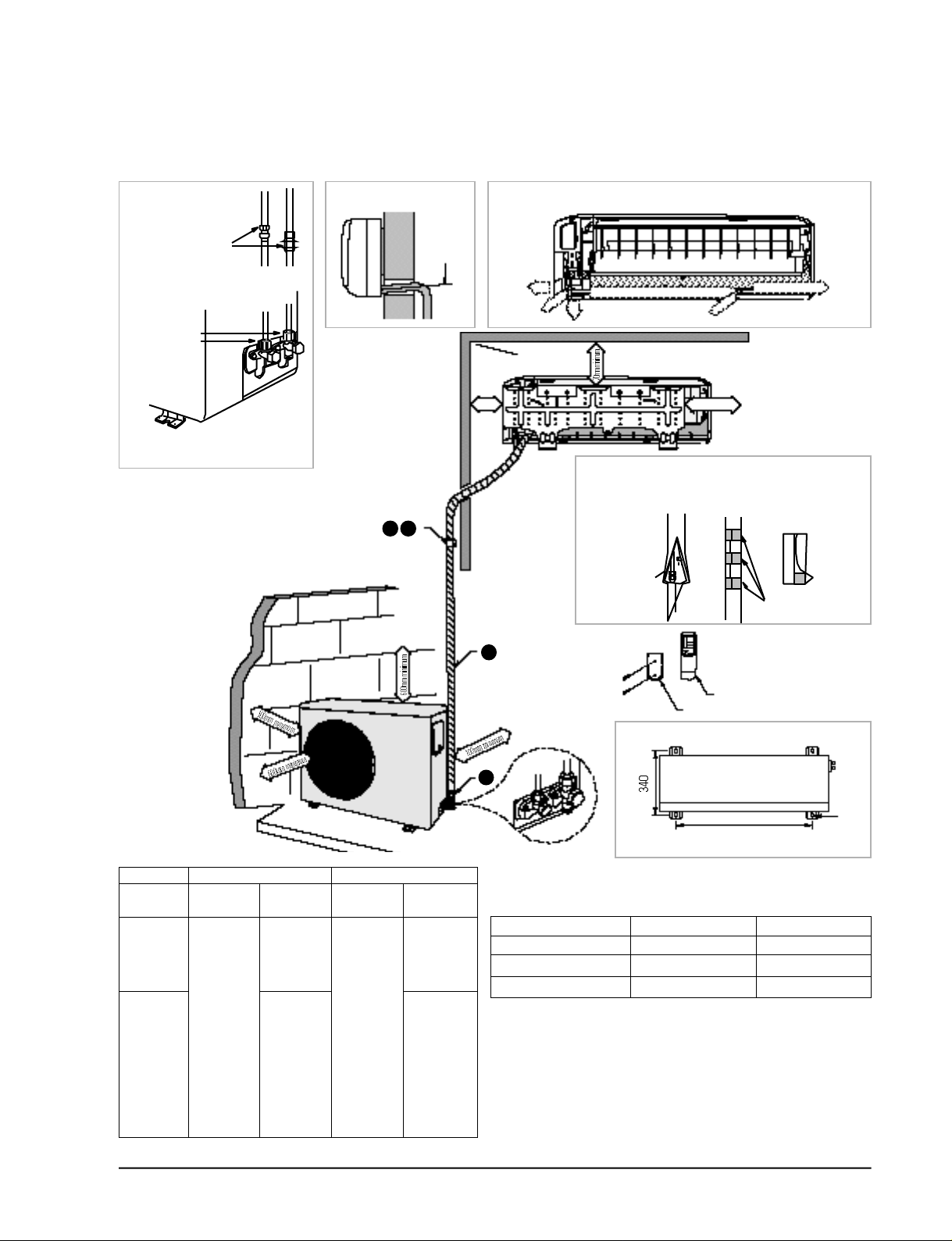

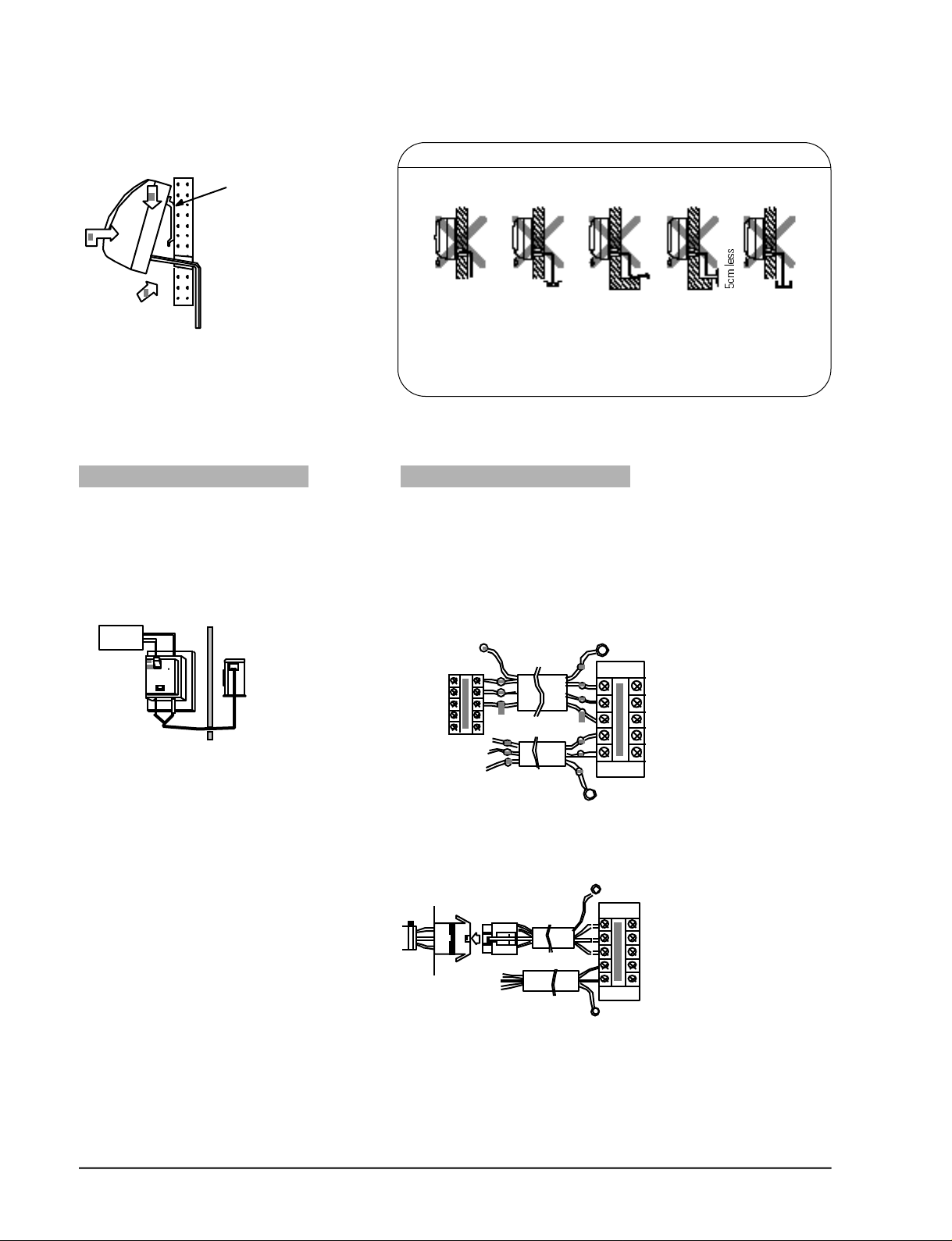

3-2-2(a) Fixing the Installation Plate

CUTTING A HOLE

When the refrigerant piping are hooked up from the rear.

Installation plate

Pipe hole (ø65mm)

MOUNTING THE INSTALLATION PLATE

When the installation plate is directly mounted on the wall.

250mm 145mm

Pipe hole

(ø65mm)

260mm

Installation plate

Indoor unit

Weight

200mm 100mm

Determine the pipe hole position for installation

and drill the pipe hole (65mm inner diameter)

so that it slants slightly downward.

1. Install the installation plate horizontally on

structural members (studs, etc.) in the wall.

2. To mount the installation plate on a concrete

wall with anchor bolts, utilize the anchor bolt

holes as illustrated in the left figure.

250mm350mm

3. When the anchor bolts are already driven in the

wall, also utilize the anchor bolts holes to secure

the installation plate. (If an anchor bolt is too

long, adjust the projecting length to 20mm or

less.)

Mounting at the window frame.

3-6

1. As the left Fig.

Fix the wood pillar at the wood frame and

install installation plate with screw tap.

2. Fix the wood pillar with enough strength to

bear the weight of the indoor unit.

Wood pillarScrew wood

Samsung Electronics

Operating Instructions and Installation

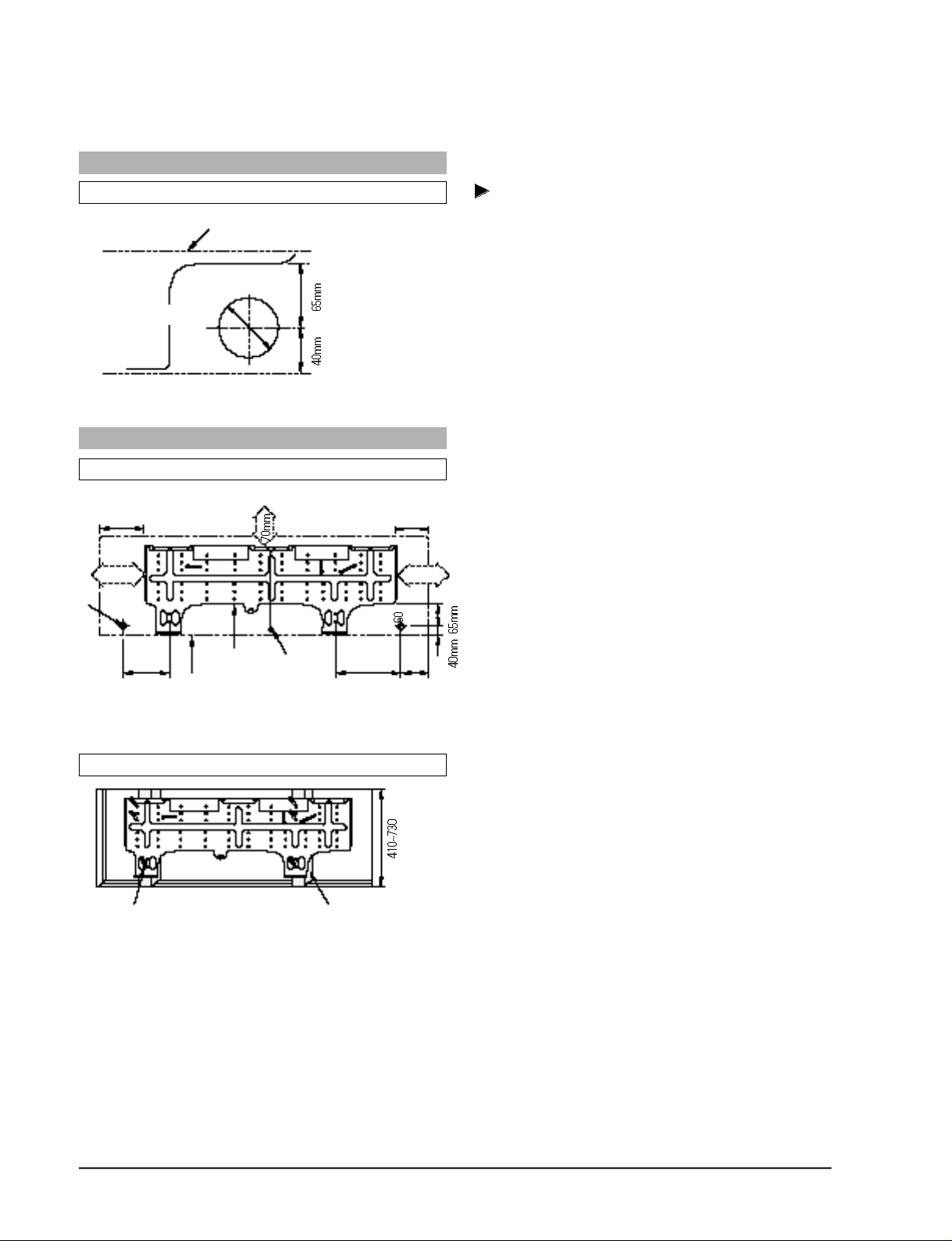

3-2-2(b) Wiring connection(Indoor unit)

1. Open the Grille and remove the

screw securing the cover.

AS-24**

2. AS-18**: Pass the assembly cable

through the rear of the indoor

unit and connect the assembly

cable to terminals 1~3.

*Each wire is labelled with the

corresponding terminal number.

AS-24**: Firmly connet the cable

connector with connector.(6pin,

4-cable)

3. Assembly every parts by contrary

order to disassembly.

3-2-2(c) Piping and drain hose installation

1 . Fix the drain hose right the refrigerant piping.

2. Be careful not to form a slack of the drain hose.

3. Do not allow the piping to jut out from the back of the indoor unit.

4. Insulate both of the refrigerant pipings so that dewing and troubles

may not happen.

5. Be careful in bending the pipes. The bending radius must be

100mm or larg e r.

Conneitor

AS-18**

Indoor

unit

Outdoor

unit

Screw

Tape

Piping

Drain hose

Assembly cable

A.Right-hand connection with piping C.Under-side connection with pipingB.Left-hand connection with piping

1. Cut out the knock-out piece from the

rightside of the rear body with a knife,

etc. Smooth the cut edges.

1. Cut out the knock-out piece from the

leftside of the rear body with a knife,

etc. Smooth the cut edges.

2. Cut out the Holder-pipe slit part.

3. Support the above section to be bent

with your hand and bend the pipes

there.

A

C

B

1. Cut out the knock-out piece from the

underside of the rear body with a knife,

etc. Smooth the cut edges.

2. Cut out the Holder-pipe on its slit part.

Set the drain hose in the inner part of the

indoor unit and the assembly cable in lower part of it.

Wind tape round them.

Piping

Assembly cable

Installation plate

Drain hose

Samsung Electronics

3-7

Operating Instructions and Installation

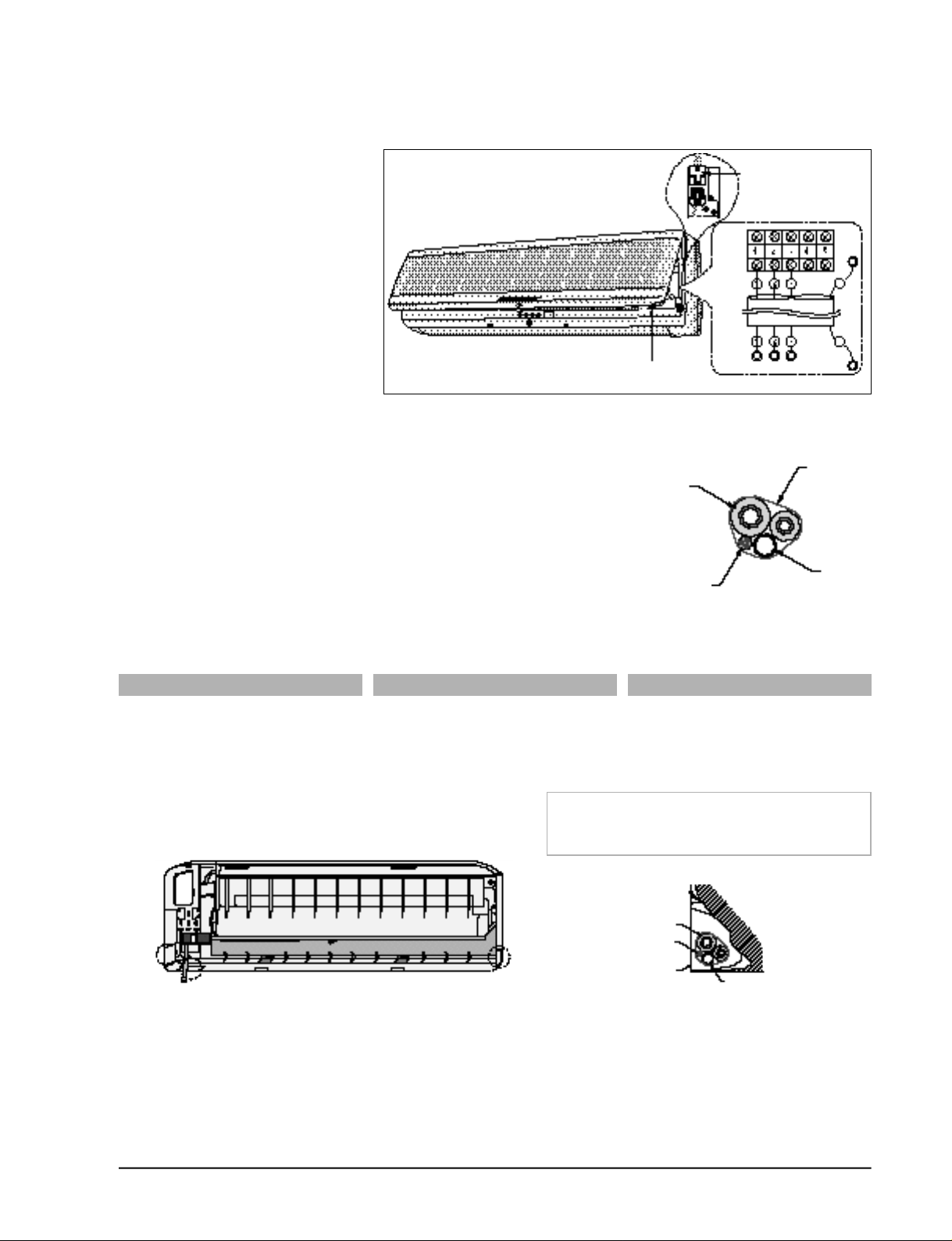

3-2-2(d) Indoor unit installation

DRAINAGE

1. Pass the pipes

Hook

here

t h rough the

hole in the

wall and hook

the indoor

unit to the

i n s t a l l a t i o n

plate at the

upper and

lower hooks.

2. Move the indoor unit to the right and

left to make sure that the unit is

s e c u rely hooked on to the installation

p l a t e .

1. Run the drain hose sloped downward .

2. Do not install the drain hose as illustrated below.

Do not form

a rise

3. Put water in the drain pan and make sure that the water is drained outdoor.

4. When connecting the extension drain hose, insulate the inside part of the

extension drain hose with shield.

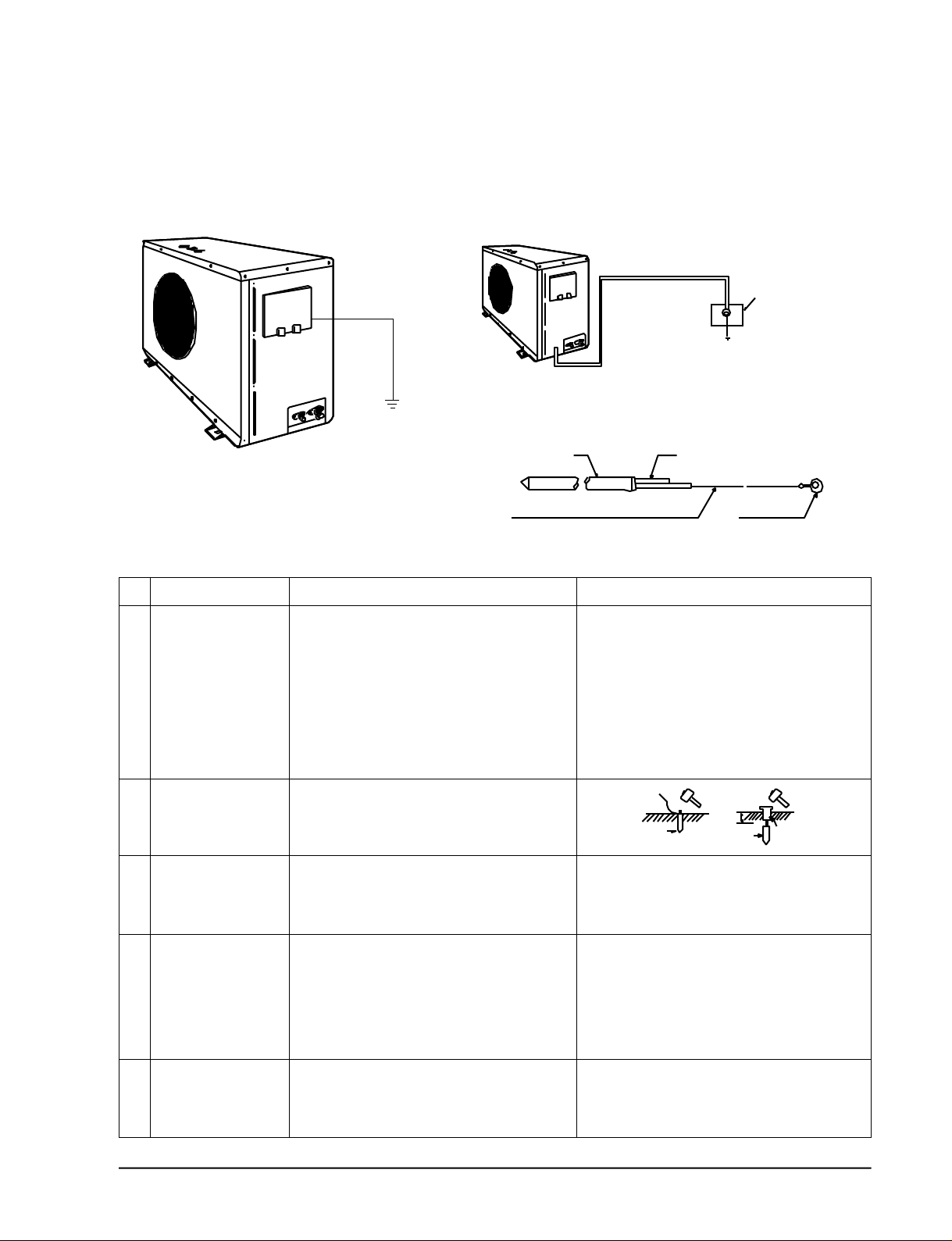

3-2-2(e) Wiring connection(outdoor unit)

AUXILIARY POWER S/W WIRING CONNECTION

Do not put the

drain hose end

into water

Do not wave

the hose

Keep a distance

at least 5cm

or more

Ditch

Do not put the

drain hose end

in the ditch

A u x i l i a ry power S/W should be installed

near indoor unit so that each access is

p o s s i b l e .

Main/Outdoor unit power cords are

connected to upper/lower terminal of

a u x i l i a ry power S/W.

distributind

board

Auxiliary

power S/W

Indoor unit connector wire should be

connected to both indoor unit connector

( t e rminal board) and outdoor unit term i n a l

b o a rd as shown in the figure below.

AS-18**

(POWER CABLE)

<Indoor unit>

(ASSEMBLY CABLE)

AS-24**

(ASSEMBLY CABLE)

EARTH WIRE

<Outdoor unit>

EARTH WIRE

EARTH WIRE

3-8

(POWER CABLE)

<Indoor unit> <Outdoor unit>

EARTH WIRE

Samsung Electronics

3-2-2(f) Grounding

(The Parts for this work are optional.)

Operating Instructions and Installation

• A g rounding terminal can be found on

the outdoor unit as illustrated.

1. When an existing grounding terminal is avilable.

( G rounding wire of ø1.6mm or larger<solid w i re > o r

2 m m2or larger <standard wire > )

Terminal used exclusively

for grounding.

Grounding resistance ;

Less than 100 ohms

(existing grounding electrode)

2. Use of a grounding electro d e .

• Specifications of grounding electro d e .

Steel coreCarbon plastic

PVC-Insulated(2mm2x3.5m), green Terminal, M4

No. JOB EXPLANATION PRECAUTIONS

1 Determine the • Suitable location • Avoid sandy or gravelly soil as its grounding

grounding position. a) Place that is always dank. resistance is high.

b) Hard soil rather than loose sandy soil. • The grounding wire for the telephone line cannot

be used for the grounding of the air conditioner.

• Unsuitable location • When the grounding electrode is to be installed

a) Where there are underground structures or under a place with heavy traffic, its wire must be

facilites such as gas pipes, water pipes, connected firmly with the utmost care.

telephone lines, underground cables, etc.

b) A place 2m or less from the lightning arrester

grounding electrode and its cable.

2 Drive the grounding a) Dig a hole to the size illustrated,

electrode into position. and drive in the grounding electrode.

b) Cover the top of the grounding

electrode with excavated soil.

3 Put the grounding a) If the grounding wire is too short, connect an • The grounding wire should be a green

wire in order. extention lead to it. Solder the joint and insulated wire of ø1.6mm or 2mm2or larger.

wrap it with tape. • The soldered joint should not be buried

b) Fasten the grounding wire with staples. underground.

4 Check the a) After grounding work, measure the grounding

workmanship, resistance with a grounding resistance tester.

and provide

corrective b) If the resistance is above a specified level,

measures if drive the grounding electrode in deeper

necessary. or increase the number of grounding

electrodes.

5 Connect the Secure the grounding wire to the

grounding grounding terminal of the air conditioner

wire to the air

conditioner.

Samsung Electronics

3-9

Operating Instructions and Installation

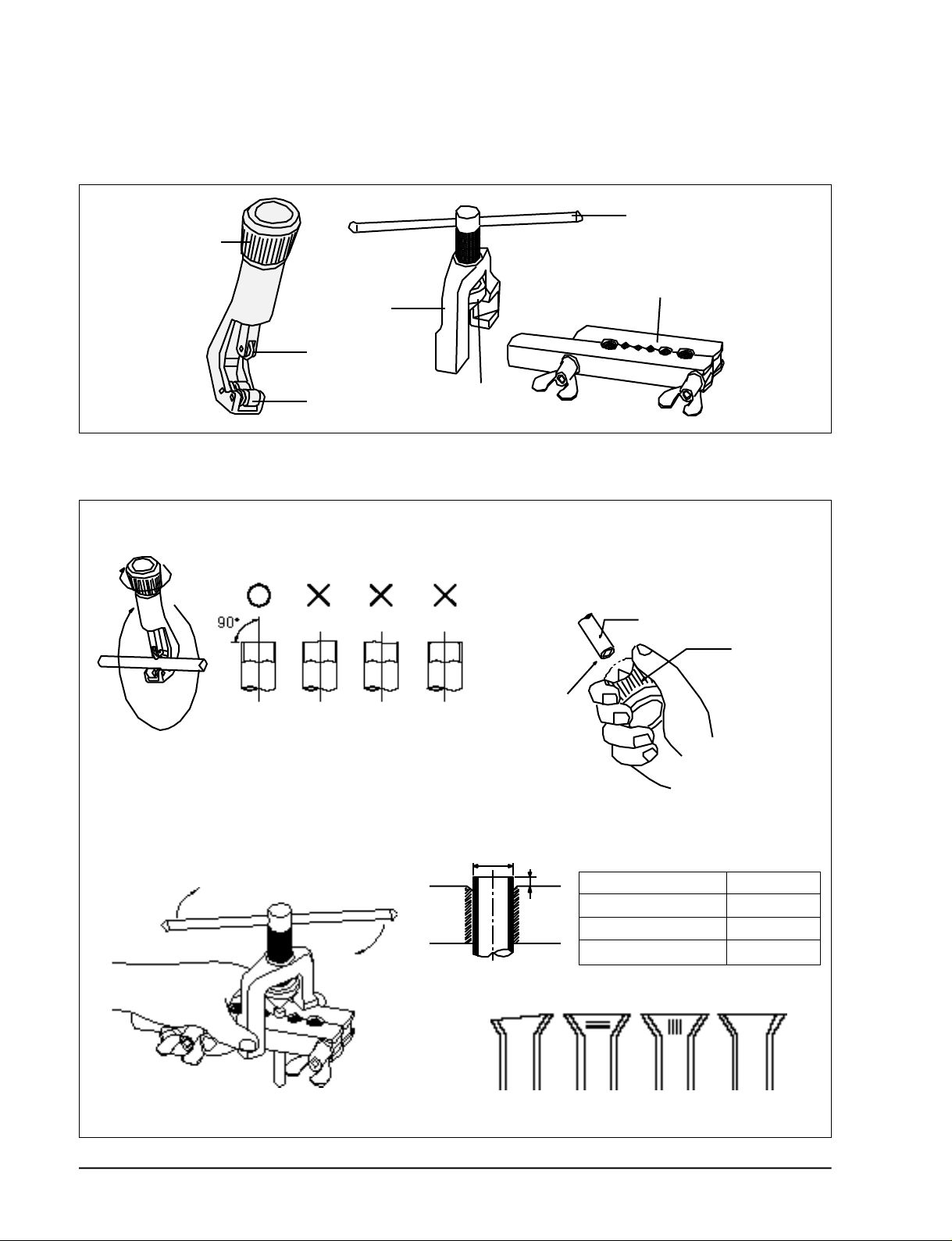

3-2-2(g) Flare modification

• Tools used

Tightening

knob

Cutting wheel

Clamp handle

Bar

Yoke

Roller

• Flare modification procedure

1) Cut the pipe using a pipe cutter.

Oblique Raughness Burr

3) Insert a flare nut into the pipe and modifty flare.

Cone

2) Remove burrs at the tip of the pipe cut.

Caution : Burrs not removed may result

in leakage of gas.

Pipe

Reamer

Point

down

3-10

D

A

• Unproper flaring

Inclined Surface

damaged

Outer diameter A(mm)

ø6.35mm 1.3

ø12.7mm 2.0

ø15.8mm 2.2

Cracked Uneven

thickness

Samsung Electronics

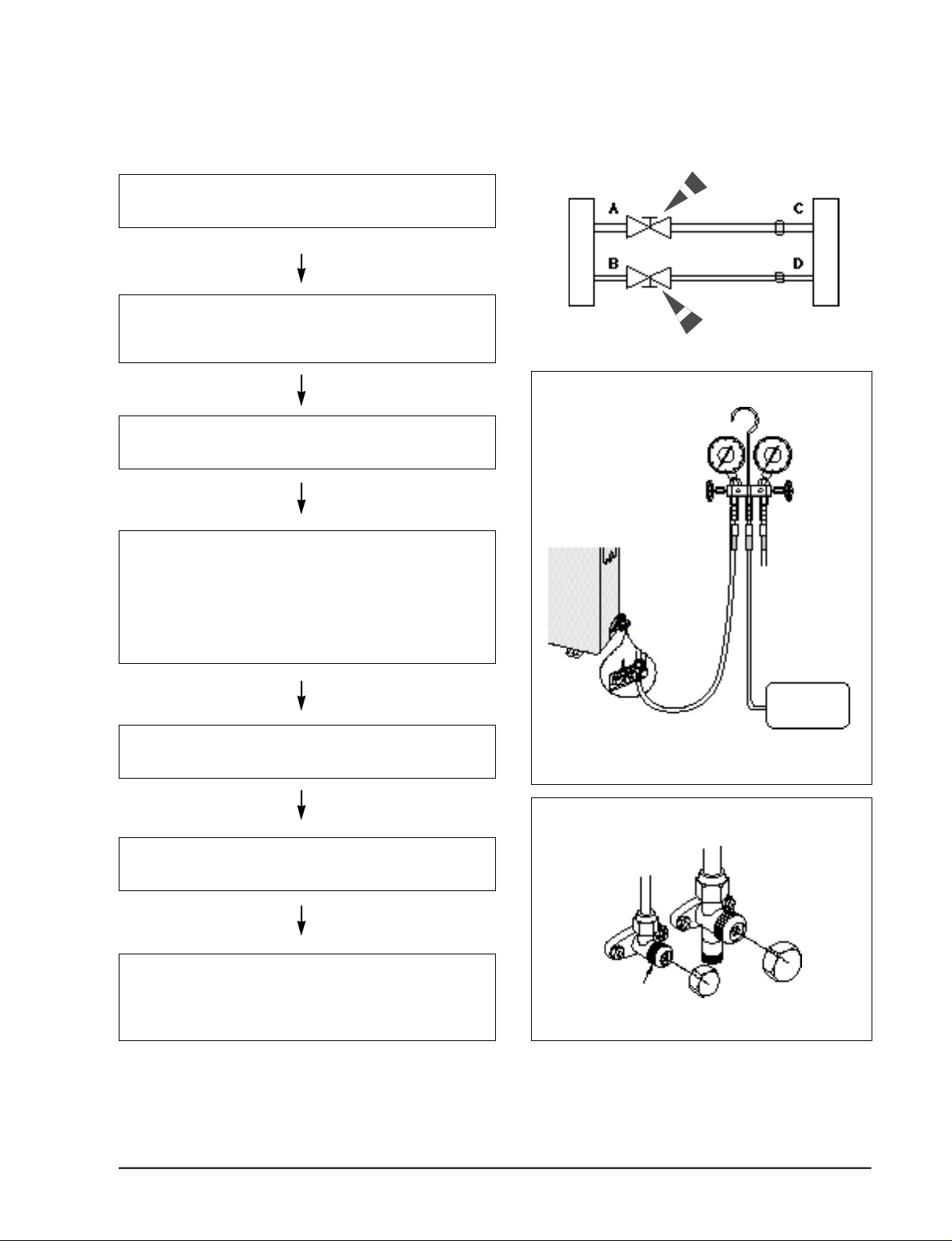

3-2-2(h) Air-Purge Procedure

Operating Instructions and Installation

1. Connect each assembly pipe to the appropriate valve on the

outdoor unit and tighten the flare nut.

2 Connect the charging hose of low pressure side of manifold

gauge to the packed valve having a service port (3/8” or

1/2” Packed valve) as shown at the figure.

3 Open the valve of the low pressure side of manifold gauge

counter-clockwise.

4. Purge the air from the system using vacuum pump for about

10 minutes.

- Close the valve of the low pressure side of manifold gauge

clockwise.

- Remove the hose of the low pressure side of manifold

gauge.

Outdoor unit

Indoor unit

Gas pipe side

Liquid pipe side

5. Set valve cork of both liquid side and gas side of packed

valve to the open position.

6. Mount the valve stem nuts to the 2-way and 3-way valve.

And mount the service port cap to 3-way valve.

7. Check for gas leakage.

- At this time, especially check for gas leakage from the

3-way valve’s stem nuts, and from the service port cap.

Valve stem

B

(liquid)

Vacuum Pump

A

(gas)

Stem cap

Samsung Electronics

3-11

Loading...

Loading...