Samsung AR**MXWS Series, AR**NXPX Series, AR**MXPD Series, AR**NXWX Series, AR**NXCX Series Installation Manual

Air conditioner

Installation manual

AR**MXWS*** / AR**MXPD***/ AR**NXPX*** /

AR**NXWX*** / AR**NXCX***

• Thank you for purchasing this Samsung air conditioner.

• Before operating this unit, please read this user manual carefully and retain it for future

reference.

2

English

Contents

Installation 3

Safety Information on Installation 3

Preparation 8

Step 1.1 Choosing the installation location

Step 1.2 Checking and preparing accessories and tools

Step 1.3 Drilling a hole through the wall

Step 1.4 Taping the pipes, cables, and drain hose

Indoor Unit Installation 12

Step 2.1 Disassembling the cover panel

Step 2.2 Disassembling the installation plate

Step 2.3 Connecting the power and communication cables (assembly cable)

Step 2.4 Optional: Extending the power cable

Step 2.5 Installing and connecting the drain hose

Step 2.6 Optional: Extending the drain hose

Step 2.7 Optional: Changing the direction of the drain hose

Step 2.8 Installing and connecting the assembly pipes to the refrigerant pipes (assembly pipe)

Step 2.9 Shortening or extending the refrigerant pipes (assembly pipe)

Step 2.10 Fixing the installation plate

Step 2.11 Fixing the indoor unit to the installation plate

Step 2.12 Assembling the cover panel

Outdoor Unit Installation 21

Step 3.1 Fixing the outdoor unit in place

Step 3.2 Connecting the power and communication cables and the refrigerant pipes

Step 3.3 Evacuating the air

Step 3.4 Adding refrigerant

Step 3.5 Important information: regulation regarding the refrigerant used

Installation Inspection 25

Step 4.1 Performing the gas leak tests

Step 4.2 Running the Smart Install mode

Step 4.3 Performing final check and trial operation

Maintenane Procedures 28

Sub PCB installation(optional) 29

For information on Samsung’s environmental commitments and product-specific regulatory obligations, e.g.

REACH, WEEE, Batteries, visit : samsung.com/uk/aboutsamsung/samsungelectronics/corporatecitizenship/

data_corner.html

3

English

Installation

Carefully follow the precautions listed below because

they are essential to guarantee the safety of both the air

conditioner and the workers.

• Always disconnect the air conditioner from the

power supply before servicing it or accessing its

internal components.

• Verify that installation and testing operations are

performed by qualified personnel.

• Verify that the air conditioner is not installed in an

easily accessible area.

General information

• Carefully read the content of this manual before

installing the air conditioner and store the manual in

a safe place in order to be able to use it as reference

after installation.

• For maximum safety, installers should always

carefully read the following warnings.

• Store the operation and installation manual in a safe

location and remember to hand it over to the new

owner if the air conditioner is sold or transferred.

• This manual explains how to install an indoor unit

with a split system with two SAMSUNG units. The

use of other types of units with different control

systems may damage the units and invalidate the

warranty. The manufacturer shall not be responsible

for damages arising from the use of non compliant

units.

• The manufacturer shall not be responsible for

damage originating from unauthorised changes

or the improper connection of electric and

requirements set forth in the “Operating limits”

table, included in the manual, shall immediately

invalidate the warranty.

• The air conditioner should be used only for the

applications for which it has been designed: the

indoor unit is not suitable to be installed in areas

used for laundry.

• Do not use the units if damaged. If problems occur,

switch the unit off and disconnect it from the power

supply.

• In order to help prevent electric shocks, fires or

injuries, always stop the unit, disable the protection

switch and contact SAMSUNG’s technical support if

the unit produces smoke, if the power cable is hot or

damaged or if the unit is very noisy.

• Always remember to inspect the unit, electric

connections, refrigerant tubes and protections

regularly. These operations should be performed by

qualified personnel only.

• The unit contains moving parts, which should always

be kept out of the reach of children.

• Do not attempt to repair, move, alter or reinstall the

unit. If performed by unauthorised personnel, these

operations may cause electric shocks or fires.

• Do not place containers with liquids or other objects

on the unit.

• All the materials used for the manufacture and

packaging of the air conditioner are recyclable.

• The packing material and exhaust batteries of the

remote control (optional) must be disposed of in

accordance with current laws.

• The air conditioner contains a refrigerant that has

to be disposed of as special waste. At the end of its

life cycle, the air conditioner must be disposed of in

authorised centres or returned to the retailer so that

it can be disposed of correctly and safely.

• Do not use means to accelerate the defrost

operation or to clean, other than those

recommended by Samsung.

• Do not pierce or burn.

• Be aware that refrigerants may not contain an

odour.

Installation of the product

• IMPORTANT: When installing the unit, always

remember to connect first the refrigerant tubes,

then the electrical lines. Always disassemble the

electric lines before the refrigerant tubes.

• Upon receipt, inspect the product to verify that

it has not been damaged during transport. If the

product appears damaged, DO NOT INSTALL it and

immediately report the damage to the carrier or

retailer (if the installer or the authorised technician

has collected the material from the retailer.)

• After completing the installation, always carry out a

functional test and provide the instructions on how

to operate the air conditioner to the user.

Safety Information on Installation

4

English

Installation

• Do not use the air conditioner in environments with

hazardous substances or close to equipment that

release free flames to avoid the occurrence of fires,

explosions or injuries.

• Our units must be installed in compliance with the

spaces indicated in the installation manual to ensure

either accessibility from both sides or ability to

perform routine maintenance and repairs. The units’

components must be accessible and that can be

disassembled in conditions of complete safety either

for people or things. For this reason, where it is not

observed as indicated into the Installation Manual,

the cost necessary to reach and repair the unit (in

safety, as required by current regulations in force)

with slings, trucks, scaffolding or any other means of

elevation won’t be considered in-warranty and will

be charged to end user.

• The outdoor unit shall be installed in an open space

that is always ventilated.

• The local gas regulations shall be observed.

• To handle, purge, and dispose the refrigerant, or

break into the refrigerant circuit, the worker should

have a certificate from an industry-accredited

authority.

• Do not install the indoor unit in the following areas:

– Area filled with minerals, splashed oil, or

steam. It will deteriorate plastic parts, causing

failure or leakage.

– Area that is close to heat sources.

– Area that produces substances such as sulfuric

gas, chlorine gas, acid, and alkali. It may cause

corrosion of the pipings and brazed joints.

– Area that can cause leakage of combustible

gas and suspension of carbon fibers,

flammable dust, or volatile flammables.

– Area where refrigerant leaks and settles.

– Area where animals may urinate on the

product. Ammonia may be generated.

• Do not use the indoor unit for preservation of food

items, plants, equipment, and art works. This may

cause deterioration of their quality.

• Do not install the indoor unit if it has any drainage

problem.

• When installing the outdoor unit at the seaside,

make sure that it is not directly exposed to sea

breeze. If you cannot find an adequate place free

from direct sea breeze, construct a protection wall or

a protective fence.

– Install the outdoor unit in a place (such as

near buildings etc.) where it can be protected

from sea breeze. Failure to do so may cause a

damage to the outdoor unit.

Sea

Sea breeze

Outdoor unit Outdoor unit

Sea breeze

Sea

• If you cannot avoid installing the outdoor unit at the

seaside, construct a protection wall around to block

the sea breeze.

• Construct a protection wall with a solid material

such as concrete to block the sea breeze. Make sure

that the height and the width of the wall are 1.5

times larger than the size of the outdoor unit. Also,

secure a space larger than 600 mm between the

protection wall and the outdoor unit for exhausted

air to ventilate.

Sea

Sea breeze

Outdoor unit

Protection wall

Outdoor unit

Protection wall

• Install the unit in a place where water can drain

smoothly.

• If you have any difficulty finding installation location

as prescribed above, contact your manufacturer for

details.

• Be sure to clean the sea water and the dust on the

heat exchanger of the outdoor unit and apply a

corrosion inhibitor on it. (At least once in a year.)

• For the multi system, this indoor unit can be

conncected to an R-32 or R-410A outdoor unit. Check

the type of refrigerant in the outdoor unit.

• In addition to table 1, make sure that the indoor and

outdoor unit are installed in a space at least of 4m²

to guarantee the regular maintenance or service

repair.

5

English

Installation

• Table 1 (defined according to EN378-1:2017)

[Unit : m2]

Installation

height (m)

1.224

1.225

1.250

1.500

1.750

2.000

2.250

2.500

0.6

No limitations

12.77 13.30 19.15 26.0 6 34.04 43.09 53.19

1 4.60 4.79 6.89 9.38 12.26 15.51 19.15

1.8 1.42 1.48 2.1 3 2.9 0 3.78 4.79 5.91

2 1.15 1. 20 1.72 2.35 3.06 3.88 4.79

2.2 0.95 0 .99 1.42 1.94 2.53 3.20 3.9 6

•IMPORTANT: it’s mandatory to consider either

the table 1 or taking into consideration the local

law regarding the minimum living space of the

premises.

•Minimum installation height of indoor unit is 0.6 m

for floor mounted, 1.8 m for wall, 2.2 m for ceiling.

Installation of the outdoor unit

• While in installation or relocation of the product, do

not mix the refrigerant with other gases including

air or unspecified refrigerant. Failure to do so may

cause pressure increase to result in rupture or injury.

• Do not cut or burn the refrigerant container or

pipings.

• Use clean parts such as manifold gauge, vacuum

pump, and charging hose for the refrigerant.

• Installation must be carried out by qualified

personnel for handling the refrigerant. Additionally,

reference the regulations and laws.

• Be careful not to let foreign substances (lubricating

oil, refrigerant, water, etc.) enter the pipings. The

application of oil or refrigerant deteriorates the

pipings to result in drain leakage. For storage,

securely seal their openings.

• When mechanical ventilation is required, ventilation

openings shall be kept clear of obstruction.

• For disposal of the product, follow the local laws and

regulations.

• Do not work in a confined place.

• The work area shall be blocked.

• The refrigerant pipings shall be installed in the

position where there are no substances that may

result in corrosion.

• The following checks shall be performed for

installation:

– The charging amount depends on the room

size.

– The ventilation devices and outlets are

operating normally and are not obstructed.

– Markings and signs on the equipment shall be

visible and legible.

• Upon leakage of the refrigerant, ventilate the room.

When the leaked refrigerant is exposed to flame, it

may cause generation of toxic gases.

• Make sure that the work area is safe from

flammable substances.

• To purge air in the refrigerant, be sure to use a

vacuum pump.

• Note that the refrigerant has no odour.

• The units are not explosion proof so they must be

installed with no risk of explosion.

• This product contains fluorinated gases that

contribute to global greenhouse effect. Accordingly,

do not vent gases into the atmosphere.

• Because the working pressure for R-32 is 1.6 times

higher than that for R-22, use exclusive pipings

and tools specified. In case of replacing an R-22

model with an R-32 model, be sure to replace the

conventional pipings and flare nuts with exclusive

ones.

• The models that use the refrigerant R-32 have a

different thread diameter for the charging port

to prevent charging failure. Therefore, check its

diameter (1/2 inch) in advance.

• Servicing shall be performed as recommended by

the manufacturer. In case other skilled persons are

joined for servicing, it shall be carried out under

supervision of the person who is competent in

handling flammable refrigerants.

• For servicing the units containing flammable

refrigerants, safety checks are required to minimise

the risk of ignition.

• Servicing shall be performed following the

controlled procedure to minimize the risk of

flammable refrigerant or gases.

• Do not install where there is a risk of combustible

gas leakage.

• Do not place heat sources.

• Be cautious not to generate a spark as follows:

– Do not remove the fuses with power on.

Charge

amount (kg)

6

English

Installation

– Do not disconnect the power plug from the

wall outlet with power on.

– It is recommended to locate the outlet in a

high position. Place the cords so that they are

not tangled.

• If the indoor unit is not R-32 compatible, an error

signal appears and the unit will not operate.

• After installation, check for leakage. Toxic gas may

be generated and if it comes into contact with an

ignition source such as fan heater, stove, and cooker.

cylinders, make sure that only the refrigerant

recovery cylinders are used.

Preparation of fire extinguisher

• If a hot work is to be done, an appropriate fire

extinguishing equipment should have been

available.

• A dry powder or CO2 fire extinguisher shall be

equipped near the charging area.

Ignition sources free

• Make sure to store the units in a place without

continuously operating ignition sources (for

example, open flames, an operating gas appliance

or an operating electric heater).

• The service engineers shall not use any ignition

sources with the risk of fire or explosion.

• Potential ignition sources shall be kept away from

the work area where the flammable refrigerant can

possibly be released to the surrounding.

• The work area should be checked to ensure that

there are no flammable hazards or ignition risks.

The “No Smoking” sign shall be attached.

• Under no circumstances shall potential sources of

ignition be used while in detection of leakage.

• Make sure that the seals or sealing materials have

not degraded.

• Safe parts are the ones with which the worker can

work in a flammable atmosphere. Other parts may

result in ignition due to leakage.

• Replace components only with parts specified by

Samsung. Other parts may result in the ignition of

refrigerant in the atmosphere from a leak.

Area ventilation

• Make sure that the work area is well ventilated

before performing a hot work.

• Ventilation shall be made even during the work.

• The ventilation should safely disperse any

released gases and preferably expel them into the

atmosphere.

• Ventilation shall be made even during the work.

Leakage detection methods

• The leakage detector shall be calibrated in a

refrigerant-free area.

• Make sure that the detector is not a potential

source of ignition.

• The leakage detector shall be set to the LFL (lower

flammability limit).

• The use of detergents containing chlorine shall be

avoided for cleaning because the chlorine may react

with the refrigerant and corrode the pipings.

• If leakage is suspected, naked flames shall be

removed.

• If a leakage is found while in brazing, the entire

refrigerant shall be recovered from the product or

isolated (e.g. using shut-off valves). It shall not be

directly released to the environment. Oxygen free

nitrogen (OFN) shall be used for purging the system

before and during the brazing process.

• The work area shall be checked with an appropriate

refrigerant detector before and during work.

• Ensure that the leakage detector is appropriate for

use with flammable refrigerants.

Labelling

• The parts shall be labelled to ensure that they have

been decommissioned and emptied of refrigerant.

• The labels shall be dated.

• Make sure that the labels are affixed on the system

to notify it contains flammable refrigerant.

7

English

Installation

Recovery

• When removing refrigerant from the system for

servicing or decommissioning, it is recommended to

remove the entire refrigerant.

• When transferring refrigerant into cylinders, make

sure that only the refrigerant recovery cylinders

are used.

• All cylinders used for the recovered refrigerant shall

be labelled.

• Cylinders shall be equipped with pressure relief

valves and shut-off valves in a proper order.

• Empty recovery cylinders shall be evacuated and

cooled before recovery.

• The recovery system shall operate normally

according to the specified instructions and shall be

suitable for refrigerant recovery.

• In addition, the calibration scales shall operate

normally.

• Hoses shall be equipped with leak-free disconnect

couplings.

• Before starting the recovery, check for the status of

the recovery system and sealing state. Consult with

the manufacturer if suspected.

• The recovered refrigerant shall be returned to the

supplier in the correct recovery cylinders with the

Waste Transfer Note attached.

• Do not mix refrigerants in the recovery units or

cylinders.

• If compressors or compressor oils are to be

removed, make sure that they have been evacuated

to the acceptable level to ensure that flammable

refrigerant does not remain in the lubricant.

• The evacuation process shall be performed before

sending the compressor to the suppliers.

• Only the electrical heating to the compressor body

is allowed to accelerate the process.

• Oil shall be drained safely from the system.

• For installation with handling the refrigerant

(R-32), use dedicated tools and piping materials.

Because the pressure of the refrigerant, R-32 is

approximately 1.6 times higher than that of R-22,

failure to use the dedicated tools and piping

materials may cause rupture or injury. Furthermore,

it may cause serious accidents such as water

leakage, electric shock, or fire.

• Never install a motor-driven equipment to prevent

ignition.

Power supply line, fuse, or circuit

breaker

• Always make sure that the power supply is

compliant with current safety standards. Always

install the air conditioner in compliance with

current local safety standards.

• Always verify that a suitable grounding

connection is available.

• Verify that the voltage and frequency of the

power supply comply with the specifications and

that the installed power is sufficient to ensure

the operation of any other domestic appliance

connected to the same electric lines.

• Always verify that the cut-off and protection

switches are suitably dimensioned.

• Verify that the air conditioner is connected to the

power supply in accordance with the instructions

provided in the wiring diagram included in the

manual.

• Always verify that electric connections (cable

entry, section of leads, protections…) are

compliant with the electric specifications and

with the instructions provided in the wiring

scheme. Always verify that all connections comply

with the standards applicable to the installation

of air conditioners.

•Be sure not to perform power cable modification,

extension wiring, and multiple wire connection.

– It may cause electric shock or fire due to poor

connection, poor insulation, or current limit

override.

– When extension wiring is required due

to power line damage, refer to "Step 2.4

Optional: Extending the power cable" in the

installation manual.

8

English

Installation

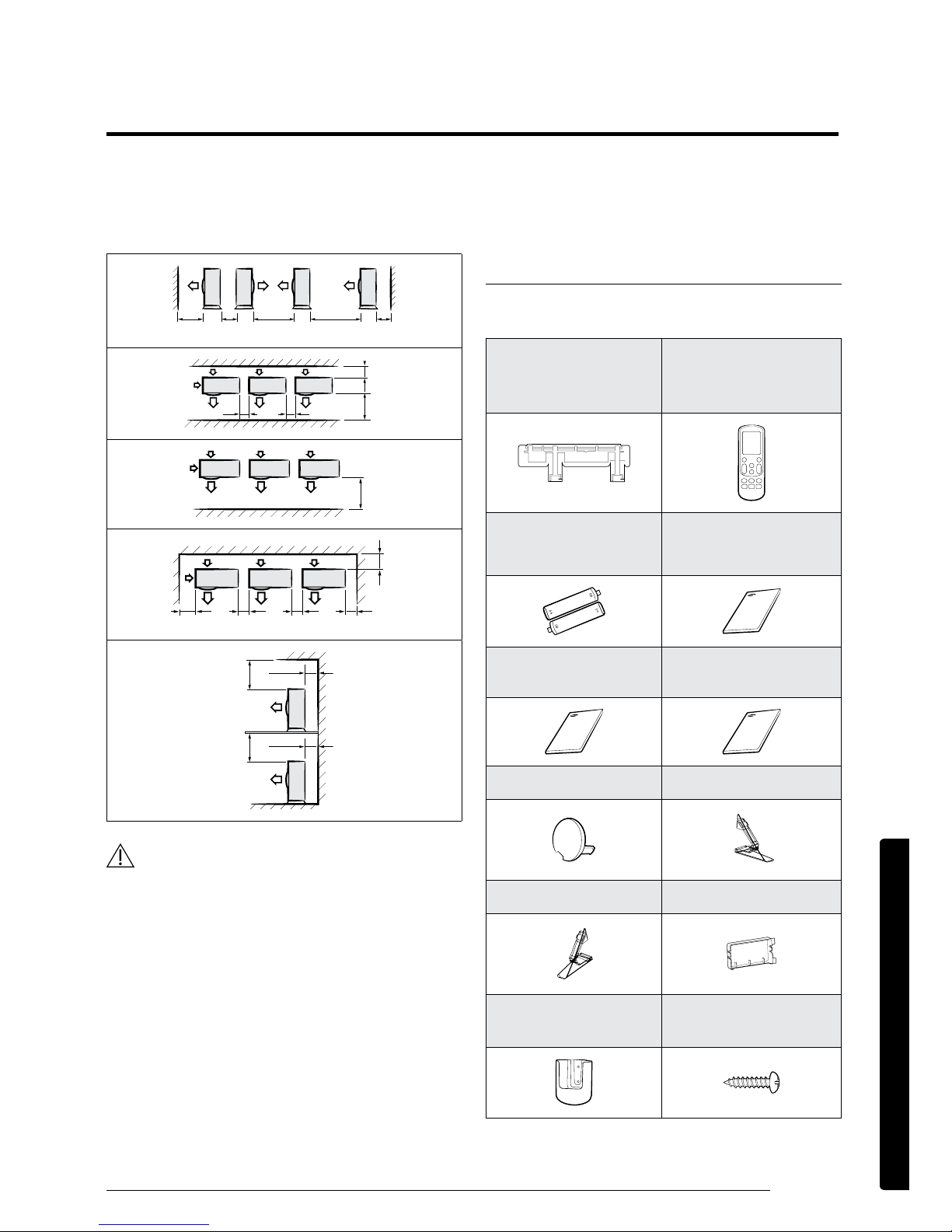

Step 1.1 Choosing the installation

location

If using a multi system, install as described in the

installation manual supplied with the outdoor

unit.

Overview of installation location requirements

CAUTION

CAUTION

• Comply with the length and height limits

described in the figure above.

• For the product that uses the R-32 refrigerant,

Install the indoor unit on the wall 1.8 m or higher

from the floor.

Minimum clearances for the outdoor unit

Wall

Minimum clearance in mm

300

600

Air flow direction

Side viewTop view

When installing 1 outdoor unit (6 cases)

(Unit: mm)

300

1500

300

150 600

1500

2000

500

300

300 1500

(Unit : m)

Model

Pipe length Pipe height

Minimum Maximum Maximum

**07*******

**09*******

**12*******

3 15 8

Preparation

100 mm or more

125 mm

or more

125 mm

or more

Drain hose hole

You can select the direction of

draining (left or right).

Maximum pipe height

Make at least one round to

reduce noise and vibration.

The actual units may look different from

the images depicted here.

Make a U-trap (A) on the pipe

(which is connected to the indoor

unit) at outer wall and cut the

bottom part of the insulation

(about 10 mm) to prevent

rainwater from getting inside

through the insulation.

Outdoor

Unit

Outer wall

Indoor

Unit

Cut insulation to have

rainwater drained

Maximum pipe

length

9

English

Installation

When installing more than 1 outdoor unit (5 cases)

(Unit: mm)

1500 600 3000 2003000

3001500

600 600

1500

300

300 600 600 600

500

300

500

300

CAUTION

• If the outdoor unit is installed with any insufficient

clearance, it may generate sound and affect the

whole product.

• Be sure to install the outdoor unit in a level place

where its vibration does not affect the whole

product.

Step 1.2 Checking and preparing

accessories and tools

Accessories

Accessories in the indoor unit package

Installation plate (1)

**07*******

**09*******

**12*******

Remote control (1)

Remote control battery (2)

User Manual (1)

AR**MX*****

AR**NX*****

User Manual (3)

AR**NXCX***

Installation Manual (1)

Cap screw (2) Guide Left (1)

Guide Right (1) Case Sub PCB (1)

Remote control holder (1)

AR**NX*****

M4 x 12 tapping screw (2)

AR**NX*****

Loading...

Loading...