Samsung APH450, APH450PG0K-AFR Troubleshooting

5. Troubleshooting

Troubleshooting

First, Items to be checked first

Second, Check the corrective actions in the case of occurrence of self-diagnosis mode

Third, When the trouble is not related to the 1st or 2nd items above, check the troubled area in

detail in accordance with the fault analysis method by symptom.

5-1 Items to be checked first

1 ) Is the supply voltage appro p r i a t e ?

The supply voltage: should be AC 187V-AC 253V/60Hz

2) Is the connecting wire between the indoor unit and outdoor unit appro p r i a t e ?

Be sure to check whether the cables for the indoor unit and outdoor unit are securely connected

by the same terminal number.

3) When any claim occurs according to the contents of the table below, it is not related the trouble of

the air-conditioner at all.

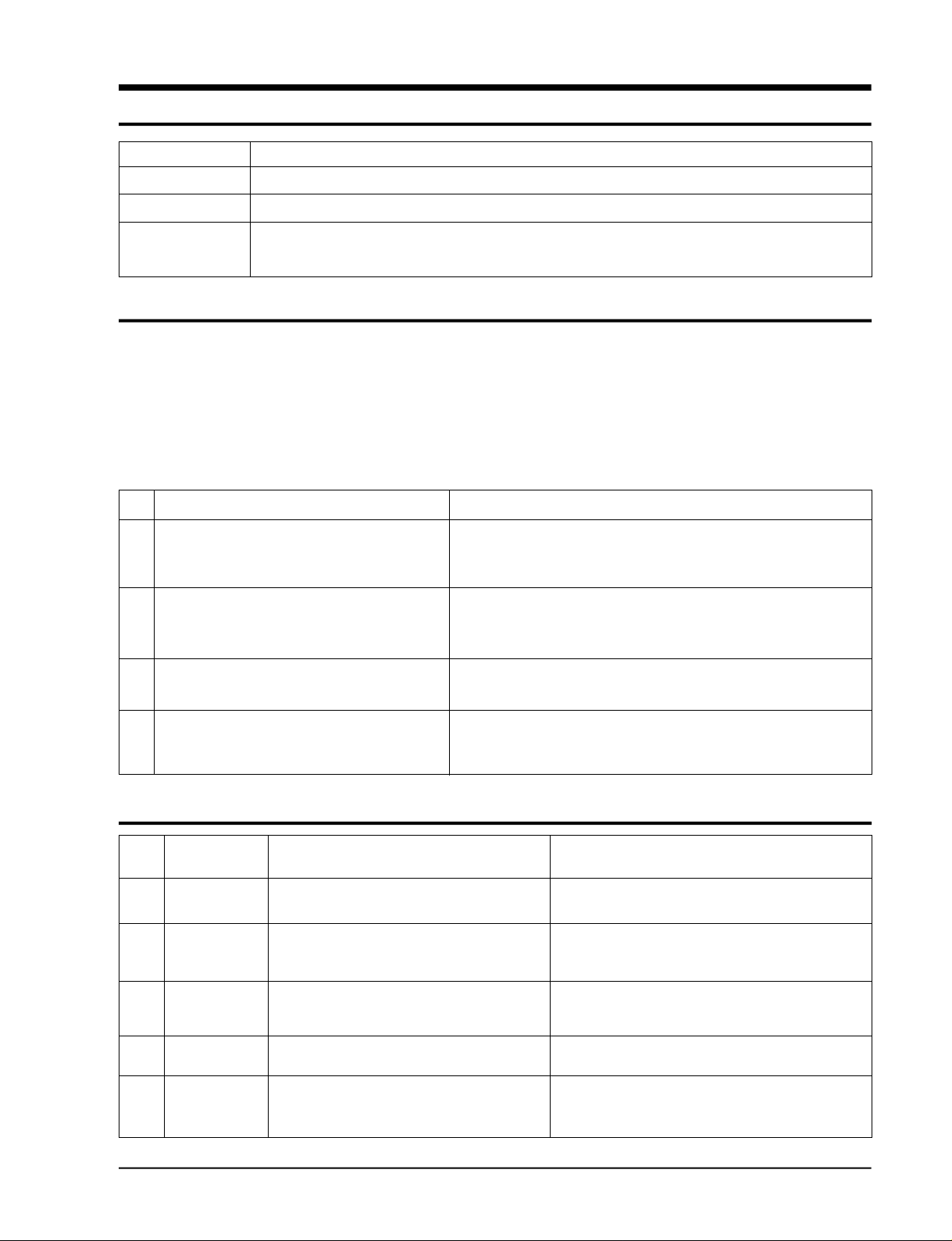

No. Operation of air-conditioner Description

1 The compressor does not operate even though The compressor operation is delayed for 3 minutes for the protection of

the desired temperature is set lower than it during the restart of compressor. It operates normally after 3 minutes

room temperature (during the cooling operation) delay even at the initial operation.

2 The hot wind does not come out even though the In order to prevent the discharging of cool wind, the room fan motor

desired temperature is set higher than the room operates only when the temperature of indoor heat exchanger is kept

temperature. (heating operation) higher than a constant one.

3 The wind quantity is not controlled during the The wind quantity is set by the micom during the automatic turbo

automatic (cooling/heating) turbo operation. operation.

4 The temperature can not be set during the The desired temperature is set automatically during the automatic

automatic (cooling/heating) turbo blowing turbo operation. The wind blowing operation is simply the operation

operation. mode for the circulation of indoor air.

5-2 Self-diagnosis and corrective actions

No. Cause Corrective actions

Temperature

display

1 E1 Short of indoor temperature sensor Check of departure of indoor temperature sensor

Open of Indoor temperature sensor Check of PCB open/short

2 E5 Short of indoor heat exchanger sensor Check of indoor exchanger sensor departure

Open of indoor heat exchanger sensor Check of PCB open/short

Replacement of sensor

3 E6 Short of outdoor heat exchanger sensor Check of outdoor exchanger sensor departure

Open of outdoor heat exchanger sensor Check of PCB open/short

Replacement of sensor

4 E7 Short of heater temperature sensor Check of heater wiring diagram

Open of heater temperature sensor Check of sensor attachment location

5 EL When the electrical heater is over heated Check of heater temperature sensor departure

Check of PCB open/shore

Replacement of sensor

Samsung Electronics

5-1

5-3 Fault Analysis by Symptom

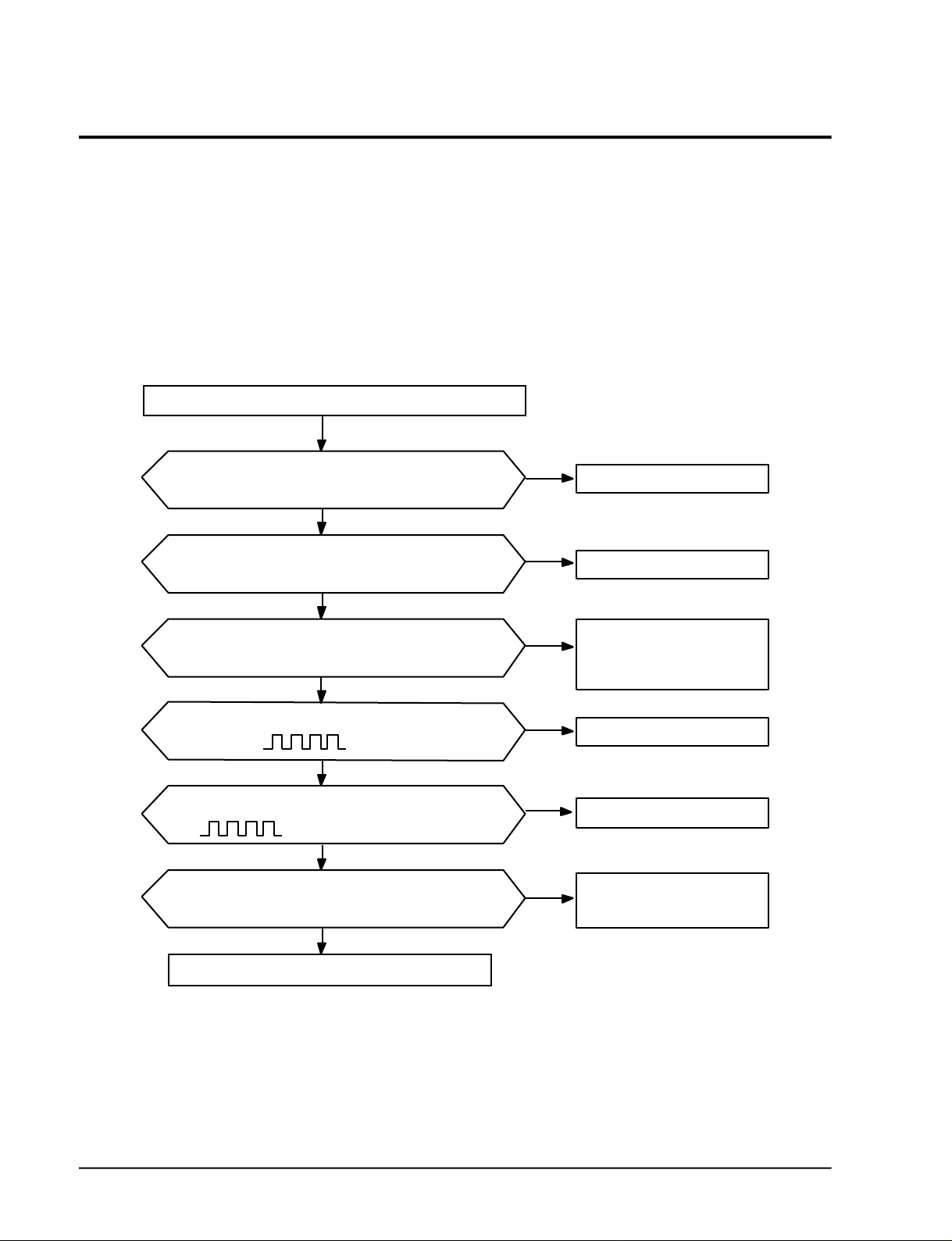

5-3-1 No Power (No display)

1) Checkpoints

(1) Is the voltage of the power source normal?(AC 187V - AC 253V)

(2) Is the power line in good contact?

(3) Check the power fuse(F701, F702) and PCB fuse(F101) for open.

(4) A re the primary and secondary sides of the power-trans in good contact with the connector?

(5) Is the output voltage of REG1(KA7812) normal?(DC 11.5V - DC 12.5V)

(6) Is the output voltage of REG2(KA 7805) normal?(DC 4.5V - DC 5.5V)

2) Checking pro c e d u res(after checking the checkpoints of clause 1)

Turn off the power, and then turn it on in 5 seconds.

Is the room temperature displayed on the temperaturre

indicator, the display lamp turned on, and the panel

shutter down when pressing the on/off button.

N

Is the voltage or the power trans AC 18V-21V secondary

side(CN11) normal?

Y

Is the output voltage of REG1 and REG2 normal?

(REG1=12V, REG2=5V)

Y

Is the output wave at the MICOM(IC1) pin (No. 33~40) a

square wave?

Y

Is the output wave at IC2 pin No. 11~18 a square wave?

Y

Is the harness between the main PCB and panel PCB well

connected?

Y

Then it is normal operation.

N

Check and replace the power trans.

N

Remove the shorted parts of the

power terminal.

Replace the defective parts.

(D101-104, REG1, REG2)

N

Check and replace the MICOM(IC1).

N

Check and replace the IC2.

N

Reassemble or replace the harness

after checking it.

5-2

Y

LED display or panel PCB defective.

Samsung Electronics

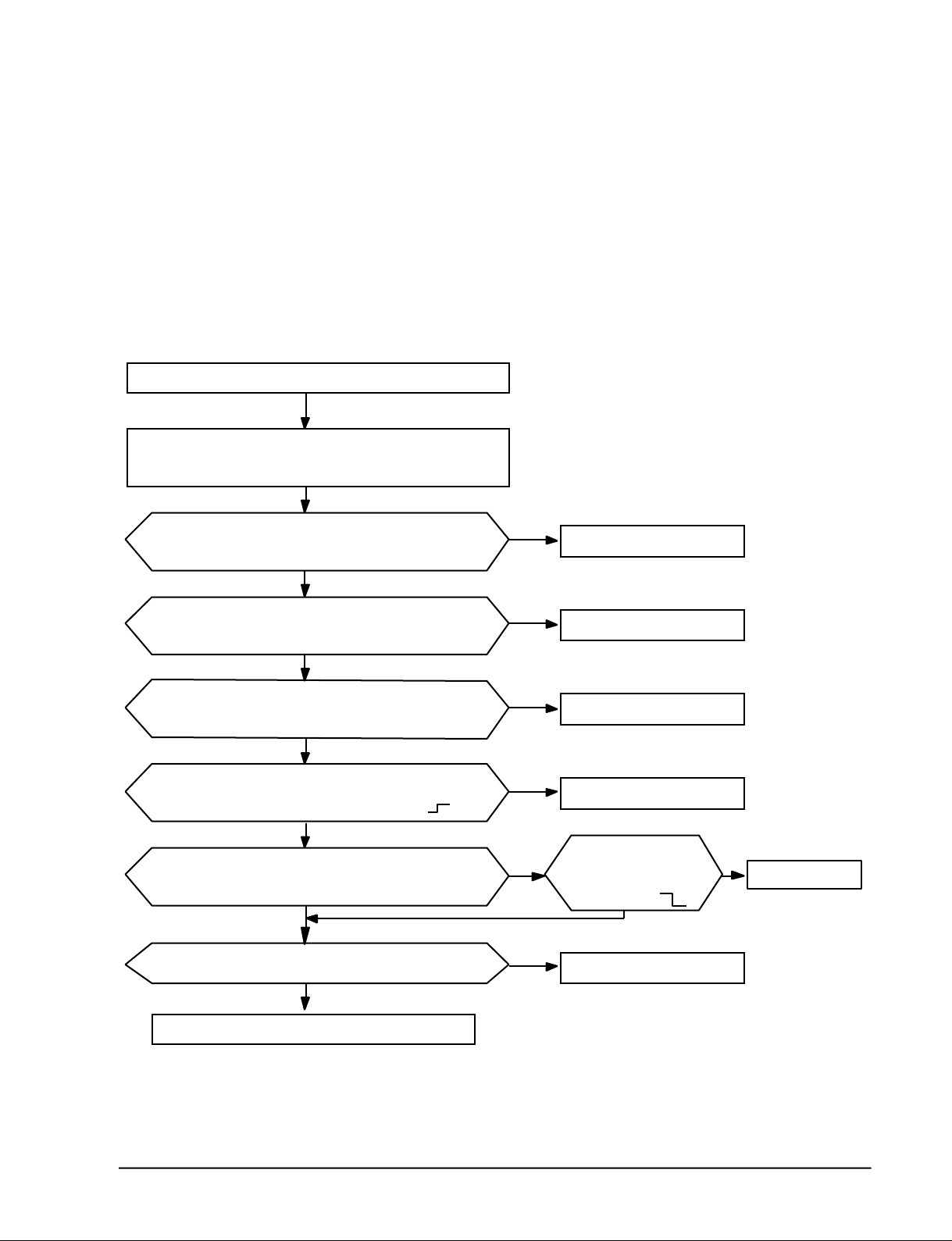

5-3-2 When the Indoor Fan Motor does not Operate.

1) Checkpoints

(1) Is the voltage of the power source normal?(AC 187V-AC 253V)

(2) Is the indoor fan connector (CN71) in good contact?

(3) Is the starting condensor of the fan motor in good contact with the terminal?

(4) Is the resistance at both ends of the relay coil approximately 400Ω?

2) Checking pro c e d u res(after checking the checkpoints of clause 1)

Turn off the power, and then turn it on in 5 seconds.

Operate the on/off button, and operation mode key, and place

it in the “FAN” position.

Troubleshooting

Does the airflow volume of the indoor fan motor change

when converting into high, medium, and low by the FAN

speed key?

N

Do the RY6(high), RY3(medium), and RY4(low) operate

when converting into high medium and low by the FAN

speed key.

N

Is the resistance at both ends/of the relay(RY 3, 4, 6) coil

approximately 400Ω?

Y

Is it “high” when checking the output wave for airflow at

the MICOM(IC1) pin No. 55, 56, and 53?

Y

Is the voltage at both ends of the relay for each airflow at

the time of selecting the fan speed(high/medium/low) DC

12V?

Y

Is the voltage at both ends/of indoor fan motor AC 187V~253V?

Y

Then the indoor fan motor is norm a l .

Y

Then the relay is normal.

N

Then replace the relay when resistance is 0¥ or i~.

N

Then check and replace the MICOM(IC1).

N

Is it low when checking

the output wave for

each airflow at the IC3

pin No. 11, 12,

and 13?

Y

N

Then check the wiring harness for open.

Check the resistance level after

t u rning off the power.

N

Then check and replace the IC3.

Check and replace the indoor fan motor.

Samsung Electronics

5-3