Samsung AM036NXMDCR, AM048NXMDCR, AM053NXMDCR, AM060NXMDCR Service Manual

Refer to the service manual in the GSPN(see the rear cover) for the more information.

AIR CONDITIONER CONTENTS

SYSTEM AIR CONDITIONER

OUTDOOR UNIT

AM036NXMDCR

AM048NXMDCR

AM053NXMDCR

AM060NXMDCR

■ Product Specifications

■ Disassembly and Reassembly

■ Refrigerant pipe installation

■ Troubleshooting

■ PCB Diagram

■ Wiring Diagram

■ Reference Sheet

■ Check Operation & Amount of

Refregent Automatically Checking

Contents

■ Product Specifications .......................................................................................... 4

1. The Feature of Product .................................................................................................................................. 4

1-1 Feature ............................................................................................................................................................................ 4

2. Product Specifications .................................................................................................................................10

■ Disassembly and Reassembly ............................................................................12

■ Refrigerant pipe installation .............................................................................. 32

1. Examples of the correct refrigerant pipe installation for Heat Recovery ................................32

2. Examples of the incorrect refrigerant pipe installation for Heat Recovery ............................33

■ Troubleshooting .................................................................................................. 34

1. Error Display .....................................................................................................................................................34

2. Error Code .........................................................................................................................................................35

3. How to take measures for each symptom ...........................................................................................38

3-1 Communication error between indoor and

outdoor units during tracking (Error Code : E201).................................................................................38

3-2 Communication error between indoor and

outdoor units after completing tracking (Error Code : E202) ...........................................................39

3-3 Communication error (1 minute) between Main and

Sub Micoms of an Outdoor unit or among Outdoor Units (Error Code : E203) .......................40

3-4 MCU branch part setup error

– inconsecutive connection with the use of 2 branch parts .............................................................41

3-5 MCU branch part setup error

– Repeated setup for the same address over 3 times ..........................................................................42

3-6 MCU branch part setup error

– non-installed address setup .........................................................................................................................43

3-7 Communication error (1 minute) between Main and

Sub Micoms of an Outdoor unit or among Outdoor Units (Error Code : E203) ...................................44

3-8 MCU branch part setup error

– Overlapping Indoor unit Address setup .................................................................................................45

3-9 MCU branch part setup error

– Set as being used without connection to an Indoor unit ..............................................................46

3-10 MCU branch part setup error

– Connect an Indoor unit to a branch part not being used ..............................................................47

3-11

MCU branch part setup error

– Connect more Indoor units than what is actually set up in MCU ............................................................48

3-12 MCU/MCU subcooler entrance/exit sensor error (Open/Short) ......................................................49

3-13 Outdoor temperature sensor error(Open/Short)

(Error Code : E221, E231, E251, E269, E276, E311 E321, E322, E323) ..............................................50

3-14 High pressure temperature sensor error (Open/Short) (Error Code : E291)

Low pressure temperature sensor error (Open/Short) (Error Code : E296) ................................51

3-15 Compressor down by antifreeze control (Error Code: E403) .............................................................52

3-16 Comp. down due to a protective control of high pressure (Error Code : E407) ........................53

3-17 Comp. down due to a protective control of low pressure (Error Code : E410) ..........................54

3-18 Comp. down due to a discharge

temperature sensor of a compressor (Error Code : E416) ..................................................................55

3-19 Reverse phase detection error (3Phase outdoor unit) (Error Code : E425) .................................56

3-20 ESC EEV open error (Error Code : E438)........................................................................................................57

3-21 Refrigerant leakage error (Error Code : E439)............................................................................................58

3-22 Prohibition of the compressor operation due to outdoor temperature

(Error Code : E440, 441) ......................................................................................................................................59

3-23 Refrigerant leakage error (during operation) (Error Code : E443) ...................................................59

3-24 Outdoor unit fan error (Error Code : E458, 475 ) ......................................................................................60

3-25 Comp down due to OLP temperature control (Error Code : E463) .................................................61

3-26 Compressor starting/rotation error (Error Code : E461, E467) ..........................................................62

3-27 Current error / PFC overload error (Error Code : E462, E484) .............................................................64

3-28 IPM over current error (Error Code : E464) ..................................................................................................65

3-29 DC-Link voltage under/over error (Error Code : E466) ..........................................................................68

3-30 Others ..........................................................................................................................................................................70

■ PCB Diagram ........................................................................................................71

1. Outdoor Unit PCB ..........................................................................................................................................71

■ Wiring Diagram .................................................................................................... 75

1. 1 Phase (AM036/048/053/060NXMDCR) ..............................................................................................75

■ Reference Sheet ................................................................................................... 76

1. Refrigerant cycle diagram ..........................................................................................................................76

1-1 AM036/048/053NXMDCR ....................................................................................................................................76

1-2 AM036/048/053NXMDCR (Cooling mode) ..................................................................................................77

1-3 AM036/048/053NXMDCR (Main cooling mode) .......................................................................................78

1-4 AM036/048/053NXMDCR (Heating mode) ..................................................................................................79

1-5 AM036/048/053NXMDCR (Main heating mode) .......................................................................................80

2. Nomenclatures ...............................................................................................................................................81

2-1 OUTDOOR UNIT ........................................................................................................................................................81

■ Check Operation & Amount of Refrigerant Automatically Checking ............ 82

1. Check Operation ...........................................................................................................................................82

1-1 Check Operation ......................................................................................................................................................82

1-2 How to troubleshoot of the "Undetermined" .............................................................................................84

1-3 Automatic Commissioning Error Code ..........................................................................................................90

2.

Automatic refrigerant amount detection function (Checking th amount of refrigerant)

.............91

4

Samsung Electronics

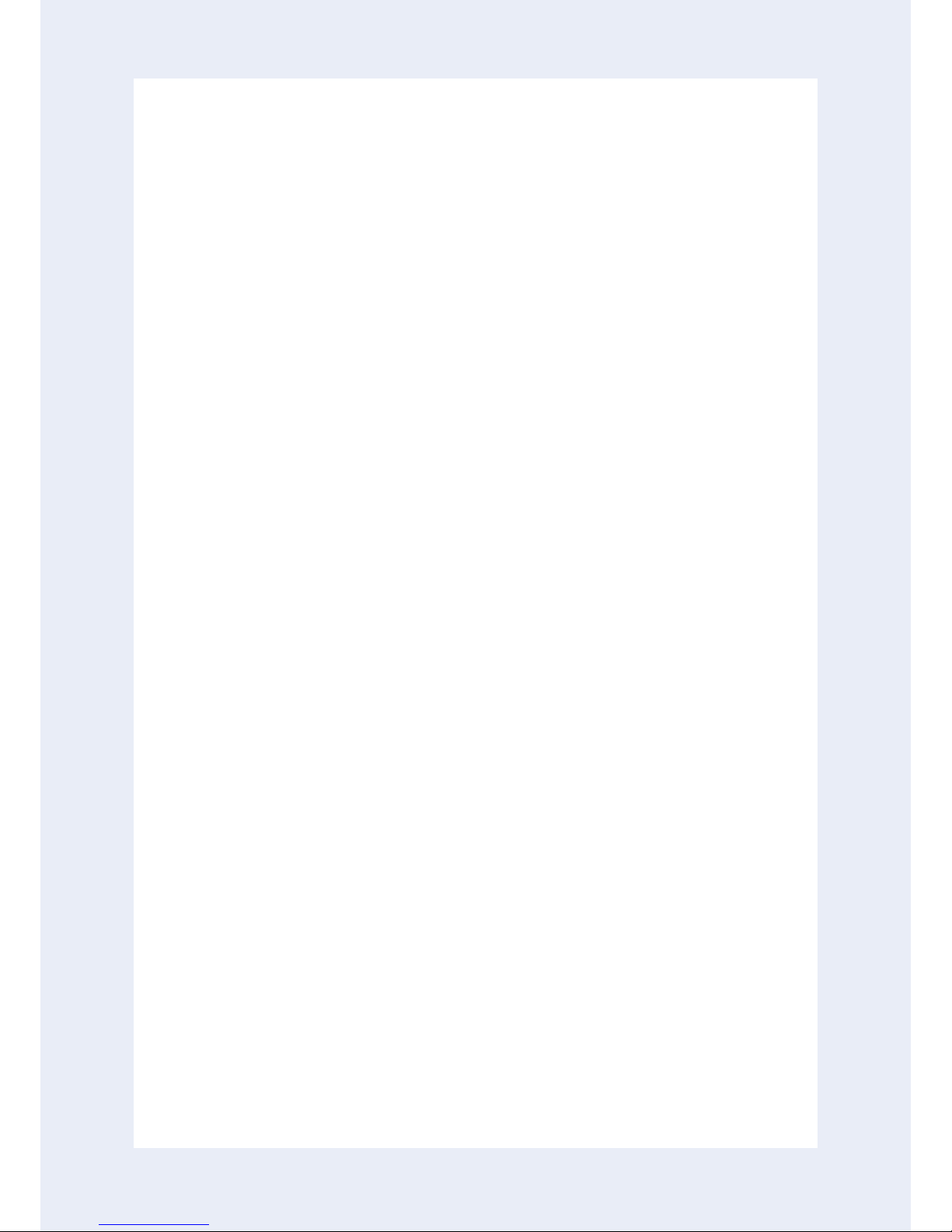

High performance BLDC fan motor

Cross section of a Turbo Inter-cooler

33% more ecient compare to AC motor

Wide speed control range, less noise

generation

Turbo Inter-cooler

Long piping up to 175m with sub-cooling

Up to 50m levela dierence is allowed for

installation

Twin BLDC compressor

Increased energy eciency

compare to conventional compressor

Stable operation with 80%

decreased vibration

Anti-chloride coated outdoor unit

heat exchanger

Anti-corrosion /erosion G-Fin

provide stable heat exchanging

performanceation

High ecient propeller fan

Reduced noise on outdoor

unit

Improved heat exchange

rate

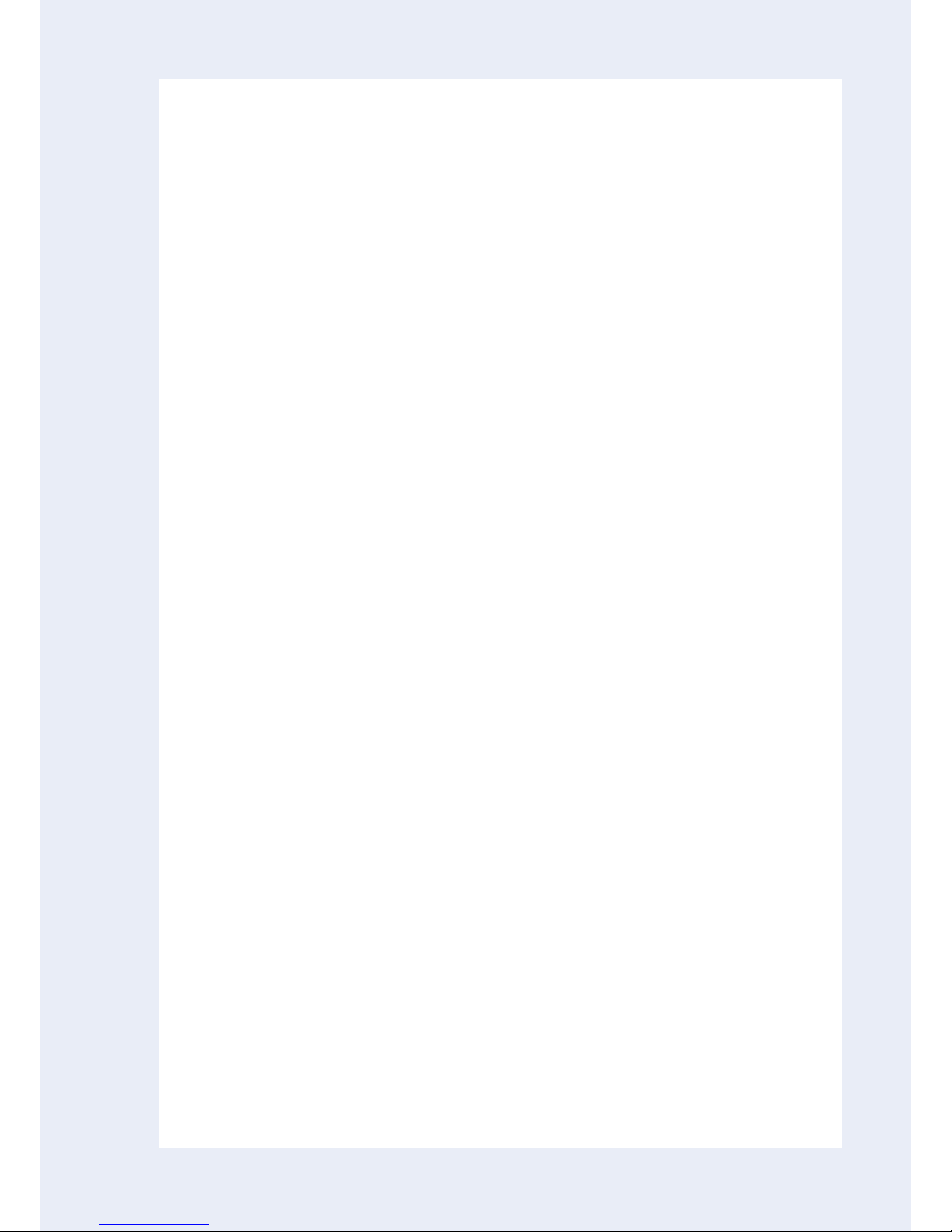

Company A

Company A

Diameter

Ø8 Ø7

Heat transfer surface area

19%

Evaporation

14.1%

Condensation

10.3%

Internal heat transfer performance

30.8%

Pressure resistance

Same

➜➜

➜

Pressure

loss in heat

exchanger

■ Product Specifications

1. The Feature of Product

1-1 Feature

High efficient heat exchanger

High efficient G-Fin & epoxy acrylic coating has increased heat transfer and hydrophilicity on heat exchanger.

Structure of outdoor unit

Product Specifications

Samsung Electronics

5

20 30 40

0

2

4

8

10

12

0.00

0.08

0.04

0.12

0.24

0.16

Amount of transferred heat (kW/m)

Refrigerant ow (Kg/h)

Increased by 30.8%

Decreased by 14%

Pressure loss (kPa/m)

Ø7 Groove Ø8 High Groove

New Ø7 wide n

Ø7 wide n

Heat transfer

amount

15%

New Ø8 wide n

Ø8 Fin

Heat transfer

amount

15%

Feature (cont.)

Optimized cooling/heating and increased system efficiency! Liquid EEV & Turbo Inter-cooler

• Liquid EEV for increased efficiency of the system

Through Liquid EEV, controlling of valve opening has become more efficient and it achieved optimized system efficssiency and

minimized noise from the refrigerant in the indoor unit.

• Turbo Inter-cooler

High performing shell & tube type heat exchanger has been applied to secure cooling/heating efficiency. It has secured enough

subcooling to acquire reliability on long piping and it also increased cooling/heating efficiency.

Application of wide fin

High efficient heat exchanger has been applied, therefore it delays the onset of frost formation and increased heat transfer efficiency.

Sub-cooled

liquid refrigerant

Low temperature

gas refrigerant

Low temperature

liquid refrigerant

Saturated liquid refrigerant

Cross section of the

Turbo inter-cooler

Cross section of the

conventional inter-cooler

*Increased heat transfer area with Shell & Tube type

온도

Temperature

Turbo Inter-cooler

Product Specifications

6

Samsung Electronics

Raw aluminum material

Anti corrosive layer (Epoxy acrylic)

Hydrophilic layer (Acrylic resin + surfactant)

Company A

No corrosion after 1,000 hours of test

Corrosion is evident after 1,000 hours of test

* Tested by Samsung

Company A

Level

dierence

between

indoor units

15m

High level

dierence

50m

Long piping

175m

(Equivalent length)

Feature (cont.)

Reinforced corrosion resistance on the heat exchanger

To prevent corrosion of the products which is installed in saline area, corrosion resistance has been reinforced.

Long piping/High level difference technology

Longest piping length is allowed up to 175m (equivalent length) and Maximum 50m of level difference is allowed for more flexible

installation.

Product Specifications

Samsung Electronics

7

Operation

time

12 hours of silent mode6 hours

7 : 00 13 : 30 19 : 00 7 : 00

End

Highest temperature

※ 3 month wort h of data can be saved

when memo ry module is instal led

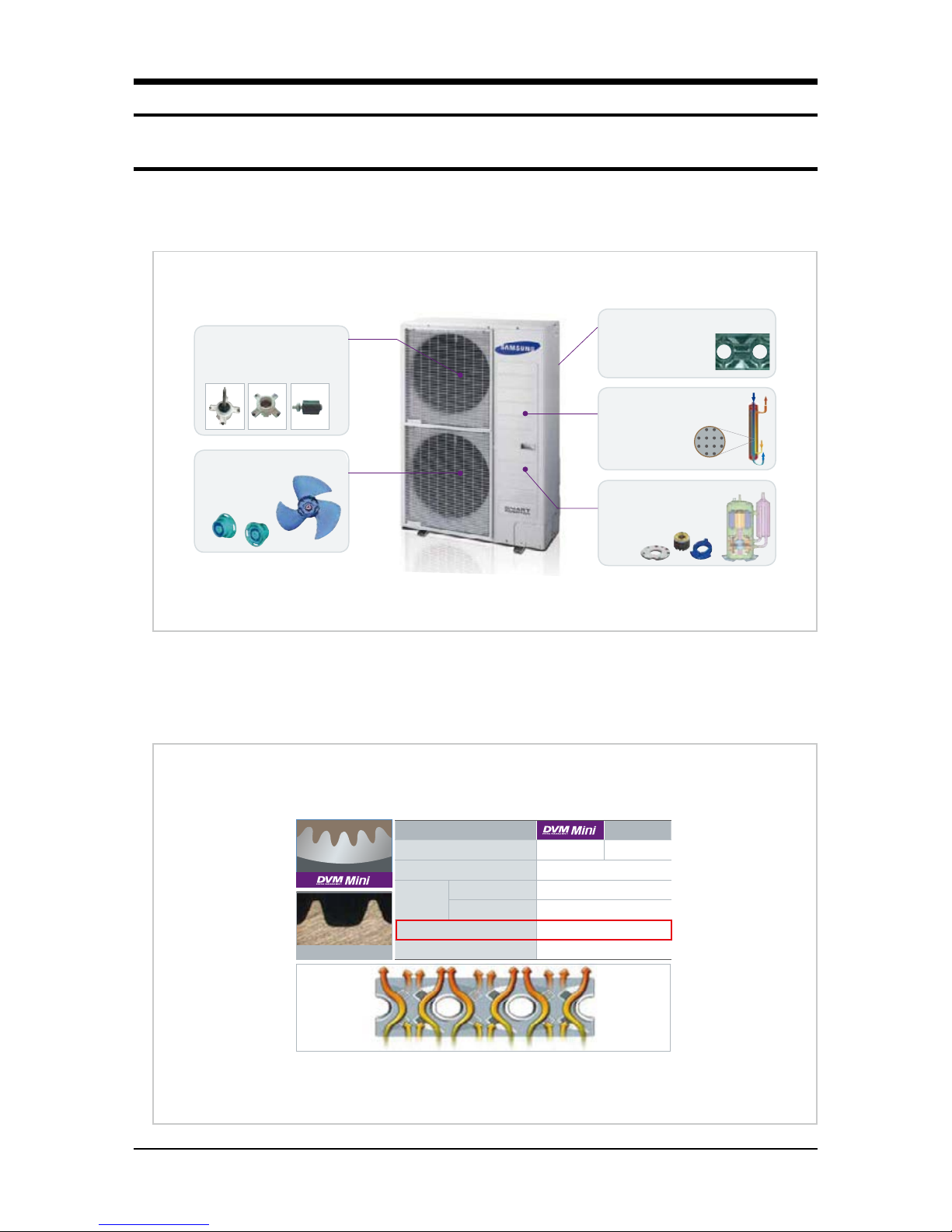

Black box function of the Main PCS

Feature (cont.)

Memory module

• Achieves world-class efficiency with hyper compressor that applies double compression technology

If outdoor unit malfunction occurs, diagnose and repair of the problem will be much quicker with the last 3 minutes worth of a data

saved before the malfunction. (With the extra memory module, 3 months worth of a data can be saved.)

Silent operation at nighttime

• When outdoor unit needs to operate more silently during nighttime, silent mode can be set from the outdoor unit option mode.

• Silent mode can be adjusted in 3 levels depending on the level of noise.

Product Specifications

8

Samsung Electronics

Refrigerant pump-down

If you need to move/replace the outdoor unit or when there are problems on indoor units or on the pipes, outdoor unit will recover

refrigerant remaining on the pipes.

Indoor unit

malfunction

Refrigerant recoveringsss

Feature (cont.)

System check through View mode

• Through the window on outdoor unit PCB display, you can check the main system data during operation.

• Shortened maintaining and inspection

• Displaying 15 main data including high pressure of system

- Outdoor temperature

- Discharge temperature of the compressor

- Condensing temperature

• Using the DIP switch on the outdoor unit PCB, you can limit the running current of the system

Product Specifications

Samsung Electronics

9

Feature (cont.)

Conventional

* For models w ith 9kW or larger (Flare t ype connection)

Convenient product installation

Service valve is not exposed to keep the neat appearance and pipe can be connected in 4 different directions which provide flexible

installation and maintenance services.

Maximum 9 indoor unit connection

Maximum 9 indoor unit connection

You may connect up to 9 indoor units on a single outdoor unit. It will allow more powerful and flexible air conditioning system

and you can select refrigerant pipe length, or number of indoor units depending on the needs for office, commercial and residential

places.

Product Specifications

10

Samsung Electronics

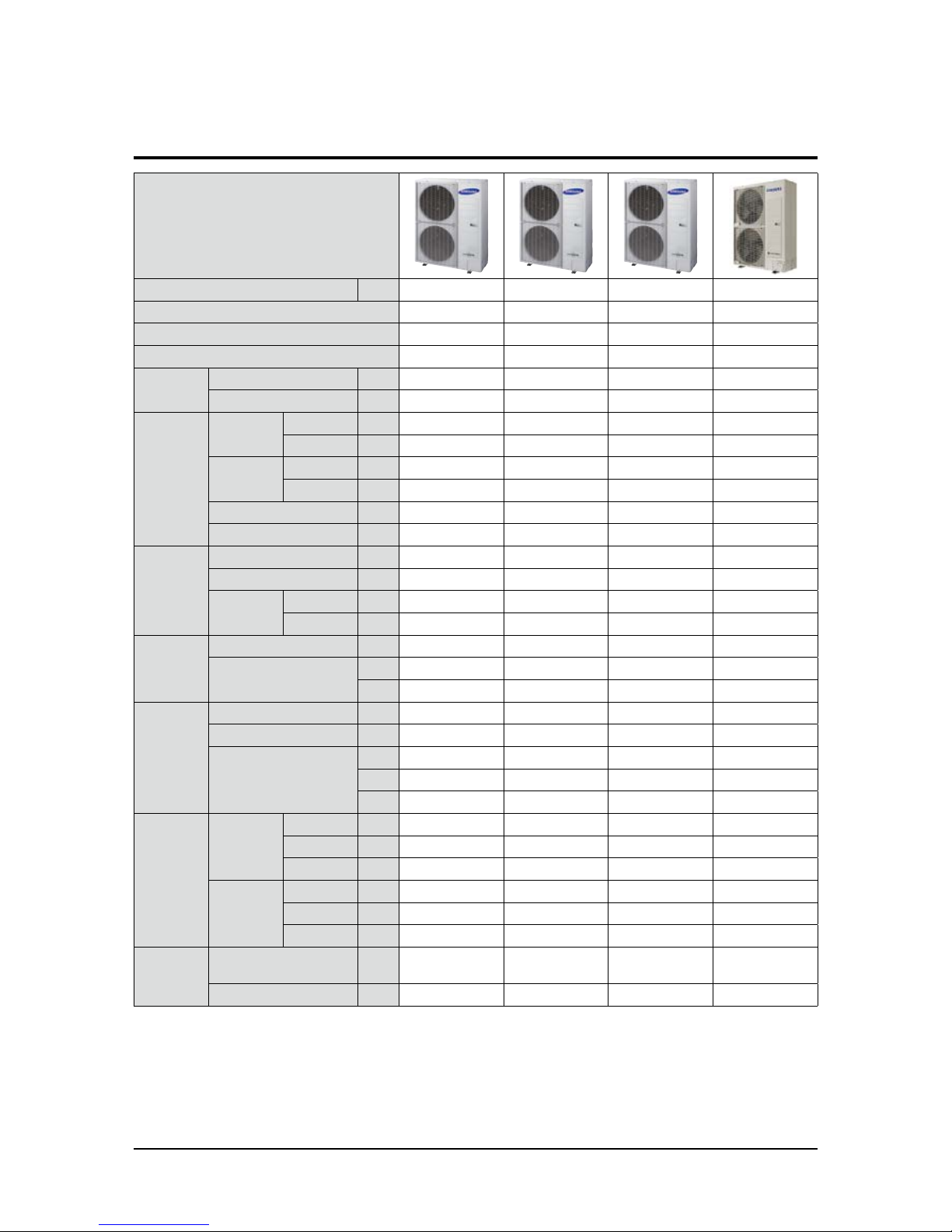

Type

Performance ton 3ton 4ton 4.5ton 5.0 ton

Model AM036NXMDCR AM048NXMDCR AM053NXMDCR AM060NXMDCR

Power Supply(Φ/V/Hz) 1,208-230,60 1,208-230,60 1,208-230,60 1,208-230,60

Mode HR HR HR HR

Performance

Cooling Btu/h 38,000 48,000 53,000 60,000

Heating Btu/h 42,000 54,000 61,000 66,000

Power

Running

Current

Cooling* A 15.0 20.3 25.6 23.0

Heating* A 16.4 21.3 26.1 23.5

Input

Cooling* W 3,100 4,200 5,300 5,200

Heating* W 3,400 4,400 5,400 5,300

MCA A 23 29 34 32

MOP A 40 50 50 50

Compressor

Type - Twin BLDC Inverter Twin BLDC Inverter Twin BLDC Inverter Scroll Inverter

Output W 4.04 4.04 4.04 ?

Lubricant

Type - PVE PVE PVE PVE

Charging cc 1700 1700 1700 2300

Refrigerant

Type - R410A R410A R410A R410A

Factory Charging

kg 3.2 3.2 3.3 3.7

lbs 7.1 7.1 7.3 8.2

FAN

Type - Propeller Fan Propeller Fan Propeller Fan Propeller Fan

Motor Output W 125x2 125x2 125x2 139x2

Airow rate

CMM 110 110 110 135

CFM 3,885 3,885 3,885 4,768

l/s 1,833 1,833 1,833 2,250

Pipe

Piping

connections

Liquid ø,mm 9.52 (3/8") 9.52 (3/8") 9.52 (3/8") 9.52 (3/8")

Sub Gas (HR) ø,mm 15.88 (5/8") 15.88 (5/8") 15.88 (5/8") 15.88 (5/8")

Gas ø,mm 19.05 (3/4") 19.05 (3/4") 19.05 (3/4") 19.05 (3/4")

Installation

Limitation

Max. Length m (ft) 300 (984) 300 (984) 300 (984) 300 (984)

Length m (ft) 150 (492) 150 (492) 150 (492) 150 (492)

Max. Height m (ft) 50 (164) 50 (164) 50 (164) 50 (164)

Cable

Main Power

(Below/about 20m)

mm2 CV 2.5/4.0 CV 2.5/4.0 CV 2.5/4.0 CV 2.5/4.0

Communication mm2 VCTF 0.75~1.5 VCTF 0.75~1.5 VCTF 0.75~1.5 VCTF 0.75~1.5

2. Product Specifications

Product Specifications

Samsung Electronics

11

Type

Performance ton 3ton 4ton 4.5ton 5.0 ton

Model AM036NXMDCR AM048NXMDCR AM053NXMDCR AM060NXMDCR

Set Size

Net weight

kg 97 97 100 125

lbs 213.8 213.8 220.5 275.6

Shipping Weight

kg 107 107 110 135

lbs 235.9 235.9 242.5 297.6

Net dimension (WxHxD)

mm 940 x 1210 x 330 940 x 1210 x 330 940 x 1210 x 330 1420 x 940 x 330

inch 37.01 x 47.64 x 12.99 37.01 x 47.64 x 12.99 37.01 x 47.64 x 12.99 55.91 x 37.00 x 12.99

Shipping dimension (WxHxD)

mm 995 x 1388 x 426 995 x 1388 x 426 995 x 1388 x 426 1578 x 995 x 426

inch 39.17 x 54.65 x 16.77 39.17 x 54.65 x 16.77 39.17 x 54.65 x 16.77 62.13 x 39.17 x 16.77

Operating

Temp. Range

Cooling

℉

23 ~ 118 23 ~ 118 23 ~ 118 23 ~ 118

Heating

℉

-13 ~ 75 -13 ~ 75 -13 ~ 75 -13 ~ 75

Maximum of connected indoor units 8 9 10 10

*

Rated Power/Current using Ducted indoor units

12

Samsung Electronics

Necessary Tools

■ Disassembly and Reassembly

Item Remark

+Screw Driver

Monkey Spanner

–Screw Driver

Nipper

Electric Motion Driver

L-Wrench

Disassembly and Reassembly

Samsung Electronics

13

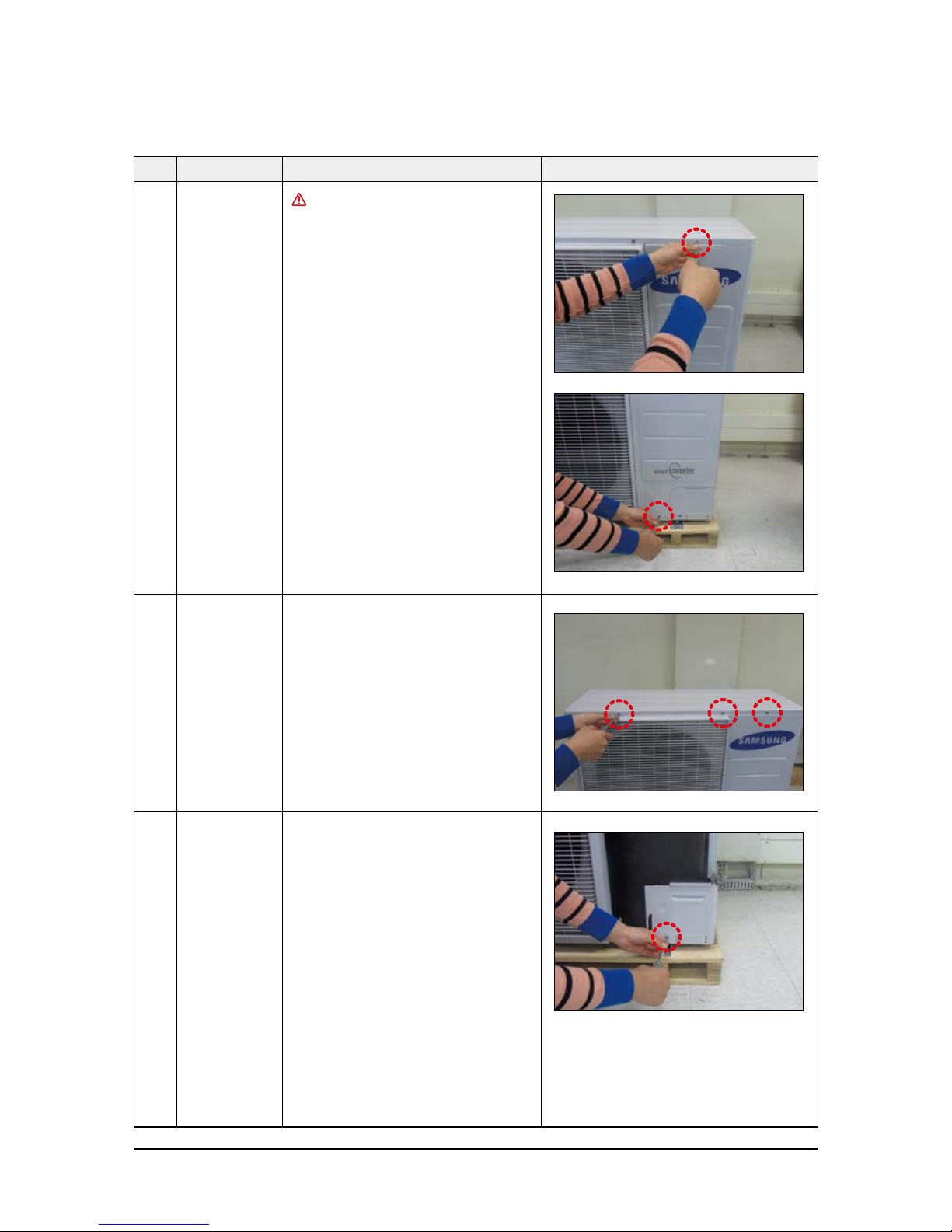

No Parts Procedure Remark

1 Cabi Front RH

You must turn off the Power before

disassembly.

1) Unscrew and remove 2 mounting screw in

the Cabinet Front RH. (Use + Screw Driver)

2 Cabi Top 1) Unscrew and remove 9 screws

on each side of the Cabinet-Top.

(Use +Screw Driver)

3 Cabi Install Front 1) Unscrew and remove 1 screw

in the Cabinet-Install Front.

(Use +Screw Driver)

AM036NXMDCR, AM048NXMDCR, AM053NXMDCR

Disassembly and Reassembly

14

Samsung Electronics

No Parts Procedure Remark

4 Guard Cond 1) Pull the sensor from Guard Cond.

2) Unscrew and remove 4 screws

in the Guard Cond. (Use + Screw Driver)

5 Cabi Back RH 1) Pull the sensor from Cabi Back RH.

2) Unscrew and remove 4 screws on

each side of the Cabinet Back RH.

(Use + Screw Driver)

Disassembly and Reassembly

Samsung Electronics

15

No Parts Procedure Remark

6 Cabi Install Back 1) Unscrew and remove 1 screw

in the Cabinet-Install Back.

(Use +Screw Driver)

7 Cabi Front LF 1) Unscrew and remove 10 screws

in the Cabinet-Front LF.

(Use +Screw Driver)

Disassembly and Reassembly

16

Samsung Electronics

No Parts Procedure Remark

8 Fan 1) Turn 2 mounting nuts as shown in the

picture and remove it.

(Use L Wrench or Monkey

Spanner or Socket Wrench )

Disassembly and Reassembly

Samsung Electronics

17

No Parts Procedure Remark

9 Motor 1) Separate the Fan Propeller.

2) Unscrew and remove the 8 Motor mounting

screws. (Use +Screw Driver)

3) Disconnect the Motor wire from

Ass’y Control Out.

10 Bracket Motor 1) Unscrew and remove 2 mounting screws in

Bracket Motor. (Use + Screw Driver)

Disassembly and Reassembly

18

Samsung Electronics

No Parts Procedure Remark

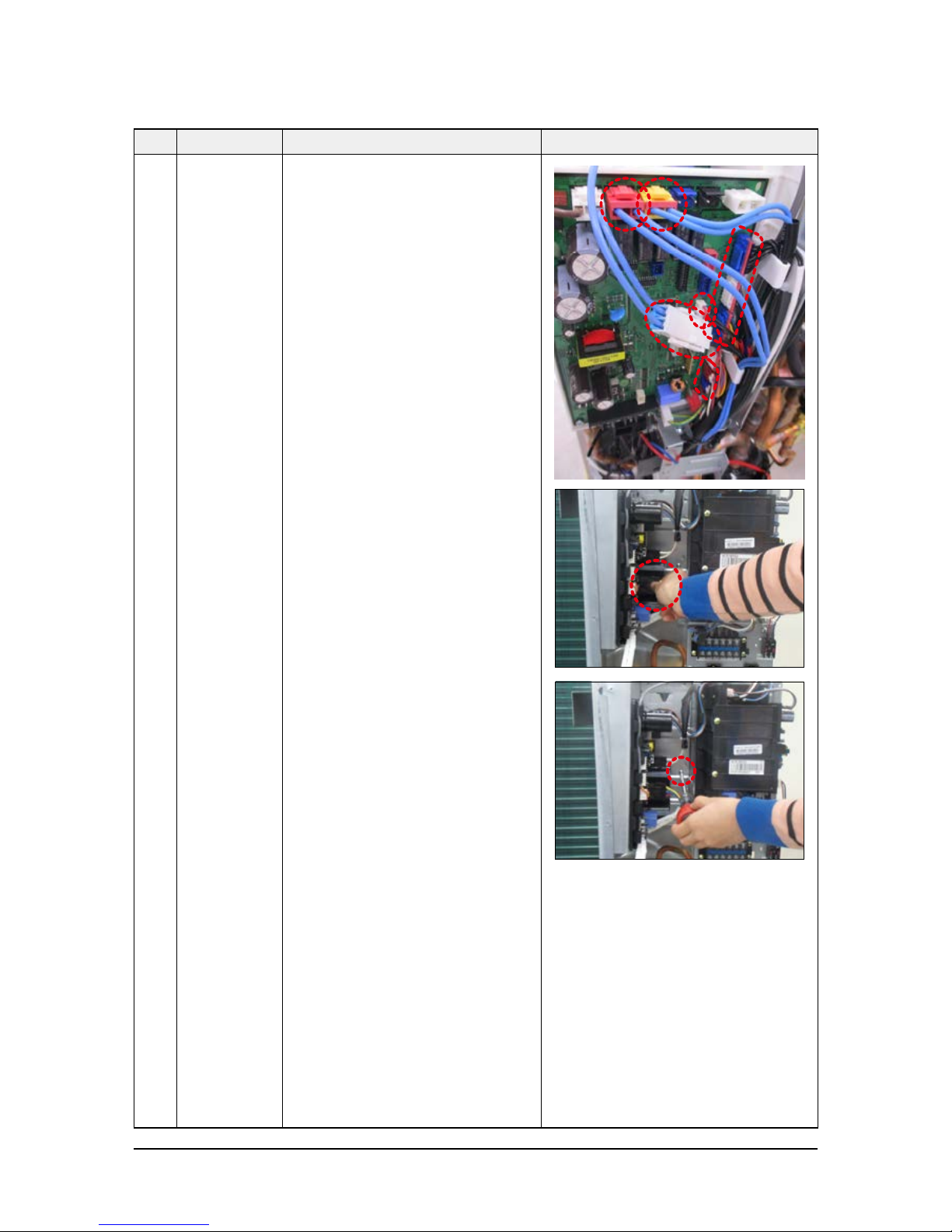

11 Control Out 1) Disconnect 10 Connectors from Ass’y control

Out.

2) Unscrew and remove 1 mounting screw in

Control Out. (Use + Screw Driver.)

3) Separate Ass’y Control Out.

Disassembly and Reassembly

Samsung Electronics

19

No Parts Procedure Remark

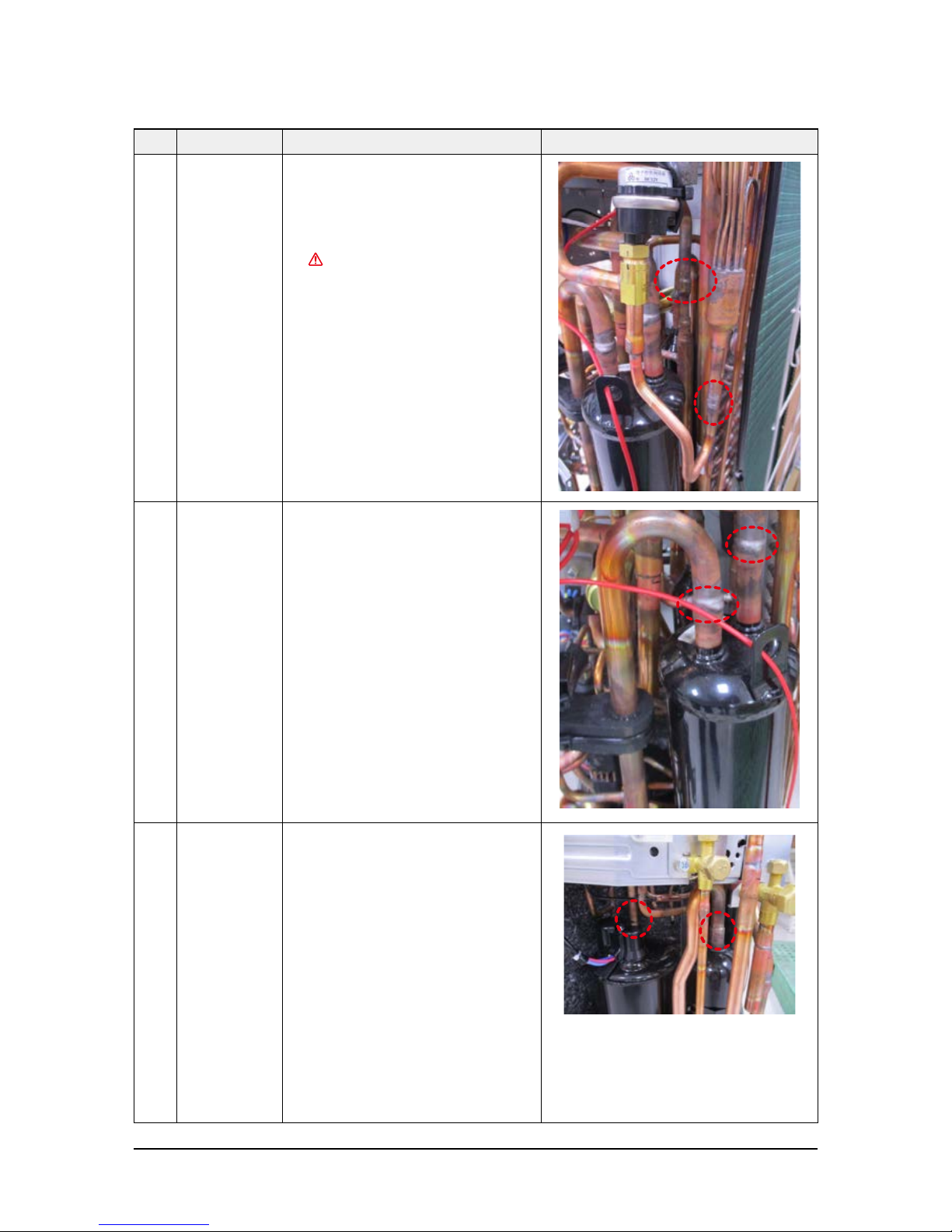

12 Ass'y Tube EEV 1) Purge the Coolant first.

2) Separate 2 parts of the pipe using a welder.

When removing the compressor,

Heat Exchanger and Pipe, purge the

refrigerant inside the Compressor

completely and remove the pipe with

a welding flame.

13 Ass'y Tube Suction 1) Separate 2 parts of the pipe using a welder.

14 Ass'y Tube 4Way 1) Separate 2 parts of the pipe using a welder.

Disassembly and Reassembly

20

Samsung Electronics

No Parts Procedure Remark

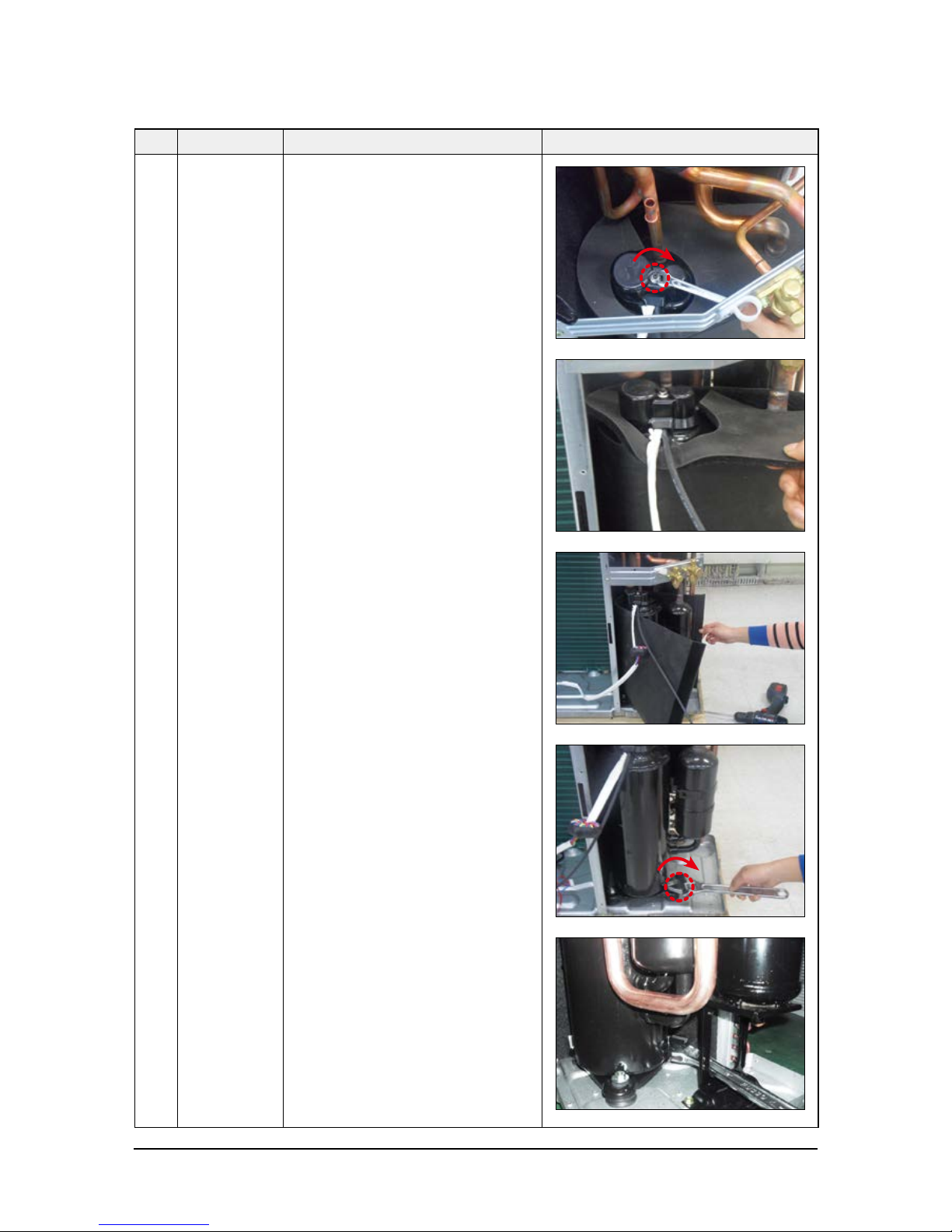

15 Compressor 1) Unscrew and remove 1 mounting

nut in bottom of the cover.

(Use Adjustable Wrench)

2) Separate the Compressor Felt.

3) As shown in the picture, unscrew and

remove 3 mounting screws from the bottom.

(Use L-Wrench or Monkey Spanner or

Socket Wrench)

Disassembly and Reassembly

Samsung Electronics

21

No Parts Procedure Remark

16 Cond Out 1) Unscrew and remove 3 screws

on each side of the Ass’y Cond Out.

(Use + Screw Driver)

Disassembly and Reassembly

22

Samsung Electronics

No Parts Procedure Remark

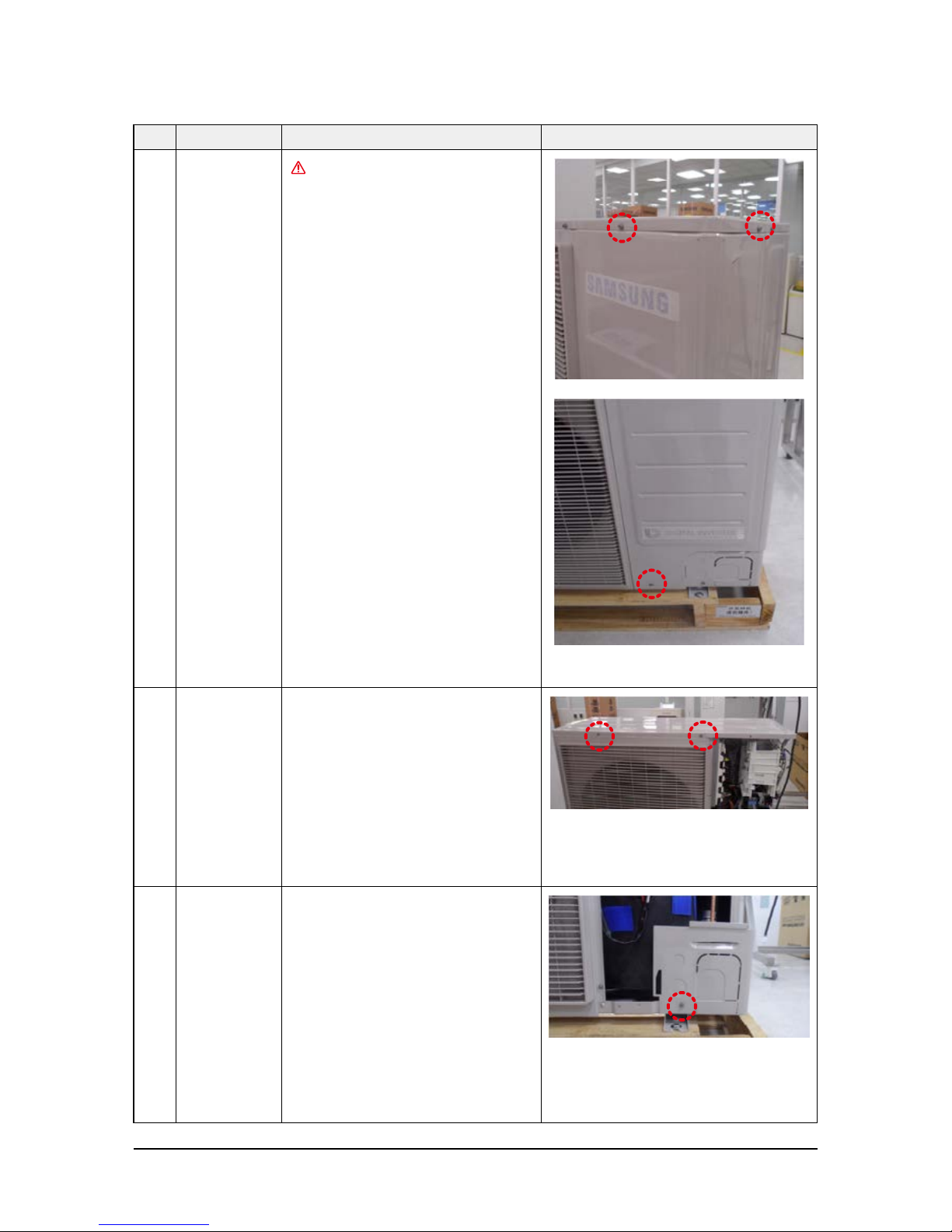

1 Cabi Front RH

You must turn off the Power before

disassembly.

1) Unscrew and remove 3 mounting screw in|

the Cabinet Front RH. (Use + Screw Driver)

2 Cabi Top 1) Unscrew and remove 8 screws on each side of

the Cabinet-Top. (Use +Screw Driver)

3 Cabi Install Front 1) Unscrew and remove 1 screw in the Cabinet

Install Front. (Use +Screw Driver)

AM060NXMDCR

Disassembly and Reassembly

Samsung Electronics

23

No Parts Procedure Remark

4 Guard Cond 1) Pull the sensor from Guard Cond.

2) Unscrew and remove 4 screws in the Guard Cond.

(Use + Screw Driver)

Disassembly and Reassembly

24

Samsung Electronics

No Parts Procedure Remark

5 Cabi Back RH 1) Pull the sensor from Cabi Back RH.

2) Unscrew and remove 4 screws on

each side of the Cabinet Back RH.

(Use + Screw Driver)

Disassembly and Reassembly

Samsung Electronics

25

No Parts Procedure Remark

5 Cabi Back RH 3) Unscrew and remove 5 screws on

side of the Case Bracket valve.

(Use + Screw Driver)

6 Cabi Install Back 1) Unscrew and remove 1 screw in the Cabinet

Install Front. (Use +Screw Driver)

Disassembly and Reassembly

26

Samsung Electronics

No Parts Procedure Remark

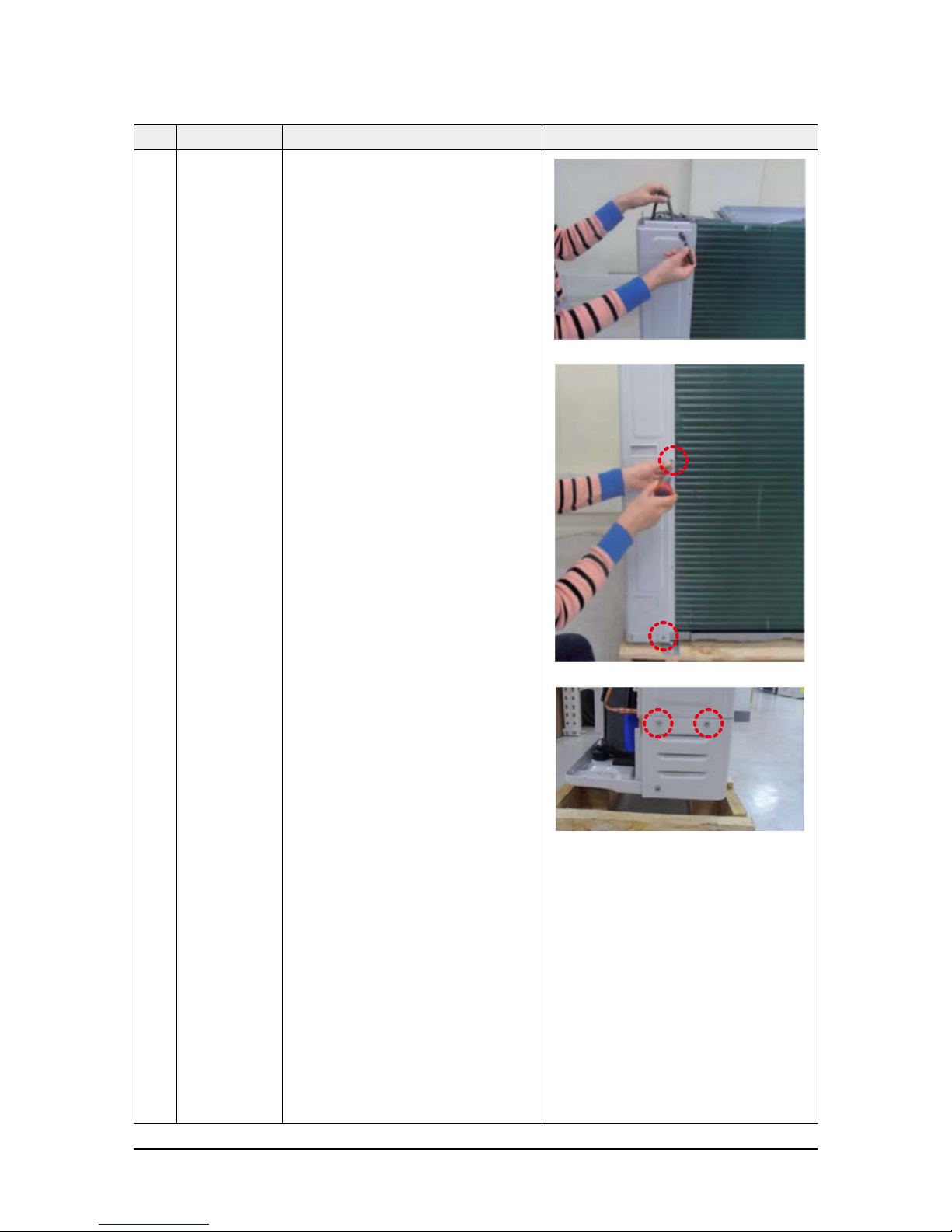

7 Cabi Front LF 1) Unscrew and remove 10 screws in the

Cabinet-Front LF. (Use +Screw Driver)

Disassembly and Reassembly

Samsung Electronics

27

No Parts Procedure Remark

7 Cabi Front LF

8 Fan 1) Turn 2 mounting nuts as shown in the

picture and remove it. (Use L Wrench

orMonkey Spanner or Socket Wrench )

Disassembly and Reassembly

28

Samsung Electronics

No Parts Procedure Remark

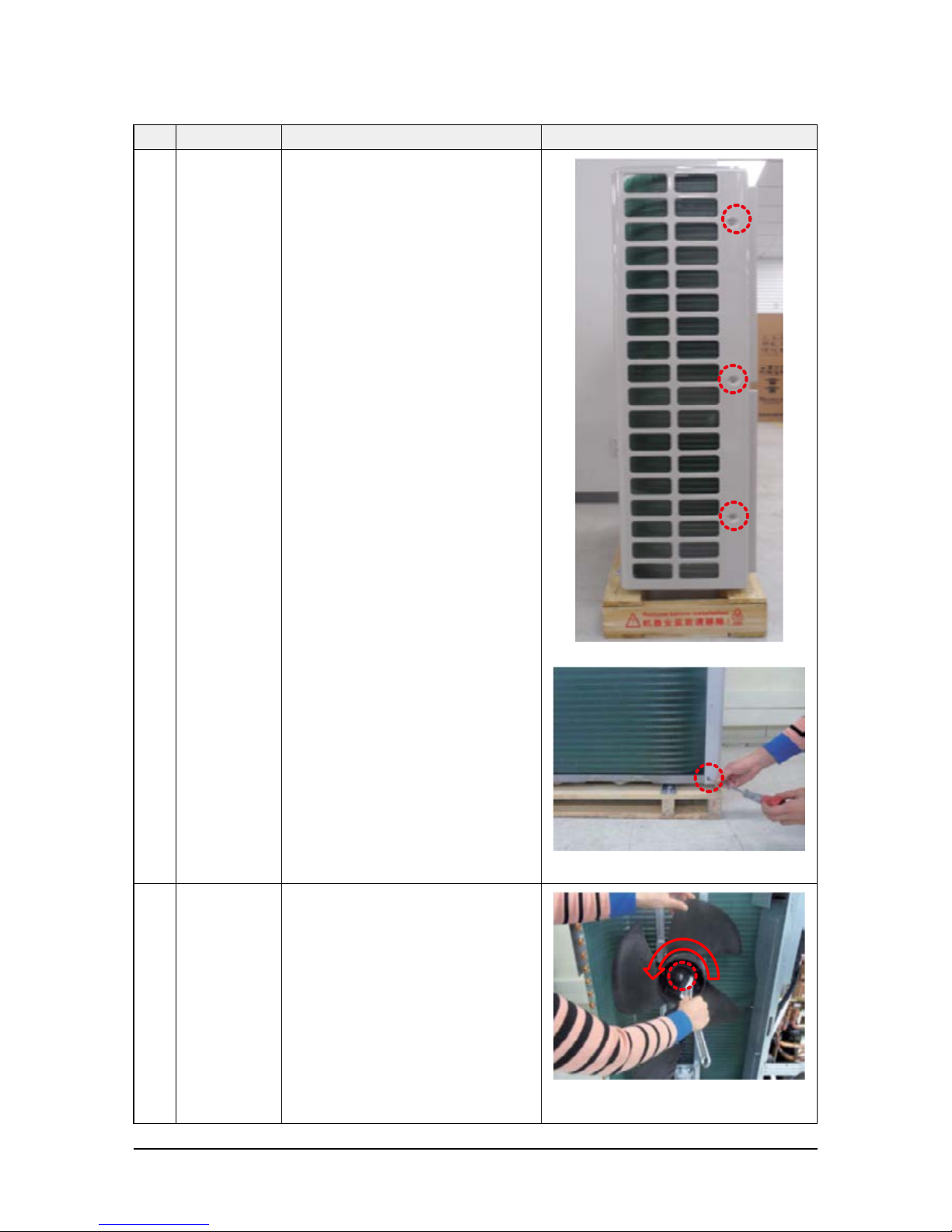

9 Motor 1) Separate the Fan Propeller.

2) Unscrew and remove the 8 Motor mounting

screws. (Use +Screw Driver)

3) Disconnect the Motor wire from

Ass’y Control Out.

10 Bracket Motor 1) Unscrew and remove 2 mounting screws

in Bracket Motor. (Use + Screw Driver)

Loading...

Loading...