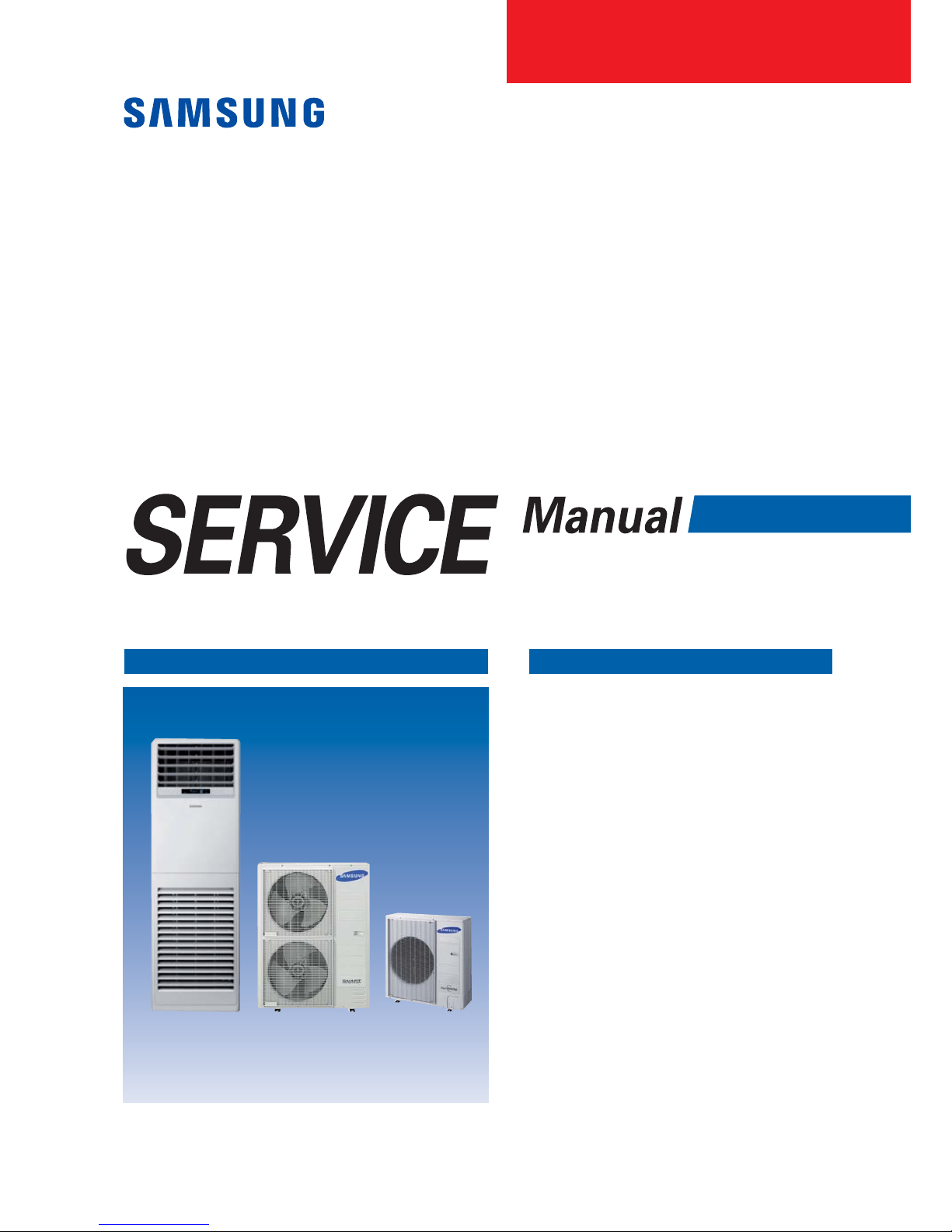

AIR CONDITIONER

CONTENTS

FLOOR STAND TYPE AIR CONDITIONER

Basic : AF55JV1MAEE

CCPQXK840CA / CCPPNK840CA : ledoM

AC036KNPPCC / AC036KXQPCC

AC140KNPDEH / AC140KXADGH

AC100KNPDEH / AC100KXADEH

AC048KNPDEC / AC048KXADGC

AC036KNPDEC / AC036KXADEC

Model Code : AC048KNPPCC/MG AC048KXQPCC/MG

AC036KNPPCC/MG AC036KXQPCC/MG

AC140KNPDEH/EU AC140KXADGH/EU

AC100KNPDEH/EU AC100KXADEH/EU

AC048KNPDEC/TL AC048KXADGC/TL

AC036KNPDEC/TL AC036KXADEC/TL

1. Precautions

2. Product Specications

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagram

6. Wiring Diagram

7. Reference Sheet

AC048KXQPCC

AC036KXQPCC

AC140KXADGH

AC048KXADGC

AC048KNPDEC/SV AC048KXADGC/SV

AC048KNPPCC

AC036KNPPCC

AC140KNPDEH

AC100KNPDEH

AC048KNPDEC

AC036KNPDEC

AC100KXADEH

AC036KXADEC

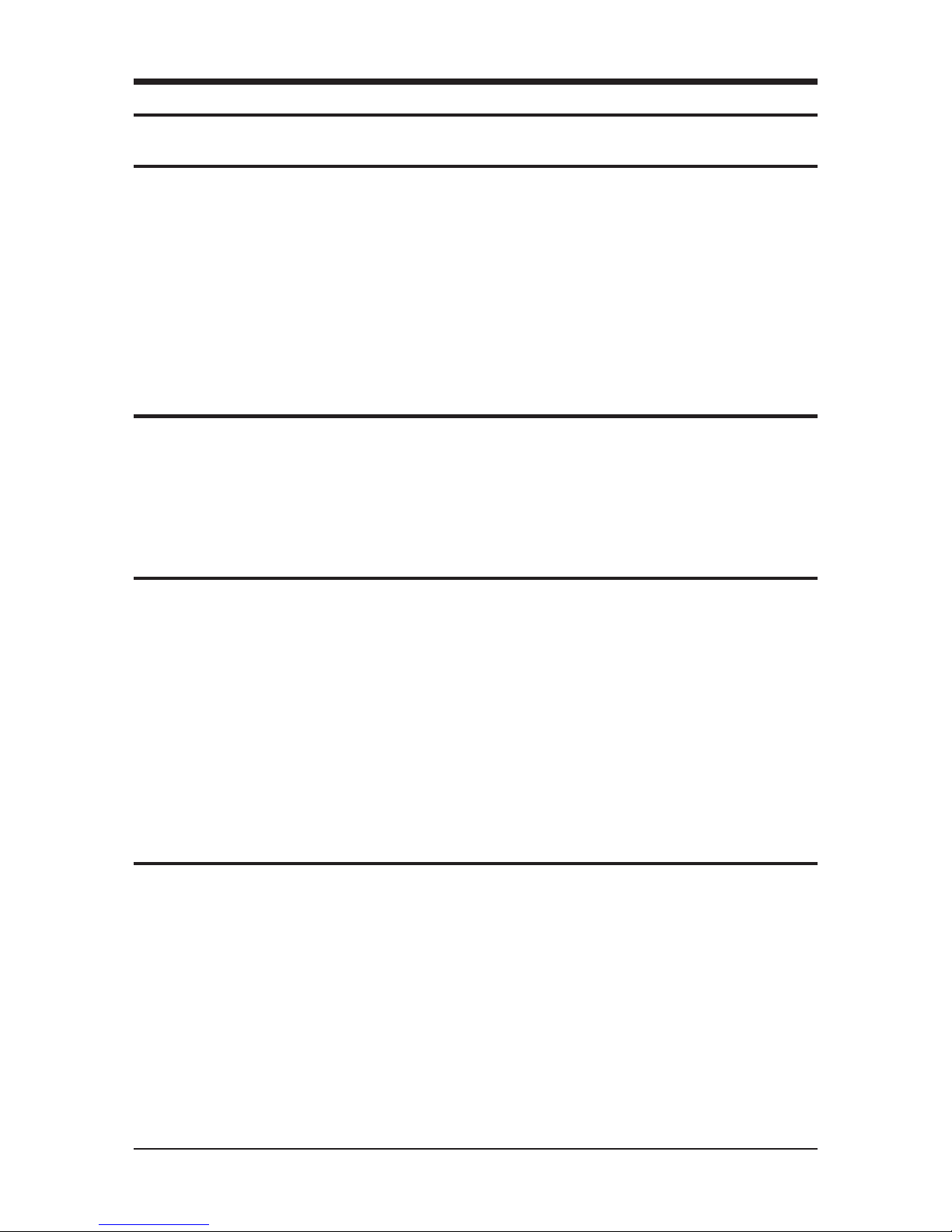

Contents

1. Precautions ······································································································································· 1-1

1-1 Precautions for the Service ············································································································ 1-1

1-2 Precautions for the Static Electricity and PL ··············································································· 1-1

1-3 Precautions for the Safety ·············································································································· 1-1

1-4 Others ················································································································································ 1-1

2. Product Specifications ·············································································································· 2-1

2-1 The Feature of Product ··················································································································· 2-1

2-1-1 Features ·································································································································· 2-1

2-1-2 Changes in comparison to basic model ············································································ 2-2

2-2 The Comparative Specifications of Product ················································································ 2-3

2-3 Accessory and Option Specifications ··························································································· 2-5

2-3-1 Filter·········································································································································· 2-5

2-3-2 Accessory ································································································································· 2-5

3. Disassembly and Reassembly ······························································································ 3-1

3-1 Indoor Unit ······································································································································· 3-2

3-2 Outdoor Unit ···································································································································· 3-10

4. Troubleshooting ···························································································································· 4-1

4-1 Indoor Display Error and Check Method ····················································································· 4-1

4-1-1 Indoor unit LED display at error detecting ······································································· 4-1

4-2 Outdoor Trouble shooting ············································································································· 4-2

4-3 Troubleshooting by symptoms ····································································································· 4-5

4-3-1 Communication error after finishing tracking (E202) ······························································ 4-5

4-3-2 Outdoor's service valve(Clog) ············································································································ 4-6

4-3-3 No Power(completely dead) - Initial diagnosis ································································· 4-7

4-3-4 E102 : Communication error between indoor and outdoor unit

E201 : Unit quantity miss matching beween Indoor and Outdoor

E202 : Abnormal state, no communication between Indoor and Outdoor Main PCB

E203 : 1min Time out of communication error(MainļInverter) ········································· 4-11

4-3-5 External Sensor Error (Error Code: E221, E231, E251, E320) ·················································· 4-12

4-3-6 E403 : Freezing control causes comp. down ··············································································· 4-13

4-3-7 E416 : Dischage temperature sensor error ··················································································· 4-14

4-3-8 E440, E441 : Abnormal outside temperature halts operation of the compressor ······· 4-15

4-3-9 Outdoor unit BLDC Fan1 or Fan2 error (E458 : Fan1 error, E475 : Fan2 error) ··············· 4-16

Contents

4-3-10 E461: Compressor start error

E467: Compressor wire missing error ·························································································· 4-17

4-3-11 E462 : Current protection control causes comp. down

E484 : PFC overload error ·················································································································· 4-18

4-3-12 E463 : OLP protection control caused comp. down ······························································ 4-19

4-3-13 E464 : O.C. (Over Current) error······································································································· 4-20

4-3-14 E466: DC Link Over voltage/ Low voltage error······································································· 4-21

4-3-15 Pipe Blocking Error (Error Code: E422) ························································································ 4-22

4-3-16 The others ················································································································································ 4-23

4-3-17 Setting an indoor unit installation option ················································································· 4-24

5. PCB Diagram ··································································································································· 5-1

5-1 Indoor unit ········································································································································ 5-1

5-1-1 Main PCB ································································································································ 5-1

5-1-2 Power PCB ······························································································································ 5-3

5-1-3 Panel PCB ································································································································ 5-4

5-2 Outdoor unit ···································································································································· 5-5

5-2-1 Main PCB Diagram ················································································································ 5-5

5-2-2 Inverter PCB ··························································································································· 5-6

5-2-3 EMI PCB ··································································································································· 5-10

6. Wiring Diagram ····························································································································· 6-1

6-1 Indoor unit ········································································································································ 6-1

6-2 Outdoor unit ···································································································································· 6-2

7. Reference Sheet ···························································································································· 7-1

7-1 Index for Model Name ···················································································································· 7-1

7-2 Refrigerating Cycle Diagram ·········································································································· 7-2

Samsung Electronics 1-1

1. Precautions

1-1 Precautions for the Service

O Use the standard parts when replacing the electric parts.

– Confirm the model name, rated voltage, rated current of the electric parts.

O Repair the disconnection of HARNESS securely when repairing the break down.

– If there is any connection error, it causes an abnormal noise and incorrect operation.

O In case that you assemble or disassemble the products with laying it on the side, do work on the work cloth.

– If not, the exterior of products can be scratched.

O

Remove dust and foreign materials from harness, connection part, and inspection part thoroughly when repairing the break down.

– It protects the danger of fire such as tracking and short.

O Tighten tightly the service valve of outdoor unit and the cap of charging valve with a monkey spanner.

O Check the assembly status of parts after repairing the break down.

– It should be same as the status before repairing.

1-2 Precautions for the Static Electricity and PL

O As the PCB power terminal has a weakness for the static electricity, pay attention to it during the repair and measurement.

– Work with insulation gloves during the repair and measurement of PCB.

O

Check the distance between the product and the other electronic appliances such as TV, video, and audio. It should be over 2m.

– If not, it causes a bad picture quality or a noise.

O Repairing the products by consumer should be strictly prohibited.

– There is a danger of electric shock or fire due to incorrect disassembly.

1-3 Precautions for the Safety

O Do not pull any electric wires and do not touch an auxiliary power switch with a wet hand.

– There is a danger of electric shock or fire.

O In case any wire or power plug has been damaged, replace it to eliminate any possible danger.

O Do not bend the power cord by force and do not put any heavy object on the power cord.

– There is a danger of electric shock or fire.

O Do not use multi socket.

– There is a danger of electric shock or fire.

O Ground the product if necessary.

– Be sure to ground the product if there is any danger of electric leakage due to water or moisture.

O Be sure to turn off the auxiliary power switch or pull out the power plug during replacement or repair of electric parts.

– There is a danger of electric shock.

O In case the product will not be in use for a long time, the battery of remote control should be kept separately.

– Leakage of inside fluid can cause break down of remote control.

1-4 Others

O Never store or load the air conditioner upside down or sideways to prevent the damage to the compressor.

O Young children or infirm persons should be always supervised when they use the air conditioner.

O Max current is measured according to IEC standard for safety.

O Current is measured according to ISO standard for energy efficiency.

O

When installing, make sure there is no leakage. When recovering the refrigerant, ground the compressor first before removing the

connection pipe. If the refrigerant pipe is not properly connected and the compressor works with the service valve open, the pipe

inhales the air and it makes the pressure inside of the refrigerant cycle abnormally high. It may cause explosion and injury.

O Pump Down Procedure (When removing the product)

- Turn on the air conditioner and select Cool mode to run the compressor for 3 minutes.

- Release the valve caps on High and Low pressure side.

- Use L wrench to close the valve on the high pressure side.

- Approximately 2 minutes after, close the valve on the low pressure side.

- Stop operation of the air conditioner.

- Disconnect the pipes.

Product Specifications

Samsung Electronics 2-1

2. Product Specifications

2-1 The Feature of Product

2-1-1 Features

O Strong Turbo/convenient long-distance operation

Quicker and more consistent air cooling/warming is guaranteed by turbo operation that provides strong

cooling/warming for 30 minutes or by long-distance operation that ensures cooling/warming even in places a

long way from the air conditioner.

O Stylish, high quality design

Neat and luxurious style boasts high-quality interior design that ts naturally into any place.

O Compact Remote Controller

A small hand-size remote control makes it even easier to use.

O Long Piping(Length & Height)

It can give the benet to the installers and aries the reliability of the air conditioner.

O Long Ambient Operation(In Low Temperature)

It can arise the reliability and the capacity of the air conditioner, especially operated in low temperature.

O Eco-friendly Product (Lead-Free, RoHS, WEEE)

O

High Performance & Energy Saving

With the advanced BLDC inverter technology, it makes a room cool with highly energy saving and arises the efficiency of air

conditioner.

Product Specifications

2-2 Samsung Electronics

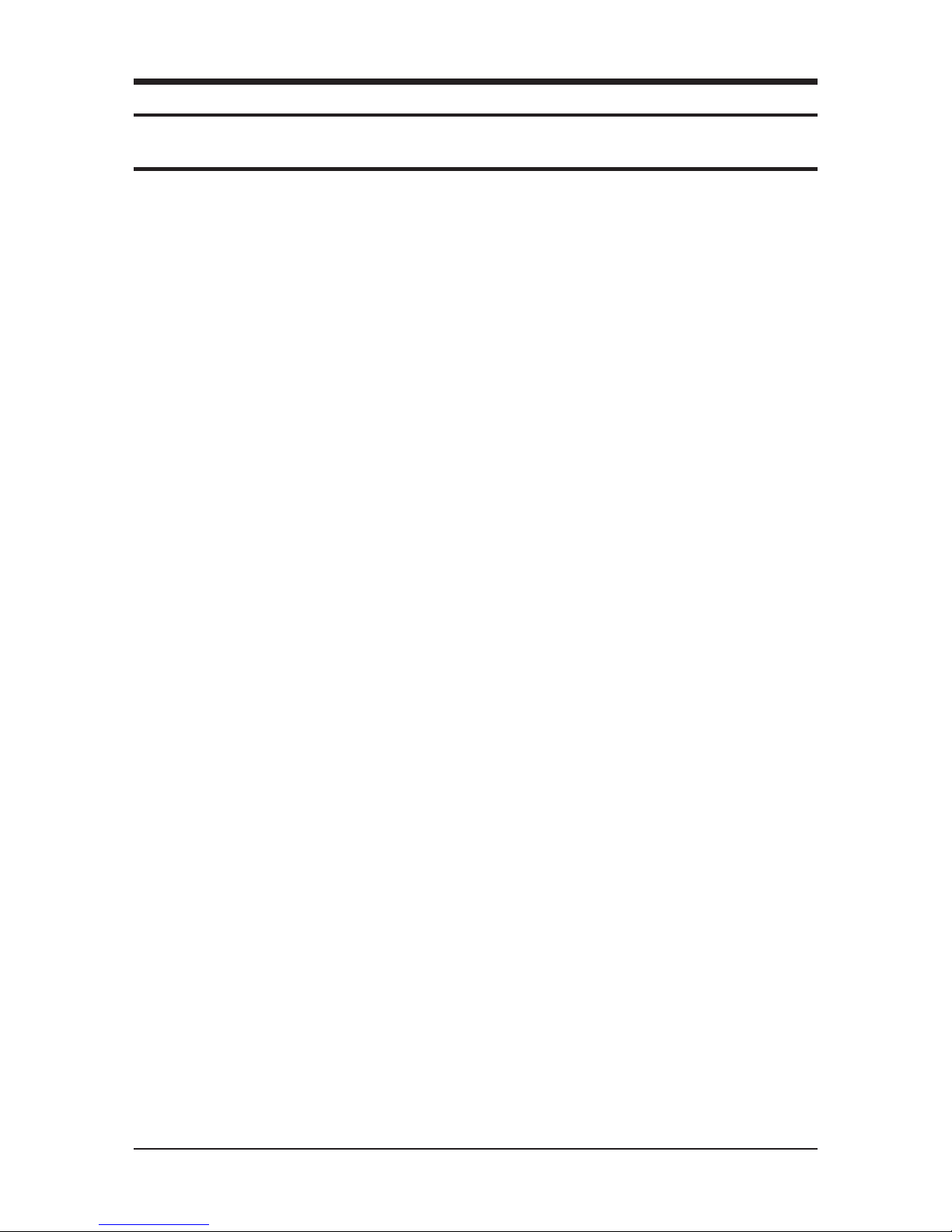

Changed part Changed item and feature Basic After changed

Indoor Unit Wi-Fi Function added.

Outdoor Unit

(AC048KXQPCC

AC036KXQPCC

AC140KXADGH

AC048KXADGC)

Inverter controller changed.

Outdoor Unit

(AC100KXADEH

AC036KXADEC)

--

2-1-2 Changes in comparison to basic model

2-3 Samsung Electronics

Product Specifications

Samsung Electronics 2-4

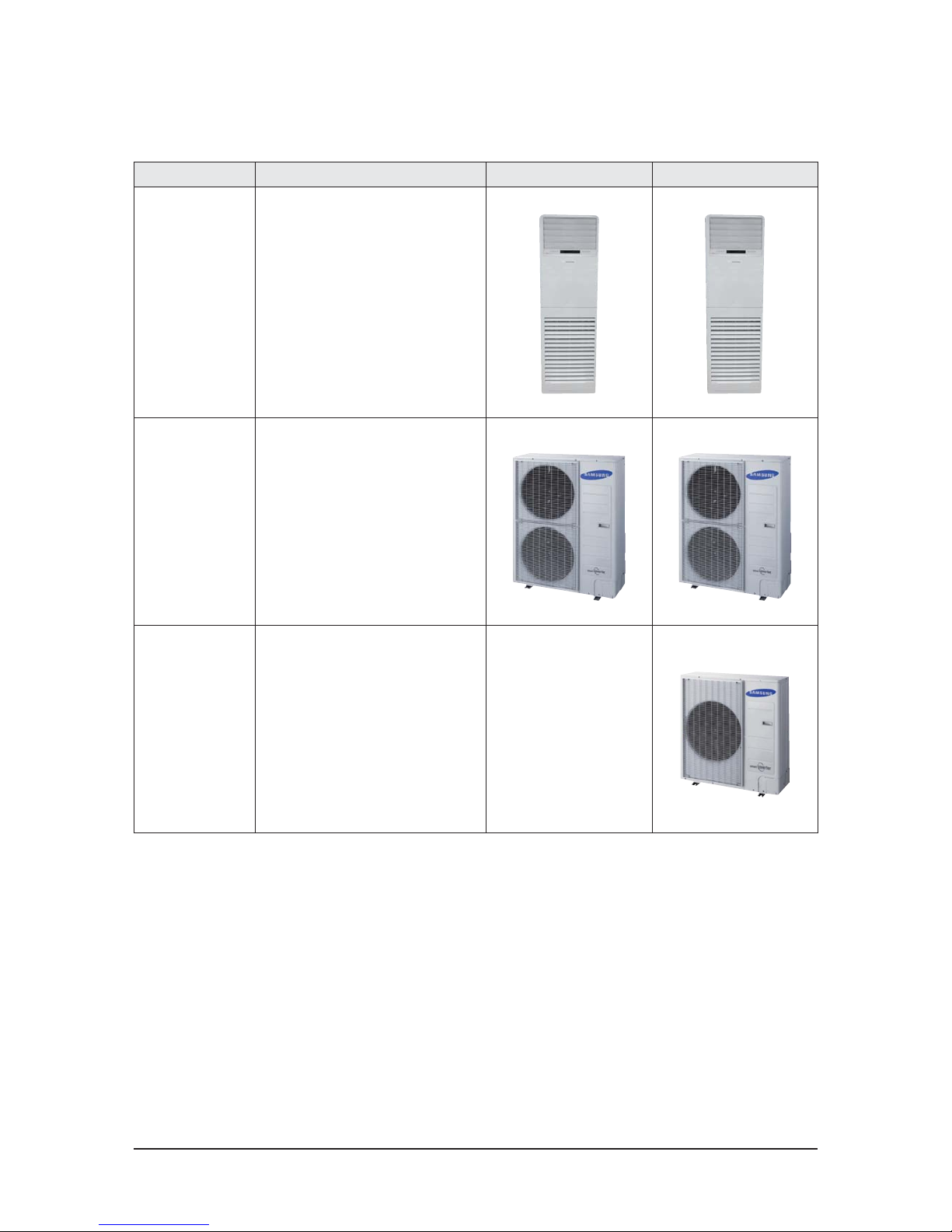

Item

Development Model Basic Model

AC048KNPPCC

AC048KXQPCC

AC036KNPPCC

AC036KXQPCC

AC140KNPDEH

AC140KXAPGH

AC100KNPDEH

AC100KXAPEH

AC048KNPDEC

AC048KXAPGC

AC036KNPDEC

AC036KXAPEC

AF55JV1MAEEN

AF55JV1MAEEX

Design

Indoor Unit

Outdoor Unit

Wireless Remote Controller

DB93-15883B DB93-15883B DB93-15883B DB93-14643X

Performance

Cooling (T1) [Btu/h or W] 15 000/48 000/60 000 12 300 / 36 000 / 45 700 4 200 / 13 400 / 16 700 3 500 / 10 000 / 12 300 3 600 / 14 000 / 16 700 3 400 / 10 000 / 13 000 15000/48000/60000

Cooling (T3) [Btu/h] 42 000 32 000 - - - - 42000

Heating [W] - - 4 000 / 15 500 / 20 000 4 200 / 11 200 / 14 000 - - -

Power Consump-

tion

Cooling (T1) [W] 890 / 4,050 / 6,600 1,100 / 3,030 / 4,000 900 / 4,320 / 5,900 1,100 / 3,700 / 4,900 820 / 5,040 / 5,600 880 / 3,270 / 4,900 890/3930/6600

Cooling (T3) [W] 4,920 3,700 - - - - 4950

Heating [W] - - 700 / 4,500 / 6,600 900 / 3,390 / 4,500 - - -

EER/COP

Cooling (T1) [Btu/h·W or W/W] 11.85 11.88 3.10 11.88 2.78 3.06 12.21

Cooling (T3) [Btu/h·W] 8.54 8.65 - 8.65 - - 8.48

Heating [W/W] - - 3.44 - - - -

SEER [W/W] - - - A+ (5.8) - - -

SCOP[ [W/W] - - - A+ (4.1) - - -

Voltage / Frequency 230V, 60Hz 3Φ 380-415V, 50Hz 220-240V, 50Hz 3Φ 380-415V, 50Hz 220-240V, 50Hz 230V, 60Hz

Operating Current

Cooling (T1) [A] 4.7 / 18.2 / 28.5 5.7 / 13.5 / 18.3 1.9 / 6.8 / 9.5 4.3 / 16.4 / 23.2 1.6 / 7.8 / 9.0 4.4 / 14.4 / 22.5 4.7/17.2/28.5

Cooling (T3) [A] 21.3 16.7 - - - - 21.1

Heating [A] - - 1.4 / 6.7 / 10.7 4.1 / 14.9 / 20.5 - - -

Noise

Indoor Unit [dBA] 51 / - 47 / - 51 / 51 47 / 47 51 / - 45 / - -

Outdoor Unit [dBA] 55 / - 51 / - 53 / 54 53 / 55 53 / - 51 / - -

Size

Net Dimension

(WxHxD)

Indoor Unit [mm] 610*1850*400 610*1850*400 610*1850*400 610*1850*400 610*1850*400 610*1850*400 610*1850*400

Outdoor Unit [mm] 940*1420*330 940*1210*330 940*1210*330 940*998*330 940*1210*330 940*998*330 940*1420*330

Shipping Dimension

(WxHxD)

Indoor Unit [mm] 705*1963*493 705*1963*493 705*1963*493 705*1963*493 705*1963*493 705*1963*493 705*1963*493

Outdoor Unit [mm] 995*1597*426 995*1388*426 995*1388*426 995*1096*426 995*1388*426 995*1096*426 995*1597*426

Weight

Net Dimension

Indoor Unit [kg] 46 46 46 42 46 42 46

Outdoor Unit [kg] 92 81 91 72 81 69 90

Shipping Dimension

Indoor Unit [kg] 52 52 52 49 52 49 51

Outdoor Unit [kg] 102 90 101 77 90 74 100

Harness

Specications

Indoor Fan Motor FMAF031SSA FMAF031SSA FMAF031SSA FMC9731SSC FMAF031SSA FMC9731SSC FMAF031SSA

Compressor UG5T450FXAJX UG5TK1450FJX UG5TK1450FJX UG8T300FUBJU UG5TK1450FJX UG8T300FUBJU UG5T450FXAJX

Outdoor Fan Motor DAO335130ZRD ATB125FGA DAO335130ZRD DAO335130ZRD DAO335130ZRD

Piping

High Pressure 3/8" 3/8" 3/8" 3/8" 3/8" 3/8" 3/8"

Low Pressure 3/4" 5/8" 5/8" 5/8" 5/8" 5/8" 3/4"

Exterior Display LED LED LED LED LED LED LED

Refrigerant Type R410A R410A R410A R410A R410A R410A R410A

Factory Charging [g] 2600 2400 3500 3000 2900 2400 2600

Additional Refrigerant (for every 1m) [g] 30 30 50 50 30 30 30

Basic Piping Length [m] 5 5 5 5 5 5 5

Max. Piping Length [m] 75 75 75 50 75 50 50

Max. Level Dierence [m] 30 30 30 30 30 30 30

Option Code 01146A-1900D7-278C00-370000 01146A-190096-276900-370000 01146A-1950C7-278C9B-370000 01146A-195085-276470-370000 01146A-1900C7-278C00-370000 01146A-190085-276400-370000 01144A-1900C7-279100-370010

2-2 The Comparative Specifications of Product

2-5 Samsung Electronics

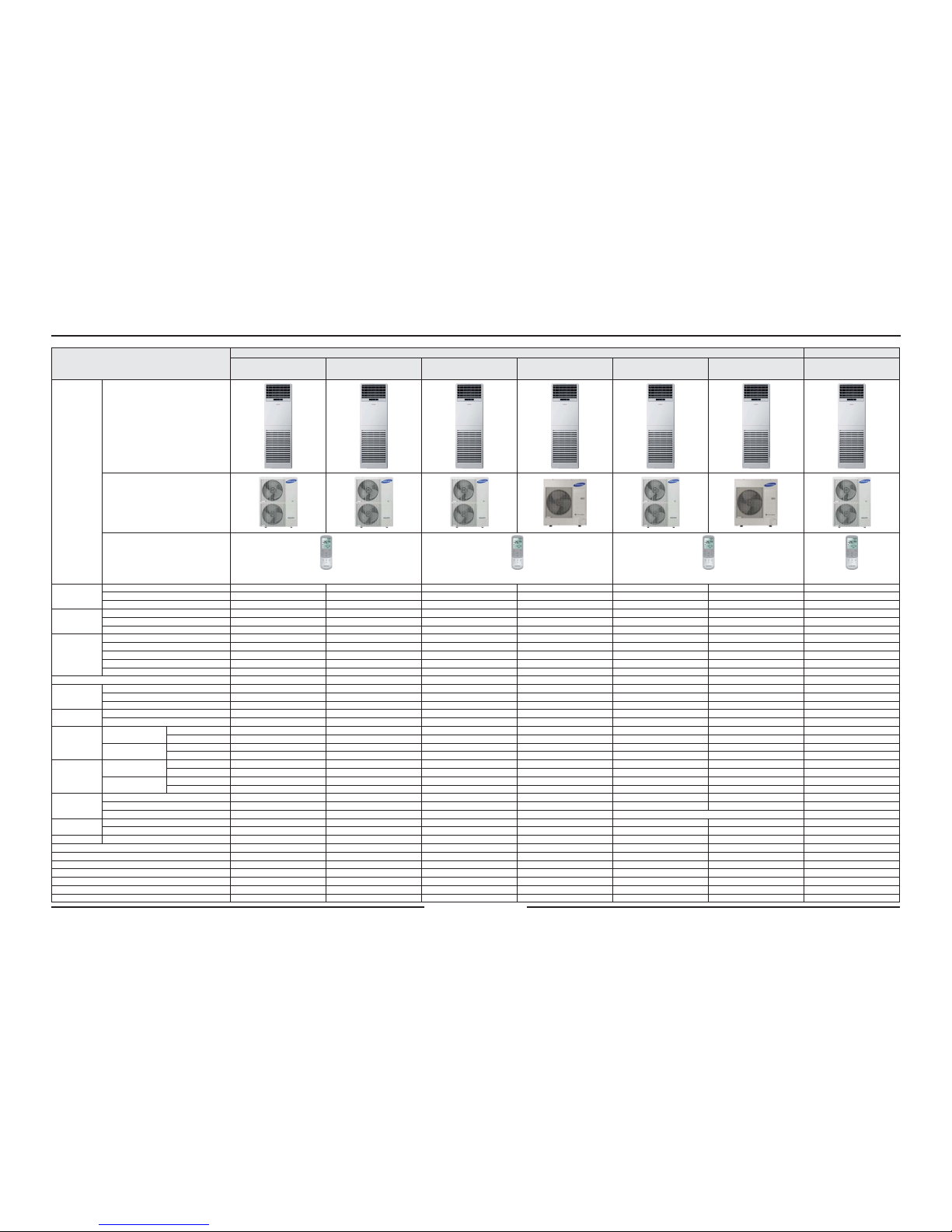

2-3-1 Filter

2-3-2 Accessory

2-3 Accessory and Option Specifications

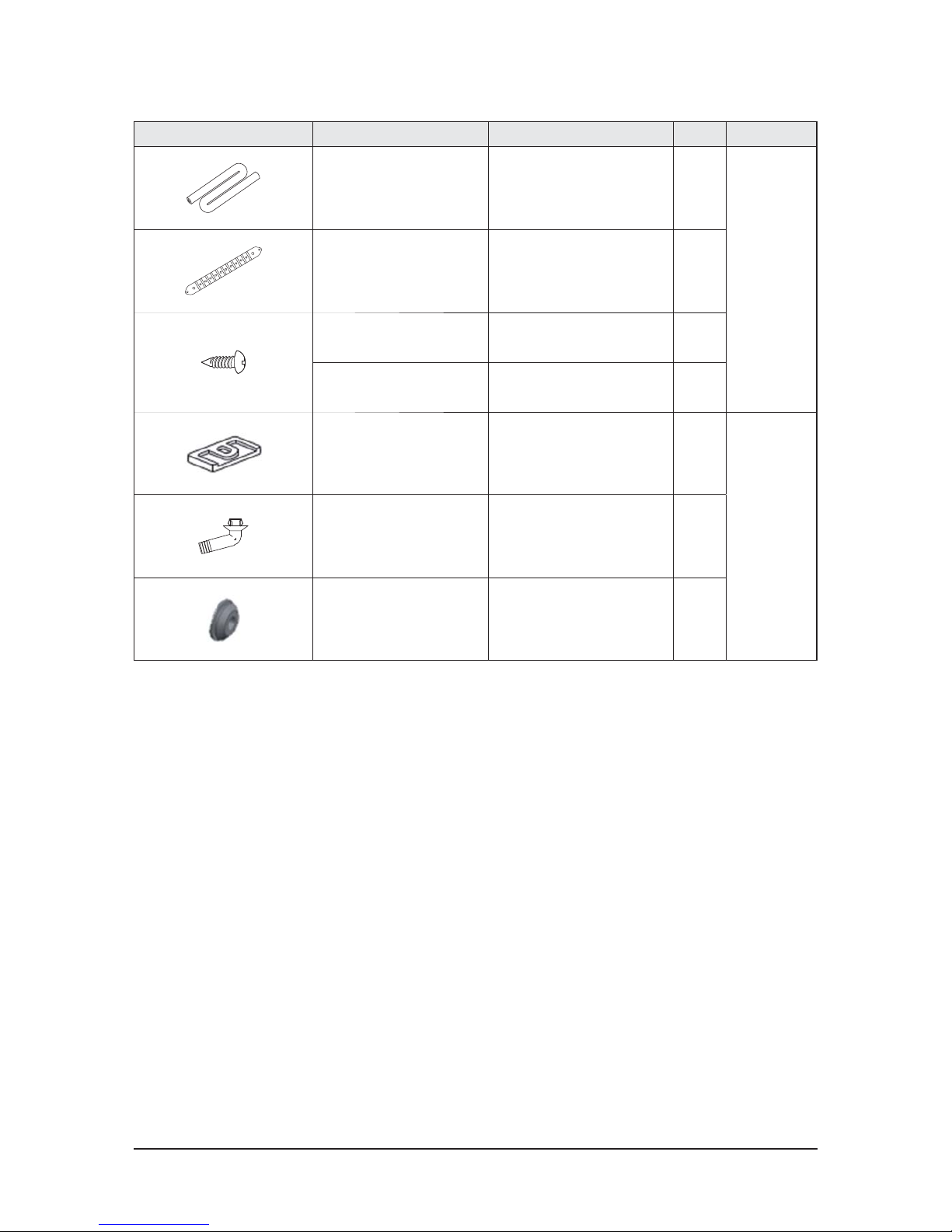

Item Descriptions Code-No. Remark

Air Filter DB63-02928B

Basic/

Water Washing

Item Descriptions Code-No. Q'ty Remark

Manual

(AC048/036KNPPCC)

DB68-04872A 1

Indoor Unit

Manual

(AC140/100KNPDEH)

DB68-06271A

DB68-06272A

1

Manual

(AC048/036KNPDEC)

DB68-06270A 1

Wireless Remocon DB93-15883B 1

Battery DB47-90024A 2

Holder Remocon DB61-06087A 1

Rubber Cabi Hole DB73-00195A 1

Insulation Tube DB62-10944A 1

Insulation

(AC048/036KN*)

DB72-50300A 1

Product Specifications

Samsung Electronics 2-6

Item Descriptions Code-No. Q'ty Remark

Insulation

(AC140/100KN*)

DB72-50300C 1

Indoor Unit

Holder Top DB61-40042B 1

Screw (L14) 6002-000538 4

Screw (L12) 6002-000231 4

Rubber leg DB73-20134A 4

Outdoor Unit

Drain Plug DB67-00806A 1

CAP Drain DB63-10355C 3

Samsung Electronics 3-1

Item Remark

+Screw driver

Monkey spanner

QNecessary Tools

3. Disassembly and Reassembly

3-2 Samsung Electronics

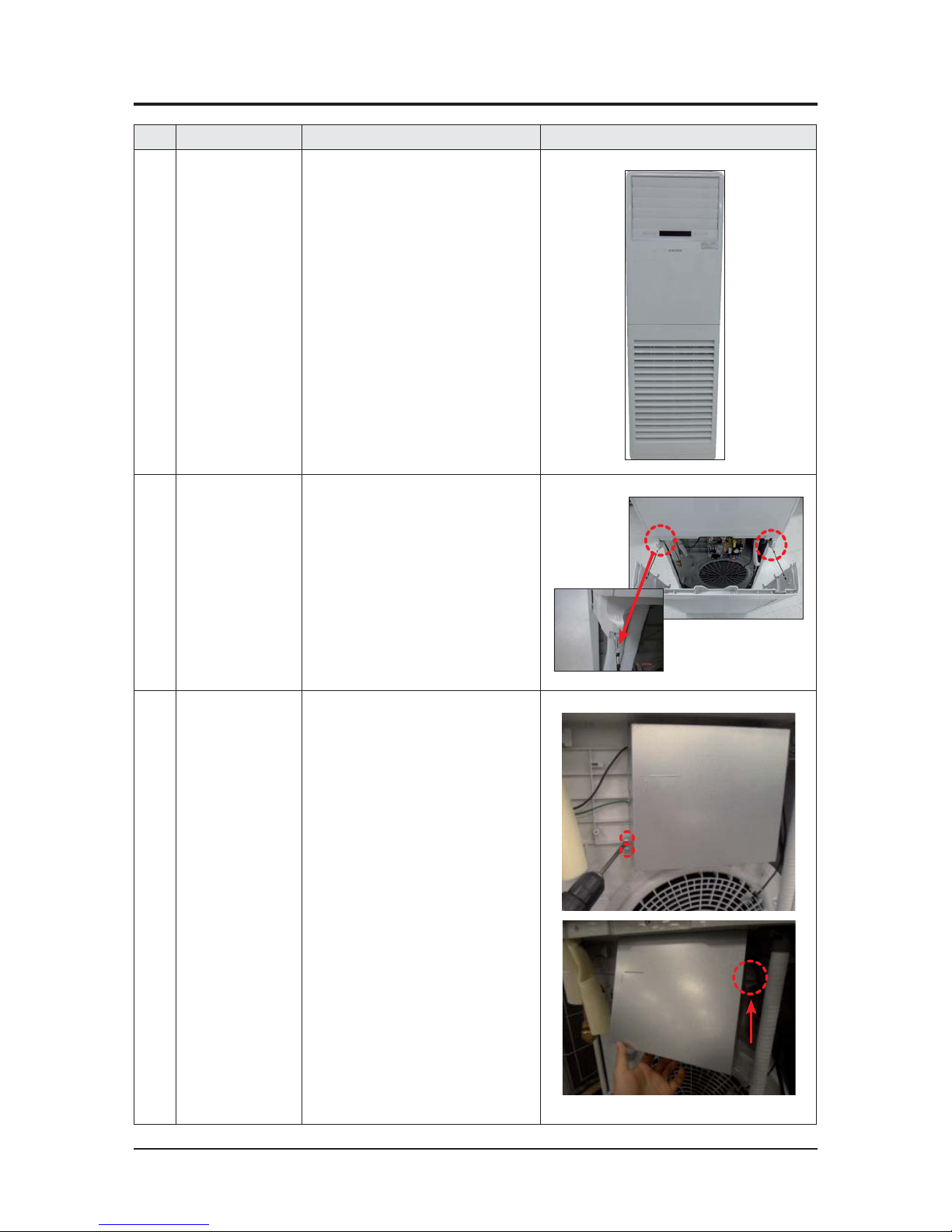

No Parts Procedure Remark

1 Indoor unit 1) Stop the operation of the air conditioner

and disconnect the main power supply.

2 Ass'y Inlet Part 1) Open the Ass'y Inlet and remove the

safety clips.

3 Ass'y Cover Control 1) Loosen one fixing screw of Ass'y Cover

Control. (Use +Screw driver) and detach

the cover.

2) Lift up the Ass'y Cover Control and detach

it by pulling the bottom outward.

3-1 Indoor Unit

Disassembly and Reassembly

Samsung Electronics 3-3

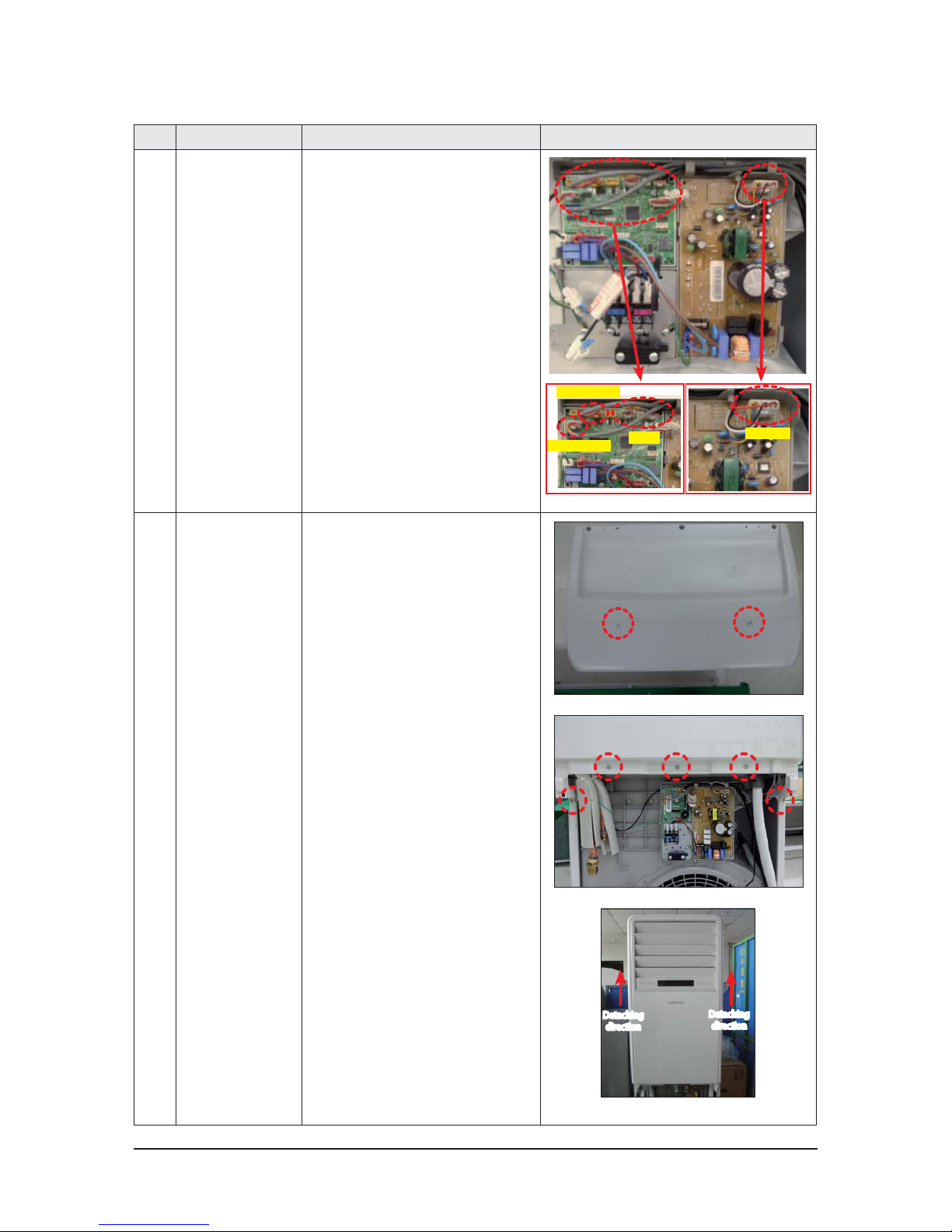

No Parts Procedure Remark

3) Detach the connectors connected to

Panel-Outlet and the Motor Connector.

Motor-In

Panel

Horizontal blade

Vertical blade

4 Ass'y Panel-outlet 1) Loosen the 7 fixing screws of

Ass'y Panel-Outlet and detach the

panel outlet by pushing upwards.

(Use +Screw driver)

Detaching

direction

Detaching

direction

Disassembly and Reassembly

3-4 Samsung Electronics

No Parts Procedure Remark

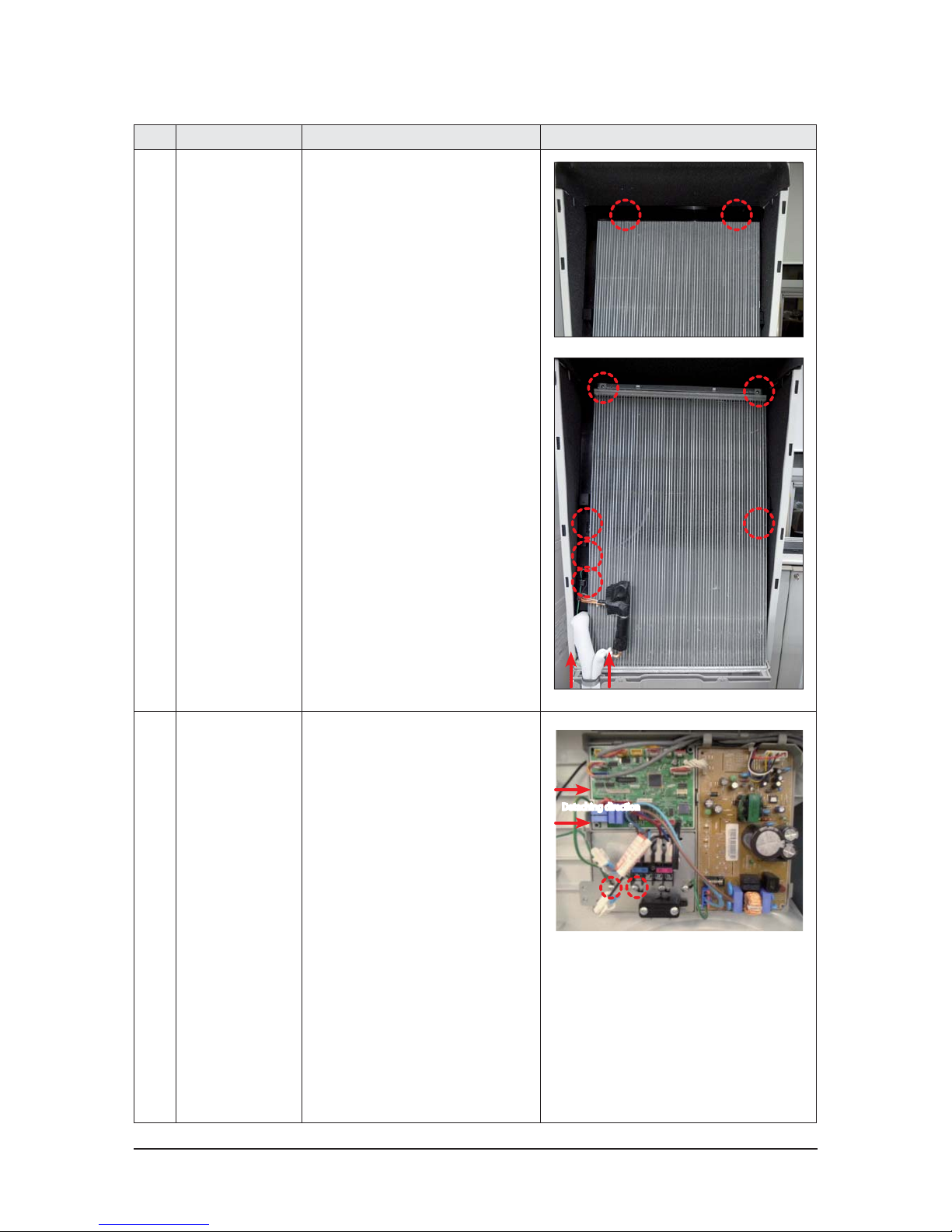

5 Ass’y Eva 1) Loosen the 2 fixing screws of Cover EVA

Top and detach the Top.

2) Loosen the 4 fixing screws of EVA.

3) Loosen the grounding screw.

4) Pull out the sensor cable.

5) Pull out the Bracket Pipe upward.

6) Pull the upper part of the Heat

Exchanger toward you and lift up the

Heat Exchanger to detach.

6 Ass'y Control In 1) Loosen the 1 fixing screw of Ass'y

Control.

2) Loosen the EVA grounding fixing screw.

3) Detach the Ass'y Control In by pushing

it to the right.

Detaching direction

❷

❶

Disassembly and Reassembly

Samsung Electronics 3-5

No Parts Procedure Remark

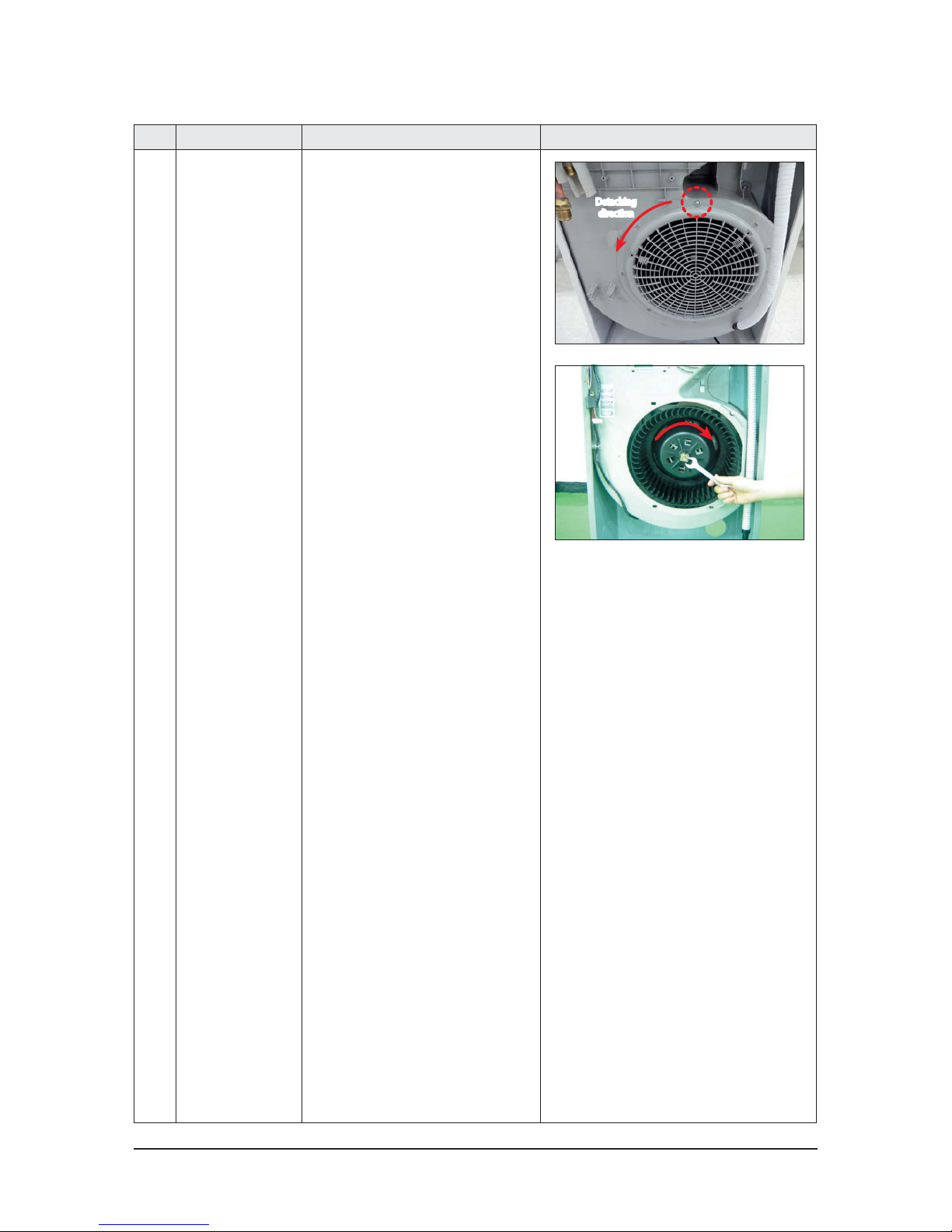

7 Ass’y Blower 1) Loosen the 1 fixing screw of Guard Fan.

(Use +Screw driver)

2) Push the Guard Fan in the arrow

direction and detach the guard.

3) Loosen the Blower nut clockwise and

pull the Blower toward you and detach

it. (Use a monkey spanner.)

Detaching

direction

Disassembly and Reassembly

3-6 Samsung Electronics

No Parts Procedure Remark

8 Ass’y Motor Blower 1) Loosen the 5 fixing screws of

Ass'y Duct Case and detach the case.

(Use +Screw driver)

2) Loosen the 3 fixing screws of

Motor and ground fixing screw.

(Use a monkey spanner.)

(Remove the connectors before

detaching the Motor.)

9 Cover Top 1) Loosen the 3 fixing screws of

Cover-Top and detach the cover.

(Use +Screw driver),

(Screw : TH type2 M4, L10, BLK)

2) Lift up the rear of Cover Top and

detach it.

Detaching direction

Disassembly and Reassembly

Samsung Electronics 3-7

No Parts Procedure Remark

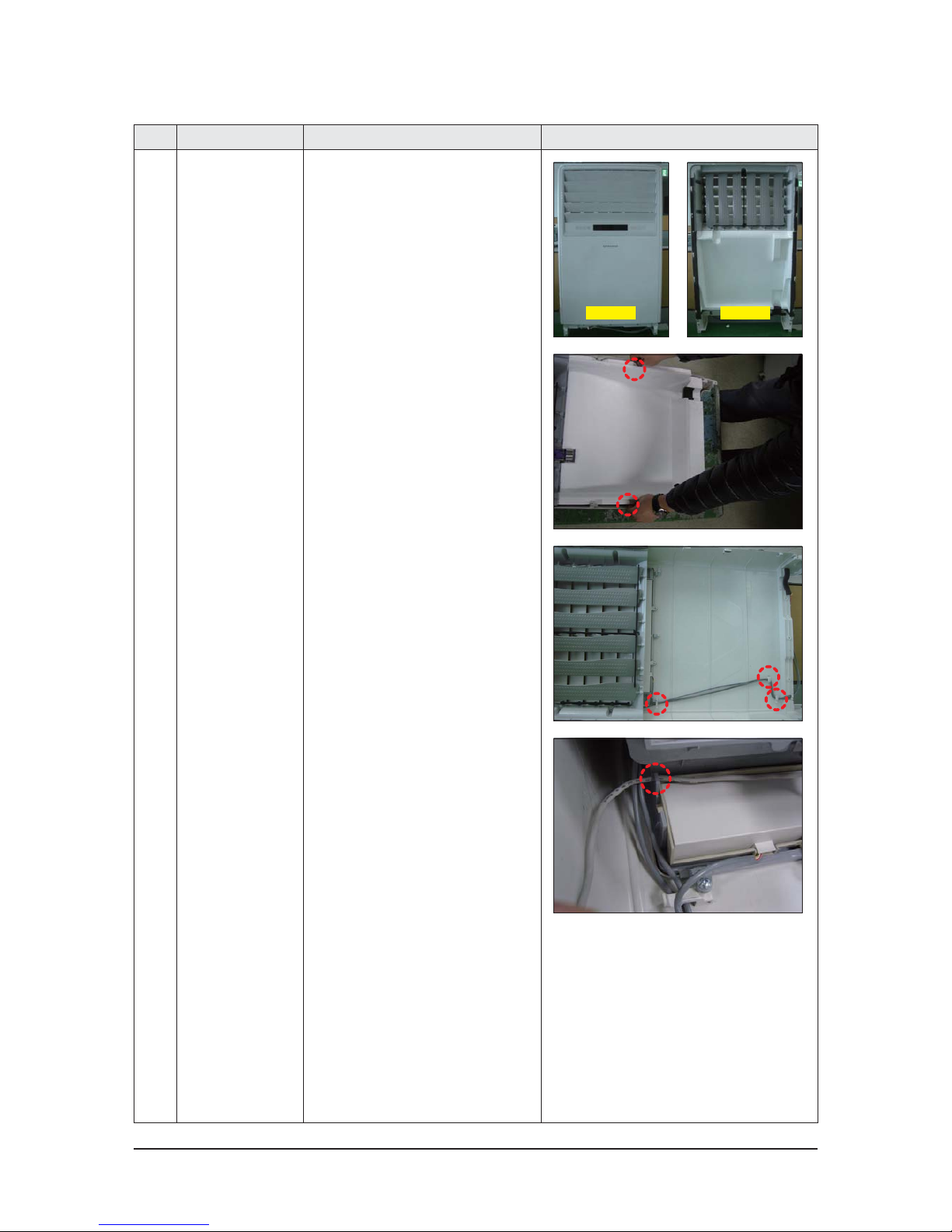

10 Ass'y Panel-Outlet

1) Panel-Outlet

2) As you push the 2 hooks on each side of

Panel outward, detach the bottom part

of Partition by lifting it toward you.

3) Detach the wire positioned with

Holder Wire.

4) Detach the wire positioned with

Holder Wire.

Rear sideFront side

Disassembly and Reassembly

3-8 Samsung Electronics

No Parts Procedure Remark

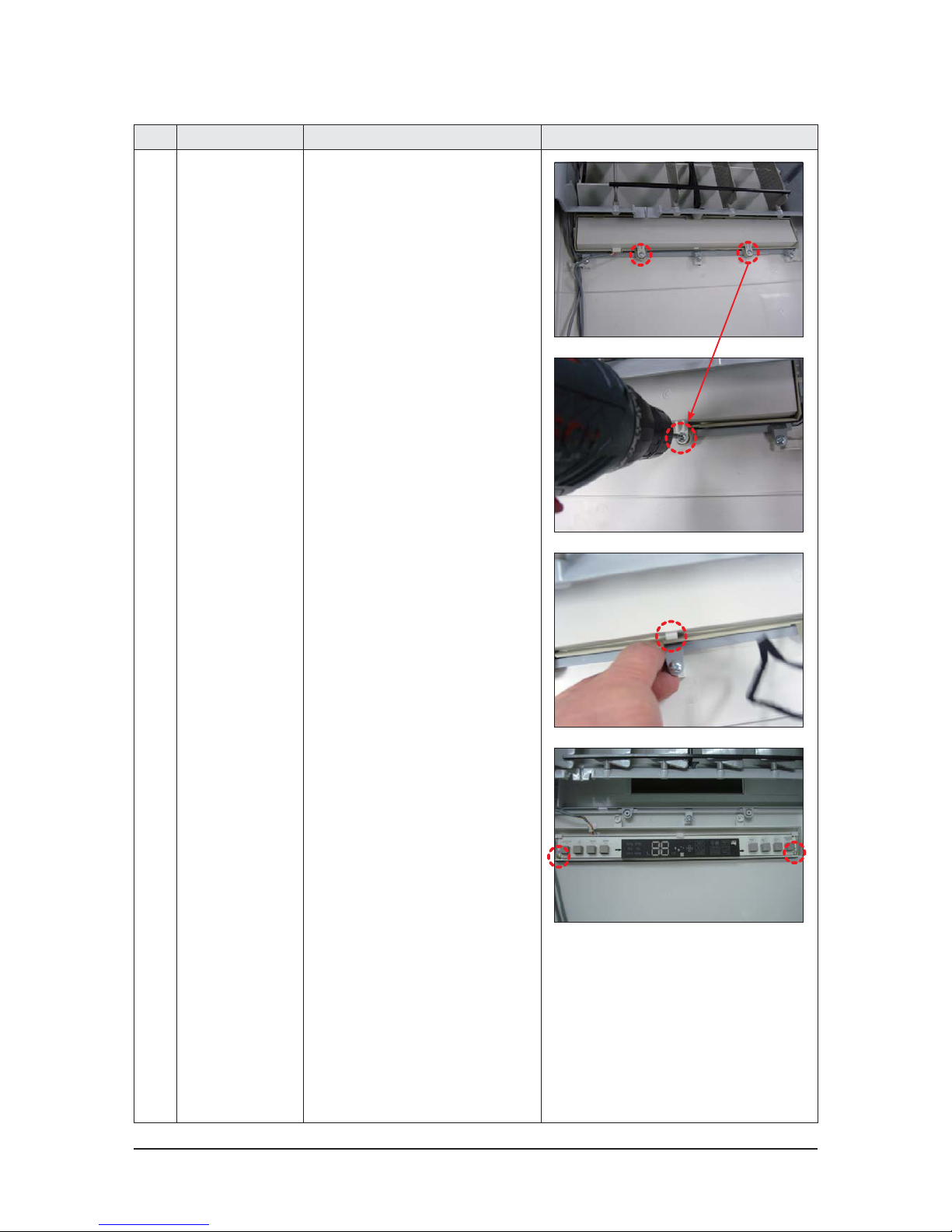

11 Ass'y Panel-outlet

- Seperate Display PBA

1) Loosen the 2 fixing screws of Case

Display PBA and detach the case.

(Use +Screw driver)

2) Unlink the fixing hook placed in the

middle of Case Display PBA.

3) Loosen the 2 fixing screws of PBA and

detach the PBA. (Use +Screw driver)

Disassembly and Reassembly

Samsung Electronics 3-9

No Parts Procedure Remark

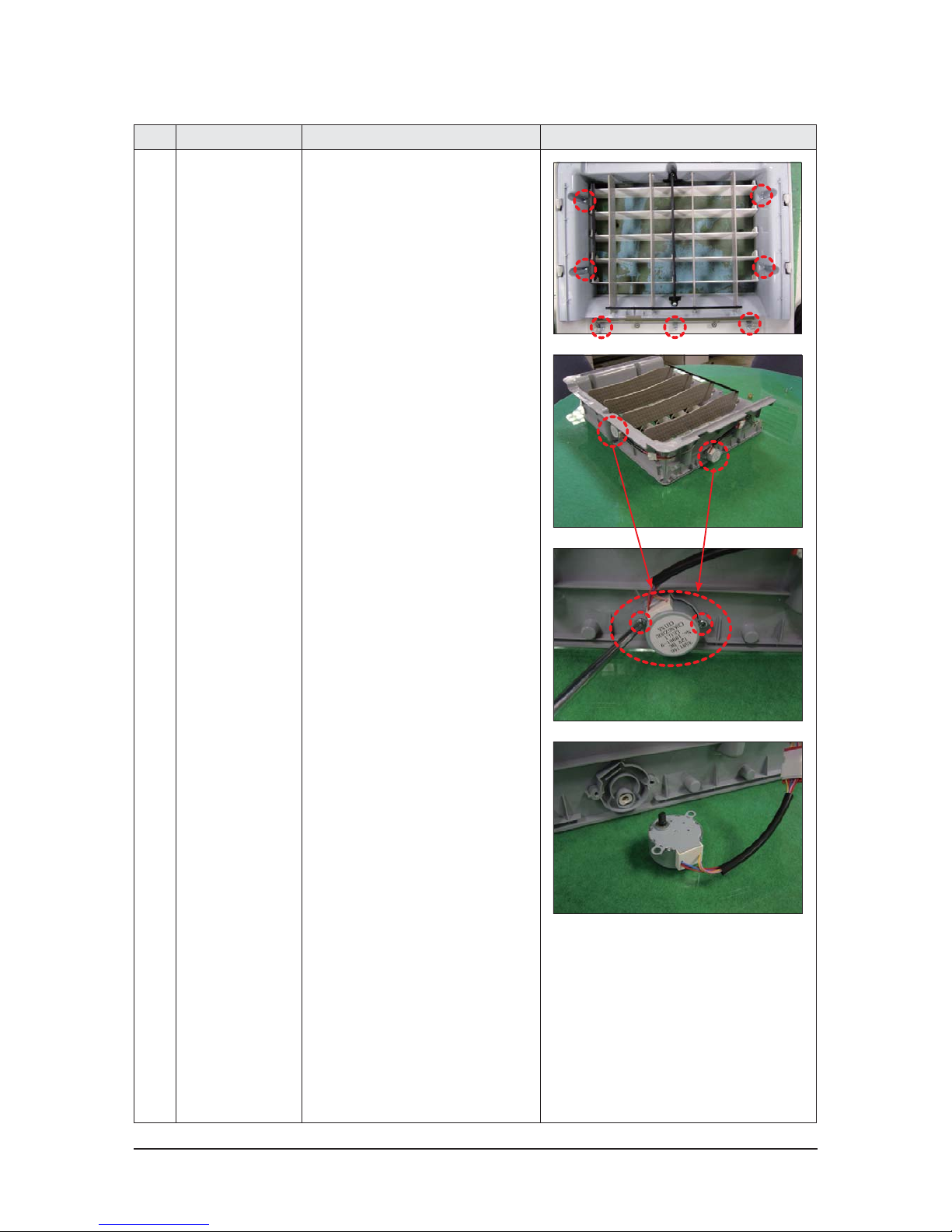

12 Ass'y Panel-outlet

- Motor Step

1) Loosen the 8 fixing screws of

Holder Blade and detach the holder.

(Use +Screw driver)

2) Loosen the 2 fixing screws of

Step Motor and detach the motor.

(Use +Screw driver)

3) The detached Step Motor.

3-10 Samsung Electronics

3-2 Outdoor Unit

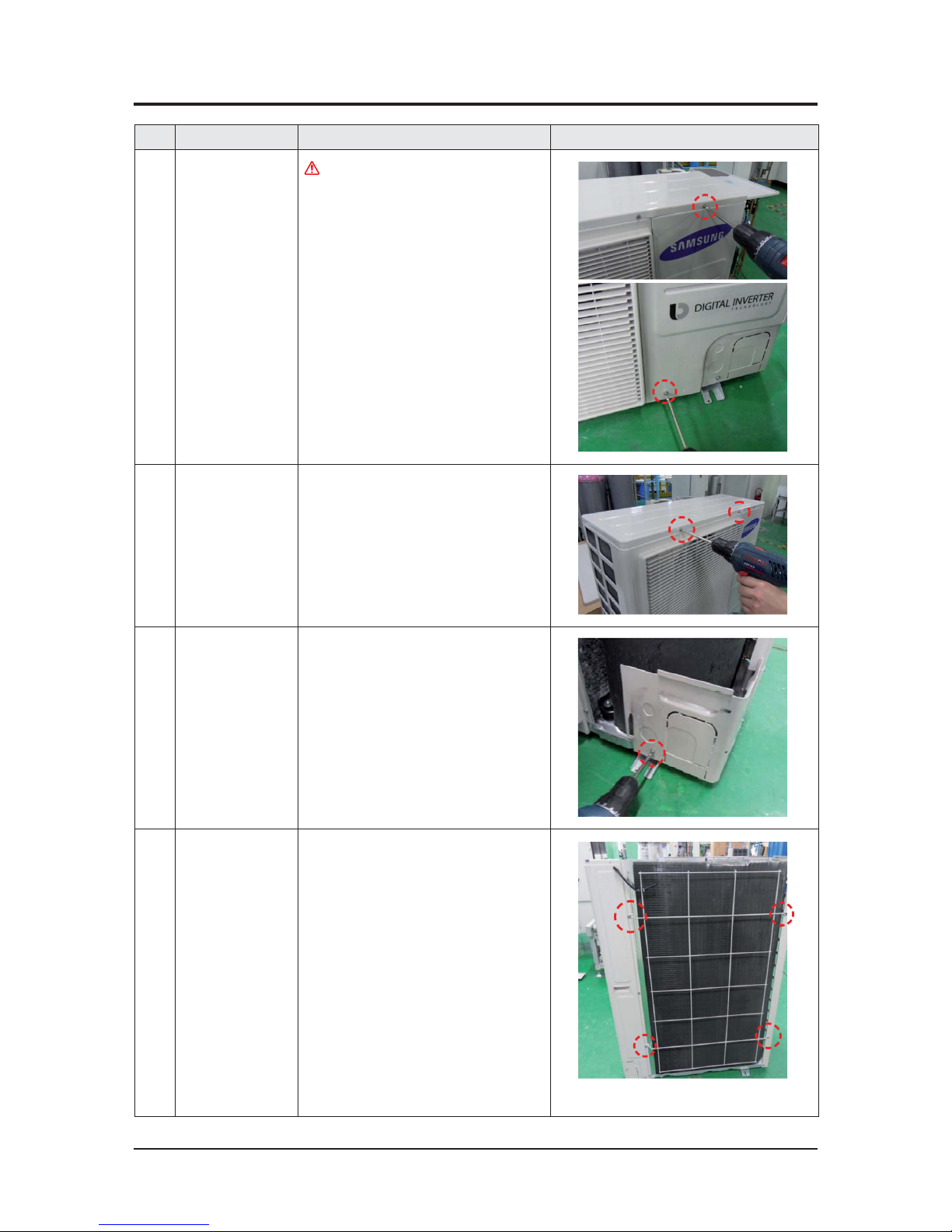

No Parts Procedure Remark

1 Cabi Front RH

You must turn off the Power before

disassembly.

1) Unscrew and remove two mounting

screw in the Cabinet Front RH.

(Use +Screw Driver)

2 Cabi Top

1) Unscrew and remove 9 screws

on each side of the Cabinet-Top.

(Use +Screw Driver)

3 Cabi Install Front

1) Unscrew and remove 1 screw

in the Cabinet-Install Front.

(Use +Screw Driver)

4 Guard Cond

1) Pull the sensor from Guard Cond.

2) Unscrew and remove 4 screws

in the Guard Cond.

(Use +Screw Driver)

Disassembly and Reassembly

Samsung Electronics 3-11

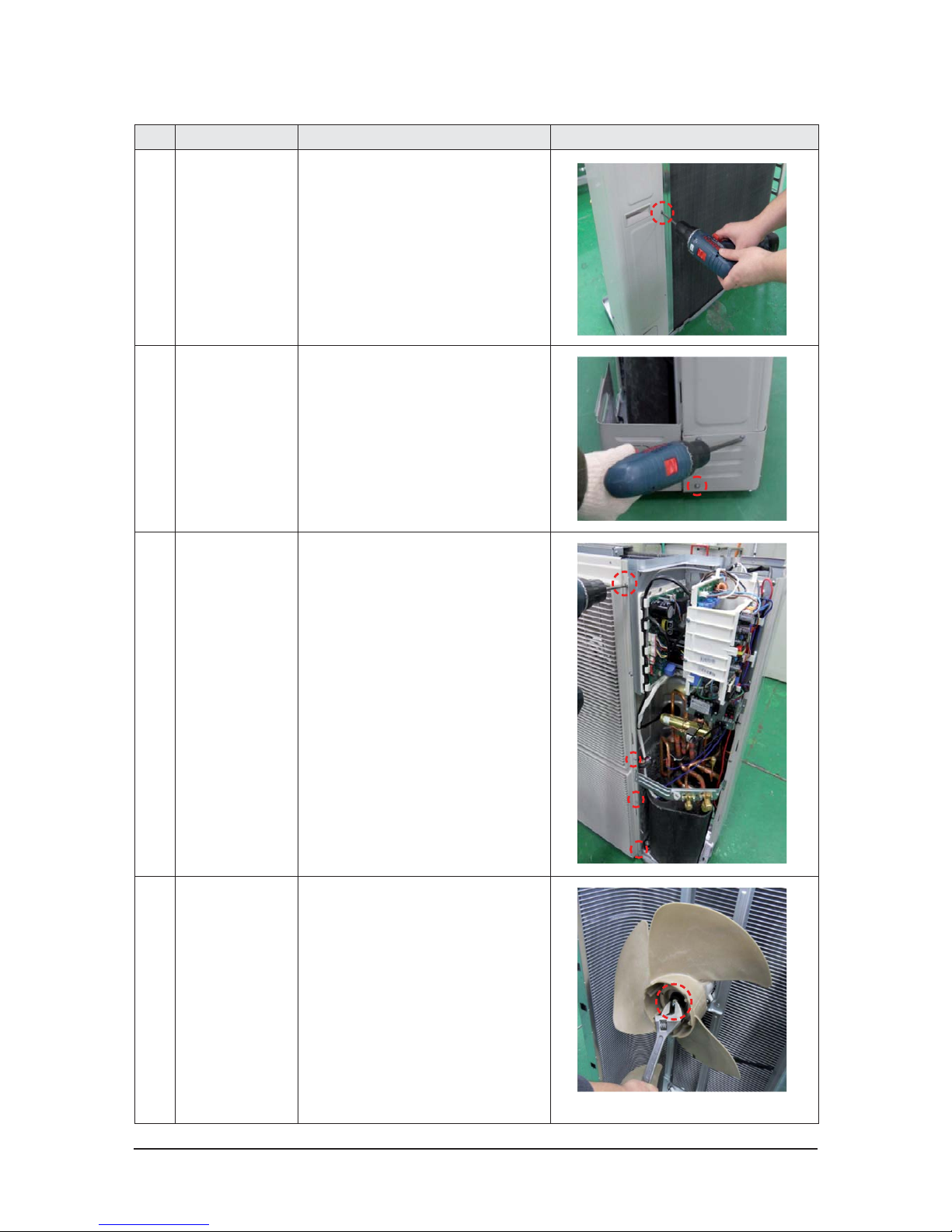

No Parts Procedure Remark

5 Cabi Back RH

1) Pull the sensor from Cabi Back RH.

2) Unscrew and remove 4 screws

on each side of the Cabinet Back RH.

(Use +Screw Driver)

6 Cabi Install Back

1) Unscrew and remove 1 screw

in the Cabinet-Install Back.

(Use +Screw Driver)

7 Cabi Front LF

1) Unscrew and remove 10 screws

in the Cabinet-Front LF.

(Use +Screw Driver)

8 Fan

1) Turn 2 mounting nuts as shown in

the picture and remove it.

(Use Adjustable Wrench)

Disassembly and Reassembly

3-12 Samsung Electronics

No Parts Procedure Remark

9 Motor

1) Separate the Fan Propeller.

2) Unscrew and remove the 8 Motor

mounting

screws. (Use +Screw Driver)

3) Disconnect the Motor wire From

Ass'y Control Out.

10 Bracket Motor

1) Unscrew and remove 2 mounting

screws in Bracket Motor.

(Use +Screw Driver)

11 Control Out

1) Disconnect 4 Connecters From

Ass'y Control Out.

2) Unscrew and remove 1 mounting

screw in Control Out.

(Use +Screw Driver)

3) Separate Ass'y Control Out.

Disassembly and Reassembly

Samsung Electronics 3-13

No Parts Procedure Remark

12 Assy 4way Valve

1) Purge the Coolant first.

2) Unscrew and remove 2 mounting

screws in Service Valve. (Use +Screw

Driver)

3) Separate the pipe from the

Entrance/Exit using a welder.

When removing the compressor, Heat Exchanger, and Pipe,

purge the Coolant inside the

Compressor completely and

remove the pipe with a welding

flame.

13 Assy EEV Valve

1) Unscrew and remove 2 mounting

screws in Service Valve.

(Use +Screw Driver)

2) Separate the pipe from the Entrance/

Exit using a welder.

Samsung Electronics 4-1

4. Troubleshooting

4-1 Indoor Display Error and Check Method

4-1-1 Indoor unit LED display at error detecting

- Thins to check before diagnosis

Display Explanation Check list

Product operation

Diagnosis

Method

Indoor

FAN

Outdoor

FAN

COMP

Indoor and Outdoor unit

communication Error

● Check the connection wire.

● Change the Main PCB.

Operation

OFF

Operation

OFF

Operation

OFF

Indoor unit room

temperature sensor

SHORT/OPEN

● Change the temperature sensor.

(Wire type)

Operation

OFF

Operation

OFF

Operation

OFF

Indoor unit Eva_in sensor

SHORT/OPEN

● Change the temperature sensor.

(Wire type)

Operation

OFF

Operation

OFF

Operation

OFF

Indoor unit

Fan motor Error

● Check the connection wire.

● Change the Fan motor.

● Change the Main PCB.

※ BLDC Motor is used as Fan Motor,

therefore if you connect or disconnect

the connector while the power is still

on, it may get damaged. Make sure to

turn off the power before performing

any operation.

Operation

OFF

Operation

OFF

Operation

OFF

EEPROM ERROR

● Change PCB.

Operation

OFF

Operation

OFF

Operation

OFF

EEPROM Option

Setting Error

● Input option.

- Cannot input KEY

Operation

OFF

Operation

OFF

Operation

OFF

Thermal Fuse Error

(TERMINAL BLOCK)

● Check the connection wire.

Operation

OFF

Operation

OFF

Operation

OFF

Duplicated address

setting error

● Check address setting of Indoor units.

Operation

OFF

Operation

OFF

Operation

OFF

No response error of

address from indoor unit

● Check indoor unit's quantity setting

in outdoor unit.

● Check electrical connection and set-

ting.

Operation

OFF

Operation

OFF

Operation

OFF

Troubleshooting

4-2 Samsung Electronics

4-2 Outdoor Trouble shooting

The table below give indication about self diagnostic routine. Some of error code requires activities exclusively

for Authorized Service Center.

Outdoor unit

If an error occurs during the operation, it is displayed on the outdoor unit PCB LED, both MAIN PCB and

INVERTER PCB.

No. Error Code Meaning Remarks

1 E108

Error due to repeated address setting(when 2 or more devices has

same address within the network)

Check on repeated indoor unit main address

2 E121 Error on indoor temperature sensor of indoor unit(Short or Open) Indoor unit Room Thermistor Open/Short

3 E122 Error on EVA IN sensor of indoor unit(Short or Open) Indoor unit EVA_IN Thermistor Open/Short

4 E123 Error on EVA OUT sensor of indoor unit(Short or Open) Indoor unit EVA_OUT Thermistor Open/Short

5 E153 Error on float switch (2nd detection)

"Indoor unit Float Switch Open/Short Drain Pump

operation Check"

6 E154 RPM feedback error of indoor unit Check on indoor unit indoor Fan operation

7 E162 Outdoor unit EEPROM Read/Write error (H/W) Check Outdoor EEPROM PBA

8 E163 Outdoor unit EEPROM Read/Write error (Option) Check Outdoor EEPROM Data

9 E198 Error on thermal fuse of indoor unit (Open)

Thermal Fuse Open Check of indoor unit Terminal

Block

10 E201

"Communication error between indoor and outdoor

unit(Installation number setting error repeated

indoor unit address,indoor unit communication cable error)"

Check indoor quantity setting in outdoor

11 E202

"Communication error between indoor and outdoor

unit(Communication error on all indoor unit,

outdoor unit communication cable error)"

Check electrical connection and setting between

indoor unit and outdoor unit

12 E205

Communication error on all PBA within the outdoor unit

C-Box,communication cable error

-

13 E206

E206-C002 : Fan PBA communication error, E206-C003 : INV PBA

communication error

-

14 E221 Error on outdoor temperature sensor (Short or Open) Check Outdoor sensor Open / Short

15 E231 Error on outdoor COND OUT sensor (Short or Open) Check Cond-Out sensor Open / Short

16 E251

Error on discharge temperature sensor of compressor 1 (Short or

Open)

Check Discharge sensor Open / Short

17 E320 Error on OLP sensor (Short or Open) Check OLP sensor Open / Short

18 E346 Error due to operation failure of Fan2 FAN2 error

19 E347 Motor wire of Fan2 is not connected FAN2 error

20 E348 Lock error on Fan2 of outdoor unit FAN2 error

21 E353 Error due to overheated motor of outdoor unit's Fan2 FAN2 error

22 E355 Error due to overheated IPM of Fan2 FAN2 error

23 E378 Error due to overcurrent of Fan2 FAN2 error

24 E386 Over-voltage/low-voltage error of Fan2 FAN2 error

25 E387 Hall IC connection error of Fan2 FAN2 error

26 E389 V-limit error on Fan2 of compressor FAN2 error

27 E391 Error due to DataFlash of Fan2 FAN2 error

28 E393 Output current sensor error of Fan2 FAN2 error

Troubleshooting

Samsung Electronics 4-3

No. Error Code Meaning Remarks

29 E396 DC voltage sensor error of Fan2 FAN2 error

30 E399 Heat sink temperature sensor error of Fan2 FAN2 error

31 E403 Compressor down due to freeze protection control Check Outdoor Cond.

32 E404 System stop due to overload protection control Check Comp. when it start

33 E416 System stop due to discharge temperature

-

34 E422 Blockage detected on high pressure pipe

1. Check if the service valve is open

2. Check for refrigerant leakage(pipe connections,

heat exchanger) and charge refrigerant if

necessary

3. Check if there's any blockage on refrigerant

cycle(indoor unit/outdoor unit)

4. Check if additional refrigerant has been added

after pipe extension

35 E425 Reverse phase or open phase

Check whether 3 phase is reversed or opened.

36 E440 Heating mode restriction due to high air temperature

HEATING

37 E441 Cooling mode restriction due to low air temperature

COOLING

38 E446 Error due to operation failure of Fan1

FAN1 error

39 E447 Motor wire of Fan1 is not connected

FAN1 error

40 E448 Lock error on Fan1 of outdoor unit

FAN1 error

41 E452 Error due to ZCP detection circuit problem or power failure

-

42 E453 Error due to overheated motor of outdoor unit's Fan1

FAN1 error

43 E455 Error due to overheated IPM of Fan1

FAN1 error

44 E458 Fan speed error

FAN1 ERROR

45 E461 Error due to operation failure of inverter compressor

-

46 E462 System stop due to full current control

-

47 E463 Over current trip / PFC over current error

Check OLP sensor

48 E464 IPM Over Current(O.C)

IPM

49 E465 Comp. Over load error

-

50 E466 DC-Link voltage under/over error

Check AC Power and DC Link Voltage

51 E467

Error due to abnormal rotation of the compressor or unconnected

wire of compressor

Check Comp wire

52 E468 Error on current sensor (Short or Open)

Check Outdoor Inverter PBA.

53 E469 Error on DC-Link voltage sensor (Short or Open)

-

54 E471

Outdoor EEPROM checksum error between MAIN and INVERTER

(AC

777

KXAPNH)

Check Outdoor EEPROM PBA

55 E472 AC Line Zero Cross Signal out

-

56 E473 Comp Lock error

-

57 E474 Error on IPM Heat Sink sensor of inverter 1 (Short or Open)

heck Outdoor Inverter PBA

58 E475 Error on inverter fan 2

FAN2 ERROR

59 E478 Error due to overcurrent of Fan1

FAN1 error

60 E484 PFC Overload (Over current) Error

Check Outdoor Inverter PBA.

61 E485 Error on input current sensor of inverter 1 (Short or Open)

Check Outdoor EEPROM PBA

62 E486 Over-voltage/low-voltage error of Fan1

FAN1 error

Troubleshooting

4-4 Samsung Electronics

No. Error Code Meaning Remarks

63 E487 Hall IC connection error of Fan1

FAN1 error

64

E489 V-limit error on Fan1 of compressor

FAN1 error

65

E491 Error due to DataFlash of Fan1

FAN1 error

66

E493 Output current sensor error of Fan1

FAN1 error

67

E496 DC voltage sensor error of Fan1

FAN1 error

68

E499 Heat sink temperature sensor error of Fan1

FAN1 error

69

E500 IPM over heat error on inverter 1

Check Outdoor Inverter PBA.

70

E508 Smart install is not installed

-

71

E554 Gas leak detected

Check the refrigerant

72

E556

Error due to mismatching capacity of indoor and outdoor

unit

Check the indoor and Outdoor unit

Capacity

73

E557

Option code miss matching among the indoor units (only

for DPM)

Check the indoor option code

74

E590

Outdoor EEPROM checksum error between MAIN

and INVERTER (AC

777

JXAFKH, AC

777

JXAFNH,

AC

777

JXAPNH)

-

75

E660 Inverter Boot Code error

-

Troubleshooting

Samsung Electronics 4-5

4-3 Troubleshooting by symptoms

4-3-1 Communication error after finishing tracking (E202)

1. Check items

1) Is the communication cable short/open?

2) Is there a response from the indoor unit PCB?

2. Check procedure

No

Yes

Is there a response from the

indoor unit PCB?

No

Yes

In this case, is the

voltage waveform between the lines square

wave with amplitude over ±0.7V as shown

in the following picture?

+0.7V

-0.7V

Good

Bad

Check the communication cable and

replace the indoor unit PCB?

Remove the communication cable

connecting the outdoor unit to indoor unit,

and measure the signal on LINE 2 of the

outdoor unit with a scope

Reconnect the cable connecting

the outdoor unit to the indoor unit

and restart the unit.

If the communication still doesn’t work,

eht ecalper indoor unit PCB and

Check the communication

cable in each PCB

and replace the PCB

Yes

Is the power/communication

cable connected correctly?

No

Connect the power/communication

cable correctly.

outdoor unit PCB in order of mention.

cf.) If there is no oscillo scope, it can be replaced multimeter instead of osillo scope.

Troubleshooting

4-6 Samsung Electronics

4-3-2 Outdoor's service valve(Clog)

Wire remote controller display

E422

Symptom

Clogging of outdoor's service valve

Failure

Valve clog

NoNo

Yes Yes

Is the outdoor service

valve clogged?

Was lacking in refrigerant?

Check the normal of EVA-IN

TEMP SENSOR.

Open the outdoor's service valve Refrigerant Charge.

Troubleshooting

Samsung Electronics 4-7

4-3-3 No Power(completely dead) - Initial diagnosis

Outdoor unit is not powered on – Initial diagnosis (1phase)

1. Check items

1) Is the power supply voltage 220V?

2) Is the AC power connected correctly?

3) Are the LEDs in the main PCB and inverter PCB of the outdoor unit ON?

4) Is the input power voltage of the indoor unit 220V?

5) Is the wired remote controller connected correctly?

2. Check procedure

Yes

Turn off the main power switch

(circuit break of power outlet) and turn on

again after 30 seconds.

Check the input power

No

Is the outdoor unit power

supply (L-N) 220V?

Yes

Check the connection of the terminal block

No

Is the outdoor unit power

voltage (L-N) 220V?

Yes

Replace the inverter PBA

No

Is the voltage between

the terminal 2 (~) and 4 (~) of the

bridge diode 220V?

Yes

Replace the fuse

No

Is the fuse connected?

Yes

Replace the inverter PBA

No

Is the resistance value of R001 200?

Cont.

Troubleshooting

4-8 Samsung Electronics

Yes

Outdoor unit is not powered on – Initial diagnosis (1phase) (cont.)

Yes

Connect the reactor

No

Is the reactor connector

connected correctly?

Replace the PBA.

Cont.

Troubleshooting

Samsung Electronics 4-9

Cont.

Outdoor unit is not powered on – Initial diagnosis ( 3phase)

1. Check items:

1) Is the power supply voltage 380V?

2) Is the AC power connected correctly?

3) Are the LEDs in the main PCB and inverter PCB of the outdoor unit ON?

4) Is the input power voltage of the indoor unit 220V?

5) Is the wired remote controller connected correctly?

2. Troubleshooting procedure

No

No

No

No

No

Check the input power

Check connection of the outdoor unit

terminal block

Check the connection wires and

connectors of the indoor and outdoor units

Replace the PCB of the indoor unit if

the PCB (Transformer, fuse, pcd, etc.) fails

Replace the wired remote controller

Turn off the main power switch

(circuit break of power outlet) and turn on again

after 30 seconds.

Is the outdoor unit power

supply (N-R, N-S, N-T) 220Vac?

Is the outdoor unit power

voltage (L-N) 220Vac?

Is the indoor unit power supply

voltage (L-N) 220Vac?

Is the indoor unit power supply

voltage (V1-V2) 12Vdc?

Does the air conditioner

operate when pressing ON/OFF button of the

wired remote controller?

Troubleshooting

4-10 Samsung Electronics

Yes

Outdoor unit is not powered on – Initial diagnosis ( 3phase) (cont.)

Yes

Yes

Reconfigure the option DIP switches

Check the system depending

on the error display

No

No

Are the option DIP switches

inside the wired remote controller configured

correctly?

Is there an error

message displayed on the wired remote

controller display?

Check the target temperature

Cont.

Troubleshooting

Samsung Electronics 4-11

4-3-4 E102 : Communication error between indoor and outdoor unit

E201 : Unit quantity miss matching beween Indoor and Outdoor

E202 : Abnormal state, no communication between Indoor and Outdoor Main PCB

E203 : 1min Time out of communication error(MainļInverter)

1. Checklist :

1) Is the communication cable between the indoor unit and outdoor unit connected correctly?

2) Isn’t the power cable and communication cable wiring error?

2. Troubleshooting procedure

Yes

Restart after power off.

Is the communication error

occurred again?

Isn't the power cable and

communication cable wiring error?

Replace the outdoor unit PCB.

Terminate the service.

Correct the wrong wiring.

Is the connection of

communication cable normal?

Correct the connection of

communication cable.

Yes

Yes

No

No

No

Troubleshooting

4-12 Samsung Electronics

4-3-5 External Sensor Error (Error Code: E221, E231, E251, E320)

1. Test Item

1) Check the connection of the temperature sensor connector.

2) Check the resistance value of the temperature sensor.

2. Check procedure

Error Code Description

E221 Error of the temperature sensor of the outdoor unit

E231 Error of the COND. sensor of the outdoor unit

E251 Error of the discharge sensor of the outdoor unit

E320 Error of the OLP sensor of the outdoor unit

Power OFF

Is the temperature sensor connector

reconnected?

No

Yes

Yes

Replace the temperature sensor, ױ

Power ON. ױ

After confirming the state is normal, end the service.

No

Is the temperature

sensor-measuring resistance similar to the

table on the left?

After confirming the state is normal,

end the service.

No

Yes

Replace the outdoor unit PBA. ױ

Power is on. ױ After confirming the state is

normal, end the service.

(Example) COND. sensor/outdoor unit temperature sensor measuring resistance value by temperature: E231, E221

(Example) OLP sensor/discharge temperature sensor measuring resistance value by temperature: E320, E251.

Current temperature (°C)

Resistance

(KΩ)

Current temperature (°C)

Resistance

(KΩ)

70 4 20 10

60 5 10 20

50 6 0 30

40 7 -10 40

30 8

Current temperature (°C)

Resistance

(KΩ)

Current temperature (°C)

Resistance

(KΩ)

80 40 30 180

70 50 20 220

60 60 10 320

50 90 0 550

40 110

Is the temperature sensor connector

connected?

e.g.) Room temperature: 26ఁ

- Resistance: 10.28 KΩ

e.g.) Room temperature: 21ఁ

- Resistance: 205.4 KΩ

Does the same error occur again

after power is on?

Troubleshooting

Samsung Electronics 4-13

4-3-6 E403 : Freezing control causes comp. down

No

No

No

Yes

Yes

Yes

Check the indoor fan.

Check the EEV.

Same as when checking other temp sensors.

Check for clogging in the suction area of the

indoor machine.

The indoor FAN/MOTOR operates normally?

The indoor EEV operates normally?

The indoor heat Exchanger sensor displays the

temperature ok?

Outdoor unit display E403

Criteria

t"MMUIFPQFSBUJOHJOEPPSNBDIJOFTEPOPUSFBDI¡$GPSNPSFUIBOGJWFNJOVUFT

Cause of problem

t$IFDLJGUIFJOEPPS'"/.0503PQFSBUFTOPSNBMMZ

t$IFDLJGUIFJOEPPS&&7PQFSBUFTOPSNBMMZ

t$IFDLUIFJOEPPSIFBU&YDIBOHFShT*/065TFOTPS

t$IFDLGPSDMPHHJOHJOUIFTVDUJPOBSFBPGUIFJOEPPSNBDIJOF

1. How to check

Troubleshooting

4-14 Samsung Electronics

4-3-7 E416 : Dischage temperature sensor error

No

Yes

Yes

Yes

Check the amount of coolant.

The sensor's resistance normal?

(Refer to E251.)

The outdoor/indoor EEV operates normally?

All the sub valves open?

Clogging in the pipeline?

(ex-filter)

Outdoor unit display E416

Criteria

t5IFDPNQSFTTPSUFNQFSBUVSFBCPWF¡$

Cause of problem

t*OTVGGJDJFOUDPPMBOU

t$MPHHJOHJOUIFPVUEPPSNBDIJOFhTTPMFOPJEWBMWF

t$MPHHJOHJOUIFTVCWBMWF

t.BMGVODUJPOJOHFYIBVTUHBTUFNQTFOTPS

t$MPHHJOHJOUIFQJQFMJOFBOEUIFGJMUFS

t-JRVJE&&7EBNBHFE

1. How to check

Test operation

Check the amount of coolant.

Connect S-net to vacuum.

(Forceful)

Open the sub valve.

Check the EEV.

Check the pipeline.

Troubleshooting

Samsung Electronics 4-15

4-3-8 E440, E441 : Abnormal outside temperature halts operation of the compressor

Outdoor unit display

E440 (No heater operation with the outside temperature above 30°C.)

E441 No AC operation with the outside temperature below -10°C.)

Criteria

t5IFDPNQSFTTPSUFNQFSBUVSFBCPWF¡$

Cause of problem

E440: If the outside temperature is above 30°C, operation of the indoor heater with a

remocon causes this error.

E441:The indoor machine remocon ON signal. If the outside temperature is below -10°C

before the AC runs, this error occurs.

Cause of problem

t0-14&/403UFNQBCPWF5SJQ@%JT

1. How to check

The above malfunction codes do not indicate a malfunction of the product. All you have to do is change the temperature suitably for

the limits shown in the manual. When the product malfunctions, if the actual situation does not match the above diagnosis, measure

the temperature of incoming air with S-net to see if the measurement is the same as the actual outdoor temperature. If not, replace

the temperature sensor.

Troubleshooting

4-16 Samsung Electronics

4-3-9 Outdoor unit BLDC Fan1 or Fan2 error (E458 : Fan1 error, E475 : Fan2 error)

1. Checklist :

1) Isn’t the fan locked?

2) Is the sensor placed correctly?

3) Does the both terminal of sensor satisfy the resistance value in accordance with temperature?

4) Is the resistance value of sensor connection pull_up correct?

2. Troubleshooting procedure

Isn't the Fan locked?

Is the connector connected correctly?

Is the color of Fan wire matched correctly?

Remove the Fan lock.

Connect the connector.

Replace the Fan.

Replace the PCB. Normal operation

Exit

Yes

Yes

Yes

No

No

No

No

Troubleshooting

Samsung Electronics 4-17

4-3-10 E461: Compressor start error

E467: Compressor wire missing error

1. Checklist :

1) Is the connection of cable for the compressor and power?

2) Is the interphase resistance of compressor normal?

2. Troubleshooting procedure

Yes

Restart after power off.

Is the restart error occurred again?

Is the interphase resistance value of

compressor(ulv, vlw, wlu) normal?

Is the connection cable for the

compressor and power terminal normal?

Replace the PCB.

Terminate the service.

Replace the compressor.

Is the compressor body and

interphase resistance insulated?

Replace the compressor.

Correct the cable connection.

Yes

Yes

Yes

No

No

No

No

Troubleshooting

4-18 Samsung Electronics

4-3-11 E462 : Current protection control causes comp. down

E484 : PFC overload error

No

No

Yes

Finished inspections

Outdoor unit display E462,E484

Criteria

t5IFPVUEPPSNBDIJOFJOQVUDVSSFOUBCPWF*@5SJQ

Cause of problem

t$IFDLUIFDPNQSFTTPSJOQVUWPMUBHFFSSPSGPSMPXWPMUBHF

t$IFDLUIFPWFSDVSSFOUPQUJPOTFUUJOH

1. How to check

Overcurrent option setting ok?

Compressor input voltage supplied ok?

Check the input power terminal.

Correct the overcurrent setting.

Troubleshooting

Samsung Electronics 4-19

4-3-12 E463 : OLP protection control caused comp. down

Outdoor unit display E463

Criteria

t0-14&/403UFNQBCPWF5SJQ@%JT

Cause of problem

t4FFJGUIFTVCWBMWFJTPQFO

t$IFDLUIFBNPVOUPGDPPMBOU

t$IFDLUIF0-1TFOTPS

1. How to check

No

No

No

No

No

Yes

Yes

Yes

Check the amount of coolant.

The sensor's resistance normal?

(Refer to E20.)

The outdoor/indoor EEV operates normally?

All the sub valves open?

Clogging in the pipeline?

(ex-filter)

Test operation

Replace the OLP sensor

Connect S-net to vacuum. (forceful)

Open the sub valve.

Check the EEV.

Check the pipeline.

Troubleshooting

4-20 Samsung Electronics

4-3-13 E464 : O.C. (Over Current) error

1. Checklist :

1) Is the refrigerant charged properly?

2) Does the compressor rotate normally?(Reverse rotation, Locking etc.)

3) Is connection of compressor wire normal?

4) Is compressor motor normal?(Insulation, Coil resistance etc.)

5) Does a temporary cycle overload condition happened?

2. Troubleshooting procedure

Yes

Yes

No

No

No

No

No

No

Yes

Yes

Yes

Does the compressor wire connected to the

compressor normally?

Yes

Yes

Replace the compressor

Reinstall and remove the obstructionIs the installation of outdoor unit good?

Reinstall and remove the obstruction

Is the installation of indoor unit good?

Open valve screw to the end.

Are the service valves full opened?

Correct the compressor wire connection

Is insuration resistance between each

compressor terminal and body normal?

Replace INVERTER PCB

No

Does the compressor rotate normally?

Did AC power voltage interruption happen

during the compressor in operation?

Replace the compressor

Check AC power source

Troubleshooting

Samsung Electronics 4-21

4-3-14 E466: DC Link Over voltage/ Low voltage error

1. Checklist :

1) Is the power voltage normal?(Lightning, Power interruption etc.)

2) Is AC Power cable connection normal?(Detaching the wire)

2. Troubleshooting procedure

Yes

No

No

No

No

Yes

Yes

Yes

Push the center bar of M/C and mesure the resis-

tance of each contact.

Yes

No

Replace M/C

Check and reconnecting the

AC power cable wire

Is the AC Power cable connection to the outdoor

unit terminal block good?

Check and reconnecting the reactor wire

at the TAB terminal

Is the connection of reactor terminal good?

Replace the blown FUSEAre the FUSEs on EMI PCB blown?

Is each contact resistance normal?

(less than 0.1ohm)

Does the error reappear frequently

The cause of this error may be power source trou-

ble as like power interruption.

Check the power source.

Replace INVERTER PCB

Troubleshooting

4-22 Samsung Electronics

4-3-15 Pipe Blocking Error (Error Code: E422)

1. Test Item

1) Check the open state of the outdoor unit ser vice valve.

2) Check the connection of the pipe.

3) Check the operation of the EE V.

4) Check the refrigerant leak age.

5) Check the connection of the indoor unit PBA EVA sensor.

6) Check the fault in the indoor unit E VA sensor.

2. Check procedure

Yes

Yes

Yes

If there occurs E422 error, reset the power and

check in the following order.

Check whether the pipe is empty and open all

the service valves on the gas and liquid pipes.

Change and connect the pipes immediately

and empty the pipes and then open the service

valves.

Check the replacement of the EEV (body/coil)

and the refrigerant leaking part. After that,

recharge.

Check the temperature value through

S-NET, etc. and then if there is a fault, replace

and reconnect.

No

No

No

No

Check the opening of the outdoor unit

service valve.

Check the connection of

the pipes (such as disconnection, bent, or

cross-connection with other sets).

Check the EEV operation and

the refrigerant leakage.

Check the fault in the indoor unit EVA

sensor and the connection state.

Troubleshooting

Samsung Electronics 4-23

4-3-16 The others

1. E465 : Compressor over load error

t*GBDPNQSFTTPSXPSLTJNQSPQFSMZDIBOHFUIFDPNQSFTTPSBOEDIFDLJGJUXPSLTQSPQFSMZ

¤ If a compressor is normal, check the assembly between Heatsink-Inverter PBA. If it is fine, change Inverter PBA.

2. E468 : Current sensor error

t

Check EEPROM data.

t

Check PCB operates properly.

3. E471 : Oudoor EEPROM error

t

Upload EEPROM on Outdoor unit Main PBA.

4. E474 : IPM(IGBT Module) or PFCM Temperature sensor Error

t

E500 : IPM is over heated

t

Check IPM is well assembled to heatsink

t

Check whether inlet port is clogged.

t

Change IPM if it is defective one

5. E554 : Gas leak error

t

Check refrigerant charge

t

Check Indoor EVA sensor

t

Check Service valve is open.

t

Check the pipes and wires correctly connected.

6. E556 : Capacity miss match between indoor and outdoor

t

Check the model name of indoor and outdoor unit and set option code on indoor unit again.

7. Outdoor overload protection control (at the stop of the compressor.) : E404

t

Check whether the fan and the motor operate normally.

t

Check the operation of EEV.

t

Check the temperature sensor of the indoor unit heat Exchanger.

t

Check the indoor unit inlet blocking.

Troubleshooting

4-24 Samsung Electronics

4-3-17 Setting an indoor unit installation option

䯴 Setting an indoor unit installation option(suitable for the condition of each installation location)

1. Check whether power is supplied or not.

- When the indoor unit is not plugged in, there should be additional power supply in the indoor unit.

2. The panel(display ) should be connected to an indoor unit to receive option.

3. Set the installation option according to the installation condition of an air conditioner.

- The default setting of an indoor unit installation option is 02000-100000-200000-300000.

4. Set the indoor unit option by wireless remote controller.

▶ Heating setting compensation (SEG21) is applied to Heat pump model only.

SEG1 SEG2 SEG3 SEG4 SEG5 SEG6

0 2 RESERVED RESERVED RESERVED RESERVED

SEG7 SEG8 SEG9 SEG10 SEG11 SEG12

1 RESERVED RESERVED RESERVED RESERVED RESERVED

SEG13 SEG14 SEG15 SEG16 SEG17 SEG18

2 External control

External control

output

RESERVED RESERVED RESERVED

SEG19 SEG20 SEG21

3 RESERVED

Heating setting

compensation

Samsung Electronics 5-1

5. PCB Diagram

5-1 Indoor unit

5-1-1 Main PCB

▶ This Document can not be used without Samsung’s authorization.

PCB Diagram and Parts List

5-2 Samsung Electronics

①

#1 : DETECT_OV_UV

#2 : INRUSH_RY

#3 : PWR_RY

#4 : Zerocrossing

#5 : RPM_Feedback

#6 : FAN_PWM

#7 : BLDC_PS

#8 : DC 5V

#9 : GND

#10 : DC 12V

②

#1 : -

#2 : -

#3 : FAN LOW_COMP

#4 : FAN HIGH_FAN

#5 : FAN TURBO_4WA

③

#1 : ROOM-TH

#2 : GND

#3 : EVA IN-TH

#4 : GND

④

#1 : DC 12V

#2 : ERROR_Check

#3 : DC 12V

#4 : Comp_Chec

⑤

#1 : GND

#2 : External control

⑥

#1 : DC 12V

#2 : GND

#3 : PANEL_TXD

#4 : PANEL_RXD

#5 : REMOCON_RXD

#6 : DC 5V

#7 : KEY_INT

⑦

#1 : GND

#2 : GND

#3 : SPI_Control

#4 : -

⑧

#1 : F1

#2 : F2

#3 : DC 12V

#4 : GND

#5 : F3

#6 : F4

⑨

#1 : DC 12V

#2 : UB_12B'

#3 : UB_12A'

#4 : UB_12B

#5 : UB_12A

⑩

#1 : DC 12V

#2 : UB_12B'

#3 : UB_12A'

#4 : UB_12B

#5 : UB_12A

CN02-CTRL-POWER-FAN CN01-AC LOAD CN41-EVA IN/ROOM CN81-ERROR/COMP

CN83-EXT_CTRL

CN61-STEP UP/DOWN

CN903-DISPLAY

CN63-STEP LEFT/RIGH

CN45-SPI CN302-COMM

PCB Diagram and Parts List

Samsung Electronics 5-3

5-1-2 Power PCB

▶ This Document can not be used without Samsung’s authorization.

①

CN02-MAIN PBA

#1 : DC12V

#2 : GND

#3 : DC5V

#4 : BLDC_PS

#5 : FAN_PWM

#6 : RPM_FEEDBACK

#7 : ZEROCROSS

#8 : PWR_RY_12

#9 : INRUSH_RY_12

#10 : DETECT_OV/LV

②

CN71-POWER

#1 : L

#2 : NC

#3 : N

#4 : NC

#5 : EARTH

③

CN501-BLDC MOTOR

#1 : DC310V

#2 : NC

#3 : AGND

#4 : DC15V

#5 : Vsp

#6 : RPM_FEEDBACK

④

CN02-MAIN PBA

#1 : FAN_TURBO_4WAWY_12

#2 : FAN_HIGH_FAN_12

#3 : FAN_LOW_COMP_12

#4 : HEATER_CTRL_12A

#5 : HEATER_ZC

⑤

CN72-AC LOAD

#1 : N

#2 : NC

#3 : COMPRESSOR

#4 : OUTDOOR FAN MOTOR

#5 : OUTDOOR 4WAY V/V

PCB Diagram and Parts List

5-4 Samsung Electronics

5-1-3 Panel PCB

▶ This Document can not be used without Samsung’s authorization.

①

CN903-DISPLAY

#1 : DC 12V

#2 : GND

#3 : PANEL_TXD

#4 : PANEL_RXD

#5 : REMOCON_RXD

#6 : DC 5V

#7 : KEY_INT

②

CN31-DOWNLOAD(MICOM)

#1~#20 : Download

③

CN01-DOWNLOAD(Touch-IC)

#1 : DC 5V

#2 : GND

#3 : #4 : I2C

#5 : I2C

PCB Diagram and Parts List

Samsung Electronics 5-5

5-2 OUTDOOR

5-2-1 MAIN PCB Diagram

PCB Diagram and Parts List

5-6 Samsung Electronics

#1 : L

#2 : N.C

#3 : N

#1 : N

#2 : N.C

#3 : 4WAY V/V SIGNAL

#1 : OUT TEMP

#2 : GND

#3 : COND TEMP

#4 : GND

#5 : DISCHARGE TEMP

#6 : GND

#7 : OLP TEMP

#8 : GND

#1 ~ #20 : DOWNLOAD

#1 ~ #4 : EEV SIGNAL

#5,#6 : DC 12V

#1 ~ #7 : EEPROM

#1 : COMM SIGNAL

#2 : COMM SIGNAL

#3 : GND

#4 : DC 5V

#5 : DC 12V

#6 : COMM SIGNAL

#1 : N.C

#2 : SENSOR SIGNAL

#3 : GND

#4 : DC 5V

#1 : SENSOR SIGNAL

#2 : N.C

#3 : GND

#4 : DC 5V

#1 ~ # 2: COMM SIGNAL

#1 : EARTH

CN101 - POWER CN702 - 4WAY

CN403 - SENSOR CN306 - DOWNLOAD

CN802 - EEV CN806 - EEPROM

CN305 - COMM INV

CN401 - LOW PRESSURE

CN402 - HIGH PREWSSURE

CN303 - COMM INDOOR CN103 - EARTH

PCB Diagram and Parts List

Samsung Electronics 5-7

QAC048KXQPCC

5-2-2 INVERTER PCB

①

# Reactor - A1 : WHT

# Reactor - B1 : WHT

②

# Reactor - A2 : BLK

# Reactor - B2 : BLK

③

#1 : RXD

#2 : TXD

#3 : GND

#4 : DV5V

#5 : DV12V

#6 : INV, SMPS Signal

④

#1 : RXD_INV

#2 : TXD_INV

#3 : BOOT_INV

#4 : TDO_INV

#5 : TCK_INV

#6 : TDI_INV

#7 : TMS_INV

#8 : nTRST

#9 : GND

#10~#11: 5V

#14 #18 #19 : ENC

#17 : GND

#20 : SUB

⑤

#1 : DC310V #2 : N.C

#3 : GND

#4 : DV15V

#5 : FAN RPM

#6 : FAN RPM Feedback

⑥

#1 : DC310V #2 : N.C

#3 : GND

#4 : DV15V

#5 : FAN RPM

#6 : FAN RPM Feedback

⑦

# 1 : COMP. U-phase(RED)

# 2 : COMP. V-phase(BLU)

# 3 : COMP. W-phase(YEL)

⑧

# 1 : L-phase(BRN)

# 2 : N-phase(SKY)

Reactor - A1/B1 Reactor - A2/B2 CN351 - Communicat ion CN551 - Dow nloader

CN901-FAN1

CN911-FAN 2

CN401-COMP. L , N - 220V Power

PCB Diagram and Parts List

5-8 Samsung Electronics

QAC036KXQPCC / AC100KXADEH / AC036KXADEC

①

#Reactor -A1 : WHT

#Reactor -B1 : WHT

②

#Reactor -A2 : BLK

#Reactor -B2 : BLK

③

#1 : RXD

#2 : TXD

#3 : GND

#4 : DV5V

#5 : DV12V

#6 : INV, SMPS Signal

④

#1 : RXD_INV

#2 : TXD_INV

#3 : BOOT_INV

#4 : TDO_INV

#5 : TCK_INV

#6 : TDI_INV

#7 : TMS_INV

#8 : nTRST

#9 : GND

#10~#11: 5V

#14 #18 #19 : ENC

#17 : GND

#20 : SUB

⑤

#1 : DC310V #2 : N.C

#3 : GND #4 : DV15V

#5 : FAN RPM

#6 : FAN RPM Feedback

⑥

#1 : DC310V #2 : N.C

#3 : GND #4 : DV15V

#5 : FAN RPM

#6 : FAN RPM Feedback

⑦

CN401 : COMP. U-phase(RED)

CN402 : COMP. V-phase(BLU)

CN403 : COMP. W-phase(YEL)

⑧

# 1 : L-phase(BRN)

# 2 : N-phase(SKY)

Reactor - A1/B1 Reactor - A2/B2 CN351 - Communicatio n CN551 - Downloa der

CN901-FAN1

CN911-FAN 2

CN401,402,403-COMP. L, N - 220V Power

PCB Diagram and Parts List

Samsung Electronics 5-9

QAC140KXADGH / AC048KXADGC

①

#R : AC 380~400V : WHT

#S : AC 380~400V : BRN

#T : AC 380~400V : BLK

②

#1-#3 : AC 220~240V

③

#1 : RXD, #2 : TXD

#3 : GND, #4 : DC 5V

#5 : DC 12V, #6 : INV. SMPS Signal

④

#1 : RXD_INV

#2 : TXD_INV

#3 : BOOT_INV

#4 : TDO_INV

#5 : TCK_INV

#6 : TDI_INV

#7 : TMS_INV

#8 : nTRST

#9 : GND

#10~#11: 5V

#14 #18 #19 : ENC

#17 : GND

#20 : SUB

⑤

#1 : DC310V #2 : N.C

#3 : GND #4 : DV15V

#5 : FAN RPM

#6 : FAN RPM Feedback

⑥

#1 : DC310V #2 : N.C

#3 : GND #4 : DV15V

#5 : FAN RPM

#6 : FAN RPM Feedback

⑦

#1 : COMP. U-phase(RED)

#2 : COMP. V-phase(BLU)

#3 : COMP. W-phase(YEL)

⑧

#1~#2 : Reactor

RST - AC Power 3 Phase CN152 - AC Power CN351 - Communication CN551 - Downloa der

CN901-FAN1 CN911-FAN 2 CN400-COMP.

CN101- Reactor

PCB Diagram and Parts List

5-10 Samsung Electronics

QAC048KXQPCC / AC036KXQPCC / AC100KXADEH / AC036KXADEC

①

L1:BRN

②

N1:SKY-BLU

③

#1-#3:AC220~240V

L1-AC POWER L phase N1-AC POWE R N phase CN01-AC POWER

5-2-3 EMI PCB

PCB Diagram and Parts List

Samsung Electronics 5-11

QAC140KXADGH / AC048KXADGC

①

#R:AC380~400V:WHT

#S:AC380~400V:BRN

#T:AC380~400V:BLK

②

#1-#3:AC220~240V

RST-AC POWER 3phase CN100-AC POWER

Wiring Diagram

Samsung Electronics 6-1

6. Wiring Diagram

6-1 Indoor Unit

Wiring Diagram

6-2 Samsung Electronics

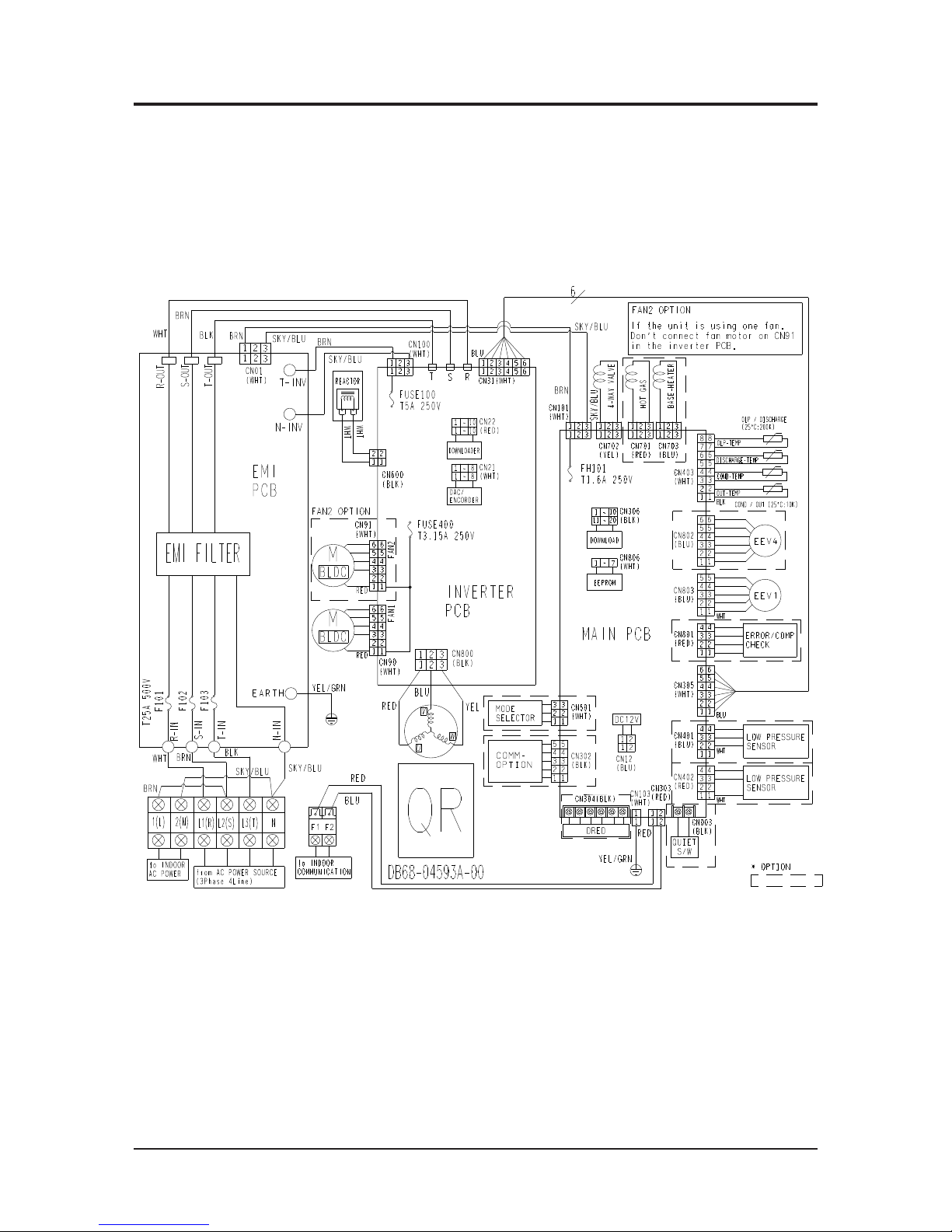

6-2 Outdoor unit

QAC048KXQPCC / AC036KXQPCC / AC100KXADEH / AC036KXADEC

This Document can not be used without Samsung’s authorization.

Wiring Diagram

Samsung Electronics 6-3

QAC140KXADGH / AC048KXADGC

This Document can not be used without Samsung’s authorization.

Samsung Electronics 7-1

7. Reference Sheet

7-1 Index for Model Name

Model Code

+

P

+

P

+

C

+

MG

+

/

+

048

+

C

+

AC

+

K

+

N

Product Type

Code Type

AM

DVM

AJ PMA

AC CAC (USD) / ASD

AE EHS

AN VTL

AK

PAK (Packaged

System)

AG CHR

Product Type

Code Type

E 2012

F 2013

H 2014

J 2015

K 2016

L 2017

Product Type

Code Type

S Set (NASA)

N Indoor (NASA)

X Outdoor(NASA)

A Set ( NASA)

B

Indoor

( No NASA)

C

Outdoor

(No NASA)

Product Type (Indoor)

Code Type

1 1 WAY CST

2 2 WAY CST

N MINI 4 WAY CST

4 4 WAY CST

H

HSP DUCT

M

MSP DUCT

L LSP DUCT

E

FRESH AIR INTAKE

DUCT

G

CEILING CONCEILED

DUCT

C CEILING

J CONSOLE

F FLOOR MOUNTING

P FAC / PAC

Product Type (Outdoor)

Code Type

A

Inv+Side+General Temp

S Inv+Side+Low Temp

Q Inv+Side+Tropical Temp

F Inv+Top+Tropical Temp

B Non Inv+Side+General Temp

N Non Inv+Side+Low Temp

R Non Inv+Side+Tropical Temp

Z Non Inv+Top+Tropical Temp

1:1

(In/

out)

->4Way : 4 , MSP Duct :

M , Ceiling : C

Product Type (Indoor)

Code Type

F FLAGSHIP

P PREMIUM

D DELUXE

S STANDARD

Product Type (Outdoor)

Code Type

A

STANDARD+GENERAL

Temp.+MODULE

B

STANDARD+LOW

Temp.+MODULE

C

STANDARD+

TROPICAL+MODULE

D

STANDARD+GENERAL

Temp.+NON MODULE

S STANDARD

T DELUXE + TROPICAL

Capacity (3 DIGIT)

KW / BTU / Liter

Rating Voltage

Code Type

A A(115V, 60hz, 1Ф)

B B(220V, 60Hz, 1Ф)

C C(208~230V, 60Hz)

D D(200~220V, 50Hz)

E E(220~240V, 50Hz)

F F(208~230V, 60Hz, 3Ф)

G G(380~415V, 50Hz, 3Ф)

H H(380V, 60Hz, 3Ф)

J J(460V, 60Hz, 3Ф)

K K(220~240V, 50/60Hz, 1Ф)

M M(127V, 50Hz)

N N (380~415V, 50/60Hz, 3Ф)

Refrigerant

Code Type

Refrigerant

C

COOLING ONLY

R410a

H HEAT PUMP

R HEAT RECOVERY

D COOLING ONLY

R22

E HEAT PUMP

A Cooling only

R134

B Heat Pump

N N/A

ö

/ can be removed from the buyer card if there are not enough digits.

Buyer Name

7-2 Samsung Electronics

7-2 Refrigerating Cycle Diagram

QAC048KXQPCC

QAC036KXQPCC

Indoor unit

Heat Exchanger PFE 12mm, 2X63X785, 6-1PASS, FP1.5, Louver

Fan Motor BLDC, Sirocco, [C/H] 510/450/390 [rpm]

Outdoor unit

Heat Exchanger FMC 16mm, 1R*69S*910, 2EA, FP1.4, Corrugate

Fan Motor BLDC, Propeller, RPM MAX : 800 [rpm]

Indoor unit

Heat Exchanger PFE 12mm, 2X63X785, 6-1PASS, FP1.5, Louver

Fan Motor BLDC, Sirocco, [C/H] 430/390/370 [rpm]

Outdoor unit

Heat Exchanger PFC 16mm, 1R*69S*910, 2EA, FP1.4, Corrugate

Fan Motor BLDC, Propeller, RPM MAX : 800 [rpm]

Samsung Electronics 7-3

QAC140KXADGH

Indoor unit

Heat Exchanger PFE 12mm, 2X63X785, 6-1PASS, FP1.5, Louver

Fan Motor BLDC, Sirocco, [C/H] 490/430/390 [rpm]

Outdoor unit

Heat Exchanger F&T Φ7W, 2R*66S*950, FP1.7, Louver

Fan Motor BLDC, Propeller, RPM MAX : 800 [rpm]

QAC100KXADEH

Indoor unit

Heat Exchanger PFE 8mm, 2X63X785, 6-1PASS, FP1.5, Louver

Fan Motor BLDC, Sirocco, [C/H] 410/370/350 [rpm]

Outdoor unit

Heat Exchanger F&T Φ7W, 2R*46S*950, FP1.7, Louver

Fan Motor BLDC, Propeller, RPM MAX : 830 [rpm]

7-4 Samsung Electronics

QAC048KXADGC

Indoor unit

Heat Exchanger PFE 12mm, 2X63X785, 6-1PASS, FP1.5, Louver

Fan Motor BLDC, Sirocco, [C/H] 490/440/390 [rpm]

Outdoor unit

Heat Exchanger F&T Φ7W, 2R*66S*950, FP1.7, Louver

Fan Motor BLDC, Propeller, RPM MAX : 800 [rpm]

QAC036KXADGC

Indoor unit

Heat Exchanger PFE 12mm, 2X63X785, 6-1PASS, FP1.5, Louver

Fan Motor BLDC, Sirocco, [C/H] 410/370/350 [rpm]

Outdoor unit

Heat Exchanger F&T Φ7W, 2R*46S*950, FP1.7, Louver

Fan Motor BLDC, Propeller, RPM MAX : 830 [rpm]

This Service Manual is a property of Samsung Electronics Co., Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© Samsung Electronics Co., Ltd. May. 2016.

Printed in Korea.

Code No. AC-00163E_1

*631*/2%$/6(59,&(3$571(51(7:25.

$UHD :HE6LWH

(XURSH&,60LGHDVW$IULFD JVSQVDPVXQJFVSRUWDOFRP

$VLD JVSQVDPVXQJFVSRUWDOFRP

1RUWK/DWLQ$PHULFD JVSQVDPVXQJFVSRUWDOFRP

&KLQD FKLQDVDPVXQJSRUWDOFRP

Loading...

Loading...