Page 1

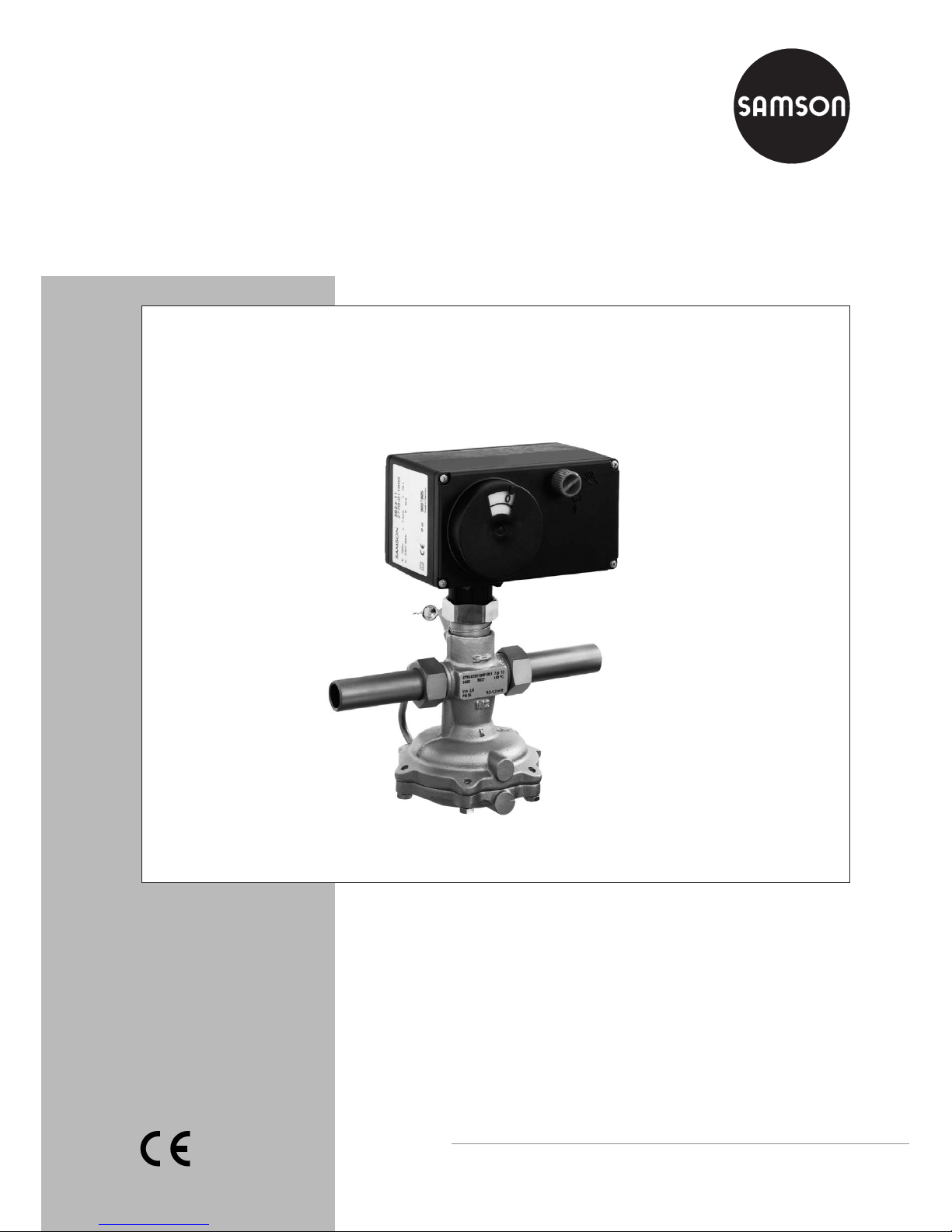

Flow Regulators

with Electric Actuator

Type 2488/5824 and

Type 2488/5825

Mounting and

Operating Instructions

EB 3135-1 EN

Edition June 2008

Fig. 1 · Type 2488/5824 Flow Regulator with Electric Actuator

Page 2

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . 4

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2 Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Additional installation instructions . . . . . . . . . . . . . . . . . . . . 6

3 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Set point adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2.1 Adjustment without actuator. . . . . . . . . . . . . . . . . . . . . . . 6

3.2.2 Adjustment with Type 5824 Actuator . . . . . . . . . . . . . . . . . . 7

3.2.3 Adjustment with Type 5825 Actuator . . . . . . . . . . . . . . . . . . 7

4 Maintenance–Replacing parts . . . . . . . . . . . . . . . . . . . . . 8

4.1 Replacing the orifice . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.2 Cleaning or replacing the plug. . . . . . . . . . . . . . . . . . . . . . 9

4.3 Replacing the diaphragm . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Nameplate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6 Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

7 Customer inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 Dimensions and weights . . . . . . . . . . . . . . . . . . . . . . . 11

2 EB 3135-1 EN

Contents

Note!

Non-electric actuators and control valve versions do not have their own potential ignition

source according to the ignition risk assessment stipulated in EN 13463-1: 2001, section

5.2, even in the rare incident of an operating fault. Therefore, they do not fall within the

scope of Directive 94/9/EC.

For connection to the equipotential bonding system, observe the requirements specified in

EN 60079-14: 1977 (VDE 0165 Part 1), section 6.3.

Page 3

General safety instructions

EB 3135-1 EN 3

General safety instructions

4

The flow regulator must be installed, started up, and serviced only by skilled

or semi-skilled staff in accordance with good engineering practice so that

employees and third persons are not exposed to danger.

All safety instructions and warnings given in these mounting and operating

instructions, particularly those concerning installation, start-up, and

maintenance, must be strictly observed.

4

The regulator complies with the requirements of the European Pressure

Equipment Directive 97/23/EC. The declaration of conformity issued for a

valve bearing the CE marking includes information on the applied

conformity assessment procedure and will be provided on request.

4

To ensure appropriate use, only use the regulator in applications where the

operating pressure and temperatures do not exceed the operating values

specified in the order.

Note that the manufacturer does not assume any responsibility for damage

caused by external forces or any other external factors.

Take appropriate safety precautions to prevent hazards that may be caused

in the regulator by the process medium, operating pressure, or moving parts.

4

Make sure the regulator is shipped and stored properly.

4

The electric actuator has been designed for use in electrical power

installations. Strictly observe the relevant safety regulations for wiring and

maintenance work. Only use disconnect devices that are protected against

accidental or inadvertent reconnection. Take special care when making

adjustments on live parts. Do not remove the covers under any

circumstances.

Important!

4

Depending on the field of application, allow the regulator to cool down or

warm up to reach ambient temperature prior to starting any work.

Always depressurize the relevant section of the plant and, if necessary, also

drain the pipeline prior to removing the regulator from the pipeline.

4

When controlling freezing media, protect the flow regulator against frost.

Page 4

1 Design and principle of

operation

The device combines a Type 2488 Flow Reg

-

ulator with a force-locking Type 5824 Actua

-

tor or a force-locking Type 5825 Electric Ac

-

tuator with fail-safe action. The electric actu

ator is attached to the regulator by means of

the adapter and allows also the temperature

to be controlled by changing the position of

the orifice (restriction) in response to the con

trol signal received from an electric control

device.

The medium flows through the valve in the

direction indicated by the arrow on the valve

body. The flow rate depends on the area released by the valve plug (3) and the adjustable orifice (8.5).

The integral positioning spring (5) determines

the upper differential pressure (0.2 bar).

The high pressure upstream of the orifice is

transmitted to the high-pressure side of the

diaphragm actuator through the control line

(7). The low pressure downstream of the orifice acts on the low-pressure side of the oper

ating diaphragm (6.1) via a hole in the valve

plug. The differential pressure generated by

the orifice (special differential pressure) is

converted into a positioning force by the op

-

erating diaphragm. This force is used to po

sition the valve plug against the force of the

positioning spring (5).

2 Installation

2.1 Mounting position

Install the regulator in a horizontal pipeline.

Make sure the direction of flow corresponds

with the arrow on the valve body. Place the

electric actuator on top of the valve body.

In cases where the control valve is to be insu

-

lated, do not insulate the actuator and cou

pling nut as well.

Make sure that the permissible ambient tem

-

perature is not exceeded especially at the ac

-

tuator stem (10.1). If necessary, use an ex

tension piece (intermediate insulating piece,

order no. 1990-1712). Refer to section 8.

The maximum distance up to the top of the

valve body that can be insulated can be extended to approx. 25 mm.

Note!

Observe the instructions for the electric actuator specified in EB 5824 EN.

Types 5824-10/-11 and 5825-10/-11 Electric Actuators with a 7.5 mm rated travel are

used for valves in sizes DN 15 to 25.

Types 5824-20 and 5825-20 Electric Actua

tors with 12 mm rated travel are required for

valves in nominal sizes DN 32 to 50.

2.2 Strainer

Install a strainer (e.g. SAMSON Type 1 NI)

upstream of the valve to prevent sealing par

-

ticles, weld spatter, pipe scale, and other im

purities carried along by the process medium

from impairing the proper operation, espe

-

cially the tight shut-off of the valve.

4 EB 3135-1 EN

Design and principle of operation

Page 5

EB 3135-1 EN 5

Installation

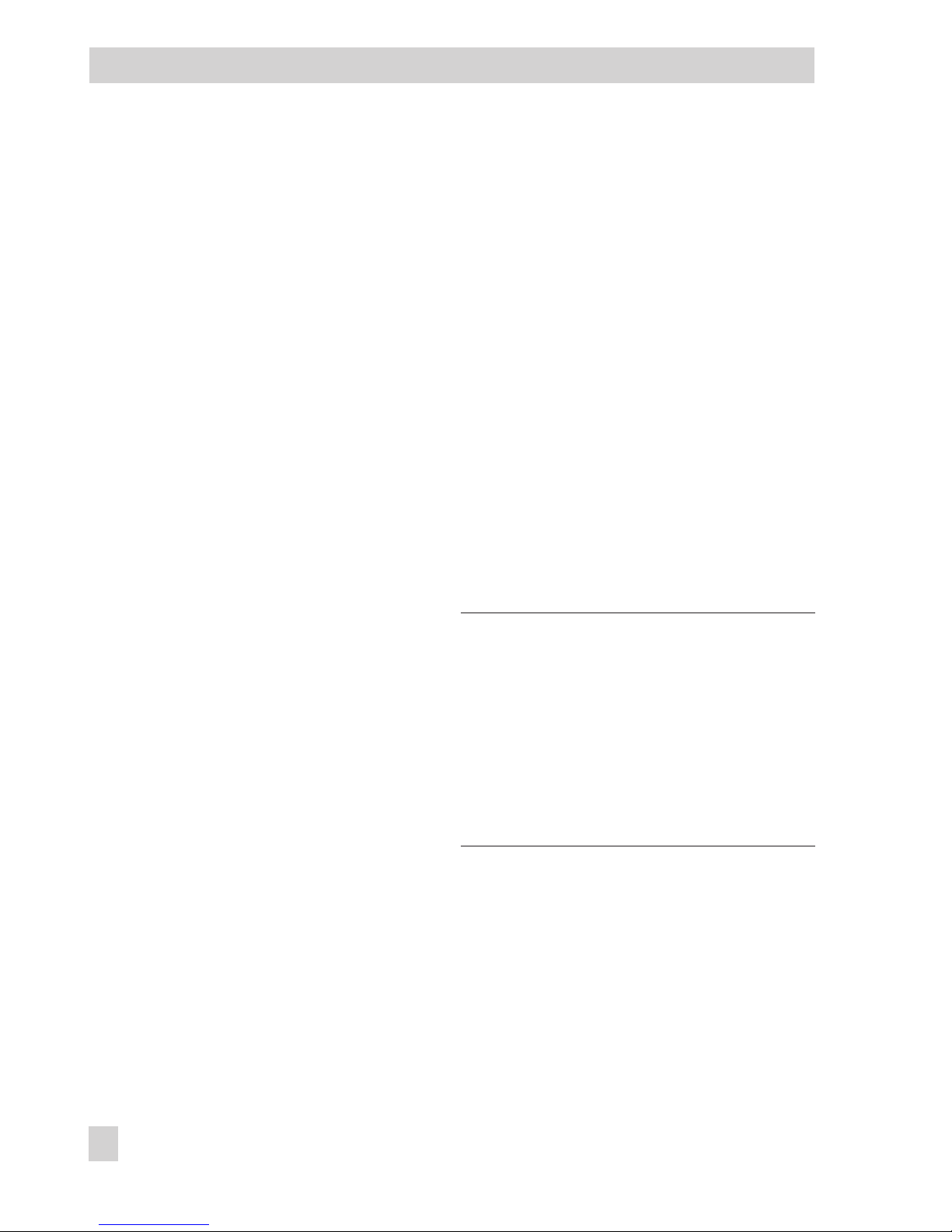

Fig. 2 · Sectional drawings

10

8.3

1

8.5

3

5

4

8.4

8

10.1

10.2

6.2

2

6 76.1

Legend

1 Valve body

2 Seat

3 Guide nipple with plug assembly

4 Plug stem

5 Positioning spring

6 Diaphragm actuator

6.1 Operating diaphragm

6.2 Screws

7 Control line

8 Adapter

8.1 Orifice stem

8.2 Set point adjuster

8.3 Adjustment screw

8.4 Lead-sealed hole

8.5 Orifice (restriction)

10 Electric actuator

10.1 Actuator stem

10.2 Coupling nut

Tightening torques for DN Nm

Coupling nut (10.2) 20

Guide nipple (3)

15...25

32...5070110

Screws (6.2)

15...25

32...50

8

18

Adapter (8)

15...25

32...5080110

10.1

10

10.2

8.1

8.2

8.4

8

8.5

DN 15 to 25, PN 25

DN 32 to 50

DN 15 to 25, PN 16

Page 6

Make sure that the medium flow corresponds

with the direction indicated by the arrow on

the strainer body. Install the strainer with the

filter element suspended downwards.

Ensure that ample space is available to re

-

move the filter.

2.3 Additional installation

instructions

Ideally, hand-operated shut-off valves should

be installed both upstream of the strainer

and downstream of the regulator. This allows

the plant to be shut down for cleaning and

maintenance routines, or when it is not oper

ated for long periods of time. To monitor the

pressures prevailing in the plant, install pressure gauges both upstream and downstream

of the regulator.

3 Operation

3.1 Start-up

Important!

Before starting up or pressurizing the regula

tor, make sure the orifice (8.5) used to limit

the flow rate is open.

To open the orifice, retract the actuator stem

of the electric actuator using the manual ad

-

juster or the electrical control signal. Discon

nect electric actuators with fail-safe action

from the power supply before disassembling

them in order to open the orifice.

Fill the plant very slowly on start-up.

When carrying out a pressure test on the

section of the plant equipped with a regula

-

tor, prevent the diaphragm actuator from be

ing damaged by the test pressure by using a

test pressure which does not exceed the max

imum permissible differential pressureΔp of

the diaphragm actuator.

3.2 Set point adjustment

The flow rate can be adjusted both with and

without the electric actuator being attached

to the valve.

3.2.1 Adjustment without actuator

For valve sizes DN 15 to 25, the flow rate

can be set by turning the adjustment screw

(8.3) at the side using a 4 mm hex wrench.

For valve sizes DN 32 to 50, the set point

adjuster (8.2) is used to adjust the flow rate.

1. Turn the adjustment screw (8.3) or set

point adjuster (8.2) clockwise as far as it

will go to close the orifice (8.5) (the orifice of valves in sizes DN 15 to 25 is

closed upon delivery).

2. Determine the number of turns of the

screw or adjuster required to achieve the

desired flow set point from the adjust

ment diagram on page 7.

(For valve size DN 15, the adjustment

curve that corresponds with the flow coef

ficient Kvs indicated on the nameplate

must be selected).

3. Based on a closed orifice, adjust the flow

set point by turning the screw or adjuster

counterclockwise. Check the flow rate

and correct it, if necessary.

4. Secure the setting using the lead-sealing

hole or leading screw.

6 EB 3135-1 EN

Operation

Page 7

3.2.2 Adjustment with Type 5824

Actuator

1. Retract the actuator stem by turning the

handwheel counterclockwise or by

applying a corresponding control signal

from the control device.

2. Continue as described in section 3.2.1.

3.2.3 Adjustment with Type 5825

Actuator

1. Switch the control device to manual mode

and change the control signal to retract

the actuator stem all the way and com

-

press the spring mechanism.

EB 3135-1 EN 7

Operation

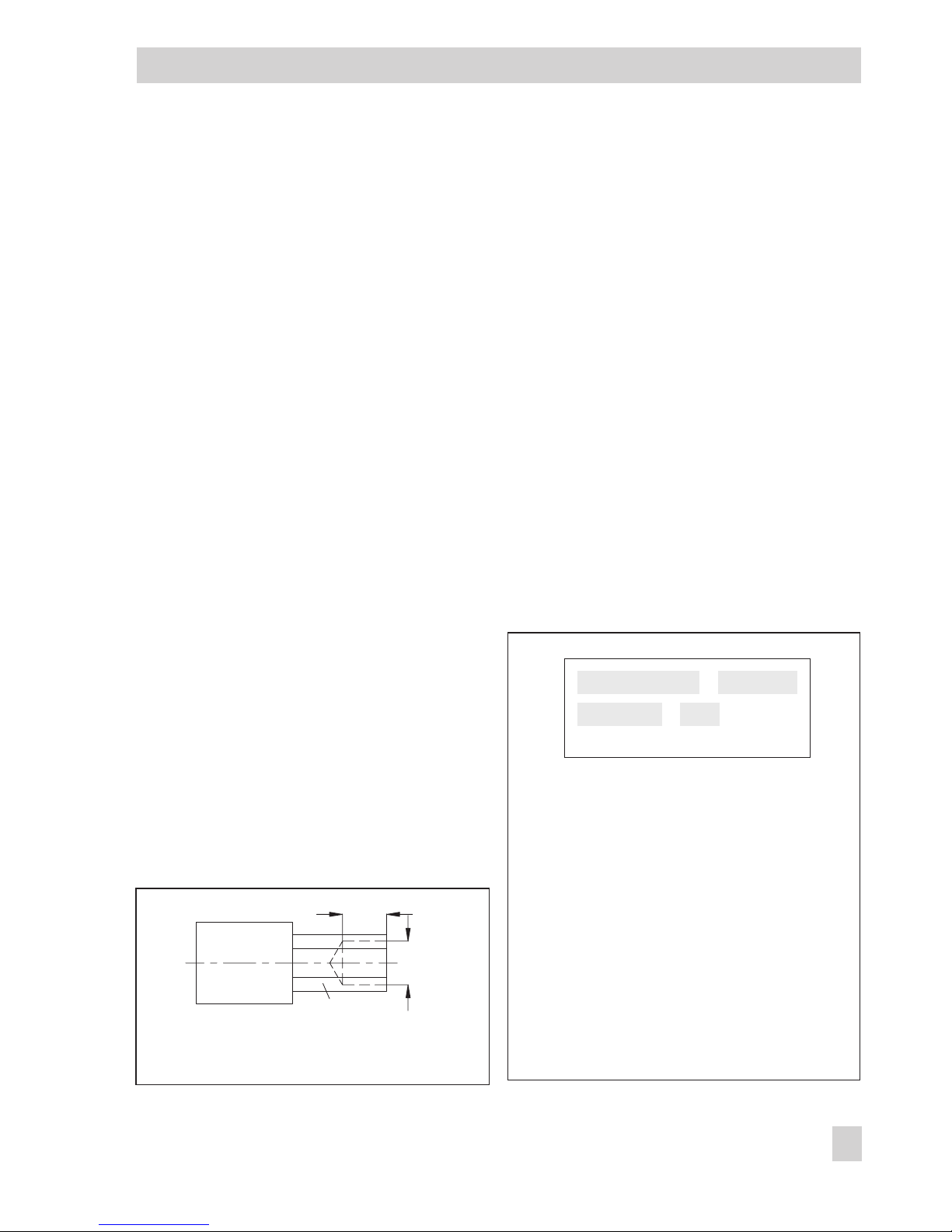

Fig. 3 · Diagram for adjusting the flow rate

0

3

4

5

5

6

10

12

0

9

4

3

2

DN 32 to 50

DN 15 to 25

6

7

11

0.01 0.05 0.1 0.5 1 5 10

1

0

2

3

4

5

6

7

8

DN 15, K

vs

...

32 40 50

V

˚

m3/h0.02 0.03 0.2 0.3 2 3 4 15

0.4

1

2.5

4

25DN20

7

8

Turns of the set point screw

Nominal size

15 20 25 32 40

1)

50

1)

K

VS

0.4 1 2.5

4

6.3 8 12.5 16/202)20/25

2)

Set point range

flow rate m³/h

0.6...1.3

3)

0.8...2.33)0.8...3.53)2...5.83)3...9.13)4...14.1

3)

0.03...0.2 0.1...0.64 0.2...1.2 0.6...2.5 0.8...3.6 0.8...5 2...10 3...12.5 4...15

1)

Also available as version with flanged body

2)

KVSfor flanged body

3)

A higher noise level will occur if the specified set point values are exceeded

Page 8

If there is no control signal, the actuator

can be adjusted manually. For manual

adjustment, remove the front case cover.

Insert a 4 mm hex wrench into the red

actuating shaft and turn it.

Only turn the shaft counterclockwise and

only up to the point at which the torque

switch in the actuator is activated. Once

the magnet has been released, the spring

mechanism will push the actuator stem

back to the fail-safe position.

Caution!

Observe the relevant safety

regulations on connecting the electric

actuator or performing any

maintenance on it.

2. Continue as described in section 4.1.

Note!

The flow rate indicated in the diagram is reduced by approximately 20 % for valves in

sizes DN 32 to 50 which are combined with

Type 5821/5822 Actuators.

4 Maintenance–Replacing parts

The flow regulator is maintenance free. Nev

-

ertheless, it is subject to natural wear, partic

-

ularly at the seat, plug, and operating dia

-

phragm.

Depending on the operating conditions that

prevail, inspect the regulator at regular inter

-

vals to avoid possible malfunctions.

If the valve does not close tightly, this may be

caused by a dirty seat and plug or due to

natural wear.

If the flow rate deviates considerably from

the adjusted set point, e.g. rapidly increasing

flow rate, check the operating diaphragm for

ruptures and replace it, if necessary.

Prior to carrying out any mainte

nance work on the flow regulator, it

must be removed from the pipeline.

For this purpose, make sure the rele

vant section of the pipeline is

depressurized and drained as well

before removing the regulator from

the pipeline.

Before removing the actuator from

the valve, switch off the power supply

and protect it from being reconnected

unintentionally.

4.1 Replacing the orifice

1. Unscrew the coupling nut (10.2). Remove

the actuator from the valve.

2. Note! For sizes DN 15 to 25, unscrew the

adjustment screw (8.3) first.

Use a socket wrench (order no.

1280-3001, or a self-made wrench (re

fer to section 4.2, step 4) to unscrew the

adapter (8) of the orifice. Then pull it out

of the valve body.

3. Replace parts with new ones and reas

semble in reverse order. Observe the

tightening torques specified in Fig. 2.

8 EB 3135-1 EN

Maintenance–Replacing parts

Page 9

4.2 Cleaning or replacing the plug

1. Unscrew the coupling nut and remove the

actuator from the valve.

2. Unscrew the control line (7).

3. Unscrew the screws (6.2). Remove the

bottom diaphragm case together with the

operating diaphragm (6.1) and dia

-

phragm plate.

4. For valve sizes DN 15 to 25, unscrew

the guide nipple of the plug assembly (3)

using a socket wrench (order no.

1280-3001) or a self-made wrench

made from a Gedore screwdriver bit (IN

19-19), for example, by drilling a 17

mm hole with a 17 mm diameter into the

19 mm hexagon bit (Fig. 4). Then pull

out the guide nipple.

For valve sizes DN 32 to 50, unscrew

the stopper first. Then pull out the plug

assembly.

5. Thoroughly clean the seat and plug.

Check the control line and screw fitting

for any blockages. Should the plug be

damaged, replace the entire plug assem

-

bly with a new one.

6. To reassemble, proceed in reverse order.

Observe the tightening torques specified

in the table in Fig. 2.

4.3 Replacing the diaphragm

1. Unscrew the coupling nut and remove the

actuator from the valve.

2. Unscrew the control line (7).

3. Unscrew the screws (6.2). Remove the

bottom diaphragm case together with the

operating diaphragm (6.1) and dia

-

phragm plate.

4. Replace the diaphragm together with the

diaphragm plates with new ones.

5. To reassemble, proceed in reverse order.

Observe the tightening torques specified

in the table in Fig. 2. Prior to reattaching

the actuator, make sure that the diaphragm has been inserted properly in the

ring groove.

5 Nameplate

EB 3135-1 EN 9

Nameplate

17

Ø 17

SW 19

Fig. 4 · Socket wrench

Fig. 5 · Labeling

1 Configuration ID

2 Type designation

3 Model number

4 Date of manufacture

In the other fields:

K

VS

or C

V

Upper differential pressure in bar or psi

Flow set point range in m³/h

Max. perm. temperature in °C or °F

Max. perm. differential pressureΔp

Nominal pressure PN or ANSI Class

1 2

3 4

Page 10

6 Troubleshooting

7 Customer inquiries

Should you have any inquiries, please submit

the following details:

4

Type and nominal size of the valve

4

Threaded or flanged connection

4

Model number

4

Upstream and downstream pressures

4

Flow rate in m³/h

4

Has a strainer been installed?

4

Installation drawing

10 EB 3135-1 EN

Troubleshooting

Fault Possible causes Solution

Flow rate

exceeds

adjusted set

point

Valve too large for

control task

Recalculate K

VS

and contact SAMSON.

Seat and plug leak Remove valve, clean seat and plug. If necessary,

replace plug (section 4.2).

Otherwise, return device for repair.

Operating diaphragm

defective

Replace diaphragm (section 4.3) or return device

for repair.

Control line blocked Remove and clean control line.

Flow set point

not reached

Incorrect set point range

selected

Check set point range and contact SAMSON.

Safety device, e.g. pressure

regulator, has been

triggered

Check plant, unlock safety device.

Electric actuator extended Check control signal from the electric control device.

Insufficient pressure drop

across the plant

Compare existing differential pressure in the plant

with the plant’s drag.

Min. diff. pressure = special diff. pressure +

(/ )

.

VK

VS

2

Strainer blocked Drain and clean filter of the strainer.

Valve installed against

direction of flow

Re-install valve such that direction of flow

corresponds to arrow on the body.

Control loop

hunts

Valve too large for

control task

Recalculate KVSand contact SAMSON.

Page 11

8 Dimensions and weights

EB 3135-1 EN 11

Dimensions and weights

Nominal size DN

15 20 25 32 40 50

Pipe external Ø d

21.3 26.8 32.7 42 48 60

Connection R

G ¾ G 1 G 1¼ G 1¾ G 2 G 2½

Width across flats SW

30 36 46 59 65 82

Length L

65 70 75 100 110 130

Height H

155 216

Height H1 PN 25

85 105 140

PN 16

105 – –

Standard versions

Welding ends L1

210 234 244 268 294 330

Weight, approx. kg

3.0 3.1 3.2 4.4 6.9 7.4

Special version with threaded ends (male thread)

Length L2

129 144 159 180 196 228

Male thread A

G ½ G ¾ G 1 G 1¼ G 1½ G 2

Weight, approx. kg

3.0 3.1 3.2 4.4 6.9 7.4

Special version with flanges PN 16/25 or version with flanged valve body (DN 32/40/50)

Length L3

130 150 160 180 200 230

Weight, approx. kg

3.6 4.3 4.9 9.1 10.4 11.9

146

6

dR

H

30

H1

L

L1

Ø116 (Ø160)

G

L3

L3

L

L2

L

A

SW

SW

SW

1

8

80

Fig. 6 · Dimensional drawings (dimensions in mm, values in parentheses for DN 40 and DN 50)

Connection nuts with welding ends Connection nuts with flanges Flanged body DN 32 to 50

Connection nuts with threaded ends Intermediate insulating piece

Page 12

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 3135-1 EN

S/Z 2008-06

Loading...

Loading...