Page 1

Translation of original instructions

EB 8222 EN

Type3310/3278 with positioner

Type3310/AT

Edition December 2016

Type3310/AT and Type3310/3278 Pneumatic Control Valve

Type3310 Segmented Ball Valve

Page 2

Note on these mounting and operating instructions

These mounting and operating instructions assist you in mounting and operating the device

safely. The instructions are binding for handling SAMSON devices.

Î For the safe and proper use of these instructions, read them carefully and keep them for

later reference.

Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service

Department (aftersalesservice@samson.de).

The mounting and operating instructions for the devices are included in

the scope of delivery. The latest documentation is available on our website

at www.samson.de > Service & Support > Downloads > Documentation.

Denition of signal words

Hazardous situations which, if not avoided,

will result in death or serious injury

Hazardous situations which, if not avoided,

could result in death or serious injury

Property damage message or malfunction

Additional information

Recommended action

DANGER

!

WARNING

!

NOTICE

!

Note

Tip

2 EB 8222 EN

Page 3

Contents

EB 8222 EN 3

1 General safety instructions .............................................................................5

2 Design and principle of operation ..................................................................6

2.1 Fail-safe position ............................................................................................6

2.1.1 TypeSRP (single-acting version) ......................................................................6

2.1.2 TypeDAP (double-acting version) ....................................................................8

3 Mounting ......................................................................................................8

3.1 Assembling valve and actuator .......................................................................8

3.1.1 Type3310-SRP ..............................................................................................8

3.1.2 Type3310/3278 ...........................................................................................9

3.2 Mounting position ........................................................................................11

3.3 Signal pressure connection ...........................................................................11

4 Operation ...................................................................................................12

4.1 Changing the fail-safe action ........................................................................12

5 Servicing.....................................................................................................12

5.1 Removing the actuator from the valve ............................................................12

5.2 Replace the packing .....................................................................................12

5.3 Replacing the seat ring seal ..........................................................................13

5.4 Assembly ....................................................................................................13

5.5 Replacing the segmented ball, shafts and bearings .........................................15

5.5.1 Disassembly ................................................................................................15

5.5.2 Assembly ....................................................................................................15

6 Changing the characteristic ..........................................................................17

7 Tools and tightening torques ........................................................................18

7.1 Special tools ................................................................................................18

7.2 Tightening torques ........................................................................................19

7.2.1 Tightening torques for ange bolts .................................................................19

8 Nameplate ..................................................................................................21

9 Accessories .................................................................................................22

10 Technical data .............................................................................................23

11 Customer inquiries ......................................................................................23

Page 4

4 EB 8222 EN

Page 5

EB 8222 EN 5

General safety instructions

1 General safety instructions

− The control valve must be mounted, started up or serviced by fully trained

and qualied personnel only; the accepted industry codes and practices are

to be observed. Make sure employees or third persons are not exposed to

any danger.

− All safety instructions and warnings given in these mounting and operating

instructions, particularly those concerning installation, start-up and maintenance, must be strictly observed.

− The control valves comply with the requirements of the European Pressure

Equipment Directive 2014/68/EU. Valves with a CE marking have a declaration of conformity, which includes information about the applied conformity

assessment procedure. The declaration of conformity can be viewed and

downloaded at uhttp://www.samson.de.

− To ensure appropriate use, only use the valve in applications where the oper-

ating pressure and temperatures do not exceed the specications used for sizing the valve at the ordering stage. The manufacturer does not assume any

responsibility for damage caused by external forces or any other external

factors.

− Any hazards that could be caused in the valve by the process medium, the

operating pressure, the signal pressure or by moving parts are to be prevented by taking appropriate precautions.

− Proper shipping and storage are assumed.

− For installation and maintenance, make sure the relevant section of the pipe-

line is depressurized and, depending on the process medium, drained as

well. Depending on the eld of application, allow the valve to cool down or

heat up to reach ambient temperature before starting any work on it.

− When working on the valve, make sure that the pneumatic air supply as well

as the control signal are disconnected to prevent any hazards caused by

moving parts.

Page 6

6 EB 8222 EN

Design and principle of operation

2 Design and principle of oper-

ation

The pneumatic control valve consists of the

Type3310 Segmented Ball Valve and either

the SAMSON PFEIFFER TypeAT or the

SAMSON Type3278 Pneumatic Rotary

Actuator.

The control valve is designed for both

throttling and on/off service in process

engineering and plants with industrial

requirements. The control valve is suitable for

liquids, vapors and gases at temperatures

from –29 to +220°C and pressure rating of

Class150 and 300.

The segmented ball valve in valve sizes

NPS1 to 12 is available with a soft-seated

or metal-seated ball. The version used is

marked on the nameplate of the valve body

(see section8).

The process medium ows through the valve.

The signal pressure applied to the rotary ac-

tuator determines the position (opening angle) of the segmented ball (8) and thus the

cross-sectional area of ow between the ball

and body (1). The actuator motion is transmitted to the segmented ball valve by a shaft

with square or key drive. The valve shaft (4)

is sealed by a self-adjusting PTFE V-ring

packing (2.3).

2.1 Fail-safe position

2.1.1 TypeSRP (single-acting

version)

The fail-safe position of the control valve upon supply air (signal pressure) failure is determined in Type3310/AT (TypeSRP single-acting version) by the version used and

in Type3310/3278 by how the rotary actuator is mounted to the valve.

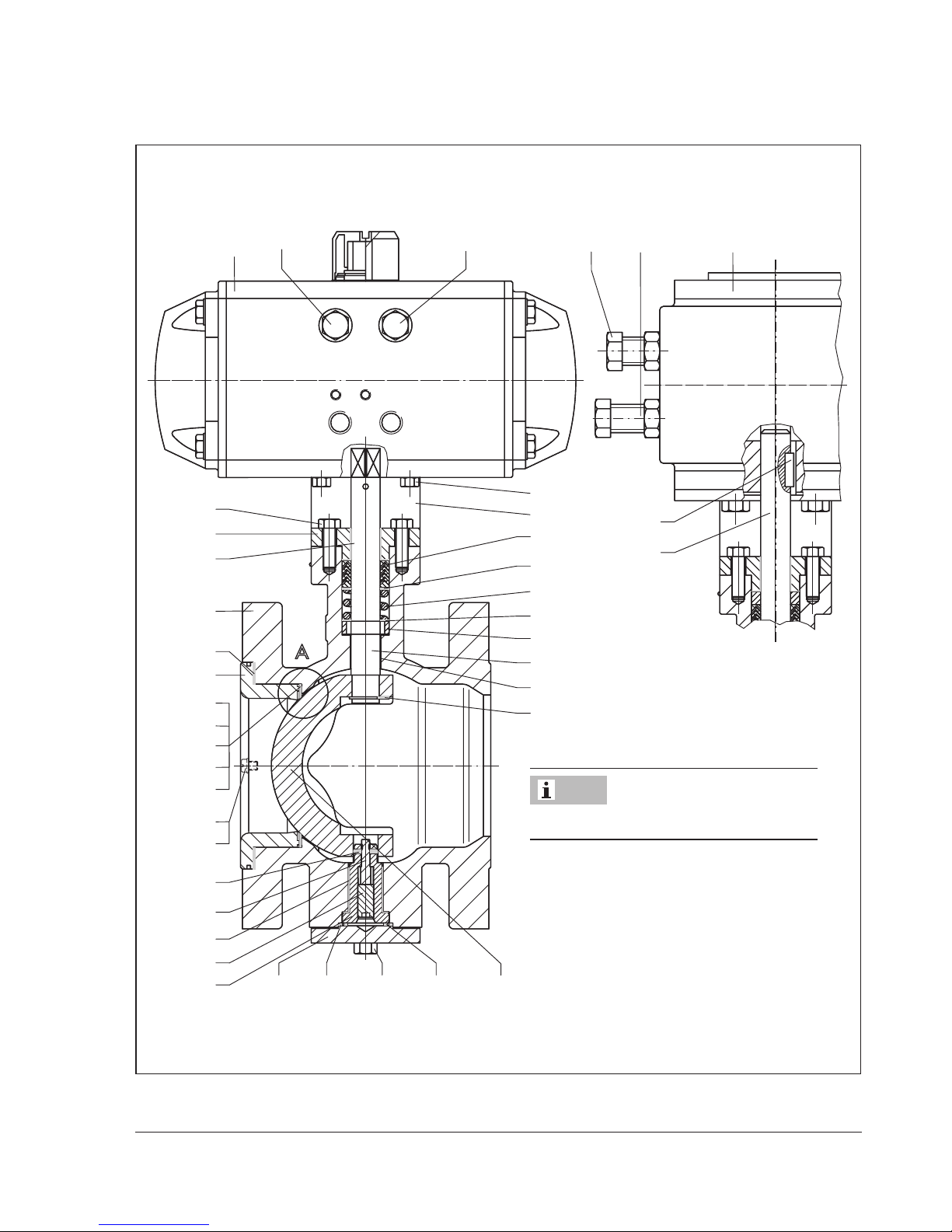

1 Body

2 Packing gland

2.1 Bearing bushing

2.2 Screws

2.3 V-ring packing

2.4 Washer

2.5 Spring

2.6 Washer

2.7 Spacer

3 Yoke

3.1 Screws

4 Shaft

4.1 Bearing bushing

4.2 Key drive

4.3 Snap ring

5 Support shaft

5.1 Bearing bushing

5.2 Threaded pin

5.3 Clamping bolt

5.4 Locking pins

8 Segmented ball

10 Bottom ange

10.1 Flange gasket

10.2 Flange ring

10.3 Flange bolts

11 Retainer

11.1 Screw

11.2 Washer

11.3 Gasket

11.4 Washer

11.5 Metal tubular seal

11.6 Seat ring (metal)

11.7 Support ring

11.8 Seat ring (PTFE)

12 Type AT Actuator

12.1 Stop bolt

12.2 Stop bolt

13 Type3278 Actuator

13.1 Stop bolt

13.2 Stop bolt

Page 7

EB 8222 EN 7

Design and principle of operation

12.112

13.2

13.1 13

2

2.2

2.1

1

11.3

5.4

5.3

5.1

5.2

5

8

4.1

4.3

4

2.5

2.6

2.7

2.4

2.3

3.1

3

12.2

4.2

4

10 10.1 10.3 10.2

11.1

11.2

11.4

11.5

11.6

11.7

11.8

11

A

SAMSON PFEIFFER TypeAT Actuator

SAMSON Type3278 Actuator

Detail A (seal) is shown in Fig.3.

Note

Fig.1: Sectional drawing of Type3310 Valve

Page 8

8 EB 8222 EN

Mounting

Fail-close

When the pressure is relieved from the

rotary actuator or the supply air fails, the

actuator springs close the valve. The valve

opens opposing the force of the actuator

springs when the signal pressure increases.

Fail-open

When the pressure is relieved from the

rotary actuator or the supply air fails, the

actuator springs open the valve. The valve

closes opposing the force of the actuator

springs when the signal pressure increases.

2.1.2 TypeDAP (double-acting

version)

The TypeDAP Rotary Actuator (double-acting) has no springs. A dened nal position

is not reached when the supply air fails.

3 Mounting

3.1 Assembling valve and

actuator

3.1.1 Type3310-SRP

Proceed as follows if the valve and actuator

have not been assembled by SAMSON:

In the standard actuator version (SRP =

single-acting with spring return mechanism),

the spring return mechanism is designed to

close clockwise when there is no signal

pressure.

If you require a different direction of rotation

or a double-acting actuator (DAP = double-

acting without spring return mechanism), this

specication must be submitted on ordering

the actuator.

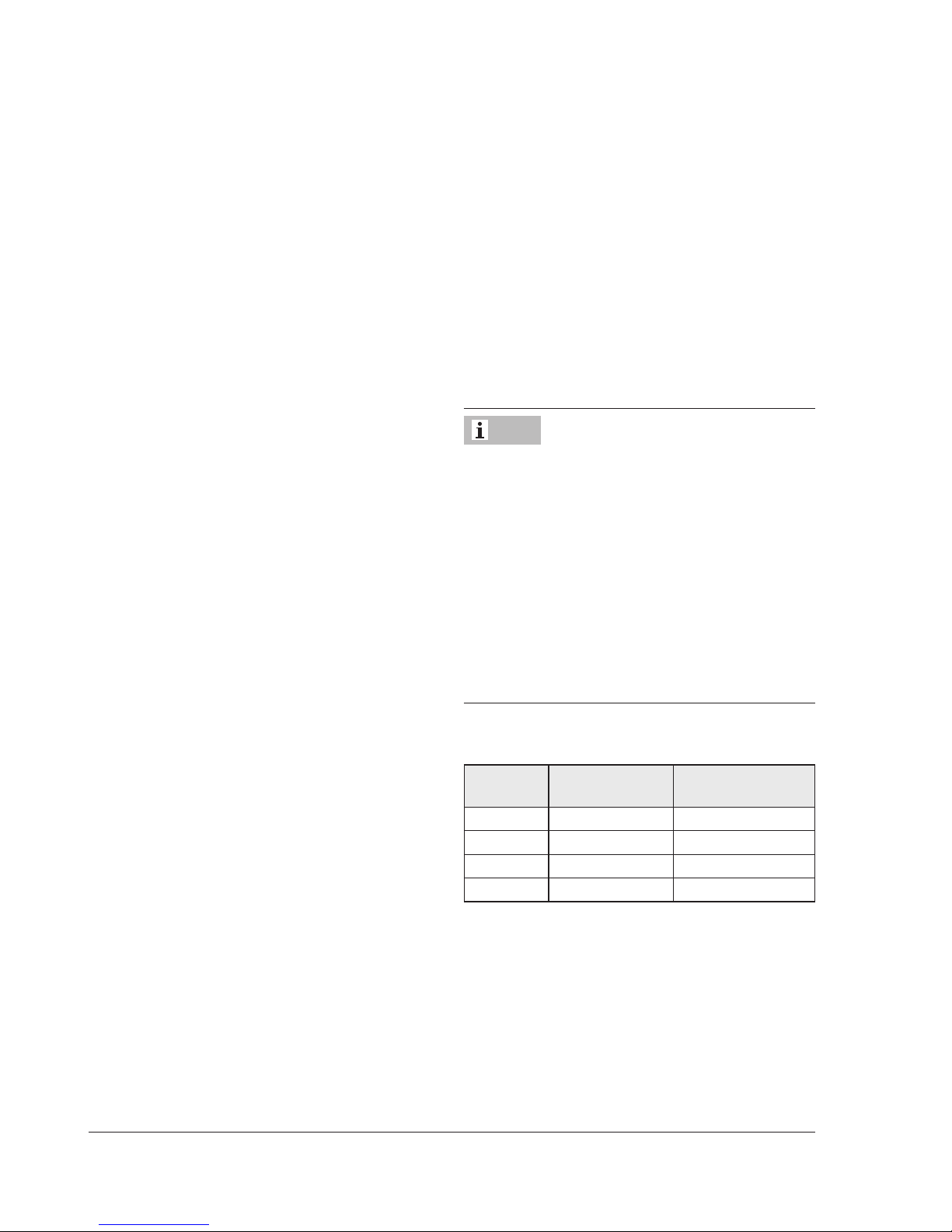

Table1: Type3310-SRP

Fail-safe

position

Springs Characteristic

Fail-close Clockwise Equal percentage

Fail-close Counterclockwise Linear

Fail-open Clockwise Linear

Fail-open Counterclockwise Equal percentage

The square drive allows the actuator to be

mounted on the segmented ball valve offset

at angles of 90° in such a way that it is either in the upright or horizontal position to

meet the installation requirements.

Note

Page 9

EB 8222 EN 9

Mounting

Fail-close

1. Place the segmented ball (8) of the valve

in the CLOSED position (0° angle of rotation).

2. Fasten the yoke (3) to the ange of the

valve shaft using two or four screws (depending on the valve size).

3. If necessary, place the shaft adapter on

the valve shaft. Slide the actuator over

the adapter or valve shaft (4) and fasten

it onto the yoke with four screws.

4. Adjust the stop bolt (12.1 or 12.2 depending on the direction of rotation) to

the point where the valve is completely

closed and align the markings on the

shaft and packing gland.

5. Lock the position of the stop bolt with the

lock nut.

6. Apply a signal pressure to the signal

pressure connection which corresponds

to the number of actuator springs (see

actuator nameplate).

7. Turn the other stop bolt until the segmented ball stops at an opening angle of 90°.

8. Lock the position of the stop bolt with the

lock nut.

Fail-open

1. Place the segmented ball (8) of the valve

in the OPEN position (90° angle of rotation).

2. Fasten the yoke (3) to the ange of the

valve shaft using two or four screws (depending on the valve size).

3. If necessary, place the shaft adapter on

the valve shaft. Slide the actuator over

the adapter or valve shaft (4) and fasten

it onto the yoke (3) with four screws

(3.1).

4. Adjust the stop bolt (12.1 or 12.2 depending on the direction of rotation) to

the point where the valve is completely

open at 90° and align the markings on

the shaft and packing gland.

5. Lock the position of the stop bolt with the

lock nut.

6. Apply a signal pressure to the signal

pressure connection which corresponds

to the number of actuator springs (see

actuator nameplate).

7. Turn the other stop bolt until the segmented ball is completely closed and align the

markings on the shaft and packing

gland.

8. Lock the position of the stop bolt with the

lock nut.

3.1.2 Type3310/3278

If the valve and actuator have not been assembled by SAMSON, mount the actuator

onto the body ange 1 or 2 depending on

the characteristic and fail-safe position.

'1' or '2' is cast on the corresponding side of

the body.

Table2: Type3310/3278

Fail-safe

position

Characteristic Body ange

Fail-close Equal percentage 2

Fail-close Linear 1

Fail-open Equal percentage 1

Fail-open Linear 2

Page 10

10 EB 8222 EN

Mounting

The four feather key notches on the actuator

shaft arranged every 90° allow the rotary

actuator to be mounted on the segmented

ball valve offset at angles of 90° in such a

way that it is either in the upright or horizontal position to meet the installation requirements.

Fail-close

1. Completely undo both stop bolts (13.1

and 13.2) on the rotary actuator. Turn

the stop bolt (13.2) clockwise until the

grooves of the actuator shaft are aligned

with the actuator axis horizontally or vertically.

2. Place the segmented ball (8) of the valve

in the CLOSED position (0° angle of rotation).

3. Fasten the yoke (3) to the ange of the

valve shaft using two or four screws (depending on the valve size).

4. Slide the actuator over the valve shaft (4)

and fasten it onto the yoke (3) with four

screws.

5. Undo the stop bolt (13.2) again.

6. Adjust the stop bolt (13.2) to the point

where the valve is completely closed and

align the markings on the shaft and

packing gland.

7. Apply a supply pressure required for the

spring range (see actuator nameplate) to

the loading pressure connection to open

the valve.

8. Turn the stop bolt (13.1) clockwise until

the segmented ball (8) of the valve is in

the OPEN position (90° angle of rotation).

9. Lock the position of both stop bolts with

the lock nuts.

Fail-open

1. Completely undo both stop bolts (13.1

and 13.2) on the rotary actuator. Turn

the stop bolt (13.1) clockwise until the

grooves of the actuator shaft are aligned

with the actuator axis horizontally or vertically.

2. Place the segmented ball (8) of the valve

in the OPEN position (90° angle of rotation).

3. Fasten the yoke (3) to the ange of the

valve shaft using two or four screws (depending on the valve size).

4. Slide the actuator over the valve shaft (4)

and fasten it onto the yoke (3) with four

screws.

5. Undo the stop bolt (13.1) again.

6. Apply a supply pressure required for the

spring range (see actuator nameplate) to

the loading pressure connection to close

the valve.

7. Adjust the stop bolt (13.1) to the point

where the segmented ball is completely

closed and align the markings on the

shaft and packing gland.

8. Disconnect the supply air from loading

pressure connection.

9. Turn the stop bolt (13.2) clockwise until

the segmented ball (8) of the valve is in

the OPEN position (90° angle of rotation).

10. Lock the position of both stop bolts with

the lock nuts.

Page 11

EB 8222 EN 11

Mounting

3.2 Mounting position

Prior to installing the valve into the pipeline,

place it in the CLOSED position to allow the

seat to be centered properly with the segmented ball.

The control valve can be installed into a

pipeline either in the upright or horizontal

position. However, the following points regarding the direction of ow must be observed:

− Install the valve into the pipeline in such

a way that the bottom half of the segmented ball opens in the direction of the

ow.

This helps to prevent dirt deposits from

accumulating and blocking the valve

when it opens. The direction of medium

ow into the ball also prevents the medium from collecting unnecessarily in the

shaft bearings.

− The standard direction of ow (onto the

segmented ball) is indicated by SAMSON

by an arrow on the valve body.

− If the direction of ow is be reversed,

e.g. required for abrasive media, indicate the reversed direction by using the

arrow plate and the two slotted pins included in the scope of delivery.

This direction of ow causes the pressure

of the process medium to constantly act

on the packing. On tightening the ange

bolts, make sure that an even pressure is

exerted on the gaskets.

3.3 Signal pressure connection

The signal pressure connection of the rotary

actuator is designed as a borehole with a

G

1

/

8

female thread for small actuators and

with G¼ female thread for large actuators.

The connection allows in compliance with

VDE/VDE3845 guidelines the connection of

a solenoid valve, e.g. Type3963, or a limit

switch with or without a solenoid valve

(Type3776/3777).

The corresponding accessories are available

to mount SAMSON positioners.

Note

Page 12

12 EB 8222 EN

Operation

4 Operation

4.1 Changing the fail-safe

action

The fail-safe action of Type3278 Actuator

can be changed from fail-close to fail-open

or vice versa after the valve has been installed. In this case, the side where the rotary

actuator is mounted must be changed (see

Table2).

The pistons of the TypeSRP Actuator must be

reversed to change the fail-safe action.

Refer to the mounting and operating instructions of the rotary actuator used for further

details, for example about changing the

spring range to achieve other actuator

torques.

5 Servicing

The control valve is subject to normal wear,

especially at the seat, segmented ball and

packing. Depending on the operating conditions, check the valve at regular intervals to

prevent possible failure before it can occur.

External leakage can indicate that the packing is defective.

If the valve does not close tightly, tight shutoff may be impaired by dirt stuck between

the seat ring and segmented ball or by damaged facings.

Î If you intend to remove parts to clean

them, rst mark the position of the seat

ring (11.8) in the body for a valve with

soft-seated ball. This will help you to replace the seat ring in its correct position

on reassembling the valve.

Î To replace the seat ring (11.6 or 11.8),

proceed as described in section5.3.

Î Before starting any work on the valve

body, rst remove the actuator (see section5.1).

Remove the valve from the pipeline before

removing any parts from the valve. Before

proceeding, depressurize the relevant plant

section.

Wait until the medium cools down if hot media are used.

5.1 Removing the actuator

from the valve

Î Unscrew the two or four screws on the

ange of the valve shaft and pull off the

actuator together with the yoke (3) from

the valve.

5.2 Replace the packing

The valves in NPS1 to 12 are tted with a

V-ring packing.

1. Undo the screws (2.2). Lift off the pack-

ing gland (2) with the bearing bushing

(2.1).

Note

WARNING

!

Page 13

EB 8222 EN 13

Servicing

2. Pull all the packing parts out of the packing chamber using a suitable tool. Clean

the packing chamber thoroughly.

3. Renew the packing (2.3). Slide the packing parts over the shaft (4) into the packing chamber.

4. Push the packing gland (2) together with

bearing bushing (2.1) onto the shaft (4).

Tighten the packing gland using the

screws (2.2).

5. Assemble as described in section5.4.

5.3 Replacing the seat ring

seal

1. Remove both anchoring screws (11.1)

with washers (11.2).

2. Take out the retainer (11) together with

the gasket (11.3).

If you are unable to remove the retainer,

use the special tool listed in Table3.

3. Soft-seated version: remove the support

ring (11.7) and seat ring (11.8).

Metal-seated version: remove in

sequence any washer(s) (11.4), metal

tubular seal (11.5) and seat ring (11.6).

4. Assemble as described in section5.4.

5.4 Assembly

Assemble in the reverse order. Special tools

are not necessary.

The retainer (11) can be pressed into the

body using, for example, a blank ange, by

tightening the ange bolts accordingly. In

this case, rst place the valve in the CLOSED

position to center the seat ring and segmented ball.

Tip

4

2.2

2

2.1

2.3

2.4

2.5

2.6

2.

7

2 Packing gland

2.1 Bearing bushing

2.2 Screws

2.3 V-ring packing

2.4 Washer

2.5 Spring

2.6 Washer

2.7 Spacer

4 Shaft

Fig.2: Packing

Page 14

14 EB 8222 EN

Servicing

Checking the friction torque

Check the friction torque (breakaway torque)

needed to open the valve according to Table4.

If the friction torque is different from the

torque specied in the table, proceed as follows:

Î Soft-seated version: turn the segmented

ball clockwise by 360° in the valve body

two or three times to let the seal adapt itself.

Î Metal-seated version: change the num-

ber of washers (11.4) used. If necessary,

omit the bottom washer on the valve

body side.

11

11.7

11.8

1

1

111811.1 11.2 11.3

11.5

11.6

11

11.4

Soft-seated version Metal-seated version

Seal

1 Body

8 Segmented ball

11 Retainer

11.1 Screw

11.2 Washer

Soft-seated version:

11.7 Support ring

11.8 Seat ring (PTFE)

Metal-seated version:

11.4 Washer

11.5 Metal tubular seal

11.6 Seat ring (metal)

Fig.3: Seat ring seal

Page 15

EB 8222 EN 15

Servicing

5.5 Replacing the segmented

ball, shafts and bearings

Risk of valve damage.

No clearance may exist between the

segmented ball and shafts. Therefore, the

shafts need to be replaced as well when the

segmented ball is replaced with a new one.

Furthermore, renew the bearing bushings

and seat rings as well as the ring and gasket

on the bottom ange as well.

5.5.1 Disassembly

1. Unscrew both bolts (10.3) and lift off

bottom ange (10) together with the ring

(10.2). Remove the ange gasket (10.1).

2. Unscrew the threaded pin (5.2) out of the

shaft and remove the clamping bolt

(5.3). Make sure that the locking pins

(5.4) do not get lost

3. Press out the support shaft.

If this is not possible, screw in a screw with a

washer (see Table3) in place of the threaded

pin. Turning the screw against the washer

loosens the support shaft.

4. Pull the bearing bushing (5.1) out of the

body.

5. Undo the screws (2.2) and lift off the

packing gland (2) with the bearing bushing (2.1).

6. Use snap ring pliers to pull the snap ring

(4.3) off the shaft and pull the shaft out

of the body using disassembling tool.

7. Pull all the packing parts out of the packing chamber using a suitable tool. Clean

the packing chamber thoroughly.

8. Remove the lower bearing bushing (4.1).

9. Take the segmented ball out of the body.

The segmented ball of valves in NPS1, 1 ½

and 2 must be removed from the retainer

side. Proceed as described in section5.3,

dismantling rst the retainer and then the

seat ring parts.

5.5.2 Assembly

We recommend ordering the assembly tools

listed in Table3 for reassembling the valve.

Assemble in the reverse order. Observe the

tightening torques specied in section7.

On inserting the shaft (4) into the body and

segmented ball, make sure that the shaft is

aligned correctly with the segmented ball

(the red marking on the shaft must be positioned at a right angle to the pipeline when

the valve is closed).

1. Insert the segmented ball (8) into the

valve body.

2. Push the bearing bushing (4.1) into the

body, then align the shaft (4) and use an

NOTICE

!

Tip

Note

Tip

Page 16

16 EB 8222 EN

Servicing

assembling tool to press the bearing

bushing into the segmented ball.

3. Use the part of the tool that is in the

bearing of the support shaft to slide the

segmented ball (8) onto the shaft (4) and

attach the snap ring (4.3).

4. Insert the locking pins (5.4) into the holes

of the support shaft (5), then position the

complete support shaft (5, 5.2, 5.3 and

5.4) on the bearing bushing (5.1) and

use the packing gland (2) to press them

in.

5. Align the segmented ball (8) centrally.

6. Screw the threaded pin (5.2) against the

clamping bolt (5.3) to obtain a

force-locking connection between the

support ange and segmented ball.

10

10.1

10.2

10.3

111811.1 11.2 11.3

44.3 4.15.35.25.15 5.4

1 Body

4 Shaft

4.1 Bearing bushing

4.3 Snap ring

5 Support shaft

5.1 Bearing bushing

5.2 Threaded pin

5.3 Clamping bolt

5.4 Locking pins

8 Segmented ball

10 Bottom ange

10.1 Flange gasket

10.2 Flange ring

10.3 Flange bolts

11 Retainer

11.1 Screw

11.2 Washer

11.3 Gasket

Fig.4: Sectional drawing

Page 17

EB 8222 EN 17

Changing the characteristic

7. Mount the packing with spacer (2.7),

washer (1.6), spring (2.5), thrust washer

(2.4), packing (2.3) and packing gland

(2).

Checking the friction torque

Check the friction torque (breakaway torque)

needed to open the valve according to Table4.

If the friction torque deviates from the

specied torque, proceed as described in

section5.4 on Checking the friction torque.

6 Changing the characteristic

Changing the characteristic from equal

percentage to linear and vice versa can be

performed by changing the actuator's

direction of rotation (see Table1 and

Table2).

Page 18

18 EB 8222 EN

Tools and tightening torques

7 Tools and tightening torques

7.1 Special tools

Table3: Special tools

Extracting tool for retainer (11)

Extracting tool

for support

shaft (5)

Tool to mount and remove the

shaft

Crossbeam Flange

Press tool for

support shaft

Press tool for

actuator shaft

NPS Order no.

1 1281-0011

1281-0007

1281-0026

1281-0019

1281-0023

1½ 1281-0012

2 1281-0013

1281-0008 1281-0020

3 1281-0014

4 1281-0015

1281-0009 1281-0027 1281-0021 1281-0024

6 1281-0016

8 1281-0017

1281-0010 1281-0028 1281-0022 1281-002510

1281-0018

12

Adapter for torque

wrench

Shaft with square drive Shaft with key drive

NPS

1, 1½, 2, 3 1281-0029 1281-0032

4, 6 1281-0030

1281-00338, 10

1281-0031

12

Page 19

EB 8222 EN 19

Tools and tightening torques

7.2 Tightening torques

Table4: Tightening and friction torques

Valve size NPS 1 1½ 2 3 4 6 8 10 12

Tightening torques in Nm

Screws (2.2) on packing gland

Bolts (10.3) on bottom ange

35 35 35 35 35 35 60 60 60

Friction torque to open the valve in Nm

Metal seal 8 10 11 19 40 70 100 155 155

Soft seal 9 12 14 24 50 100 170 260 260

7.2.1 Tightening torques for ange bolts

Table5: ANSI version

NPS Class

Flange bolts

(quality 8.8)

Min. tightening torque

inNm

1

150 4 x ½“ 35

300 4 x

5

/

8

” 45

1½

150 4 x ½” 45

300 4 x ¾” 65

2

150 4 x

5

/

8

” 90

300 8 x

5

/

8

” 45

3

150 4 x

5

/

8

” 125

300 8 x ¾” 65

4

150 8 x

5

/

8

” 80

300 8 x ¾” 80

6

150 8 x ¾” 125

300 12 x ¾” 80

8

150 8 x ¾” 165

300 12 x

7

/

8

” 125

10

150 12 x

7

/

8

” 155

300 16 x 1” 135

12

150 12 x

7

/

8

” 155

300 16 x

9

/

8

” 125

Page 20

20 EB 8222 EN

Tools and tightening torques

Table6: DIN version

DN PN

Flange bolts

(quality 8.8)

Min. tightening torque

inNm

25 10/40 4 x M12 40

40 10/40 4 x M16 55

50 10/40 4 x M16 75

80

10/16 8 x M16 55

25/40 8 x M16 55

100

10/16 8 x M16 70

25/40 8 x M20 85

150

10/16 8 x M20 125

25/40 8 x M24 150

200

10 8 x M20 165

16 12 x M20 110

25 12 x M24 135

40 12 x M27 150

250

10 12 x M20 140

16 12 x M24 165

25 12 x M27 185

40 12 x M30 205

300

10 12 x M20 140

16 12 x M24 165

25 16 x M27 140

40 16 x M30 165

Page 21

EB 8222 EN 21

Nameplate

8 Nameplate

The nameplate includes all details required to identify the valve.

DN3-

90˚

70˚

Kvs

Made in france

SAMSON

PN

3310 -

12 3

45

67

9

8

10

11

Fig.5: Nameplate

1 Type number

2 Serial number

3 Valve size DN.../NPS...

4 Plug seal:

ME Metal seal

PT PTFE

PK PEEK 450G Victrex

®

PK1 PEEK 450FC30 Victrex

®

5 Body material

6 Pressure rating PN…/Class…

7 Flow coefcient KVS…/CV…

Characteristic:

% Equal percentage

LIN Linear

8 PED text

9 Notied body

10 Year of manufacture

11 Direction of ow and maximum opening angle

Page 22

22 EB 8222 EN

Accessories

9 Accessories

Table7: Accessories

NPS

TypeSRP/DAP

Actuator (AT)

Connecting

ange

DIN3337

Mounting kit

order no.

Actuator area

in cm²

(Type3278)

Mounting kit

order no.

1

30

60

F05 1400-7316

160 (F07)

1400-7251

1½

60

100

F05

F07

1400-7316

1400-7317

2

60

100

150

F05

F07

F07

1400-7348

1400-7239

1400-7239

1400-7252

3

100

150

220

F07

F07

F10

1400-7239

1400-7239

1400-7732

4

220

300

450

F10

F10

F12

1400-7240

1400-7240

1400-7241

320 (F12) 1400-7255

6

300

450

600

F10

F12

F12

1400-7240

1400-7241

1400-7241

8

600

900

1200

F12

F14

F14

1400-7755

1400-7243

1400-7243

10

900

1200

F14

F14

1400-7243

12

900

1200

F14

F14

1400-7243

Page 23

EB 8222 EN 23

Technical data

10 Technical data

The technical data as well as the dimensions

and weights for the DIN and ANSI versions

of the Type3310 Segmented Ball Valve are

listed in the corresponding Data Sheet

uT8222.

11 Customer inquiries

Please submit the following details:

− Order number (specications on the

nameplate)

− Type, model number, nominal size and

valve version

− Pressure and temperature of the process

medium

− Flow rate in m³/h

− Signal pressure range (bench range)

− Installation drawing

Page 24

2019-02-14 · English

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

samson@samson.de · www.samson.de

EB 8222 EN

Loading...

Loading...