Page 1

Pneumatic Controller for Temperature

Type 3301

Pneumatic Controller for Temperature

Type301-1

Mounting and

Operating Instructions

EB 7065 EN

Edition January 2014

Page 2

Denition of the signal words used in these mounting and operating instructions

Note:

Supplementary explanations, information and tips

2 EB 7065 EN

Page 3

Contents

Contents Page

1 General safety instructions .............................................................................4

2 Process medium and scope of application .......................................................5

2.1 Transportation and storage ............................................................................. 5

2.2 Versions ........................................................................................................5

3 Design and principle of operation ..................................................................6

3.1 Operating and indicating elements ..................................................................7

3.2 Pneumatic connections....................................................................................7

4 Installation ....................................................................................................8

4.1 Mounting position ..........................................................................................8

5 Operation ...................................................................................................10

5.1 Adjusting the operating direction ..................................................................10

5.2 Set point adjustment .....................................................................................10

5.3 Adjusting the proportional band ...................................................................10

5.4 Zero adjustment ...........................................................................................11

6 Maintenance ...............................................................................................11

7 Nameplate ..................................................................................................11

8 Technical data .............................................................................................12

9 Dimensions .................................................................................................12

10 Customer service .........................................................................................13

EB 7065 EN 3

Page 4

General safety instructions

1 General safety instructions

− The device must be mounted, started up or serviced by fully trained and

qualied personnel only; the accepted industry codes and practices are to

be observed. Make sure employees or third persons are not exposed to any

danger.

− According to these mounting and operating instructions, trained person-

nel refers to individuals who are able to judge the work they are assigned

to and recognize possible dangers due to their specialized training, their

knowledge and experience as well as their knowledge of the applicable

standards.

− To ensure appropriate use, only use the device in applications where the op-

erating pressure and temperatures do not exceed the specications used for

sizing the regulator at the ordering stage.

− The manufacturer does not assume any responsibility for damage caused by

external forces or any other external factors.

− Any hazards that could be caused in the controller by the process medium,

operating pressure or by moving parts are to be prevented by taking appropriate precautions.

− Proper transport, storage, installation, operation and maintenance are as-

sumed.

− SAMSON does not assume any liability for damage caused when the device

is not used as intended.

4 EB 7065 EN

Page 5

Process medium and scope of application

2 Process medium and scope of application

Pneumatic controller functioning as a proportional controller to control the temperature of gases

and vapors at the point of measurement with a pneumatic control valve.

Medium temperatures from 0 to 300 °C

The controller compares the temperature measured by the xed expansion bulb sensor with the

adjusted set point and issues a pneumatic signal between 0.2 to 1bar at the output. This signal

pressure acts on the connected pneumatic control valve. The controller requires a supply pres-

sure of 1.4bar. The measured temperature is indicated at the controller.

2.1 Transportation and storage

Transportation and storage in the permissible temperature range from –10 to +90°C. Protect

the controller against adverse inuences, such as dirt or moisture during storage.

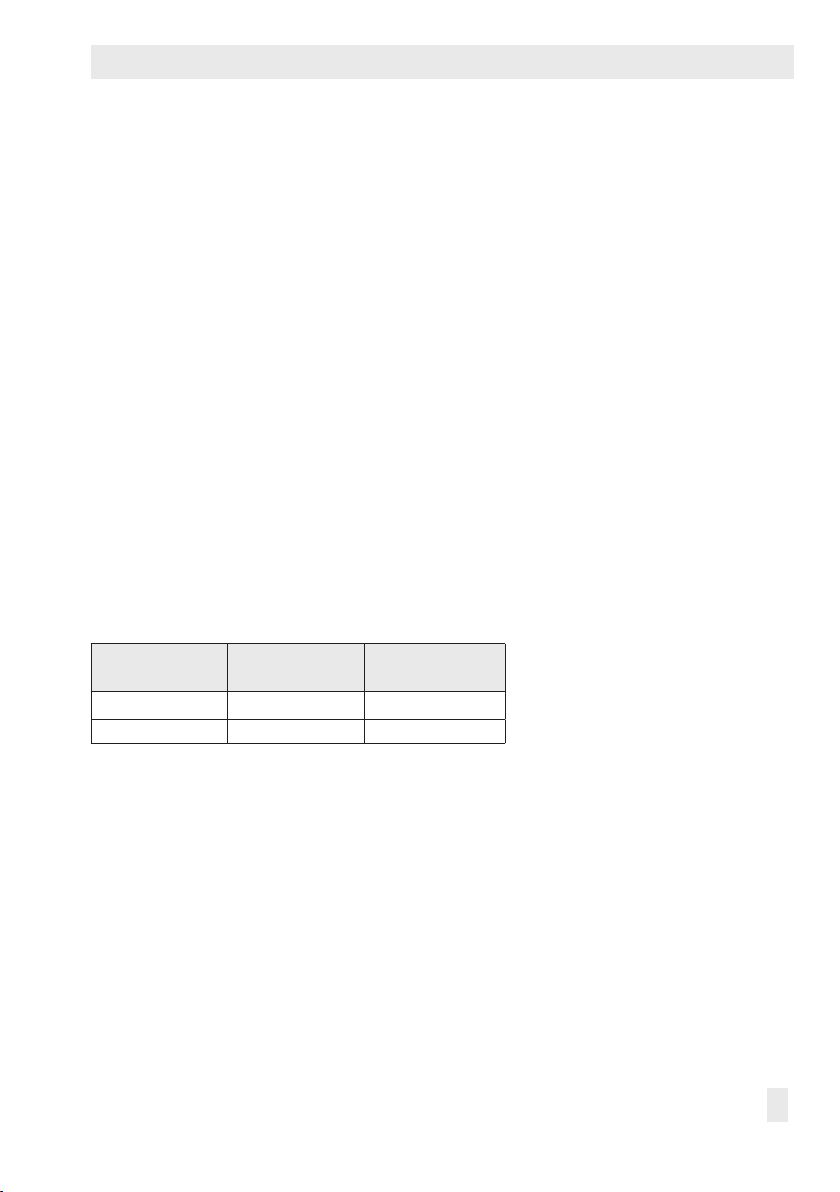

2.2 Versions

Two versions of the Type3301 Controller are available that have different set point ranges.

Table 1: Type3301∙ Versions

Type Set point range

3301-9001

3301-9002

0 to 200°C

100 to 300°C

Conguration ID

(Var.-ID)

Var.-ID 1063422

Var.-ID 1294879

The mounting parts are not included in the scope of delivery. They must be ordered separately

(see section 4 on page 8, Fig. 4 and Fig. 5).

EB 7065 EN 5

Page 6

Design and principle of operation

3 Design and principle of op-

eration

The controller mainly consists of the controller

housing containing a nozzle and apper system, pressure gauges for supply air and output pressure as well as the temperature sensor

with an outer tube (11) and Invar rod (12).

The different expansion properties of the Invar rod and tube materials produce a de-

ection each time the temperature at the sensor changes. This deection causes the differ-

ential plate (3) mounted on the plate spring

(9) to tilt on the ball (5), and causes the dis-

tance between the nozzle (2) and apper (4)

to change. The supply air pZ (1.4± 0.1bar)

ows through the restriction (1) to the nozzle

(2). These two components act as a pressure

divider controlled by the apper. As a result,

the output pressure pA (controlled variable 0.2

to 1bar) is regulated proportional to the system deviation and in relation to the xed operating point of 0.6bar.

The set point is adjusted at the screw (8) connected to the set point pointer (7). The proportional band is adjusted at the adjustment

screw (6). The position of the red dot on the

screw (6) indicates the operating direction adjusted.

Position in scale range^: The output pressure p

increases as the controlled variable

A

increases.

Position in scale range^: The output pres-

sure p

decreases as the controlled variable

A

increases.

1 Restriction

2 Nozzle

3 Differential plate

4 Flapper

5 Ball

6 Adjustment screw for Xp

(proportional band)

7 Set point pointer

8 Screw for set point adjustment

9 Plate spring

10 Base plate

11 Outer tube

12 Invar rod

Supply air (1.4± 0.1bar)

p

p

Z pA

Fig. 1: Functional diagram of Type3301

Z

Output pressure (0.2 to 1bar)

p

A

6 EB 7065 EN

Page 7

3.1 Operating and indicating elements

Set point pointer

Screw for set

point adjustment

Adjustment screw

for Xp and operating direction

Design and principle of operation

Pressure gauge for

supply air p

Z

Fig. 2: View from the front

Connection for

supply air p

Z

Connection for

output pressure p

A

output pressure p

A

3.2 Pneumatic connections

Pressure gauge for

The connections for supply air pZ and output pressure pA are located underneath the controller. They are designed as

Various screw ttings to connect pipes and plastic hoses are available.

Fig. 3: Pneumatic connections underneath the controller

1

/

8

NPT tapped holes.

Supply air

Output

EB 7065 EN 7

Page 8

Installation

4 Installation

The controller may be installed in any position. Make sure that the effective length of the

sensor (330mm) is completely surrounded by

the medium.

Install a reference thermometer close to the

controller to monitor the temperature (and to

check zero).

Screw gland (PN10)

Suitable for pipes and pressure vessels up to

max. 10bar. Seal the screw tting. Push in the

sensor with screw gland and coupling nut. Tighten the coupling nut.

*) G ½: Order no.: 1080-4881

G ¾: Order no.: 1080-4882

Screw gland with clamping nut (PN 40)

For use with pressure up to max. 40bar.

Tighten the clamping nut (instead of the coupling nut).

*) G ½: Order no.: 1080-4884

G ¾: Order no.: 1080-4885

4.1 Mounting position

To install the controller, a coupling sleeve with

G½ or G¾ female thread must be present at

the point of measurement. Screw or seal one

of the mounting parts shown in Fig.4 and 5

into this sleeve.

The mounting parts are not included in the

scope of delivery. They must be ordered separately. Select accessories required for the operating conditions at the site of installation.

Thermowell with thread (PN63) for pressures up to 63bar

A thermowell must be used in place of the screw

gland if the pressure at the sensor is greater than

the nominal pressure, if the medium to be controlled is corrosive or the controlled system is to

continue to operate while the controller is being

replaced. Screw the thermowell into the sleeve.

Push the temperature sensor into the thermowell

and fasten with the coupling nut.

*) G ½: Order no.: 1080-4888

G ¾: Order no.: 1080-4889

Fig. 4: Mounting parts for sensor · Screw glands and thermowell

8 EB 7065 EN

Page 9

Thermowell for welding (PN 63) for pressures up to 63 bar

Installation

Order no.: 1080-4890

Thermowell with ange DN 25 for PN 40 or PN 100

Order no.: 1080-4891 (PN40)

Order no.: 1080-4892 (PN100)

SW 32

Ø 22.3

373

SW 32

Ø 21.3

335 40

Clamping ange

For wall mounting, e.g. on pressureless vessels

in air-conditioning and ventilation plants.

32

8 Ø50

Screw the ange to the wall using the two

screws. Attach the temperature sensor in the

Ø12

ange using two other screws.

Order no.: 1090-9547 (PN40)

Order no.: 1080-4892 (PN100)

Ø26

Ø9.5

55

Fig. 5: Mounting parts for sensor · Thermowells and clamping ange

EB 7065 EN 9

75

Page 10

Operation

5 Operation

See Fig. 1 on page 6.

2.

Turn the adjustment screw (8) until the set

point pointer (7) points to the required

temperature on the scale.

5.1 Adjusting the operating

direction

Adjust the operating direction before start-up

as follows:

1.

Undo the screw on the cover and swivel

the guard plate out of the way.

Screw with guard plate

2.

Use a screwdriver to adjust the adjustment

screw (6) counterclockwise () or clockwise () to make the red dot on the screw

point to the required operating direction

on the scale.

Adjustment screw (6)

− Increasing/increasing^:

The output pressure p

temperature at the sensor increases.

− Increasing/decreasing ^:

The output pressure p

temperature at the sensor increases.

increases as the

A

decreases as the

A

Adjustment screw (8)

Note:

Do not turn the pointer past the adjustment range of the scale.

5.3 Adjusting the proportional

band

The continuously variable adjustment of the

gain is performed at the adjustment screw (6).

Gain

High

Low

Make sure that the adjustment is only performed within the operating direction determined in section 5.1, i.e. either on the left or

right side of the scale.

The gain can be adjusted continuously in the

direction of the arrow between 2 and 20%.

The red dot on the adjustment screw (6) serves

as the orientation mark.

5.2 Set point adjustment

1.

Undo the screw on the cover and swivel

the guard plate out of the way.

10 EB 7065 EN

Page 11

Maintenance

5.4 Zero adjustment

If the measured temperature (reading at the

reference thermometer) and the adjusted set

point of the controller deviate from each other, you need to readjust zero.

Unscrew the four corner screws on the

1.

cover and remove cover.

Use a screwdriver to hold the screw for

2.

set point adjustment (8) inplace and turn

the set point pointer (7) until the indicated

value matches the temperature measured

at the reference thermometer.

Set point pointer (7)

Screw for set point adjustment (8)

3. Adjust the set point again.

6 Maintenance

See Fig. 1 on page 6.

The controller only functions properly when

the supply air entering the device is always

clean. Therefore, check the air lter and trap

installed in the upstream air reducing station

regularly. If necessary, clean or renew the lter.

Insufciently cleaned supply air will cause the

restriction (1) to become blocked.

To clean the restriction, remove the nozzle

head (between the pneumatic connections underneath the housing, see photo).

Screw with Nozzle head

catch

1.

Undo screw for catch using a suitable

screwdriver.

Move the catch to release the nozzle

2.

head.

3. Pull out the nozzle head. Use compressed

air to blow a blocked nozzle. Insert a ne

wire (max. Ø 0.25 mm) to remove any

stubborn dirt particles.

→

→

7 Nameplate

SAMSON 3301-

Pneumatischer P-Regler für Temperatur

Pneumatic P-Controller for Temperature

Régulateur pneumatique P de Température

2

1

3

Made in France

Fig. 6: Nameplate

EB 7065 EN 11

Page 12

Technical data

8 Technical data

All pressures in bar (gauge)· Materials according to DINEN

Type 3301 Pneumatic Controller for Temperature

Measuring system

Bulb sensor Ø12mm, 400mm long, minimum immersion depth 330mm,

Material Stainless steel 1.4571

Set point, continuously adjustable 0 to 200 °C or 100 to 300 °C

Output

Control signal y 0.2 to 1 bar

Supply air Supply air 1.4± 0.1bar

Air consumption in steady state

Max. air output capacity

Proportional band X

Operating point 0.6bar

Temperature inuence 0.03 %/K

Ambient temperature range –10 to +90 °C

Max. operating pressure at the sensor 60 bar

Weight Approx. 2 kg

p

Mechanical-type expansion sensor

3

/h

0.25 m

n

3

/h

0.11 m

n

Continuously adjustable between 2 and 20 %

9 Dimensions

Ø12

130

Immersion

depth

330

100

400

54

Fig. 7: Dimensions in mm

12 EB 7065 EN

10

Page 13

10 Customer service

If malfunctions or defects occur, contact the

SAMSON After-sales Service Department

for support. Please send your inquiries to:

service@samson.de

The addresses of SAMSON AG, its subsidiaries, representatives and service facilities

worldwide can be found on the SAMSON

website, in all SAMSON product catalogs or

on the back of these Mounting and Operating Instructions.

To assist diagnosis and in case of an unclear

mounting situation, specify the following details:

(see section 7 on page 11):

− Model number

− Serial no.

− Temperature and process medium

− Installation drawing showing the exact

location of the controller and all the additionally installed components (shut-off

valves, thermometer, control valve etc.)

− For return inquiries: Phone number or e-

mail address

Customer service

EB 7065 EN 13

Page 14

Page 15

Page 16

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 7065 EN

2014-01-27

Loading...

Loading...