Page 1

Electric Control Valve

Type 3222 N/5857

Type 3222 N/5857 Electric Control Valve consisting of

Type 3222 N Globe Valve with soldering ends and Type 5857 Actuator

Mounting and

Operating Instructions

EB 5867 EN

Edition October 2009

Page 2

Definitions of the signal words used in these instructions

DANGER!

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING!

WARNING indicates a hazardous situation

which, if not avoided, could result in death

or serious injury.

2 EB 5867 EN

NOTICE

NOTICE indicates a property damage

message.

Note: Supplementary explanations, infor

mation and tips

-

Page 3

Contents

Contents Page

1 General safety instructions . . . . . . . . . . . . . . . . . . . . . . . 4

2 Design and principle of operation . . . . . . . . . . . . . . . . . . . 5

2.1 Technical data for Type 3222 N Globe Valve . . . . . . . . . . . . . . 6

2.1.1 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1.2 Customer inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Additional installation instructions . . . . . . . . . . . . . . . . . . . . 8

4 Combination with Type 5857 Electric Actuator . . . . . . . . . . . . . 9

4.1 Technical data for actuator . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Mounting the actuator on the valve. . . . . . . . . . . . . . . . . . . 10

4.3 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . 10

5 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

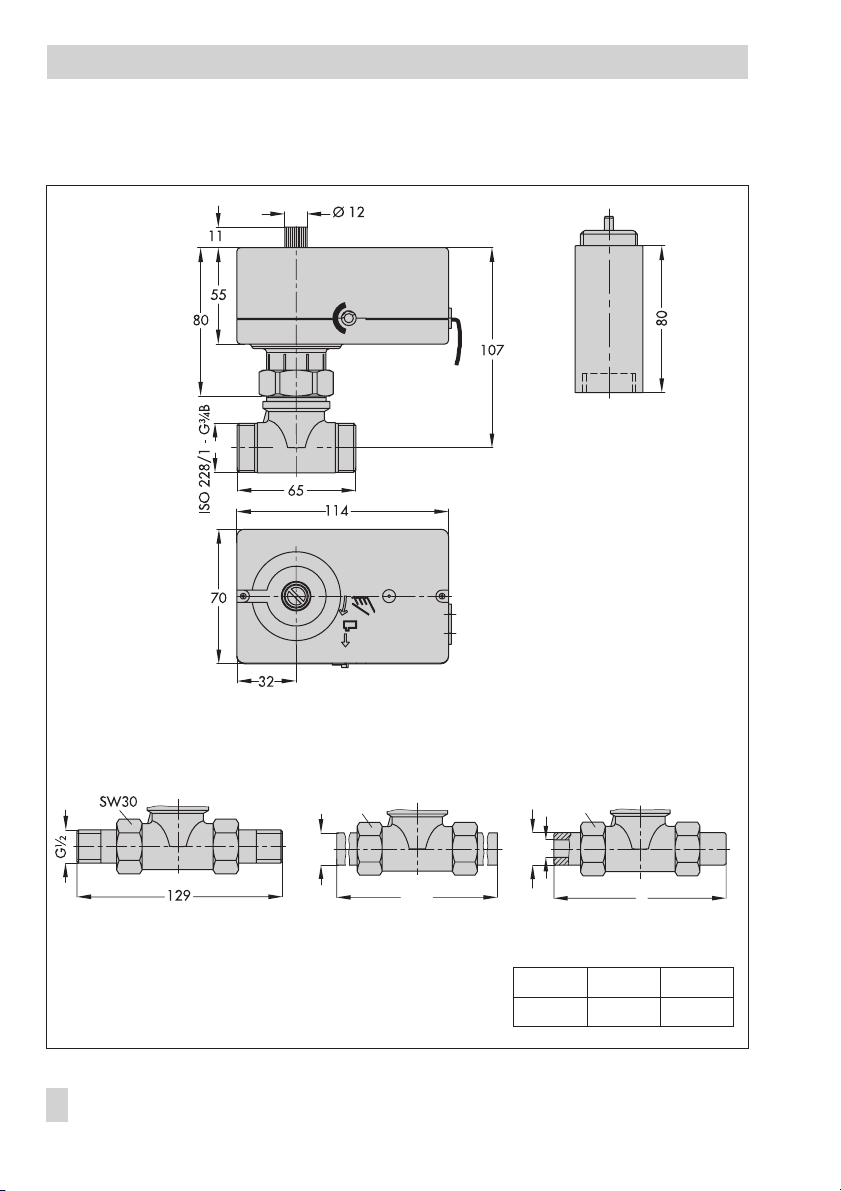

6 Dimensions in mm and weights . . . . . . . . . . . . . . . . . . . . 14

Note: More detailed information on Type 5857 Electric Actuator can be found in the

Mounting and Operating Instructions EB 5857 EN available on the Internet at

www.samson.de.

EB 5867 EN 3

Page 4

General safety instructions

1 General safety instructions

For your own safety, follow these instructions concerning the mounting, start up and opera

tion of the control valve:

The control valves must be installed, started up and serviced by fully trained and qualified

4

personnel only, observing the accepted industry codes and practices.

Make sure employees or third persons are not exposed to any danger.

All safety instructions and warnings in these mounting and operating instructions,

particularly those concerning installation, start-up and maintenance, must be observed.

For appropriate operation, make sure that the control valve is only used in applications

4

where the operating pressure and temperatures do not exceed the operating values

based on the sizing data submitted in the order.

Note that the manufacturer does not assume any responsibility for damage caused by

external forces or any other external factors.

Any hazards which could be caused in the control valve by the process medium or

operating pressure are to be prevented by means of appropriate measures.

For installation and maintenance, make sure the relevant section of the pipeline is

4

depressurized and, depending on the process medium, drained as well. If necessary, allow the control valve to cool down or warm up to reach ambient temperature prior to

starting any work on it.

The actuators are designed for use in low voltage installations.

4

For wiring and maintenance, you are required to observe the relevant safety regulations.

Take necessary measures to ensure that the power supply cannot be reconnected inadver-

4

tently.

Take care while performing adjustment work on live parts. Never remove any covers!

4

-

To avoid damage to any equipment, the following also applies:

Proper shipping and appropriate storage are assumed.

4

Note: The control valves fulfill the requirements of the European Pressure Equipment Directive

97/23/EC. Valves with a CE marking have a declaration of conformity which includes infor

mation about the applied conformity assessment procedure. The declaration is available on

request.

4 EB 5867 EN

-

Page 5

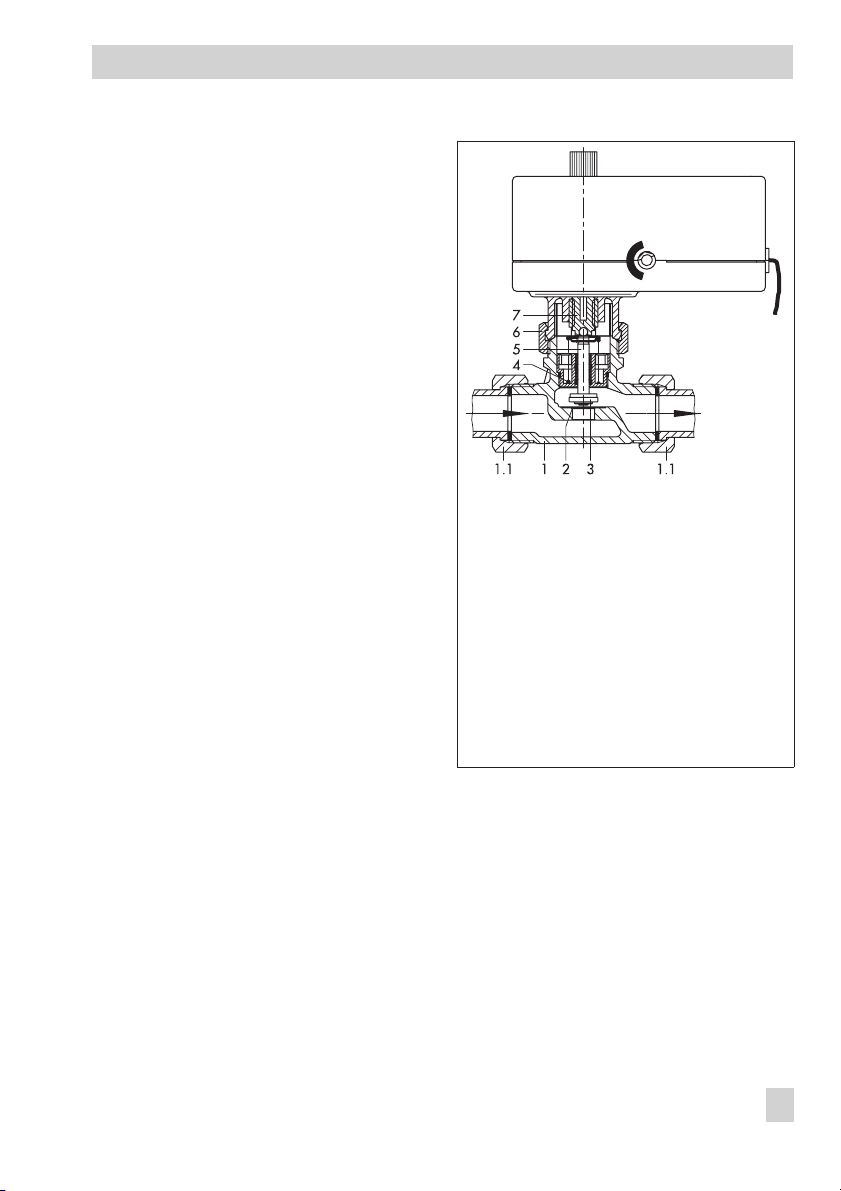

2 Design and principle of

operation

The actuator in the three-point stepping ver

sion consists of a reversible synchronous

motor and a maintenance-free gear.

The version with digital positioner contains a

stepper motor which can be supplied with

any voltage regardless of the frequency.

Actuator and valve are connected (forcelocking) over a coupling nut (6). An interme

diate insulating piece can be used for insu

lated pipelines.

The medium flows through the single-seated

globe valve in the direction indicated by the

arrow. The position of the plug (3) determines the flow rate across the area released

between plug and valve seat (2).

The linear actuating force is transmitted directly over the actuator stem (7) to the plug

stem (5). When the actuator stem extends,

the valve plug (3) moves in the closing direction. The plug stem follows the actuator stem

owing to the force of the valve spring (4) as

the actuator stem retracts, causing the valve

to open.

-

Design and principle of operation

-

-

1 Valve body

1.1 Connection nut with gasket and

welding ends (accessories)

2 Seat

3 Plug

4 Valve spring

5 Plug stem

6 Coupling nut

7 Actuator stem

Fig. 1 · Type 3222 N/5857 Control Valve

Type 5857

Actuator

EB 5867 EN 5

Page 6

Design and principle of operation

2.1 Technical data for Type 3222 N Globe Valve

Nominal size DN 15

Connection ISO 228/1-G ¾ B

Threaded ends G ½

Type of end connections (optional)

Nominal pressure PN 16

K

VS

coefficient

Standard 2.5

Special version 0.25 · 0.4 · 0.63 · 1 · 1.6

Valve travel 6 mm

Characteristic Equal percentage

Pressure balancing None

Max. perm. differential pressure Δp 6 bar

1 Metal sealing

K

≤

Type of sealing

VS

K

= 1.6 and 2.5 Soft sealing

VS

Leakage rate (Class I acc. to IEC 60534) < 0.05 % of K

Max. permissible temperature 120 °C

Max. permissible

medium temperature

Treated water 120 °C

Non-flammable gases 80 °C

z value 0.43

Materials

Valve body CW602N (brass)

Plug

Up to K

K

= 1 1.4305

VS

= 1.6 and 2.5 1.4305 with EPDM seal

VS

Plug stem 1.4305

Seat

Up to K

K

= 1 1.4305

VS

= 1.6 and 2.5 CW602N (brass)

VS

Valve spring 1.4310 K

Welding ends 1.0254 (St 37)

Threaded ends Brass

Soldering ends CC491K (red brass, Rg 5)

Intermediate insulating piece 1.4305, CW617N (brass), PTFE, EPDM, FPM

Welding ends

Soldering ends

coefficient

VS

6 EB 5867 EN

Page 7

Design and principle of operation

2.1.1 Nameplate 2.1.2 Customer inquiries

SAMSON

2

4

Kvs

1 Type designation

2 Configuration ID (Var.-ID)

3 Date of manufacture

4 Model number

5 Max. permissible temperature

coefficient

6K

VS

7 Max. permissible differential pressure

p

Δ

1

3

5

76

Please submit the following details:

Type designation

4

Configuration ID (Var.-ID)

4

Date of manufacture

4

EB 5867 EN 7

Page 8

Installation

3 Installation

If the valve and actuator are delivered sepa

rately, first install the valve in the pipeline

and then mount the actuator.

3.1 Mounting position

Choose the place of installation where

4

the ambient temperature does not ex

ceed or fall below the permissible limits

specified for the actuator and that allows

you to freely access the control valve

even after the entire plant has been com

pleted.

Flush the pipeline thoroughly before in-

4

stallation.

Never install the valve with the actuator

4

suspended downwards.

Install a strainer (SAMSON Type 2 NI)

4

upstream of the control valve to prevent

any sealing parts, weld spatter or other

foreign matter carried along by the process medium from impairing the proper

functioning of the valve, in particular, the

tight shut-off.

The valve must be installed free of stress.

4

If necessary, support the piping near the

connections.

3.3 Additional installation

-

-

-

instructions

We recommend to install a hand-operated

shut-off valve both upstream of the strainer

and downstream of the control valve to be

able to shut down the plant for cleaning and

maintenance, and when the plant is not

used for longer periods of time.

3.2 Strainer

Install the strainer with the filter element

4

facing downwards upstream of the valve

inlet.

Choose the place of installation to allow

4

enough space to remove the filter.

Install the strainer with the flow direction

4

as indicated by the arrow on the body.

8 EB 5867 EN

Page 9

Combination with Type 5857 Electric Actuator

4 Combination with Type 5857 Electric Actuator

4.1 Technical data for actuator

Type 5857 Actuator Version Three-point stepping version With digital positioner

Connection to valve Force-locking Force-locking

Rated travel 6 mm 6 mm

2)

Transit time for rated travel 20 s

30/20

Nominal thrust 300 N 300 N

Power supply

230 V (±10 %), 50 Hz

24 V (±10 %), 50 Hz

24VAC(±10 %), (50 and 60 Hz)

24 V DC (±10 %)

Power consumption Approx. 3 VA 5 VA

Manual override Yes Yes

Permissible ambient temperature 0 to 50 °C 0 to 50 °C

Permissible storage temperature –20 to 70 °C –20 to 70 °C

Degree of protection IP 42 IP 42

Protection class II II

Noise immunity EN 61000-6-2 EN 61000-6-2

Noise emission EN 61000-6-3 EN 61000-6-3

Weight Approx. 0.7 kg Approx. 0.7 kg

Digital positioner –

Input signal

Position feedback 0 to 10 V

–

0 to 10 V

Characteristic Linear

1)

Value adjustable in TROVIS-VIEW Configuration and Operator Interface.

Refer to EB 5857 EN for more details (also included in TROVIS-VIEW).

2)

Default setting

3)

10 s applies to 24 V DC (–0 %, +10 %) for

Transit time for rated travel

setting

/10 s

1)

1)

1)

1)

3)

EB 5867 EN 9

Page 10

Combination with Type 5857 Electric Actuator

Handwheel

Travel

indicator

NOTICE

The handwheel is used to move the actuator

stem. Only operate the handwheel when the

actuator is in the de-energized state.

In the version with digital positioner, do not op

erate the handwheel while the actuator is in service (absolute travel adjustment, see

EB 5857 EN), otherwise the feedback signal will

be shifted.

Fig. 2 · Manual override of Type 5857

4.2 Mounting the actuator on the

valve

4.3 Electrical connection

DANGER!

Risk of electric shock!

When installing electric cables, you are

required to observe the regulations

governing electrical power plant

installation according to

DIN VDE 0100 as well as the

regulations of your local power supply

company.

Use a suitable power supply which

guarantees that no dangerous voltages

-

reach the device in normal operation

or in case of a fault in the system or

any other system parts.

Connect the actuator to the electrical

network only after the power supply is

first switched off. Make sure the power

cannot be switched on unintentionally!

Especially when a 24 V voltage supply

is used, wires with sufficiently large

wire cross-sections must be used to

guarantee that the permissible voltage

tolerances of

10 % are not exceeded!

±

1. Turn the handwheel (Fig. 2) counter

-

clockwise only after disconnecting the

actuator from the power supply to re

tract the actuator stem as far as it will

go.

2. Place the actuator on the valve connec

tion or the intermediate insulating piece

and secure with the coupling nut (tight

ening torque 20 Nm).

10 EB 5867 EN

-

-

-

Page 11

Three-point stepping version

Connect the cable as shown in Fig. 3,

4

observing the following instructions.

The control signals of the connected con

troller are connected to the terminals eL

and aL:

If a voltage is applied to eL, the ac

4

tuator stem retracts into the actuator

(direction of action ”Stem retracts“).

If a voltage is applied to aL, the ac

4

tuator stem extends out of the actua

tor (direction of action “Stem ex

tends“).

Important note:

Decoupling capacitors Ce in the output

4

circuit of the connected controller may

not exceed a value of 2.5 nF in order to

guarantee the proper functioning of the

actuator.

Combination with Type 5857 Electric Actuator

Controller

L

Actuator

-

Ce Ce

eL

aL

-

-

-

-

N

aL eL

BNWH GN

eL Actuator stem retracts

aL Actuator stem extends

WH white

BN brown

GN green

Fig. 3 · Electrical connection

(version with three-point stepping signal)

EB 5867 EN 11

Page 12

Combination with Type 5857 Electric Actuator

Version with digital positioner

WARNING!

Directly after connecting the voltage to the

actuator, a zero calibration is automatically

performed when the absolute travel adjust

ment is set (state of delivery), causing the

actuator stem to move.

Do not touch the actuator stem or obstruct it

to avoid risk of injury to hands or fingers.

For 24 V DC connection

_+_

Feedback,

output

++

Control

signal

24 V DC 0...10 V 0...10 V

_

OG YE RD BK BN GN

NOTICE

During zero calibration, the control valve

moves through a part of the travel range.

As a result, do not connect the wires of the

actuator while a process is running. Instead,

close the shut-off valves in the plant first.

Connect the 6-wire cable according to

Fig. 4.

For 24 V AC connection

_+_

Feedback,

output

+

Control

signal

24 V AC 0...10 V 0...10 V

NL

OG YE RD BK BN GN

M

Fig. 4 · Electrical connection – Version with digital positioner

12 EB 5867 EN

M

OG orange

YE yellow

RD red

BK black

BN brown

GN green

Page 13

5 Maintenance

WARNING!

For maintenance work on the valve, make

sure the relevant section of the pipeline is

depressurized and, depending on the pro

cess medium, drained as well.

For high medium temperatures, allow the

section of the pipeline to cool down before

you start.

Make sure the control signal for the actuator

is switched off.

The control valve is subject to natural wear.

Depending on the conditions the valve is operated in, it needs to be checked at regular

intervals.

If leakage to the atmosphere occurs, disassemble the valve and replace the damaged

parts.

-

Maintenance

EB 5867 EN 13

Page 14

Dimensions in mm and weights

6 Dimensions in mm and weights

Intermediate

insulating piece

Type 3222 N/5857 (basic version)

Type 3222 N Valve with Type 5857 Actuator

Version with threaded ends

Weights:

Valve without actuator: Approx. 0.3 kg

Valve with actuator: Approx. 1.0 kg

14 EB 5867 EN

SW30

Ø21.3

210

Version with welding ends

SW30

di

Ø21.3

L

Version with soldering ends

Inside∅di 15 18

Length L 107 103

Page 15

EB 5867 EN 15

Page 16

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 5867 EN

2009-11

Loading...

Loading...