Samson 3222/5857, 3222/5824, 3222/5825, 3222/5757-3, 3222/5757-7 Mounting And Operating Instructions

...Page 1

Mounting and

Operating Instructions

EB 5866 EN

Translation of original instructions

Edition July 2016

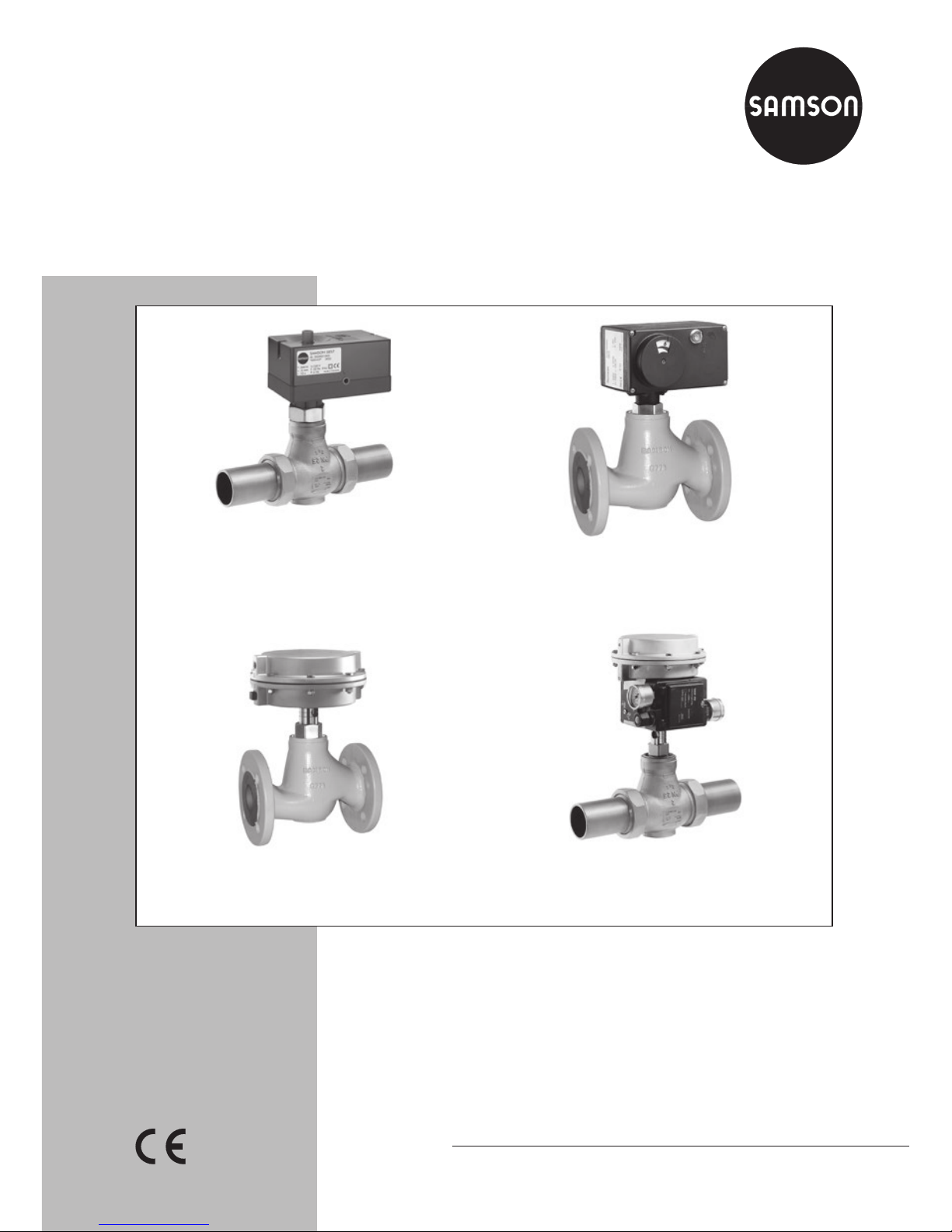

Type3222/5857

Type3222/5757-3

Type3222/5757-7

Type3222/5825

Type3222/5725-7

Type3222/2780-1

Type3222/2780-2 with Type3760

Positioner

Electric Control Valves

Types 3222/5857, 3222/5824, 3222/5825, 3222/5757-3,

3222/5757-7, 3222/5724-3, 3222/5724-8, 3222/5725-3,

3222/5725-7, 3222/5725-8

Pneumatic Control Valves

Type3222/2780

Page 2

2 EB 5866 EN

Note on these mounting and operating instructions

These mounting and operating instructions assist you in mounting and operating the device

safely. The instructions are binding for handling SAMSON devices.

Î For the safe and proper use of these instructions, read them carefully and keep them for

later reference.

Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service

Department (aftersalesservice@samson.de).

The mounting and operating instructions for the devices are included in

the scope of delivery. The latest documentation is available on our website

(www.samson.de) > Product documentation. You can enter the document

number or type number in the [Find:] eld to look for a document.

Denition of signal words

Hazardous situations which, if not avoided,

will result in death or serious injury

Hazardous situations which, if not avoided,

could result in death or serious injury

Property damage message or malfunction

Additional information

Recommended action

DANGER

!

WARNING

!

NOTICE

!

Note

Tip

Page 3

Contents

EB 5866 EN 3

1 Safety instructions and measures ...................................................................5

1.1 Notes on possible severe personal injury .........................................................8

1.2 Notes on possible personal injury ...................................................................9

1.3 Notes on possible property damage ..............................................................10

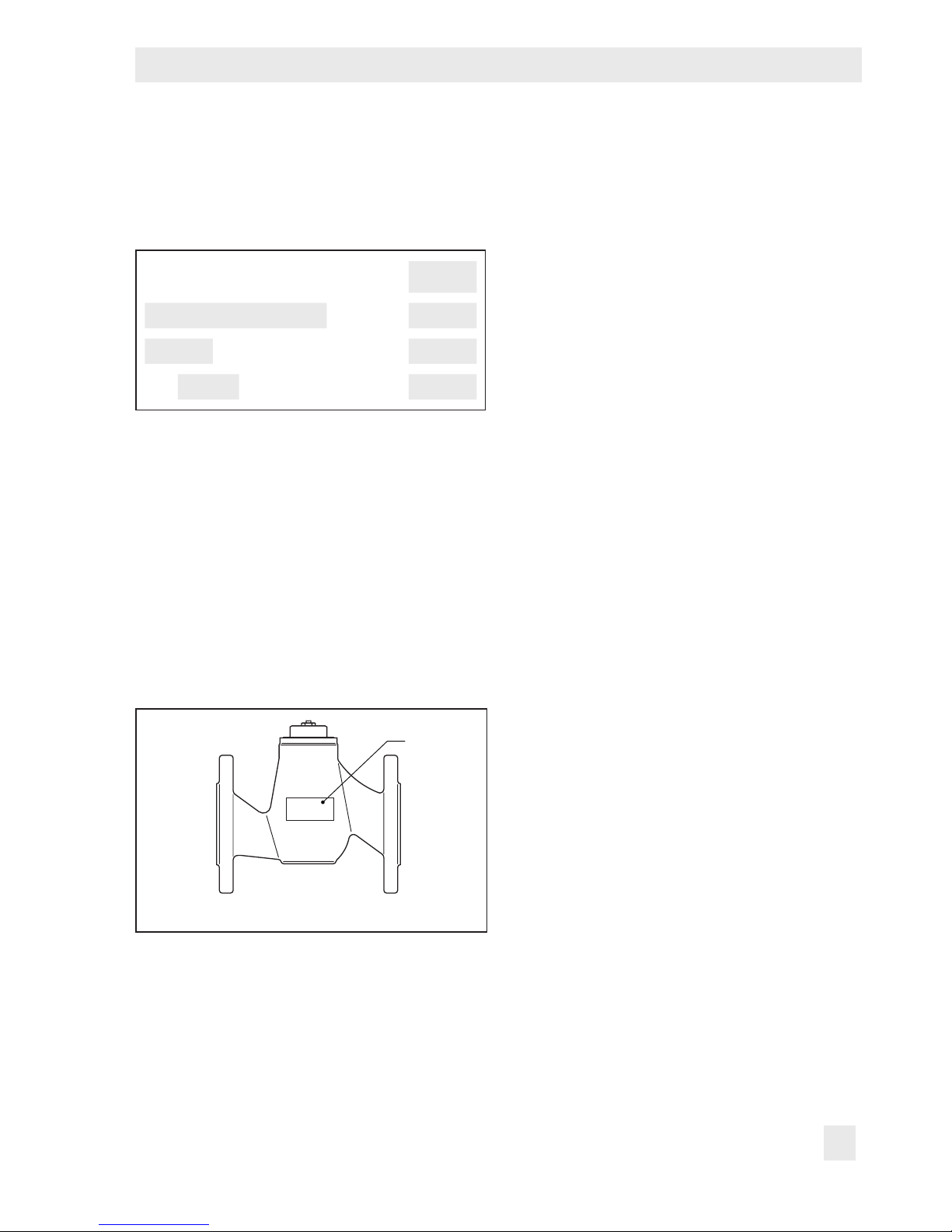

2 Markings on the device ...............................................................................11

2.1 Valve nameplate ..........................................................................................11

2.2 Actuator nameplate ......................................................................................11

3 Design and principle of operation ................................................................12

3.1 Fail-safe action ............................................................................................12

3.2 Versions ......................................................................................................14

3.3 Technical data .............................................................................................16

4 Preparation .................................................................................................22

4.1 Unpacking ..................................................................................................22

4.2 Transporting and lifting ................................................................................22

4.2.1 Transporting ................................................................................................22

4.2.2 Lifting ..........................................................................................................22

4.3 Storage .......................................................................................................22

4.4 Preparation for installation ............................................................................23

5 Mounting and start-up ................................................................................. 24

5.1 Installing the valve into the pipeline ...............................................................24

5.1.1 Checking the installation conditions ...............................................................24

5.1.2 Additional ttings .........................................................................................26

5.1.3 Installing the control valve .............................................................................26

5.2 Mounting the actuator onto the valve .............................................................27

5.2.1 Connecting the actuator ................................................................................27

5.2.2 Conguring the actuator ...............................................................................28

5.3 Quick check ................................................................................................28

6 Operation ...................................................................................................29

7 Servicing.....................................................................................................30

7.1 Preparation for return shipment .....................................................................30

7.2 Ordering spare parts and operating supplies .................................................30

Page 4

4 EB 5866 EN

Contents

8 Malfunctions ...............................................................................................31

8.1 Troubleshooting ...........................................................................................31

8.2 Emergency action ........................................................................................32

9 Decommissioning and disassembly ..............................................................33

9.1 Decommissioning .........................................................................................33

9.2 Removing the valve from the pipeline .............................................................33

9.3 Removing the actuator from the valve ............................................................34

9.4 Disposal ......................................................................................................34

10 Appendix ....................................................................................................35

10.1 After-sales service ........................................................................................35

10.2 Certicates ..................................................................................................35

Page 5

EB 5866 EN 5

Safety instructions and measures

1 Safety instructions and measures

Intended use

The SAMSON Type3222 Valve is designed for use in temperature control circuits in HVAC

plants (e.g. for DHW heating). The valve is primarily combined with the following SAMSON

actuators:

− As electric control valve: Type3222/5857, Type3222/5824, Type3222/5825,

Type3222/5757-3, Type3222/5757-7, Type3222/5724-3, Type3222/5724-8,

Type3222/5725-3, Type3222/5725-7 and Type3222/5725-8

− As pneumatic control valve: Type3222/2780

The valve with its actuator is designed to operate under exactly dened conditions (e.g. operating pressure, process medium, temperature). Therefore, operators must ensure that the control valve is only used in applications that meet the specications used for sizing the valve at

the ordering stage. In case operators intend to use the control valve in other applications or

conditions than specied, SAMSON must be contacted.

SAMSON does not assume any liability for damage resulting from the failure to use the

valve for its intended purpose or for damage caused by external forces or any other external

factors.

Î Refer to the technical data and nameplate for limits and elds of application as well as

possible uses.

Reasonably foreseeable misuse

The control valve is not suitable for the following applications:

− Use outside the limits dened during sizing and in the technical data

− For Type3222/2780 Control Valve: use outside the limits dened by the valve accesso-

ries mounted on the control valve

Furthermore, the following activities do not comply with the intended use:

− Use of non-original spare parts

− Performing servicing and repair work not described in these instructions

Page 6

6 EB 5866 EN

Safety instructions and measures

Qualications of operating personnel

The control valve must be mounted, started up, serviced, and repaired by fully trained and

qualied personnel only; the accepted industry codes and practices are to be observed. According to these mounting and operating instructions, trained personnel refers to individuals

who are able to judge the work they are assigned to and recognize possible hazards due to

their specialized training, their knowledge and experience as well as their knowledge of the

applicable standards.

Personal protective equipment

We recommend wearing the following protective equipment:

− Protective clothing and gloves in applications with hot or cold media

Î Check with the plant operator for details on further protective equipment.

Revisions and other modications

Revisions, conversions or other modications to the product are not authorized by SAMSON.

They are performed at the user's own risk and may lead to safety hazards, for example. Furthermore, the product may no longer meet the requirements for its intended use.

Safety features

In combination with the Type5825 Electric Actuator and with the TROVIS5725-3, TROVIS5725-7, and TROVIS5725-8 Electric Actuators with Process Controllers, the following

safety feature exists: upon failure of the power supply, the valve moves to a dened fail-safe

position (see section3.1). The direction of action of the fail-safe action is dened by the actuator version (see associated actuator documentation).

In combination with the Type2780 Pneumatic Actuator, the following safety feature exists:

upon failure of the air supply, the valve moves to a certain fail-safe position (see section3.1).

The fail-safe action corresponds with the direction of action. The fail-safe action of SAMSON

actuators is specied on the actuator nameplate (see actuator documentation).

Warning against residual hazards

To avoid personal injury or property damage, plant operators and operating personnel must

prevent hazards that could be caused in the control valve by the process medium, the operating pressure, the signal pressure or by moving parts by taking appropriate precautions. They

must observe all hazard statements, warning and caution notes in these mounting and operating instructions, especially for installation, start-up, and servicing.

Page 7

EB 5866 EN 7

Safety instructions and measures

Responsibilities of the operator

The operator is responsible for proper operation and compliance with the safety regulations.

Operators are obliged to provide these mounting and operating instructions as well as the

referenced documents to the operating personnel and to instruct them in proper operation.

Furthermore, operators must ensure that operating personnel or third persons are not exposed to any danger.

Responsibilities of operating personnel

Operating personnel must read and understand these mounting and operating instructions as

well as the referenced documents and observe the hazard statements, warning, and caution

notes specied in them. Furthermore, the operating personnel must be familiar with the applicable health, safety and accident prevention regulations and comply with them.

Referenced standards and regulations

The control valves comply with the requirements of the European Pressure Equipment Directive 2014/68/EU. Valves with a CE marking have a declaration of conformity which includes information about the applied conformity assessment procedure. This declaration of

conformity is included in the Appendix of these instructions (see section10.2).

The electric actuators are designed for use in low voltage installations. For wiring, maintenance, and repair, observe the relevant safety regulations.

Referenced documentation

The following documents apply in addition to these mounting and operating instructions:

− Mounting and operating instructions for mounted actuator, e.g. SAMSON actuators:

u EB5857 for Type5857

uEB5824-1/-2 for Type5824 and Type5825

uEB5757-X for TROVIS5757-X

uEB5724 for TROVIS5724-3 and TROVIS5725-3

uEB5724-8 for TROVIS5724-8 and TROVIS5725-8

uEB5725-7 for TROVIS5725-7

u EB5840 for Type2780

− For Type3222/2780 Control Valve: mounting and operating instructions for mounted

valve accessories (positioner, solenoid valve etc.)

Page 8

8 EB 5866 EN

Safety instructions and measures

1.1 Notes on possible severe personal injury

DANGER

!

Risk of bursting in pressure equipment.

Control valves and pipelines are pressure equipment. Improper opening can lead to

valve components bursting.

Î Before starting any work on the control valve, depressurize all plant sections

concerned and the valve.

Î Drain the process medium from all the plant sections concerned as well as the

valve.

Î Wear personal protective equipment.

Risk of electric shock.

Î Do not remove any covers to perform adjustment work on live parts.

Î Before performing any work on the device and before opening the device, discon-

nect the power supply and protect it against unintentional reconnection.

Î Only use power interruption devices that are protected against unintentional recon-

nection of the power supply.

Î The electric actuators are protected against spray water (IP54). Avoid jets of water.

Page 9

EB 5866 EN 9

Safety instructions and measures

1.2 Notes on possible personal injury

WARNING

!

Crush hazard arising from moving parts.

The pneumatic control valve (Type3222/2780) contains moving parts (actuator and

plug stems), which can injure hands or ngers if inserted into the valve.

Î While working on the control valve, disconnect and lock the pneumatic air supply

as well as the control signal.

Risk of personal injury when the pneumatic actuator vents.

While the valve is operating, the pneumatic actuator (Type2780) may vent during

closed-loop control or when the valve opens or closes.

Î Install the control valve in such a way that the actuator does not vent at eye level.

Î Use suitable silencers and vent plugs.

Î Wear eye protection when working in close proximity to the control valve.

Risk of personal injury due to residual process medium in the valve.

While working on the valve, residual process medium can escape and, depending on

its properties, may lead to personal injury, e.g. burns.

Î If possible, drain the process medium from all the plant sections concerned and the

valve.

Î Wear protective clothing and gloves.

Risk of burn injuries due to hot components and pipelines.

Depending on the process medium, valve components, and pipelines may get very hot

and cause burn injuries.

Î Allow components and pipelines to cool down.

Î Wear protective clothing and gloves.

Page 10

10 EB 5866 EN

Safety instructions and measures

1.3 Notes on possible property damage

NOTICE

!

Risk of damage to the electric control valve due to the power supply exceeding the

permissible tolerances.

The electric control valves are designed for use according to regulations for low-voltage installations.

Î Observe the permissible tolerances of the power supply. See associated actuator

documentation.

Risk of valve damage due to contamination (e.g. solid particles) in the pipeline.

The plant engineering company is responsible for cleaning the pipelines in the plant.

Î Flush the pipelines before start-up.

Î Observe the maximum permissible pressure for valve and plant.

Risk of valve damage due to unsuitable medium properties.

The valve is designed for a process medium with certain properties (e.g. water, oil,

steam).

Î Only use the process medium that meets the specications used for sizing the valve.

Page 11

EB 5866 EN 11

Markings on the device

2 Markings on the device

2.1 Valve nameplate

SAMSON

1

2 3

4 5

kvs 6 Δp 7

1 Type designation

2 Conguration ID

3 Date of manufacture

4 Model number

5 Max. permissible temperature

6 K

VS

coefcient

7 Max. perm. differential pressure

The nameplate (48) is afxed to the valve

body (see Fig.1).

48

Fig.1: Location of the nameplate

2.2 Actuator nameplate

See associated actuator documentation.

Page 12

12 EB 5866 EN

Design and principle of operation

3 Design and principle of oper-

ation

The medium ows through the single-seated

globe valve in the direction indicated by the

arrow. The position of the plug determines

the ow rate across the area released between plug (1) and seat (5). The valve is

opened by the valve spring when the actuator stem retracts. The plug is moved by

changing the control signal applied to the

actuator. The valve and actuator have a

force-locking connection.

A special version (see Fig.4) is available for

water above 150°C and steam.

3.1 Fail-safe action

When the Type3222 Valve is combined with

one of the following actuators, the valve

moves to the fail-safe position up upon failure of the air supply or power supply:

− Type5825 Electric Actuator

− TROVIS5725-3 and TROVIS5725-7

Electric Actuators with Process Controllers

− Type 2780 Pneumatic Actuator

The control valve has two different fail-safe

positions:

− Actuator stem extends: upon power sup-

ply or air supply failure, the actuator

stem extends.

The TROVIS5725-3, TROVIS5725-7, and

TROVIS8725-8 Electric Actuators with Process Controllers in the version with

force-locking attachment and the Type5825

Electric Actuator with "actuator stem extends" fail-safe action are tested by the German technical surveillance association TÜV

according to DINEN14597 in combination

with the SAMSON Type3222 Valve. The

registration number is available on request.

− Actuator stem retracts: upon power sup-

ply or air supply failure, the actuator

stem retracts.

The fail-safe action of pneumatic actuators

can be reversed (see associated actuator

documentation). The fail-safe action of electric actuators (with process controllers) is already determined at the ordering stage.

Note

Note

Page 13

EB 5866 EN 13

Design and principle of operation

1

5

3

7

1 Plug

3 Body

5 Seat

7 O-ring

8 Connecting piece

11 Guide nipple

14 Insulating section

15 Insulating pipe

1

5

3

7

11

8

5

1

14

15

11

Fig.2: Type3222/2780-1

Fig.3: Type3222/5875, Type3222/5757-3,

Type3222/5757-7 · Version for water,

oil, and liquids

Fig.4: Type3222/5824, Type3222/5724-3 · Version

for water above 150°C and steam

Page 14

14 EB 5866 EN

Design and principle of operation

3.2 Versions

Intermediate insulating piece

An intermediate insulating piece is available

for insulated pipes.

Electric actuators

The electric actuators can be controlled either using a three-step signal or, in the version with positioner, with continuous signals

adjustable in the range from 0 to 20mA or

from 0 to 10V. Various electrical accessories

can be optionally installed.

Type5825 Actuator is able to perform a failsafe action. Refer to Table1.

Electric actuators with process controllers

Electric actuators with process controllers are

a combination of an electric actuator and a

digital process controller. The TROVIS57573, TROVIS5724-3, and TROVIS5725-3

Electric Actuators with Process Controller are

suitable for domestic hot water heating.

TROVIS5757-7 and TROVIS5725-7 are

suitable for heating and cooling applications.

TROVIS5724-8 and TROVIS5725-8 have

two PID control modules and are readywired for heating and cooling applications.

TROVIS5725-3, TROVIS5725-7, and

TROVIS5725-8 Actuators are able to perform a fail-safe action (see Table1).

Pneumatic actuators

The Type2780-1 Pneumatic Actuator uses a

control signal from 0.4 to 1bar and

Type2780-2 uses a control signal from 0.4

to 2bar which is applied to the signal pressure connection.

The pneumatic actuators require a supply

pressure of at least 0.2bar above the maximum bench range. All actuators are available for fail-safe action "Actuator stem extends (FA)" or "Actuator stem retracts (FE)".

Page 15

EB 5866 EN 15

Design and principle of operation

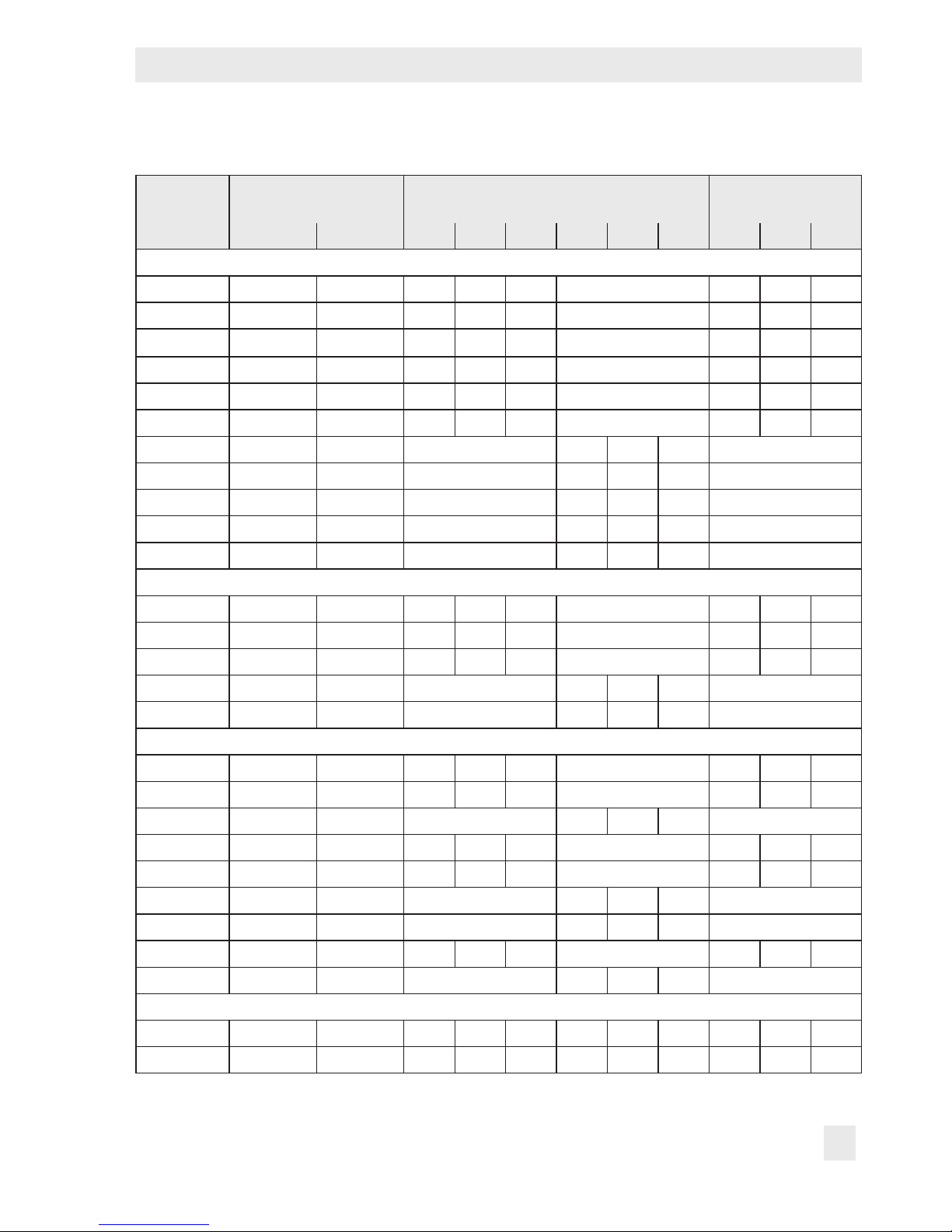

Table1: Available versions and possible combinations (valve/actuator)

Type/TROVIS

Fail-safe action:

Actuator stem Nominal size DN Thread size G

Extends Retracts 15 20 25 32 40 50 ½ ¾ 1

Electric actuators

5857 – – • • • – • • •

5824-10 – – • • • – • • •

5824-13

1)

– – • • • – • •

•

5825-10 • – • • • – • • •

5825-13

1)

• – • • • – • • •

5825-15 – • • • • – • • •

5824-20 – – – • • • –

5824-23 – – – • • • –

5825-20 • – – • • • –

5825-23 • – – • • • –

5825-25 – • – • • • –

Electric actuators with process controllers for domestic hot water heating

5757-3 – – • • • – • • •

5724-310 – – • • • – • • •

5725-310 • – • • • – • • •

5724-320 – – – • • • –

5725-320 • – – • • • –

Electric actuators with process controller for heating and cooling applications

5757-7 – – • • • – • • •

5724-810 – – • • • – • • •

5724-820 – – – • • • –

5725-710 • – • • • – • • •

5725-715 – • • • • – • • •

5725-720 • – – • • • –

5725-725 – • – • • • –

5725-810 • – • • • – • • •

5725-820 • – – • • • –

Pneumatic actuators

2780-1 • • • • • • • • • • •

2780-2 • • • • • • • • • • •

1)

Version with half transit time

Page 16

16 EB 5866 EN

Design and principle of operation

3.3 Technical data

The nameplates on the valve and actuator provide information on the control valve version.

See section2.1 and the associated actuator documentation.

Table2: Technical data for Type3222

Nominal size

Globe valve with male thread connec-

tion or with anged body

DN

15 20 25 32 40 50

Connection size

Globe valve with female thread

G ½ ¾ 1 – – –

Nominal pressure PN 25

Seat-plug seal

Metal seal for K

VS

≤2.5

Soft seal for KVS ≥3.6

Rated travel mm 6 12

Rangeability 50 : 1

Leakage class according to IEC60534-4 Class I (≤0.05% of K

VS

coefcient)

Compliance

·

Version for water, oil and other liquids

Max. permissible temperature 150°C

1)

Max. permissible differential pressure ∆p

Type5824/5825, TROVIS5724-3/

5724-8/5725-3/ 5725-7/5725-8,

Type2780

bar 20 20 20 12/16

4)

12 12

Type5857, TROVIS5757-3,

TROVIS5757-7

bar 20 20 20 – – –

Version for water above 150°C and steam

Max. permissible temperature 200°C

Max. permissible differential pressure ∆p

Type5824/5825, TROVIS5724-3/

5724-8/5725-3/5725-7/5725-8,

Type2780

bar 20 · 10 with 3.6≤K

VS

≤8 8 8 8

Type5857, TROVIS5757-3,

TROVIS5757-7

bar

20

2)

·

5

3)

5 5 – – –

1)

Use an intermediate insulating piece (see section5.1.2, Intermediate insulating piece)

2)

Differential pressure with KVS = 1 and 1.6

3)

Differential pressure with KVS = 2.5 and 4

4)

Applies to KVS = 10

Page 17

EB 5866 EN 17

Design and principle of operation

Table3: Nominal sizes and K

VS

coefcients

Nominal size

Globe valve with male

thread connection or

with anged body

DN 15 20 25 32 40 50

Connection size

Globe valve with female

thread

G ½ ¾ 1 – – –

K

VS

coefcients 4

1)

· 3.6

2)

6.3

1)

·

5.7

2)

8

1)

·

7.2

2)

16

1)

20

1)

25

1)

Reduced K

VS

coefcients

0.1· 0.16 · 0.25

· 0.4 · 0.63 ·

1.0 · 1.6 · 2.5

1.0 · 1.6 · 2.5 ·

4

1)

· 3.6

2)

10

3)

– –

Rated travel

mm

6 6 6 12 12 12

1)

Version with male thread connection or with anged body

2)

Version with female thread

3)

6mm rated travel

Table4: Materials

Valve body CC499K (CuSn5Zn5Pb2-C)

Version with anged body EN-GJS-400-18-LT (GGG-40.3)

Seat Stainless steel 1.4305

Plug

1.4305/CW602N with soft seal

1.4305 with 0.1≤K

VS

≤2.5

Valve spring Stainless steel 1.4310K

Packing EPDM/FPM (FKM) · Oil-resistant version: FPM

Welding ends St 37

Threaded ends CC491K (red brass)

Screwed-on anges St 37.2

Noise emission

SAMSON is unable to make general statements about noise emission as it depends on the

valve version, plant facilities, and process medium. On request, SAMSON can perform calculations according to IEC60534, Part8-3 and Part8-4 or VDMA24422 (edition89).

Page 18

18 EB 5866 EN

Design and principle of operation

Dimensions and weights

Table5 provides a summary of the dimensions and weights of the valve. The lengths and

heights in the dimension diagrams are shown on page19 onwards.

Table5: Dimensions and weights for Type3222 Valve

Valves with male thread connection

Nominal size DN 15 20 25 32 40 50

Length L mm 65 70 75 100 110 130

Height H2 mm 45.5 45.5 45.5 94 94 94

Version for water above 150°C

and steam or version with

intermediate insulating piece

140 140 140 185 185 185

Height H3 mm 30 30 30 55 55 55

Valves with welding ends

Thread size R G ¾ 1 1¼ 1¾ 2 2½

Pipe Ød mm 21.3 26.8 33.7 42 48 60

Width across ats SW 30 36 46 59 65 82

Length L1 mm 210 234 244 268 294 330

Weight without actuator kg (approx.) 1.4 1.8 2.3 4.0 4.4 6.8

Version for water above 150°C

and steam or version with

intermediate insulating piece

1.9 2.3 2.8 4.5 4.9 7.3

Valves with threaded ends

Length L2 mm 129 144 159 180 196 228

Male thread A G ½ ¾ 1 1¼ 1½ 2

Width across ats SW 30 36 46 59 65 82

Weight without actuator kg (approx.) 1.4 1.8 2.3 4.0 4.4 6.8

Version for water above 150°C

and steam or version with

intermediate insulating piece

1.9 2.3 2.8 4.5 4.9 7.3

Valves with anges

Width across ats SW 30 36 46 59 65 82

Length L3 mm 130 150 160 180 200 230

Weight without actuator kg (approx.) 2.5 3.4 4.1 6.9 7.7 10.7

Version for water above 150°C

and steam or version with

intermediate insulating piece

3.0 3.9 4.6 7.4 8.2 11.2

Page 19

EB 5866 EN 19

Design and principle of operation

Valves with female thread

Connection size G ½ ¾ 1 –

Width across ats SW 30 36 46 –

Length L4 mm 65 75 90 –

Female thread G ½ ¾ 1 –

Weight without actuator kg (approx.) 1.2 1.4 1.5 –

Version for water above 150°C

and steam or version with

intermediate insulating piece

1.7 1.9 2.0 –

Valves with anged body

Nominal size DN 15 20 25 32 40 50

Height H2 mm 45.5 45.5 45.5 94 94 92

Length L3 mm 130 150 160 180 200 230

Weight without actuator kg (approx.) 2.5 3.4 4.1 6.9 8.4 11.6

Version for water above 150°C

and steam or version with

intermediate insulating piece

3.0 3.9 4.6 7.4 8.9 12.1

Dimensional drawings

SW

L2

A

SW

L4

G

80

Version with threaded ends Version with female thread Intermediate

insulating

piece

SW

L3

L3

H2

Version with anges Version with anges

Page 20

20 EB 5866 EN

Design and principle of operation

Dimension diagrams for electric control valves

Ø12

55

80

11

L

L1

H2

114 x 70

H3

R

d

SW

L

L1

146 x 103*

113

H2

H3

R

d

SW

Type3222/5857: DN15 to 25

Type3222/5757-3: DN15 to 25

Type3222/5757-7: DN15 to 25

Type3222/5824: DN15 to 50

Type3222/5825: DN15 to 50

Type3222/5724-3: DN15 to 50

Type3222/5724-8: DN15 to 50

Type3222/5725-3: DN15 to 50

Type3222/5725-7: DN15 to 50

Type3222/5725-8: DN15 to 50

* Dimensions for Types 5824-x3, 5825-x3

Actuators:

146 x 136

146 x 103*

113

L

L1

H2 + 80

H3

R

d

SW

Version for water above 150°C and steam

Type3222/5824: DN15 to 50

Type3222/5825: DN15 to 50

Type3222/5724-3: DN15 to 50

Type3222/5724-8: DN15 to 50

Type3222/5725-3: DN15 to 50

Type3222/5725-7: DN15 to 50

Type3222/5725-8: DN15 to 50

* Dimensions for Types 5824-x3, 5825-x3

Actuators:

146 x 136

Page 21

EB 5866 EN 21

Design and principle of operation

Dimension diagrams for pneumatic control valves

SW

R

d

L

L1

H3 H2 130

Ø168

SW

R

d

L

L1

230

Ø168

H2H3

Type3222/2780-1: DN15 to 50 Type3222/2780-2: DN15 to 50

Table6: Weights of electric actuators

Type 5857 5824 5825

Weight kg (approx.) 0.7 0.75 1.0

Table7: Weights of electric actuators with process controllers

TROVIS 5757-3/-7 5724-3/-8 5725-3/-7/-8

Weight kg (approx.) 0.7 1.1 1.3

Table8: Dimensions and weights for pneumatic actuators

Type 2780-1 2780-2

Actuator area cm² 120 120

Diaphragm ØD mm 170 170

Signal pressure connection a G

1

/

8

G

1

/

8

Weight kg (approx.) 2 3.2

Page 22

22 EB 5866 EN

Preparation

4 Preparation

After receiving the shipment, proceed as follows:

1. Check the scope of delivery. Compare

the shipment received against the delivery note.

2. Check the shipment for transportation

damage. Report any damage to SAMSON and the forwarding agent (refer to

delivery note).

4.1 Unpacking

Do not remove the packaging until immediately before installing the valve into the pipeline.

Proceed as follows to lift and install the

valve:

1. Remove the packaging from the valve.

2. Dispose of the packaging in accordance

with the valid regulations.

4.2 Transporting and lifting

SAMSON's After-sales Service department

can provide more detailed transport and lifting instructions on request.

4.2.1 Transporting

− Protect the control valve against external

inuences (e.g. impact).

− Protect the control valve against moisture

and dirt.

− Observe the permissible transportation

temperature of –20 to +65°C.

4.2.2 Lifting

Due to the low service weight, lifting equipment is not required to lift the valve (e.g. to

install it into the pipeline).

4.3 Storage

Risk of valve damage due to improper storage.

− Observe storage instructions.

− Avoid long storage times.

− Contact SAMSON in case of different stor-

age conditions or long storage periods.

We recommend regularly checking the control valve and the prevailing storage conditions during long storage times.

Storage instructions

− The control valves can be stored horizon-

tally.

− Protect the control valve against external

inuences (e.g. impact).

Note

Tip

NOTICE

!

Note

Page 23

EB 5866 EN 23

Preparation

− Protect the control valve against moisture

and dirt. Store it at a relative humidity of

less than 75%. In damp spaces, prevent

condensation. If necessary, use a drying

agent or heating.

− Make sure that the ambient air is free of

acids or other corrosive media.

− Observe the permissible storage tem-

perature from –20 to +65°C.

− Do not place any objects on the control

valve.

SAMSON's After-sales Service department

can provide more detailed storage instructions on request.

Special storage instructions for elastomers

Elastomer, e.g. actuator diaphragm

(Type2780 Pneumatic Actuator)

− To keep elastomers in shape and to pre-

vent cracking, do not bend them or hang

them up.

− We recommend a storage temperature of

15°C (59°F) for elastomers.

− Store elastomers away from lubricants,

chemicals, solutions, and fuels.

SAMSON's After-sales Service department

can provide more detailed storage instructions on request.

4.4 Preparation for installation

Proceed as follows:

Î Flush the pipelines.

The plant engineering company is responsible for cleaning the pipelines in the plant.

Î Check the valve to make sure it is clean.

Î Check the valve for damage.

Î Check to make sure that the type desig-

nation, valve size, material, pressure rating and temperature range of the valve

match the plant conditions (size and

pressure rating of the pipeline, medium

temperature etc.).

Î Check any mounted pressure gauges to

make sure they function.

Î When the valve and actuator are al-

ready assembled, check the bolted joints.

Components may loosen during transport.

Tip

Tip

Note

Page 24

24 EB 5866 EN

Mounting and start-up

5 Mounting and start-up

SAMSON valves are delivered ready for

use. The valve and actuator are delivered

separately and must be assembled on site.

The procedure to mount and start up the

valve are described in the following.

We recommend rst installing the valve into

the pipeline and mounting the actuator afterwards.

Risk of valve damage due to excessively high

or low tightening torques.

Observe the specied torques on tightening

control valve components. Excessively tightened torques lead to parts wearing out

quicker. Parts that are too loose may cause

leakage.

5.1 Installing the valve into the

pipeline

For medium temperatures above 150°C

only

the dark gray graphite seals supplied with

the valve are to be used. Do not use the UDP

seals available as accessories as they are

only suitable for temperatures up to 150°C.

5.1.1 Checking the installation

conditions

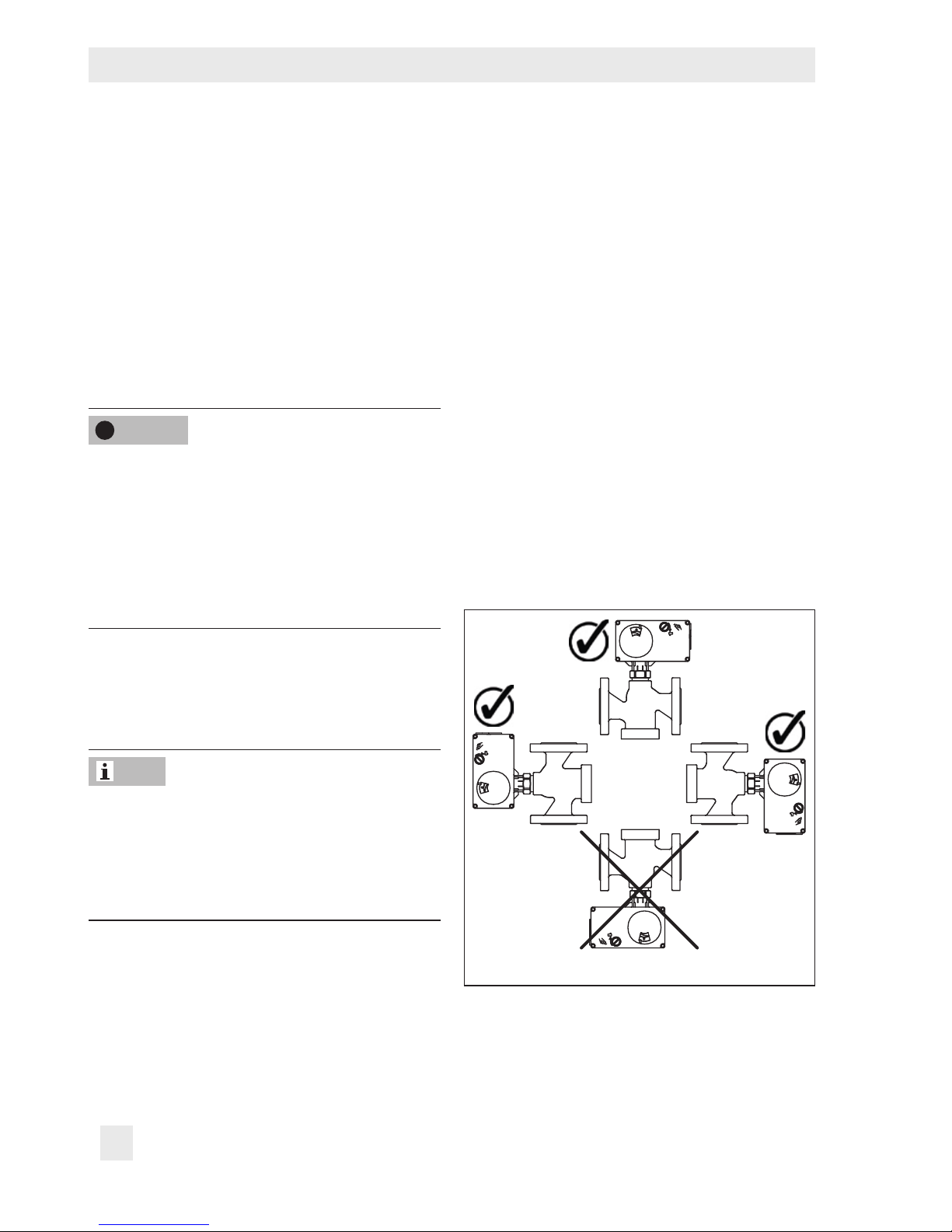

Mounting position

Generally, we recommend installing the

valve with the actuator upright and on top of

the valve.

For versions for water, oil, and other liquids,

the actuator must not be suspended downwards (see Fig.5).

In the following versions, the valve must be

installed with the actuator on top in a horizontal pipeline:

− Version for water above 150°C and

steam

Î Contact SAMSON if the mounting posi-

tion is not as specied here.

Fig.5: Mounting position

NOTICE

!

Note

Page 25

EB 5866 EN 25

Mounting and start-up

Support or suspension

Depending on the valve version and mounting position, the control valve and pipeline

must be supported or suspended. The plant

engineering company is responsible in this

case.

Premature wear and leakage due to insufcient support or suspension. In the following

versions, the control valve must be supported

or suspended:

− Valves that are not installed with the actua-

tor upright on top of the valve.

Attach a suitable support or suspension to

the valve.

Insulation of cold systems

To insulate cold systems, we recommend to

proceed as follows:

1. Fill the plant and carefully rinse it.

2. Shut down the plant and let it heat up

until all the condensation water has dried

off.

3. Mount and insulate the intermediate insulating piece (1990-1712).

Observe the following on installing the control valve:

Î Make sure that the electric actuator re-

mains accessible after installation.

Î Make sure that the plug stem can move

freely and does not touch the insulation.

Î Make sure that the actuator stem does

not touch the insulation.

The insulation thickness depends on the medium temperature and the ambient conditions. 50mm is a typical thickness.

Pipeline routing

To ensure the control valve functions properly, follow the installation instructions given

below:

Î Do not exceed the maximum permissible

ow velocity.

The plant engineering company is responsible for determining the maximum permissible ow velocity. SAMSON's After-sales Service department can support you to determine the ow velocity for your plant.

Î Install the valve free of stress and with the

least amount of vibrations as possible. If

necessary, attach supports to the valve.

Î Install the valve allowing sufcient space

to remove the actuator and valve or to

perform service and repair work on

them.

Vent plug (Type3222/2780 only)

Vent plugs are screwed into the exhaust air

ports of pneumatic devices. They ensure that

any exhaust air that forms can be vented to

the atmosphere (to avoid excess pressure in

the device). Furthermore, the vent plugs allow air intake to prevent a vacuum from

forming in the device.

NOTICE

!

Note

Note

Page 26

26 EB 5866 EN

Mounting and start-up

Î Locate the vent plug on the opposite side

to the workplace of operating personnel.

Risk of personal injury when the actuator

vents.

− Install the control valve in such a way that

the actuator does not vent at eye level.

− Use suitable silencers and vent plugs.

− Wear eye protection when working in

close proximity to the control valve.

Î On mounting valve accessories, make

sure that they can be operated from the

workplace of the operating personnel.

The workplace of operating personnel is the

location from which the valve, actuator and

any mounted valve accessories can be accessed to operate them.

5.1.2 Additional ttings

Strainer

We recommend installing a SAMSON

Type2NI Strainer upstream of the valve. It

prevents solid particles in the process medium from damaging the valve.

Î Make sure the direction of ow of the

strainer and valve are the same.

Î Install the strainer with the lter element

facing downwards.

Î Allow sufcient space to remove the lter.

Bypass and shut-off valves

We recommend installing a shut-off valve

both upstream of the strainer and downstream of the valve and setting up a bypass

line. The bypass line ensures that the plant

does not need to be shut down for service

and repair work on the valve.

Intermediate insulating piece

An intermediate insulating piece (1990-

1712) must be used under the following conditions:

− For medium temperatures from –15°C

(red brass) or –10°C (EN-GJS-400-18LT) to +5°C (actuators according to Table1)

− In networks with a constant medium tem-

perature >135°C (TROVIS5724-3,

TROVIS5724-8, TROVIS5725-3,

TROVIS5725-7, TROVIS5725-8,

Type5824, Type5825 Actuators)

− For liquids >120°C (TROVIS5757-3,

TROVIS5757-7, and Type5857 Actuators)

Î Do not insulate the actuator and the cou-

pling nut as well.

Î Only insulate the intermediate insulating

piece up to 25mm at the maximum.

5.1.3 Installing the control

valve

1. Close the shut-off valve in the pipeline

while the valve is being installed.

2. Remove any protective caps from the

valve ports before installing the valve.

WARNING

!

Note

Page 27

EB 5866 EN 27

Mounting and start-up

3. Lift the valve to the site of installation (see

section4.2). Observe the ow direction

through the valve. The arrow on the

valve indicates the direction of ow.

4. Version with anges: make sure that the

correct ange gaskets are used.

5. Version with threaded ends (female/

male thread) and anges: bolt the valve

to the pipeline free of stress.

Version with welding ends: weld the

valve free of stress into the pipeline.

6. Depending on the eld of application,

allow the valve to cool down to reach

ambient temperature before start up.

7. Slowly open the shut-off valve in the

pipeline after the valve has been installed.

Risk of valve damage due to a sudden pressure increase and resulting high ow velocities.

Slowly open the shut-off valve in the pipeline

during start-up.

8. Check the valve to ensure it functions

properly and that there is no leakage.

5.2 Mounting the actuator onto

the valve

Proceed as described in the actuator documentation if the valve and actuator have not

been assembled by SAMSON:

− Type5857 Electric Actuator uEB5857

− Type5824 Electric Actuator

uEB5824-1/-2

− Type5825 Electric Actuator

uEB5824-1/-2

− TROVIS5757-3 Electric Actuator with

Process Controller uEB5757

− TROVIS5724-3 Electric Actuator with

Process Controller uEB5724

− TROVIS5724-8 Electric Actuator with

Process Controller uEB5724-8

− TROVIS5725-8 Electric Actuator with

Process Controller uEB5724-8

− TROVIS5725-3 Electric Actuator with

Process Controller uEB5724

− TROVIS5757-7 Electric Actuator with

Process Controller uEB5757-7

− TROVIS5725-7 Electric Actuator with

Process Controller uEB5725-7

− Type2780 Pneumatic Actuator

uEB5840

Remove the mounted actuator before mounting the other actuator (see associated actuator documentation).

5.2.1 Connecting the actuator

Perform the electrical or pneumatic connection of the actuator as described in the associated actuator documentation.

NOTICE

!

Note

Page 28

28 EB 5866 EN

Mounting and start-up

5.2.2 Conguring the actuator

The electric actuator versions with positioner

as well as electric actuators with process

controllers can be adapted to the control

task.

Congure the actuator as described in the

associated actuator documentation.

For electric control valves with positioner, an

initialization needs to be performed after the

initial start-up (see associated documentation).

5.3 Quick check

SAMSON valves are delivered ready for

use. To test the valve's ability to function, the

following quick checks can be performed:

Travel motion

The movement of the actuator stem must be

linear and smooth.

Î Open and close the valve, observing the

movement of the actuator stem.

Î Apply the maximum and minimum con-

trol signals to check the end positions of

the valve.

Î Check the travel reading at the travel in-

dicator scale.

Fail-safe position with pneumatic actuators

Î Shut off the signal pressure line.

Î Check whether the valve moves to the

fail-safe position.

Fail-safe action for electric actuators and

electric actuators with process controllers

with fail-safe action

Î Switch off the power supply.

Î Check whether the valve moves to the

fail-safe position.

Pressure test

During the pressure test, make sure the following conditions are met:

− Retract the plug stem to open the valve.

− Observe the maximum permissible pres-

sure for valve and plant.

The plant engineering company is responsible for performing the pressure test.

SAMSON's After-sales Service department

can support you to plan and perform a pressure test for your plant.

Note

Note

Page 29

EB 5866 EN 29

Operation

6 Operation

Immediately after completing mounting and

start-up (see section5), the valve is ready for

use.

Type3222/2780: crush hazard arising from

moving parts (actuator and plug stem).

Do not insert hands or nger into the yoke

while the valve is in operation.

Type3222/2780: risk of personal injury

when the actuator vents.

Wear eye protection when working in close

proximity to the control valve.

Risk of burn injuries due to hot components

and pipeline.

Valve components and the pipeline may become very hot. Risk of burn injuries.

Wear protective clothing and gloves.

Type3222/2780: operation disturbed by a

blocked actuator or plug stem.

Do not impede the movement of the actuator

or plug stem by inserting objects into their

path.

WARNING

!

WARNING

!

WARNING

!

NOTICE

!

Page 30

30 EB 5866 EN

Servicing

7 Servicing

The control valve was checked by SAMSON

before it left the factory.

− The product warranty becomes void if ser-

vicing or repair work not described in

these instructions is performed without prior agreement by SAMSON's After-sales

Service department.

− Only use original spare parts by

SAMSON, which comply with the original

specications.

7.1 Preparation for return shipment

Defective valves can be returned to SAMSON for repair.

Proceed as follows to return valves to SAMSON:

1. Put the control valve out of operation (see

section9).

2. Remove any residual process medium.

3. Fill in the Declaration on Contamination,

which can be downloaded from our

website at uwww.samson.de > Services

> Check lists for after sales service >

Declaration on Contamination.

4. Send the control valve to your nearest

SAMSON subsidiary. SAMSON subsidiaries are listed on our website at

uwww.samson.de > Contact.

7.2 Ordering spare parts and

operating supplies

Contact your nearest SAMSON subsidiary

or the SAMSON After-sales Service department for information on spare parts, lubricants, and tools.

Note

Page 31

EB 5866 EN 31

Malfunctions

8 Malfunctions

Depending on the operating conditions, check the valve at certain intervals to prevent possible failure before it can occur. Operators are responsible for drawing up a test plan.

SAMSON's After-sales Service department can support you to draw up an inspection plan

for your plant.

8.1 Troubleshooting

Malfunction Possible reasons Recommended action

Actuator or plug stem does not

move on demand.

Actuator is blocked. Check attachment.

Unblock the actuator.

No or incorrect power supply

connected.

Check the power supply and

connections.

Signal pressure too low Check the signal pressure.

Check the signal pressure line for

leakage.

Actuator or plug stem does not

move through the whole range.

No or incorrect power supply

connected.

Check the power supply and

connections.

Signal pressure too low Check the signal pressure.

Check the signal pressure line for

leakage.

The valve leaks to the atmosphere (fugitive emissions).

Plug stem seal defective Contact SAMSON's After-sales

Service department.

Increased ow through closed

valve (seat leakage)

Dirt or other foreign particles

deposited between the seat and

plug.

Shut off the section of the pipeline and ush the valve.

Valve trim is worn. Contact SAMSON's After-sales

Service department.

Contact SAMSON's After-sales Service department for malfunctions not listed in the table.

Tip

Note

Page 32

32 EB 5866 EN

Malfunctions

8.2 Emergency action

The valve, on which the electric actuator with

fail-safe action is mounted, is moved to its

fail-safe position upon power supply failure

(voltage supply, signal pressure). See section3.1.

Operators are responsible for emergency action to be taken in the plant.

In the event of a valve malfunction:

1. Close the shut-off valves upstream and

downstream of the control valve to stop

the process medium from owing

through the valve.

2. Check the valve for damage. If necessary, contact SAMSON's After-sales Service department.

Putting the valve back into operation after

a malfunction

Î Slowly open the shut-off valves. Allow

the process medium to ow into the valve

slowly.

Page 33

EB 5866 EN 33

Decommissioning and disassembly

9 Decommissioning and disas-

sembly

Risk of bursting in pressure equipment.

Control valves and pipelines are pressure

equipment. Improper opening can lead to

bursting of the valve.

− Before starting any work on the control

valve, depressurize all plant sections concerned and the valve.

− Drain the process medium from all the

plant sections concerned as well as the

valve.

− Wear personal protective equipment.

Risk of electric shock.

− Before performing any work on the device

and before opening the device, disconnect

the power supply and protect it against unintentional reconnection.

− Only use power interruption devices that

are protected against unintentional reconnection of the power supply.

Risk of personal injury due to residual process medium in the valve.

While working on the valve, residual process

medium can escape and, depending on its

properties, may lead to personal injury, e.g.

burns.

Wear protective clothing and gloves.

Risk of burn injuries due to hot components

and pipeline.

Valve components and the pipeline may become very hot. Risk of burn injuries.

− Allow components and pipelines to cool

down.

− Wear protective clothing and gloves.

9.1 Decommissioning

To decommission the control valve for disassembly, proceed as follows:

1. Close the shut-off valves upstream and

downstream of the control valve to stop

the process medium from owing

through the valve.

2. Completely drain the pipelines and

valve.

3. Disconnect and lock the pneumatic air

supply or power supply to depressurize

or de-energize the actuator.

4. If necessary, allow the pipeline and valve

components to cool down.

9.2 Removing the valve from

the pipeline

1. Put the control valve out of operation (see

section9.1).

2. Version with threaded ends (female/

male thread) or anges: undo the ange

joint or screw connection.

Version with welding ends: cut the pipeline in front of the weld seam.

DANGER

!

DANGER

!

WARNING

!

WARNING

!

Page 34

34 EB 5866 EN

Decommissioning and disassembly

3. Remove the valve from the pipeline (see

section4.2).

9.3 Removing the actuator

from the valve

See associated actuator documentation.

9.4 Disposal

Î Observe local, national, and internation-

al refuse regulations.

Î Do not dispose of components, lubri-

cants, and hazardous substances together with your other household waste.

Page 35

EB 5866 EN 35

Appendix

10 Appendix

10.1 After-sales service

Contact SAMSON's After-sales Service department for support concerning servicing or

repair work or when malfunctions or defects

arise.

E-mail

You can reach the After-sales Service Department at aftersalesservice@samson.de.

Addresses of SAMSONAG and its subsidiaries

The addresses of SAMSON AG, its subsidiaries, representatives, and service facilities

worldwide can be found on the SAMSON

website, in all SAMSON product catalogs or

on the back of these Mounting and Operating Instructions.

Required specications

Please submit the following details:

− Order number and position number in

the order

− Type, model number, nominal size, and

valve version

− Pressure and temperature of the process

medium

− Flow rate in m³/h

− Bench range (e.g. 0.2 to 1bar) or input

signal of the actuator (e.g. 0 to 20mA

or 0 to 10V)

− Is a strainer installed?

− Installation drawing

10.2 Certicates

The declarations of conformity are included

on the next pages.

Page 36

36 EB 5866 EN

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3 60314 Frankfurt a m Main

Telefon: 069 4009-0 · Telefax: 069 400 9-1507

E-Mail: samson@sam son.de

Revison 01

ce_modul_d_de_en_rev01.d ocx

Modul/Module D / N° CE-PED-D-SAM 001-13-DEU

SAMSON erklärt in alleiniger Verantwortung für folgende Produkte/explaines in sole resposibility for the following products:

Geräte/Devices

Bauart/Series

Typ/ Type

Ausführung/Version

Stellgerät für Heiß wasser und Dampf

mit Sicherheitsfunk tion/Safety

Accessories for Hot W ater and Steam

3374 (2000 N)

mit Typ/with Type No. 2811, 2814, 2823, 3 321, 3241, 3267

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-11-0017

Sicherheitsabsperrei nrichtung für

Feuerungsanlagen/

Safety Accessories f or Firing Plants

240 3241

3241-4362,

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-11-0018

240 3241

3241-4364,

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-11-0019

Stellgerät für Heiß wasser und Dampf

mit Sicherheitsfunk tion/

Safety Accessories f or Hot Water and

Steam

240 3241

mit/with 3271,

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-10-0006

240, 3267 3241, 3267

mit/with 3271 und/an d 3277, 240cm²

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-10-0007

240, 3267 3241, 3267

mit/with 3271 und/an d 3277, 350cm²

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-10-0008

240 3241

auch druckentlastet/ also pressure relie ved

mit/with 3271 und/an d 3277

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-10-0009

3274 (1800 N)

mit/with 3241, 2423, 2823, 3267

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-10-0027

3274 (3000 N)

mit/with 3241, 3214, 2814

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-10-0028

Stellgerät für Was ser und Dampf mit

Sicherheitsfunktion/

Safety Accessories f or Water and

Steam

3222, 3213,

2488, 2489,

2487, 2491,

2494, 2495,

2423, 3214

2770

mit/with 3267, 2814, 2823, 2710, 2730

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-09-0008

Sicherheitsabsperrei nrichtung für

Gasbrenner und Gasg eräte/Safety

Accessories for Gas- burners and Gas-

Equipment

240 3241

3241-0261 bis/to 324 1-0275

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-02-0017

Stellgerät zur Leck gasableitung für

Gasbrenner und Gasg eräte/Control

Valve for draining for Gas-burners and

Gas-equipm.

240 3241

3241-4321

Zertifikat-Nr./Certifi cate No.: 01 202 9 31-B-02-0018

die Konformität mit nachfolgender Anforderung/we declare conformity with the demands of the:

Richtlinie

des Europäischen Parla

ments und des Rates zur Harmonisierung der

Rechtsvorschriften der Mitgliedstaaten über die Bereitstellung von Druckgeräten auf dem

Markt/Directive of the European Parliament and oft the Council on the harmonisation of the

laws of the Member States relating to the making available on the market of pressure

equipmentSiehe auch Artikel 41 und 48/See also Article 41 and 48

2014/68/EU

vom/of

15.05.2014

Angewandtes Konformitätsbewertungsverfahren/

Applied Conformity Assessment Procedure

für Fluide nach Art. 4 Abs. 1/for fluids acc. to Article 4, Section 1

Modul D/

Module D

durch/by

Bureau Veritas

0062

Das Qualitätssicherungssystem des Herstellers wird von folgender benannten Stelle überwacht/The Manufacturer’s

Quality Assurance System is monitored by following Notified Body:

Bureau Veritas S. A. nr 0062 67/71, boulevard du Château, 92200 Neuilly-sur-Seine, France

Angewandte technische Spezifikation/Technical Standards used: DIN EN12516-2; DIN EN12516-3; ASME B16.34

Hersteller/Manufacturer: SAMSON AG, Weismüllerstraße 3, 60314 Frankfurt

Frankfurt, 19.07.2016

Klaus Hörschken

Zentralabteilungsleiter / Head of Central Department

Entwicklung Ventile und Antriebe / R&D Valves and Actuators

Günther Scherer

Zentralabteilungsleiter / Head of Central Department

Qualitätsmanagement / Total Quality Management

Page 37

EB 5866 EN 37

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3 60314 Frankfurt a m Main

Telefon: 069 4009-0 · Telefax: 069 400 9-1507

E-Mail: samson@sam son.de

Revison 01

Modul/Module H / N° CE-PED-H-SAM 001-13-DEU

SAMSON erklärt in alleiniger Verantwortung für folgende Typen / explaines in sole resposibility for the following products:

Ventile für elektrische Stellgeräte / Globe and three-way valves equipped with electric actuators

Typ / Type 3213, 3222 (Erz.-Nr. / Model No.. 2710); 3323, 3535 (2803); 3213, 3531 (2811); 3214 (2814); 2423E (2823); 241 (3241); 244

(3244); 267 (3267);

die Konformität mit nachfolgender Anforderung / the conformity with the following requirement.

Richtlinie des Europäischen Parlaments und des Rates zur Harmonisierung der Rechtsvorschriften

der Mitgliedstaaten über die Bereitstellung von Druckgeräten auf dem Markt (siehe auch Artikel 41

und 48).

2014/68/EU vom 15.05.2014

Directive of the European Parliament and oft the Council on the harmonisation of the laws of the

Member States relating of the making available on the market of pressure equipment (see also Article

41 and 48).

2014/68/EU of

15.05.2014

Angewandtes Konformitätsbewertungsverfahren für Fluide nach Art. 4 Abs.1 Pkt. c.i erster

Gedankenstrich.

Modul siehe

Tabelle

durch

certified by

Bureau Veritas

S. A. (0062)

Conformity assessment procedure applied for fluids according to Article 4, Section 1, Subsection c.i,

first indent.

For type of mo-

dule, see table

Nenndruck Nominal

pressure

DN

NPS

15½ 20¾ 251 32

1¼ 401½ 502 65- 803

1004 125- 1506 2008 250

10

300

12

400

16

PN 25

ohne

(1)

A

(2)

H

-

PN 40

ohne

(1)

H

-

Class 150

ohne

(1)

A

(2)

H

-

Class 300

ohne

(1)

H

-

(1) Das auf dem Stellgerät aufgebrachte CE-Zeichen hat keine Gültigkeit im Sinne der Druckgeräterichtlinie

The CE marking affixed to the control device does not refer to the Pressure Equipment Directive.

(2) Das auf dem Stellgerät aufgebrachte CE-Zeichen gilt ohne Bezeichnung der Notifizierten Stelle (Kennr. 0062)

The CE marking affixed to the control device is valid, but does not refer to the notified body (ID No. is invalid).

Geräte, denen laut Tabelle das Konformitätsbewertungsverfahren Modul H zugrunde liegt, beziehen sich auf die

„Zulassungsbescheinigung eines Qualitätssicherungssystems“ ausgestellt durch die Notifizierte Stelle.

The module H conformity assessment procedure applied to the valves according to the table is based on the “Certificate of

Quality System Approval” issued by the notified body.

Dem Entwurf zu Grunde gelegt sind Verfahren aus: / The design is based on the methods of:

DIN EN 12516-2, DIN EN 12516-3 bzw. / respectively ASME B16.24, ASME B16.34, ASME B16.42

Das Qualitätssicherungssystem des Herstellers wird von folgender benannter Stelle überwacht

The Manufactur`s Quality Assurance System is monitored by following Notifed Body

Bureau Veritas S.A. nr 0062 67/71, boulevard du Chateau, 92200 Neuilly-sur-Seine, France

Hersteller / Manufacturer: SAMSON AG / Weismüllerstraße 3 / 60314 Frankfurt

Frankfurt am Main, den 19.07.2016

Klaus Hörschken Günther Scherer

Zentralabteilungsleiter / Head of Central Department Zentralabteilungsleiter / Head of Central Department

Entwicklung Ventile und Antriebe / Development Valves and Actuators Total Quality Management / Total Quality Management

Page 38

38 EB 5866 EN

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3 60314 Frankfurt a m Main

Telefon: 069 4009-0 · Telefax: 069 400 9-1507

E-Mail: samson@sam son.de

Revison 01

Modul/Module H / N° CE-PED-H-SAM 001-13-DEU

SAMSON erklärt in alleiniger Verantwortung für folgende Typen / explaines in sole resposibility for the following products:

Ventile für elektrische Antriebe / Globe and three-way valves equipped with electric actuators

Typ / Type 3213, 3222 (Erz.-Nr. / Model No. 2710); 3226, 3260* (2713*); 3323, 3535 (2803); 3213, 3531 (2811); 3214 (2814); 2423E (2823);

241 (3241); 244 (3244); 267 (3267)

die Konformität mit nachfolgender Anforderung / the conformity with the following requirement.

Richtlinie des Europäischen Parlaments und des Rates zur Harmonisierung der Rechtsvorschriften

der Mitgliedstaaten über die Bereitstellung von Druckgeräten auf dem Markt (siehe auch Artikel 41

und 48).

2014/68/EU vom 15.05.2014

Directive of the European Parliament and oft the Council on the harmonisation of the laws of the

Member States relating of the making available on the market of pressure equipment (see also Article

41 and 48).

2014/68/EU of

15.05.2014

Angewandtes Konformitätsbewertungsverfahren für Fluide nach Art. 4 Abs.1 Pkt. c.ii und Pkt. c.i

zweiter Gedankenstrich.

Modul siehe

Tabelle

durch

certified by

Bureau Veritas

S. A. (0062)

Conformity assessment procedure applied for fluids according to Article 4, Section 1 Subsection c.ii

and Subsection c.i second indent.

For type of mo-

dule, see table

Nenndruck Nominal

pressure

DN

NPS

15½ 20¾ 251 32

1¼ 401½ 502

65

803 1004 125

1506 2008 250

10

300

12

400

16

PN 16

ohne/without

(1)

A

(2)

H

PN 25

ohne/without

(1)

A

(2)

H

-

PN 40

ohne/without

(1)

A

(2)

H

-

Class 150

ohne/without

(1)

A

(2)

H

-

Class 300

ohne/without

(1)

A (2) H

-

(1) Das auf dem Stellgerät aufgebrachte CE-Zeichen hat keine Gültigkeit im Sinne der Druckgeräterichtlinie

The CE marking affixed to the control device does not refer to the Pressure Equipment Directive.

(2) Das auf dem Stellgerät aufgebrachte CE-Zeichen gilt ohne Bezeichnung der Notifizierten Stelle (Kennr. 0062)

The CE marking affixed to the control device is valid, but does not refer to the notified body (ID No. is invalid).

* Für Ventile vom Typ 3260 sind ab DN 150 Fluide nach Art. 4 Abs.1 Pkt. c.ii erster Gedankenstrich nicht zugelassen.

Fluids according to Art. 4, Section 1, Subsection c.ii, first indent are not permissible for Type 3260 Valves with DN equal or bigger than 150.

Geräte, denen laut Tabelle das Konformitätsbewertungsverfahren Modul H zugrunde liegt, beziehen sich auf die

„Zulassungsbescheinigung eines Qualitätssicherungssystems“ ausgestellt durch die Notifizierte Stelle.

The module H conformity assessment procedure applied to the valves according to the table is based on the “Certificate of

Quality System Approval” issued by the notified body.

Dem Entwurf zu Grunde gelegt sind Verfahren aus: / The design is based on the methods of:

DIN EN 12516-2, DIN EN 12516-3 bzw. / respectively ASME B16.1, ASME B16.24, ASME B16.34, ASME B16.42

Das Qualitätssicherungssystem des Herstellers wird von folgender benannter Stelle überwacht

The Manufactur`s Quality Assurance System is monitored by following Notifed Body

Bureau Veritas S.A. nr 0062 67/71, boulevard du Chateau, 92200 Neuilly-sur-Seine, France

Hersteller / Manufacturer: SAMSON AG / Weismüllerstraße 3 / 60314 Frankfurt

Frankfurt am Main, den 19.07.2016

Klaus Hörschken Günther Scherer

Zentralabteilungsleiter / Head of Central Department Zentralabteilungsleiter / Head of Central Department

Entwicklung Ventile und Antriebe / Development Valves and Actuators Total Quality Management / Total Quality Management

Page 39

EB 5866 EN 39

Page 40

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

samson@samson.de · www.samson.de

EB 5866 EN

2017-05-16 · English

Loading...

Loading...