Page 1

Electric Control Valves/

Controller with Electric Actuator

Type 3222/5724, Type 3222/5725 and Type 3222/5757

Type 3222/5725 Globe Valve mounted on

Controller with Electric Actuator

Type 3222/5757 Globe Valve mounted on

Controller with Electric Actuator

Mounting and

Operating Instructions

EB 5766 EN

Edition July 2008

Page 2

Contents

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . 4

1.1 Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.2 Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3 Additional installation instructions . . . . . . . . . . . . . . . . . . . . 9

3 Attaching the actuator to the valve . . . . . . . . . . . . . . . . . . 10

3.1 Type 5757/-7 Controller with Electric Actuator . . . . . . . . . . . . . 10

3.2 Type 5724/5725 Controller with Electric Actuator . . . . . . . . . . . 10

4 Electrical connections . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Type 5757-7 Controller with Electric Actuator. . . . . . . . . . . . . . 11

4.2 Type 5757 Controller with Electric Actuator. . . . . . . . . . . . . . . 11

4.3 Type 5724/5725 Controller with Electric Actuator . . . . . . . . . . . 12

5 Manual override . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Type 5757/-7 Controller with Electric Actuator . . . . . . . . . . . . . 13

5.2 Type 5724/5725 Controller with Electric Actuator . . . . . . . . . . . 13

6 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

7 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

8 Dimensions in mm and weights . . . . . . . . . . . . . . . . . . . . 16

9 Appendix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

9.1 Wiring for Type 5757-7 . . . . . . . . . . . . . . . . . . . . . . . . 18

9.2 Wiring for Type 5757 . . . . . . . . . . . . . . . . . . . . . . . . . 20

9.3 Wiring for Type 5724/5725 . . . . . . . . . . . . . . . . . . . . . 22

2 EB 5766 EN

Typetest

The Type 5725 Controller with Electric Actuators with safety function used in

conjunction with Type 3222 Valves are typetested according to DIN 32730

by the German technical inspectorate TÜV.

Register number available on request.

Page 3

General safety instructions

General safety instructions

The control valves may only be mounted, started up or serviced by fully

4

trained and qualified personnel, observing the accepted industry codes and

practices. Make sure employees or third persons are not exposed to any

danger.

All safety instructions and warnings in these mounting and operating

instructions, particularly those concerning assembly, start-up and

maintenance, must be observed.

The control valves fulfill the requirements of the European Pressure Equip

4

ment Directive 97/23/EC. Valves with a CE marking have a declaration of

conformity which includes information about the applied conformity assess

ment procedure. The declaration of conformity is available on request.

For appropriate operation, make sure that the control valve is only used in

4

applications where the operating pressure and temperature do not exceed

the operating values which are based on the valve sizing data submitted in

the order.

The manufacturer does not assume any responsibility for damage caused by

external forces or any other external influence!

Any hazards which could be caused in the control valve by the process

medium, the operating pressure, the signal pressure or by moving parts are

to be prevented by means of the appropriate measures.

Proper shipping and appropriate storage of the control valve are assumed.

4

-

-

Caution!

For installation and maintenance, make sure the relevant section of the

4

pipeline is depressurized and, depending on the process medium, drained

as well. If necessary, allow the control valve to cool down or warm up to

reach ambient temperature prior to starting any work on the valve.

The electric actuators have been designed for use in electrical power

4

installations. For wiring and maintenance, you are required to observe the

relevant safety regulations.

Only use power interruption devices which are protected against

4

unintentional reconnection of the power supply.

Take special care when making adjustments on live parts. Do not remove

4

any covers!

EB 5766 EN 3

Page 4

Design and principle of operation

1 Design and principle of

operation

The control valves consist of a single-seated

Type 3222 Globe Valve and either a

Type 5757, Type 5757-7 or Type 5724

Controller with Electric Actuator or a Type

5725 Controller with Electric Actuator with

safety function.

The process medium flows through the globe

valve in the direction indicated by the arrow

on the body. The position of the valve plug

determines the flow rate over the cross-sec

tional area of flow released between the

plug (3) and valve seat (2). The plug stem

(4) with plug is connected with the stem of

the actuator (10) by a force-locking connection. The valve is opened by the valve spring

(5) following the retracting movement of the

actuator stem. A special version is required

for water above 150 °C and for steam

(Fig. 1). The plug is moved by a change in

the control signal acting on the actuator.

The electric actuator with safety function

(Type 5725) has a spring mechanism and

an electromagnet that can be connected to a

safety control circuit. When the control cir

cuit is interrupted or the power supply fails,

the magnet disengages the gear from the

self-locking motor and releases the spring

mechanism. The valve is closed in the event

of a safety situation (fail-safe action

“actuator stem extends”).

The electric actuators contain a digital con

troller integrated into the actuator. The con

trolled variable is recorded over the directly

connected Pt 1000 sensor (see Table 2).

The output signal of the digital controller

acts as a three-point stepping signal on the

-

-

-

synchronous motor of the actuator and is

transferred over the connected gear as a

positioning force onto the actuator stem.

The Type 5757, Type 5724 and Type 5725

are particularly suitable for DHW heating in

instantaneous heating systems and for fixed

set point control circuits in mechanical engi

neering applications.

Type 5757-7 is suitable for heating applica

tions.

1.1 Versions

PN DN EB

Electric control valve/Controller with electric

actuator

Type 3222/5757

Type 3222/5757-7

Type 3222/5724

… with safety function

Type 3222/5725

1)

Refer to the listed Mounting and Operating

Instructions (EB) for details on the controllers

with electric actuators

2)

Controller with electric actuator for domestic

hot water heating in instantaneous heating

systems and for fixed set point control circuits

in mechanical engineering applications

3)

Controller with electric actuator for heating

applications

-

2)

25 15 to 25 5757

3)

25 15 to 25 5757-7

2)

25 15 to 50 5724

2)

25 15 to 50 5724

-

-

1)

4 EB 5766 EN

Page 5

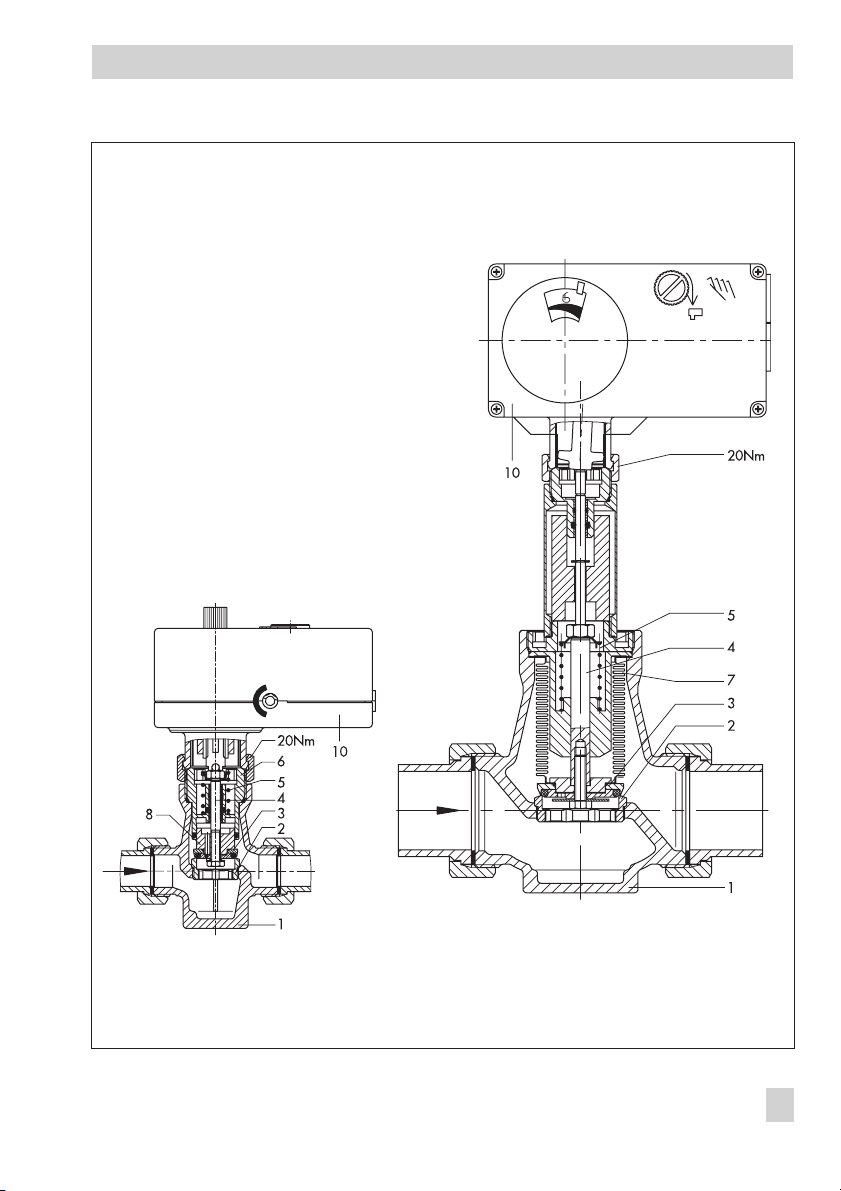

1 Valve body

2 Seat

3 Plug

4 Plug stem

5 Valve spring

6 Guide nipple

7 Balancing bellows

8 Balancing piston

10 Controller with electric

actuator

Design and principle of operation

Type 3222/5757

Fig. 1 · Type 3222/5757 and Type 3222/5724 Electric Control Valves/Controller with Electric Actuator

Special version for temperatures up to 200 °C and

Type 3222/5724

with plug balanced by a bellows

EB 5766 EN 5

Page 6

Design and principle of operation

1.2 Technical data

1. Single-seated Type 3222 Globe Valve

Nominal size DN 15 20 25 32 40 50

Version with threaded ends

Thread size G ½¾1 –––

Version with female thread • • • – – –

Nominal pressure PN 25

Seat/plug sealing Metal sealing for K

Rated travel mm 6 12

Rangeability 50 : 1

Leakage class acc. to DIN EN 1349 Class I (< 0.05 % of K

Version for water, oil and other liquids

Max. permissible temperature 150 °C

Max. permissible differential pressureΔp in bar

Types 5724 and 5725 20 12

Type 5757 20 –

Version for water and steam

Max. permissible temperature 200 °C

Max. permissible differential pressureΔp in bar

Types 5724 and 5725 20 · 10 for 3.6≤K

Type 5757 20

Materials

Valve body Red brass CC491K · EN-JS1049 (flanged body)

Seat Stainless steel 1.4104

Plug 1.4104/CW509L with soft sealing · 1.4104 for 0.1≤K

Valve spring Stainless steel 1.4310 K

Packing EPDM/FPM (FKM) · Oil-resistant version: FPM

Welding ends St 37

Threaded ends Red brass CC491K

Screwed-on flanges St 37.2

with flanges

as flanged body

••••••

2.5 · Soft sealing for K

≤

VS

coefficient)

VS

1, 2)

88

≤

3)

4)

· 5

VS

5–

3.6

≥

VS

2.5

≤

VS

6 EB 5766 EN

Page 7

Design and principle of operation

Nominal size DN 15 20 25 32 40 50

Thread size G ½¾1–––

coefficients

K

VS

Version with female thread 3.6 5.7 7.2 – – –

Version with male thread 4 6.3 8 16 20 25

Reduced K

coefficients

VS

0.1· 0.16 · 0.25 · 0.4

0.63 · 1.0 · 1.6 · 2.5

Rated travel mm 6 12

1)

Use an intermediate insulating piece for temperatures above 130 °C to protect the actuator

2)

DN 15 to 25 with Type 5757 Actuator:

Use an intermediate insulating piece for temperatures above 110 °C to protect the actuator

3)

Differential pressure for KVS= 1 and 1.6

4)

Differential pressure for KVS= 2.5 and 4

5)

Version with male thread

6)

Version with female thread

1.0 · 1.6 · 2.5

5)

6)

· 3.6

4

–––

EB 5766 EN 7

Page 8

Design and principle of operation

2. Controllers with electric actuators

Type

Nominal size DN 15 to 25 15 to 25 15 to 25 32 to 50 15 to 25 32 to 50

Scope of application Heating

Safety function Without Without With

Rated travel mm 6 6 6 12 12 6 6 12 12

Transit time for rated travel s 20 35 18 70 35 35 18 70 35

Transit time upon fail-safe

action

s – – 4466

Fail-safe action – – Stem extends

Nominal thrust kN 0.3 0.7 0.5

Manual override Yes Yes Possible

Power supply 230 V (±10 %), 50 Hz

Power consumption approx. VA 3 3 37375959

Permissible temperatures

Ambient °C 0 to 50 0 to 50 0 to 50

Storage °C –20 to 70 –20 to 70 –20 to 70

At connecting rod °C 0 to 110 0 to130 0 to 130

Degree of protection IP 42 IP 54 (upright position, acc. to DIN IEC 529)

Inputs and outputs of the digital controller

Temperature sensor Pt 1000 3 x 1 x 1 x 1 x

Setting range °C 1 to 150 0 to 150 1 to 150 1 to 150

Potentiometer input

1100/2000

Water flowmeter input – 530 pulses/l 530 pulses/l 530 pulses/l

Current input – 4 (0) to20 mA 4 (0) to 20 mA 4 (0) to 20 mA

Binary input BE1

Binary input BE2

2)

2)

Op. mode

switchover

230 V/50 Hz

Binary output BA

Cir. pump/Ex

ternal demand

1)

Manual override using a 4 mm hex screwdriver (after removing the housing cover);

always returns to fail-safe position after safety release.

2)

Recommendation for Type 5724, Type 5725 and Type 5757: With gold contacts

5757 5724 5725

5757-7 5757 -10 -13 -20 -23 -10 -13 -20 -23

DHW heating in instantaneous heating systems,

fixed set point control circuits in mechanical engineering

1)

1000 to

Ω

–– –

Switching between internal set points/

Deactivation of function to maintain temperature constant

– Flow switch

-

–– –

8 EB 5766 EN

Page 9

2 Installation

Caution!

Versions designed to handle temperatures

up to 200 °C must be fitted with the dark

gray graphite supplied with the valve. Do

not use the UDP seals available as accesso

ries as they are only suitable for tempera

tures up to 150 °C.

-

Installation

Install a strainer (SAMSON Type 2 NI)

4

upstream of the control valve to prevent

any sealing parts, weld spatter or other

foreign matter carried along by the pro

cess medium from impairing the proper

functioning of the valve, in particular, the

-

tight shut-off.

The valve must be installed free of stress.

4

If necessary, support the piping near the

connections.

-

2.1 Mounting position

Choose the place of installation where

4

the ambient temperature does not ex

ceed or fall below the permissible limits

specified for the actuator and that allows

you to freely access the control valve

even after the entire plant has been completed.

Flush the pipeline thoroughly before in-

4

stallation.

Do not install the valve with the actuator

4

suspended downwards.

Install versions for water and steam up to

200 °C with the actuator installed up

right in a horizontal pipeline.

If you wish to insulate the control valve,

4

install an intermediate insulating piece

between valve and actuator. Make sure

the insulation ends 25 mm above the

valve body. Do not insulate the actuator

and coupling nut as well.

2.2 Strainer

Install the strainer with the filter element

4

-

facing downwards upstream of the valve

inlet.

Choose the place of installation to allow

4

enough space to remove the filter.

Install the strainer with the direction of

4

flow as indicated by the arrow on the

body.

2.3 Additional installation

instructions

-

We recommend to install a hand-operated

shut-off valve both upstream of the strainer

and downstream of the control valve to be

able to shut down the plant for cleaning and

maintenance, and when the plant is not

used for longer periods of time.

EB 5766 EN 9

Page 10

Attaching the actuator to the valve

3 Attaching the actuator to the

valve

If the actuator has not already been

mounted on the valve by the manufacturer

or when the original actuator on a valve is

to be replaced with a controller with electric

actuator, proceed as follows.

Note!

Fasten the actuator and valve together either

at the valve connection or at the intermedi

ate insulating piece, depending on the valve

version, with a tightening torque of 20 Nm.

-

3.1 Type 5757/-7 Controller

with Electric Actuator

1. Turn the handwheel (see section 5.1)

counterclockwise when the actuator is

disconnected from the power supply to

retract the actuator stem as far as it will

go.

2. Place the actuator on the connection

piece and secure with the coupling nut.

3.2 Type 5724/5725 Controller

with Electric Actuator

Type 5724

1. Turn the handwheel (see section 5.2)

counterclockwise to retract the actuator

stem as far as it will go.

2. Place the actuator on the connection

piece and secure with the coupling nut.

Type 5725 with fail-safe action “Actuator

stem extends”

1. Unfasten the front cover and place a

4 mm hex screwdriver on the actuator

stem (see section 5.2).

2. Turn the screwdriver counterclockwise

only and only until the travel final value

is reached at the maximum, which activates the bottom torque switch.

Caution!

Turning the actuator too far will destroy

it.

10 EB 5766 EN

3. Hold the screwdriver in place. Secure the

actuator and connection piece with the

coupling nut.

4. Remove screwdriver and carefully

refasten the front cover.

Page 11

Electrical connections

4 Electrical connections

Upon installing the electrical cables,

you are required to observe the regula

tions concerning electrical power in

stallations according to DIN VDE 0100

as well as the regulations of your local

power supplier.

Use a suitable power supply to ensure

that no dangerous voltages from the

system or parts of the system reach the

device in standard operation or in case

of a fault.

Warning!

Only connect the device to the main

power network when the power is

switched off. Make sure the power

cannot be switched on unintentionally!

Perform the electrical wiring as required

4

depending on the application (refer to

section 4.1 to 4.3).

As soon as the actuator is connected to the

power supply, the initialization procedure

starts:

The actuator stem extends and the red and

yellow LEDs located under the cover on top

of the actuator light up. As soon as the actu

ator stem has reached the final position, the

red LED is turned off. The yellow LED re

mains illuminated and indicates that the

controller with electric actuator is ready for

operation.

4.1 Type 5757-7 Controller with

Electric Actuator

Heating application: The controller with

-

electric actuator requires a Pt 1000 temper

-

ature sensor to be connected to measure the

flow temperature. Depending on the control

task, an outdoor sensor or a room sensor or

a room panel can be connected. Combining

one of these sensors with a return flow sen

sor is usually possible. Additionally, the con

troller with electric actuator has a potenti

ometer input 1000 to 1100/2000Ω. The

non-floating pump output can alternatively

be used as an binary output for an external

request for heat demand.

The default setting (WE) is configured for an

application with a flow sensor, outdoor sensor and return flow sensor as well as with

an active binary input to switchover the operating modes (see Fig. 2).

-

-

-

-

4.2 Type 5757 Controller with

Electric Actuator

Domestic hot water heating in instanta

neous heating system: The controller with

electric actuator requires a Pt 1000 temper

ature sensor to be connected for it to func

-

tion. Two set points W1 and W2 can be

used for control. A binary input BE1 is used

-

to switch between them.

In addition, a water flowmeter or a flow

switch can be connected to quickly recog

nize when hot water is being tapped.

The 0(4) to 20 mA current input can be used

in place of the Pt 1000 sensor for control

purposes.

-

-

-

-

EB 5766 EN 11

Page 12

Electrical connections

The default setting (WE) is configured for an

application with a Pt 1000 flow temperature

sensor and water flowmeter (see Fig. 3).

4.3 Type 5724/5725 Controller

with Electric Actuator

Domestic hot water heating in instanta

neous heating system: The electric wiring

options are the same as for the Type 5757

Controller with Electric Actuator, (see

section 4.2). In addition, the pump control

output can be configured as a fault alarm

output.

The default setting (WE) is configured for an

application of the electric actuator with a

Pt 1000 flow temperature sensor, water

flowmeter and pump control output (see

Fig. 4).

-

VS

Pt 1000

or ye rd br blk gr br bl blk

Fig. 2 · Wiring of Type 5757-7 (default)

blk black

bl blue

br brown

Pt 1000

ASRüS

Pt 1000

Pt 1000

34 6521LL´N

* Caution! Live wires!

gr green

or orange

1)

230 V, 50 Hz

rd red

ye yellow

230V, 50Hz

*

Note!

Refer to the appendix of these instructions

for other possible circuits with the necessary

configuration settings or refer to the Mount

ing and Operating Instructions

EB 5757-7 EN, EB 5757 EN and

EB 5724 EN of the corresponding controller

with electric actuator.

12 EB 5766 EN

5V GND L N

or ye rd br gr blk

-

Fig. 3 · Wiring of Type 5757 (default)

1)

Water flowmeter

3)

Pump control output or fault alarm output

4)

Electromagnet, Type 5725 only

3)

230V, 50Hz

LL1 N 5V INS1 S2

4)

Fig. 4 · Wiring of Type 5724/5725 (default)

Pt 1000

1)

S1

Page 13

Manual override

5 Manual override

The direction of action and travel can be

read off the travel indication scale.

5.1 Type 5757/-7 Controller

with Electric Actuator

Caution!

Only activate the handwheel when the actu

ator is disconnected from the power supply.

Turn handwheel clockwise to extend the

4

actuator stem

Turn handwheel counterclockwise to

4

retract the actuator stem

5.2 Type 5724/5725 Controller

with Electric Actuator

Type 5724

Adjust the travel by turning the handwheel

(approx. 4 turns for 1 mm travel):

Turn clockwise to extend the actuator

4

stem

Turn counterclockwise to retract the

4

actuator stem

Type 5725

Caution!

The actuator is live!

1. Undo the front cover and place a 4 mm

hex screwdriver onto the red actuating

shaft.

2. Turn the screwdriver counterclockwise

-

only, and only until the travel final value

is reached at the maximum, which acti

vates the bottom torque switch (switching

off the motor).

Caution!

Turning the actuator too far will destroy

it.

After the fail-safe action has been triggered by the magnet, the spring mechanism pushes the actuator stem out and the

valve always move to its fail-safe position.

3. Remove screwdriver and carefully

refasten the front cover.

-

Handwheel

Travel indication

Fig. 5 · Manual override of Type 5757/-7, Type 5724 and Type 5725 (from left to right)

Travel indication Travel indication

Handwheel

Handwheel

EB 5766 EN 13

Page 14

Operation

6 Operation

The controllers with electric actuators are

adapted to the required control task by

configuration and parameterization per

formed in TROVIS-VIEW Operator Interface:

Type 5757-7: TROVIS-VIEW

4

6661-1066

Type 5757: TROVIS-VIEW 6661-1062

4

Type 5724 and Type 5725: TROVIS-

4

VIEW 6661-1060

Note!

Instructions on how to operate the

TROVIS-VIEW Operator Interface as well as

on the function and parameter settings are

contained in the Mounting and Operating

Instructions EB 5757-7 EN, EB 5757 EN

and EB 5724 EN for the corresponding controller with electric actuator.

-

14 EB 5766 EN

Page 15

7 Maintenance

The control valve is subject to natural wear.

Depending on the conditions the valve is op

erated in, it needs to be checked at regular

intervals.

If leakage to the atmosphere occurs, remove

the valve from the pipeline and replace the

damaged parts.

Warning!

For maintenance work on the valve,

make sure the relevant section of the

pipeline is depressurized and,

depending on the process medium,

drained as well.

For high medium temperatures, allow

the section of the pipeline to cool down

before you start.

Make sure the control signal for the

actuator is switched off.

Maintenance

-

EB 5766 EN 15

Page 16

Dimensions in mm and weights

8 Dimensions in mm and weights

Nominal size DN 15 20 25 32 40 50

Thread size G ½¾1 –––

Pipe Ød 21.3 26.8 33.7 42 48 60

Threadsize RG ¾ G 1G1¼G1¾G 2G2½

Width across flats SW 30 36 46 59 65 82

Length L 65 70 75 100 110 130

Length with welding ends L1 210 234 244 268 294 330

Height H2 45.5 94

Versions for temperatures up to 200 °C

and with intermediate insulating piece

Height H3 30 55

Weight without actuator approx. kg 1.4 1.8 2.3 4.0 4.4 6.8

Versions for temperatures up to 200 °C

and with intermediate insulating piece

Version with threaded ends (male thread)

Length L2 129 144 159 180 196 228

Male thread A G ½ G ¾ G 1 G1¼ G 1½ G 2

Weight without actuator approx. kg 1.4 1.8 2.3 4.0 4.4 6.8

Versions for temperatures up to 200 °C

and with intermediate insulating piece

Version with flanges

Length L3 130 150 160 180 200 230

Weight without actuator approx. kg 2.5 3.4 4.1 6.9 7.7 10.7

Versions for temperatures up to 200 °C

and with intermediate insulating piece

Version with female thread

Length L4 65 75 90 –

Female thread G G ½ G ¾ G 1 –

Weight without actuator approx. kg 1.2 1.4 1.5 –

Versions for temperatures up to 200 °C

and with intermediate insulating piece

Version with flanged valve body

Height H2 45.5 94

Length L3 130 150 160 180 200 230

Weight without actuator approx. kg 2.5 3.4 4.1 6.9 8.4 11.6

Versions for temperatures up to 200 °C

and with intermediate insulating piece

1.9 2.3 2.8 4.5 4.9 7.3

1.9 2.3 2.8 4.5 4.9 7.3

3.0 3.9 4.6 7.4 8.2 11.2

1.7 1.9 2.0 –

3.0 3.9 4.6 7.4 8.9 12.1

140 185

16 EB 5766 EN

Page 17

Dimensions in mm and weights

Weights of controllers with electric actuators

Type 5757/-7 5724 5725

Weight without valve, approx. kg 0.7 1.1 1.3

Intermediate

insulating piece

Type 3222/5757(-7),

only up to DN 25

Types 3222/5724

Types 3222/5725

Version with

flanges

Version with

threaded ends

Fig. 6 · Top: Valve dimensions (version with welding ends) · Bottom: Other valve versions

Flanged valve

body version

Version with

female thread

EB 5766 EN 17

Page 18

Appendix

9 Appendix

9.1 Wiring for Type 5757-7 (refer to EB 5757-7 EN)

Note! The pump output L´ is non-floating (230 V~).

Note: Terminals at point of installation, not included in scope of delivery

blk black · bl blue · br brown · gr green · or orange · rd red · ye yellow

Application with flow, return flow, and outdoor

sensors as well as binary input to switch between

operating modes = Default setting (WE)

Functions WE Configuration

Control w. reference variable 1 F01 - 1

Outdoor sensor 0 F02 - 0

Potentiometer/binary input 0 F05 - 0

BA as pump control output 0 F09 - 0

Return flow sensor 1 F11 - 1

VS

Pt 1000

or ye rd br blk gr br bl blk

ASRüS

Pt 1000

Pt 1000

34 6521LL´N

230 V, 50 Hz

Application with flow sensor and outdoor sensor

Functions WE Configuration

Control w. reference variable 1 F01 - 1

Outdoor sensor 0 F02 - 0

BA as pump control output 0 F09 - 0

Diagram abbreviations:

VS Flow sensor · RüS Return flow sensor · AS Outdoor sensor

18 EB 5766 EN

VS

Pt 1000

or ye rd br blk gr br bl blk

AS

Pt 1000

34 6521LL´N

230 V, 50 Hz

Page 19

Application with flow, return flow, and outdoor

sensors as well as a potentiometer for adjusting the set

points

Functions WE Configuration

Control w. reference variable 1 F01 - 1

Outdoor sensor 0 F02 - 0

Potentiometer/binary input 0 F05 - 1

Remote adjuster 0 F06 - 1

BA as pump control output 0 F09 - 0

Return flow sensor 1 F11 - 1

Application with flow, return flow, and room sensors

with operating mode switchover and set point adjuster

Functions WE Configuration

Control w. reference variable 1 F01 - 1

Room sensor 0 F02 - 1

Potentiometer/binary input 0 F05 - 1

Type 5257-7 Room Panel 0 F06 - 0

BA as pump control output 0 F09 - 0

Return flow sensor 1 F11 - 1

Appendix

VS

Pt 1000

or ye rd br blk gr br bl blk

VS

Pt 1000

or ye rd br blk gn br bl blk

ASRüS

Pt 1000

RüS

Pt 1000

21LL´N

Pt 1000

34 6521LL´N

Type 5257-7

Room Panel

1432

34 65

100/

1000 Ω

1000 Ω

230 V, 50 Hz

230 V, 50 Hz

EB 5766 EN 19

Page 20

Appendix

9.2 Wiring for Type 5757 (refer to EB 5757 EN)

Note: Terminals at point of installation, not included in scope of delivery

1)

Water flowmeter

2)

Flow switch

blk black · bl blue · br brown · gr green · or orange · rd red · ye yellow

Operation with Pt 1000 sensor and water flowmeter

= Default setting (WE)

Functions WE Configuration

Hot water tapping recognition 1 F01 - 1

Water flowmeter 1 F02 - 1

Current input 0 F05 - 0

Pt 1000

or ye rd br gr blk

1)

5V GND L N

230V, 50Hz

Operation with Pt 1000 sensor

Functions WE Configuration

Hot water tapping recognition 1 F01 - 0

Current input 0 F05 - 0

Operation with Pt 1000 sensor and binary contact for

switching between set points

Functions WE Configuration

Hot water tapping recognition 1 F01 - 0

Current input 0 F05 - 0

Binary input function 0 F08 - 1

20 EB 5766 EN

Pt 1000

5V GND L N

or ye rd br gr blk

Pt 1000

BE1

5V GND L N

or ye rd br gr blk

230V, 50Hz

230V, 50Hz

Page 21

Operation with Pt 1000 sensor and flow switch

Functions WE Configuration

Hot water tapping recognition 1 F01 - 1

Flow switch 1 F02 - 0

Current input 0 F05 - 0

Operation with Pt 1000 sensor and external set point

over an mA signal

Functions WE Configuration

Hot water tapping recognition 1 F01 - 0

Current input 0 F05 - 0

Current input function 0 F06 - 1

Pt 1000

or ye rd br gr blk

+ 4(0)...20mA –

Pt 1000

or ye rd br gr blk

2)

BE2

5V GND L N

5V GND L N

Appendix

230V, 50Hz

230V, 50Hz

Operation with mA signal input

Functions WE Configuration

Hot water tapping recognition 1 F01 - 0

Current input 0 F05 - 0

Current input function 0 F06 - 0

+ 4(0)...20mA –

230V, 50Hz

5V GND L N

or ye rd br gr blk

EB 5766 EN 21

Page 22

Appendix

9.3 Wiring for Type 5724/5725 (refer to EB 5724 EN)

1)

Water flowmeter

2)

Flow switch

3)

Pump control output or fault alarm output

4)

Electromagnet, Type 5725

Domestic hot water heating in instantaneous heating system

Operation with Pt 1000 sensor und water flowmeter

= Default setting (WE)

Functions WE Configuration

Hot water tapping recognition 1 F01 - 1

Water flowmeter 1 F02 - 1

Current input 0 F05 - 0

Operation with Pt 1000 sensor

Functions WE Configuration

Hot water tapping recognition 1 F01 - 0

Current input 0 F05 - 0

3)

230V, 50Hz

LL1 N 5V INS1 S2

4)

3)

230V, 50Hz

LL1 N 5V INS1 S2

Pt 1000

Pt 1000

1)

S1

S1

Operation with Pt 1000 sensor and binary contact for

switching between set points

Functions WE Configuration

Hot water tapping recognition 1 F01 - 0

Current input 0 F05 - 0

Binary input function 0 F08 - 1

22 EB 5766 EN

4)

3)

230V, 50Hz

LL1 N 5V INS1 S2

4)

Pt 1000

BE1

S1

Page 23

Operation with Pt 1000 sensor and

flow switch

Functions WE Configuration

Hot water tapping recognition 1 F01 - 1

Flow switch 1 F02 - 0

Current input 0 F05 - 0

Mechanical engineering applications

Operation with Pt 1000 sensor and external set point

over an mA signal input

Functions WE Configuration

Hot water tapping recognition 1 F01 - 0

Current input 0 F05 - 0

Current input function 0 F06 - 1

3)

230V, 50Hz

LL1 N 5V INS1 S2

4)

3)

230V, 50Hz

LL1 N 5V INS1 S2

4)

Pt 1000

S1

+–4(0) ... 20mA

Pt 1000

S1

BE2

Appendix

2)

Operation with mA sensor input

Functions WE Configuration

Hot water tapping recognition 1 F01 - 0

Current input 0 F05 - 0

Current input function 0 F06 - 0

3)

230V, 50Hz

LL1 N 5V INS1 S1S2

4)

+–4(0) ... 20mA

EB 5766 EN 23

Page 24

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 5766 EN

2008-11

Loading...

Loading...