Page 1

Flow and Temperature Regulator

Type 2469/2430 K

Mounting and

Operating Instructions

EB 3132-2 EN

Edition November 2011

Fig. 1 · Type 2469/2430 K

Page 2

2 EB 3132-2 EN

Contents

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . . . . 4

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.1 Strainer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.1.2 Additional installation instructions . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Installing the temperature sensor . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.1 Capillary tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Mounting the thermostat . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Set point adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.1 Flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2.2 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4 Maintenance – Replacing parts . . . . . . . . . . . . . . . . . . . . . . . 8

4.1 Cleaning or replacing the plug . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 Replacing the diaphragm . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

6 Description of the nameplate . . . . . . . . . . . . . . . . . . . . . . . . 11

7 Customer inquiries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8 Dimensions in mm and weights . . . . . . . . . . . . . . . . . . . . . . 12

CAUTION!

indicates a hazardous situation which, if not

avoided, may result in injury.

NOTICE

indicates a property damage message.

Note: Supplementary explanations, informa

-

tion and tips

Definitions of the signal words used in these instructions

Page 3

EB 3132-2 EN 3

Safety instructions

General safety instructions

4

The regulator is to be mounted, started up or serviced by fully trained and

qualified personnel only, observing the acceptedindustry codes andpractices.

Make sure employees or third persons are not exposed to any danger.

All safety instructions and warnings in these mounting and operating instruc

tions, particularly those concerning assembly, start-up and maintenance, must

be observed.

4

According to these mounting and operating instructions, trained personnel is

referred to as individuals who are able to judge the work they are assigned to

and recognize possible dangers due to their specialized training, their knowl

edge and experience aswell as their knowledgeof theapplicable standards.

4

The regulator fulfils the requirements of the European Pressure Equipment Di

rective 97/23/EC. Valves with a CE marking have a declaration of conformity

that includes information aboutthe appliedconformity assessment procedure.

The declaration of conformity is available on request.

4

For appropriate operation, make sure that the regulator is only used in areas

where the operating pressure and temperatures do not exceed the operating

values specified in the order that the valve sizing data are based on.

The manufacturer does not assume any responsibility for damage caused by

external forces or any other external influence!

Any hazards that could be caused in the regulator by the process medium, the

operating pressure or by moving parts are tobe preventedby meansof theappropriate measures.

4

Proper shipping and storage are assumed.

Note! Non-electric actuator and valve versions do not have their own potential ig

-

nition source according to the risk assessment stipulated in EN 13463-1:2009,

section 5.2, even in the rare incident of an operating fault. Therefore, such valve

versions do not fall within the scope of Directive 94/9/EC. For connection to the

equipotential bonding system, observe section 6.3 of EN 60079-14:2008

VDE 0165-1.

Page 4

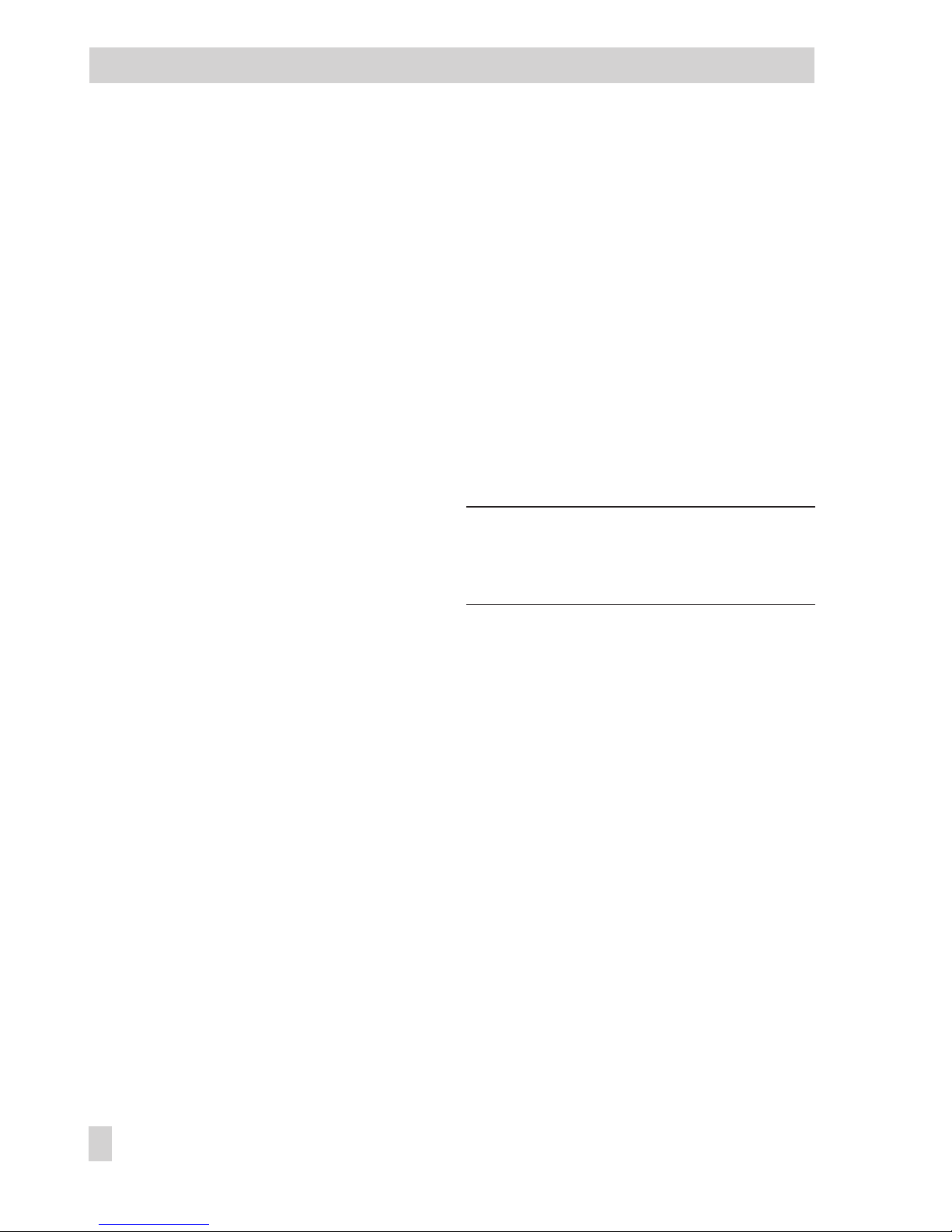

1 Design and principle of oper

-

ation

The regulator consists of the Type 2469 Valve

with restriction (orifice), seat and plug, the

closing actuator with operatingdiaphragm as

well as the thermostat with set point adjuster,

capillary tube and temperature sensor.

The regulator isdesigned to keep theflow rate

and temperature constant at the adjusted set

point. The valve closes when the controlled

variable increases.

Versions for safety equipment are addition

-

ally equipped with a Type 2403 Safety Ther

mostat to function as safety temperature monitors (FR/TR/STM). They can also be

equipped with a Type 2439 K Safety Thermostat to function as safety temperature limiters

(FR/TR/STL). For further details, refer to the

Mounting and Operating Instructions:

EB 2183 EN for Type 2403 and

EB 2185 EN for Type 2439 K.

The medium flows through the valve in the direction indicated by the arrow on the body.

The flow rate is determined by the area re

leased between the adjustable restriction

(1.2) and the valve plug (3).

The high pressure upstream of the restriction

is transmitted through the attached control

line to the high-pressure side of the actuator.

The low pressure created downstream of the

restriction acts on the low-pressure side of the

operating diaphragm (6.1) through a bore in

the plug.

The differential pressure created by the re

striction is converted into a positioning force

at the operatingdiaphragm. This forceis used

to move the valve plug depending on the

force of the positioning spring (5).

The medium temperature creates a pressure

in the temperature sensor, which is transmit

-

ted through the capillary tube (24) to the op

erating bellows (23) where is it converted into

a positioning force. This force moves the cou

pling rod (8) and thus the valve plug (3) de

pending on the force of the spring (21)

pretensioned by the set point adjuster (22).

The largest signal isused toactuate thevalve.

2 Installation

Choose a place of installation where the per

missible ambient temperature of 80 °C is not

exceeded.

NOTICE

Protect the regulator against frost when it is

used to control freezing process media.

2.1 Mounting position

Install the regulator in a horizontal pipeline

with the actuator and thermostat vertically

suspended (pointing down). Regulators in

DN 15 to 25 can also be installed in vertical

pipelines.

Use the includedconnection nuts with welding

ends to connect the regulator. Make sure the

direction of flow matches the arrow on the

valve body.

2.1.1 Strainer

Install a strainer (SAMSON Type 1NI) up

stream of the regulator to prevent that any

sealing parts, weld spatter and other impuri

ties carried along by the process medium im

pair the proper functioning of the valve,

above all the tight shut-off.

4 EB 3132-2 EN

Design and principle of operation

Page 5

EB 3132-2 EN 5

Installation

Tightening torques

Nm

10 Coupling nut

20

3 Plug section

DN 15 to 25

DN 32 to 50

70

110

7 Screws

DN 15 to 25

DN 32 to 50

8

18

14

13

12

11

1

1.2

1.1

2

3

4

5

6.2

6.1

7

6

8

10 (20Nm)

20

24

25

21

22

23

Fig. 2 · Sectional drawing

1 Valve body

1.1 Connection nut with

gasket and welding

end

1.2 Restriction (orifice

plate)

2 Seat

3 Plug section with

guide nipple

4 Plug stem

5 Positioning spring

6 Actuator

6.1 Operating diaphragm

6.2 Diaphragm plate

7 Body screws

8 Coupling rod

10 Coupling nut

11 Control line

12 Set point screw

13 Lock nut

14 Cap

20 Control thermostat

21 Spring

22 Set point adjuster

23 Bellows with actuator

stem

24 Capillary tube

25 Temperature sensor

Page 6

Install the strainer with the direction of flow

matching the arrow on the body. Make sure

the filter element is vertically suspended. Re

-

member to leave enough space to remove it.

2.1.2 Additional installation in

-

structions

We recommend to install a hand-operated

shut-off valve both upstream of the strainer

and downstream of theregulator to beable to

shut down the plant for cleaning and mainte

nance.

To monitor the pressures in the plant, install a

pressure gauge both upstream and down

stream of the regulator.

To check the adjusted set point, we recommend to install a thermometer near the sensor

that extends into the process medium.

2.2 Installing the temperature

sensor

Refer to Mounting and Operating Instructions

EB 2430 EN for details on the Type 2430 K

Thermostat and to EB 2430-3 EN for details

on the Type 2430 K Thermostat (vapor pres

sure).

The temperature sensor may be installed in

any desired position. Make sure its entire

length is immersed in the process medium.

Choose a place of installation where neither

overheating nor considerable idle times oc

cur.

Weld in a sleeve with G ½ or G ¾ female

thread at the place of installation.

Seal the screw gland or thermowell into the

welded-in sleeve. Insert the sensor and fasten

it with the clamping screw.

NOTICE

To prevent damage caused by corrosion,

make sure to use the same kinds of materials

when installing a sensor or thermowell. For

example, avoid using a thermowell or tem

perature sensor made of non-ferrous metal in

a stainless steel heat exchanger. In this case,

the sensor is to be used together with a stain

less steel thermowell.

2.2.1 Capillary tube

Install the capillary tube such that no mechan

ical damage can occur. The smallestpermissi

ble bending radius is 50 mm.

Roll up the excess tube to form a ring; never

bend or shorten it.

Make sure the capillary tube is not exposed to

excessive temperature fluctuations.

2.3 Mounting the thermostat

Place the thermostat on the connection of the

actuator and tighten it using the coupling

nut (10) and a tightening torque of 20 Nm.

6 EB 3132-2 EN

Installation

Page 7

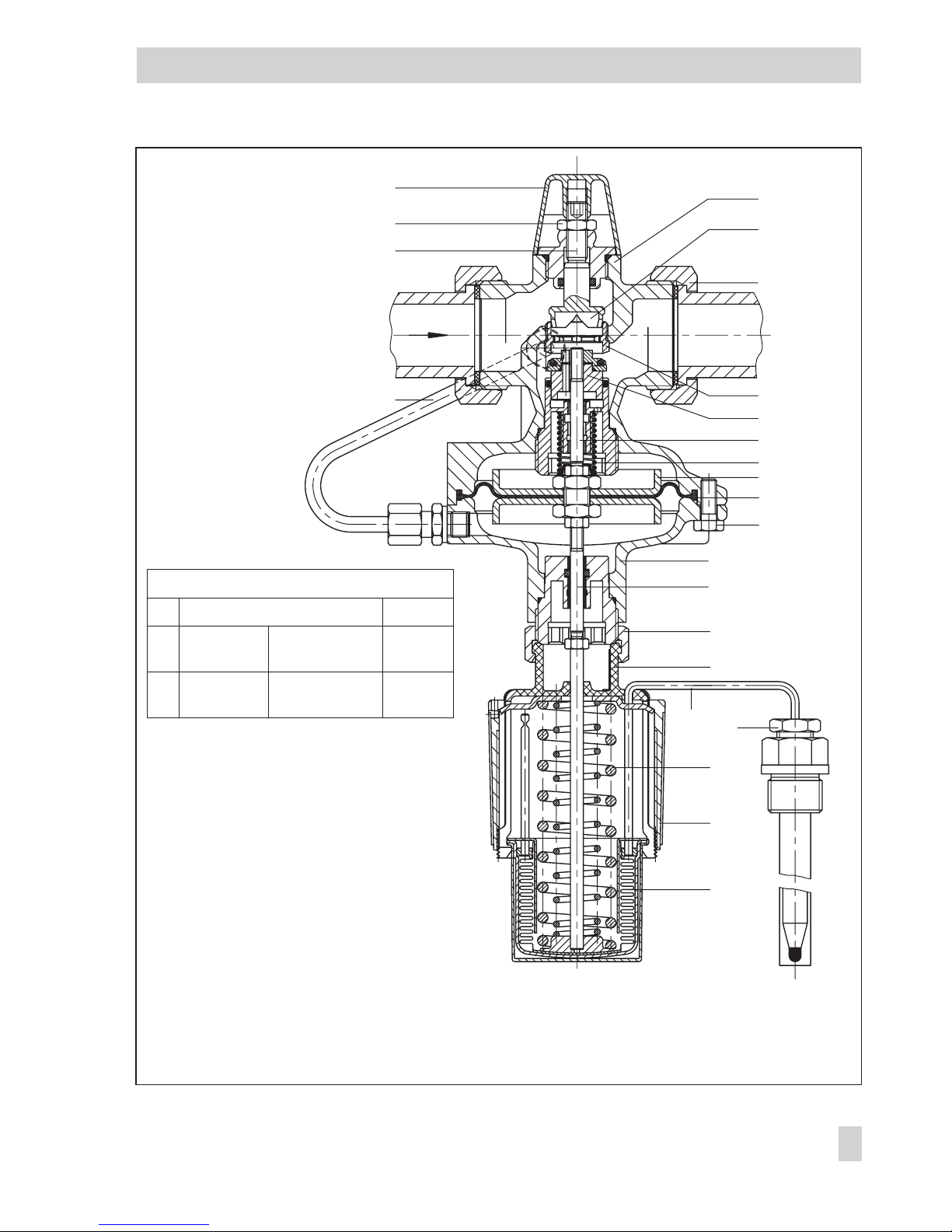

3 Operation

3.1 Start-up

NOTICE

Open the restriction (1.2) used to adjust the

flow rate before starting up the regulator.

Fill the plant slowly.

CAUTION!

When pressure-testing the pipelines with the

regulator installed, the test pressure must not

exceed 1.5 times the nominal pressure.

EB 3132-2 EN 7

Operation

1

2

3

4

5

6

7

8

9

10

11

0.01 0.02 0.03 0.05 0.1 0.2 0.3 0.5 1 2 3 4 5 6 78 910 15

0.4K

VS

1 2.5

V

m

3

/h

DN 15

DN20,

K

VS

6.3

DN25,

KVS8

DN32,

KVS12.5

DN40,

KVS16/20

3)

DN50,

K

VS

20/25

3)

4

Nominal size

DN 15 20 25 32 40

2)

50

2)

KVScoefficient

0.4

1)

1

1)

2.5 4

1)

6.3 8 12.5 16/203)20/25

3)

Flow rate set

point range

m³/h

0.01

to 0.2

0.02

to 0.64

0.02

to 1.2

0.1

to 2.5

0.1

to 3.6

0.1 to 5

0.3

to 10

0.4

to 12.5

0.4

to 15

1)

Special versions

2)

Also as version with flanged body

3)

KVSwith flanged body

Fig. 3 · Flow rate diagram

Turns of the

set point screw

Page 8

3.2 Set point adjustment

3.2.1 Flow rate

Proceed as follows to set or change the flow

rate set point:

Unscrew the cap (14).

Loosen the lock nut (13) and turn the set point

screw:

4

Turn the screw clockwise (P)toreduce

the flow rate.

4

Turn the screw counterclockwise (Q)to

increase the flow rate.

The diagram serves as a guide for flow rate

adjustment. The required number of turns of

the set point screw is based on a closed restriction (1.2).

Refer to the regulator's nameplate for the adjustable set point range. In DN 15, several

ranges are possible due to the different flow

coefficients (see table).

When the desired flow rate value has been

reached, tighten the lock nut and screw the

cap back on.

In the special version with scaled cap, the set

point can be adjusted directly (one scale

marking equals one turn of the set point

screw).

3.2.2 Temperature

Adjust the set point on the black plastic ring

(set point adjuster 22; continuously adjust

-

able) observing the reference thermometer.

4

Turn the adjuster clockwise to reduce (P)

the temperature.

4

Turn the adjuster counterclockwise (Q)to

increase the temperature.

The adjusted temperature set point can be

lead-sealed through the bore in the set point

adjuster.

4 Maintenance – Replacing

parts

The regulator is maintenance free. Neverthe

less, it is subject to natural wear, particularly

at the seat, plug and operating diaphragm.

Depending on the operating conditions, the

regulator needs to be checked at regular in

tervals to detect and remove possible mal

functions.

If the regulator's tight shut-off is impaired,

there may be either dirt or natural wear on

the seat and plug.

If the flow rate deviates considerably from the

adjusted set point, leak-test the operating diaphragm and replace it, if necessary.

CAUTION!

For installation and maintenance

work on theregulator, makesure the

relevant plant section has been

depressurized and, depending on

the process medium, drained as

well.

For high medium temperatures, al

-

low the plant section to cool down to

ambient temperature before starting

any work.

We recommend to remove the regu

-

lator from the pipeline.

8 EB 3132-2 EN

Maintenance – Replacing parts

Page 9

4.1 Cleaning or replacing the

plug

1. Remove the regulator from the pipeline.

2. Unscrew the control line (11).

3. Unscrew the body screws (7) and remove

the lower diaphragm case including the

diaphragm (6.1) and diaphragm plate.

4. For sizes DN 15 to 25, unscrew the guide

nipple of the plug section (3) using a

socket wrench (order no. 1280-3001)

and pull it out.

This wrench can also be made, for exam

ple from a GEDORE screwdriver bit

(IN 19-19) by boring a 17-mm-deep hole

(Ø 17) into the 19 mm hexagon bit (see

Fig. 4)

For sizes DN 32 to 50, unscrew the stopper and pull out the plug section.

5. Thoroughly clean the seat and plug section.

Check that the control line is not clogged.

If the plug is damaged, replace the entire

plug section.

4

Reassemble the regulator in reverse or

der, observing the tightening torques

given in the table in Fig. 2.

4.2 Replacing the diaphragm

1. Unscrew the control line (11).

2. Unscrew the body screws (7) and remove

the lower diaphragm case including the

diaphragm (6.1) and diaphragm plate.

3. Replace the diaphragm complete with the

diaphragm plate.

4

Reassemble the regulatorin reverse order,

observing the tightening torques given in

the table in Fig. 2.

EB 3132-2 EN 9

Maintenance – Replacing parts

17

Ø 17

SW 19

Fig. 4 · Socket wrench

Page 10

5 Troubleshooting

10 EB 3132-2 EN

Troubleshooting

Fault Possible cause Solution

Flow rate Leakage between seat and plug Remove the regulator from the pipeline. Clean

the seat and plug. If necessary, replace the plug

(section 4.1). Otherwise, return the regulator to

SAMSON for repair.

Flow rate set point

exceeded

Operating diaphragm defective Replace the diaphragm (section 4.2) or return

the regulator to SAMSON for repair.

Control line clogged Remove the control line and clean it.

Valve too large for control task Recalculate the K

VS

coefficient and contact

SAMSON.

Flow rate set point

not reached

Set point range incorrectly

selected

Check the set point range and contact

SAMSON.

Safety device (e.g. pressure

limiter) triggered

Check the plant. Unlock the safety device.

Insufficient differential pressure

across the plant

Compare the existing differential pressure across

the plant with the plant drag.

Min. differential pressure = differential pressure

at restriction + (

V

•

/KVS)²

Strainer clogged Drain the strainer's filter and clean it.

Valve incorrectly installed Install the regulator with the direction of flow

matching the arrow on the valve body.

Temperature Leakage between seat and plug Remove the regulator from the pipeline. Clean

the seat and plug. If necessary, replace the plug

(section 4.1). Otherwise, return the regulator to

SAMSON for repair.

Temperature set

point at the sensor

exceeded or not

reached

Sensor installed in the wrong

location

Check that the sensor is fully immersed in the

process medium. Check that it is not installed in

a place where idle times or heat accumulation

occur.

Safety device (e.g. safety tem

perature limiter or monitor)

triggered

Check the plant. Unlock the safety device.

Temperature set

point at the sensor

exceeded

Insufficient energy available for

heating or cooling

Draw up an energy balance.

Thermostat defective Return the thermostat to SAMSON for repair.

Page 11

6 Description of the nameplate

EB 3132-2 EN 11

Description of the nameplate

Control loop

oscillates

Valve too large for control task Recalculate the K

VS

coefficient and contact

SAMSON.

Time constant too large for con

-

trol loop

Fill the thermowell with conductive paste, remove

the thermowell and use a sensor with a smaller

time constant.

Fig. 5 · Nameplate

1 Model number

2 Modification index

3 Date of manufacture

4 Type designation

Entries in the other spaces:

K

VS

or CVcoefficient

Upper differential pressure in bar or psi

Flow rate set point in m³/h

Max. permissible temperature in °C or °F

Max. permissible differential pressureDp

Nominal pressure as PN or ANSI Class

1 2

4

3

Page 12

7 Customer inquiries

If malfunctions or defects occur, contact the SAMSON After-sales Service for support.

The addresses of SAMSON AG, its subsidiaries, representatives and service facilities world

wide can be found on the Internet at www.samson.de, in a SAMSON product catalog or on the

back of these mounting and operating instructions.

Include the following details when making inquiries:

4

Regulator type and nominal size

4

Model number

4

Threaded or flange connection

4

Upstream and downstream pressures

4

Flow rate in m³/h

4

Has a strainer been installed?

4

Installation drawing

8 Dimensions in mm and weights

Nominal size

DN 15 DN 20 DN 25 DN 32 DN 40 DN 50

Pipe Ø d

21.3 26.8 32.7 42 48 60

Connection R

G ¾ G 1 G 1¼ G 1¾ G 2 G 2½

Width across flats SW

30 36 46 59 65 82

Length L

65 70 75 100 110 130

Height H

32 45

Height H1

245 265 295

Standard version

Welding ends L1

210 234 244 268 294 330

Approx. weight in kg

2.4 2.5 2.7 4.0 6.2 7.0

Special version with threaded ends (male thread)

Length L2

129 144 159 180 196 228

Male thread A

G ½ G ¾ G 1 G 1¼ G 1½ G 2

Approx. weight in kg

2.2 2.3 2.4 5.9 6.4 6.9

Special version with flanges PN 16 or PN 25, or version with flanged body (DN 32, DN 40 and DN 50)

Length L3

130 150 160 180 200 230

Approx. weight in kg

3.6 4.3 4.9 9.1 10.4 11.9

12 EB 3132-2 EN

Customer inquiries

Page 13

EB 3132-2 EN 13

Dimensions in mm and weights

L3

L3

L

L2

L

A

SW

SW

SW

L1

L

59

(85)

245 (295)

dR

G½

(G¾)

G½

(G¾)

185 (220)

185 (220)

Ø12 (Ø19)

Ø9.5 (Ø16)

Fig. 6 · Dimensional drawings

Connection nuts

with threaded ends

Connection nuts

with flanges

Flanged body

DN 32, 40 and 50

Connection nuts

with welding ends

Values in parentheses

for DN 32 to 50

Version with

thermowell

Bulb sensor with

screw gland

Page 14

14 EB 3132-2 EN

Page 15

EB 3132-2 EN 15

Page 16

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 3132-2 EN

S/Z 2011-12

Loading...

Loading...