Page 1

Mounting and

Operating Instructions

EB 2183 EN

Translation of original instructions

Edition June 2018

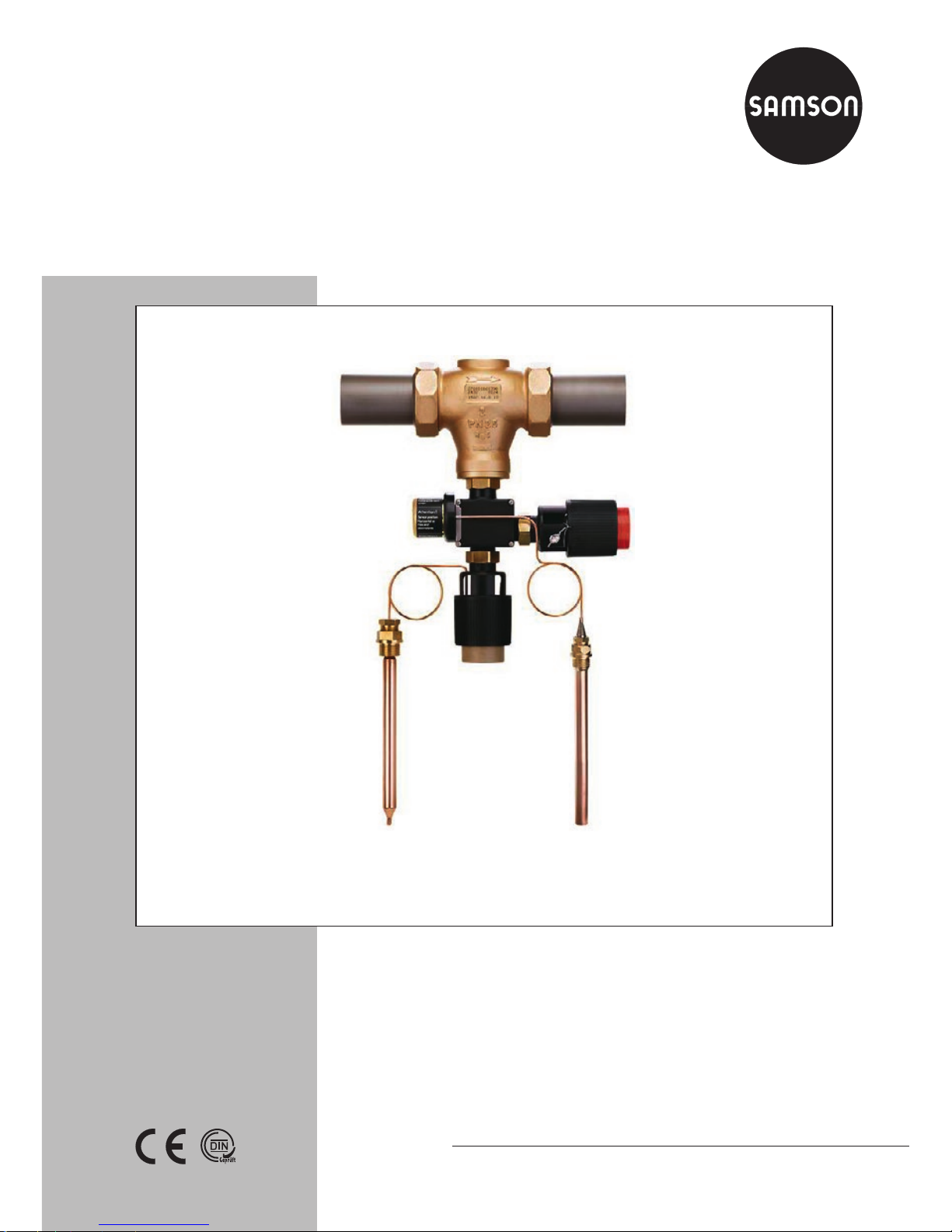

Type2432/2430/2403 TR/STM

Self-operated Temperature Regulators

Type 2403 Safety Temperature Monitor

(STM)

Page 2

2 EB 2183 EN

Note on these mounting and operating instructions

These mounting and operating instructions assist you in mounting and operating the device

safely. The instructions are binding for handling SAMSON devices.

Î For the safe and proper use of these instructions, read them carefully and keep them for

later reference.

Î If you have any questions about these instructions, contact SAMSON‘s After-sales Service

Department (aftersalesservice@samson.de).

The mounting and operating instructions for the devices are included in

the scope of delivery. The latest documentation is available on our website

(www.samson.de) > Product documentation. You can enter the document

number or type number in the [Find:] eld to look for a document.

Denition of signal words

Hazardous situations which, if not avoided,

will result in death or serious injury

Hazardous situations which, if not avoided,

could result in death or serious injury

Property damage message or malfunction

Additional information

Recommended action

DANGER

!

WARNING

!

NOTICE

!

Note

Tip

Page 3

Contents

EB 2183 EN 3

1 Safety instructions and measures ...................................................................4

1.1 Notes on possible severe personal injury .........................................................6

1.2 Notes on possible personal injury ...................................................................7

1.3 Notes on possible property damage ................................................................8

2 Markings on the device .................................................................................9

2.1 Material number ............................................................................................9

3 Design and principle of operation ................................................................10

3.1 Technical data .............................................................................................12

3.2 Process medium and scope of application ......................................................12

4 Measures for preparation ............................................................................18

4.1 Unpacking ..................................................................................................18

4.2 Transporting and lifting ................................................................................18

4.3 Storage .......................................................................................................18

4.4 Preparation for installation ............................................................................19

5 Mounting and start-up ................................................................................. 19

5.1 Mounting the safety temperature monitor onto the valve ..................................19

5.2 Additional ttings .........................................................................................20

5.3 Combination with control thermostat ..............................................................20

5.4 Installing the valve into the pipeline ...............................................................21

5.4.1 Installation conditions ...................................................................................21

5.4.2 Installing the temperature sensor ...................................................................21

5.5 Start-up ....................................................................................................... 23

5.5.1 Gases and liquids ........................................................................................23

5.5.2 Steam .........................................................................................................23

6 Operation ...................................................................................................24

6.1 Adjusting the limit temperature ......................................................................24

6.2 Fine adjustment of the limit temperature .........................................................25

7 Servicing.....................................................................................................26

7.1 Preparation for return shipment ..................................................................... 26

8 Malfunctions ...............................................................................................27

9 Decommissioning and disassembly ..............................................................28

9.1 Decommissioning .........................................................................................28

9.2 Disposal ......................................................................................................28

10 Appendix ....................................................................................................29

10.1 After-sales service and spare parts ................................................................29

10.2 Certicates ..................................................................................................29

Page 4

4 EB 2183 EN

Contents

1 Safety instructions and measures

Intended use

The Type2403 Safety Temperature Monitor (STM) with valve is designed for temperature

monitoring and control of the energy supply to heat generators (e.g. heat exchangers) by

closing the valve. The connection of an additional Type2430 Control Thermostat converts the

safety temperature monitor (STM) into a temperature regulator with safety temperature

monitor (TR/STM).

The devices are designed to operate under exactly dened conditions (e.g. operating

pressure, process medium, temperature). Therefore, operators must ensure that the devices

are only used in operating conditions that meet the specications used for sizing the devices

at the ordering stage. In case operators intend to use the devices in other applications or

conditions than specied, contact SAMSON.

SAMSON does not assume any liability for damage resulting from the failure to use the

device for its intended purpose or for damage caused by external forces or any other

external factors.

Î Refer to the technical data and nameplate for limits and elds of application as well as

possible uses.

Reasonably foreseeable misuse

The devices are not suitable for use outside the limits dened during sizing and by the techni-

cal data. Furthermore, the following activities do not comply with the intended use:

− Use of non-original spare parts

− Performing service and repair work not described in these instructions

Qualications of operating personnel

The devices must be mounted, started up, serviced and repaired by fully trained and

qualied personnel only; the accepted industry codes and practices are to be observed.

According to these mounting and operating instructions, trained personnel refers to

individuals who are able to judge the work they are assigned to and recognize possible

hazards due to their specialized training, their knowledge and experience as well as their

knowledge of the applicable standards.

Personal protective equipment

We recommend checking the hazards posed by the process medium being used (e.g.

uGESTIS (CLP) hazardous substance database).

Page 5

EB 2183 EN 5

Safety instructions and measures

Î Provide protective equipment (e.g. safety gloves, eye protection) appropriate for the pro-

cess medium used.

Î Wear hearing protection when working near the valve.

Î Check with the plant operator for details on further protective equipment.

Revisions and other modications

Revisions, conversions or other modications of the product are not authorized by SAMSON.

They are performed at the user's own risk and may lead to safety hazards, for example. Fur-

thermore, the product may no longer meet the requirements for its intended use.

Warning against residual hazards

To avoid personal injury or property damage, plant operators and operating personnel must

prevent hazards that could be caused in the device by the process medium, the operating

pressure or by moving parts by taking appropriate precautions. They must observe all hazard statements, warning and caution notes in these mounting and operating instructions, especially for installation, start-up and service work.

We also recommend checking the hazards posed by the process medium being used (e.g.

uGESTIS (CLP) hazardous substance database).

Î Observe safety measures for handling the device as well as re prevention and explosion

protection measures.

Responsibilities of the operator

The operator is responsible for proper operation and compliance with the safety regulations.

Operators are obliged to provide these mounting and operating instructions as well as the

referenced documents to the operating personnel and to instruct them in proper operation.

Furthermore, the operator must ensure that operating personnel or third persons are not exposed to any danger.

Responsibilities of operating personnel

Operating personnel must read and understand these mounting and operating instructions as

well as the referenced documents and observe the specied hazard statements, warnings

and caution notes. Furthermore, the operating personnel must be familiar with the applicable

health, safety and accident prevention regulations and comply with them.

Page 6

6 EB 2183 EN

Safety instructions and measures

Referenced standards and regulations

The devices comply with the requirements of the European Pressure Equipment Directive

2014/68/EU. Devices with a CE marking have an EU declaration of conformity, which includes information about the applied conformity assessment procedure. This EU declaration

of conformity is included in the Appendix of these instructions (see section10.2).

Non-electric valve versions whose bodies are not lined with an insulating material coating do

not have their own potential ignition source according to the risk assessment stipulated in

EN13463-1:2009, section5.2, even in the rare incident of an operating fault. Therefore,

such valve versions do not fall within the scope of Directive 2014/34/EU.

Î For connection to the equipotential bonding system, observe the requirements specied in

section 6.4 of EN60079-14 (VDE0165 Part 1).

Referenced documentation

The following documents apply in addition to these mounting and operating instructions:

− Mounting and operating instructions for valves, e.g. uEB2171, uEB2172 and

uEB2173

− Mounting and operating instructions for the control thermostats, e.g. uEB2430 and

uEB2430-3

− Mounting and operating instructions for the safety temperature limiter, e.g. uEB2185

1.1 Notes on possible severe personal injury

DANGER

!

Risk of bursting in pressure equipment.

Valves and pipelines are pressure equipment. Improper opening can lead to valve

components bursting.

Î Before starting any work on the valve, depressurize all plant sections concerned as

well as the valve.

Î Drain the process medium from all the plant sections concerned as well as the

valve.

Î Wear personal protective equipment.

Page 7

EB 2183 EN 7

Safety instructions and measures

1.2 Notes on possible personal injury

WARNING

!

Risk of personal injury due to residual process medium in the valve.

While working on the valve, residual process medium can escape and, depending on

its properties, may lead to personal injury, e.g. (chemical) burns.

Î If possible, drain the process medium from all the plant sections concerned and the

valve.

Î Wear protective clothing, safety gloves and eyewear.

Risk of burn injuries due to hot or cold components and pipelines.

Depending on the process medium, valve components and pipelines may get very hot

or cold and cause burn injuries.

Î Allow components and pipelines to cool down or heat up.

Î Wear protective clothing and safety gloves.

Damage to health relating to the REACH regulation.

If a SAMSON device contains a substance which is listed as being a substance of very

high concern on the candidate list of the REACH regulation, this circumstance is indicated on the SAMSON delivery note.

Î Information on safe use of the part affected,

see uhttp://www.samson.de/reach-en.html.

Page 8

8 EB 2183 EN

Safety instructions and measures

1.3 Notes on possible property damage

NOTICE

!

Risk of irreparable regulator damage caused by the regulator components being

taken apart.

The thermostat, set point adjuster and capillary tube form an inseparable hydraulic

unit. If these components are dismantled (e.g. removal of the capillary tube), the regulator will be irreparably damaged and will no longer be able to fulll its monitoring

and control task.

Î Do not dismantle the regulator.

Î Only perform allowed activities on the regulator.

Î Contact SAMSON's After-sales Service department before replacing spare parts.

Risk of valve damage due to contamination (e.g. solid particles) in the pipeline.

The plant operator is responsible for cleaning the pipelines in the plant.

Î Flush the pipelines before start-up.

Î Observe the maximum permissible pressure for valve and plant.

Risk of valve damage due to unsuitable medium properties.

The valve is designed for a process medium with dened properties.

Î Only use the process medium specied during sizing.

Risk of leakage and valve damage due to excessively high or low tightening

torques.

Observe the specied torques on tightening valve components.

Excessively tightened torques lead to parts wearing out quicker. Parts that are too loose

may cause leakage.

Î Observe the specied tightening torques.

Page 9

EB 2183 EN 9

Markings on the device

2 Markings on the device

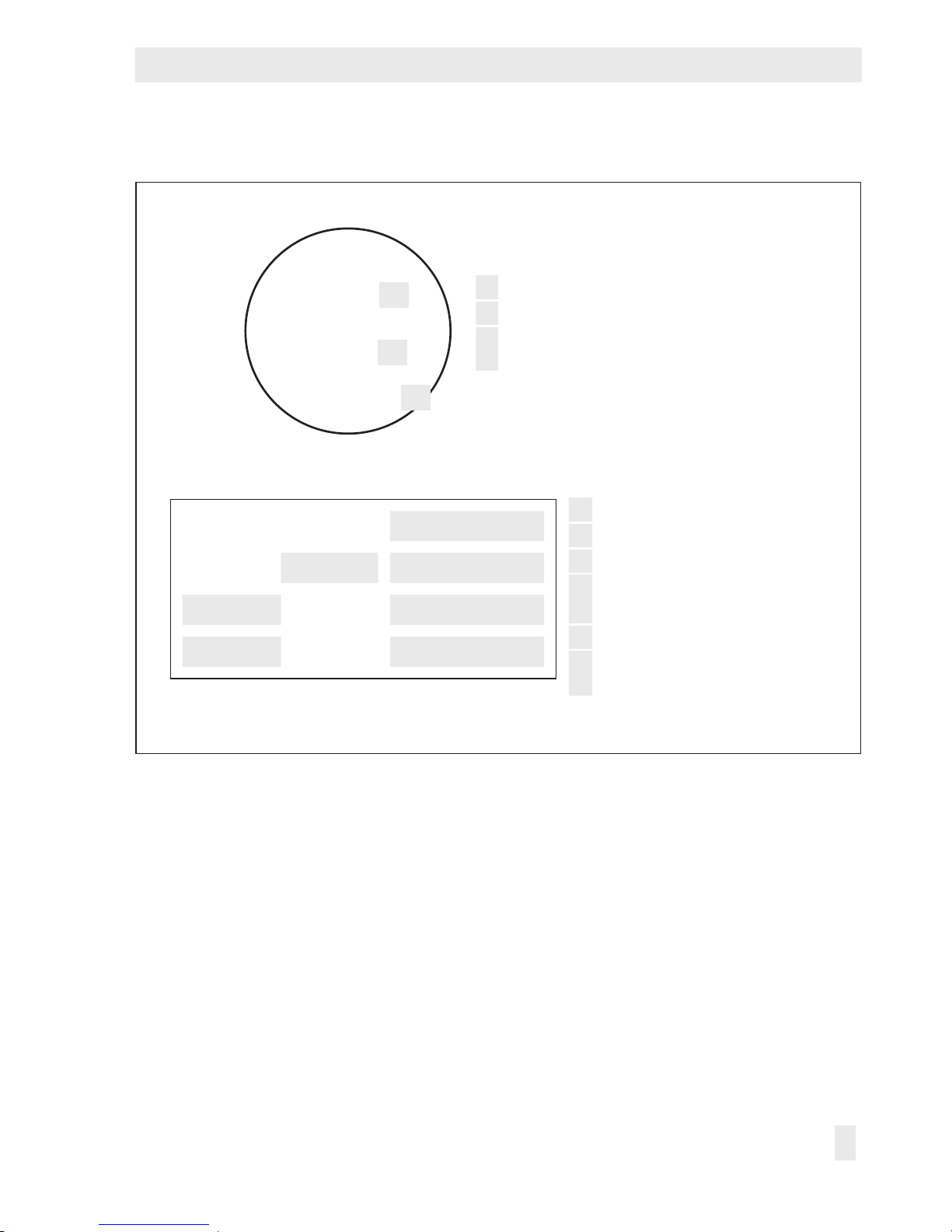

SAMSON

2750-5

2403

... °C

...°F

STM 60104

1

2

3

Specications on the scaled cap on the adjustment knob to adjust the limit

1 Model number

2 Limit value range in °C and °F

3

Register number (type test

according to DINEN14597)

Specications on the valve

1 Type designation (valve)

2 Conguration ID

3 Date of manufacture

4 K

VS/CV

5 Max. permissible temperature

6 Nominal pressure (valve)

7 Max. permissible differential

pressure ∆p

SAMSON 1

2710 - 2 3

4 5

6 7

Fig.1: Nameplate

2.1 Material number

Specifying the conguration ID, you can contact us to nd out which material is used. The

conguration ID is specied on the nameplate (2, conguration ID). For more details on the

nameplate, see Fig.1.

Page 10

10 EB 2183 EN

Design and principle of operation

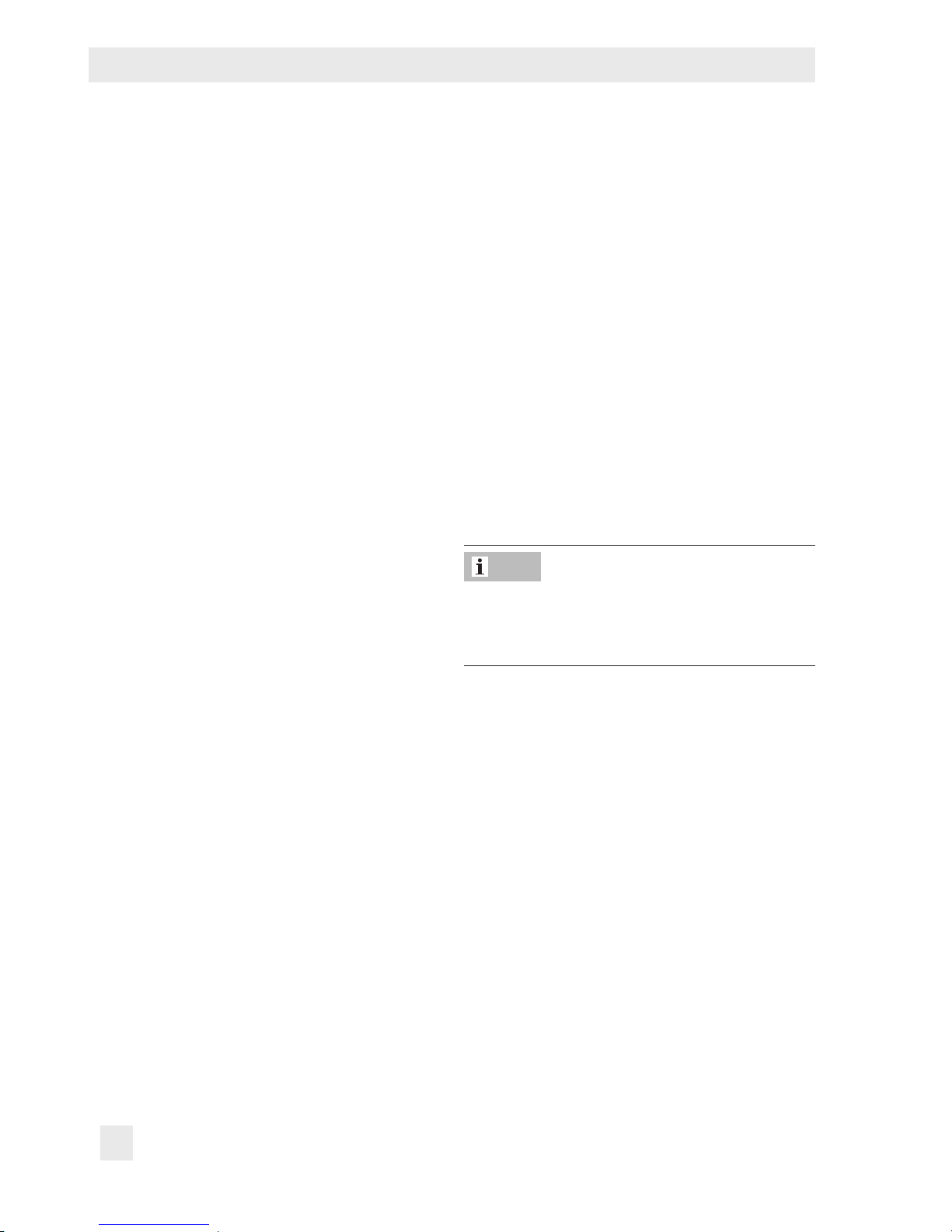

3 Design and principle of oper-

ation

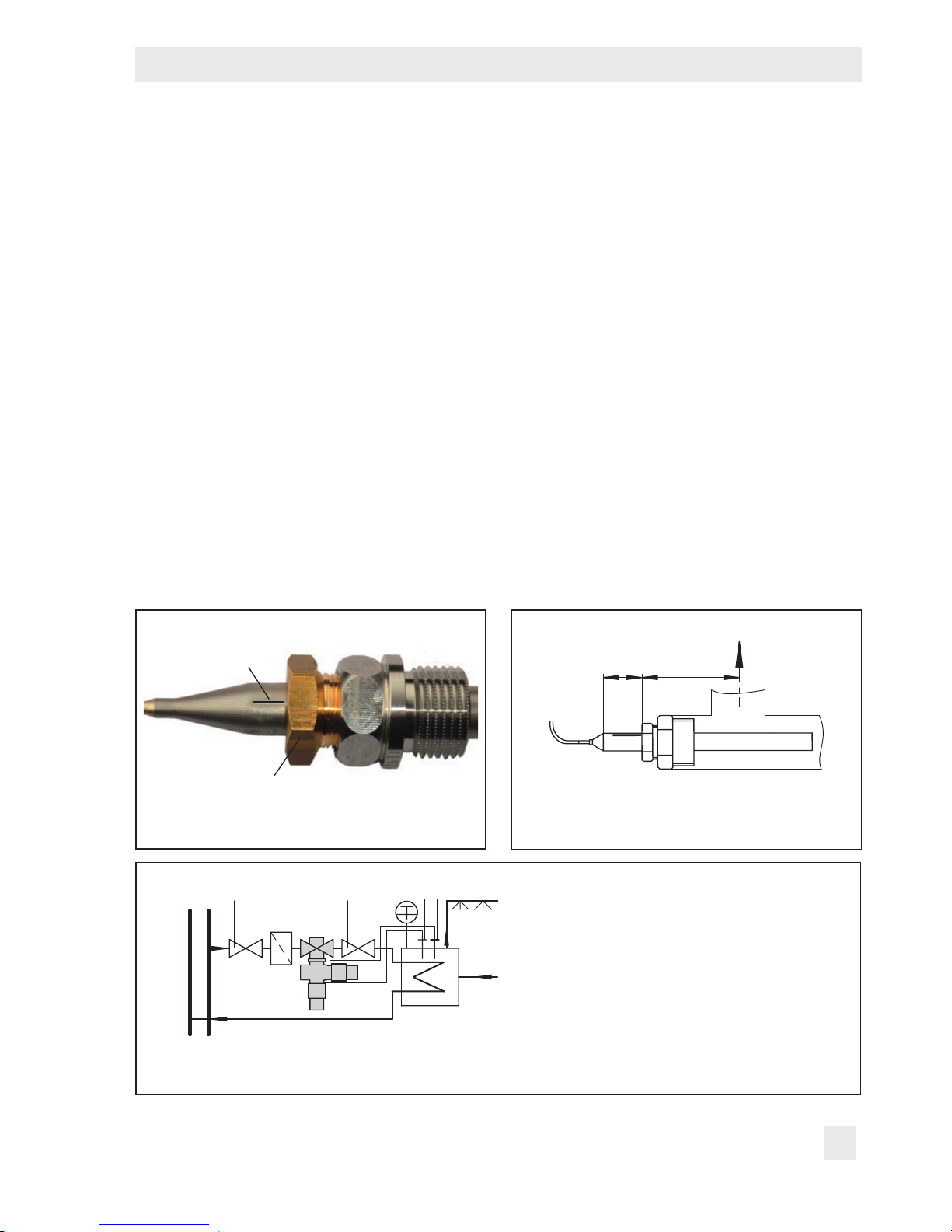

The Type2403 Safety Temperature Monitor

(STM) with a valve operates without auxiliary energy and is designed for extended safety according to DINEN14597. The safety

temperature monitor is used to limit the temperature by closing a SAMSON Series43

Valve connected to the safety thermostat.

The safety temperature monitor mainly

consists of a valve and safety thermostat with

capillary tube (8) and bulb sensor (9).

The connection of an additional Type2430

Control Thermostat (20) converts the safety

temperature monitor (7) into a temperature

regulator with safety temperature monitor

(TR/STM). See Fig.2.

The valve is closed by a spring mechanism

when the temperature reaches the adjusted

limit, when the capillary tube breaks or

when leakage occurs in the sensor system.

The safety temperature monitor works according to the vapor pressure principle. The

temperature of the medium creates a pressure in the temperature sensor (9) which is

proportional to the measured temperature.

This pressure is transferred through the capillary tube (8) to the bellows of the operating

element (10) and converted into a position-

ing force. The force is transferred over the

pin (11) of the operating element to the plug

stem (4) of the valve and the plug (3). The

position of the plug determines the ow rate

of the heat transfer medium across the area

released between the seat (2) and plug.

The safety temperature monitor closes the

valve when the temperature reaches the ad-

justed limit temperature. The safety tempera-

ture monitor resets itself automatically when

the temperature has fallen to a value of ap-

prox. 5K below the adjusted limit tempera-

ture.

Fail-safe position

When the capillary tube ruptures or there is

a leak in the sensor, the spring mechanism

reacts to the reduced system pressure and

the pin of the operating element (11) closes

the valve. The valve cannot be reset. In this

case, the Type2403 Safety Temperature

Monitor must be replaced.

The adjusted limit temperature must have a

minimum temperature difference of 15K to

the set point of the temperature regulator.

Note

Page 11

EB 2183 EN 11

Design and principle of operation

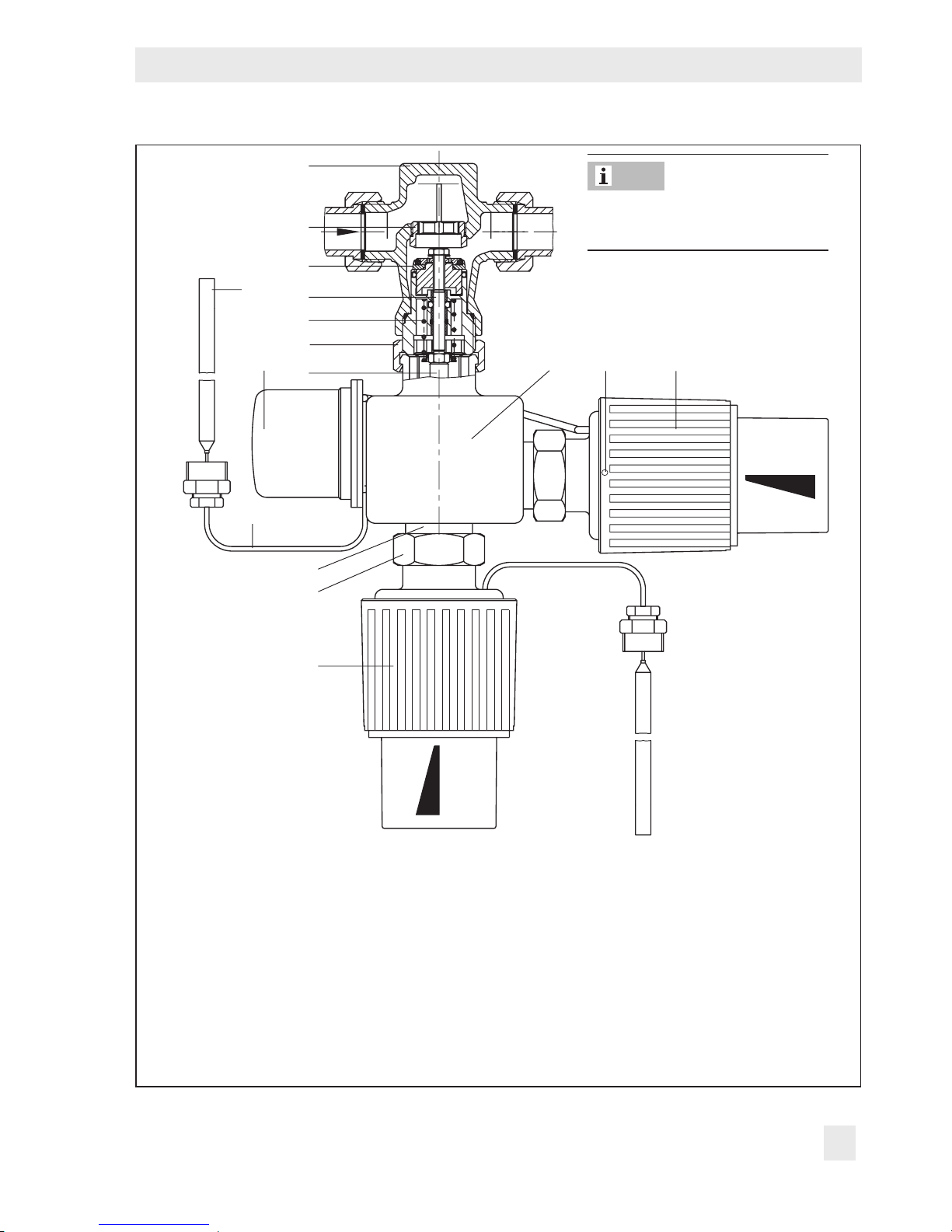

1 Valve body

2 Seat

3 Plug

4 Plug stem

5 Valve spring

6 Coupling nut

7 Type 2403 Safety Temperature Monitor (STM)

8 Capillary tube

9 Temperature sensor

10 Operating element

11 Pin of operating element

12 Limit adjustment knob

13 Lead-seal hole

14 Mounting location for Type2430 Thermostat

20 Type 2430 Thermostat (optional)

1

2

3

4

5

6

11

10

12

8

9

13

7

6

14

20

Tightening torque for coupling

nut (6): 20Nm

Note

Fig.2: Design and principle of operation (TR/STM)

Page 12

12 EB 2183 EN

Design and principle of operation

3.1 Technical data

3.2 Process medium and scope

of application

Safety temperature monitoring of the energy

supply for heat generators or heat exchangers by closing the valve.

For limit signals from 60 to 120°C·Valves

G½ to G1·DN15 to 50·Nominal pres-

sure PN16 or 25·Max. 200°C

The Type2403 Safety Temperature Monitor

(STM) with a valve operates without auxiliary

energy and is designed for extended safety

according to DINEN14597. The valve is

closed by a spring mechanism when the

temperature reaches the adjusted limit, when

the capillary tube breaks or when leakage

occurs in the sensor system. The devices are

automatically reset and put back into

operation after the temperature has fallen

below the limit and the fault has been

remedied.

Further details and technical data of the

valves and control thermostats are listed in

the following mounting and operating instructions:

− Mounting and operating instructions for

valves, e.g. uEB2171, uEB2172 und

and uEB2173

− Mounting and operating instructions for

the control thermostats, e.g. uEB2430

and uEB2430-3

− Mounting and operating instructions for

the safety temperature limiter, e.g.

uEB2185

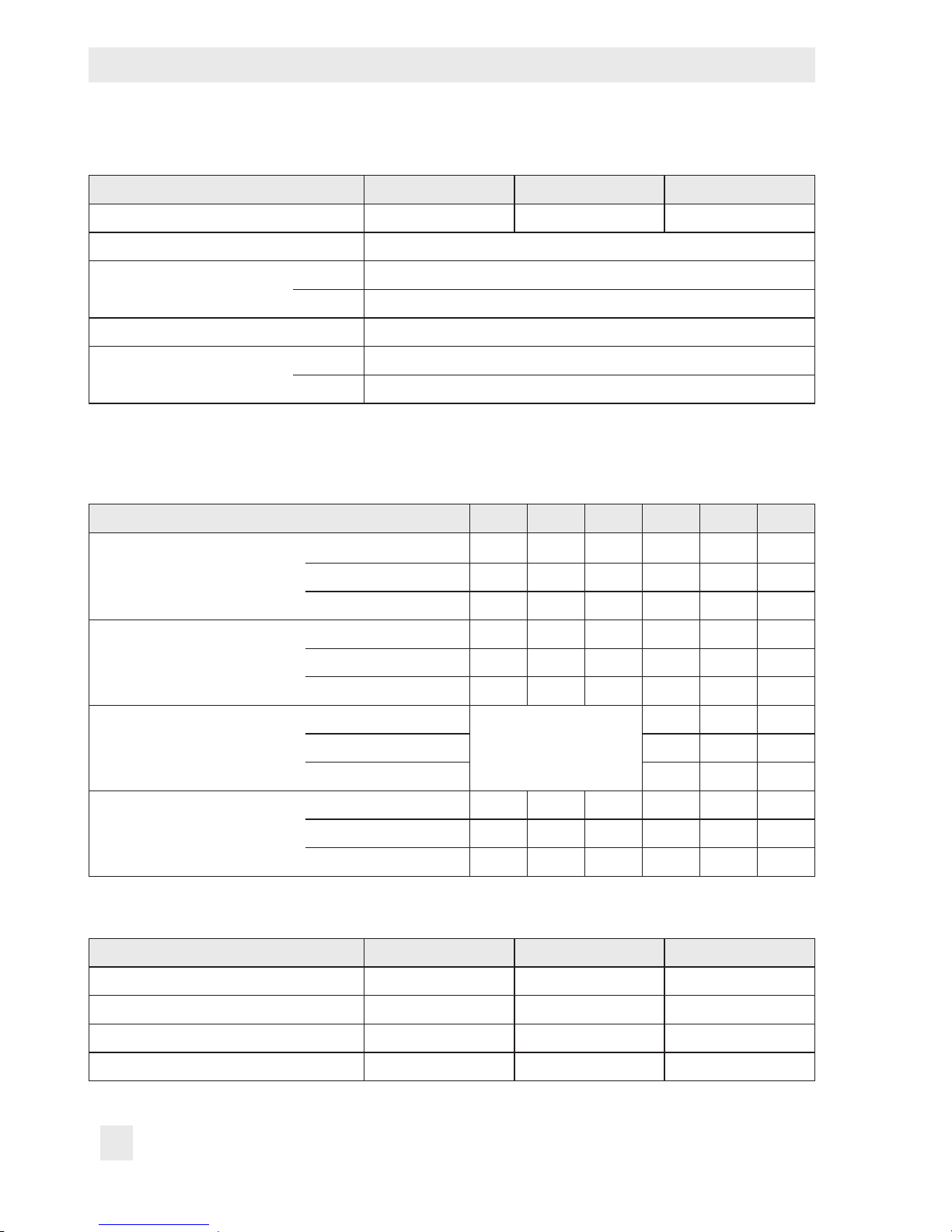

Dimensions and weights

Table2 and Table3 provide a summary of

the dimensions and weights. The lengths and

heights are shown in the dimensional draw-

ings (Fig.3 to Fig.5).

Typetesting

The safety temperature monitor is tested by

the German Technical Inspectorate (TÜV) according to DINEN14597 under the type

designation 2750-5. The registration number

is available on request.

Note

Page 13

EB 2183 EN 13

Design and principle of operation

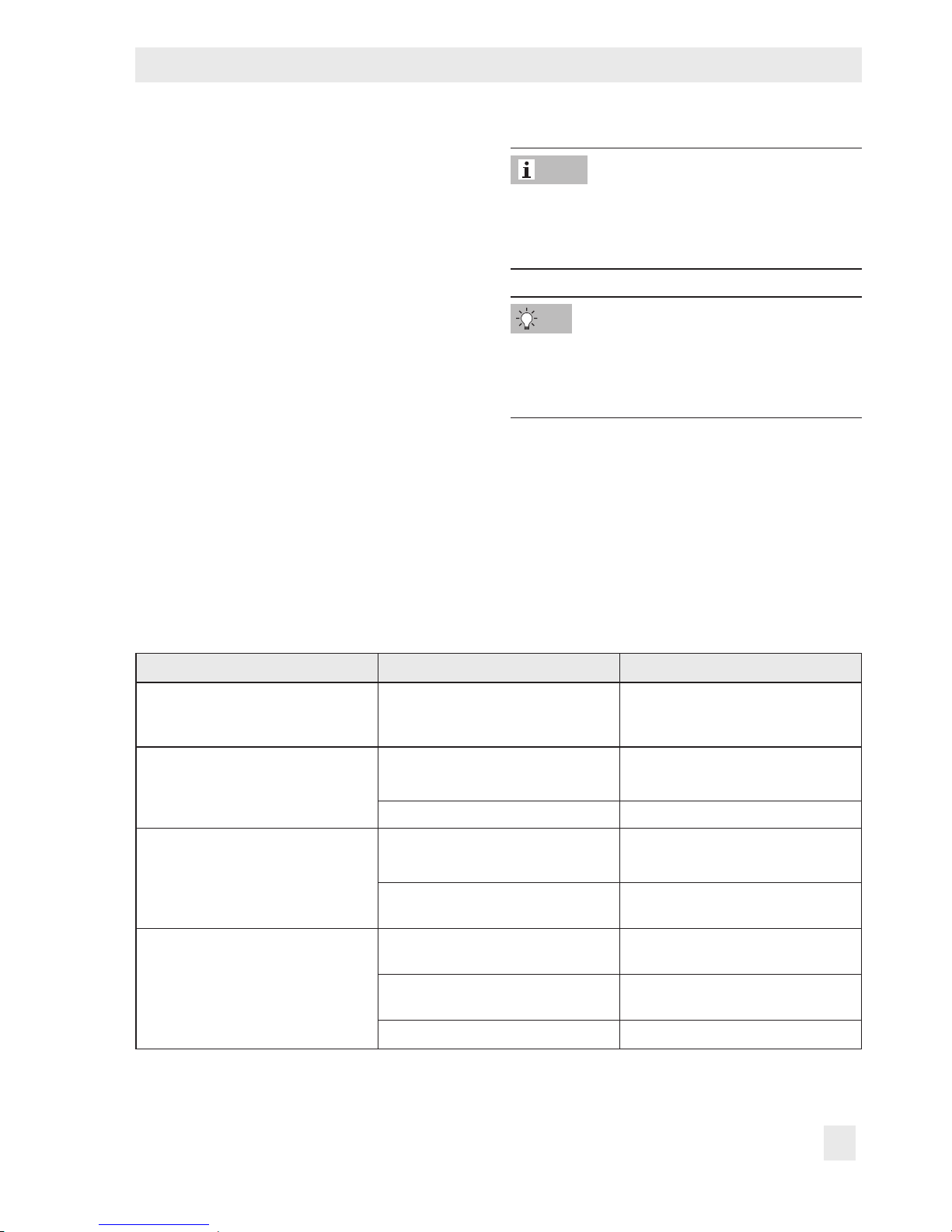

Table1: Technical data · All pressures (gauge)

Type 2403 Safety Temperature Monitor

Connection M32x1.5

Adjustment range of limit value 60 to 75°C·75 to 100°C·100 to 120°C

Permissible ambient temperature Max. 50°C

Perm. temperature at the sensor 25K above the adjusted limit

Perm. pressure at sensor 25bar

Capillary tube length 5m

Compliance

·

Table2: Dimensions in mm

Table 2.1: Type2432/2403·Type2433/2403·Type2436/2403·Type2437/2403

Valve size DN 15 20 25 32 40 50

Pipe Ød d 21.3 26.8 32.7 42 48 60

AF 30 36 46 59 65 82

Length L 65 70 75 100 110 130

With welding ends L1 210 234 244 268 294 330

With threaded ends L2 129 144 159 180 196 228

With anges L3 130 150 160 180 200 230

Male thread A G½ G¾ G1 G1¼ G1½ G2

Type2432/2403

H 140 190

H1 30 55

Type2433/2403

H 135 145

H2 112 122 124 144 157 165

H3 72 77 82 100 108 114

H4 72 80 82 105 110 115

Type2436/2403

H – 160

H1 – 95

Type2437/2403

H 220 270

H1 30 55

Page 14

14 EB 2183 EN

Design and principle of operation

Table 2.2: Type2431/2403·Type2433/2403·Type2435/2403·Type2436/2403

Connection size G½ G¾ G1

Face-to-face dimensions L 65 75 90

Type2431/2403 H 140

Type2433/2403

H 140

H1 40

Type2435/2403 H 220

Type2436/2403

H 145

H1 46

Table3: Weights in kg

Table 3.1: Type2432/2403·Type2433/2403·Type2436/2403·Type2437/2403

Valve size DN 15 20 25 32 40 50

Type2432/2403 kg (approx.)

With welding ends 2.5 2.8 3.1 5.1 5.8 7.6

With threaded ends 2.4 2.7 3.0 5.0 5.7 7.5

With anges 3.9 4.8 5.6 8.3 9.8 11.6

Type2433/2403 kg (approx.)

With welding ends 2.9 3.2 3.4 4.8 5.1 6.4

With threaded ends 2.9 3.2 3.4 4.8 5.1 6.4

With anges 5.0 6.2 7.1 9.6 11 14

Type2436/2403 kg (approx.)

With welding ends

–

3.8 4.2 4.6

With threaded ends 3.8 4.2 4.6

With anges 7.0 8.2 9.6

Type2437/2403 kg (approx.)

With welding ends 2.7 3.0 3.3 5.5 6.2 8.1

With threaded ends 2.6 2.9 3.2 5.5 6.2 8.1

With anges 4.1 5.0 5.8 8.5 10 12

Table 3.2: Type2431/2403·Type2433/2403·Type2435/2403·Type2436/2403

Connection size G½ G¾ G1

Type2431/2403 kg (approx.) 2.0 2.1 2.2

Type2433/2403 kg (approx.) 2.2 2.3 2.4

Type2435/2403 kg (approx.) 2.5 2.6 2.7

Type2436/2403 kg (approx.) 2.4 2.5 2.6

Page 15

EB 2183 EN 15

Design and principle of operation

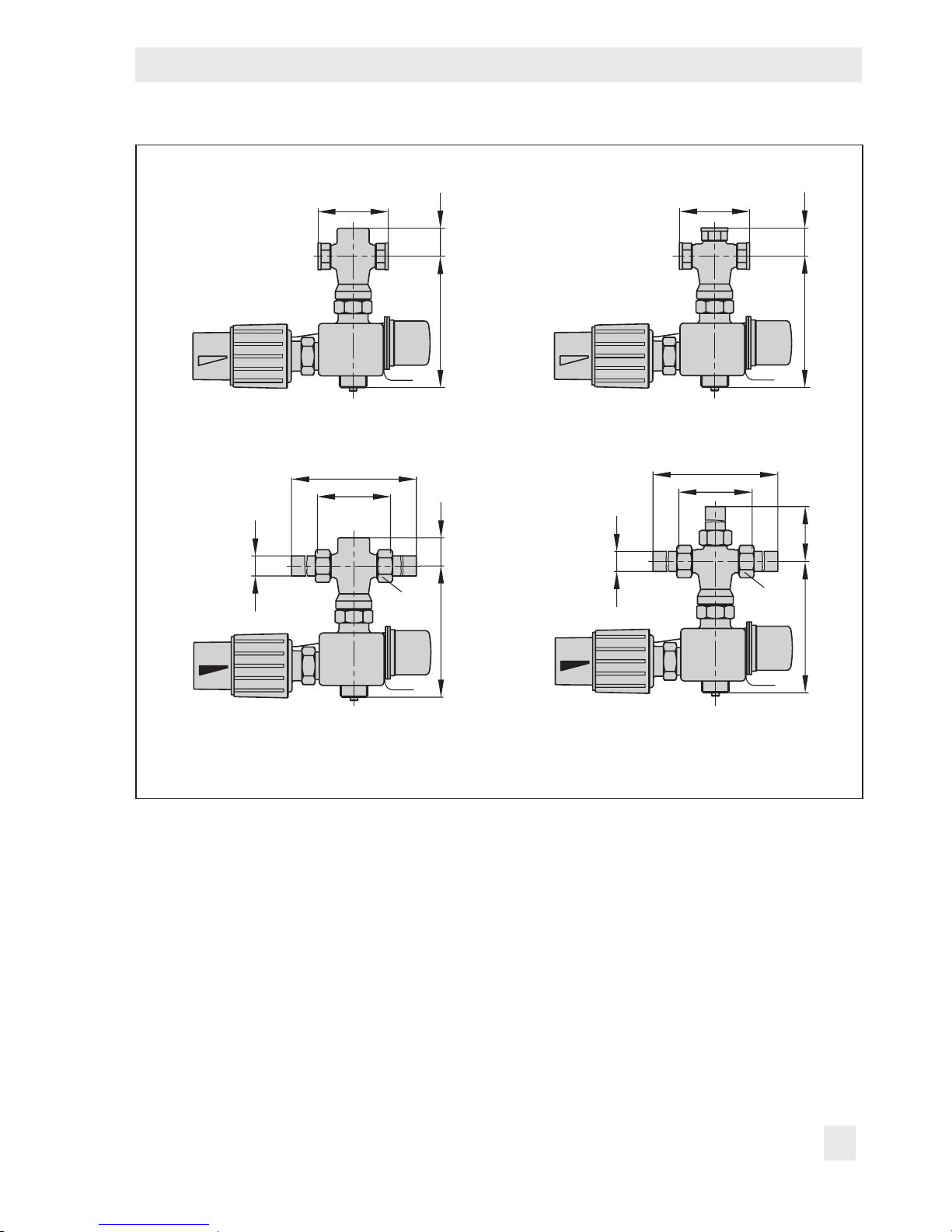

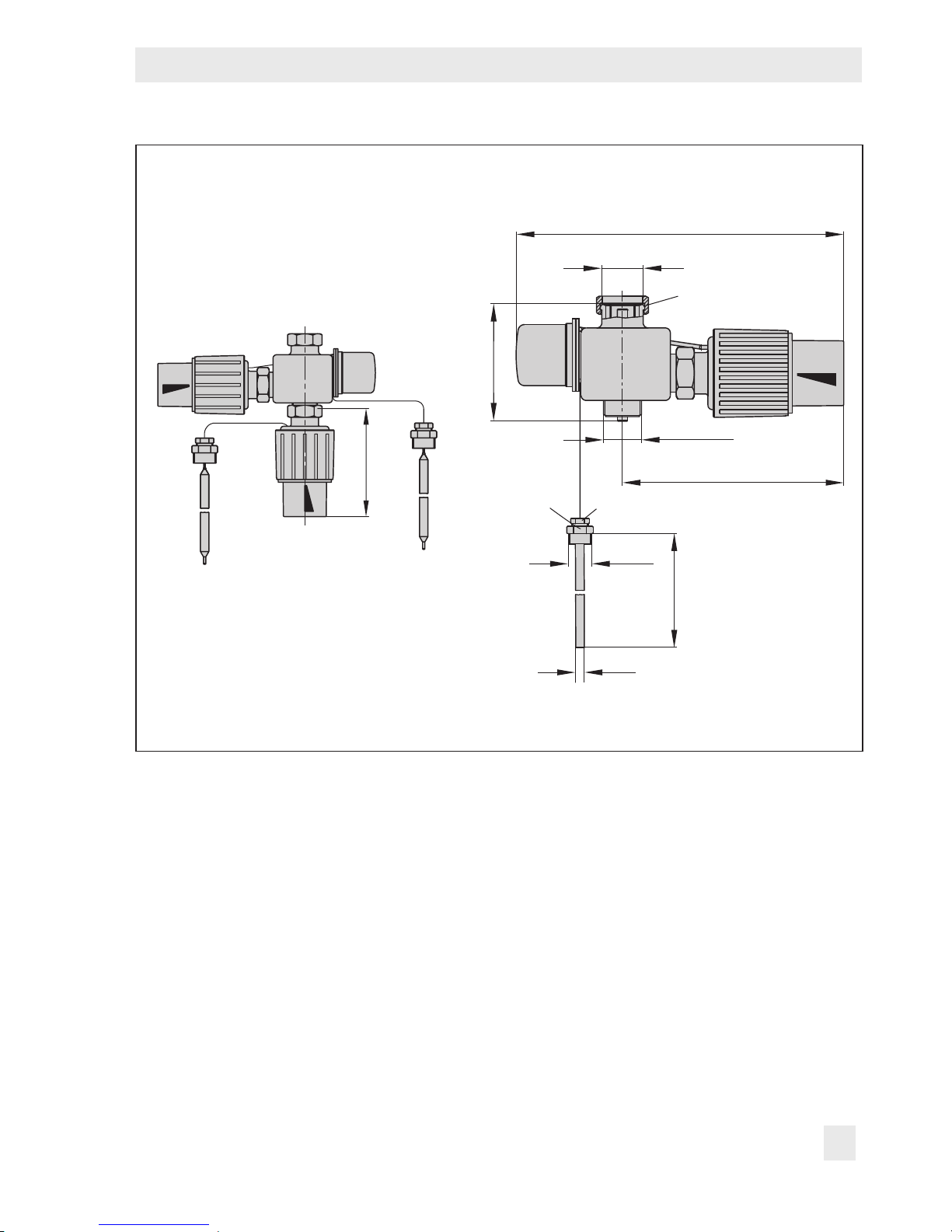

Dimensional drawings of safety temperature monitors (STM)

L

H30

L

HH

1

Type2431/2403·Type2435/2403 Type2433/2403·Version with female thread

L

d

L1

H

SW

H1

L

d

L1

H

SW

H2

Type2432/2403·Type2436/2403 Type2433/2403 · Version with welding ends

Fig.3: Dimensional drawings

Page 16

16 EB 2183 EN

Design and principle of operation

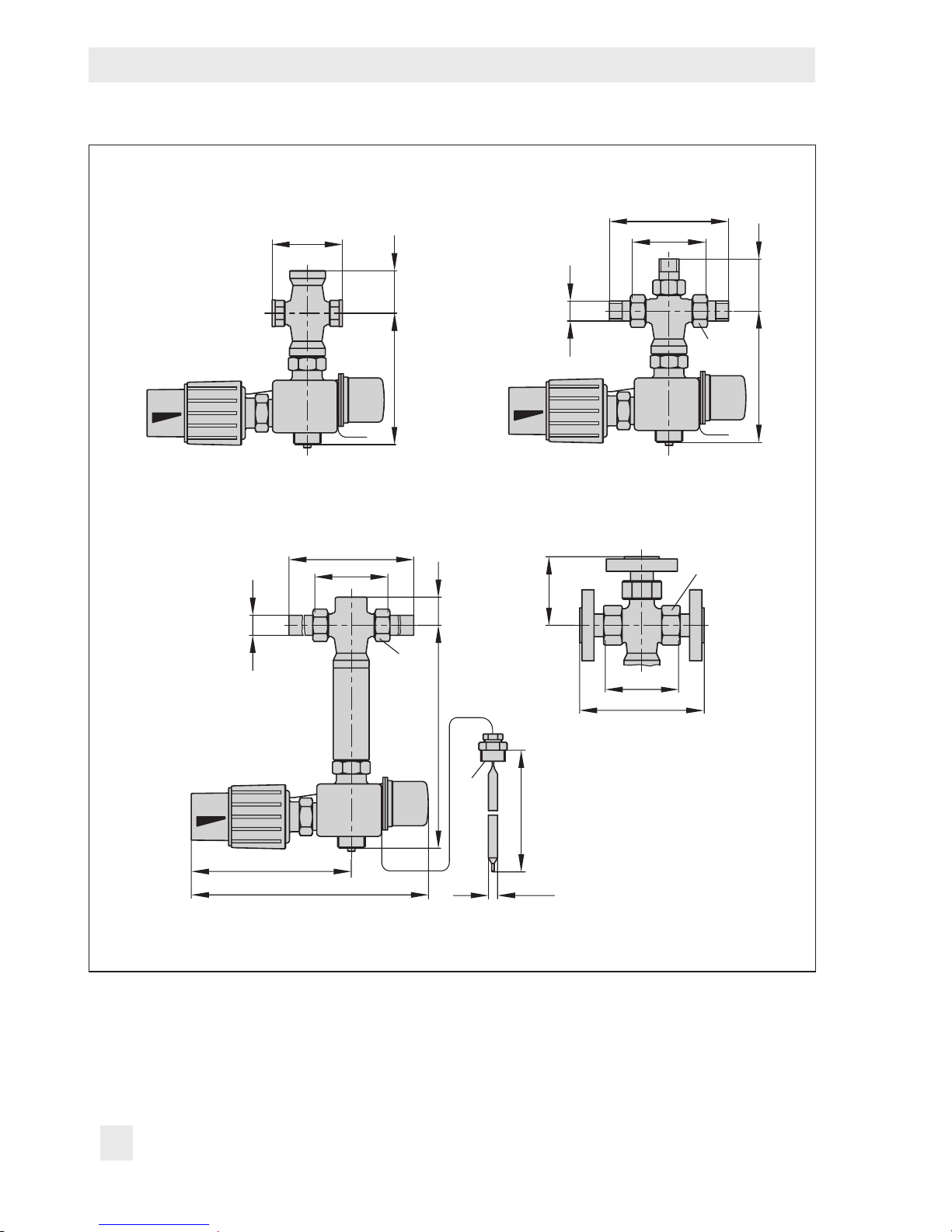

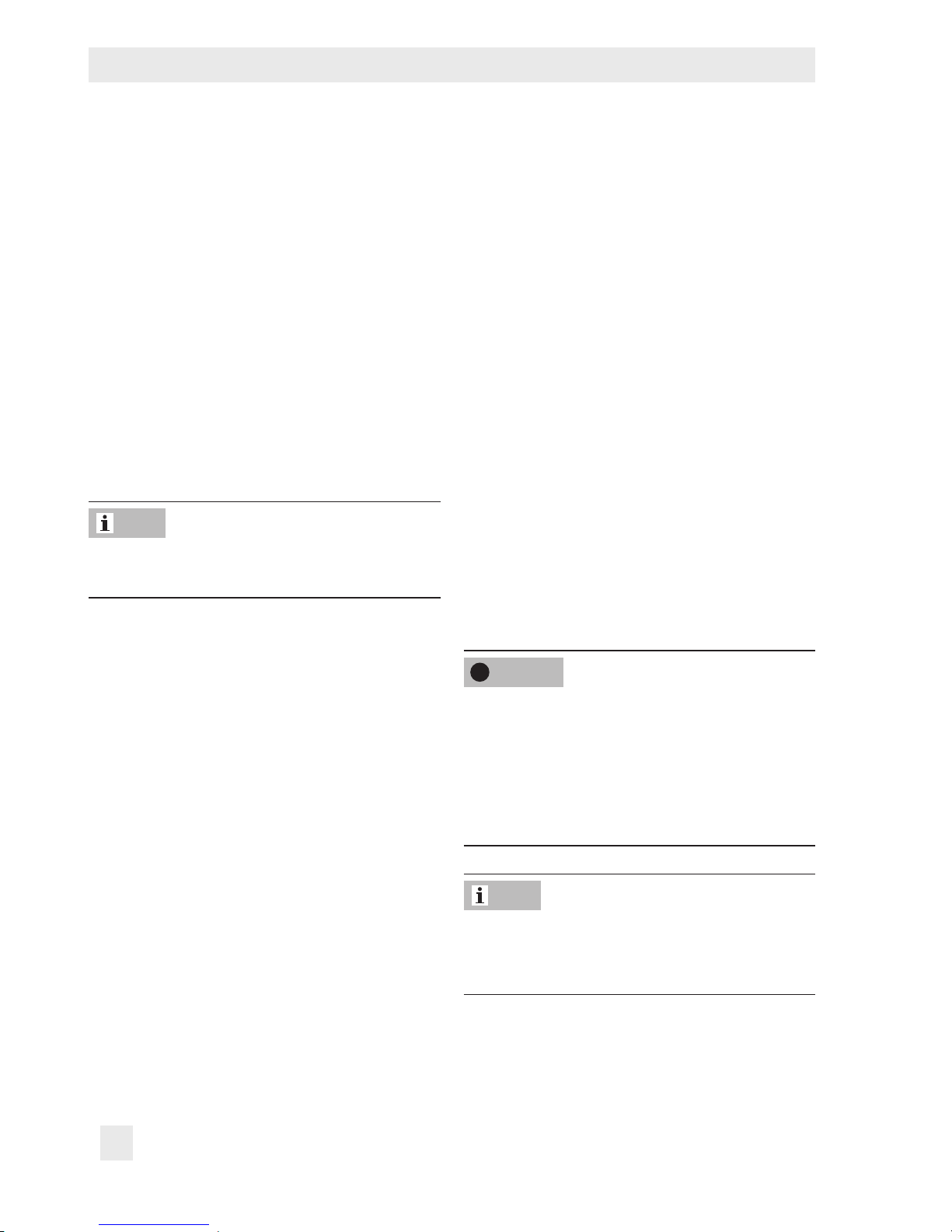

Dimensional drawings of safety temperature monitors (STM)

L

H50

L

A

L2

HH3

SW

Type2436/2403·G½ to G1 Type2433/2403

Version with threaded ends

H4

S

W

L

d

L1

H

170

255

SW

H1

L

L3

Ø12

G½

225

Type2433/2403 · Version with anges

Fig.4: Dimensional drawings

Page 17

EB 2183 EN 17

Design and principle of operation

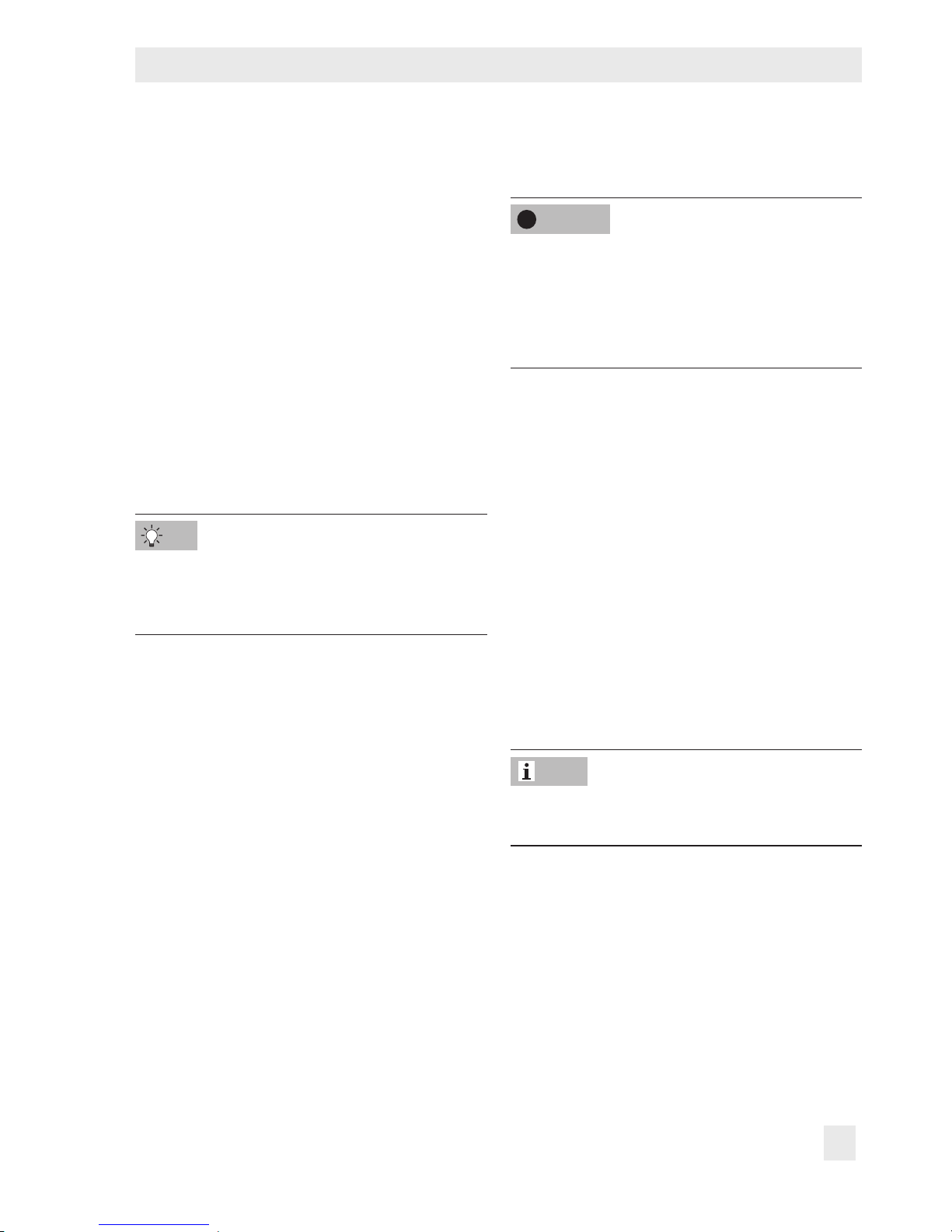

Dimensional drawings of temperature regulator with safety temperature monitor (TR/

STM)

125

M32 x 1.5

255

SW 36

90

M32 x 1.5

170

SW 17

SW 22

Ø12

250

G ½

Type243 …/2430/2403

Fig.5: Dimensional drawings

Page 18

18 EB 2183 EN

Measures for preparation

4 Measures for preparation

After receiving the shipment, proceed as fol-

lows:

1. Check the scope of delivery. Compare

the shipment received with the delivery

note.

2. Check the shipment for transportation

damage. Report any damage to

SAMSON and the forwarding agent

(refer to delivery note).

4.1 Unpacking

Do not remove the packaging until immediately before mounting it onto the valve.

Proceed as follows to lift and install the device:

1. Remove the packaging from the device.

2. Dispose of the packaging in accordance

with the valid regulations.

Note

4.2 Transporting and lifting

Due to the low service weight, lifting equipment is not required to lift and transport the

safety temperature monitor (e.g. to mount it

onto the valve).

Transport instructions

− Protect the device against external inu-

ences (e.g. impact).

− Do not damage the corrosion protection

(paint, surface coatings). Repair any

damage immediately.

− Protect the device against moisture and

dirt.

− Observe the permissible ambient tem-

peratures (see section3.1).

4.3 Storage

Risk of device damage due to improper storage.

− Observe storage instructions.

− Avoid long storage times.

− Contact SAMSON in case of different stor-

age conditions or long storage periods.

We recommend regularly checking the device and the prevailing storage conditions

during long storage periods.

NOTICE

!

Note

Page 19

EB 2183 EN 19

Mounting and start-up

Storage instructions

− Protect the safety temperature monitor

against external inuences (e.g. impact).

− Protect the device against moisture and

dirt. Store it at a relative humidity of less

than 75%. In damp spaces, prevent con-

densation. If necessary, use a drying

agent or heating.

− Make sure that the ambient air is free of

acids or other corrosive media.

− Observe the permissible ambient tem-

peratures (see section3.1).

− Do not place any objects on the device.

SAMSON's After-sales Service department

can provide more detailed storage instructions on request.

4.4 Preparation for installation

Proceed as follows:

Î Check to ensure that the connection for

the safety temperature monitor at the

valve is clean.

Î Check the safety temperature monitor for

damage.

Î Check to make sure that the type desig-

nation, pressure rating and temperature

range of the safety temperature monitor

match the plant conditions (size and

pressure rating of the pipeline, medium

temperature etc.).

Î Check any mounted thermometers to

make sure they function.

Tip

5 Mounting and start-up

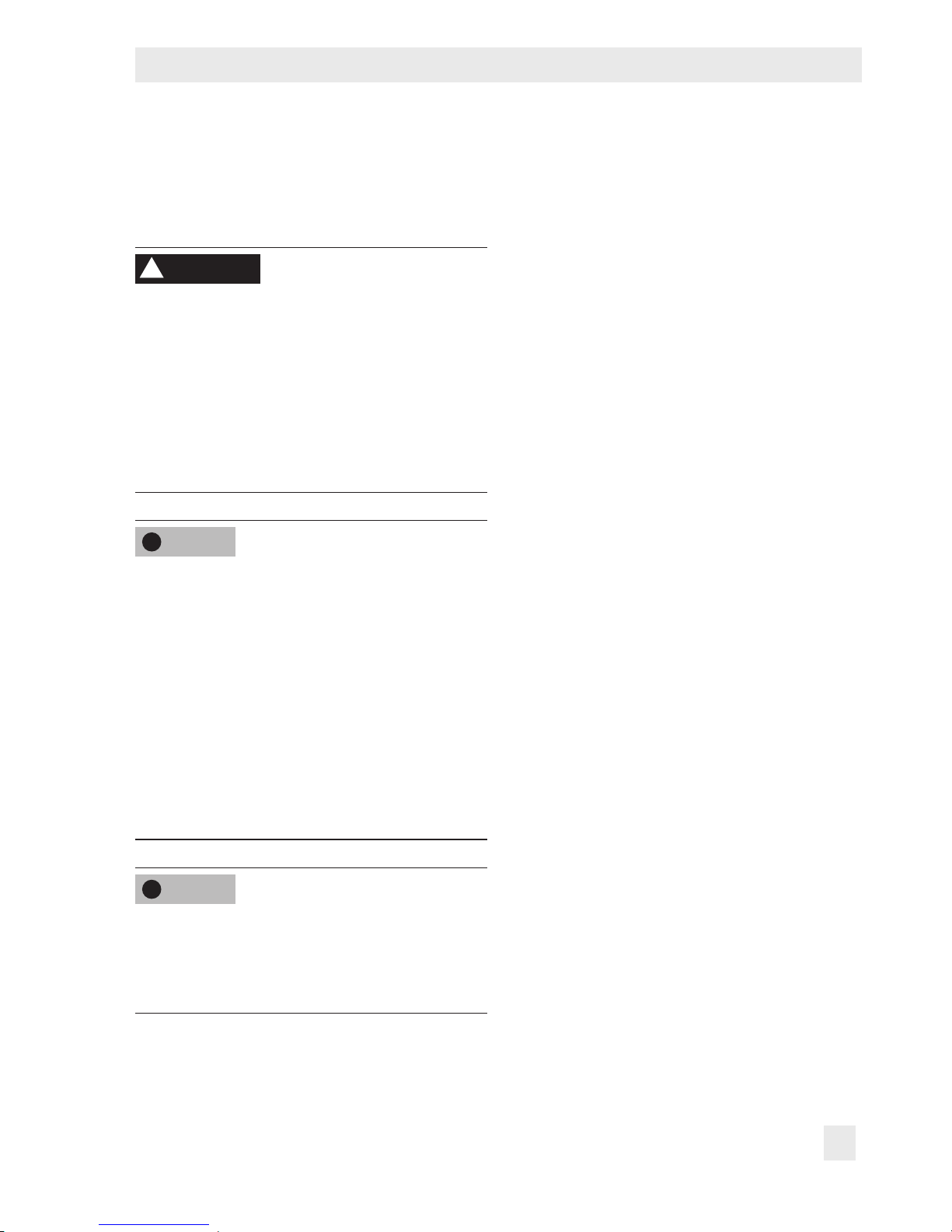

Risk of overheating due to excessive ambient

temperatures or insufcient heat dissipation

when components are insulated.

− Do not include the safety temperature mon-

itor in the insulation of the pipeline.

5.1 Mounting the safety

temperature monitor onto

the valve

The safety temperature monitor is always installed in the plant in combination with a

valve. The Type2403 Safety Temperature

Monitor can be attached to the valve body

either before or after the valve is installed in

the pipeline.

Î Connect the safety temperature monitor

(7) to the valve body (1) by tightening

the coupling nut (6) with 20Nm.

The Type2403 is installed without

thermowell.

NOTICE

!

NOTICE

!

Note

Page 20

20 EB 2183 EN

Mounting and start-up

5.2 Additional ttings

Strainer

A strainer installed upstream in the ow pipe

holds back any dirt or other foreign particles

carried along by the medium. For example,

the SAMSON Type1NI Strainer is suitable

(uT1010).

The following points must be observed

during installation of the strainer:

− Do not use the strainer to permanently

lter the process medium.

− Install the strainer upstream of the regu-

lator.

− Allow sufcient space to remove the lter.

− Observe the ow direction.

− In horizontal pipelines with gases or liq-

uids, the lter element faces downward.

The lter element faces sideways in ap-

plications with steam.

− Install strainers in vertical pipelines with

the medium owing upward with the

drain plug facing upward.

Remember to leave enough space to remove

the lter element for cleaning.

Tip

Shut-off valve

Install a hand-operated shut-off valve both

upstream of the strainer and downstream of

the regulator. This allows the plant to be shut

down for cleaning and maintenance, and

when the plant is not used for longer periods

of time.

Thermometer

Install a thermometer downstream of the regulator to monitor the temperatures prevailing

in the plant. See Fig.8.

5.3 Combination with control

thermostat

An additional Type2430 Control Thermostat

is mounted in the TR/STM version.

If the limit temperature has not yet been adjusted, adjust it before mounting the control

thermostat (see section6.1).

Î Connect the Type2430 Control Thermo-

stat to the safety temperature monitor (7)

by tightening the coupling nut (6) with

20Nm.

Note

Page 21

EB 2183 EN 21

Mounting and start-up

5.4 Installing the valve into the

pipeline

5.4.1 Installation conditions

− Choose a place of installation that allows

you to freely access the regulator even

after the entire plant has been completed.

− Make sure the direction of ow matches

the direction indicated by the arrow on

the body.

− Install the regulator free of stress and

with the least amount of vibrations as

possible.

− Observe the permissible ambient tem-

perature of max. 50°C.

5.4.2 Installing the

temperature sensor

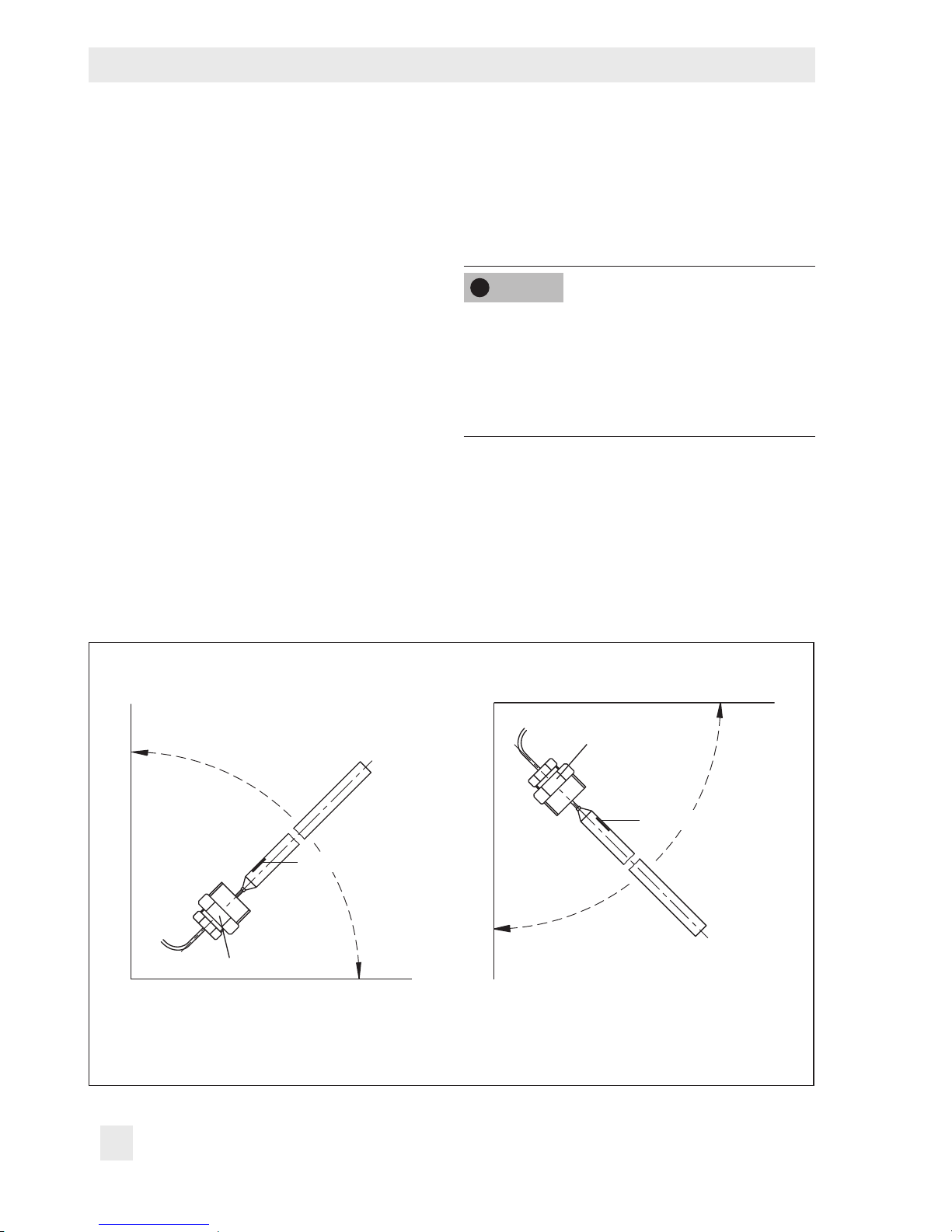

Mounting position

The mounting position of the temperature

sensor depends on the sensor version:

Sensor in horizontal position or with sensor

tip pointing up · Marked by an embossed

'o' on the screw gland.

To help align the sensor in the horizontal position, a marking bead (see Fig.6) is located

on the sensor. This marking must face upward.

Marking bead

Screw gland

Fig.6: Sensor with marking bead

Approx.

10 mm

Max.

60 mm

Fig.7: Process medium owing over the

sensor

1123 546

1 Shut-off valve

2 Strainer

3 Temperature regulator

4 Thermometer

5 Temperature sensor TR

6 Temperature sensor STM

Fig.8: Sample installation·TR/STM on a water-heated boiler

Page 22

22 EB 2183 EN

Mounting and start-up

Sensor in horizontal position or with sensor

tip pointing down · Marked by an embossed

'u' on the screw gland.

To help align the sensor in the horizontal position, a marking bead (see Fig.9) is located

on the sensor. This marking must face upward.

The screw gland seals off the sensor.

Î Weld a welding socket with G½ female

thread at the place of installation.

Î Make sure that almost all of the process

medium being monitored ows around

the sensor (of Type2403). See sectionFig.7.

Î It must be installed in a location where

overheating or considerable idling times

cannot occur.

Capillary tube

Î Carefully run the capillary tube (8) with-

out bending or twisting it. Make sure that

the capillary tube is not damaged.

Risk of capillary tube damage due to incorrect handling.

− Do not shorten the capillary tube.

− Roll up excess tube to form a ring. The

smallest bending radius is 50mm.

− Observe the permissible ambient tem-

perature of max. 50°C over the entire

length of the capillary tube.

NOTICE

!

'o' marking 'u' marking

U

O

'o' marking

'u' marking

Marking bead

Marking bead

Tip of sensor in horizontal position or pointing

up, with intermediate positions

Tip of sensor in horizontal position or pointing

down, with intermediate positions

Fig.9: Installing the temperature sensor (vapor pressure)

Page 23

EB 2183 EN 23

Mounting and start-up

5.5 Start-up

Fill the plant very slowly with the process medium on start-up.

Risk of burn injuries due to hot or cold components and pipelines.

Depending on the process medium, valve

components and pipelines may get very hot

or cold and cause burn injuries.

− Allow components and pipelines to cool

down or heat up.

− Wear protective clothing and safety gloves.

Malfunction and damage due to adverse effects of weather conditions (temperature, humidity).

Do not install the safety temperature monitor

outdoors or in rooms prone to frost. If such a

location cannot be avoided, protect the regulator against freezing up if the process me-

dium owing through the valve can freeze

up. Either heat the regulator or remove it

from the plant and completely drain the residual medium.

Risk of the valve being destroyed by steam

hammering.

− Drain off any condensate in the pipeline.

− Vent the plant.

WARNING

!

NOTICE

!

NOTICE

!

Î Fill the plant very slowly with the process

medium on start-up.

Once the safety temperature monitor is

mounted onto the valve, it can be put into

operation.

5.5.1 Gases and liquids

Î Open the shut-off valves slowly prefera-

bly starting from the upstream pressure

side.

Î Avoid pressure surges.

5.5.2 Steam

Î Completely drain and dry steam lines to

prevent water hammering.

Î Slowly allow the steam to enter the plant

to ensure that the pipes and valves warm

up evenly and to avoid excessive ow

velocities.

Î Before the full capacity is reached, drain

off the start-up condensate.

Î Make sure that the air contained in the

plant escapes as quickly as possible.

Î Open the shut-off valves slowly prefera-

bly starting from the upstream pressure

side.

Î Avoid pressure surges.

Page 24

24 EB 2183 EN

Operation

6 Operation

See Fig.2.

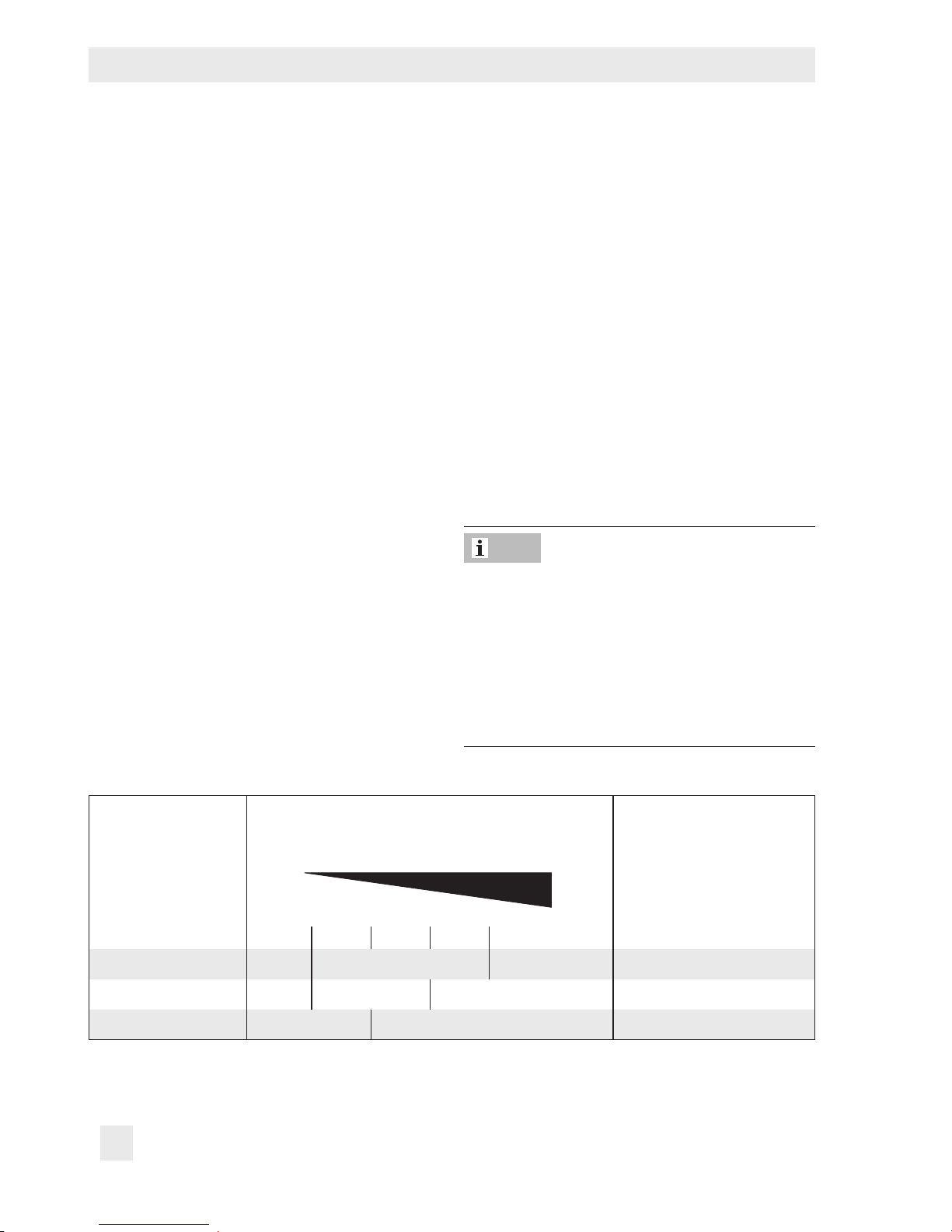

6.1 Adjusting the limit

temperature

1. If necessary, unscrew the Type2430

Control Thermostat.

2. Set the target limit temperature by turn-

ing the black adjustment knob (12, see

Fig.2) according to the scale (see Table4).

Turn the adjustment knob clockwise ()

to reduce the limit temperature.

Turn the adjustment knob counterclock-

wise () to increase the limit temperature.

3. Pull the wire through the lead-seal hole

(13) and lead-seal it to x the adjusted

limit.

4. Mount the Type2430 Control Thermostat

onto the valve (see section5.3).

The limit temperature is continuously adjust-

able.

The limit can be changed roughly by turning

the adjuster according to the specications

(limit change per turn). After reaching the

limit temperature, the Type2403 Safety Temperature Monitor must close the valve completely (leakage rate 0.05% of the K

VS

coef-

cient).

When the Type2403 Safety Temperature

Monitor is combined with a Type2430 Con-

trol Thermostat, make sure that there is a

minimum difference of approximately +15K

between the adjusted limit temperature of the

safety temperature monitor and the set point

temperature of the control thermostat.

Note

Table4: Rough limit adjustment

1)

Limit value range Scale intervals Limit change per turn

01 2

3

4

Approx.

60 to 75°C 60°C 75°C 2.6°C

75 to 100°C 75°C 100°C 2.2°C

100 to 120°C 100°C 120°C 2.4°C

1)

Precise adjustment is only possible using a thermometer (see section6.2).

Page 25

EB 2183 EN 25

Operation

6.2 Fine adjustment of the limit

temperature

Risk of bursting in pressure equipment.

Valves and pipelines are pressure equipment. Improper opening can lead to valve

components bursting.

− Before starting any work on the valve, de-

pressurize all plant sections concerned as

well as the valve.

− Drain the process medium from all the

plant sections concerned as well as the

valve.

− Wear personal protective equipment.

Risk of personal injury due to residual process medium in the valve.

While working on the valve, residual process

medium can escape and, depending on its

properties, may lead to personal injury, e.g.

(chemical) burns.

− If possible, drain the process medium from

all the plant sections concerned and the

valve.

− Wear protective clothing, safety gloves and

eyewear.

Risk of burn injuries due to hot or cold components and pipelines.

Depending on the process medium, valve

components and pipelines may get very hot

or cold and cause burn injuries.

DANGER

!

WARNING

!

WARNING

!

− Allow components and pipelines to cool

down or heat up.

− Wear protective clothing and safety gloves.

In case you want to make ne adjustments to

the safety temperature monitor or the limit

value deviates, proceed as follows:

Fine adjustment using a thermometer

installed in the plant

1. Adjust the limit temperature of the safety

temperature monitor to approx. 10K below the required limit (see section6.1).

2. When a control thermostat is mounted

on the safety temperature monitor, adjust

the limit temperature to approx. 10°C

above the limit temperature.

3. Read the resulting temperature at the

thermometer installed in the plant (after

approx. 5min.).

4. When the limit temperature is still too

low:

slowly turn the rotary knob (12) at the

safety temperature monitor clockwise to

increase the limit until the temperature at

the thermometer reaches and remains at

the limit temperature.

After the temperature reaches the limit

temperature:

turn the rotary knob clockwise () one

more turn.

5. When a control thermostat is mounted,

readjust it to the required set point.

Page 26

26 EB 2183 EN

Servicing

7.1 Preparation for return shipment

Defective devices can be returned to

SAMSON for repair. Proceed as follows to

return devices to SAMSON:

1. Put the device out of operation. See sec-

tion9.

2. Decontaminate the valve. Remove any

residual process medium.

3. Fill in the Declaration on Contamination,

which can be downloaded from our

website at uwww.samson.de > Services

> Check lists for after sales service >

Declaration on Contamination.

4. Send the device together with the lled-in

form to your nearest SAMSON subsidiary. SAMSON subsidiaries are listed on

our website at uwww.samson.de >

Contact.

7 Servicing

The safety temperature monitor does not require any maintenance. Nevertheless, it is

subject to natural wear, particularly at the

soldered joints.

The device was checked by SAMSON before

it left the factory.

− The product warranty becomes void if ser-

vice or repair work not described in these

instructions is performed without prior

agreement by SAMSON's After-sales Service department.

− Only use original spare parts by

SAMSON, which comply with the original

specications.

Note

Page 27

EB 2183 EN 27

Malfunctions

8 Malfunctions

The malfunctions listed in Table5 are caused

by mechanical faults and incorrect regulator

sizing. In the simplest case, the functioning

can be restored following the recommended

action. Special tools may be required for re-

pair work.

Depending on the operating conditions,

check the valve at certain intervals to prevent

possible failure before it can occur. Opera-

tors are responsible for drawing up an inspection plan.

Table5: Troubleshooting

Malfunction Possible reasons Recommended action

The temperature adjusted at the

control thermostat reaches the

adjusted limit temperature.

Control thermostat defective Î Replace the control thermostat.

Temperature exceeds the adjusted

limit.

Foreign particles blocking the valve

plug

Î Remove foreign particles.

Î Replace damaged parts.

Valve trim is worn. Î Replace damaged parts.

Increased ow through closed valve

(seat leakage)

Foreign particles blocking the valve

plug

Î Remove foreign particles.

Î Replace damaged parts.

Valve trim, particularly with soft seat,

is worn.

Î Replace damaged parts.

Heat supply has been interrupted.

STM is defective and has moved to

the fail-safe position.

Î Replace the STM.

Temperature sensor not correctly

installed.

Î Check installation. Observe notes

on installation (see section5.4).

Strainer blocked Î Clean strainer.

Contact SAMSON's After-sales Service department for malfunctions not listed in the table.

SAMSON's After-sales Service department

can support you to draw up an inspection

plan for your plant.

Note

Tip

Page 28

28 EB 2183 EN

Decommissioning and disassembly

− Allow components and pipelines to cool

down or heat up.

− Wear protective clothing and safety gloves.

9.1 Decommissioning

To decommission the safety temperature

monitor before removing it, proceed as follows:

1. Close the shut-off valve on the upstream

side of the valve.

2. Close the shut-off valve on the down-

stream side of the valve.

3. Completely drain the pipelines and

valve.

4. Depressurize the plant. Shut off or dis-

connect the control line, if installed.

5. If necessary, allow the pipeline and de-

vice to cool down or heat up.

6. Remove the sensor from the pipeline

and, if necessary, seal the opening.

7. Remove the safety temperature monitor

from the valve.

9.2 Disposal

Î Observe local, national and internation-

al refuse regulations.

Î Do not dispose of components, lubricants

and hazardous substances together with

your household waste.

9 Decommissioning and

disassembly

Risk of bursting in pressure equipment.

Valves and pipelines are pressure equipment. Improper opening can lead to valve

components bursting.

− Before starting any work on the valve, de-

pressurize all plant sections concerned as

well as the valve.

− Drain the process medium from all the

plant sections concerned as well as the

valve.

− Wear personal protective equipment.

Risk of personal injury due to residual process medium in the valve.

While working on the valve, residual process

medium can escape and, depending on its

properties, may lead to personal injury, e.g.

(chemical) burns.

− If possible, drain the process medium from

all the plant sections concerned and the

valve.

− Wear protective clothing, safety gloves and

eyewear.

Risk of burn injuries due to hot or cold components and pipelines.

Depending on the process medium, valve

components and pipelines may get very hot

or cold and cause burn injuries.

DANGER

!

WARNING

!

WARNING

!

Page 29

EB 2183 EN 29

Appendix

10 Appendix

10.1 After-sales service and

spare parts

After-sales service

Contact SAMSON's After-sales Service de-

partment for support concerning service or

repair work or when malfunctions or defects

arise.

E-mail

You can reach the After-sales Service De-

partment at aftersalesservice@samson.de.

Addresses of SAMSONAG and its subsidiaries

The addresses of SAMSON AG, its

subsidiaries, representatives and service

facilities worldwide can be found on the

SAMSON website (uwww.samson.de) or in

all SAMSON product catalogs.

Required specications

Please submit the following details:

− Order number and position number in

the order

− Type and nominal size (valve)

− Conguration ID (Type2403 STM)

− Conguration ID (Type2430 TR)

− Limit value range

− Temperature and process medium

− Is a strainer installed?

− Installation drawing showing the exact

location of the regulator and all the

additionally installed components

(Type2430 Control Thermostat, shut-off

valves, pressure gauge, etc.)

Spare parts

There are no spare parts available for the

safety temperature monitor.

10.2 Certicates

The EU declarations of conformity are in-

cluded on the next pages.

Page 30

30 EB 2183 EN

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3 60314 Frankfurt am Main

Telefon: 069 4009-0 · T elefax: 069 4009-1 507

E-Mail: samson@sams on.de

Revision 03

Modul D/Module D, Nr./No. / N° CE-0062-PED-D-SAM 001-16-DEU-rev-A

SAMSON erklärt in alleiniger Verantwortung für folgende Produkte:/For the following products, SAMSON hereby declares

under its sole responsibility:

Sicherheitstemperaturbegrenzer STB 2403 (2750-5)/Safety Temperature Monitor STM 2403 (2750-5)

in Kombination mit Ventilen/combined with valves

2431, 2432, 2433, 2435, 2436, 2437, 2479, 2488 (2710, 2720, 2730)

die Konformität mit nachfolgender Anforderung/the conformity with the following requirement.

Richtlinie des Europäischen Parlaments und des Rates zur

Harmonisierung der Rechtsvorschriften der Mitgliedstaaten über die

Bereitstellung von Druckgeräten auf dem Markt.

2014/68/EU vom 15.05.2014

Directive of the European Parliament and of the Council on the

harmonization of the laws of the Member States relating of the making

available on the market of pressure equipment.

2014/68/EU of 15 May 2014

EG-Baumusterprüfbescheinigung

EC Type Examination Certificate

Modul B

Module B

Zertifikat-Nr./Certificate no.

01 202 931-B-12-0009

Angewandtes Konformitätsbewertungsverfahren

Conformity assessment procedure applied

Modul D

Module D

Zertifikat-Nr./Certificate no.

CE-0062-PED-D-SAM-001-16-DEU-rev-A

Dem Entwurf zu Grunde gelegt sind Verfahren aus:/The design is based on the procedures specified in the following standards:

DIN EN 12516-2, DIN EN 12516-3 bzw./or ASME B16.1, ASME B16.24, ASME B16.42

Das Qualitätssicherungssystem des Herstellers wird von folgender benannter Stelle überwacht:

The manufacturer’s quality management system is monitored by the following notified body:

Bureau Veritas S.A. Nr./No. 0062, Newtime, 52 Boulevard du Parc, IIle de la Jatte, 92200 Neuilly sur Seine, France

Hersteller:/Manufacturer: SAMSON AG, Weismüllerstraße 3, 60314 Frankfurt am Main, Germany

Frankfurt am Main, 08. Februar 2017/08 February 2017

Klaus Hörschken Dr. Michael Heß

Zentralabteilungsleiter/Head of Central Department Zentralabteilungsleiter/Head of Central Department

Entwicklung Ventile und Antriebe/R&D, Valves and Actuators Product Management & Technical Sales

EU

-Konformitaetserklaerung_ Blatt-16_Modul-B_und_Modul-D_DE-EN_Rev.03_2017-02-08.docx

Page 31

EB 2183 EN 31

SAMSON AKTIENGESELLSCHAFT

Weismüllerstraße 3 60314 Frankfurt am Main

Telefon: 069 4009-0 · T elefax: 069 4009-1 507

E-Mail: samson@sams on.de

Revision 03

Modul H/Module H, Nr./No. / N° CE-0062-PED-H-SAM 001-16-DEU-rev-A

SAMSON erklärt in alleiniger Verantwortung für folgende Produkte:/For the following products, SAMSON hereby declares

under its sole responsibility:

Ventile für Temperaturregler/Valves for temperature regulators

Typ/Type 2111, 2121, 2431, 2432, 2435, 2436, 2437 (Erz.-Nr./Model No. 2710), 2433, 2118 (2713), 2119 (2803), 2111, 2121 (2811), 2114

(2814)

die Konformität mit nachfolgender Anforderung/the conformity with the following requirement.

Richtlinie des Europäischen Parlaments und des Rates zur Harmonisierung der Rechtsvorschriften

der Mitgliedstaaten über die Bereitstellung von Druckgeräten auf dem Markt.

2014/68/EU vom 15. 05.2014

Directive of the European Parliament and of the Council on the harmonization of the laws of the

Member States relating of the making available on the market of pressure equipment.

2014/68/EU of 15 May 2014

Angewandtes Konformitätsbewertungsverfahren für Fluide nach Art. 4(1)(c.ii) und (c.i) zweiter

Gedankenstrich.

Modul siehe

Tabelle

durch

certified by

Bureau Veritas

S. A. (0062)

Conformity assessment procedure applied for fluids according to Artic le 4(1)(c.ii) and (c.i), second

indent

See table for

module

Nenndruck

Pressure rating

DN

NPS

15½ 20¾ 251 321¼40

1½ 502

65

803 1004 125

1506 2008 250

10

PN 16 ohne/without

(1)

A

(2)(3)

H

PN 25 ohne/without

(1)

A

(2)(3)

H

PN 40 ohne/without

(1)

A

(2)(3)

H

Class 150 ohne/without

(1)

A

(2)(3)

H

Class 300 ohne/without

(1)

A

(2)(3)

H

(1) Das auf dem Stellgerät aufgebrachte CE-Zeichen hat keine Gültigkeit im Sinne der Druckgeräterichtlinie.

The CE marking affixed to the control valve is not valid in the sense oft the Pressure Equipment Directive.

(2) Das auf dem Stellgerät aufgebrachte CE-Zeichen gilt ohne Bezeichnung der benannten Stelle (Kenn-Nr. 0062).

The CE marking affixed to the control valve is valid without specifying the notified body (ID number 0062).

(3) Die Identifikationsnummer 0062 von Bureau Veritas S.A. gilt nicht für Modul A.

The identification number 0062 of Bureau Veritas S.A. is not valid for Modul A.

Geräte, denen laut Tabelle das Konformitätsbewertungsverfahren Modul H zugrunde liegt, beziehen sich auf die

„Zulassungsbescheinigung eines Qualitätssic herungssystems“ ausgestellt durch die Notifizierte Stelle.

Devices whose conformity has been assessed based on Module H refer to the certificate of approval for the quality management system

issued by the notified body

.

Dem Entwurf zu Grunde gelegt sind Verfahren aus:/The design is based on the procedures specified in the following standards:

DIN EN 12516-2, DIN EN 12516-3 bzw./or ASME B16.1, ASME B16.24, ASME B16.34, ASME B16.42

Das Qualitätssicherungssystem des Herstellers wird von folgender benannter Stelle überwacht

The manufacturer’s quality management system is monitored by the following notified body:

Bureau Veritas S.A. Nr./No. 0062, Newtime, 52 Boulevard du Parc, IIle de la Jatte, 92200 Neuilly sur Seine, France

Hersteller:/Manufacturer: SAMSON AG, Weismüllerstraße 3, 60314 Frankfurt am Main, Germany

Frankfurt am Main, 08. Februar 2017/08 February 2017

Klaus Hörschken Dr. Michael Heß

Zentralabteilungsleiter/Head of Central Department Zentralabteilungsleiter/Head of Central Department

Entwicklung Ventile und Antriebe/R&D, Valves and Actuators Product Management & Technical Sales

EU

-Konformitaetserklaerung_ Blatt-05_Modul-A_Modul-H_DE-EN_Rev.03_2017-02-08.docx

Page 32

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

samson@samson.de · www.samson.de

EB 2183 EN

2018-06-20 · English

Loading...

Loading...