Page 1

Self-operated Pressure Regulators

Pressure Reducing Valve Type 2357-1/-6

Excess Pressure Valve Type 2357-2/-7

Type 2357-1 Pressure

Reducing Valve

Type 2357-2 Excess

Pressure Valve

Type 2357-6 Pressure

Reducing Valve

Mounting and

Operating Instructions

EB 2557 EN

Edition April 2011

Page 2

Contents

Contents Page

1 Design and principle of operation . . . . . . . . . . . . . . . . . . . . . . 3

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.2 Shut-off valve and pressure gauge . . . . . . . . . . . . . . . . . . . . . . 5

3 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 Set point adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.2 Changing the set point range. . . . . . . . . . . . . . . . . . . . . . . . . 7

4 Dimensions in mm and weights . . . . . . . . . . . . . . . . . . . . . . . 9

General safety instructions

The regulators must be installed, started up and serviced by fully trained and

4

qualified personnel only, observing the accepted industry codes and

practices. Make sure employees or third persons are not exposed to any

danger.

All safety instructions and warnings in these instructions, particularly those

concerning installation, start-up and maintenance, must be observed.

For appropriate operation, make sure that the regulator is only used in

4

applications where the operating pressure and temperatures do not exceed

the operating values based on the sizing data submitted in the order.

Note that the manufacturer does not assume any responsibility for damage

4

caused by external forces or any other external factors.

Any hazards which could be caused in the regulator by the process medium

or operating pressure are to be prevented by means of appropriate

measures.

Proper shipping and appropriate storage are assumed.

4

The declaration of conformity issued for a valve bearing the CE marking

4

includes information on the applied conformity assessment procedure and

will be provided on request.

2 EB 2557 EN

Page 3

Design and principle of operation

1 Design and principle of

operation

The pressureregulators maintain the pressure

at an adjusted set point and are particularly

suitable for cryogenic applications.

Type 2357-1 and Type 2357-6 Regulators

(globe valves)

The regulators act as pressure reducing

valves when the medium flows from port A to

port B. When no pressure is applied, the

valve is open.

The pressure downstream of the valve B is

transmitted to the operating diaphragm (3).

The resulting positioning force moves the

valve plug (2) in relation to the spring force,

which can be adjusted at the set point adjuster (10). The valve closes as the pressure

downstream of the valve B increases.

When the regulators are used as pressure

build-up regulators, the medium flows from

port B to port A. The pressure upstream of the

valve (B) is transmitted to the operating diaphragm (3). The valve closes as the pressure

upstream of the valve increases and opens as

the upstream pressure drops.

The pressure build-up regulator additionally

assumes the function of a safety valve,

depressurizing the pressurized valve when

the set point is exceeded by more than 5 bar.

When the pressure has overcome the force of

the springs located on top, the valve opens to

balance the pressures.

Type 2357-2 and Type 2357-7 Regulators

(angle valves)

The regulators functioningas excesspressure

valves, the medium always flows from port A

to port B. When no pressure is applied, the

valve is closed. The pressure at port A acts on

the operating diaphragm (3) in the valve

body. The resulting force opposes the adjust

able spring force. As the pressure increases,

the valve opens until the set point is reached.

Regulators functioning as excess pressure

valves can optionally be equipped with a

non-return unit (12) which prevents the me

dium from flowing back.

EC type examination

An EC type examination according to the

Pressure Equipment Directive 97/23/EC,

Module B has been performed on the regulator versions for PN 50.

-

-

EB 2557 EN 3

Page 4

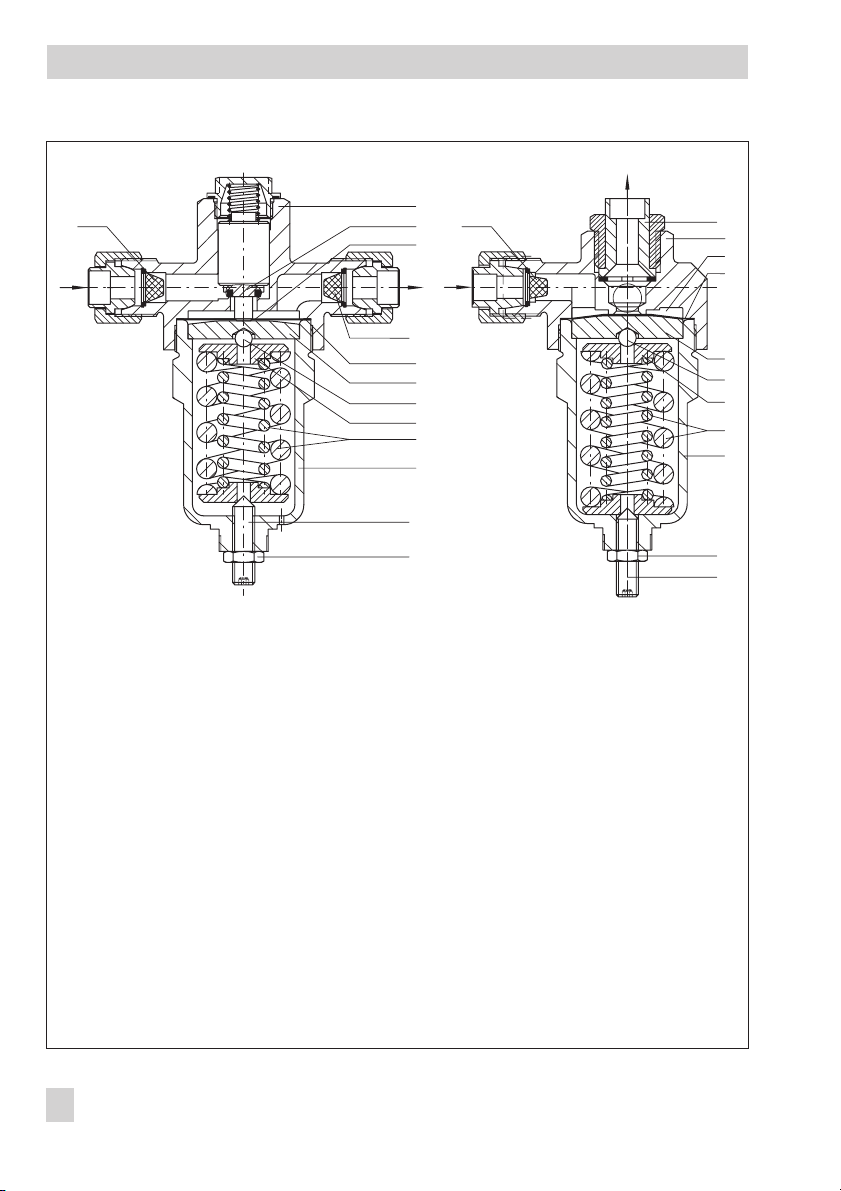

Design and principle of operation

7

B

1

2

13

13

3

AA

B

12

1

3

4

13

4

5

5

6

6

7

8

9

8

9

10

11

1 Body

2 Plug

3 Operating diaphragm

4 Gasket

5 Diaphragm plate

6 Ball

Fig. 1 · Sectional drawings of Type 2357-1/-6 (left) and Type 2357-2/-7 (right)

7 Spring plate

8 Set point spring(s)

9 Lower section of body

10 Set point adjuster

11 Lock nut

12 Non-return unit

13 Strainer

4 EB 2557 EN

11

10

Page 5

Installation

2 Installation

2.1 Mounting position

The pressure regulator must be in

stalled with the actuator housing

hanging downward.

Observe the following directions of flow:

A to B in pressure reducing valves

4

B to A in pressure build-up regulators

4

with safety function

A to B in excess pressure valves

4

equipped with a non-return unit. Port B

must point upward.

The ports are marked.

Note: Make sure that any impurities carried

along by the process medium in the connected pipelines do not impair the proper

functioning and especially the tight shut-off of

the regulator.

-

2.2 Shut-off valve and pressure

gauge

We recommend installing a hand-operated

shut-off valve bothupstream anddownstream

of the regulator to be able to shut down the

plant for cleaning and maintenance, and

when the plant is not used for longer periods

of time.

Install a pressure gauge both upstream and

downstream of the regulator to monitor the

pressures prevailing in the plant.

11232

1 Shut-off valve

2 Pressure gauge

3 Pressure regulator

Fig. 2 · Typical installation

EB 2557 EN 5

Page 6

Set point adjustment

3 Operation

3.1 Set point adjustment

The pressure regulator is adjusted at the

factory to the set points listed in the table.

However, you can change them by turning

the set point adjuster (10).

When pressure gauges are installed in the

connected pipelines, you can adjust the de

sired set point directly while monitoring the

corresponding pressure gauge.

When no pressure gauge is installed, use the

adjustment diagram to adjust the set point.

To increasethe set point, turn the setpoint ad

juster into the body, and to decrease the set

point, turn the set point adjuster out of the

body.

1. Undo the lock nut to allow the set point

adjuster to move freely.

2. Determine the difference between the

fixed set point (table below) and the required set point. Turn the set point adjuster the required amount of turns as

specified in the diagram.

Any subsequent change in set point can

be also be made by determining the re

quired number of turns using the specifi

cations listed in the table in “Set point

change per turn”.

-

3. Secure the setting with the lock nut.

Set point/Set point range in bar

40

35

-

30

25

-

20

15

10

5

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14

-

Fig. 3 · Adjustment diagram

10 to 36

5 to 25

1 to 25

Turns of the set point adjuster

8 to 40

1 to 8

Table 1 · Set point adjustment

Nominal pressure PN 40 PN 50

Set point range in bar 0.2 to 3 1 to 25 10 to 36 0.2 to2.5 1 to 8 5 to 25 8 to 40

Set point

adjusted at the

factory to

approx. … bar

Set point change per turn

in bar

2357-1 1 12 20 1 3 12 25

2357-2 1 13 21 1 4 13 26

0.4 2.5 3.5 0.4 1 2.5 3.5

6 EB 2557 EN

Page 7

Operation

3.2 Changing the set point range

The set point ranges adjusted by themanufac

turer can be changed subsequently by ex

changing the set point springs (8) and the op

erating diaphragms (3).

In case of doubt, we recommend you to let

SAMSON perform this work for you.

The addresses ofSAMSON AG, its subsidiar

ies, representatives and service facilities

worldwide can be found on the Internet at

www.samson.de, in a SAMSON product cat

alog or on the back of these mounting and

operating instructions.

CAUTION!

Always remove the regulator from the pipe

when performing anyassembly work. Prior to

removing the regulator, relieve the pressure

as well as thaw and drain the corresponding

section of the plant.

1. Unscrew the lock nut (11). Completely re

-

-

-

-

-

lieve the set pointsprings (8)of tension by

turning the set point adjuster (10) in a

counterclockwise direction.

2. Place the lower section of the body (9)

into avise, but do notclamp it. Better: use

a box wrench with width across flats =

55 mm. Unscrew the body (1) using an

open-end wrench with width across flats

= 36 mm and remove all parts from the

lower section of the body. Be careful not

to damage the operating diaphragms

(3).

3. Install set point spring(s) for the required

set point range, the spring plates (7), the

ball (6) and the diaphragm plate (5) in

the lower section of the body.

4. Place the required number of diaphragms (see table of spare parts) onto

the diaphragm plate and replace the

PTFE gasket (4) of the valve body, if required.

5. Carefully place the body onto the lower

section of the body. Then screw the body

onto thelower section of the body using a

tightening torque of approx. 180 Nm for

PN 40 and approx. 250 Nm for PN 50.

-

EB 2557 EN 7

Page 8

Spare parts

Table 2 · Spare parts list with order numbers

Spare parts list Order no.

PN 40 PN 50

Set point range in bar

Pos. Spare part

3

Number of diaphragms 33357

Set of accessories:

with 20 diaphragms

with 50 diaphragms

4

Seals, set of accessories:

with 20 seals

with 50 seals

8 Set point springs

Non-return unit

12

for Type 2357-2

13 Strainer

Connecting parts:

Soldering nipple with

connection nut

1 to 25 10 to 36 1 to 8 5 to 25 8 to 40

1400-9747

1400-9747

1400-7626

1400-7627

1400-7630

1400-7631

1 to 25 bar

10 to 36 bar

1400-5129 (15 mm) or 1400-5139 (16 mm)

1400-5136 (270 x 10

1400-5126 (50 x 10

1400-5133 (1 xÆ15)

1400-5134 (2 xÆ15)

1400-5138 (1 xÆ16)

1400-5137 (2 xÆ16)

1400-9383 1 to 8 bar

1400-7640 5 to 25 bar

1400-7305 8 to 40 bar

1400-7623

1400-7624

1400-7628

1400-7629

-6

m mesh size) or

-6

m mesh size)

Note: Accessories and spare parts with order

numbers 1400-xxxxx are always delivered

"free from oil and grease for oxygenservice."

8 EB 2557 EN

Page 9

4 Dimensions in mm and weights

Dimensions in mm and weights

150

110

51(35)

140 (95)

Type 2357-1

Weight approx. 2.0 (0.9) kg

118

60

75

55

Ø16

G/

40

3

4

25

140 (95)

G/

3

4

Type 2357-2

Weight approx. 1.7 (0.8) kg

Values in parentheses for PN 40 version

Ø15

Ø16

Ø15

60

G/

3

4

40

Ø15

140

Type 2357-6

Weight approx. 3.0 kg

Fig. 4 · Dimensions

140

Type 2357-7

Weight approx. 2.5 kg

EB 2557 EN 9

Page 10

10 EB 2557 EN

Page 11

EB 2557 EN 11

Page 12

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 2557 EN

S/Z 2011-04

Loading...

Loading...