Page 1

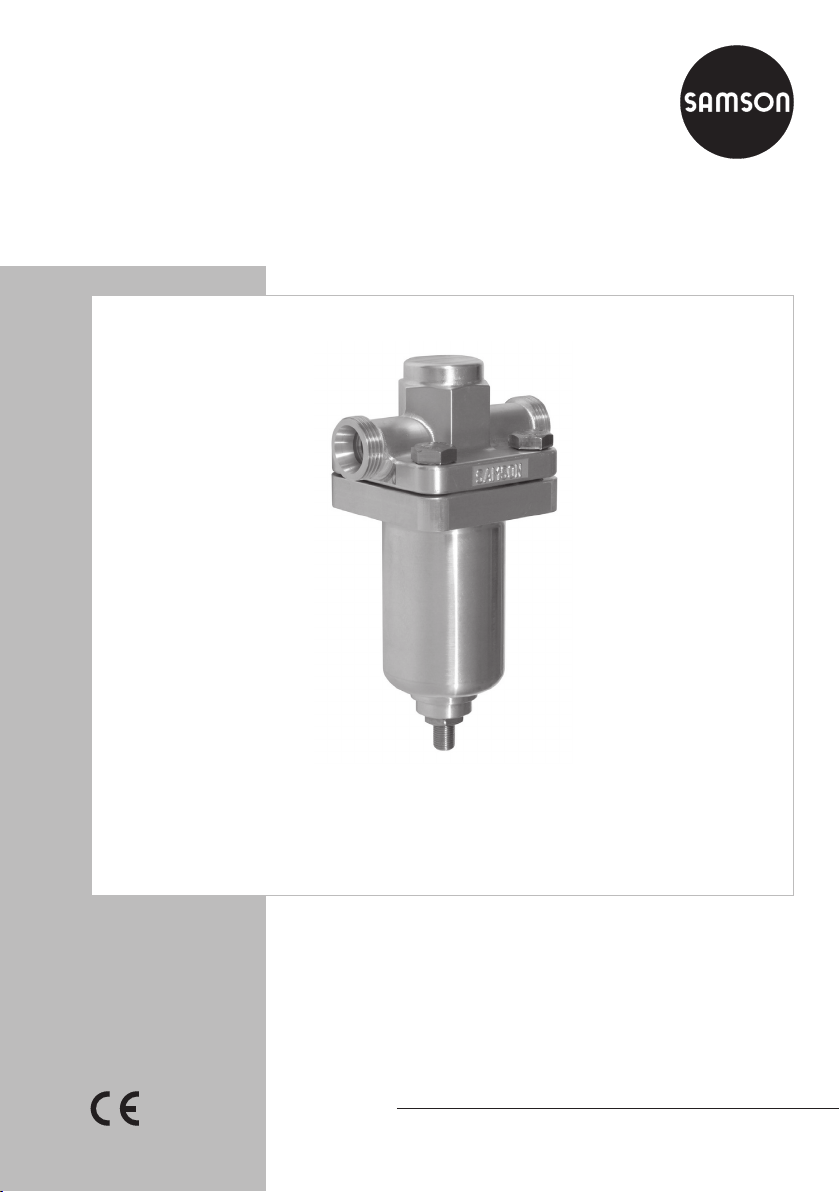

Self-operated Pressure Regulators

Type 2357-11 Pressure Build-up Regulator

Type 2357-21 Excess Pressure Valve

Type2357-11 Pressure Build-up Regulator/Type 2357-21 Excess Pressure Valve

Mounting and

Operating Instructions

EB 2560 EN

Edition August 2014

Page 2

Denition of signal words

DANGER!

Hazardous situations which, if not

avoided, will result in death or seri

ous injury

WARNING!

Hazardous situations which, if not

avoided, could result in death or se

rious injury

2 EB 2560 EN

-

-

NOTICE

Property damage message or malfunction

Note:

Additional information

Tip:

Recommended action

Page 3

Contents

1 General safety instructions .............................................................................4

2 Process medium and scope of application .......................................................5

2.1 Transportation and storage .............................................................................5

3 Design and principle of operation ..................................................................6

4 Installation ....................................................................................................8

4.1 Mounting position ..........................................................................................8

4.2 Shut-off valve .................................................................................................8

5 Operation .....................................................................................................8

5.1 Start-up .........................................................................................................8

5.2 Set point adjustment .......................................................................................8

5.2.1 Changing the set point range ..........................................................................9

5.3 Decommissioning .........................................................................................10

6 Maintenance ...............................................................................................10

6.1 Exchanging the seat and plug .......................................................................10

6.2 Exchanging the non-return unit .....................................................................11

7 Customer service .........................................................................................12

8 Nameplate ..................................................................................................12

9 Dimensions and weights ..............................................................................13

10 Technical data .............................................................................................14

EB 2560 EN 3

Page 4

General safety instructions

1 General safety instructions

− The regulators are to be mounted, started up or serviced by fully trained and

qualied personnel only; the accepted industry codes and practices are to

be observed. Make sure employees or third persons are not exposed to any

danger.

− All safety instructions and warnings given in these mounting and operating

instructions, particularly those concerning installation, start-up and maintenance, must be strictly observed.

− According to these mounting and operating instructions, trained person-

nel refers to individuals who are able to judge the work they are assigned

to and recognize possible dangers due to their specialized training, their

knowledge and experience as well as their knowledge of the applicable

standards.

− The regulators comply with the requirements of the European Pressure Equip-

ment Directive 97/23/EC. The declaration of conformity issued for a regulator bearing the CE marking includes information on the applied conformity

assessment procedure. The declaration of conformity is available on request.

− To ensure appropriate use, only use the regulator in applications where the

operating pressure and temperatures do not exceed the specications used

for sizing the regulator at the ordering stage.

− The manufacturer does not assume any responsibility for damage caused by

external forces or any other external factors.

− Any hazards that could be caused in the pressure regulator by the process

medium, operating pressure or by moving parts are to be prevented by taking appropriate precautions.

− Proper transport, storage, installation, operation and maintenance are as-

sumed.

4 EB 2560 EN

Page 5

Process medium and scope of application

2 Process medium and scope of application

Pressure regulators for cryogenic gases and liquids as well as other liquids, gases and va-

pors. Operating pressures up to 63bar, with set points from 1 to 40bar. Temperature range

from –200 to +200°C. Oxygen clean according to international standards and guidelines.

The regulators are designed to keep the pressure constant to the adjusted set point, especially in cryogenic plants.

WARNING!

Risk of injury and property damage due to high pressure in the plant!

A suitable overpressure protection must be installed on site in the plant section.

2.1 Transportation and storage

The regulators must be carefully handled, transported and stored. Protect the regulators

against adverse inuences, such as dust, dirt or moisture before they are installed.

In the delivered state, the pressure regulators are packed to be free of oil and grease for oxygen service. To avoid contamination, do not open the packaging until immediately before installation.

EB 2560 EN 5

Page 6

Design and principle of operation

3 Design and principle of op-

eration

See Fig. 1 on page7.

Ports A and B are marked on the valve body.

Type 2357-11 Pressure Build-up Regulator

Functioning as a Type 2357-11 Pressure

Build-up Regulator (Fig. 1) with direction of

ow from port B to port A, the pressure upstream of the valve (port B) is transmitted to

the operating diaphragm. The valve closes

when the upstream pressure increases and

opens when the upstream pressure decreases.

The pressure build-up regulator operates

as a safety valve and relieves the pressure

chamber of pressure when the pressure exceeds the set point by 5bar. After overcoming the force of the top plug spring (16), the

valve opens to equalize the pressures.

The valve is open when no pressure is applied. The pressure upstream of the valve

(port B) is transmitted to the operating diaphragm (3). The positioning force produced

moves the valve plug (2) depending on the

spring force adjustable at the set point adjuster (10). The valve closes when the pressure upstream of the valve (port B) increases.

moves the valve plug (2.1) depending on the

spring force adjustable at the set point adjuster (10). The valve closes when the pressure downstream of the valve (port B) rises.

Type 2357-21 Excess Pressure Valve

The medium ows through the Type 2357-21

Excess Pressure Valve (Fig. 3) from port B to

port A. The valve is closed when no pressure

is applied. The pressure at port B is transmitted internally to the operating diaphragm

(3). The positioning force produced opposes

the adjustable spring force. The valve opens

when the pressure increases until the set

point is reached. The integrated non-return

unit prevents the medium from owing back.

EC type examination

An EC type examination according to the

Pressure Equipment Directive 97/23/EC,

Module B has been performed on the regulators.

Type 2357-11 Pressure Reducing Valve

The process medium ows from port A to

port B when the Type2357-11 Pressure Reg-

ulator is used as a pressure reducing valve.

The valve is open when no pressure is ap-

plied. The pressure downstream of the valve

(port B) is transmitted to the operating diaphragm (3). The positioning force produced

6 EB 2560 EN

Page 7

16

2.1

15

11

10

4.1

BA

Design and principle of operation

Pressure build-up regulator

Pressure reducing valve

1

B

A

3

5

6

7

8

7

9

Direction of ow

1 Valve body

2.1 Plug

3 Operating diaphragm

4.1 Gasket (bottom section of the body)

5 Diaphragm plate

6 Ball

7 Spring plate

8 Set point springs

9 Spring housing (bottom section of the

body)

10 Set point adjuster (hexagon socket,

5mm)

11 Lock nut (17mm)

12 Integrated non-return unit

14 Body screws

15 Seat

16 Plug spring

12

3

4.1

Fig. 1: Functional diagram

Type2357-11

Type2357-21

1

14

5

6

7

8

EB 2560 EN 7

Page 8

Installation

4 Installation

In the delivered state, the regulators are

packed to be free of oil and grease for oxygen service.

WARNING!

Use of oil and grease in oxygen atmospheres!

Risk of explosion!

Make sure that the regulator is absolutely clean and free of oil and grease

on installing it.

Flush and clean the pipeline thoroughly before installing the regulator.

− Make sure the regulator is installed free

of stress.

− Install a strainer upstream of the regu-

lator.

Otherwise, impurities in the pipeline

may impair the proper functioning of the

valve, above all the tight shut-off.

4.1 Mounting position

Install the pressure regulator with

the actuator housing suspended

downward in horizontal pipelines.

Observe the ow direction.

Type 2357-11 Pressure Build-up Regulator

with safety function

− Direction of ow from port B to port A

Type 2357-11 Pressure Reducing Valve

− Direction of ow from port A to port B

Type 2357-21 Excess Pressure Valve with

with non-return unit

B

− Direction of ow from port B to port A

The ports are marked.

Required spare parts and accessories are

listed in Data Sheet uT2570EN.

4.2 Shut-off valve

We recommend installing a hand-operated shut-off valve both upstream and downstream of the regulator. This allows the plant

to be shut down for cleaning and maintenance, and when the plant is not used for

longer periods of time.

Install a pressure gauge at a suitable point to

monitor the pressures prevailing in the plant.

5 Operation

See Fig. 1 on page7.

5.1 Start-up

First start up the regulator after mounting all

parts.

A

5.2 Set point adjustment

Every pressure regulator is delivered with the

set point listed in Table 1 already adjusted.

Turn the set point adjuster (10) using Al-

len key (size 5mm) to change the default set

point.

Provided a pressure gauge has been in-

stalled at a suitable point in the plant, the

required set point can be directly adjusted

8 EB 2560 EN

Page 9

Operation

while monitoring the pressure reading at the

gauge.

When a pressure gauge is not installed, adjust the set point using the adjustment diagram Fig. 2.

To increase the set point, turn the set point

adjuster into the body () and out of the

body () to reduce it.

NOTICE!

Set point adjuster screwed too tight!

The regulator is blocked and the medium ow through it is restricted. Pressure regulation is no longer possible!

Only screw the set point adjuster up

to the point where the spring tension

can still be felt!

How to proceed:

1. Loosen the lock nut (11, size 17mm) to

allow the set point adjuster to move freely.

2. Determine the difference between the

xed set point (Table 1) and the required

set point. Turn the set point adjuster (10)

the required amount of turns as specied

in Fig. 2 on page10.

Based on the default setting, any subsequent

change to the set point can be also be made

by determining the required number of turns

using the specications listed in Table 1.

3. Lock the setting with the lock nut (11).

5.2.1 Changing the set point

range

The default set point ranges can be adapt-

ed to your specic requirements. Contact

SAMSON (see section7) for further details.

Table 1: Set point adjustment (default)

Set point range 1 to 8bar 5 to 25bar 8 to 40bar

Set point adjusted at the factory

(approx.)

Set point change per turn 1bar 2.5bar 3.5bar

EB 2560 EN 9

2357-11 3bar 12bar 25bar

2357-21 4bar 13bar 26bar

Page 10

Maintenance

Set point

[bar]

40

35

30

5...2

1...8 bar

8...40 bar

5 bar

25

20

15

Set point ranges

10

5

0

012345678910 11 12 13 14

Turns of the set point adjuster

: to increase the set point

: to reduce the set point

Fig. 2: Adjustment diagram

5.3 Decommissioning

Close rst the shut-off valve on the upstream

side of the valve and then on the downstream side of the valve.

6 Maintenance

The regulators do not require any maintenance. Nevertheless, they are subject to natural wear, particularly at the seat, plug and

operating diaphragm.

Depending on the operating conditions,

check the regulator at regular intervals to

avoid possible malfunctions.

WARNING!

Process medium can escape uncontrolled on dismantling the regulator.

Risk of cold burns!

Allow the regulator to defrost before

depressurizing and draining it and remove it from the pipeline.

If faults or malfunctions cannot be remedied,

contact SAMSON (see section7).

6.1 Exchanging the seat and

plug

See Fig. 1 on page7.

1. Loosen the lock nut (11) and turn the set

point adjuster (10) counterclockwise to

fully relieve the internal set point springs

(8).

2. Unscrew the body screws (14) using an

open-end wrench (size 19mm). Lift off

the valve body (1).

3. Unscrew the seat (15) using a seat

wrench (size 30mm socket). Remove the

plug (2.1).

10 EB 2560 EN

Page 11

Maintenance

4. Insert the plug spring (16) into the new

plug (Type2357-11 only). Tighten the

seat using a seat wrench and a tight-

ening torque of 20Nm. Use a suitable

high-performance lubricant (e.g. Gleitmo

595, SAMSON order no. 8150-0116).

5. Check the PTFE gasket (4.1) and replace

it, if necessary.

6. Carefully mount the valve body (1) and

fasten it onto the bottom section of the

body (9) (tightening torque 25Nm).

6.2 Exchanging the non-return

unit

See Fig. 1 on page7.

1. Loosen the lock nut (11) and turn the set

point adjuster (10) counterclockwise to

fully relieve the internal set point springs

(8).

2. Unscrew the body screws (14) using an

open-end wrench (size 19mm). Lift off

the valve body (1).

3. Unscrew the integrated non-return unit

(12) using a seat wrench (30mm size

socket) and lift off the valve body (1).

4. Check the ball and seating surface. If

necessary, replace the entire non-return

unit. Mount the non-return unit using a

seat wrench (tightening torque 20Nm).

Use a suitable high-performance lubri-

cant (e.g. Gleitmo 595, SAMSON order

no. 8150-0116).

5. Check the PTFE gasket (4.1) and replace

it, if necessary.

6. Carefully mount the valve body (1) and

fasten it onto the spring housing (9) using the body screws (14) (tightening

torque 25Nm).

EB 2560 EN 11

Page 12

Customer service

7 Customer service

If malfunctions or defects occur, contact the SAMSON After-sales Service Department for

support.

The addresses of SAMSON AG, its subsidiaries, representatives and service facilities worldwide can be found on the SAMSON website (uwww.samson.de), in all SAMSON product

catalogs or on the back of these Mounting and Operating Instructions.

Please send your inquiries to: service@samson.de

To assist diagnosis and in case of an unclear mounting situation, specify the following details

(see section8):

− Type designation and KVS coefcient

− Model number with index

− Upstream and downstream pressure

− Temperature and process medium

− Min. and max. ow rate

− Is a strainer installed?

− Installation drawing showing the exact location of the regulator and all the additionally

installed components (shut-off valves, pressure gauge, etc.)

8 Nameplate

1

2

3

Fig. 3: Nameplate details

12 EB 2560 EN

Details on lower section of body

1 Set point range/date of manufacture

2 Type designation with index

3 Customer-specic details

CE compliance

Page 13

9 Dimensions and weights

51

140

Dimensions and weights

140

100

G ¾ A

Type 2357-11 Pressure Regulator/Type 2357-21 Excess Pressure Valve with welding ends

(accessories)

Weight: approx. 4kg

All dimensions in mm

Fig. 4: Dimensions and weights

EB 2560 EN 13

Page 14

Technical data

10 Technical data

Type 2357-11 2357-21

coefcient 0.8 1.25

K

VS

Set point ranges

Max. perm.operating pressure p

Safety function for Type 2357-11 5 bar above the set point

Max. perm. differential pressure

∆p

max

Temperature range –200 to +200 °C

1)

Further set point ranges on request

2)

For oxygen p

1)

in bar 1 to 8 · 5 to 25 · 8 to 40

max

63bar

2)

Types 2357-11 Pressure Reducing Valves: Gases 30 bar

Liquids 6 bar

Type 2357-21 Excess Pressure Valve: 3bar (> 3bar only with

special accessories)

= 40bar

max

14 EB 2560 EN

Page 15

EB 2560 EN 15

Page 16

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main, Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

samson@samson.de · www.samson.de

EB 2560 EN

2014-09-16 · English

Loading...

Loading...