Page 1

Self-operated Temperature Regulators

Type 2040

Safety Temperature Monitor (STM)

Mounting and

Operating Instructions

EB 2090 EN

Edition October 2014

Fig. 1 · Type 2040 Safety Temperature Monitor

Page 2

Contents Page

1 Design and principle of operation. . . . . . . . . . . . . . . . . . . . 4

2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3 Set point adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3.1 New adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Set point adjuster with set point indication . . . . . . . . . . . . . . . . 7

4 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

8 Nameplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2 EB 2090 EN

Contents

CAUTION!

Indicates a hazardous situation which, if not

avoided, could result in minor or moderatein

-

jury.

Note! Indicates supplementary explanations,

information and tips.

Definitions of the signal words used in these instructions

Page 3

EB 2090 EN 3

Safety instructions

General safety instructions

4

The regulator may only be mounted, started up or operated by trained and

experienced personnel familiar with the product.

According to these mounting and operating instructions, trained personnel refers

to individuals who are able to judge the work they are assigned to and recognize

possible dangers due to their specialized training, their knowledge and

experience as well as their knowledge of the relevant standards.

All safety instructions and warnings in these mounting and operating instructions,

particularly those concerning assembly, start-up and maintenance, must be

observed.

4

For appropriate operation, make sure that the regulator is only used in

applications where the operating pressure and temperatures do not exceed the

operating values based on the sizing data submitted in the order.

4

Note that the manufacturer does not assume any responsibility for damage

caused by external forces or any other external factors.

Any hazards which could be caused in the regulator by the process medium or

operating pressure are to be prevented by means of appropriate measures.

4

The Type 2040 Safety Temperature Monitors do not have their own potential

ignition source according to the ignition risk assessment stipulated in

EN 13463-1: 2001, section 5.2, even in the rare incident of an operating fault.

Therefore, they do not fall within the scope of Directive 94/9/EC.

4

The regulator complies with the requirements of the European Pressure Equipment

Directive 97/23/EC. The declaration of conformity issued for a valve bearing the

CE marking includes information on the applied conformity assessment procedure.

The declaration of conformity can be provided on request.

TÜV typetesting/EC type examination

The Type 2040 Safety Temperature Monitors are typetested by TÜV (German technical surveil

lance association). The test mark is available on request.

An EC type examination according to Pressure Equipment Directive 97/23/EC, Module B has

been performed on the Type 2040 Safety Temperature Monitor.

Page 4

1 Design and principle of oper

-

ation

The Type 2040 Safety Temperature Monitor

protects downstream plants against exces

-

sively low temperatures in applications in

volving the storage of cryogenic media as

well as liquids, gases and vapors.

These safety temperature monitors close

whenever the medium temperature falls be

low the adjusted temperature set point (limit)

to prevent cold media entering the connected

consumer plant.

The safety temperature monitor consists of the

body (1) with integrated temperature sensor

(6) and set point adjuster (3). It operates ac

cording to the liquid expansion principle.

The volume of the temperature-sensitive filling

medium confined in the integrated temperature sensor (6) expands as the temperature

rises and contracts again as the temperature

falls. The valve is normally open. If the medium temperature falls below the adjusted set

point (when the medium is too cold), the liquid

inside the sensor contracts and the tubular

plug (5) is pushed by the positioning springs

(4) against the soft-sealed seat (2). As the me

dium temperature drops, the plug moves in

the closing direction, restricting the medium

flow. If the medium temperature drops fur

ther, the valve is closed completely when the

temperature reaches the adjusted set point.

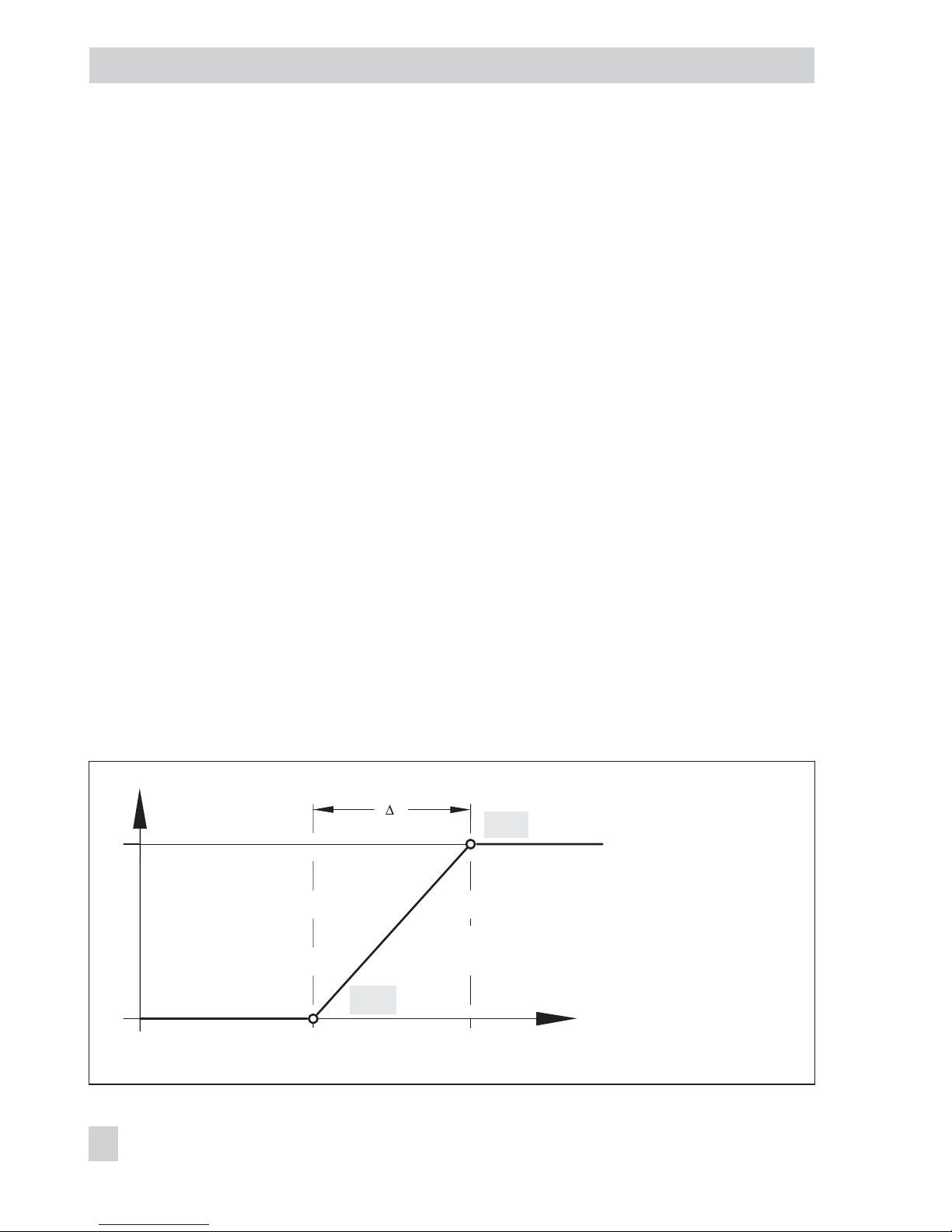

The set point temperature and the throttling

range in front of it can be adjusted within the

set point range. The valve first opens again

when the medium temperature has exceeded

the adjusted set point by 2 K.

The temperature span between the adjusted

set point temperature T

set point

and the point at

which the regulator starts to close is 17 K. The

valve is fully open (KV= 5) at a medium tem

-

perature of >T

set point

+ 17 K. At a medium

temperature less than T

set point

+ 17 K the medium flow is already throttled and the KVcoefficient gets smaller (Fig. 2).

If the sensor system is defective, the valve

closes (fail-safe position).

4 EB 2090 EN

Design and principle of operation

K

v

-200

0

-3

5

T

T

[˚C]

Fig. 2 · Control behavior

∆

T = 17 K temperature differential between

open and closed (throttling range)

T

set point

= –20 °C (point at which the

regulator is fully closed)

The regulator starts to close when the

medium temperature has dropped below a

value which is still approx. 17 K above the

adjusted set point.

Closed

Open

–20

T

set point

Normal range of

medium temperature

–3

Page 5

EB 2090 EN 5

Design and principle of operation

3

1

2

4

5

6

7

3.1

3.2

Fig. 3 · Functional diagram of Type 2040 Safety Temperature Monitor

1 Body with connection

2 Valve seat with soft sealing

3 Set point adjuster

3.1 Cap

3.2 Lock nut

4 Positioning spring

5 Tubular plug

6 Temperature sensor

7 Connection nut with spherical liner (accessories)

8 Connection nut with flat gasket (accessories)

8

Connection nut with flat gasket · Connection with

soldering nipples (brass) or welding ends (stain

-

less steel)

Connection nut with

soldering nipples (brass)

or welding ends

(stainless steel)

Page 6

2 Installation

Connection fittings (accessories) must be pro

-

vided at the site of installation.

Note!

Do not install the regulator directly next to an

air vaporizer. Otherwise, the regulator could

close due to the low outdoor temperature. The

closing function of the regulator does not de

pend on whether the sensor temperature is

determined by the outdoor air or by the me

dium.

For outdoor installation, we recommend an

adjusted set point temperature of –37 °C together with the point at which the regulator is

fully closed at –20 °C (set point range –45 to

–10 °C).

The following points generally apply:

4

The regulator can be installed in any de

-

sired position

4

The direction of flow must match the ar

-

row on the valve body

3 Set point adjustment

See Figs. 3 and 4

The safety temperature monitor has been ad

-

justed by the manufacturer to a set point tem

-

perature (limit) of T

set point

= –10 °C (set point

range from –30 to +10 °C) or –37 °C (set

point range from –45 to –10 °C).

After removing the cap (3.1) and undoing the

lock nut (3.2), the required set point

temperature (T

set point

) can be adjusted within

the set point range using the set point adjuster

(3).

6 EB 2090 EN

Installation

2.0

1.5

1.0

0.5

0.5

1.0

1.5

2.0

10-10 -5 0 5-30 -25 -20 -15

[˚C]

Fig. 4 · Adjustment diagram at a set point temperature T

set point

= –10 °C (point at which regulator is fully closed)

Turns of the set

point adjuster

T

set point

Turns of the set

point adjuster

Page 7

Use the adjustment diagram (Fig. 4) as a

guide to change the set point temperature

from the default setting. One turn of the set

point adjuster corresponds to a change in set

point temperature of approx. 13 K.

The set point temperature together with the

point at which the regulator is fully closed shift

to lower temperatures when the set point

adjuster (3) is turned clockwise P.

3.1 New adjustment

Adjustment of the set point temperature from

an unknown setting:

Note! The ambient temperature must be

within the set point range.

4

Remove cap (3.1) and undo lock nut

(3.2). Make sure that the medium flow

and outside air have the same temperature.

4

Turn the set point adjuster (3) counterclockwise until the flow noise inside the

regulator ceases, i.e. the valve is closed.

4

Calculate the temperature difference be

tween the momentary ambient

temperature and the required set point

temperature (T

set point

) to be adjusted.

4

Divide the calculated temperature differ

ence by 13. The result shows how may

turns of the set point adjuster (Fig. 4) are

required.

4

Turn the set point adjuster clockwise by

the determined number of turns.

4

Lock set point adjuster (3) with the lock

nut (3.2) and screw cap (3.2) back on.

4

Secure setting, if necessary, with sealing

wire through the holes in the cap and

valve.

3.2 Set point adjuster with set

point indication

In a special version, the set point adjuster is

fitted with a marked ring for set point

indication. The distance between two marks

corresponds to a temperature difference of

approx. 10 K (10 °C).

EB 2090 EN 7

Set point adjustment

Page 8

4 Maintenance

CAUTION!

Prior to performing any work on the regula

-

tors, decommission the plant by slowly clos

-

ing the shut-off valves. Depressurize and, de

pending on the process medium, drain the

plant section as well.

CAUTION!

Regulators for oxygen service are labeled to

indicate that the regulators must be kept free

of oil and grease for oxygen service.

These versions are cleaned and assembled

under special conditions. Gloves must be

worn when exchanging parts which come

into contact to oxygen. These parts must not

come into contact with oil or grease.

When returning regulators for oxygen service

to SAMSON for repair, the sender is responsible for ensuring that the regulators are han

dled in conformance with the specifications in

the German regulation VBG 62 or equivalent

regulations until receipt at SAMSON. If this is

not the case, SAMSON AG will not assume

any responsibility for the suitability of these

regulators for oxygen service.

If the point at which the regulator closes devi

ates strongly from the adjusted set point, shut

off may be impaired because the seat and

plug are clogged up with dirt or due to natu

ral wear.

In this case, remove the regulator from the

pipeline and clean it. If necessary, replace the

plug seal with a new one.

5 Service

If malfunctions or defects occur, contact the

SAMSON After-sales Service for support.

The addresses of SAMSON AG, its subsidiar

ies, representatives and service facilities

worldwide can be found on the Internet at

www.samson.de, in a SAMSON product cat

alog or on the back of these mounting and

operating instructions.

Include the following details when making in

quiries:

4

Type and nominal size of the regulator

4

Process medium

4

Set point temperature range

4

Production number 3- ...

4

Model number with modification index

4

Flow rate in m³/h

4

Installation drawing indicating the exact

location of the regulator (e.g. outdoors

or indoors) and all additionally mounted

units (shut-off valves, pressure gauges

etc.)

8 EB 2090 EN

Maintenance

Page 9

6 Dimensions

EB 2090 EN 9

Dimensions

ØD

Ød

ØD

Ød

L1±1

H1

133±1

L3 ±3

L3 ±3

L2 ±1

H1

133±1

Fig. 5 · Dimensions

Dimensions in mm DN 15 DN 25

L3

100

∅

d

For pipe∅16 For pipe∅28

Soldering nipple (brass)

Dimensions in mm DN 15 DN 25

L1

155

L2

165

∅

d

16.1 28.5

∅

D

21.3 33.7

Welding ends (stainless steel)

Height H1

Without set point indication: H1 = 108±1 mm

With set point indication: H1 = 116±1 mm

Weight: 1.8 kg (without connecting parts)

Connecting parts with spherical liner

Connecting parts with flat gasket

Page 10

7 Technical data

10 EB 2090 EN

Technical data

Table 1 · Technical data · All pressures in bar (gauge)

Type 2040 Safety Temperature Monitor

Body connection

G 1¼ (see Fig. 4 for connecting parts)

K

VS

coefficient

5

Set point ranges

–30 °C to +10 °C

–45 °C to –10 °C

1)

Max. perm. operating pressure

40 bar

Max. perm. differential pressure∆p

25 bar

Leakage rate

≤

0.05 % of KVSat –10 °C

≤

0.1 % of KVSat –45 °C

Hysteresis

2 K

Accuracy

±

1 °C

Permissible temperature range

–60 °C to +60 °C

Temperature differential between open/closed

17 K

1)

On request

Table 2 · Materials · Material number according to DIN EN

Type 2040 Safety Temperature Monitor

Body

CC491K (G-CuSn5ZnPb)

Bellows

CW453K (CuSn8F40)

Spring

1.4310

O-ring

NBR

Seat

CW617N (CuZn40Pb2)/NBR

Tubular plug

1.4571/1.4404

Page 11

8 Nameplate

Laser inscription on the regulator body

EB 2090 EN 11

Nameplate

Fig. 6 · Nameplate specifications

Flow of direction

Production number: 3- ...

Model number with modification index

Valve coefficient KVS= 5

Set point temperature with unit

Test mark

1)

Keep regulator free of oil and grease

1)

Omitted at a set point temperature between –31 °C and –45 °C

Page 12

SAMSON AG · MESS- UND REGELTECHNIK

Weismüllerstraße 3 · 60314 Frankfurt am Main · Germany

Phone: +49 69 4009-0 · Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 2090 EN

S/Z 2016-12

Loading...

Loading...