Page 1

Specifications

MP-100 Meter

Liquid Controls MP Series Bi-Rotor Positive Displacement

(PD) Meters offer the ultimate in m easu rement accuracy for

custody transfer of petroleum and aviation fuels.

Superior performance featur es

Low pressure drop – the straight-thr ough path and floating rotor

design cr eates a very low pressure dr op at maxi mum flow.

Sustai n ed accur acy – no metal-to-metal contact insi de the

measuring ch amber means mi nimal wear and deterioration i n

accuracy over t ime, fewer recal ibr ations and a longer se rvi ce life.

Wide viscosity range – LC meter s can accuratel y meter

products up to 1000 cP (please consult factor y for higher

viscosity).

Compact design – no upstream or downstream pipe lengths are

necessary.

Double case construction – the measuring unit i s removable, as

a single subassembl y, from the outer flanged.

Low piping vibration – the bi-rotor desi gn produce s very low

piping vi brati ons perm itti ng to reach hi gher flowrates.

Accuracy/Performance

Repeatability

Mechanical registration: capable of 0.05% of reading over entire range

Electronic registration: capable of 0.03% of reading over entire range

Linearity

Over 5:1 range

Mech. registration: capable of ±0.125% or better from max nom. flow rate

Elect. registration: capable of ±0.10% or better from max. nom. flow rate

Over 10:1 range

Mech. registration: capable of ±0.22% or better from max. nom. flow rate

Elect. registration: capable of ± 0.10% or better from max. nom. flow rate

Over 40:1 range

Mech. registration: capable of ±0.5% or better from max. nom. flow rate

Elect. registration: capable of ±0.15% or better from max. nom. flow rate

Temperature range

-2.2° F to 356° F (-29° C to 180° C)

Note: with POD installed directly on the meter, temperature range is

reduced to: -2.2° F to 185°F (-29° C to 85 °C)

Industries served

LC MP-Series meters are

well-suited for use in

industries requiring precise

flow measurement and

reliable, extended service

life:

• Refined petroleum

products

• Crude oil

• LPG

• Power plant

• Petrochemicals

Construction

Class 1, 8 ,14

External housing:

Carbon steel ASTM A216

WCB

External cover:

Carbon steel ASTM A216

WCB

Housing:

Cast iron (1, 14)

316 stainless steel (8)

Bearing plate:

Cast iron (1, 14)

316 stainless steel (8)

Sleeve bearing:

Carbon/420 stainless steel

(1, 14)

Carbon/316 stainless steel

(8)

Rotors:

Cast iron (1, 14)

316 stainless steel (8)

Gear:

420 stainless steel (1, 14)

316 stainless steel (8)

Internal hardware:

Stainless steel

Seal material:

Teflon

Packing gla nd:

Stainless steel/teflon

Page 2

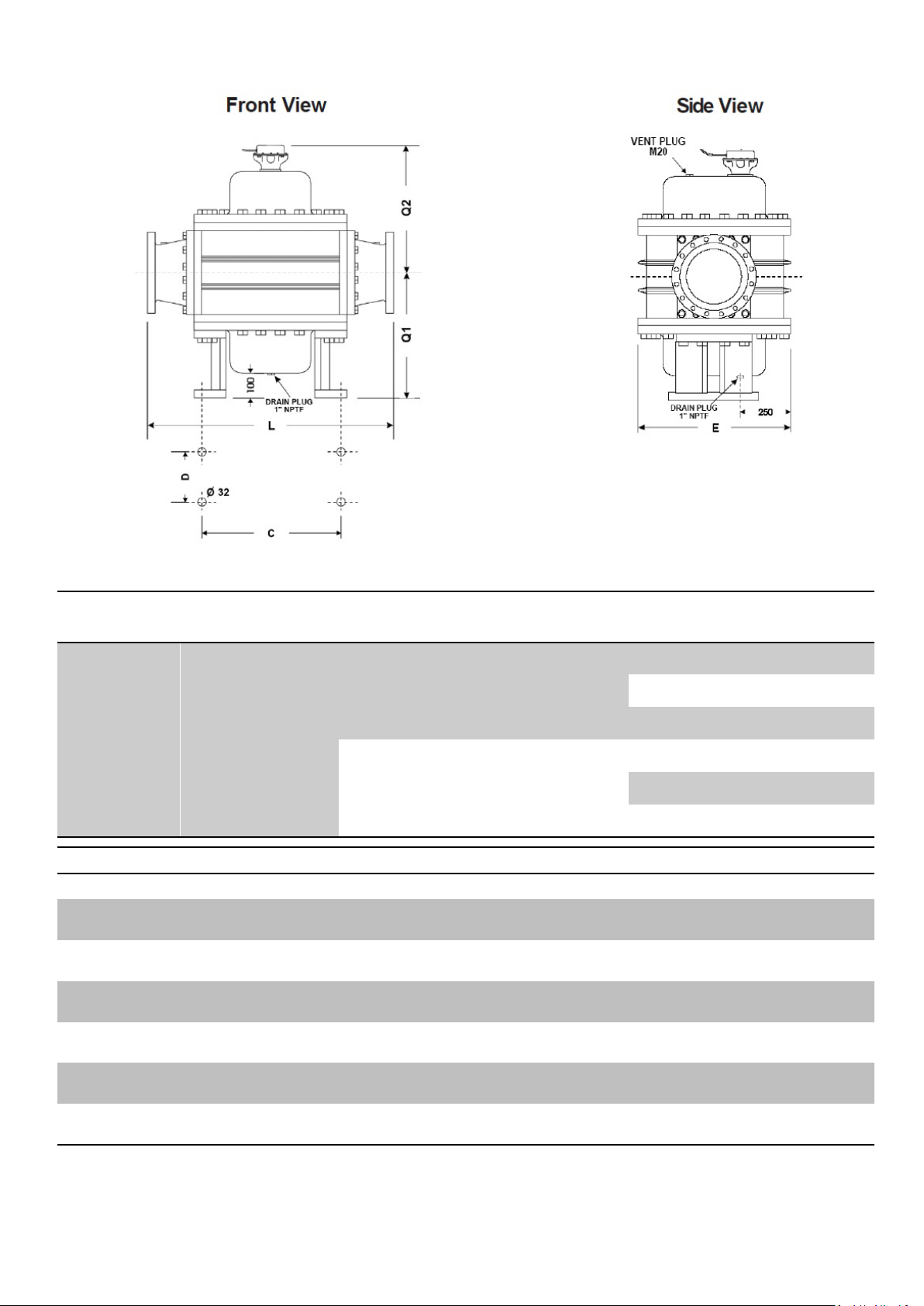

Dimensions: flow meters w ith pulse tr ansmitter

Model Flow rate Flange size Net weight Max working pressure

19 bar @ -29°C to 38°C

MP100

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

3086 lbs

(1400 kg)

3307 lbs

(1500 kg)

26.7

678

26.7

678

26.7

678

26.7

678

26.7

678

26.7

678

13.8

350

13.8

350

13.8

350

13.8

350

13.8

350

13.8

350

12” ANSI 150

12” ANSI 300

Dimensions

27.3

693

27.3

693

27.3

693

27.3

693

27.3

693

27.3

693

Intermittent (1):

4403 GPM

(1000 m³/h)

Nominal (2):

3523 GPM

(800 m³/h)

C D E Q1 Q2 L

23.6

600

23.6

600

23.6

600

23.6

600

23.6

600

23.6

600

18 bar @ -29°C to 85°C

14 bar @ -29°C to 180°C

49 bar @ -29°C to 38°C

47 bar @ -29°C to 85°C

44 bar @ -29°C to 180°C

28.8

731

28.8

731

28.8

731

28.8

731

28.8

731

28.8

731

47.2

1200

47.2

1200

47.2

1200

50.4

1280

50.4

1280

50.4

1280

Note (1): Maximum intermittent flow rate (batch use) means 8/24 hours of operation per day.

Note (2): Maximum nominal flow rate (continuous use) means 24/24 hours of operation per day.

Page 3

Construction and application classes

LC MP series PD m eters are suitable for metering a

broad range of products as listed below . The

appropriate meter class can be used to specify a

desired meter by using the table below.

Class Description

1 Refined petroleum products

8

14 Crude oil

Acid pH liquids includes: nitric,

phosphoric, glacial acetic acids, citric

juices, vinegar

Loading...

Loading...