Page 1

Specifications

M-15 Meter

Liquid Controls M and MA Series rotary motion positive

displacement (PD) meters offer the ultimate in m easu rem ent

accuracy for custody transfer of petroleum products,

aviation fuels, LPG and a broad of industrial liquids.

Superior performance featur es

Low pressu r e dr op – w ill operate on gravity flow or pump

pressure.

Sustained accur acy – no metal-to-metal contact inside the

measuring chamber means minimal wear and deterioration

in accuracy over time, fewer recalibrations and a longer

service life. Meters conform to NIST and International

Weight and Measu res accuracy requirem ent s.

Wide viscosity range – LCE meters can accurately meter

products from less than 30 SSU (1 cP) to 1500000 SSU

(325000 cP).

Maximum adaptability - choice of stock or custom

elbows/fittings provides unequaled mounting flexibility to

meet widely varying installation requirements.

Industries served

LC series M and MA meters

are well-suited for use in

industries requiring precise

flow measurement and

reliable, extended service

life:

• Refined petroleum

products

• Aviation fuels

• LPG

• Agricultural chemicals

• Paints and coatings

• Foods and beverages

• Petrochemicals

• Pharmaceuticals

• Cosmetics

• Printing inks

• Textiles

Accuracy/Performance

Repeatability

Mechanical registration: capable of 0.05% of reading over entire range

Electronic registration: capable of 0.03% of reading over entire range

Linearity

Over 5:1 range

Mech. registration: capable of ±0.125% or better from max nom. flow rate

Elect. registration: capable of ±0.10% or better from max. nom. flow rate

Over 10:1 range

Mech. registration: capable of ±0.22% or better from max. nom. flow rate

Elect. registration: capable of ± 0.10% or better from max. nom. flow rate

Over 40:1 range

Mech. registration: capable of ±0.5% or better from max. nom. flow rate

Elect. registration: capable of ±0.15% or better from max. nom. flow rate

Temperature range

-40° F to 160° F (-40° C to 71° C)

Construction

Meter housing and rotors

Cast aluminum (other

metallurgies, available

including brass, cast-iron

and stainless steel)

Internal components

Aluminum, Ni-Resist,

stainless steel

Seal material

UL recognize component:

Buna-N, Viton, Teflon

Bearings

Carbon, Teflon, Ni-Resist

Page 2

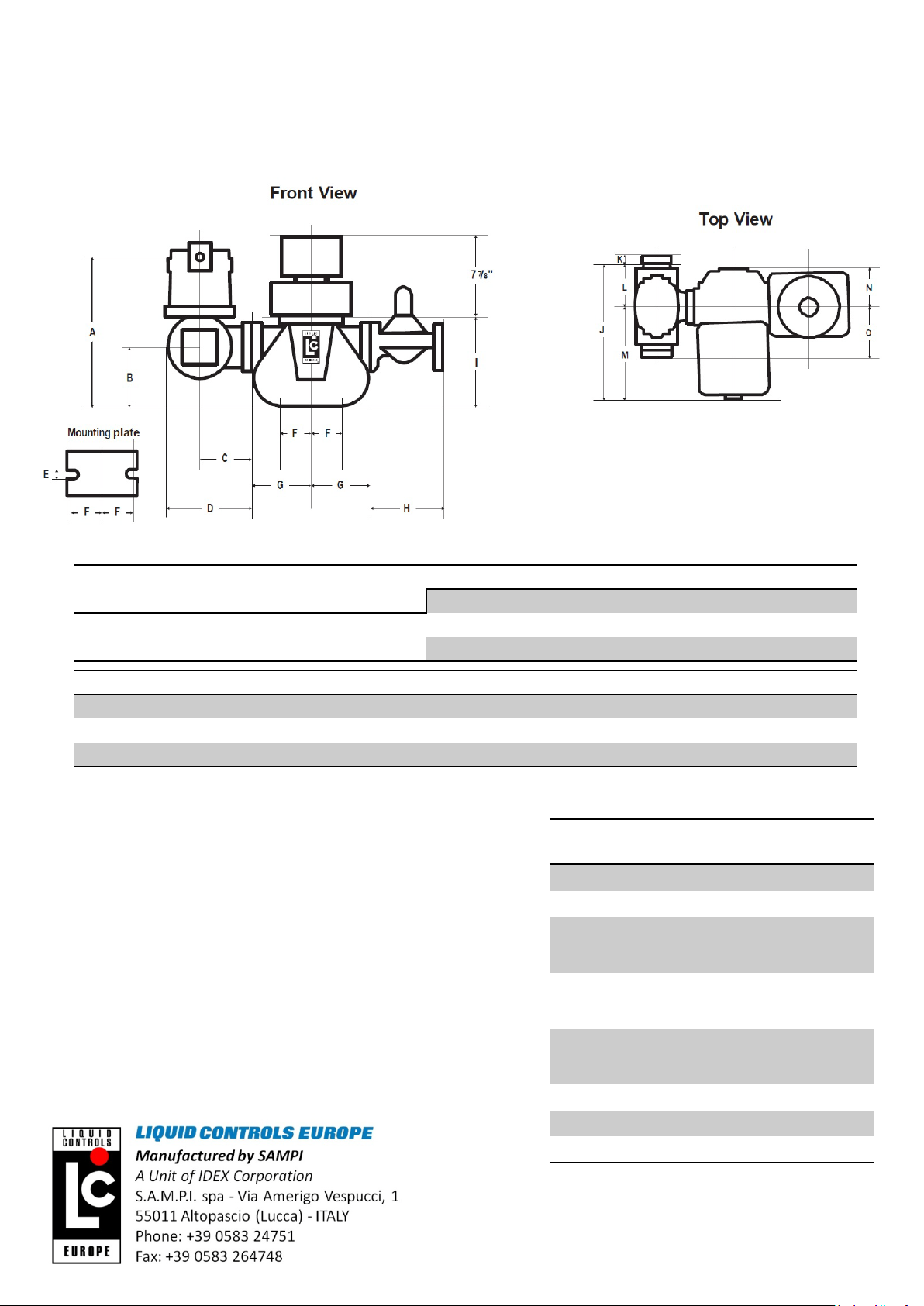

Dimensions: flow meters w ith electronic registration

Note: Dim ensions sh ow n are not for construction use. C onsult fact ory w hen certified

engineering prints are required.

Model

M-15

in 5.5 12 10.8 16.1 1.3 5 11.1 5.1 6.5

mm 140 291 273 410 32 127 238 129 165

Flange

size

3” or 3” in,

2” out

Max nom.

Flow rate

1000 l/min

(264 GPM)

G H I J K L M N O

Working

pressure

10,5 bar

(150 PSI)

Net

weight

16,8 kg

(37 lbs)

A B C D E F

in 17 7.5 5 7.7 .69 3.8

mm 432 191 127 195 17 95

Dimensions

Class Description

Construction and application classes

Dimensions

1 Refined petroleum products Ni-Resist

2 Aviation and jet fuel Ni-Resist

LC series M and MA PD meters are suitable for

metering a broad range of products as listed below.

The appropriate meter class can be used to specify a

desired meter by using the table on the next page of

this publication.

14 Crude oil Ni-Resist

16 General solvents Carbon

30 Herbicides Carbon

Variety of product includes:

3

liquid sugars, sweeteners,

syrups, vegetable oils

Treated waters and solvents

4

where no red metals are

allowed

Acid pH liquids includes: nitric,

8

phosphoric, glacial acetic acids,

citric juices, vinegar

Bearing

Material

Ni-Resist

Carbon

Carbon

Loading...

Loading...