Page 1

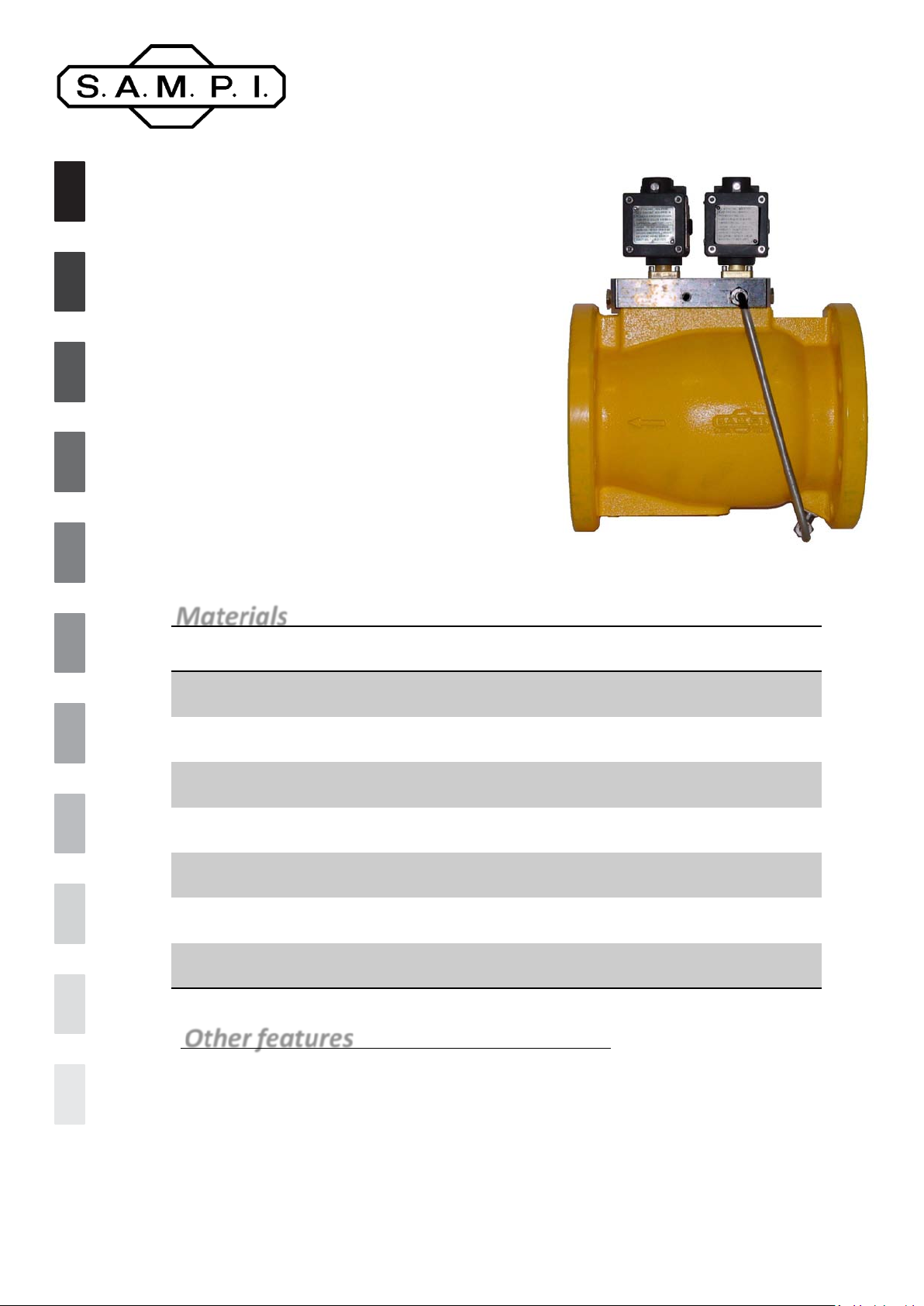

HPV Hydraulic V alve

Specifications Sheet

The operating principle is as follows:

The fluid passes from the “inlet chamber” to the “intermediate

chamber” through a hole in the cap and then through a dirt-proof

filter. Then, it fills the “shutter chamber” through an orifice. Next,

it reaches the solenoid valve holder block through a connecting

hole. Inside the block the fluid finds two paths that run parallel to

each other to reach the “discharge chamber”. The fluid undergoes

to pressure drops along this path depending on the opening level

of the orifices and on the opening of the valves. An intermediate

pressure is established between the delivery pressure and the

discharge pressure, as a result of these pressure drops in the

“shutter chamber”. Together with the contrasting action of the

spring, this pressure moves the axial position of the shutter,

which, in turn, influences the upstream/downstream pressure

values of the valve and therefore also the “shutter chamber”

pressure. Consequently, the equilibrium of the forces is further

modified, which regulates the position of the shutter itself. This

phenomenon ceases once the position of equilibrium is reached,

where the effect of the pressure of the “shutter chamber”, added

to the force of the spring, is equal to the effect of the delivery

pressure.

Materials

Part Material

Body Carbon steel or aluminium

Shutter Alluminium

Fixed parts Aluminium

Other details Stainless steel or carbon steel

Dynamic sealing ring PTFE loaded carbon

Shutter seal packing Viton on incorporated metallic core

Rest of the packing Viton

Other features

The valve works according to three operating regimes;

• Closed;

• Intermediate low flow position;

• High flow position.

The high flow position can, at worst, also coincide with the valve position completely

open, but nonetheless it can be regulated to limit the capacity of the line. The high

and low flow positions are regulated manually from the outside by means of needles

for adjustment.

Page 2

Specifications

Operating temperature range -20°C to 70°C (-4°F to 158 °F)

Max kinematic viscosity 40 cST In the standard version

Max operating pressure (steel body) 10 bar (145 PSI) Up to 70°C (158°F)

Max operating pressure (aluminium body) 10 bar (145 PSI)

Up to 70°C (158°F) – reduces to 5 bar

(73 PSI) up to 125°C (257°F)

Min. valve opening pressure 0,09 bar (1.31 PSI)

Max pressure in no-return function 1,5 bar (21.8 PSI)

Capacity coefficient Cv 270 GPM/PSI

Max flow rate for 0,5 bar (7.3 PSI) pressure

drop

2500 l/min (660 GPM)

With diesel and gasoline (it decrease

in proportion to the viscosity)

Flanges DN4” – ANSI 150 B 16.5 RF SF

Closing time < 4 sec. Adjustable

Opening time From 3 to 6 sec. adjustable

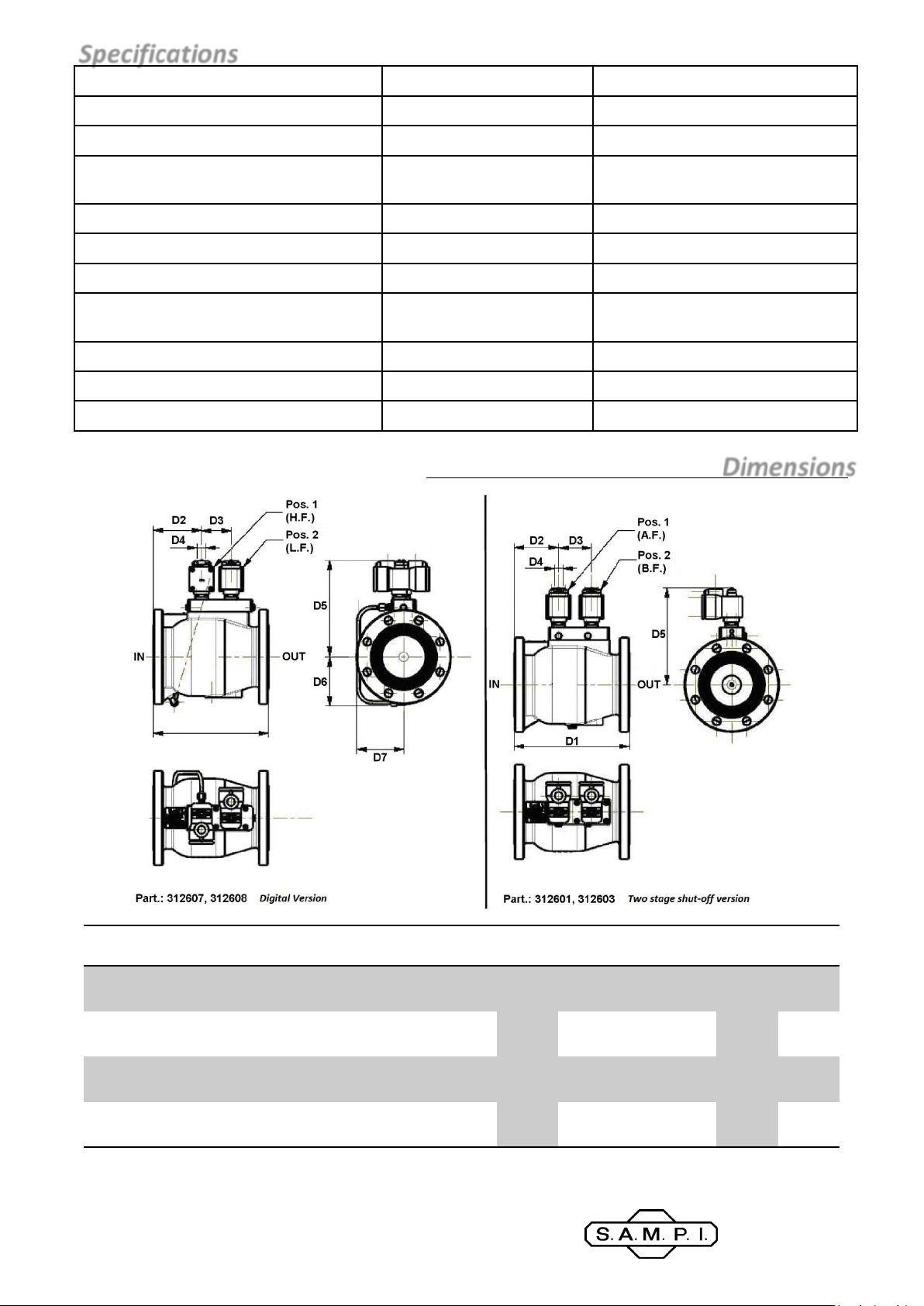

Dimensions

Model Version

312601

312603

312607 Digital

312608 Digital Aluminium

Two

stage

Two

stage

Material

(body)

Aluminium

Carbon

steel

Carbon

steel

mm

in

mm

in

mm

in

mm

in

D1 D2 D3 D4 D5 D6 D7 Flange

280

11.01

280

11.01

280

11.01

280

11.01

108

4.25

108

4.25

117

4.60

117

4.60

80

3.15

80

3.15

71.5

2.81

71.5

2.81

RP ½”

ISO 7/1

234.5

9.23

234.5

9.23

234.5

9.23

234.5

9.23

- -

- - 35 (77)

117

4.60

117

4.60

126

4.96

126

4.96

DN 4”

ANSI

150RF

(Ø 229

mm – 9

SAMPI spa

A unit of IDEX Corporation

Via Amerigo Vespucci, 1

55011 Altopascio (Lucca) – Italy

Phone: +39 0583 24751

Fax: +39 0583 264748

www.sampi.it

Weight

Kg (lbs)

15 (33)

35 (77)

in)

15 (33)

Loading...

Loading...