Dealer:

Ploegstraat 4 8308 AA Nagele The Netherlands Tel (+31) 527 – 652 500

Fax (+31) 527 – 652 916 www.samon.nl info@samon.nl

SAMON

ONION LIFTER

Manual & Parts list

Type:

SU2M SU2H1 SU2H3

Uitvoering:

Rotating harvest shaft

Serienr.:

27011751 - >>>

V1-2018-EN

Table of Contents

1. Introduction ............................................................................................................................................... H1

2. Warranty and liability ................................................................................................................................. H2

2.1 Guarantee ......................................................................................................................................... H2

2.2 Liability .............................................................................................................................................. H2

3. Safety and the environment ....................................................................................................................... H3

3.1 General safety ................................................................................................................................... H3

3.2 Environment ...................................................................................................................................... H3

3.3 warning labels and pictograms ......................................................................................................... H4

4. Checks before and during use ..................................................................................................................... H5

4.1 Checks needed before use ................................................................................................................ H5

4.2 Shortening the PTO shaft .................................................................................................................. H5

4.3 Connecting the SAMON Onion Lifter ................................................................................................ H6

4.4 Inspection after +/- 5 meters ............................................................................................................ H6

4.5 Inspection after +/- 5 ha.................................................................................................................... H6

5. Maintenance .............................................................................................................................................. H7

5.1 Lubrication schedule ......................................................................................................................... H7

5.2 Setting the shakers ............................................................................................................................ H8

5.3 Setting the collecting trays ................................................................................................................ H8

5.4 Gear drive maintenance .................................................................................................................... H9

5.4.1 Topping up the gear drive oil ........................................................................................... H9

5.4.2 Changing gear drive oil ..................................................................................................... H9

6. Transport and storage .............................................................................................................................. H10

6.1 Transport by transport vehicles ...................................................................................................... H10

6.2 Transport by tractor ....................................................................................................................... H10

6.3 Storage ............................................................................................................................................ H10

7. Technical data .......................................................................................................................................... H11

8. Ordering parts .......................................................................................................................................... H12

9. Troubleshooting ....................................................................................................................................... H13

10. EC declaration of conformity .................................................................................................................. H14

H1

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

1. Introduction.

This edition of the manual is intended for buyers of a SAMON Onion Harvester.

It contains information for the use and maintenance of this machine.

When this guide was compiled the utmost care was taken to ensure that the illustrations and technical data are

correct and current for this manual.

Ellens Landbouwtechniek BV recommends users to carefully read this manual, instructions, directions and

comments before using the machine.

References to the left or right side of the machine are determined based on the driving direction of the

machine.

Ellens Landbouwtechniek BV reserves the right to change the content of this manual without notice.

This machine was designed in accordance with the provisions of the machinery directive 89/392/EEC +

amendments.

H2

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

2. Warranty and liability.

2.1 Warranty.

SAMON agricultural machinery comes with a warranty period of 1 season.

SAMON Onion Lifters are designed and intended for harvesting onions.*

If the SAMON Onion Lifter is used in a manner other than intended such will be considered to be improper use.

* For harvesting any other types of deciduous species and crops, always first check with your Samon dealer.

This warranty is provided on construction defects in the machine encountered during normal use.

Parts that are subject to wear are not covered by this warranty, these are:

Sprockets, chains, guide wheels,

Sieve belts

Harvest shafts,

Bearings,

Tillers,

Coulter disks,

Other parts subject to wear.

The Warranty on hydraulic components, PRO shafts and gear drives is given only on construction defects of the

components, which result in failure, in the opinion of the producer.

This warranty lapses in the following instances:

Constructive adjustments and changes to the machine without permission from Ellens Agricultural

Engineering BV.

Installation and use of components on or to the Onion Lifter that has an adverse impact on the solidity

of the construction.

Failure of components due to maintenance intervals not being observed.

Changes to or non-adherence to adjustments and settings prescribed, which could result in damage.

Our dealers and manufacturing service points are all available to provide information and guidance.

2.2 Liability.

Ellens agricultural engineering BV is not liable for damage to Samon agricultural machinery; tractors; machines

of third parties; injuries to humans, animals and products as a result of:

improper use.

not following instructions and instructions described in the manual.

NOTE!!!

The SAMON Onion Lifter must be operated, maintained and repaired by persons who are familiar with the

machine and its safety procedures.

H3

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

3. Safety and the environment.

3.1 General safety.

NOTE!!!

Make sure that all persons that work with the SAMON Onion Lifter and/or that perform maintenance on it

read this manual carefully and take the required precautions for their own safety and others in the area

while operating the SAMON Onion Lifter.

Always keep the following points in mind when working with or on the SAMON Onion Lifter.

The SAMON Onion Lifter must only be operated, maintained and repaired by persons who are familiar

with the machine and who are familiar with the safety procedures.

When performing inspections and maintenance on the SAMON Onion Lifter always switch the tractor

engine off and remove the key from the ignition.

The SAMON Onion Lifter is equipped with rotating sieve belts that can entrap body parts.

Never come close to a SAMON Onion lifter while in operation.

Always wait until the sieve belts have come to a complete halt before approaching the machine.

Keep in mind that the sieve belts will keep turning for a while after the SAMON Onion Lifter has been

switched off.

Keep away from the SAMON Onion Lifter while it is in operation.

When an object is hit, switch off the SAMON Onion Lifter and check for damage before switching back

on again.

The SAMON Onion Lifter contains a number of parts that are fitted locking pins and safety belts and/or

chains. These must always be connected.

Damaged and broken safety devices and locking agents must be replaced immediately.

Protective covers, sleeves and rubber flaps must always be undamaged. Always replace when dented

or cracked.

Always use original SAMON parts as they are specifically designed for the Samon Onion Lifter.

3.2 Environment.

For ecological reasons cleaning and maintenance to the SAMON Onion Lifter must take place on a hard, liquidproof floor.

NOTE!!!

Dispose of used lubricants in an environmentally friendly manner. We recommend delivering old oil in a

closed tank at a recycling centre or a collection point. Never dispose of old oil in a ditch, drain or sewer or

on the soil.

H4

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

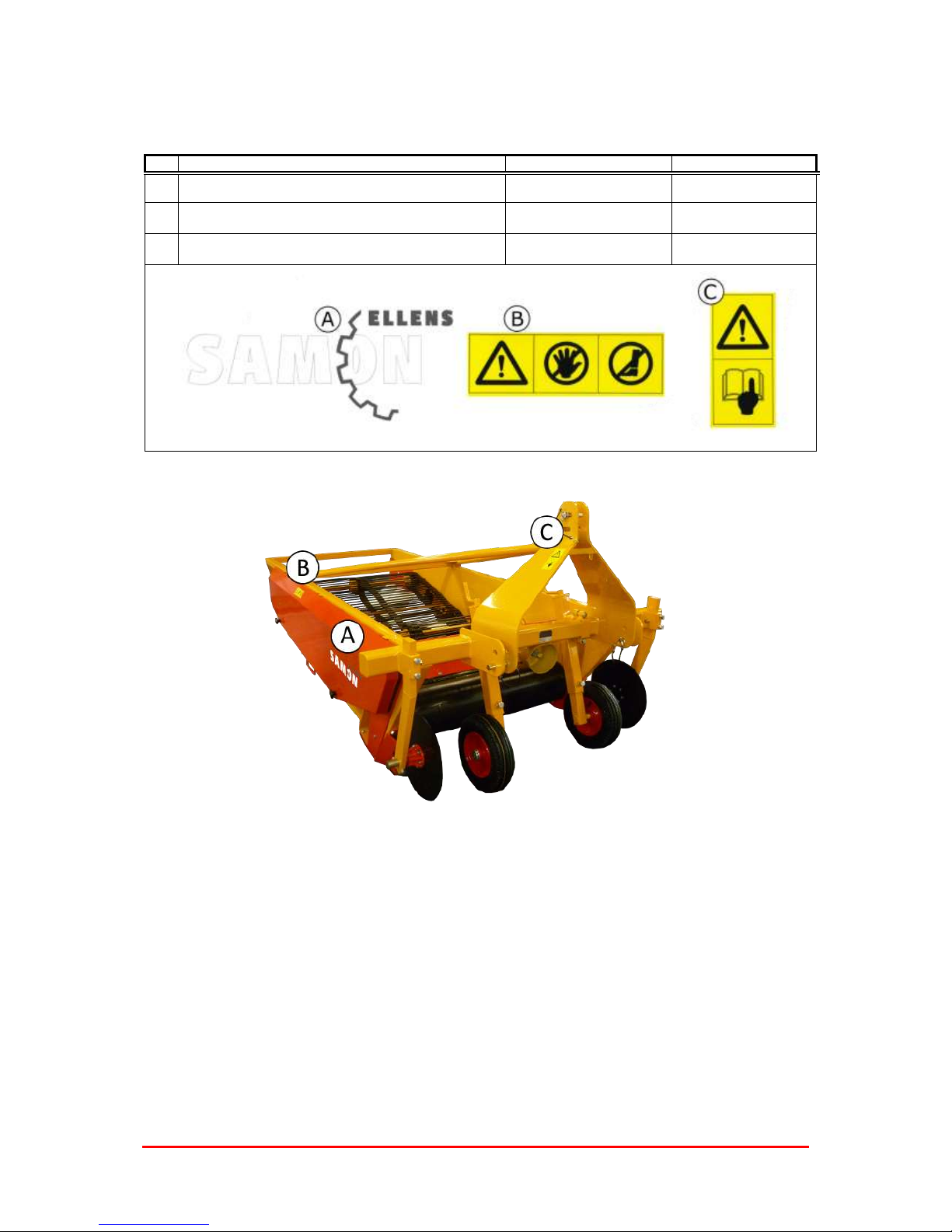

3.3 Warning labels and pictograms.

Each SAMON Onion Lifter is fitted with the following stickers and warning pictograms:

Description:

Measurements.: (w x h)

Order no.

A:

“Samon” sticker

24.8 x 7.8

TL6304

B:

“Be careful with your hand/foot” sticker

19.3 x 6.4

TL6309

C:

“Check the manual” sticker

13.3 x 6.4

TL6310

Onion Lifter stickers.

If any of these stickers should be missing or illegible you can order a replacement at your SAMON dealer.

H5

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

4. Inspect before and after use.

WARNING!!!

When performing maintenance on the SAMON Onion Lifter always switch the tractor engine off and

remove the key from the ignition.

4.1 Checks to be performed before use.

Check the gear drive for leaks.

Check the tire pressure. (4.5 Bar)

Check the length of the PTO shaft (see 4.2)

Check the protective cover of the PTO shaft for cracks.

Check that the safety chains of the PTO shaft are mounted.

Check if the locking clips and safety cords are in place.

Check the drive chain for cracks and tears.

Check the tension of the drive chain and do so regularly while in use.

Check the harvest shaft for damage and wear.

Check the sieve belt and drive wheels for damage and wear.

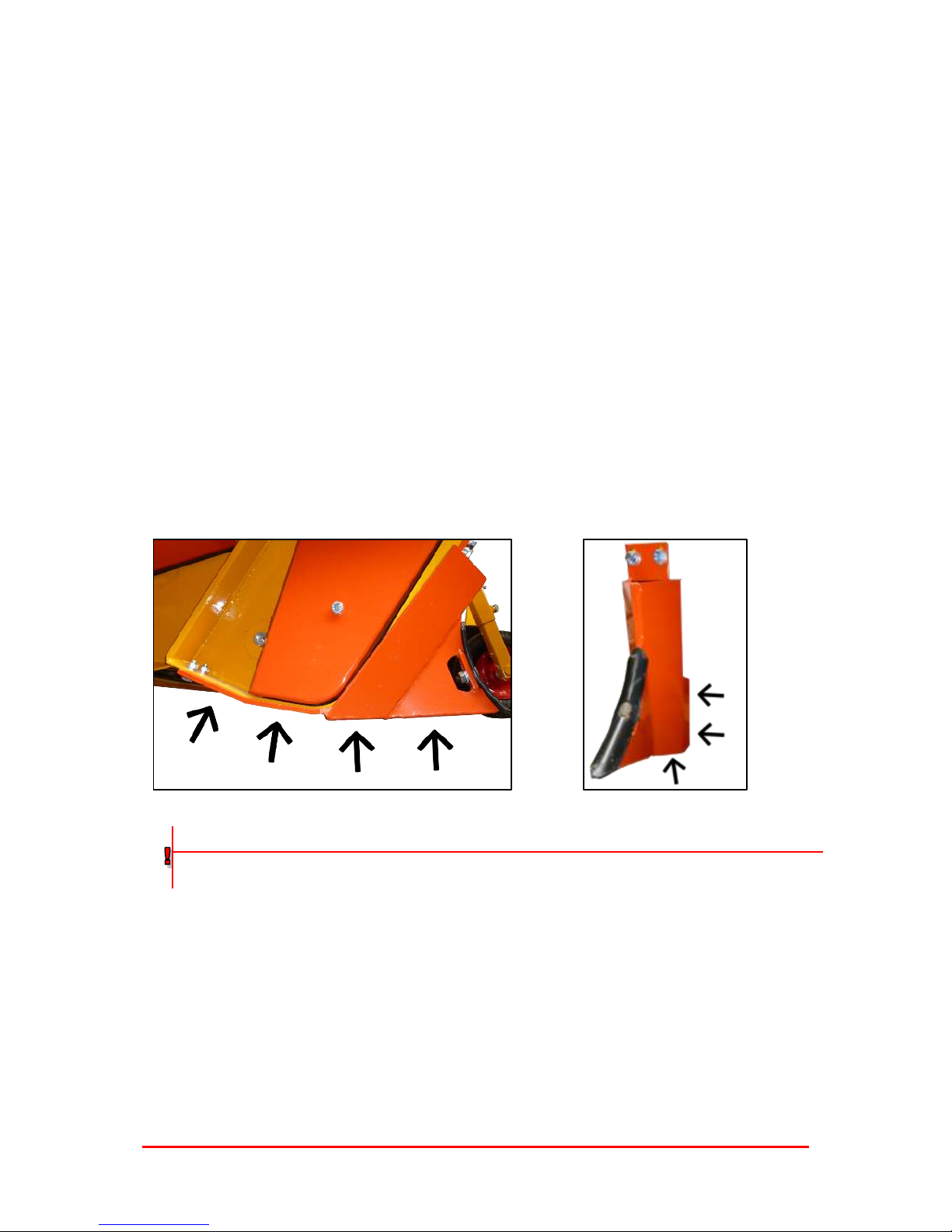

4.2 Shortening the PTO shaft.

If it should appear during inspection that the PTO shaft is too long, it can be shortened as follows:

Connect the machine to the tractor

Position the PTO shafts together as short as possible.

Measure distance "A" of the PTO shafts.

Measure distance "B" of the PTO shafts.

(See the illustration for the measuring points)

Subtract length "A” from length "B"

Shorten the PTO shaft with the result (see example)

Calculation example:

A=400 mm

B=450 mm

B(450) - A(400) = 50 mm +10 mm

Trimming length = 60 mm

H6

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

4.3 Connecting the SAMON Onion Lifter.

Connect the machine to the tractor

Attach the mechanical pins and confirm with the locking clips.

Check that the top rod is free.

Mount the PTO shaft (540 PTO).

Put the safety chains of the protective cover of the PTO.

4.4 Inspection after ± 5 metres.

Check if the depth of the harvest shaft is correct.

Check if the onions are damaged.

Check if the collecting trays are adjusted correctly.

Check if the coulter disks are adjusted correctly.

Check that the top rod is free.

4.5 Inspection and maintenance after ± 5 ha.

Inspect the sieve belt for cracks and tears.

Check the tension of the drive chains and adjust if necessary.

Check the tiller ends and the tillers for wear, particularly the bottom and inner sides. The tillers are

there to protect the frame of the SAMON Onion Lifter, so make sure to replace early to prevent

damage to the frame or bearings.

WARNING!!!

Due to the various compositions of soil types it is possible that the tillers could wear out faster. Inspect

them regularly to prevent damage to the SAMON Onion Lifter.

H7

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

5. Maintenance.

WARNING!!!

When performing maintenance on the SAMON Onion Lifter always switch the tractor engine off and

remove the key from the ignition.

5.1 Lubrication schedule.

Lubricate periodically to ensure that the SAMON Onion Lifter works optimally.

Schedule for lubricating the Samon Onion Lifter.

Lubricating point:

Interval:

Item:

A

3 hours

Harvest shaft

B

8 hours

Bearings, coulter disks, chains, chain tensioner,

wheels, pressure rollers.

C

50 hours

PTO shaft.

H8

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

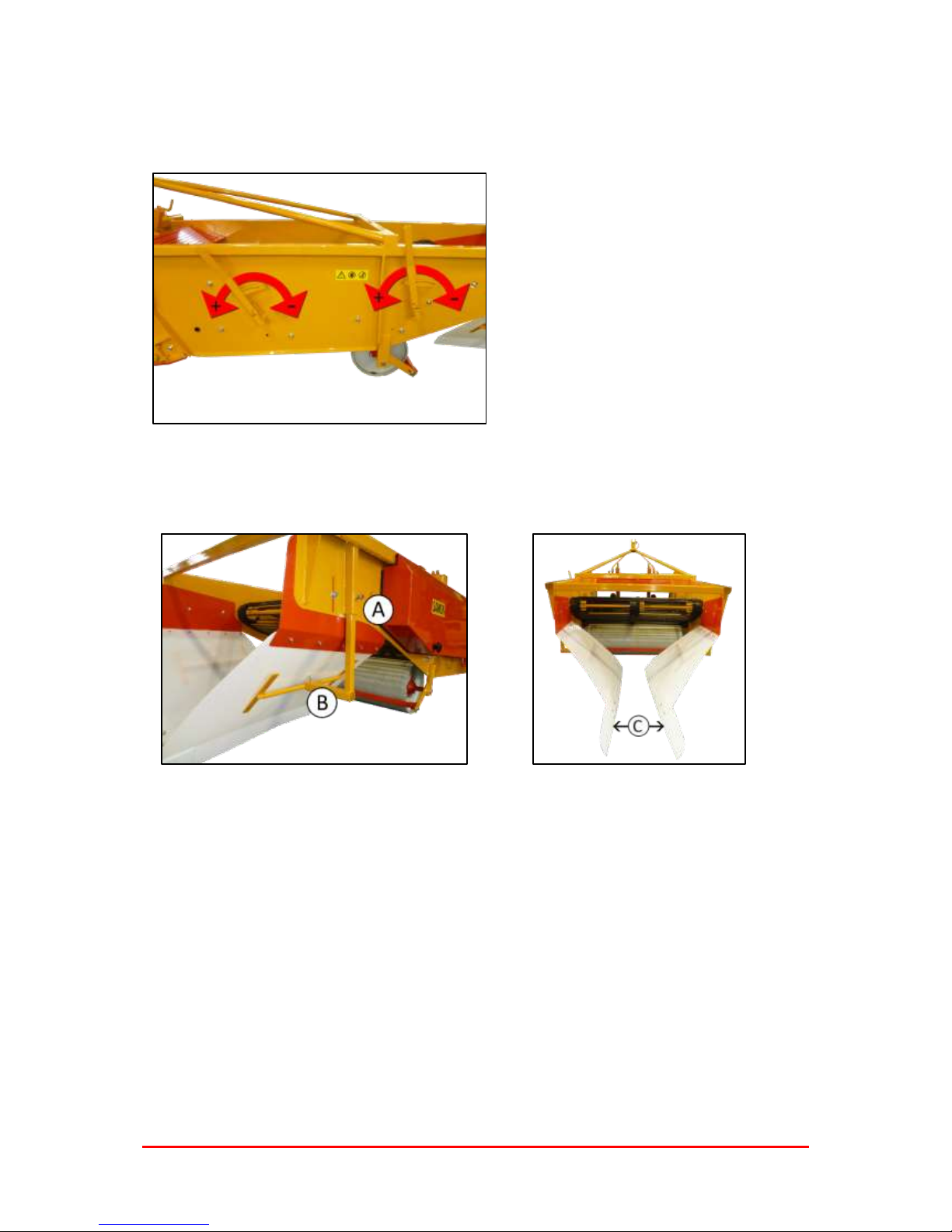

5.2 Adjusting the shakers.

The shakers can be adjusted on the sieve belt by turning the handles on the side of the SAMON Onion Lifter.

Turn the handle to the left to increase the intensity of shaking.

5.3 Setting the collecting trays.

For adjusting the collecting trays.

The space between the collecting trays can be adjusted by setting the collecting tray holder.

Use bolt "A" to adjust the height of the collection tray holder.

Use bolt "B" to adjust the angle of the collecting trays.

Normally space "C" is about:

o Track 1.5 m = 60 cm

o Track 1.8 m = 70 cm

Secure the bolts properly after completing the settings.

H9

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

5.4 Gear drive maintenance.

The gear drive is filled in the factory with gearbox oil (SAE 90).

NOTE!!!

The gearbox oil must be replaced every 2 years.

5.4.1 Topping up the gear drive oil.

Make sure the SAMON Onion Lifter is standing on a flat, level surface.

Remove the PTO shaft.

Remove the plug at the rear of the gear drive.

Fill the gear drive with oil (SAE 90) until oil starts coming from the plug.

Put the plug back in place.

Mount the PTO shaft

5.4.2 Replacing the gear drive oil.

Remove the PTO shaft.

Remove the drive shaft.

Remove the gear drive from the frame.

Remove the plug at the rear of the gear drive.

Drain the gear drive and collect the oil in a container - make sure to dispose of it in ecologically

responsible manner.

Put the gear drive back in the frame.

Fill the gear drive with oil (SAE 90) until oil starts coming from the plug.

Mount the plug.

Mount the drive shaft.

Mount the PTO shaft

H10

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

6. Transport and storage.

6.1 Transport by transport vehicles.

When transporting the machine, make sure that it is firmly secured with rope or tensioning belts.

Block the wheels and pressure rollers with wheel blocks.

6.2 Transport by tractor.

Take local traffic rules into account when taking your SAMON Onion Lifter onto a public road with a

tractor.

Before lifting the SAMON Onion Lifter with a lifting device, make sure that it is switched off and that

the sieve belts are not running.

When driving, keep in mind that the SAMON Onion Lifter has a tail swing.

Also keep in mind that the sight of the driver is limited when the SAMON Onion Lifter is connected to

a tractor.

6.3 Storage.

Clean the machine properly.

NOTE!!!

When using a high pressure cleaner, do not spray directly on/in the bearings or any electronics.

Check the tire pressure and inspect for damage. (4.5 Bar)

Check the drive chains.

Check the harvest shaft and other parts subject to wear and replace in time.

Check all bearings and replace when clearance is excessive.

Inspect the sieve belt for damage and cracks.

Inspect the intake roller for damage and cracks.

Check the pressure roller for cracks and tears.

Lubricate the machine as a whole (see Lubrication for more details).

Check the oil level in de gear drive and top up if necessary.

Check the cross connections and the turning parts of the PTO shaft for wear.

Lubricate the cross connections and the turning parts of the PTO shaft.

Check the protective cover of the PTO shaft for cracks.

Check the safety chains of the PTO shaft.

NOTE!!!

When the machine is not in use (also for shorter periods of time) and the PTO shaft is left

in the machine, attach the safety chain to the eye on the machine reserved for that

purpose to prevent damage to the protective cover and the cross connection.

Inspect the safety cords and locking clips for damage and cracks.

Store the machine dry.

H11

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

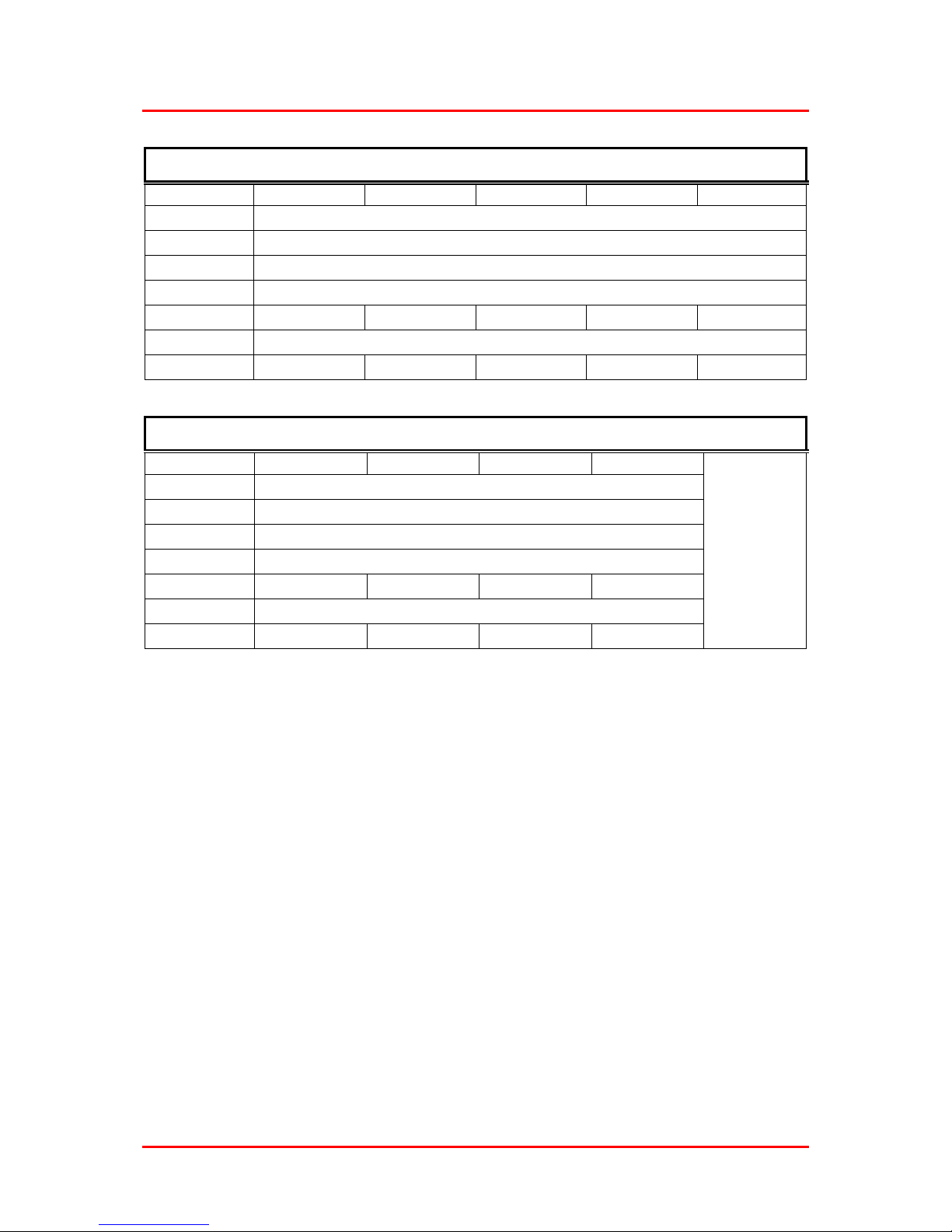

7. Technical data.

SAMON Onion Lifter “SU2M”

Belt width:

1.00 m

1.15 m

1.25 m

1.35 m

1.45 m

Type:

Harvest shaft

Drive:

Mechanical

PTO shaft:

540 PTO

Gear drive oil:

SAE.90EP / 2.5 l

Measurements:

375x165x150

375x180x150

375x200x150

375x200x150

375x200x150

Number of sieve

2

Weight: *

… kg

… kg

900 kg

920 kg

… kg

SAMON Onion Lifter “SU2M”

Belt width:

1.50 m

1.65 m

1.75 m

2.00 m

Type:

Harvest shaft

Drive:

Mechanical

PTO shaft:

540 PTO

Gear drive oil:

SAE.90EP / 2.5 l

Measurements:

375x230x150

375x230x150

375x240x150

375x265x150

Number of sieve

2

Weight: *

… kg

… kg

… kg

1000 kg

* Depending on options and additional extras.

H12

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

8. Ordering parts.

Follow the instructions below for ordering parts to ensure quick and correct delivery.

1. Only order parts from official SAMON dealers.

2. Include the type, model and serial number of your machine as stated on the type shield.

The type shield is located on the frame of the PTO shaft.

3. Measure the width of the SAMON Onion Lifter as many parts are dependent on the width of

the sieve belt.

4. Always state the part number and the description thereof in full.

H13

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

9. Troubleshooting.

General troubleshooting.

Defect:

Cause:

Solution:

The lifter does not want to go into

the ground.

The tiller ends are worn.

Replace the tiller ends.

Harvest shaft worn.

Replace the harvest shaft.

The top rod is too long.

Adjust the top rod.

H14

www.samon.nl - info@samon.nl

V1-2017-EN

27011752 - >>>

10. EC declaration of conformity.

We, Ellens Agricultural Engineering BV

Ploegstraat 4, 8308 AA Nagele, The Netherlands,

declare under our own and completely individual responsibility that the product to which this declaration

relates, is in accordance with the following standard(s):

NEN-EN 292-1, NEN-EN 292-2, prNEN 1050

In accordance with the Machinery Directive 89/392/EEC + amendments

Nagele, January 2018

Spare Parts List

Parts list index

Samon Onion Lifter SU2M, SU2H1, SU2H3:

Index.

Description.

Page:

A.

Rotating bar, shares, intake roller, and automatic grease system.

S-1

B.

Rotating bar drive.

S-3

C.

PTO.

S-7

D.

Sieve belt drive.

S-9

E.

Sieve belt drive wheels, sieve belt drive shafts, and driven roll.

S-15

F.

Sieve belts.

S-21

G.

Sieve belt parts.

S-23

H.

Rollers and scrapers.

S-25

I.

Roller parts.

S-29

J.

Support wheel and coulter disk.

S-31

K.

Pressure roller.

S-33

L.

Protective cover, linkage pins and collecting trays.

S-35

M.

Adjustable windrow frame

S-37

N.

Gearbox.

S-39

O.

Paddle intake.

S-41

P.

Automatic depth control (without discs).

S-43

Q.

Automatic depth control (with discs).

S-45

R.

Hydraulic driven discs.

S-47

S.

Automatic depth control system.

S-49

T.

Valve block for automatic depth control.

S-51

U.

Tailgate storage bunker.

S-53

S-1

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

A. Rotating bar, shares, intake roller, and automatic grease system

SU2M, SU2H1, SU2H3

S-2

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

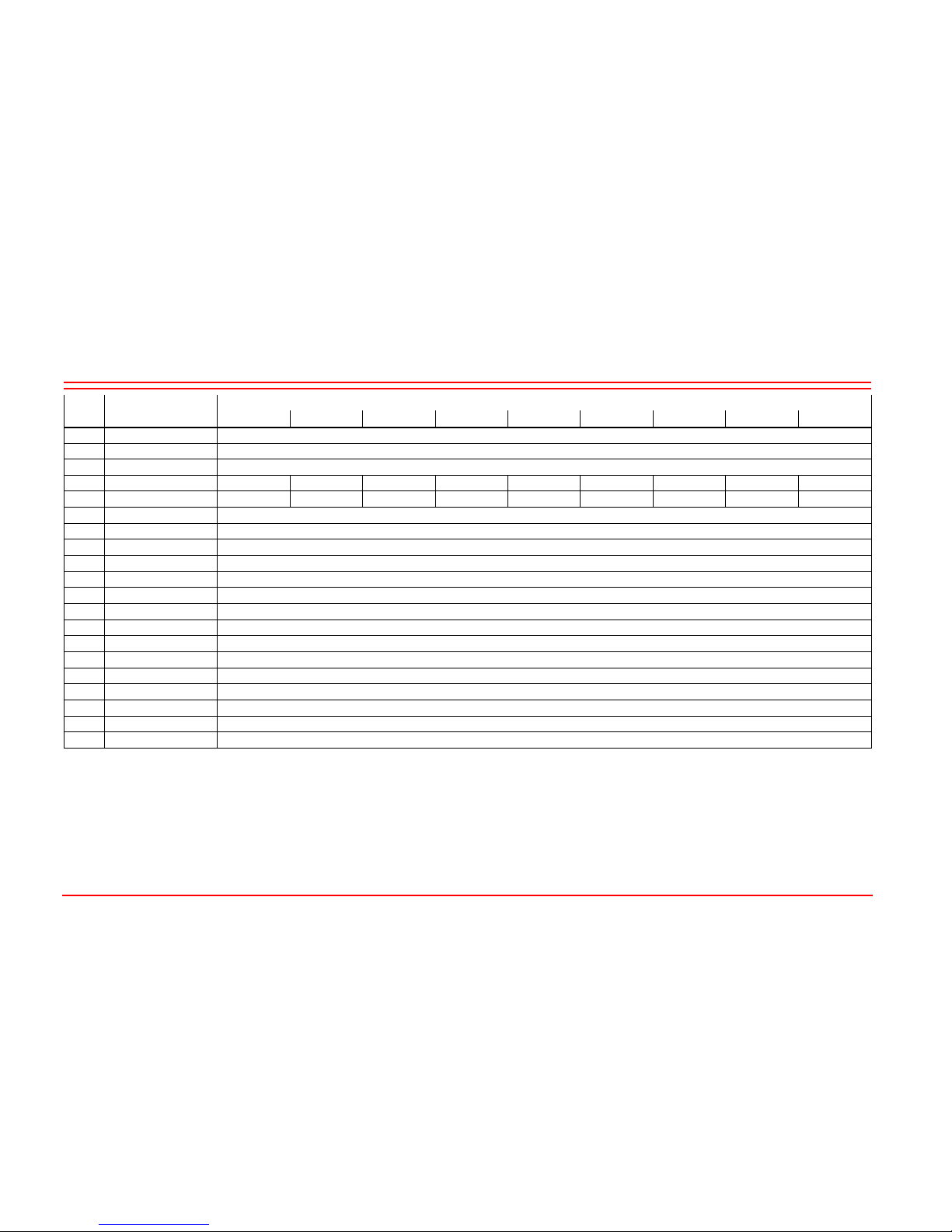

A. Rotating bar, shares, intake roller, and automatic grease system

SU2M, SU2H1, SU2H3

Sieve belt width: (m)

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Rotating bar

PE6600/100

PE6600/115

PE6600/125

PE6600/A

PE6600/145

PE6600/B

PE6600/C

PE6600/D

PE6600/E

01a

Twisted rotating bar

PE6600/100

PE6600/115

PE6600/125T

PE6600/AT

PE6600/145T

PE6600/BT

PE6600/CT

PE6600/DT

PE6600/ET

02

Bronze bush

PE6601

03

Bronze ring

PE6602

04

Bronze ring

PE6603

05

Bolt

TL6684

06

Rotating bar bearing

TL6605

07

Grease nipple

TL2088

07a

Grease nipple

TL6679 (for automatic grease system)

08*

Share (R)

PE6624

09*

Share (L)

PE6623

10

Share end

TL6622

11

Bolt for share end

PE6621

12

Complete intake roller

PE6650/100

PE6650/115

PE6650/125

PE6650/A

PE6650/145

PE6650/B

PE6650/C

PE6650/D

PE6650/E

13

Intake roller

TL6647/100

TL6647/115

TL6647/125

TL6647/A

TL6647/145

TL6647/B

TL6647/C

TL6647/D

TL6647/E

14

Intake roller inner

PE6626/100

PE6626/115

PE6626/125

PE6626/A

PE6626/145

PE6626/B

PE6626/C

PE6626/D

PE6626/E

15

Intake roller shaft

PE6648/100

PE6648/115

PE6648/125

PE6648/A

PE6648/145

PE6648/B

PE6648/C

PE6648/D

PE6648/E

16

Carrier

PE6627

17

Bearing

TL817

18

Ring

PE6646

19

Intake roller left arm

PE6629

20

Intake roller right arm

PE6630

21

Bolt

TL6634

22

Shock adjustment

PE6633

23

Compression spring

TL675

24

Grease nipple

TL6680

25

Grease system support

PE1365

26

Grease system

TL5915

27

Grease nipple

TL5917

28

Filling nipple

TL5918

29

Grease gun

TL5919

Grease line

TL6681

* For onion lifters with hydraulic driven discs see page S-45/S-46

S-3

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

B. Rotating bar drive.

SU2M, SU2H1

S-4

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

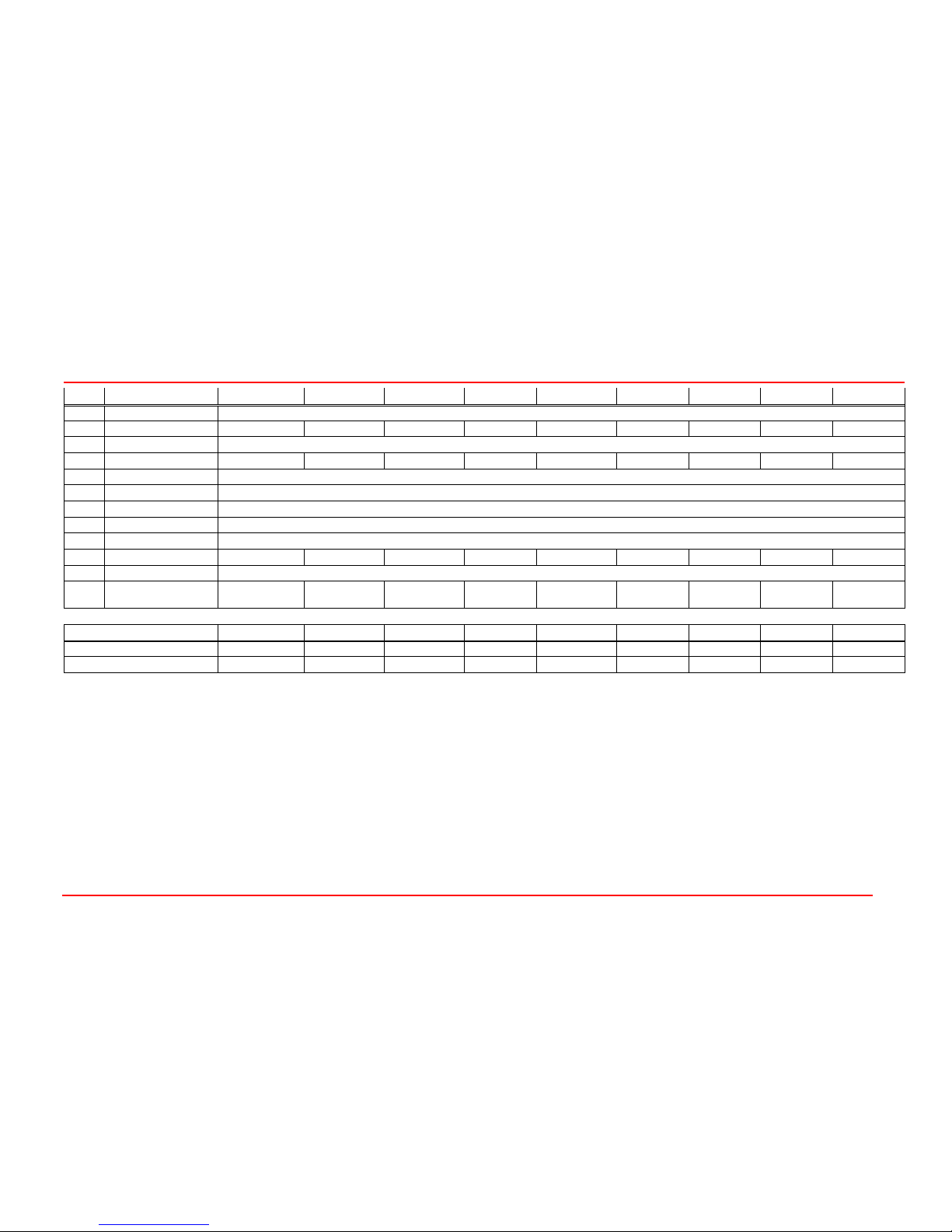

Sieve belt width: (m)

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Gearbox

TL801

02

Key

TL673

03

Chain wheel

PE969

04

Chain wheel

PE6610

05

Chain

TL970

06

Switch

TL976

07

Key

TL846

08

Drive shaft

PE6607/100

PE6607/11

PE6607/125

PE6607/A

PE6607/145

PE6607/B

PE6607/C

PE6607/D

PE6607/E

09

Bearings

TL6605

10

Bearings

TL6686

11

Chain wheel

TL6611

12

Rotating bar chain

TL6685

13

Switch

TL6618

14

Chain wheel

PE6604

15

Key

TL6635

16

Ring

PE6609

17

Bolt

TL6636

18

Tensioner

PE6644

19

Shaft

PE6614

20

Bearings

TL2084

21

Circlip

TL887

22

Chain wheel

PE2085

23

Circlip

TL815

24

Grease nipple

TL2010

25

Complete tensioner

PE6689

26

Coupling

TL6680

27

Grease line

TL6681

28

Cutting ring

TL6682

29

Clamp

TL6683

B. Rotating bar drive.

SU2M,SU2H1

S-5

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

B. Rotating bar drive.

SU2H3

S-6

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

Sieve belt width: (m)

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Hydraulic motor

TL3104

02

Grease nipple

TL2010

03

Chain wheel

PE6632

04

Rotating bar chain

TL6685

05

Chain link

TL6618

06

Rotating bar bearing

TL6605

07

Chain wheel

PE6604

08

Keu

TL6635

09

Ring

PE6609

10

Bolt

TL6636

11

Complete tensioner

PE6689

12

Tensioner

PE6644

13

Shaft

PE6614

14

Bearing

TL2084

15

Circlip

TL887

16

Chain wheel

PE2085

17

Circlip

TL815

18

Coupling

TL6680

19

Grease line

TL6681

20

Cutting ring

TL6682

21

Clamp

TL6683

B. Rotating bar drive.

SU2H3

S-7

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

C. PTO.

SU2M, SU2H1

S-8

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Complete PTO

TL707

TL707

TL707

TL707

TL707

TL707

TL708

TL708

TL708

02

Slip clutch

TL791

TL791

TL791

TL791

TL791

TL791

TL792

TL792

TL792

03

Cross & Bearing kit

TL745

04

Shaft yoke

TL746

05

Shaft

TL749

06

Tube

TL748

07

Tube yoke

TL750

08

Tractor yoke

TL751

09

Bearing set

TL776

10

Guard

TL777

Sieve belt width: (m)

C. PTO.

SU2M, SU2H1

S-9

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

D. Sieve belt drive.

SU2M

S-10

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

D. Sieve belt drive.

SU2M

Sieve belt width: (m)

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Bearing

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL3102

02

Curve

TL2089

03

Sleeve

TL2087

04

Grease nipple

TL2088

05

Chain wheel

PE983

PE983

PE983

PE983

PE983

PE983

PE983

PE983

PE983/40

06

Chain 2nd sieve belt

TL6642

07

Chain link

TL6643

08

Chain wheel

PE6616

PE6616

PE6616

PE6616

PE6616

PE6616

PE6616

PE6616

PE6616/40

09

Chain 1st sieve belt

TL6645

10

Chain wheel

PE6612

11

Tensioner

TL260

12

Shaft

PE6613

13

Bearing

TL2084

14

Chain wheel

PE2085

15

Circlip

TL815

16

Pipe nipple

TL734

17

Complete tensioner

PE6692

S-11

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

D. Sieve belt drive.

SU2H1

S-12

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

D. Sieve belt drive.

SU2H1

Sieve belt width: (m)

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Chain wheel

PE6612

02

Chain 1st Sieve belt

TL6645

03

Chain link

TL6643

04

Chain wheel

TL1027

TL1027

TL1027

TL1027

TL1027

TL1027

TL1027

TL1027

TL1027/40

05

Bearing

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL3102

06

Hydraulic motor

TL3105

07

Vibration damper

TL7554

08

Motor mount

PE3116

09

Bearing

TL5313

10

2/2 valve, web stop

TL7653

11

Complete tensioner

PE6692

12

Tensioner

TL260

13

Shaft

PE6613

14

Bearing

TL2084

15

Circlip

TL815

16

Chain wheel

PE2085

17

Curve 1/8”

TL2089

18

Pipe nipple 1/8”

TL734

19

Sleeve 1/8”

TL2087

20

Grease nipple 1/8”

TL2010

S-13

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

D. Sieve belt drive.

SU2H3

S-14

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

D. Sieve belt drive.

SU2H3

Sieve belt width: (m)

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Hydraulic motor

TL3105

02

Vibration damper

TL7554

03

Motor mount

PE3116

04

Bearing

TL5313

05

2/2 valve, web stop

TL7653

S-15

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

E. Sieve belt drive wheels and sieve belt shafts.

SU2M

S-16

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

E. Sieve belt drive wheels and sieve belt shafts.

SU2M

Sieve belt width: (m)

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Key

TL855

02

Hub

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6709

03

Drive wheel

See table D-1

04

Bearing

TL2425

TL2425

TL2425

TL2425

TL2425

TL2425

TL2425

TL2425

TL3102

05

Grease nipple

TL2010

06

Drive shaft 1st web

PE849/100

PE849/115

PE849/125

PE849/A

PE849/145

PE849/B

PE850

PE1103

PE849/E

07

Drive shaft 2nd web

See table D-2

D-1. Sieve belt drive wheel

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

Sieve belt pitch 36 mm:

TL6703

Sieve belt pitch 42 mm:

TL6701

Sieve belt pitch 45 mm:

TL6704

Sieve belt pitch 50 mm:

TL6705

D-2. Drive shaft 2nd web

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

Standard:

PE849/100

PE849/115

PE849/125

PE849/A

PE849/145

PE849/B

PE850

PE1103

PE849/E

Web with overhang:

PE849/100/O

PE849/115/O

PE849/125/O

PE849/A/O

PE849/145/O

PE849/B/O

PE850/O

PE1103/O

PE849/E/O

S-17

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

E. Sieve belt drive wheels, sieve belt shafts, and driven roll.

SU2H1

S-18

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

E. Sieve belt drive wheels, sieve belt shafts, and driven roll.

SU2H1

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Key

TL855

02

Hub

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6709

03

Drive wheel

See Table D-1

04

Bearing

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL3102

05

Bearing

TL2425

TL2425

TL2425

TL2425

TL2425

TL2425

TL2425

TL2425

TL3102

06

Key

TL944

07

Chain wheel

PE866

PE866

PE866

PE866

PE866

PE866

PE866

PE866

PE866/40

08

Chain wheel

PE6610

09

Tensioner chain wheel

TL1317

10

Chain

TL1324

11

Chain lock

TL679

12

Drive shaft 1st web

PE1318/100

PE1318/115

PE1318/125

PE1318/A

PE1318/145

PE1318/B

PE1318/C

PE1318/D

PE1318/E

13

Drive shaft 2nd web

See table D-3

14

Driven roll

PE7671/100

PE7671/115

PE7671/125

PE7671/A

PE7671/145

PE7671/B

PE7671/C

PE7671/D

PE7671/E

D-3. Drive shaft 2nd web

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

Standard:

PE849/100/H

PE849/115/H

PE849/125/H

PE849/A/H

PE849/145/H

PE849/B/H

PE850/H

PE1103/H

PE849/E/H

Web with overhang:

PE849/100/H/O

PE849/115/H/

PE849/125/H/O

PE849/A/H/O

PE849/145/H/O

PE849/B/H/O

PE850/H/O

PE1103/H/O

PE849/E/H/O

S-19

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

E. Sieve belt drive wheels, sieve belt shafts, and driven roll.

SU2H3

S-20

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

E. Sieve belt drive wheels, sieve belt shafts, and driven roll.

SU2H3

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Key

TL855

02

Hub

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6702

TL6709

03

Drive wheel

See table D-1

04

Bearing

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL6686

TL3102

05

Bearing

TL6686

06

Bearing

TL5313

07

Motor support

PE3116

08

Vibration damper

TL7554

09

Hydraulic motor

TL5314

10

Drive shaft 1st web

PE849/100/H

PE849/115/H

PE849/125/H

PE849/A/H

PE849/145/H

PE849/B/H

PE850/H

PE1103/H

PE849/E/H

11

Drive shaft 2nd web

See table D-4

12

Driven roll

PE7671/100/H

PE7671/115/H

PE7671/125/H

PE7671/A/H

PE7671/145/H

PE7671/B/H

PE7671/C/H

PE7671/D/H

PE7671/E/H

D-4. Drive shaft 2nd web

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

Standard:

PE849/100/H

PE849/115/H

PE849/125/H

PE849/A/H

PE849/145/H

PE849/B/H

PE850/H

PE1103/H

PE849/E/H

Web with overhang:

PE849/100/H/O

PE849/115/H/O

PE849/125/H/O

PE849/A/H/O

PE849/145/H/O

PE849/B/H/O

PE850/H/O

PE1103/H/O

PE849/E/H/O

S-21

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

F. Sieve belts.

SU2M,SU2H1,SU2H3

S-22

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

F. Sieve belts.

SU2M,SU2H1,SU2H3

Sieve belt width: (m)

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

1st Sieve belt

See table D-5

02

2nd Sieve belt

See table D-6 & table D-7

D-5. 1st Sieve belt

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

Sieve belt pitch 36 mm:

- - -

TL5878

TL6791

TL6780

TL5879

TL5880

TL6781

Sieve belt pitch 42 mm:

TL5864/100

TL5864/115

TL5864/125

TL5864

TL5864/145

TL1084

TL5865

TL5877

TL6720

Sieve belt pitch 45 mm:

- - -

TL1076

-

TL6782

TL6783

TL6784

TL6785

Sieve belt pitch 50 mm:

-

-

TL6830/125

TL6830

-

TL6831

TL6832

TL6844

TL6841

D-6. 2nd Sieve belt

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

Sieve belt pitch 36 mm:

- - -

TL1078

TL6792

TL6786

TL1079

TL1156

TL6787

Sieve belt pitch 42 mm:

TL1080/100

TL1080/115

TL1080/125

TL1080

TL1080/145

TL1085

TL1081

TL1157

TL6721

Sieve belt pitch 45 mm:

-

-

TL1082/125

TL1082

-

TL6788

TL1083

TL6789

TL6790

Sieve belt pitch 50 mm:

- - -

TL6833 - - - TL6845

TL6842

D-7. 2nd Sieve belt

With overhang

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

Sieve belt pitch 36 mm:

- - -

TL1078/O

-

TL6786/O

TL1079/O - -

Sieve belt pitch 42 mm:

- - -

TL1080/O

TL1080/145/O

TL1085/O

TL1081/O

TL1157/O

-

Sieve belt pitch 45 mm:

- - -

TL1082/O

-

TL6788/O

TL1083/O - -

Sieve belt pitch 50 mm:

- - - - - - - - -

- = on demand

S-23

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

G. Sieve belt parts.

SU2M,SU2H1,SU2H3

S-24

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

G. Sieve belt parts.

SU2M,SU2H1,SU2H3

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Lockbar

TL6762/100

TL6762/115

TL6762/125

TL6762/A

TL6762/145

TL6762/B

TL6762/C

TL6762/D

TL6762/E

02

Lockbar with

overhang

TL6762/100/O

TL6762/115/O

TL6762/125/O

TL6762/A/O

TL6762/145/O

TL6762/B/O

TL6762/C/O

TL6762/D/O

-

03

Lock (set)

See table D-8

04

Latch plate

TL105

05

Rivet

TL104

06

Rivet bar

TL109/100

TL109/115

TL109/125

TL109/A

TL109/145

TL109/B

TL110

TL111

TL109/E

07

Rivet bar with

overhang

TL109/100/O

TL109/115/O

TL109/125/O

TL109/A/O

TL109/145/O

TL109/B/O

TL110/O

TL111/O

-

D-8. Sieve belt lock

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

Sieve belt pitch 36 mm:

TL6713

Sieve belt pitch 42 mm:

TL6714

Sieve belt pitch 45 mm:

TL6715

Sieve belt pitch 50 mm:

TL6716

S-25

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

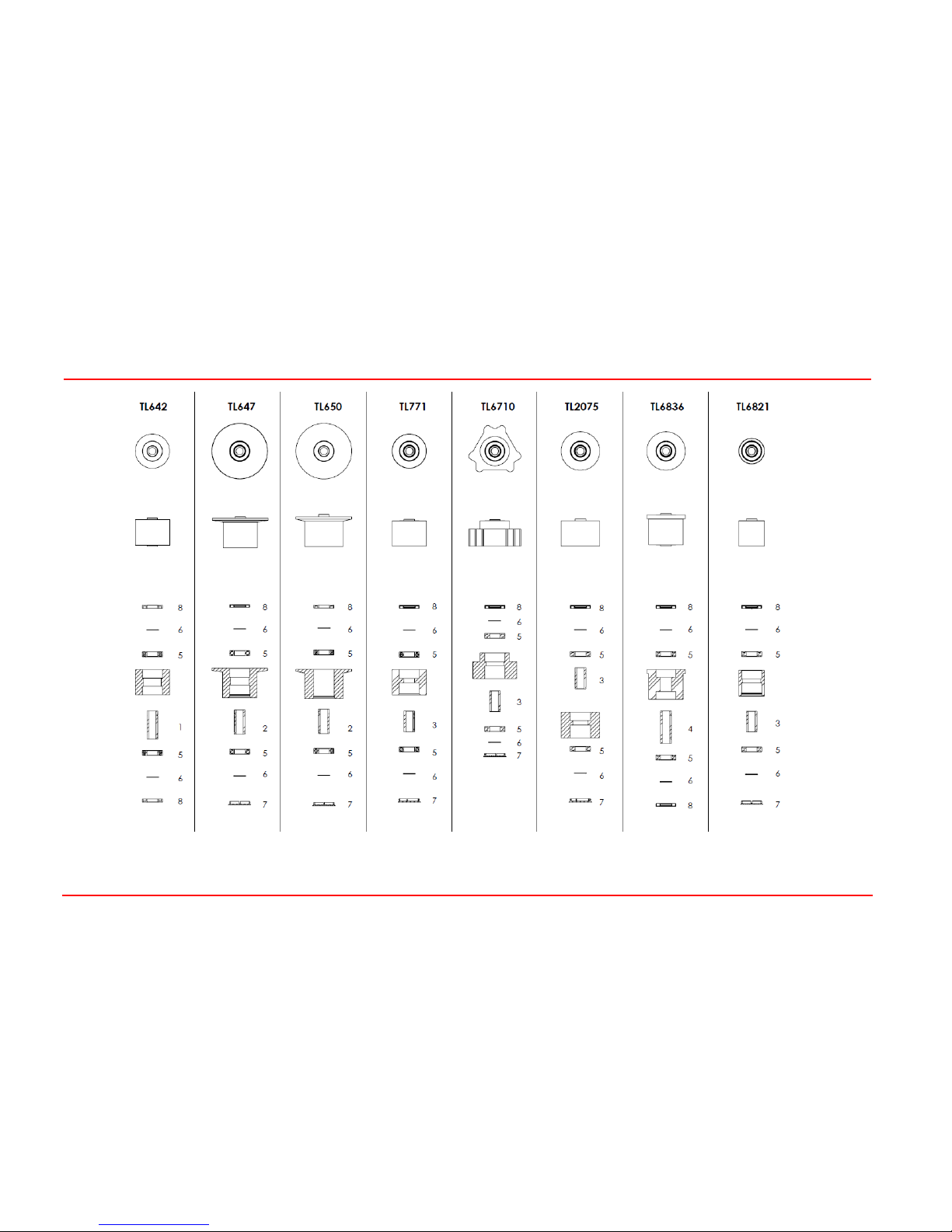

H. Rollers and scrapers (standard 2nd web).

SU2M/SU2H1/SU2H3

S-26

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

H. Rollers and scrapers (standard 2nd web).

SU2M/SU2H1/SU2H3

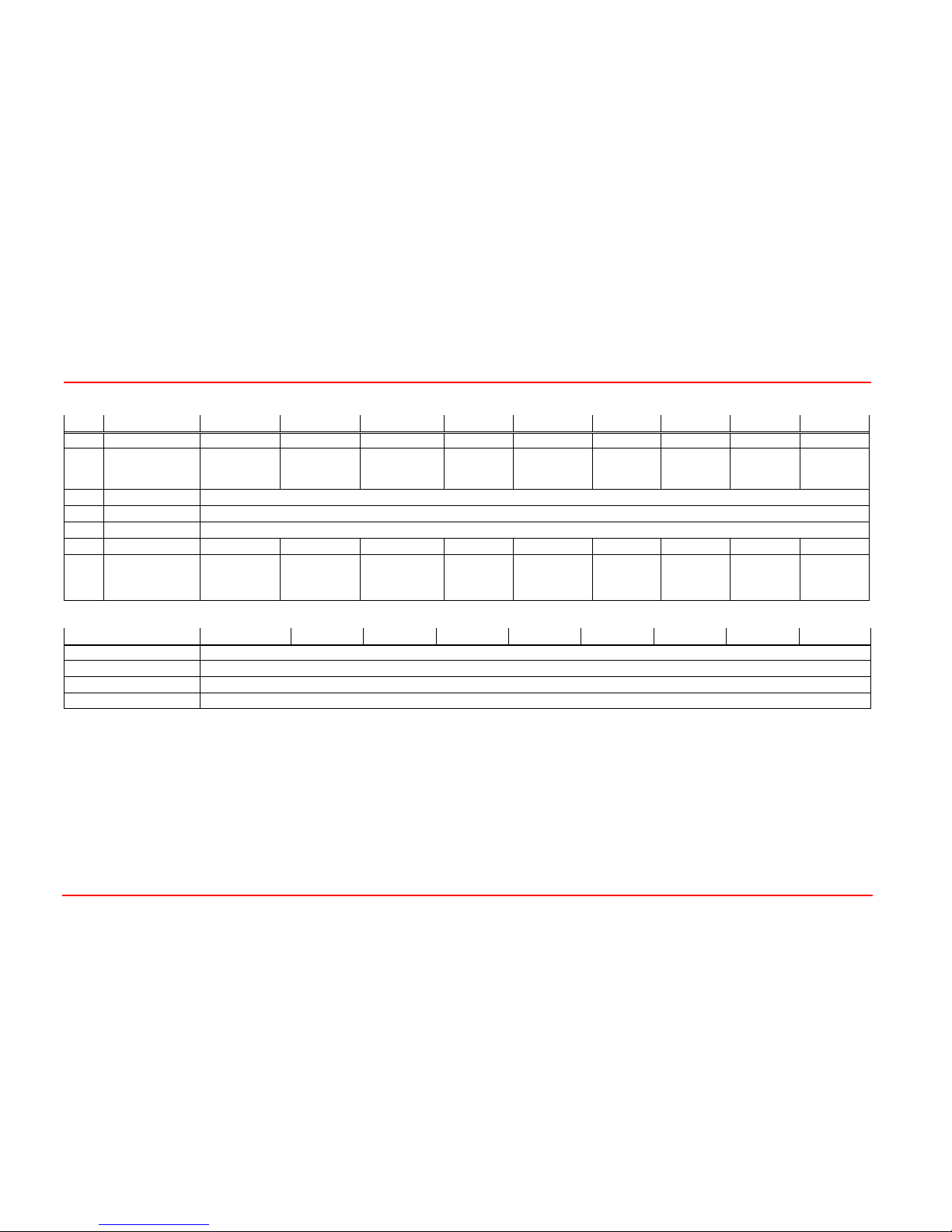

Sieve belt width: (m)

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Steel roller Ø80 *

TL642

02

Steel roller flanged Ø80

TL647

03

Scraper

PE6628

04

Steel roller Ø80

TL771

05

Rubber roller Ø90 **

TL2075

06

Rubber roller flanged Ø90

TL650

07

Shaker

TL6710

08

Filling bush

PE1165

09

Steel roller Ø60***

TL6821

*From sieve belt with 1.65 mtr. also a steel roller at the middle of the second web (+ scraper).

** Only with sieve belts with a pitch of 36/45/50 mm.

*** Only with driven roll.

S-27

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

H. Rollers and scrapers (2nd web with overhang).

SU2M,SU2H1,SU2H3

S-28

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

H. Rollers and scrapers (2nd web with overhang).

SU2M,SU2H1,SU2H3

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Steel roller Ø80 *

TL642

02

Steel roller Ø80

TL771

03

Shaker

TL6710

04

Scraper

PE6628

05

Rubber roller Ø90

TL2075

05a

Rubber roller Ø90 **

TL2075

06

Steel roller flanged Ø80

TL647

07

Steel roller flanged Ø80

TL6836

08

Steel roller Ø60***

TL6821

09

Roller support (long)

PE1321

10

Roller support (short)

PE1319

*From sieve belt with 1.65 mtr. also a steel roller at the middle of the second web (+ scraper).

** Only with sieve belts with a pitch of 36/45/50 mm.

*** Only with driven roll.

S-29

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

I. Roller parts.

SU2M,SU2H1,SU2H3

S-30

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

I. Roller parts.

SU2M,SU2H1,SU2H3

Sieve belt width: (m)

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Shaft busing

TL1150

02

Shaft busing

TL6730

03

Shaft busing

TL6731

04

Shaft busing

TL6733

05

Bearings

TL1195

06

Circlip

TL815

07

Cover

TL5807

08

Oil seal

TL5818

S-31

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

J. Support wheel and coulter disk.

SU2M,SU2H1,SU2H3

S-32

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

J. Support wheel and coulter disk.

SU2M,SU2H1,SU2H3

Sieve belt width: (m)

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Clamp

PE6649

02

Complete wheel housing

PE6694

03

Turning arm

PE729

04

Wheel housing

PE6656

05

Bearing

TL730

06

Spindle

PE728

07

Wheel foot

PE6659

08

Lamellar seal

TL535

09

Bearing

TL684

10

Wheel

TL632

11

Circlip

TL891

12

Wheel cap

TL897

13

Pin

PE3101

14

Shaft

PE1127

15

Split pin

TL1036

16

Hub

TL617

17

Felt ring

TL885

18

Lamellar seal

TL886

19

Bearing

TL661

20

Circlip

TL887

21

Nut

TL622

22

Seal

TL619

23

Coulter disk

TL6653

24

Complete hub

PE1322

S-33

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

K. Pressure roller.

SU2M,SU2H1,SU2H3

S-34

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

K. Pressure roller.

SU2M,SU2H1,SU2H3

Sieve belt width: (m)

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Scraper

PE6662/100

PE6662/115

PE6662/125

PE6662/A

PE6662/145

PE6662/B

PE6662/C

PE6662/D

PE6662/E

02

Shaft

PE6661/100

PE6661/115

PE6661/125

PE6661/A

PE6661/145

PE6661/B

PE6661/C

PE6661/D

PE6662/E

03

Bearing

TL975

04

Cap

PE995

05

Inner ring

PE903

06

Nylon busing

PE981

07

PVC Roll

TL6660/100

TL6660/115

TL6660/125

TL6660/A

TL6660/145

TL6660/B

TL6660/C

TL6660/D

TL6660/E

08

Complete roller

PE6663/100

PE6663/115

PE6663/125

PE6663/A

PE6663/145

PE6663/B

PE6663/C

PE6663/D

PE6663/E

S-35

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

L. Protective cover, locking pins and windrow chutes.

SU2M,SU2H1,SU2H3

S-36

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

L. Protective cover, locking pins and windrow chutes.

SU2M, SU2H1,SU2H3

Sieve belt width: (m)

Pos.:

Description.:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Protective plate

TL6665/100

TL6665/115

TL6665/125

TL6665/A

TL6665/145

TL6665/B

TL6665/C

TL6665/D

TL6665/E

02

Cover plate

TL6666/100

TL6666/115

TL6666/125

TL6666/A

TL6666/145

TL6666/B

TL6666/C

TL6666/D

TL6666/E

03

Protective cover

PE6667/100

PE6667/115

PE6667/125

PE6667/A

PE6667/145

PE6667/B

PE6667/C

PE6667/D

PE6667/E

04

Chain casing

SU2M/SU2H1

PE6675

04a

Chain casing SU2H3

PE6675/H

05

Chain casing rubber

TL6676

06

Grease nipple

TL2088

07

Chain casing SU2M

PE6678

07a

Chain casing SU2H1

PE6697

08

Star knob

TL6664

09

Seal ring

PE6669

10

Top chute (L)

PE6670

11

Top chute (R)

PE6671

12

PVC chute (L)

PE933

PE933

PE933

PE933

PE933

PE933

PE1093

PE1093

PE1093

13

PVC chute (R)

PE934

PE934

PE934

PE934

PE934

PE934

PE1094

PE1094

PE1094

14

Scraper

PE935

15

Support bracket

PE6672

16

Chute support

PE1004

17

Chain casing support

PE6673

18

Clamp

TL6674

19

Safety cord

TL1086

20

Locking pin

TL880

21

Lower link pin

PE208

22

Top link pin

PE205

23

Locking pin

TL860

S-37

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

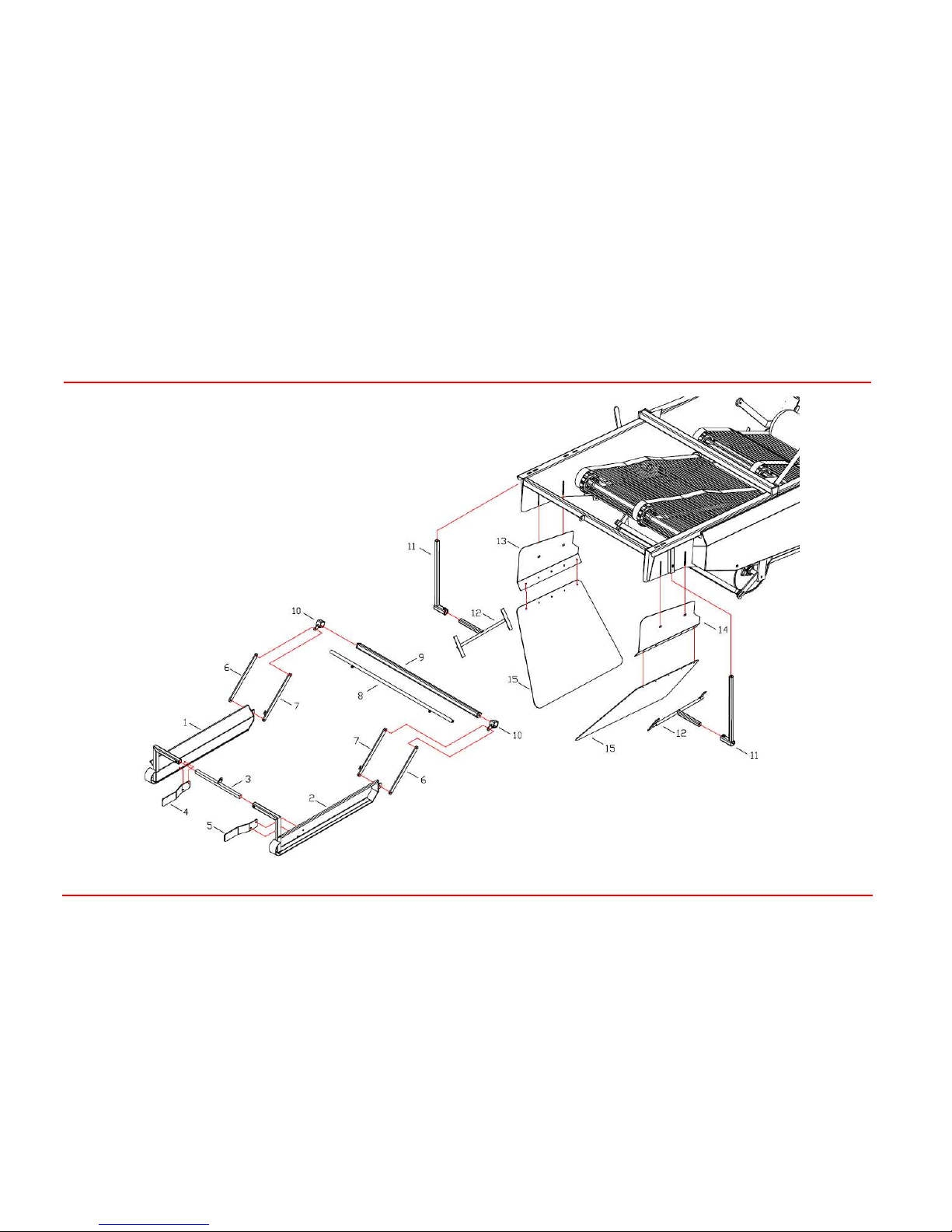

M. Adjustable windrow frame.

SU2M, SU2H1,SU2H3

S-38

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

M. Adjustable windrow frame.

SU2M, SU2H1,SU2H3

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Windrow frame (L)

PE1327

02

Windrow frame (R)

PE1328

03

Adjustment bar

PE1329

PE1329

PE1329

PE1329

PE1329

PE1350

PE1350

PE1350

PE1350

04

Plate left

PE1332

05

Plate right

PE1333

06

Support

PE1334

07

Support

PE1343

08

Shaft for chain

PE1344/100

PE1344/115

PE1344/125

PE1344/A

PE1344/145

PE1344/B

PE1344/C

PE1344/D

PE1344/E

09

Mounting tube

PE1345/100

PE1345/115

PE1345/125

PE1345/A

PE1345/145

PE1345/B

PE1345/C

PE1345/D

PE1345/E

10

Mount

PE1346

11

Support bracket

PE1347

PE1347

PE1347

PE1347

PE1347

PE1347

PE6672

PE6672

PE6672

12

Chute support

PE1348

13

Steel chute (L)

PE6670

14

Steel chute (R)

PE6671

15

PVC chute

PE1349

S-39

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

N. Gearbox TL801.

SU2M,SU2H1,SU2H3

S-40

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

N. Gearbox TL801.

SU2M,SU2H1,SU2H3

Sieve belt width: (m)

Pos.:

Description:

1.00

1.15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Gear drive housing

TL1171

02

Spacer ring

TL1172

03

Oil seal

TL1183

04

Bearings

TL2046

05

Oil seal

TL1182

06

Seal

TL1173

07

Bolt

9331225

08

Circlip

TL2044

09

Drive shaft

TL1174

10

Bearing flange

TL1175

11

Spacer ring

TL1176

12

Gear wheel

TL1177

13

Bearings

TL1184

14

Lid

TL1178

15

Gear wheel

TL1179

16

Plug

TL1180

17

Key

TL1181

S-41

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

O. Intake paddle.

SU2M,SU2H1,SU2H3

S-42

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

O. Intake paddle.

SU2M,SU2H1,SU2H3

Sieve belt width: (m)

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Hydraulic motor

TL575

02

Key

TL846

03

Spider

TL417

04

Coupling

PE3113

05

Coupling housing

PE3111

06

Bearings

TL1154

07

Grease nipple

TL2010

08

Key

TL673

09

Shaft

PE3110/100

PE3110/115

PE3110/125

PE3110/A

PE3110/145

PE3110/B

PE3110/C

PE3110/D

PE3110/E

10

Mounting plate

TL1129/100

TL1129/115

TL1129/125

TL1129/A

TL1129/145

TL1129/B

TL1130

TL1131

TL1129/E

11

Rubber

PE5868/100

PE5868/115

PE5868/125

PE5868/A

PE5868/145

PE5868/B

PE5869

PE5870

PE5868/E

12

Terminal strip

PE1121/100

PE1121/115

PE1121/125

PE1121/A

PE1121/145

PE1121/B

PE1122

PE1123

PE1121/E

S-43

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

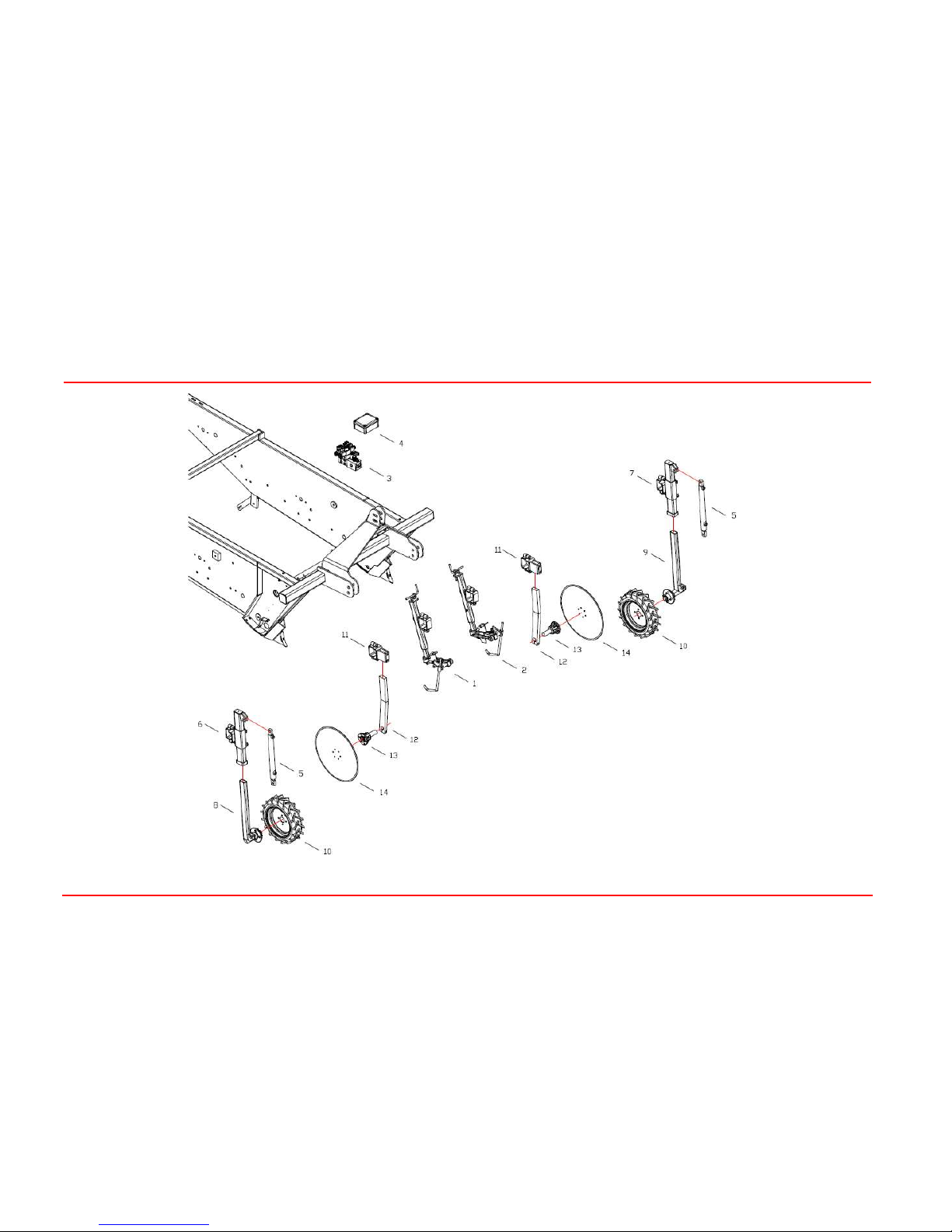

P. Automatic depth control (without discs).

SU2M,SU2H1,SU2H3

S-44

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

P. Automatic depth control (without discs).

SU2M,SU2H1,SU2H3

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Depth control (R)

See page S49/S50

02

Depth control (L)

See page S49/S50

03

Valve block

See page S51/S52

04

Electric box

TL6501

05

Cylinder

TL2419

06

Wheel housing (R)

PE1354

07

Wheel housing (L)

PE1355

08

Wheel foot (R)

PE1356

09

Wheel foot (L)

PE1357

10

Wheel

TL1358

11

Support bracket

PE1359

12

Holder

PE3103

13

Complete hub

PE1322

See page S31/S32

14

Coulter disc Ø580 6-holes

TL1360

S-45

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

Q. Automatic depth control (with discs).

SU2M,SU2H1,SU2H3

S-46

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

Q. Automatic depth control (with discs).

SU2M,SU2H1,SU2H3

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Depth control (R)

See page S49/S50

02

Depth control (L)

See page S49/S50

03

Valve block

See page S51/S52

04

Electric box

TL6501

05

Cylinder

TL2419

06

Cylinder mount

PE1353

07

Wheel mount (R)

PE1361

08

Wheel mount (L)

PE1362

09

Wheel

TL8003

10

Spring

PE6907

11

Ring

PE6906

12

Thread shaft

PE1351

13

Mount

PE6904

14

Ring

PE6901

15

Disc support

PE1352

16

Disc unit

See page S47/S48

17

Share (L)

PE6623/S

18

Share (R)

PE6624/S

S-47

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

R. Hydraulic driven discs.

SU2M,SU2H1,SU2H3

S-48

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

D-9. Scraper

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Scraper Ø300mm

PE5320

02

Scraper Ø350mm

PE5321

03

Scraper Ø410mm

PE5322

Table D-10: Disc

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Disc Ø300mm

TL5312

02

Disc Ø350mm

TL5308

03

Disc Ø410mm

TL5304

R. Hydraulic driven discs.

SU2M,SU2H1,SU2H3

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Complete disc unit

PE5307

02

Hydraulic motor 125CC

TL1296

02a

Hydraulic motor 160CC

TL1297

03

Ring

PE1325

04

Coupling

PE416

05

Spider

TL417

06

Circlip

TL891

07

Bearing

TL2009

08

Housing

PE5306

09

Cover

PE5306

10

Grease nipple

TL2010

11

Scraper

See table D-9

12

Scraper bracket

PE5316

13

Bearing

TL5317

14

Oil seal

TL1182

15

Oil seal

TL1326

16

Shaft

PE5305

17

Key

TL473

18

Disc

See table D-10

S-49

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

S. Automatic depth control system.

SU2M,SU2H1,SU2H3

S-50

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

S. Automatic depth control system.

SU2M,SU2H1,SU2H3

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Housing (R)

PE1363

02

Housing (L)

PE1364

03

Feet

PE6505

04

Pin

PE6524

05

Arm (R)

PE6511

06

Arm (L)

PE6510

07

Probe bracket (R)

PE6516

08

Probe bracket (L)

PE6515

09

Probe

PE6509

10

Arm reaction plate

PE6514

11

Reaction plate (R)

PE6513

12

Reaction plate (L)

PE6512

13

Sensor

TL6502

14

Veer

TL6517

15

Bolt

PE6518

S-51

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

T. Valve block for automatic depth control.

SU2M,SU2H1,SU2H3

S-52

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

T. Valve block for automatic depth control.

SU2M,SU2H1,SU2H3

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Valve block complete

TL6530

02

Controlled check valve NG6

TL7645

03

Control valve NG6

TL1340

04

Coil 12V

TL7532

05

Set bolts M5x85 NG6

TL1341

06

2/2 Valve

TL3376

07

Flow control valve

TL8090

08

Pressure relief valve

TL1342

09

Seal kit

PE6531

S-53

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

U. Tailgate storage bunker.

SU2M,SU2H1,SU2H3

S-54

Modifications for technical improvements reserved

V1-2018-EN

27011752 - >>>

www.samon.nl - info@samon.nl

U. Tailgate storage bunker.

SU2M,SU2H1,SU2H3

Pos.:

Description:

1,00

1,15

1,25

1,35

1,45

1,50

1,65

1,75

2,00

01

Bunker

On demand

02

Plate

On demand

03

Rubber

On demand

04

Cylinder mount

On demand

05

Cylinder

On demand

06

Pin

PE2417

07

Pin

On demand

Loading...

Loading...