Page 1

2 YEAR LIMITED WARRANTY

The SM5-KIT manufactured by Samlex America, Inc. (the “Warrantor“) is warranted to be

free from defects in workmanship and materials under normal use and service. The warranty period is 2 years for the United States and Canada, and is in effect from the date of

purchase by the user (the “Purchaser“).

Warranty outside of the United States and Canada is limited to 6 months. For a warranty

claim, the Purchaser should contact the place of purchase to obtain a Return Authorization Number.

The defective part or unit should be returned at the Purchaser’s expense to the authorized

location. A written statement describing the nature of the defect, the date of purchase,

the place of purchase, and the Purchaser’s name, address and telephone number should

also be included.

If upon the Warrantor’s examination, the defect proves to be the result of defective material or workmanship, the equipment will be repaired or replaced at the Warrantor’s option

without charge, and returned to the Purchaser at the Warrantor’s expense. (Contiguous

US and Canada only)

No refund of the purchase price will be granted to the Purchaser, unless the Warrantor is

unable to remedy the defect after having a reasonable number of opportunities to do so.

Warranty service shall be performed only by the Warrantor. Any attempt to remedy the

defect by anyone other than the Warrantor shall render this warranty void. There shall

be no warranty for defects or damages caused by faulty installation or hook-up, abuse or

misuse of the equipment including exposure to excessive heat, salt or fresh water spray, or

water immersion.

No other express warranty is hereby given and there are no warranties which extend

beyond those described herein. This warranty is expressly in lieu of any other expressed

or implied warranties, including any implied warranty of merchantability, tness for the

ordinary purposes for which such goods are used, or tness for a particular purpose, or

any other obligations on the part of the Warrantor or its employees and representatives.

There shall be no responsibility or liability whatsoever on the part of the Warrantor or

its employees and representatives for injury to any persons, or damage to person or

persons, or damage to property, or loss of income or prot, or any other consequential or

resulting damage which may be claimed to have been incurred through the use or sale of

the equipment, including any possible failure of malfunction of the equipment, or part

thereof. The Warrantor assumes no liability for incidental or consequential damages of

any kind.

5-hole

Solar Panel

Owner's

Manual

Please read this

manual before

installing your kit

Mounting

Bracket Kit

SM5-KIT

INTRODUCTION

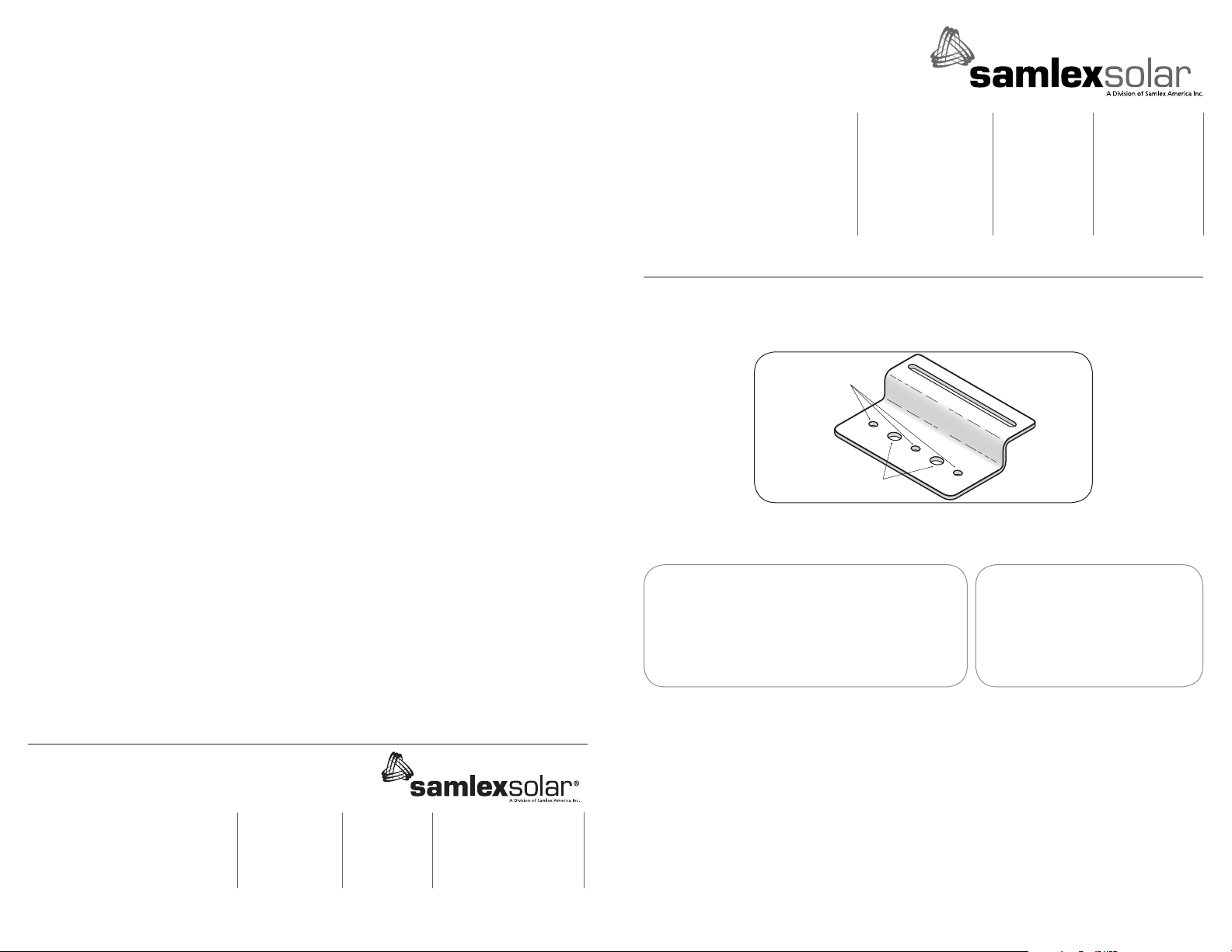

The SM5-KIT includes four sturdy 5-hole Aluminum mounting brackets (Fig. 1) with stainless steel hardware

required to securely fasten a solar panel to the roof of your Recreational Vehicle (RV) or any other at surface.

1/4” holes

3/8” holes

Fig.1. 5-hole mounting bracket

List of Parts (Included in the kit)

Part Description Quantity Illustration

1. 5-hole aluminum mounting bracket 4 Fig. 1

2. Stainless steel serrated ange bolt ¼”-20 x ¾" 4 Fig. 7

3. Stainless steel nylon insert locknut, ¼” 4 Fig. 7

4. Stainless steel at washer, ¼”-20 8 Fig. 7

5. Well Nut-Nut thread: ¼”-20, length: 1”, shank dia.: ½” 4 Fi g. 2

6. Stainless steel serrated ange bolt, ¼”-20 x 1¼” 4 F ig. 8

Required Tools (Not included in the kit)

7/16” wrench 3/8” wrench

Hand Drill ½” drill bit

Pliers Punch or Awl

Samlex America Inc. (the “Warrantor”)

www.samlexamerica.com

4

103 - 4268 Lozells Ave.

Burnaby, BC

Canada V5A 0C6

T: 604 525 3836

F: 604 525 5221

TF: 1 800 561 5885

e-mail: samlex@samlexsolar.com

website: www.samlexsolar.com

11013-SM5-KIT-1112

MAN-10004

Pre-installation

With the incidence of sunlight on all photovoltaic modules, a voltage appears at the output terminals of the

photovoltaic module turning it into a live power source. To avoid a shock hazard make sure the solar module

is covered with an opaque (dark) material such as paper / cloth.

Stainless Steel can be subject to a process called “thread galling” in which bolts can twist off and/or the bolt

threads seize to the nut’s thread. Apply anti-galling lubricant available at most hardware or auto-parts stores

to all the stainless steel fasteners before installation. If anti-galling lubricant is not available, any standard

lubricant will minimize the occurrence of “thread galling”.

1

Page 2

solar module

1/4” -20x3/4” ange bolt

1/4” at washer

1/4” locknut

mounting bracket

RV roof

Rubber bushing material expands

when bolt is tightened to securely

anchor hardware

solar

module

¼”-20 x 1¼” ange bolt

¼” at washer

Well-Nut

mounting bracket

RV roof material

up to approx. 3/8”

thickness

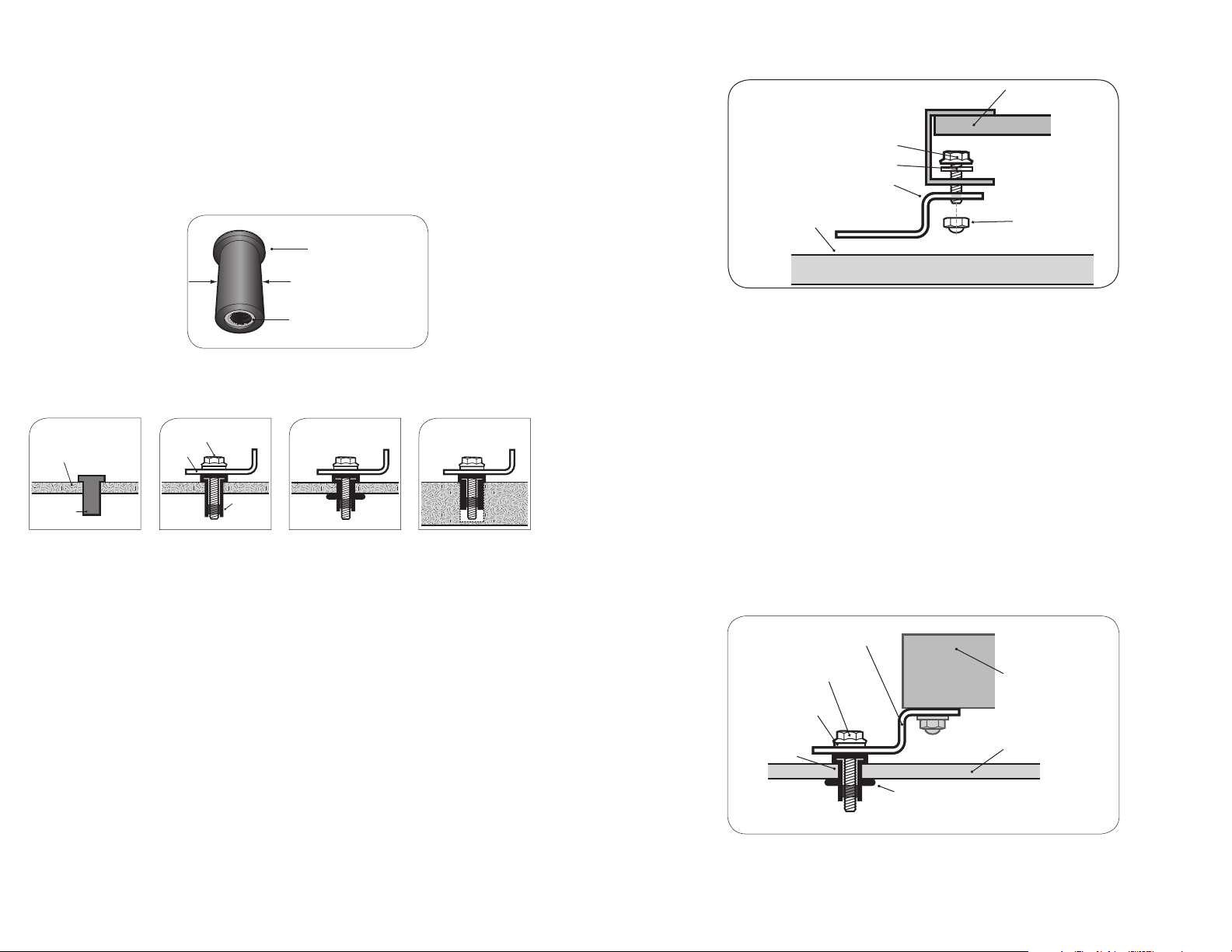

Well Nut for anchoring mounting bracket to the RV Roof or at surface

ange

1/2” diameter

1/4” captive brass nut

RV Roong

Material

Well Nut

1/4”-20 x 1

1/4

”

Serrated

Flange Bolt

Mounting

Bracket

Captive

Brass Nut

A Well-Nut is a bushing of tough neoprene rubber with a ange at the top end and a captive brass nut

mounted within the bore at the bottom end (Fig. 2). This is used to anchor the mounting bracket (Fig.1)

on to the roof of the RV or to other at surface. Typical installation is shown in Figs 3 to 6. Tightening

a conventional machine bolt or screw engages the captive nut thereby causing the bushing to expand

outwards. This fastens securely to thinner RV roofs by bulging up and against the bottom surface of the roof

(Fig. 5). If used in a blind hole in a solid surface material, the rubber will expand outwards to create a secure

fastening (Fig. 6). The neoprene and brass resist most environmental conditions. Additionally, the Well-Nut

seals the drilled hole effectively against air and liquid leakage.

Fig. 2. Construction of a Well Nut

Typical Installation of a Well-Nut

Fig. 3. Well-Nut is inserted

into a pre-drilled hole

with its ange against the

outer surface. There is no

need for access to the

inner side.

Fig. 4. The 5-hole mounting

bracket is placed against

the ange of the Well-Nut

and is secured by the 1/4"-

1/4

20 x 1

" serrated ange

bolt engaging the captive

brass nut.

Fig. 5. As the bolt is tightened, the neoprene body of

the Well-Nut is compressed

and expanded, forcing it

tightly into the bolt's threads

and against the inner surface

of the thin RV roof material.

Fig. 6. Installed in a

blind hole in a solid material, the body of the

Well-Nut expands tightly

against the walls of the

hole, effecting a secure,

dependable fastening.

Fig. 7. Attaching solar panel to 5-hole mounting bracket

4. Position the panel with the attached mounting brackets at the desired location on the RV roof and

mark the position of the mounting holes by tracing the hole in the mounting bracket. Please ensure

that the mounting surface on the RV roof is strong enough to support the mounting hardware, solar

panel and wind loads.

5. The centre and end holes on the mounting brackets (Fig. 1) are sized to accept the ¼” hardware

supplied with the kit. If the use of larger sized hardware is desired, holes 2 and 4 can be used.

6. To install the Well-Nuts, for anchoring the brackets to the RV roof or a at surface, drill holes 1¼”

deep at the marked positions using a ½” size drill bit. Make sure that drilling does not interfere with

pre-existing wiring installations.

7. Apply silicone or any appropriate sealant recommended by your RV dealer generously to the drilled

holes for water-proo ng.

8. Insert the ¼” Well-Nut into the drilled holes so that only the ange section remains above the roof

surface (Fig. 3).

9. Fasten the mounting brackets to the roof surface by inserting the ¼ x 1¼” serrated ange bolt into

the Well-Nut. Tighten using a 3/8” wrench to a recommended torque of 15 lbs. When the serrated

ange bolt is screwed into the Well-Nut, the material surrounding the well nut bulges slightly

securing the structure to the RV roof (Fig. 5, 8).

10. Ensure that all fasteners are tightened to the recommended tightening torque.

11. Make sure all bolts and mounting brackets are covered by good amounts of suitable RV sealant

recommended by your local RV dealer.

INSTALLATION PROCEDURE

1. Determine the position of the solar panel on the RV roof or at surface. While positioning panels, avoid

shading of the solar panel by neighbouring obstacles such as vents, air-conditioners, TV antennas etc. As

far as possible, position the panels to minimize wiring distance between the solar panel and the charge

controller. Place the panel at least 8-10 inches away from the RV roof edges and leave suf cient space to

walk around the panel and access the mounting hardware.

2. Make sure the thickness of the roof at the installation location is at least ½” thick and the material

is strong enough to provide mechanical support to the solar panel and mounting hardware against

possible wind loading. Place the panel length-wise to reduce the effects of wind loading on the RV.

3. Fix the mounting brackets to the frame of the previously positioned solar panel using the slotted

opening and the ¼”-20 x ¾" Flange Bolt, Nylon Locknut and at washer (Fig. 7). Using a 7/16” wrench,

tighten the nuts to secure the mounting brackets to the PV panel. Recommended tightening torque is

15 lbs.

Fig. 8. Attaching 5-hole mounting bracket to RV roof

32

Loading...

Loading...