Page 1

N + 1

DC Power

System

Owner's

Manual

Please read this

manual BEFORE

installing the

unit

SEC-4825BRM

11001-SEC-4825BRM-0114.indd 1 14-01-07 1:15 PM

Page 2

OWNER'S MANUAL | Index

SECTION 1

Safety Instructions ................................................................. 3

SECTION 2

Layout, Dimensions & Input/Output Connections ................ 5

SECTION 3

Design & Principle of Operation ........................................... 7

SECTION 4

Protections ........................................................................ 19

SECTION 5

Installation ........................................................................ 21

SECTION 6

Operation ........................................................................ 23

SECTION 7

Limiting Electro-Magnetic Interference (EMI) ...................... 25

SECTION 8

Troubleshooting Guide ....................................................... 28

SECTION 9

Speci cations ..................................................................... 31

SECTION 10

Warranty ........................................................................ 33

2 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 2 14-01-07 1:15 PM

Page 3

SECTION 1 | Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS

This manual contains important Safety and Operating Instructions. Please read

before using this unit .

The following safety symbols will be used in this manual to highlight safety

and information:

Please read these instructions before installing or operating the unit to prevent

personal injury or damage to the unit.

1. DO NOT OPEN TO REDUCE RISK OF FIRE OR ELECTRIC SHOCK. THERE ARE NO USER

2. The unit should be grounded to reduce the risk of electric shock. It comes with

3. It is recommended that you return your power supply to a qualied dealer for any

4. To reduce the risk of electric shock, unplug the power supply from the outlet before

5. To reduce risk of damage to electric plug and cord, pull by plug rather than cord

6. An extension cord should not be used unless absolutely necessary. If an extension

WARNING!

!

Indicates possibility of physical harm to the user in case of non-compliance.

!

CAUTION!

Indicates possibility of damage to the equipment in case of non-compliance.

!

WARNINGS!

SERVICEABLE PARTS INSIDE—REFER TO QUALIFIED SERVICE PERSONNEL.

attached power cord that has a 3 prong, grounded 30A, NEMA L5-30P plug. The

grounding prong of the plug is internally connected to the chassis of the unit. When

the power cord is plugged into the corresponding NEMA L5-30R outlet, the chassis

of the unit is automatically connected to the Earth Ground through the Equipment

Grounding Conductor that is connected to the grounding slot of the outlet. The power cord must be plugged into a corresponding NEMA L5-30R outlet that is properly

installed and grounded in accordance with all local codes and ordinances. Never alter

the power cord that has been provided. If the plug of the cord will not t the outlet,

have a proper outlet installed by a qualied electrician. Improper connection can

result in risk of electric shock.

service or repair. Incorrect assembly may result in electric shock or re.

attempting any maintenance or cleaning. Turning off controls will not reduce this risk.

when disconnecting the unit.

cord is used, make sure that it has 3-prong, grounded male plug (NEMA L5-30P) and

SAMLEX AMERICA INC. | 3

11001-SEC-4825BRM-0114.indd 3 14-01-07 1:15 PM

Page 4

SECTION 1 | Safety Instructions

3-prong, grounded female receptacle (NEMA L5-30R). The size of the current carrying

conductors should be at least AWG#10 for NEMA L5-30.

7. Place the unit in an area that will allow air to ow freely around the unit. DO NOT

block or obstruct vent openings on the sides and at the back or install the unit in an

enclosed compartment.

8. Keep the unit away from moisture and water.

9. NEVER OPERATE TWO OR MORE UNITS IN PARALLEL.

10. Precautions when working with batteries.

- Batteries contain very corrosive diluted Sulphuric Acid as electrolyte. Precautions should be

taken to prevent contact with skin, eyes or clothing.

- Batteries generate Hydrogen and Oxygen during charging resulting in evolution of explosive gas mixture. Care should be taken to ventilate the battery area and follow the battery

manufacturer’s recommendations.

- NEVER smoke or allow a spark or ame near the batteries.

- Use caution to reduce the risk of dropping a metal tool on the battery. It could spark or

short circuit the battery or other electrical parts and could cause an explosion.

- Remove metal items like rings, bracelets and watches when working with batteries. The

batteries can produce a short circuit current high enough to weld a ring or the like to metal

and thus cause a severe burn.

- If you need to remove a battery, always remove the Negative Ground Terminal from the

battery rst. Make sure that all the accessories are off so that you do not cause a spark.

CAUTIONS!

!

1. Please ensure that the battery is connected with correct polarity - Positive of the battery to the “Battery +” terminal and the Negative of the battery to the “Battery -”

terminal. Reversal of polarity will blow external Fuse F1. DAMAGE DUE TO REVERSE

POLARITY IS NOT COVERED UNDER WARRANTY.

2. Protect the unit against AC line input transients. Use Transient Suppressor in line with

the AC input.

4 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 4 14-01-07 1:15 PM

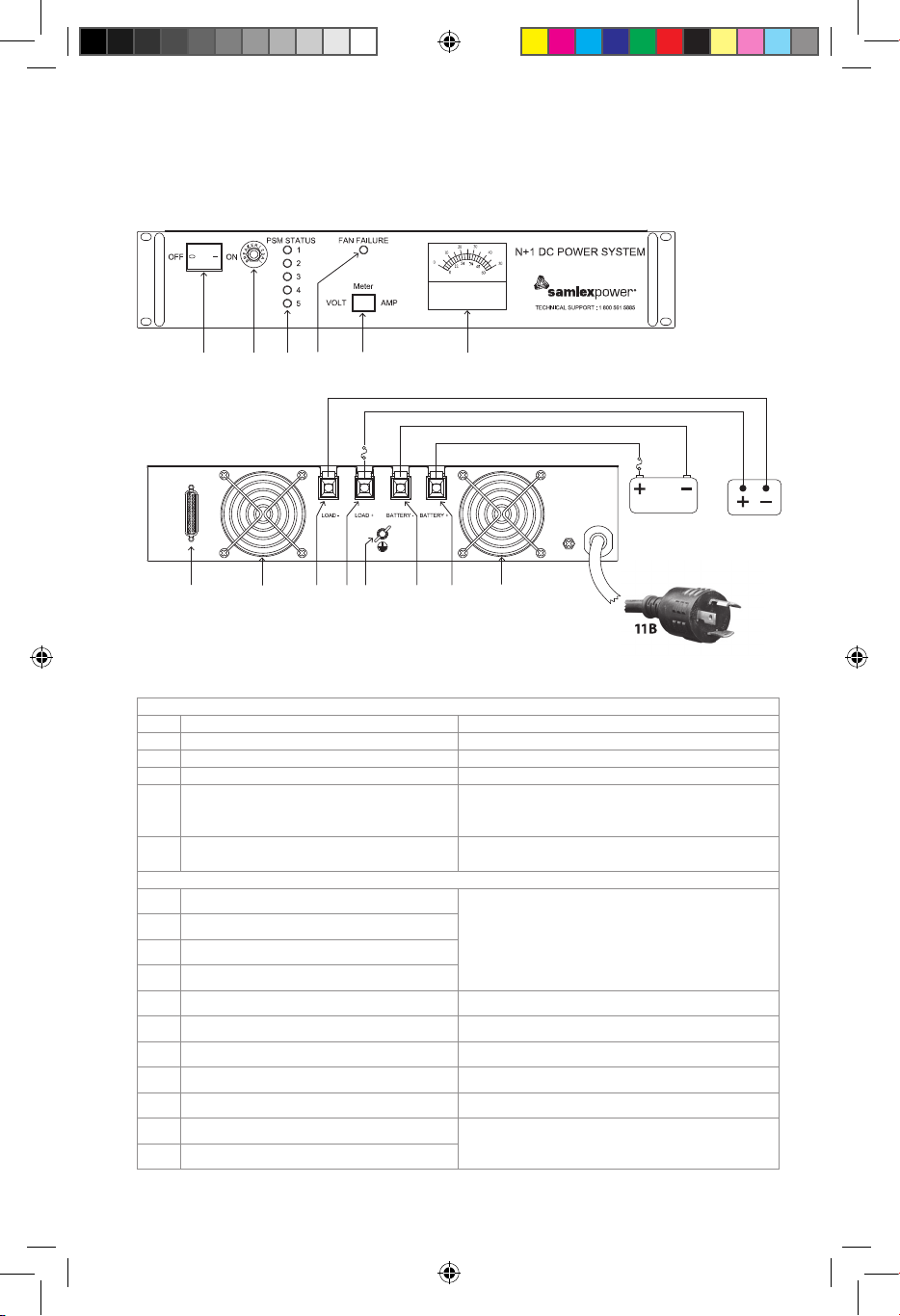

Page 5

SECTION 2 | Layout, Dimensions &

Fig. 2.1 FRONT VIEW

1

1B

Input/Output Connections

1 2 5 346

F2

F1

48V Battery

12 9 98A8B107A7B 11A

Fig. 2.1 BACK VIEW

11B

Fig. 2.1 Layout and Input/Output Connections

Legend - Fig 2.1

FRONT VIEW

1

AC Power ON/OFF Switch Illuminates RED when ON

2

AC Input Breaker 25A.

3

DC Volt Meter / Ammeter Voltage / current on Load Terminals

4

Voltmeter / Ammeter Selector Switch Switches display on Voltmeter / Ammeter (3)

Green LED for Power Supply Modules (PSM)

5

1 to 5

Red LED for fan failure or over temperature

6

of heat sink on the PSM

BACK VIEW

7A Positive (+) Load Terminal

7B Negative (−) Load Terminal

8A Positive (+) Battery Terminal

8B Negative (−) Negative Terminal

9 Cooling Fan 2 x 48V fans. Run continuously

10 Grounding Lug Connect to Earth Ground / System Ground

11A Attached AC Input Power Cord 3 Conductors - each AWG #12

11B AC Input Power Cord Plug 30A, NEMA L5-30P

12 DB-25, D-Sub Connector For remote signaling (Pin Out - Fig 3.2)

F1 External Battery Side Fuse

F2 External Load Side Fuse

STEADY ON: PSM is operating normally

BLINKING: No output. PSM is not synchronizing

OFF: No output. Defective

STEADY ON: Fan failure or PSM over temperature

TUBULAR HOLE: 5/16” Diameter

SET SCREW: 5/16” X 3/8” Long x 24 TPI

25A, 80V (Not supplied)

- ATO Style, FKS Series by Littelfuse

- Part No. 166.7000.525

48V Load

SAMLEX AMERICA INC. | 5

11001-SEC-4825BRM-0114.indd 5 14-01-07 1:15 PM

Page 6

SECTION 2 | Layout, Output Connection

& Dimensions

1. Dimensions Overall

(including protrusions)

Wide(W): 482.6 mm / 19.00”

Depth (D) : 407.6 mm / 16.05”

407.6

407.6

Height (H): 87.7 mm / 3.45”

2. Dimensions (Mounting Holes)

Width (W): 466.73 mm / 18.38”

Height (H): 76.2 mm / 3.00”

407.6

407.6

482.6

466.73

76.2

482.6

Fig. 2.2 Dimensions

6 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 6 14-01-07 1:15 PM

7.94

87.7

87.7

Page 7

SECTION 3 | Design & Principle of Operation

DESCRIPTION

SEC-4825BRM is a Switch Mode Power Supply (SMPS), which converts 120 VAC, 50/60 Hz

to 48VDC Nominal (actually 54.8VDC at no load to 54.2V at 25A). It has additional provision for 48V battery backup with 2A charging in conjunction with external 48V Lead

Acid Battery (not supplied).

FEATURES

• 19”,2U(3.5”)heightRackMountdesign

• AdvancedSwitchModeTechnology

• N+1Redundancy:5x5APowerSupplyModulesoperateinparallelunder

forced current share control

• RemotemonitoringthroughOptoIsolated,OpenCollector/OpenEmitter

output signals

• Reliable,48VDCUninterruptiblePowerSource(DCUPS)inconjunction

with external 48V Lead Acid backup Battery (not supplied)

• Highefciencyandcompact

• Protectedagainstshortcircuit,overload,overvoltageandovertemperature

PRINCIPLE OF OPERATION

The unit consists of 2 Sections - Switch Mode Power Supply (SMPS) Section and Battery

Backup and Charging Section.

The SMPS Section is designed using advanced switch-mode technology and active load

share circuitry for high reliability, high efciency and minimum size and weight. It is

modular in construction consisting of 5 x 5A Power Supply Modules (PSM) that are

connected in parallel and operate under forced current share control to deliver a total

of 25A. Each PSM is a stand-alone, 55V Power Supply, which delivers up to a maximum

of 5A continuous. By equalizing the output currents, uniform thermal stress of the

individual PSMs is ensured which has utmost importance for long-term reliability of electronic components. The operating principle of current share mechanism is to measure

the output current of each PSM and to modify the output voltages of the 5 PSMs until

all the 5 PSMs deliver equal output current. Typically, the output currents of the 5 paralleled PSMs will be within 10% of each other at full output current. The module with

the highest voltage at switching ON automatically assumes the role of a Master and the

others operate as Slaves. Each PSM is required to be interconnected with one another to

a common “SHARE BUS” through a pair of parallel pins marked “JUMP 1” and jumper

wires (Fig. 3.5).

For proper operation of Current Share Control Circuitry / Master - Slave operation, a minimum load current is required to ow through each PSM to produce adequate feed back

signal. This minimum pre-load current is provided by the sum of the currents drawn by

the 2 cooling fans and by an internal static load resistor connected across the load output

terminals. This internal pre-load current* is kept to the minimum to reduce dissipation.

SAMLEX AMERICA INC. | 7

11001-SEC-4825BRM-0114.indd 7 14-01-07 1:15 PM

Page 8

SECTION 3 | Design & Principle of Operation

* NOTE: It is likely that due to drift in the pre-set values of components, the minimum

internal preload current may not be suf cient to provide adequate feedback signal

strength resulting in shut down of one or more modules when no external load is

present (The associated PSM Status LED will ash and also, the associated signal for

remote indication will oscillate between High and Low). As soon as external load is

applied to the unit, the feed back signal strength will increase and the PSM(s) that

were shut down will also operate normally.

The output is delivered through an isolating Schottky diode to enable connection of

external 48V battery (not supplied) for un-interrupted DC power output. The external

backup battery is kept charged by “Taper Type of Float Voltage Charging” through a

current limiting series resistor that limits the maximum charging current to 2A when the

battery is completely discharged.

The SMPS Section along with the Battery Backup and Charging Section work as a DC

Uninterruptible Power Source (DC UPS) in conjunction with an external 48V, Lead Acid

backup battery (battery is not supplied). As long as 120VAC input power is available,

the unit will put out 54.8VDC to 54.2VDC at the Load Terminals (7A, 7B - Fig 2.1). At

the same time, charging current of up to a maximum of 2A (when battery is completely

discharged to Standing Voltage of 42.8V) will be fed through the Battery Terminals (8A,

8B - Fig 2.1) to charge the external battery. The voltage at the Battery Terminals (8A, 8B

- Fig 2.1) will always be clamped to the actual voltage of the battery corresponding to its

State of Charge. If AC input power fails, the DC load will be instantaneously transferred

to the external 48V backup battery and the battery will start discharging. When AC

input power is restored, the DC load will once again be transferred instantaneously to

the Power Supply Section and the external backup battery will be recharged and kept in

charged condition all the time at oat Voltage of 54V to 54.6V (when fully charged). If

battery backup function is not used (external 48V backup battery is not connected), the

unit will work as a normal 48V nominal Power Supply.

N+1 Redundancy

5 Power Supply Modules operating in parallel with equal current sharing provides

redundancy. Chance of failure of all the 5 modules is reduced tremendously. If say one

module fails, the remaining 4 modules will share the load current equally. Such redundancy is also called N+1 redundancy i.e. if “N” number of paralleled modules are

required to service a certain load, the unit should have 1 additional module (total “N+1”

modules) to provide redundancy. For example, if the rated load drawn from this unit is

20A, 4x5A modules will be required. Using 1 additional 5A module (total 25A) will have

the capacity to service the full load of 20A even if 1 module fails.

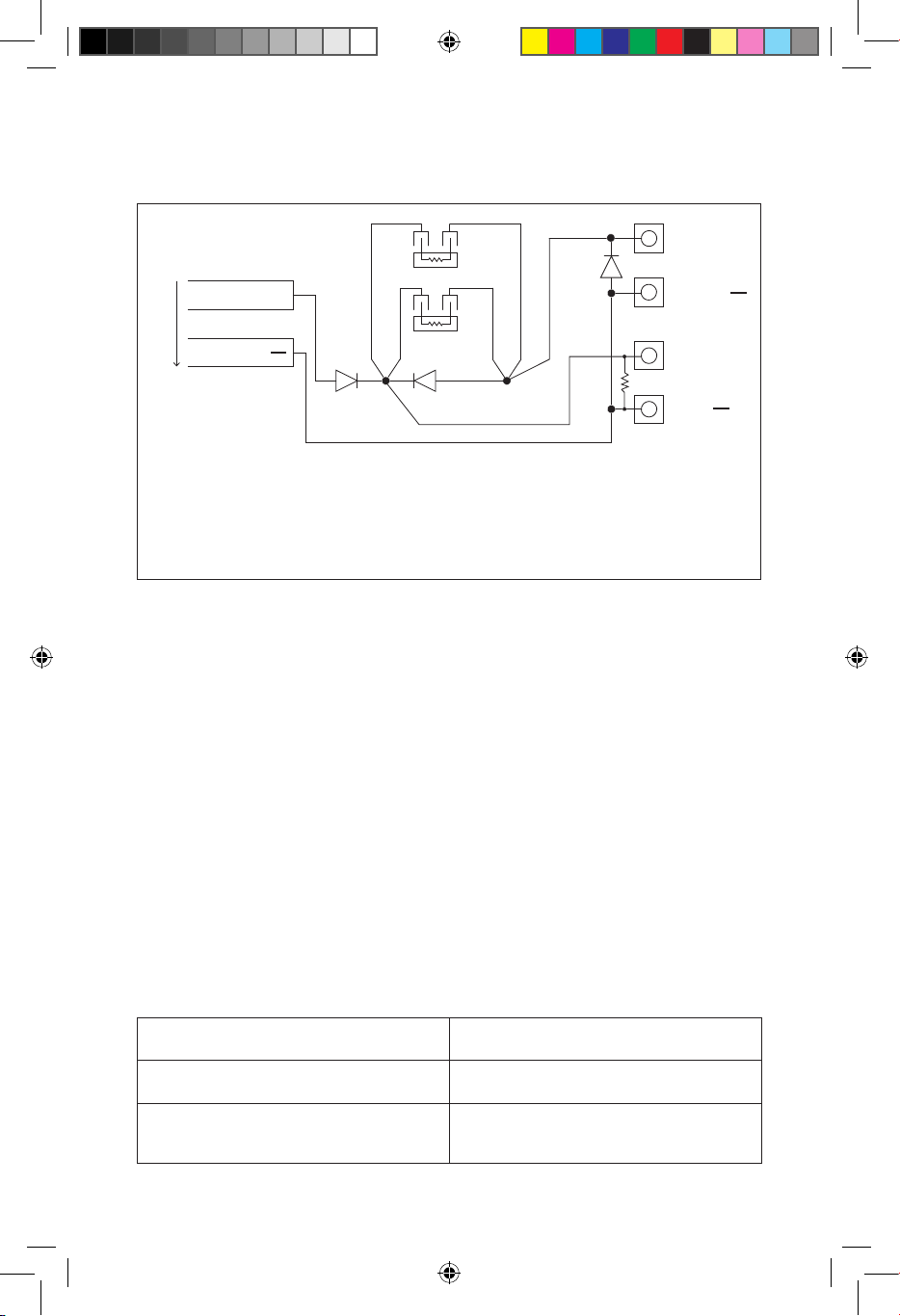

OPERATION OF BATTERY BACK-UP AND CHARGING SECTION

Please refer to the schematic at Fig 3.1 (page 9).

Regulated output voltage of 55VDC from the modules (measured at screw terminals

S5 and S6 (Fig. 3.4) is fed to the Positive and Negative DC bus bars and from there to

the output terminals LOAD (+) and LOAD (−) through the isolating Schottky Diode D1.

Although the output voltage at the module terminals S5 and S6 (Fig.3.4) or at the

8 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 8 14-01-07 1:15 PM

Page 9

SECTION 3 | Design & Principle of Operation

R

BATTERY

BATTERY

LOAD

+

LOAD

POSITIVE BUS BAR

55V

from

PSM

NEGATIVE BUS BAR

+

R1

D3

R2

D2D1

LEGEND

D1, D2 Schottky Diode, 40CPQ060 by International Rectier

D3 10A, 600V Diode “10A6” for reverse polarity protection

R1, R2 Power Resistor 12 Ohm, 35W

R Static Load Resistor, 1K, 5W

Fig 3.1 Schematic - Battery Backup

common DC bus bar (before the Schottky Diode D1) is tightly regulated at the preset

value of 55VDC, the voltage at the output terminals Load (+) and Load (−) will vary

slightly due to the forward voltage drop “Vf” of the isolating Schottky Diode D1 and

the drop along the DC bus bar and wiring. The voltage at the output terminals LOAD

(+) and LOAD (−) will be as follows:

• Atnoexternalload Approximately54.8VDC

• At25Aload Approximately54.2VDC

+

When there is a requirement of un-interrupted DC power to the load, an external 48V

battery should be connected at the terminals Battery (+) and Battery (−). When input

AC power is available, the load current is supplied by the Power Supply Section through

Isolating Schottky Diode D1. At the same time, the battery is charged to Float Voltage

Level by “Taper Type of Charging” through 2 x 12 Ohm resistors R1 & R2 in parallel with

an effective series resistance of 6 Ohm. This effective series resistance of 6 Ohm will limit

the maximum charging current to 2A. The charging current will be determined by the

following equation (Battery’s internal impedance and battery cable resistance have been

disregarded as their values are negligible as compared to the 6 Ohm effective series

resistance):

Charging Current = (Load Terminal Voltage – Battery’s Intrinsic

Maximum Charging Current (At completely

discharged voltage of 42.8V)

Charging current when fully charged to maximum Float Voltage of 54.6V

State of Charge Voltage) ÷ 6 Ohm

= (54.8V – 42.8V) ÷ 6 Ohm = 2A

25 mA (0.1% of Ah capacity of the battery to

compensate for self-discharge. Battery with

25Ah capacity has been considered)

SAMLEX AMERICA INC. | 9

11001-SEC-4825BRM-0114.indd 9 14-01-07 1:15 PM

Page 10

SECTION 3 | Design & Principle of Operation

From the above equation, it will be seen that the battery will be charged at a maximum

charging current of around 2A when the battery is completely discharged to Standing Voltage of 42.8V and the charging current will taper to a very low value of around

25mA when the battery is charged to Float Voltage Level of 54.6V.

If input A.C. power is interrupted, the external battery feeds the load instantaneously

through the Schottky Diode D2 (D2 will be forward biased and will by-pass resistors R1

& R2). Voltage available to the load will be approximately 0.2V lower than the battery

voltage due to forward voltage drop across D2. Availability of AC power is signaled for

remote monitoring through opto-isolated signal through D-Sub Connector (Pins 2 and

16 of D-Sub Connector, Fig 3.2. Also see below under “Remote Monitoring of Operational Status”). This signal may also be used to indicate that the load is being powered

by battery (In case external battery is used for battery back-up). When AC input power

returns, load current will be supplied by the Power Supply Section, Diode D2 will be reverse biased and the discharged battery will be taper charged through 6 Ohm effective

resistance of R1& R2.

* NOTE: The value of charge limiting resistors R1 and R2 is based on a typical 48V,

25Ah deep cycle marine battery. If a different type of battery is used, the value of

the resistor should be adjusted to meet associated charging requirements.

REMOTE MONITORING OF OPERATIONAL STATUS

A provision has been made for remote monitoring of the following operational

conditions and parameters:

a) Operational status of the 5 Power Supply Modules (PSM)

b) Failure condition of the cooling fan(s)

c) Availability of AC input power (Through 120VAC to 5VAC transformer)

d) Output voltage measurement (Across Load Terminals)

e) Output current measurement (Voltage across an internal shunt with Shunt Ratio of

25 mV / 50A or 0.5 mV per Amp)

Signals for remote monitoring of operating conditions at Srls (a), (b) and (c) above are

transmitted to the remote receiving device through open Collector and open Emitter

pins of phototransistor of internal Opto-Isolator (Figs 3.2 & 3.3A).

Outputs for voltage and current measurements at Serials (d) and (e) above are direct

analogue voltages.

The Pin Out of the 25 Pin D-Sub Connector (12, Fig 2.1) providing the above signals for

user interface is given at Fig 3.2.

10 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 10 14-01-07 1:15 PM

Page 11

SECTION 3 | Design & Principle of Operation

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

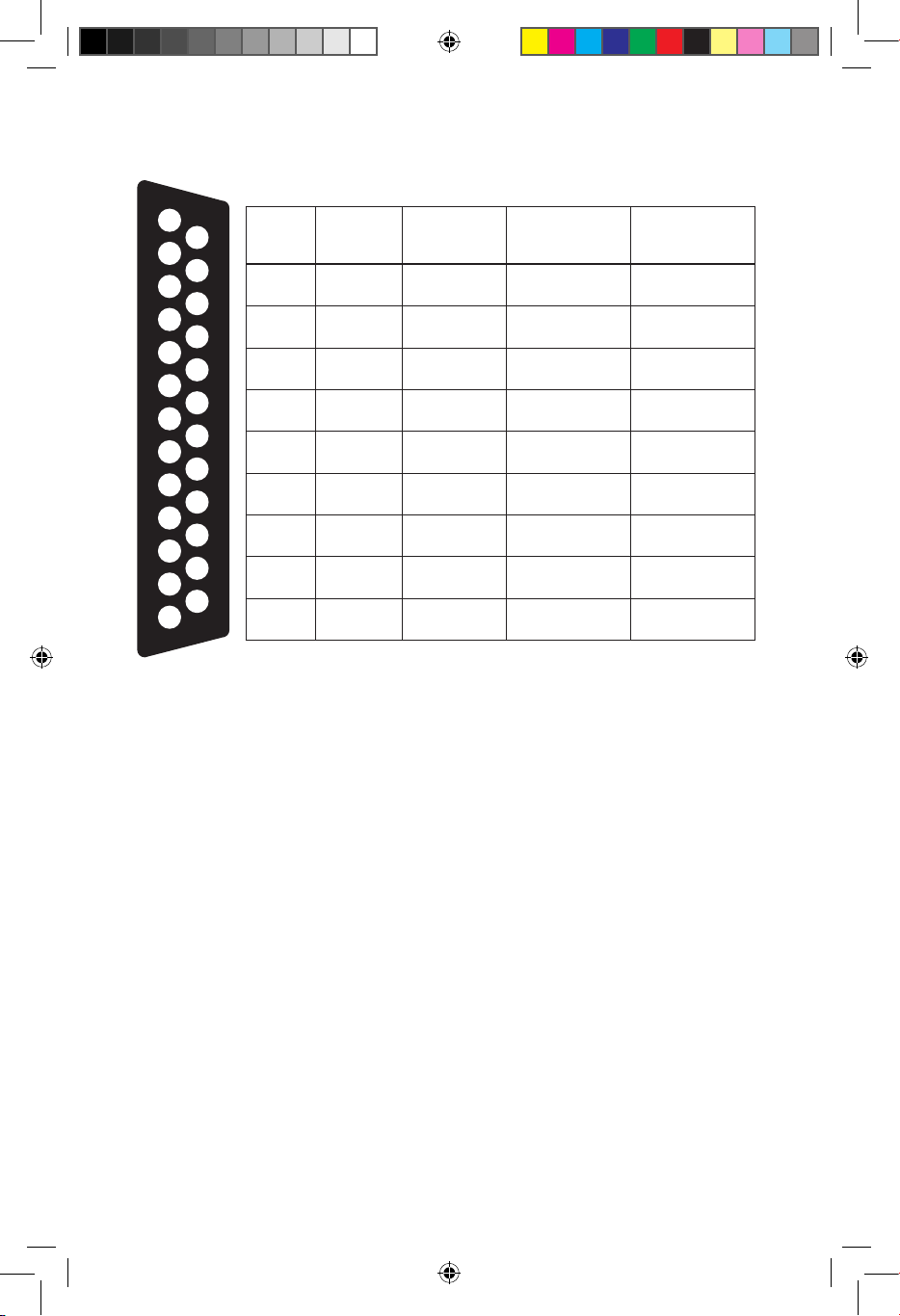

Item Pin No.

1

2

3

4

5

6

7

8

9

2

16

12

19

7

20

8

21

9

22

10

23

11

24

25

13

18

6

Color Code

of Wire

Black

White

Orange

Green

Gray

Violet

Violet

Blue

Blue

Greeb

Green

Yellow

Yellow

Orange

Red

Black

Gray

Blue

Output Pins of

Opto Isolator

Collector

Emitter

Collector

Emitter

Collector

Emitter

Collector

Emitter

Collector

Emitter

Collector

Emitter

Collector

Emitter

- Voltmeter +

- *Ammeter +

Notes:

† For operational conditions at Items 1 to 7, the Transistor Switch inside the

Opto Isolator is in “Saturation” condition (near short circuit between

Collector and Emitter terminals)

* Shunt Ratio 25mV/50A or 0.5mV/Amp.

Fig. 3.2 Pin Out of 25 Pin D-Sub Connector (12, Fig 2.1) for Remote Monitoring

†Operational

Condition or

Parameter (High)

AC input is

available

Fan failure

PSM 1 Normal

PSM 2 Normal

PSM 3 Normal

PSM 5 Normal

PSM 5 Normal

Voltmeter -

*Ammeter -

OPTO-ISOLATED TRANSFER OF SIGNALS FOR REMOTE MONITORING

In this power supply, signals for remote indication of operating conditions at Serials (a),

(b) and (c) on page 10 are transmitted to the remote receiving device through open

Collector and open Emitter pins of NPN phototransistor of internal Opto-Isolator (Fig 3.2

above and Fig 3.3A on page 12). The NPN phototransistor can provide a maximum of

50 mA with a Collector to Emitter voltage of up to 35V. Use of opto-isolated signal

transfer ensures the following at the receiving location:

• Isolatesnoise,groundloops,and/orhighvoltagesfromthepowersupply

from being fed to the external remote monitoring device.

• The+Vccvoltagethatisconnectedtothepull-upresistor(s)/alarmsandrelaysfor

generating alarm signals at the receiving monitoring device (Figs 3.3 B to D, page 12)

comes from an external voltage source and hence, maximum isolation is provided

• AbilitytogenerateTTLlogicsignalswithVccof3.3V/5V(Fig3.3Bfor5VVcc)

• Driverelays/LEDswithVcc of up to 35VDC (e.g. 5V / 12V / 24V) and drive current of

up to 50 mA (Figs 3.3C and 3.3D)

• Abilitytocombinethesignals(OR’d)toformasinglesignalsharingcommon

Logic Ground

11001-SEC-4825BRM-0114.indd 11 14-01-07 1:15 PM

SAMLEX AMERICA INC. | 11

Page 12

SECTION 3 | Design & Principle of Operation

PSM1 PCB

“M-20-48V”

5V

PSM GND

LED 1

PIN 1 is

HIGH (5V)

when PSM 1

is Normal

GR AY

VIOLET

Opto-Isolator

PCB “M-20-P”

IC-1

1 4

C

E

2

VCE – Max 35V

IC – Max 50mA

DB-25 Connector

GR AY

VIOLET

3

Fig. 3.3A: Schematic for Remote Signalling for “PSM 1 Normal”

+ Vcc = 5V

R

= 10K

Pull Up

From Fig. 3.3A

7

20

Vcc Ground

To Micro-controller

Fig. 3.3B: 5V TTL Logic Drive

+ V

= 5V / 12V / 24V (Max. 35V)

cc

NC

Common

NO

From Fig. 3.3A

IN4001

7

20

Vcc Ground

Relay 5V / 12V / 24V:

Choose coil resistance

to limit coil current

to < 50 mA

7

7

To Figures:

3.3B/3.3C/3.3D

20

20

PSM 1 Normal – Low (0 to 0.5V)

PSM 1 Defective – High (2.7V to 5V)

PSM 1 Normal – Relay energizes

PSM 1 Defective – Relay de-energized

Fig. 3.3C: 5V / 12V / 24V Relay Drive

+ Vcc = 5V/12V/24V (Max. 35V)

1.5K

7

From Fig. 3.3A

20

PSM 1 Normal – LED “ON”

LED

PSM 1 Defective – LED “OFF”

Vcc Ground

Fig. 3.3D: LED Drive

12 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 12 14-01-07 1:15 PM

Page 13

SECTION 3 | Design & Principle of Operation

Principle of operation is explained in Figs 3.3A to 3.3D below using example of remote

monitoring of the operational status of Power Supply Module No. 1 (PSM1).

Operation Inside the Power Supply

Please refer to Fig 3.3A.

When PSM1 is operating normally, 5V (HIGH) drive signal is fed to Pins 1 and 2 of Infrared Diode inside the Opto-Isolator “IC1”. The diode conducts and optically transfers

HIGH Base drive condition to the NPN Photo-Transistor with Pin 4 (Open Collector) and

Pin 3 (Open Emitter). The Photo-Transistor will be in “Saturated” condition (near short

circuit between Collector (Pin 4) and Emitter (Pin 3). Pins 4 and 3 are connected to Pins 7

and 20 respectively of the DB25 Connector (Fig 3.2).

Operation at Remote Monitoring Location

Monitoring of status from the DB-25 Connector can be undertaken at the remote

monitoring location in 3 ways shown in Fig 3.3B, 3.3C and 3.3D.

S3

S4

S1

L N

S2

+

LED 1

LED 2

VR1

F1

VCC

+

S-5

JUMP 1

S6

NOT TO SCALE

Legend

S1 to S4 Holes for 4 screws to fasten the module to the chassis

S5 & S6 Holes for 2 screws to connect to the Positive & Negative output BUS Bars

L & N L (Line) and N (Neutral) terminals for 120V, 60 Hz input power supply wires

LED 1 Terminal for remote indication of PSM status

LED 2 Terminal for “LED” PSM status (Front Panel)

JUMP 1 Jumper terminal for connecting share BUS wire

VCC Connector for feeding Vcc to PCB for fan monitoring

F1 Fuse: 250V, 4A

VR1 Potentiometer for output voltage adjustment

Figure 3.4 Layout of Power Supply Module “M20-48V”

SAMLEX AMERICA INC. | 13

11001-SEC-4825BRM-0114.indd 13 14-01-07 1:15 PM

Page 14

SECTION 3 | Design & Principle of Operation

1

2

1

2

1

2

1

2

1

2

PSM 1 PSM 2

PSM 3

PSM 4 PSM 5

PCB (Printed Circuit Board)

Jump 1 Jump 1 Jump 1 Jump 1 Jump 1

PSM 1 PSM 2

Jump 1 Jump 1 Jump 1 Jump 1 Jump 1

LEGEND:

1. Female terminal for the Daisy Chain Wire Connector

2. Male, 2-pin terminal marked “Jump 1” on the Power Supply Module

PSM 3

1

2

1

2

PSM 4 PSM 5

1

2

PCB (Printed Circuit Board)

Fig 3.5 Daisy Chaining of Share Bus Jumps (Jump 1)

Unused

female

socket

Shorting Link

1

2

1

2

Fig 3.6 Shorting Unused Jump 1 Daisy Chain Wire Connector

OUTPUT VOLTAGE ADJUSTMENT

As explained earlier, the Power Supply Section of this unit has 5 Power Supply Modules

operating in parallel under forced current share control. Each module has rated current

output of 5A and hence, the total rated current output of the unit is 25A. For the forced

current share / Master –Slave operation to work properly, it is important that the “set

output voltage” of each of the 5 modules is exactly the same. If the output voltage of

any module is below the “set voltage”, its current share control circuitry (slave operation) will not function properly and it’s associated “PSM x” LED will start ashing. The

other modules which are putting out the “set voltage” will function normally under

Master/ Slave operation and their “PSM x” LEDs will remain continuously lighted and

the output voltage of the common DC bus (before Schottky Diode D1) will be equal to

the “set voltage”. If the output voltage of any module is higher than the “set voltage”,

it will become the Master and it’s associated “PSM x” LED will remain continuously

lighted. However, the other Modules with voltage lower than the “set voltage” will

14 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 14 14-01-07 1:15 PM

Page 15

SECTION 3 | Design & Principle of Operation

not be able to function normally as Slaves and their associated LEDs “PSM x” will ash

randomly.

The output voltage of the common DC bus (before Schottky Diodes D1) will read the

higher voltage of this module.

The output voltage of each module measured at the module output pads under S-5

and S-6 (See Fig.3.4) is factory pre-set at 55V to provide no load voltage of 54.8V at the

Load Terminals. A precision multi-turn potentiometer VR1 is provided for ne adjustment of the output voltage of each of the modules. The adjustment range of module

output voltage is 53V to 56.3V.

If the output voltage of the modules is required to be set to a value other than the

preset value of 55V, the individual output voltage of each of the 5 modules will be required to be adjusted one by one to the same new “set voltage” within the adjustment

range of 53V to 56.3V. This is done by feeding AC input power to only the module

under adjustment and disconnecting AC input power to the other modules. Similarly,

during operation and during replacement of defective module with new module, the

output voltage of the all the individual modules will be required to be adjusted to the

desired value.

As explained under Operation Of Battery Back Up And Charging Section on page 8,

although the output voltage of the module at terminals S5 and S6 (Fig.3.4) or at the

common DC bus (before the Schottky Diode D1) is tightly regulated at the preset value

of 55V, the voltage at the output terminals Load (+) and Load (−) will vary due to the

forward voltage drop of the isolating Schottky Diode D1 and the drop along the DC

bus and wiring. Table 3.1 below gives details of voltage settings and actual voltages

available under no load and under loaded conditions.

TABLE 3.1 VOLTAGE SETTINGS

Module Output

Voltage at Terminals

S5 and S6 (Fig 3.4)

Preset Voltage 55V

Adjustment range:

53V to 56.3V

Load Current

(Combined Current of

5 paralleled Modules)

No load (0A) 0.2V 54.8V

15A 0.6V 54.4V

25A 0.8V 54.2V

No Load 0.2V 52.8V to 56.1V

15A 0.6V 52.4V to 55.7V

25A 0.8V 52.2V to 55.5V

Forward Voltage drop

“Vf” Across Schottky

Diode D1

Voltage Available at

Load Terminals Load (+)

and Load (−)

(Module Voltage - “Vf”)

Procedure for Adjusting Output Voltage of Modules

1. Switch OFF the unit and unplug the AC input power cord.

2. The output voltage of each individual module is adjusted one by one starting from

say, the left most module – PSM 1 and progressing to the right most module – PSM

SAMLEX AMERICA INC. | 15

11001-SEC-4825BRM-0114.indd 15 14-01-07 1:15 PM

Page 16

SECTION 3 | Design & Principle of Operation

No. 5. AC input is connected only to the module being adjusted. AC input to the

remaining modules is disconnected.

Procedure for Adjusting Output Voltage of Modules (continued)

3. Prepare PSM 1 for adjustment by Removing AC input connections (female quick

connect terminals connected to the L and N male tab terminals on the module –

Fig. 3.4) from PSM Nos. 2, 3, 4 and 5. Temporarily insulate these female quick connect terminals with insulating tape for safety. Now, only PSM No. 1 can be

energized.

4. Switch ON the power supply. Only PSM No. 1 will operate. Adjust the output

voltage of this module to the desired “set value” with the help of potentiometer

VR1 (Fig.3.4). Measure output voltage of the module at the screw terminals S5

and S6 (Fig. 3.4).

5. Switch OFF the power supply. Remove the AC input connections from PSM No. 1.

Temporarily insulate these terminals with insulation tape.

6. Prepare PSM No 2 for adjustment by removing temporary insulation from the

AC connectors for PSM 2 and connect them to PSM 2. Now only PSM 2 can be

energized.

7. Switch ON the power supply. Only PSM No. 2 will operate. Adjust the output

voltage of this module to the same “set value” with the help of potentiometer

VR1 (Fig. 3.4). Measure the output voltage of the module at the screw terminals

S5 and S6 (Fig. 3.4)

8. Continue to adjust the voltage of the remaining Module Nos. 3, 4 and 5 individually as explained above making sure that the AC input power is connected to only

the module being adjusted.

9. After the output voltage of all the 5 modules has been adjusted to the same

“set value”, connect the AC input back to all the ve modules.

10. Power ON the unit and check that all the 5 “PSM Status” LEDs are lighted. This

will con rm that the voltage adjustment has been completed successfully.

NOTE: As explained under Principle of Operation on page 7, it is likely that the

minimum internal preload current for the new value of the output voltage may not

be suf cient to provide adequate feedback signal strength resulting in shut down of

one or more PSM(s) when no external load is present (The associated PSM Status

LED will ash and also, the associated signal for remote indication will oscillate

between High and Low). In such a case, apply an external load to increase the feed

back signal strength. If there is no other defect, the PSM(s) that were shut down will

also operate normally.

16 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 16 14-01-07 1:15 PM

Page 17

SECTION 3 | Design & Principle of Operation

INSTALLATION AND REMOVAL OF POWER SUPPLY MODULES

Please refer to Figs. 3.4, 3.5 and 3.6 (pages 13 & 14).

Replacing Defective Module with new Module

Replacement Module can be ordered under Model No. “SEC-0548MPSB”.

The optional module comes with an LED and LED holder. It’s output voltage is

pre-set at 55V.

Removal and replacement procedure is given below:

1. Switch OFF 120 VAC, 60 Hz input power and unplug the power cord from the

main outlet.

2. Remove the top cover plate by unscrewing the 10 screws.

3. Remove the AC input power supply wires from terminals “L” and “N” of the

defective module (Fig 3.4).

4. Remove connectors from terminals “LED 1 & LED 2” (Fig 3.4). Terminal marked

LED2 is used for the front panel LED under “PSM Status”. Terminal marked LED1 is

used to feed 5V “PSM ON” drive signal to the associated Infrared Diode of optocoupler on the small opto-coupler PCB & from there it is fed to DB-25 Connector as

Open Collector / Open Emitter signal for remote indication.

5. Remove female connector of the Daisy Chained “SHARE BUS” wire loop connected to male terminal “JUMP1” on the module (Fig 3.4, Fig 3.5).

6. Each module sits on 6 stand-offs under holes S1 to S6 (Fig.3.4). Remove these

screws and then remove the defective Module.

7. If this module has Temperature Sensor mounted on its heat sink, remove the Temperature Sensor by removing its holding screw.

8. Place the new module on the stand-offs with the L an N terminals (Fig. 3.4)

towards the front panel. Align the holes and x the module with the 6 screws.

WARNING! Please ensure that screws S5 and S6 are very tight as the pads under

these two screws connect the output of the module to the DC bus bar underneath. A loose connection under these screws will result in sparking, overheating

and consequent damage to the module.

9. As explained earlier under “Procedure for Adjusting Output Voltage of Modules”

(page 15), the output voltage at the individual modules (measured at points

S5 & S6 of the module as shown at Fig. 3.4) is required to be set exactly at the

same voltage for proper current share control. Each module is factory preset at a

voltage of 55V with the help of potentiometer VR1. Although the new module

SEC-0548MPSB is factory preset at 55V, it may differ slightly due to tolerance. It is,

therefore, necessary to ensure that the voltage of all the 5 individual paralleled

modules i.e. the existing modules and the new replaced module is set exactly at

55V. For this, follow instructions given under “Procedure for Adjusting Output

Voltage of Modules” (page 15).

SAMLEX AMERICA INC. | 17

11001-SEC-4825BRM-0114.indd 17 14-01-07 1:15 PM

Page 18

SECTION 3 | Design & Principle of Operation

10. Replace the top cover. Power on the unit and con rm that the “PSM Status”

LEDs of all the installed modules are lighted.

Bypassing Defective Module - (Pending Replacement with New Module)

Assume one of the 5 modules is defective and a new replacement module is not available. In this case, the defective module can be bypassed. As only 4 modules will be

sharing the current, only 20A will be available. Assuming battery-charging current of

maximum 2A, the load current should be limited to < 18A.

1. Switch OFF 120VAC, 60 Hz input power and unplug the power cord from the

main outlet.

2. Remove the top cover plate by unscrewing the 10 screws.

3. Remove the AC input power supply wires from terminals “L” and “N” of the

defective module (Fig 3.4). Insulate temporarily with insulation tape.

4. Remove connectors from terminals “LED 1 & LED 2” (Fig 3.4).

5. Remove female connector of the Daisy Chained “SHARE BUS” wire loop connected

to male terminal “JUMP1” on the module (Fig 3.4, Fig 3.5).

6. It is mandatory to short the two female sockets on this unused female connector with

a shorting link. (See Fig. 3.6). This will ensure that there is no break in the “Share

Bus” Daisy Chain and that all the “Jump1” terminals are interconnected.

7. It is necessary to ensure that the voltages of the 4 remaining active individual paralleled modules are set exactly at 55V. For this, follow instructions given under “Procedure for Adjusting Output Voltage of Modules” (page 16).

8. Replace the top cover. Power on the unit and con rm that the “PSM Status” LEDs for

the 4 modules are lighted.

COOLING

Due to modular design, each Power Supply Module has its own heat sink that is

mounted on its PCB. As these heat sinks are not thermally connected to the metal chassis of the unit, cooling by convection through the surface area of the metal chassis is

not adequate. Hence, 2 fans (running all the time) are used for cooling of the modules.

These fans suck cool air from the ventilation slots on the sides and discharge through

the fan openings at the back (9, Fig 2.1).

The unit is protected against over temperature by monitoring the operation of the 2

cooling fans and heat sink temperature of one of the Power supply Modules. In case of

abnormal conditions, buzzer and LED alarm are activated locally and alarm signal is also

provided for remote signaling. Details are given below:

• Incaseanyoneofthe2fansfails(opencircuit,shortcircuit,lowRPM),buzzeralarm

will be sounded and front panel Red LED “Fan Failure” (6, Fig 2.1) will be lighted. At

the same time, alarm signal will be provided for remote signaling (Pins 12 and 19 of

DB-25 Connector at the back of the unit - 12, Fig 2.1)

• OneofthePowersupplyModuleshasaTemperatureSensormountedonitsheat

18 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 18 14-01-07 1:15 PM

Page 19

SECTION 3 | Design & Principle of Operation

sink. If the fans are operating normally but the ambient temperature of cooling air is

higher than 40°C and the unit is operating at full load, the temperature of the heat

sink will rise. When the temperature exceeds allowable threshold, buzzer alarm will

be sounded and front panel Red LED “Fan Failure” (6, Fig 2.1) will be lighted. At the

same time alarm signal will be provided for remote signaling (Pins 12 and 19 of

DB-25 Connector at the back of the unit - 12, Fig 2.1).

WARNING!

!

In both the above conditions, immediate remedial action must be taken to

ensure adequate cooling. Defective fan(s) should be replaced / availability

of cool airow should be checked and ensured / load should be decreased.

PLEASE NOTE THAT THE UNIT WILL NOT SHUT DOWN AUTOMATICALLY AND

PROLONGED OPERATION IN THE ABOVE OVER TEMPERATURE CONDITIONS

MAY DAMAGE THE UNIT.

SECTION 4 | Protections

NOTE: Please refer to Figs 2.1 & 3.1, and explanation under Section 3 “Design &

Principles of Operation”.

OVER LOAD / SHORT CIRCUIT CURRENT PROTECTION

Battery Backup Function is not Used - External Battery is not Connected and

the Unit is Used as a Power Supply

In this case, the entire load current will be supplied by the Power Supply Section and will

be limited to a maximum of 30A by its Current Limit Circuitry. If the load tries to draw

a higher current than the current limit value of 30A, the output voltage at the Load

Terminals and the Battery Terminals will not be regulated and will drop below

58.5V± 0.3V. If the load impedance is further reduced, the current will remain limited at

30A but the voltage will drop further. In case of short circuit, maximum limited current

of 30A will continue to be supplied into the short circuit but the voltage will drop to

< 2V in case of a near dead short (Load impedance will be very low – say < 100 milli Ohm).

If over-load / short-circuit current of 30A continues over prolonged period, the external

25A load side Fuse (F2) will blow and will disconnect the load. If the overload / short

circuit is removed before the external 25A load side Fuse (F2) blows, the output voltage

at the Load / Battery Terminals will automatically recover when the load current drops

to less than the current limit value of 30A.

Battery Backup Function is Used - External Battery is Connected

If the load tries to draw current higher than the current limit value of 30A of the Power

Supply Section, the output voltage of the Power Supply Section will not be regulated

and the voltage at the Load Terminals will drop. Portion of overload current beyond

SAMLEX AMERICA INC. | 19

11001-SEC-4825BRM-0114.indd 19 14-01-07 1:15 PM

Page 20

SECTION 4 | Protections

30A will now be fed from the battery and the battery will start draining at this differential current. For example, if the overload current was 40A, the Power Supply Section will

provide 30A and the battery will provide the balance 10A. The battery will start draining

at 10A. The voltage at the Battery Terminals will start dropping and will be equal to the

voltage corresponding to its actual State of Charge. The voltage at the Load Terminals

will be around 0.3 ± 0.1V below the voltage at the Battery Terminals. External 25A Fuse

(F2) on the load side will blow only on sustained current ≥ 25A, but will not blow at

higher short duration surge currents determined by its Time Current characteristics. For

example, based on the Time Current Characteristics of 80V, 25A fuse Type 166.7000.525

from Littelfuse, the fuse can pass extremely high currents for shorter durations

as follows:

- 150A for 20 ms to 100 ms.

- 88A for 40 ms to 500 ms.

- 50A for 150 ms to 20 secs.

- 28A continuous for 100 min.

In case of short circuit on the load side, the external 25A Fuse (F2) on the load side will

blow because of very high additional current supplied by the battery (Additional battery

current supplied into the short circuit on the load side = Short circuit current - 30A from

the Power Supply Section). For example, if a short circuit current of 150A tries to ow for

> 100 ms, 30A will be supplied by the Power Supply Section and the balance 120A will be

supplied by the battery. As the external 25A Fuse (F2) on the load side will see 150A and

the external 25A Fuse (F1) on the battery side will see 120A, the external 25A load side

Fuse (F2) will blow rst.

PROTECTION AGAINST REVERSE POLARITY OF BATTERY CONNECTION

Please ensure that the external 48V battery is connected with correct polarity.

In case of reverse polarity of battery connection, internal Diode (D3, Fig 3.1) connected

across the battery terminals will be forward biased and the external 80V, 25A Fuse 1

(Fig 2.1) will blow.

OVER TEMPERATURE PROTECTION

CAUTION!

!

Keep the unit in a well-ventilated, cool and open area. DO NOT block the vent

holes on the sides or the discharge openings of the cooling fan at the back

of the unit.

The unit is protected against over temperature by monitoring the operation of the 2

cooling fans and heat sink temperature of one of the Power supply Modules. In case of

abnormal conditions, buzzer and LED alarm are activated locally and alarm signal is also

provided for remote signaling.

20 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 20 14-01-07 1:15 PM

Page 21

SECTION 4 | Protections

Details are given below:

• Incaseanyoneofthe2fansfails(opencircuit,shortcircuit,lowRPM),buzzeralarm

will be sounded and front panel Red LED “Fan Failure” (6, Fig 2.1) will be lighted. At

the same time, alarm signal will be provided for remote signaling (Pins 12 and 19 of

DB-25 Connector at the back of the unit - 12, Fig 2.1).

• OneofthePowersupplyModuleshasaTemperatureSensormountedonitsheat

sink. If the fans are operating normally but the ambient temperature of cooling air is

higher than 40°C and the unit is operating at full load, the temperature of the heat

sink will rise. When the temperature exceeds allowable threshold, buzzer alarm will

be sounded and front panel Red LED “Fan Failure” (6, Fig 2.1) will be lighted. At the

same time alarm signal will be provided for remote signaling (Pins 12 and 19 of DB25 Connector at the back of the unit - 12, Fig 2.1).

!

In both the above conditions, immediate remedial action must be taken to ensure adequate cooling. Defective fan(s) should be replaced / availability of cool airow should

be checked and ensured / load should be decreased. PLEASE NOTE THAT THE UNIT WILL

NOT SHUT DOWN AUTOMATICALLY AND PROLONGED OPERATION IN THE ABOVE OVER

TEMPERATRE CONDITIONS MAY DAMAGE THE UNIT.

WARNING!

SECTION 5 | Installation

!

PLEASE READ “SECTION 1 - SAFETY INSTRUCTIONS” FOR SAFE INSTALLATION.

NOTE:

Please refer to Fig 2.1 - Layout & Input/Output Connections

LOCATION, MOUNTING AND SAFETY

The unit is required to be installed in a safe, well-ventilated and dry location. Please see

details given under Section 1 "Safety Instructions". The unit can be mounted horizontally or vertically. When mounting vertically, please ensure that the Output Terminals

are pointing up.

AC INPUT CONNECTION

An attached power cord has been supplied (11, Fig 2.1). Plug the power cord into the

AC outlet. Please ensure that the voltage of AC input power at the outlet is 120 VAC,

50/60 Hz.

11001-SEC-4825BRM-0114.indd 21 14-01-07 1:15 PM

WARNINGS!

SAMLEX AMERICA INC. | 21

Page 22

SECTION 5 | Installation

DC OUTPUT CONNECTIONS

The Load Terminals (7A, 7B - Fig 2.1)and the Battery Terminals (8A, 8B - Fig 2.1) have

5/16” diameter tubular hole with set screw (5/16” x 3/8”long x 24TPI).

For ensuring rm connection under the set screw, 4 pieces of Pin Type of Terminal Lugs

“PTNB10-12” have been provided for crimping to the bare ends of stranded wires for the

load and battery connections. The terminal can accept wire of up to 10 mm

After crimping the Terminal Lugs, use insulating heat shrink tubing or tape to insulate

the bare cylindrical portion of the lug.

Load Connection: The load is connected to the terminals marked “Load +” and

“Load - ” (7A, 7B - Fig 2.1) through Fuse (F2) (See details below under heading

“External Fuses on Battery & Load Sides”). Please ensure that the polarity of the connection is correct - Positive of the load to the “Load +” terminal and the Negative of the

load to the “Load - ” terminal.

Battery Connection: The Positive of the battery is connected to the “Battery +” terminal

(8A, Fig 2.1) and the Negative of the battery to the “Battery - ” terminal (8B, Fig 2.1)

through 80V, 25A Fuse (F1) (See details below under heading “External Fuses on

Battery and Load Sides”). Please ensure that the polarity of connection is correct.

Recommended Battery Capacity: Battery should not be charged at very high current.

Normally, as a Rule of Thumb, the maximum charging current should be limited to 10%

of the Ah capacity at 20 Hour Rate unless higher current is allowed by the manufacturer.

Higher charging current produces higher heating which reduces the life of the battery.

Further, higher charging current will not re-charge the battery to full 100% capacity

unless the charging voltage is increased proportionately. It is recommended that the

capacity of the battery used with this unit should be in the range of 10 to 25 Ah.

DC OUTPUT WIRE SIZING

Use AWG #10, 90°C / 194°F insulation wire for the load and battery connections for a

distance of up to 10 ft. Thicker wire will be required for distance longer than 10 ft.

2

/ AWG #8.

EXTERNAL FUSES ON THE BATTERY AND LOAD SIDES

A battery is an unlimited source of current that can drive thousands of Amperes of cur-

rent into a short circuit leading to overheating and burning of wiring / circuit compo-

nents along the path from the battery terminals to the point of short circuit. This can

cause injury and is a re hazard. Similarly, a power source is also be capable of driving

considerably high value of current into a short circuit on the load side and causing

damage as above (the current will, however, be limited to the maximum rated overload

current and not unlimited as in the case of a battery). Appropriate fuse should, there-

fore, be used in series with the battery Positive post / Load terminal of power source to

protect against the above safety hazard.

22 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 22 14-01-07 1:15 PM

Page 23

SECTION 5 | Installation

!

For effective protection, appropriate sizes of fuses should be located as follows:

• ExternalBatterySideFuse(F1)shouldbeLOCATEDasclosetothebatteryPositive

post as possible, preferably within 7” of the battery Positive post

• ExternalLoadSideFuse(F2)shouldbeinstalledascloseaspossibletothePositive

Load Terminal

For this unit, external fuses must be used for protection against reverse polarity and

short circuit as follows (please see specs for F1 & F2, Fig 2.1, page 5):

• 80V,25AfastactingFuse(F1)inserieswiththePositivebatterywirewithin7”from

the battery Positive post. This fuse provides the following protections:

- Prevents overheating and burning of wiring due to very heavy current fed from the

battery into a short circuit along the length of wiring from the battery to the Battery

Input Terminals (8A, 8B, Fig 2.1).

- Prevents damage to the unit and to the load due to reverse polarity of battery connection.

• 80V,25AfastactingFuse(F2)inserieswiththePositiveloadwireandwithin7”of

the Positive Load Terminal (7A, Fig 2.1). This fuse protects against overload and short

circuit on the load side.

SECTION 6 | Operation

Please refer to Fig 2.1, page 5 - Layout & Input/Output Connections.

CAUTION!

1. If AC input power is not available and a battery has been connected for backup function, the load will be powered by the battery and the battery will continue to discharge

as long as the load is in ON condition. When the load is not delivering power, it still

draws current for its self-consumption (called "No Load Current"). When AC input

power is not available, switch OFF the load if not required, otherwise the battery will

get discharged because of the "No Load Current" drawn by the load.

2. When AC input power is NOT available/switched OFF, battery has been connected for

backup and load has been switched OFF. The battery will still discharge around

100 mA through the static load resistor connected across the load terminals (for module synchonization under no/low load conditions). In this situation, please remove Fuse

F1 to prevent unnecessary discharge of the battery.

SWITCHING ON / OFF

Switching ON (Without Battery Backup - No External Battery -

Unit Operates as a Normal Power Supply):

- Check that the load has been connected to the Load Terminals (7A, 7B - Fig 2.1)

and NOT TO THE BATTERY TERMINALS (8A, 8B, Fig 2.1)

- Switch ON the unit with the help of the Red Power ON / OFF Switch (1). If AC power is

available and the AC input breaker (2, Fig 2.1) is not tripped, the ON / OFF Switch will be

lighted Red indicating that the Power Supply Section is in ON condition

- After a few milli sec, 54.8V will be available at the Load and Battery Terminals

- Switch ON the load

SAMLEX AMERICA INC. | 23

11001-SEC-4825BRM-0114.indd 23 14-01-07 1:15 PM

Page 24

SECTION 6 | Operation

Switching ON (With Battery Backup - External Battery is Connected):

- Check that the load has been connected to the Load Terminal (7A, 7B, Fig 2.1) and NOT to

the Battery Terminals (8A, 8B - Fig 2.1).

- Check that the load has been connected to the Load Terminals (7A, 7B - Fig 2.1) through

external 25A Load Side Fuse (F2).

- Check that the external battery has been connected to the Battery Terminals (8A,

8B - Fig 2.1) through external 25A Battery Side Fuse (F1).

- Switch ON the unit with the help of the Red Power ON / OFF Switch (1). If AC power is available and the internal AC side fuse is intact, the ON / OFF Switch will be lighted Red indicating that the Power Supply Section is in ON condition.

- After a few milli sec, 54.8V will be available at the Load Terminals (7A, 7B - Fig 2.1)and the

external battery will start charging at current of up to 2A determined by its State of Charge.

The voltage at the Battery Terminals (8A, 8B - Fig 2.1) will get clamped to the actual terminal voltage of the battery corresponding to its State of Charge.

- Switch ON the load.

- The Power Supply Section will supply all the current consumed by the load (up to its rated

current limit value) and the external battery will be maintained in charged condition all the

time at Float Voltage of 54V to 54.6V (when fully charged), depending on the value of load

current being supplied.

Switching OFF:

- Switch OFF the load rst

- Switch OFF the unit with the help of the Red Power ON / OFF Switch (1). Red light inside the

ON /OFF switch will switch OFF

CHARGING AND BACKUP OPERATION

Charging current will be proportional to the discharged state of the battery and is limited to maximum of 2A when the battery is completely discharged (Standing Voltage of

42.8V). The current will taper down from 2A as the battery gets charged and its voltage

rises. When the battery is fully charged, the current will drop down to 0.1% of the Ah

capacity of the battery to compensate for self-discharge. When fully charged, the voltage at the Battery Terminals (8A, 8B - Fig 2.1) will be the Float Voltage of 54V to 54.6V

depending on value of load current.

Battery should not be charged at very high current. Normally, as a Rule of Thumb, the

maximum charging current should be limited to 10% of the Ah capacity at 20 Hour Rate

unless higher current is allowed by the manufacturer. Higher charging current produces

higher heating, which reduces the life of the battery. Further, higher charging current

will not re-charge the battery to full 100% capacity unless the Absorption Voltage is

increased proportionately. This may not be possible with chargers that do not have programmable charging voltages. It is, therefore, recommended that the capacity of the

battery used with this unit should be in the range of 10 to 25Ah which is appropriate for

2A charging current.

The voltage seen at the Battery Terminals (8A, 8B - Fig 2.1) will be the actual terminal

voltage of the battery (assuming no voltage drop in the battery cables) and will be

proportional to its State of Charge. When the battery is fully charged, the voltage at the

Battery Terminals (8A, 8B - Fig 2.1) will be 54V to 54.6V.

24 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 24 14-01-07 1:15 PM

Page 25

SECTION 6 | Operation

If AC input power fails, the DC load(s) will be instantaneously transferred to the external

48V backup battery and the battery will start discharging. When the battery is supplying

the load, the voltage seen at the Load Terminals will be 0.3V ± 0.1V less than the voltage

at the Battery Terminals. When AC input power is restored, the DC load will once again

be transferred instantaneously to the Power Supply Section and the external backup

battery will be recharged and kept in charged condition all the time at Float Voltage of

54V to 54.6V.

SURGE POWER CAPABILITY IN DC UPS BATTERY BACKUP MODE

When operating in DC UPS Battery Backup Mode (external 48V battery is connected),

the unit is capable of providing short term surge current determined by the Time versus

Current Characteristics of the load side Fuse F2.

Current = the current limit value, will be provided by the Power Supply Section and

balance will be supplied by the battery.

During the period of this short term overload, the voltage seen by the load will

be = (battery voltage – 0.3V± 0.1V).

OPERATION AS NORMAL POWER SUPPLY WITHOUT EXTERNAL BATTERY

If battery backup function is not used (external backup battery is not connected), the

unit will work as a normal power supply with ability to supply 25A continuous at 54.5V

± 0.3 VDC at the Load Terminals (

limited to 30A. Under overload conditions, the output voltage will not be regulated and

will drop.

7A, 7B, Fig 2.1). The maximum overload current will be

SECTION 7 | Limiting Electro-Magnetic

Interference (EMI)

CAUTION!

!

Conducted and radiated noises in this unit are reduced to acceptable limits by appropriate

ltration.

This unit generates, uses and can radiate radio frequency energy and, if not installed and

used in accordance with the instructions, may cause harmful interference to radio communications. However, this does not guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the measures recommended in the following

paragraphs.

UN-INTENTIONAL RF NOISE GENERATED BY SWITCHED

MODE POWER SUPPLIES (SMPS)

Switched Mode Power Supplies (SMPS) employ high frequency switching and thus, are

a source of radio interference, a recipient of radio interference and a conduit of radio

interference. (Older Linear Type, low frequency 50 / 60 Hz transformer based power

SAMLEX AMERICA INC. | 25

11001-SEC-4825BRM-0114.indd 25 14-01-07 1:15 PM

Page 26

SECTION 7 | Limiting Electro-Magnetic

Interference (EMI)

supplies do not employ high frequency switching voltages and will be quieter as compared to SMPS).

The primary emission sources originate in the switching devices due to their fast

switching current transitions: harmonics of the switching frequency and broadband

noise created by under-damped oscillations in the switching circuit. The secondary

source is from the bridge recti er, both recti er noise and diode recovery. The AC

input recti er / capacitor in the front end of the SMPS (excepting those with Power

Factor correction) generate power supply harmonics due to the non-linear input current waveform. The noise is both conducted and radiated through the input power

cord and the DC output wiring to the radio.

FILTRATION OF CONDUCTED NOISE

The conducted RF noise from this SMPS unit is limited to acceptable levels by internal

ltration. The ltered RF noise currents (< few hundred micro Amps) are bypassed to

the chassis of the power supply. The chassis is, in turn, connected to the Earth Ground

pin of the AC input power cord (for Class 1 units). Thus, the ltered noise currents are

intentionally leaked to the Earth Ground. This is termed as the “Earth Leakage Current”.

EXCESSIVE RF OUTPUT INTERFERENCE BY SMPS DUE TO INCOMING

RF INTERFERENCE WHEN POWERING RADIO TX / RX

SMPS are also recipients of radio interference. The normal operation of the power supply can be disturbed due to RF noise getting coupled into the power supply. Thus, the

power supply may generate excessive RF noise and lose output voltage regulation due

to excessive transmitter energy being coupled through the AC / DC lines to the power

supply’s regulator feedback path. This may be due to antenna being too close or due

to the antenna or feed system not radiating properly. First check the antenna system

SWR. Then, if necessary, relocate either the antenna or the power supply farther apart.

The receiver may “hear” the power supply. A slowly moving, slightly buzzing carrier

heard in the receiver may be caused by the antenna being too close. As with the transmitter related noise pick up, a loose coaxial connector or a broken or a missing ground

may aggravate this problem. Normally, this noise will be below the background or

“band” noise. Increase the separation between the power supply and the receiving antenna. Use an outdoor antenna. This will reduce the amount of signal picked up from

the power supply and also increase the amount of the desired signal.

ADDITIONAL GUIDELINES FOR REDUCING RF NOISE

• UseadditionalappropriateACRadioFrequencyInterference(RFI)PowerLineFilter

rated for minimum 25A immediately before the AC input of the power supply.

• UseadditionalappropriateDCradiofrequencyinterference(RFI)powerlinelter

rated for minimum 30A immediately after the DC output of the power supply.

• TwistthePositiveandNegativewiresfromtheoutputofthepowersupplytotheradio.

• TheDCsidePositiveandNegativeoutputsofthesepowersuppliesareisolatedfrom

26 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 26 14-01-07 1:15 PM

Page 27

SECTION 7 | Limiting Electro-Magnetic

Interference (EMI)

the chassis. As explained earlier, the noise currents are ltered to the chassis of the

unit and the chassis is connected to the Earth Ground through the Earth Ground Pin

of the AC power outlet receptacle. Avoid connecting (referencing) the DC Negative

output terminal of the power supply to the Earth Ground.

• Connecta¼”wavelengthofwireontheNegativeterminalofthepowersupply.

Connect one end of the wire to the Negative terminal and leave the other end free.

The wavelength corresponds to the wavelength of the interfering frequency. (May

not be practical for long wave lengths).

[Formula: Wave length (Meters) = 300 / frequency in MHz]

COMBINED FILTERED NOISE CURRENTS FROM MULTIPLE SMPS ON A BRANCH

CIRCUIT MAY TRIP GROUND FAULT CIRUIT INTERRUPTER (GFCI)

During malfunction or an accident, the metal chassis of a device may get energized to

unsafe voltage due to internal high voltage section coming in contact with the chassis.

If a person standing on Earth touches this energized chassis, a leakage current

proportional to the person’s skin resistance will ow through the person’s body to Earth

Ground. The leakage current through the body is higher when the skin contact resist-

ance is lower i.e. if the skin is wet or wounded. This leakage current does not return to

the power source but is dissipated in Earth Ground. A leakage current of > 5mA could

produce lethal electrical shock. Ground Fault Circuit Interrupter (GFCI) is used for safety

against electrical shock due to leakage. GFCI measures the difference between the

current sent to the load and returned from the load and will trip and disconnect the

power circuit if the difference is > 5 mA. GFCIs are normally installed in AC Branch

Circuits feeding power outlets in wet areas like marine craft, RVs, spas, hot-tubs,

kitchens, washrooms, etc.

As explained earlier, RF noise ltration circuits in SMPS generate intentional Earth Leak-

age Current. SMPS are used extensively as DC power sources in modern day electrical

/ electronic devices e.g. Audio / Video / Computing devices, power supplies, battery

chargers etc. A single GFCI outlet / GFCI breaker may be serving multiple SMPS loads

and therefore, will be sensing the sum of all the Earth Leakage Currents and, if the sum

is > 5mA after connecting this unit, the GFCI will trip. In such a case, disconnect other

SMPS based device(s) being served by this GFCI one by one till the net leakage current is

reduced to < 5mA and the GFCI does not trip. Other solution is to power this unit from

a GFCI outlet / GFCI breaker that does not have any SMPS load or power from an outlet

that is not protected by GFCI.

SAMLEX AMERICA INC. | 27

11001-SEC-4825BRM-0114.indd 27 14-01-07 1:15 PM

Page 28

SECTION 8 | Troubleshooting Guide

1. GENERAL

Symptom Possible Cause Remedy

ON/OFF Switch is ON

and is lighted. One or

more “PSM Status” LED

(s) is not lighted

Associated Power supply Module has

become defective.

• The unit will still operate normally

as the remaining working module(s)

will share a higher load. If backup

battery is connected, it will supply

balance load if the load is higher

than the combined capacity of the

remaining working module(s)

• If backup battery is not connected,

the output voltage will drop if the

value of load current is more than

the rated combined current limit

values of the remaining working

module(s)

Remove the defective module(s) and

replace with new module(s)

ON/OFF Switch is ON

and is lighted. One or

more “PSM Status”

LED(s) ash

• The output voltage of individual

modules is not equal

• Internal static load is not suf cient

for effective activation of Master/

Slave operation for forced current

share

• Forced Share Control Circuitry of

the module(s) is defective

• Adjust the output voltage of all the

modules to exactly 55V as explained

in the Adjustment Procedure at

page 15

• If after carrying out the above

adjustment, the problem still exists

under no load, then apply 5A load.

If ashing stops under load, it means

that the internal static load is not

suf cient for effective activation of

Master/Slave operation. Disregard

ashing under no load as the

module(s) will operate normally

• If the ashing continues even after

loading, the module(s) are defective.

Please call Technical Support

2. OPERATION AS A SIMPLE POWER SUPPLY - ONLY LOAD IS CONNECTED.

NO EXTERNAL BATTERY AND NO BATTERY BACKUP.

Symptom Possible Cause Remedy

ON / OFF Switch is ON

• Switch is NOT lighted

• No DC output

No AC power from the

AC outlet

AC Input Breaker on the unit is

tripped (2, Fig 2.1)

Check AC power is available at the AC

outlet. Breaker feeding the AC outlet may

have tripped. Reset the breaker

If the breaker trips again, the input

section is damaged. Please call Tech

Support

28 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 28 14-01-07 1:15 PM

Page 29

SECTION 8 | Troubleshooting Guide

Symptom Possible Cause Remedy

ON / OFF Switch is ON

• Switch is lighted

• DC Output voltage

drops

GFCI outlet / GFCI breaker

supplying AC power to

the unit trips when the

unit is switched ON

3. BATTERY BACKUP OPERATION - EXTERNAL BATTERY IS CONNECTED

Symptom Possible Cause Remedy

ON / OFF Switch is ON

• Switch is NOT lighted

• Load is ON and is operating

normally

• Output voltage at the Battery

Terminals is < 54V to 54.6V

and is dropping

• Output voltage at the Load

Terminals is 0.3V ± 0.1V lower

than the Battery Terminals and

is dropping

ON / OFF Switch is ON

• Switch is lighted

• Load is ON

• Output voltage at the Load

Terminals loses regulation and

drops below 54.2V

• Output voltage at the Load

Terminals is 0.3 ± 0.1V lower

than the Battery Terminals and

is dropping

If the voltage loses regulation

and drops to < 54.2V, the unit is

overloaded and is in current limit.

The load is trying to draw ≥ the

current limit value of 30A

If the voltage drop is considerable

with voltage < 2V, the load side is

seeing a short circuit

Additional RF noise currents from

the unit that are ltered to Earth

Ground increase the net Leakage

Current on the GFCI outlet / GFCI

breaker to > 5mA

No AC power from the

AC outlet

AC Input Breaker is tripped

Power Supply Section is overloaded and is in current limit

condition. The load is trying to

draw excessive current ≥ the current limit value of 30A. The Time

Current Characteristic of the 25A

Fuse (F2) in the Load circuit will

determine the allowable value of

overload current > 30A and the

time it can be sustained before

the fuse blows. The allowable

value will be higher for shorter

duration of overload.

Power Supply Section provides

30A in current limit condition and

the balance of current is fed from

the battery and the battery starts

discharging at current = (Overload

current - 30A)

Reduce the current drawn by the load to

less than the continuous rating of 25A.

Switch OFF the load. Remove the short

circuit on the load side.

Switch OFF other SMPS devices operating

from the same GFCI outlet / GFCI breaker

to reduce the net leakage current to

< 5mA

Move the unit to another GFCI outlet /

GFCI breaker that has lesser number of

SMPS load(s) or no SMPS load

Power the unit from normal, non GFCI

outlet or from an outlet not protected by

GFCI breaker

Check AC power is available at

the AC outlet. Breaker feeding

the AC outlet may have tripped or

there may be power outage.

Reset the breaker.

If breaker trips again, please call

Technical Support.

Remove the cause of overload

SAMLEX AMERICA INC. | 29

11001-SEC-4825BRM-0114.indd 29 14-01-07 1:15 PM

Page 30

SECTION 8 | Troubleshooting Guide

3. BATTERY BACKUP OPERATION - EXTERNAL BATTERY IS CONNECTED (continued)

Symptom Possible Cause Remedy

ON / OFF Switch is ON

• Switch is lighted

• There is no voltage at the at

the load end and the load is

shut down

• Voltage at the Load Terminals

is 54.8V

• Voltage at Battery Terminals is

0.3V ± 0.1V lower than the

voltage at the Load terminals

ON / OFF Switch is ON

• Switch is lighted

• Load is ON

• Voltage at the Load Terminals

is 54.8V to 54.2V

• Voltage at Battery Terminals is

the same as the Load Terminals

• Battery backup function does

not operate – Load shuts OFF

when AC power is interrupted

GFCI outlet / GFCI breaker

supplying AC power to the

unit trips when the unit is

switched ON

25A Fuse (F2) in the Load circuit is

blown due to:

- Excessive short time overload

current > 25A exceeding the

Time Current Characteristics of

the 25A fuse, or

- Short circuit in the load circuit

25A Fuse F1 in the battery circuit

is blown due to short circuit in

battery wiring or reversal of

battery polarity

Additional RF noise current from

the unit that is ltered to Earth

Ground increases the net Leakage

Current on the GFCI outlet / GFCI

breaker to > 5mA

Remove the cause of the overload

or short circuit.

Check that the polarity of battery

connections is correct. Replace

the fuse.

Check for short circuit in the

battery wiring and correct.

Replace the fuse.

Switch OFF other SMPS devices

operating from the same GFCI

outlet / GFCI breaker to reduce

the net leakage current to < 5mA.

Move the unit to another GFCI

outlet / GFCI breaker that has

lesser number of SMPS load(s) or

no SMPS load.

Power the unit from normal, non

GFCI outlet or from an outlet not

protected by GFCI breaker.

The unit is not in use. ON/OFF

Switch is OFF

• Battery is connected to the

Battery Terminals

• Load is OFF/disconnected

• Battery is getting discharged

Battery is draining by 100 mA

through the Static Load Resistor connected across the Load

Terminals

Remove Battery Fuse F1 when the

unit is not in use.

30 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 30 14-01-07 1:15 PM

Page 31

SECTION 9 | Specications

PARAMETER SPECIFICATION

NO OF MODULES - 5

Input Voltage 120 VAC Nominal (+6% / -10%), 50/60 Hz

AC INPUT

DC OUTPUT

EXTERNAL

BACKUP BATTERY

PROTECTIONS

COOLING Type Forced air circulation: 2 fans running all the time

BREAKER & FUSES

REMOTE

MONITORING

Input Current 20A @ 120 VAC

Peak Efciency > 83%

Power Factor 0.74 at 25A load

Output Voltage at Load Terminals No Load: 54.8V / 25A Load: 54.2V

Output Voltage at Battery

Terminals (Without battery)

Output Voltage at Battery

Terminals (With battery)

Output Voltage Noise and Ripple Ripple: 200 mV Peak to Peak

Continuous Output Current at

Load Terminals

Maximum Charging Current at

Battery Terminals (Battery Backup)

Output Current Limit at Load

Terminals

Battery Charging/type of Charging Taper Type of Float Charging at 54V to 54.6V

Output Current Limit at Battery

Terminals (Battery Backup)

Peak Efciency 85% ± 5%

Type & Voltage Lead Acid, 48V

Capacity 10Ah to 25 Ah

Short Circuit, Overload External 25A Load Side Fuse F2 will blow

Over Voltage Regulated by PWM Controller

Over Temperature / Fan Failure

Alarm

Reversal of polarity on battery

terminals

Internal Module Fuse

AC Input Breaker

External Battery Side Fuse (By User) 80V, 25A, Fast Acting

External Load Side Fuse (By User) 80V, 25A, Fast Acting

Type of Monitoring

No Load: 54.8V / 25A Load: 54.2V

Actual battery voltage corresponding to

State of Charge; 54V to 54.6V when fully charged

Noise: 2V Peak to Peak

25A (Without battery backup);

23A (With battery backup)

Up to 2A (When battery is completely discharged

to Standing Voltage of 42.8V)

• 30A when no backup battery is connected

(External 25A Fuse F2 will blow after some time)

• Surge > 30A based on Time vs Current

Charateristics of 25A Fuse F2

2A (When battery is completely discharged to

Standing Voltage of 45.4V)

Over temperature of PSM Heat sink or fan failure

activates buzzer & RED LED “Fan Failure”

External 25A Battery Side Fuse F1 will blow

250V, 4A

250V, 25A

Opto Isolated, Open Collector/Open Emitter

Signalling (Max, 35V, 50 mA):

• ON status of 5 Power Supply Modules (PSM)

• Fan failure /over temperature

• AC input available

• Output Voltage & Current

SAMLEX AMERICA INC. | 31

11001-SEC-4825BRM-0114.indd 31 14-01-07 1:15 PM

Page 32

SECTION 9 | Speci cations

PARAMETER SPECIFICATION

AC Input Connection Attached Power Cord:

INPUT / OUTPUT

CONNECTIONS

ENVIRONMENTAL Operating Temperature Range 0°C / 32°F to 40°C / 104°F

DIMENSIONS

& WEIGHT

NOTE: Above speci cations are subject to change without notice

DC Output Connectors for Load

and Battery Connections

Battery wires Minimum AWG #10

Dimensions (W x D x H)

Weight

• 3 x 12 AWG, 5 ft.

• 30A Plug, NEMA 15-30P

Terminal with Tubular Hole - Diameter 5/16”and

set screw (5/16”, 24 TPI, 3/8” long)

482.6 x 407.6 x 87.7 mm

19.00 x 16.05 x 3.45 in

11.4 kg

25 lb

32 | SAMLEX AMERICA INC.

11001-SEC-4825BRM-0114.indd 32 14-01-07 1:15 PM

Page 33

SECTION 10 | Warranty

2 YEAR LIMITED WARRANTY

SEC-4825BRM manufactured by Samlex America, Inc. (the “Warrantor“) is warranted to

be free from defects in workmanship and materials under normal use and service. The

warranty period is 2 years for the United States and Canada, and is in effect from the

date of purchase by the user (the “Purchaser“).