Page 1

2 YEAR LIMITED WARRANTY

The DC-FA-100, DC-FA-200 and DC-FA-300 fuse assemblies manufactured by Samlex America, Inc. (the “Warrantor“) is warranted to be free from defects in workmanship and materials under normal use and service. The warranty period is 2 years for the United States

and Canada, and is in effect from the date of purchase by the user (the “Purchaser“).

Warranty outside of the United States and Canada is limited to 6 months. For a warranty

claim, the Purchaser should contact the place of purchase to obtain a Return Authorization Number.

The defective part or unit should be returned at the Purchaser’s expense to the authorized

location. A written statement describing the nature of the defect, the date of purchase,

the place of purchase, and the Purchaser’s name, address and telephone number should

also be included.

If upon the Warrantor’s examination, the defect proves to be the result of defective material or workmanship, the equipment will be repaired or replaced at the Warrantor’s option

without charge, and returned to the Purchaser at the Warrantor’s expense. (Contiguous

US and Canada only)

No refund of the purchase price will be granted to the Purchaser, unless the Warrantor is

unable to remedy the defect after having a reasonable number of opportunities to do so.

Warranty service shall be performed only by the Warrantor. Any attempt to remedy the

defect by anyone other than the Warrantor shall render this warranty void. There shall

be no warranty for defects or damages caused by faulty installation or hook-up, abuse or

misuse of the equipment including exposure to excessive heat, salt or fresh water spray, or

water immersion.

No other express warranty is hereby given and there are no warranties which extend

beyond those described herein. This warranty is expressly in lieu of any other expressed

or implied warranties, including any implied warranty of merchantability, tness for the

ordinary purposes for which such goods are used, or tness for a particular purpose, or

any other obligations on the part of the Warrantor or its employees and representatives.

There shall be no responsibility or liability whatsoever on the part of the Warrantor or

its employees and representatives for injury to any persons, or damage to person or

persons, or damage to property, or loss of income or prot, or any other consequential or

resulting damage which may be claimed to have been incurred through the use or sale of

the equipment, including any possible failure of malfunction of the equipment, or part

thereof. The Warrantor assumes no liability for incidental or consequential damages of

any kind.

Samlex America Inc. (the “Warrantor”)

www.samlexamerica.com

103 - 4268 Lozells Ave.

Burnaby, BC

Canada V5A 0C6

T: 604 525 3836

F: 604 525 5221

TF: 1 800 561 5885

e-mail: samlex@samlexsolar.com

website: www.samlexsolar.com

Fuse

Assembly

Owner's

Manual

Please read this

manual before

installing your

fuse assembly

DC-FA-100

DC-FA-200

DC-FA-300

INTRODUCTION

Fuse Protection in the Battery Circuit

A battery is an unlimited source of current. If there is a short circuit along the length of the cables that

connect the battery to the inverter, thousands of Amperes of current can ow from the battery causing

shorting: a section of the cable can overheat, the insulation can melt and the cable can ultimately break. This

interruption of high current can generate hazardous, high temperature, high energy arc accompanied by

a high pressure wave that may cause re, damage to nearby objects or injury. To prevent the occurrence of

such hazards under short circuit conditions, an appropriate fuse should be used in the battery circuit with the

required current interrupting capacity (Termed AIC – Ampere Interrupting Capacity). For this purpose, fuses

with an AIC rating of 10000 A at 14 V / 5000 A at 32 V, or higher should be used.

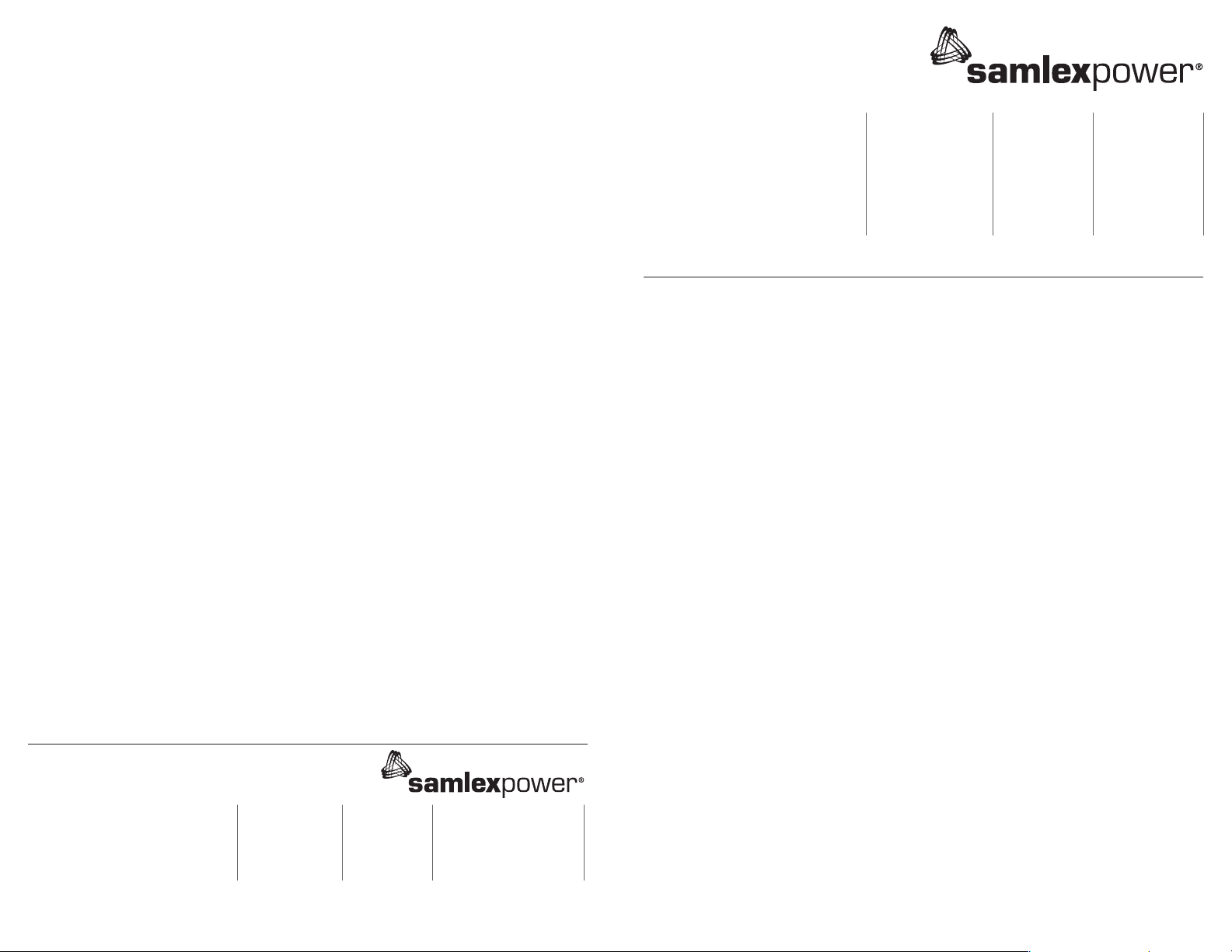

CONsTRUCTION

The DC-FA-100, DC-FA-200 and DC-FA-300 Fuse Assemblies contain 100A, 200A and 300A fuses respectively

(Fig. 1).These fuses are Marine Rated Battery Fuses (MRBF-XXX Series) and are also sold separately for

replacement. Samlex Models: MRBF-100, MRBF-200, MRBF-300.

Electrical Specications

• Voltage rating of max 58 VDC

• Current ratings are 100 A (MRBF-100), 200 A (MRBF-200) and 300 A (MRBF-300)

• AIC of 10000 A at 14VDC, 5000 A at 32 VDC and 2000 A at 58 VDC

• Ignition protected as per SAE J1171

• Weather Proof (IP66)

The MRBF Fuse provides easy, weatherproof and economical circuit protection in tight space constraints. The

fuse is installed between the Positive Battery Terminal Stud and the Positive Battery Cable with the help of a

special Clamping Fixture.

The Clamping Fixture consists of the following:

• Clamping Fixture Bar (CFBAR), Fig. 2. Has a base plate for connecting to the battery stud (with a hole

to accommodate battery stud of up to stud size 3/8” / M10) and a stud (size M-8) for connecting the

fuse MRBF and the battery cable.

• Stainless Steel nut (thread size M8, will require ½” or 13 mm wrench for tightening), Flat Washer and

Spring Washer, Fig. 3.

• An Insulating Cap, Fig. 4. It slides over the base plate of CFBAR and is used to insulate the exposed

stud and the nut of the CFBAR.

4

11013-DC-FA-100-200-300-1112

MAN-10008

1

Page 2

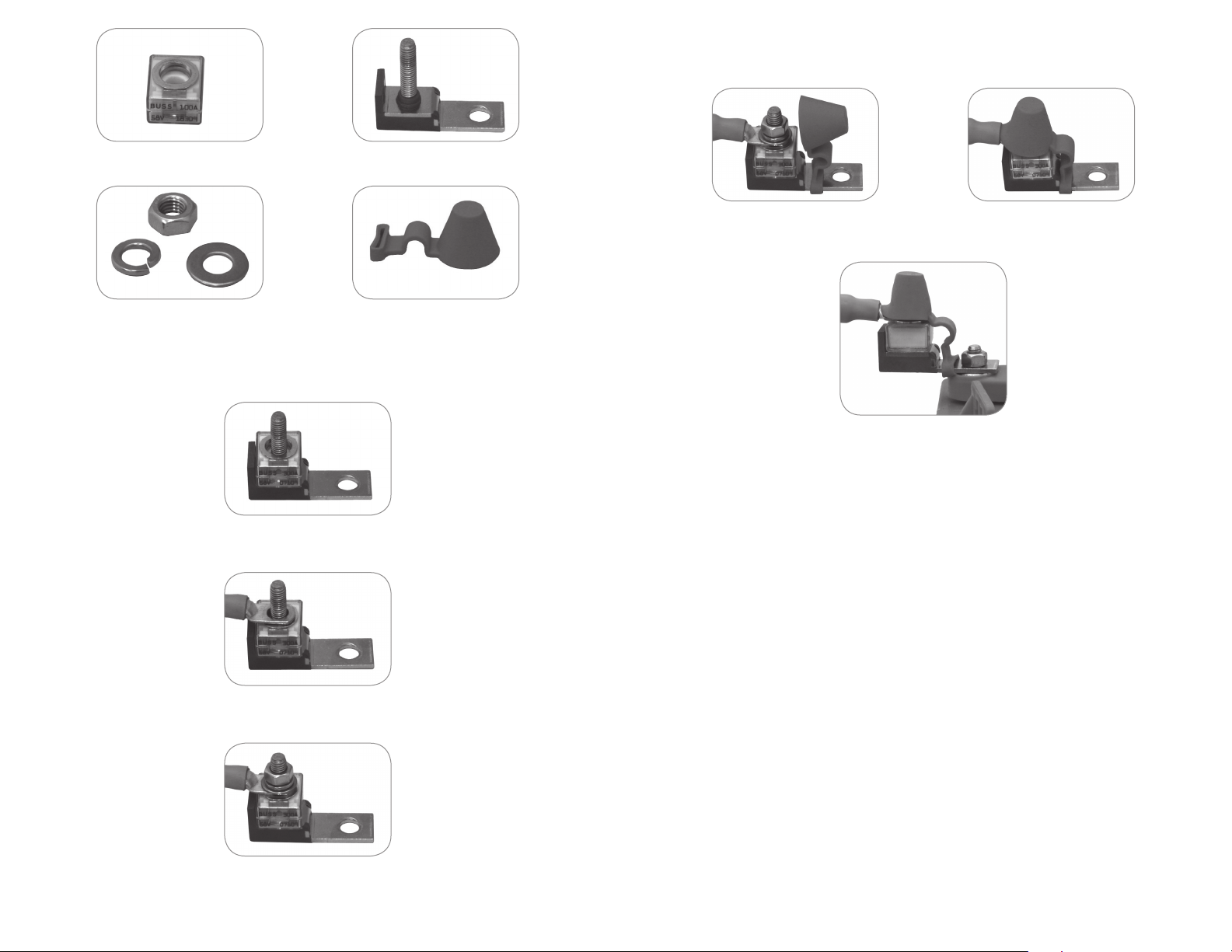

D. Slide the Insulating Cap onto the rectangular strip of the CFBAR and then insert the hood portion onto the

exposed portion of the stud of the CFBAR. See Figures 8 and 9.

Fig. 1. Marine Rated Battery Fuse (MRBF) Fig. 2. Clamping Fixture Bar (CFBAR) or

Single Pole Fuse Bar

Fig. 3. M-8 Nut, Flat Washer and Spring Washer Fig. 4. Insulating cap

INsTALLATION

A. Insert the fuse MRBF onto stud provided on the CFBAR. See Fig.5.

Fig. 5. Fuse MRBF inserted into the stud on CFBAR

B. Insert the cable lug (crimped to one end of the Positive battery cable) onto the CFBAR stud so that it sits

over the fuse MRBF. See Fig. 6.

Fig. 8. Insulating Cap slid over the rectangular portion of CFBAR Fig. 9. CFBAR with tted fuse MRBF

E. Bolt the CFBAR to the Positive terminal stud of the Battery usually denoted by the ‘+’ sign as shown in Fig. 10.

Fig. 10. Installed arrangement

F. Please ensure that all the connections are tight.

Fig. 6. Fuse MRBF and cable lug inserted into the stud of the CFBAR

C. Insert the at washer, the spring washer and the M-8 nut on to the CFBAR stud and tighten the nut with a

½” wrench. See Fig. 7.

Fig. 7. Fuse MRBF and Positive cable xed to the CFBAR

32

Loading...

Loading...