Page 1

2 YEAR LIMITED WARRANTY

The CFB2-400 manufactured by Samlex America, Inc. (the “Warrantor“) is warranted to be

free from defects in workmanship and materials under normal use and service. The warranty period is 2 years for the United States and Canada, and is in effect from the date of

purchase by the user (the “Purchaser“).

Warranty outside of the United States and Canada is limited to 6 months. For a warranty

claim, the Purchaser should contact the place of purchase to obtain a Return Authorization Number.

The defective part or unit should be returned at the Purchaser’s expense to the authorized

location. A written statement describing the nature of the defect, the date of purchase,

the place of purchase, and the Purchaser’s name, address and telephone number should

also be included.

If upon the Warrantor’s examination, the defect proves to be the result of defective material or workmanship, the equipment will be repaired or replaced at the Warrantor’s option

without charge, and returned to the Purchaser at the Warrantor’s expense. (Contiguous

US and Canada only)

No refund of the purchase price will be granted to the Purchaser, unless the Warrantor is

unable to remedy the defect after having a reasonable number of opportunities to do so.

Warranty service shall be performed only by the Warrantor. Any attempt to remedy the

defect by anyone other than the Warrantor shall render this warranty void. There shall

be no warranty for defects or damages caused by faulty installation or hook-up, abuse or

misuse of the equipment including exposure to excessive heat, salt or fresh water spray, or

water immersion.

No other express warranty is hereby given and there are no warranties which extend

beyond those described herein. This warranty is expressly in lieu of any other expressed

or implied warranties, including any implied warranty of merchantability, tness for the

ordinary purposes for which such goods are used, or tness for a particular purpose, or

any other obligations on the part of the Warrantor or its employees and representatives.

There shall be no responsibility or liability whatsoever on the part of the Warrantor or

its employees and representatives for injury to any persons, or damage to person or

persons, or damage to property, or loss of income or prot, or any other consequential or

resulting damage which may be claimed to have been incurred through the use or sale of

the equipment, including any possible failure of malfunction of the equipment, or part

thereof. The Warrantor assumes no liability for incidental or consequential damages of

any kind.

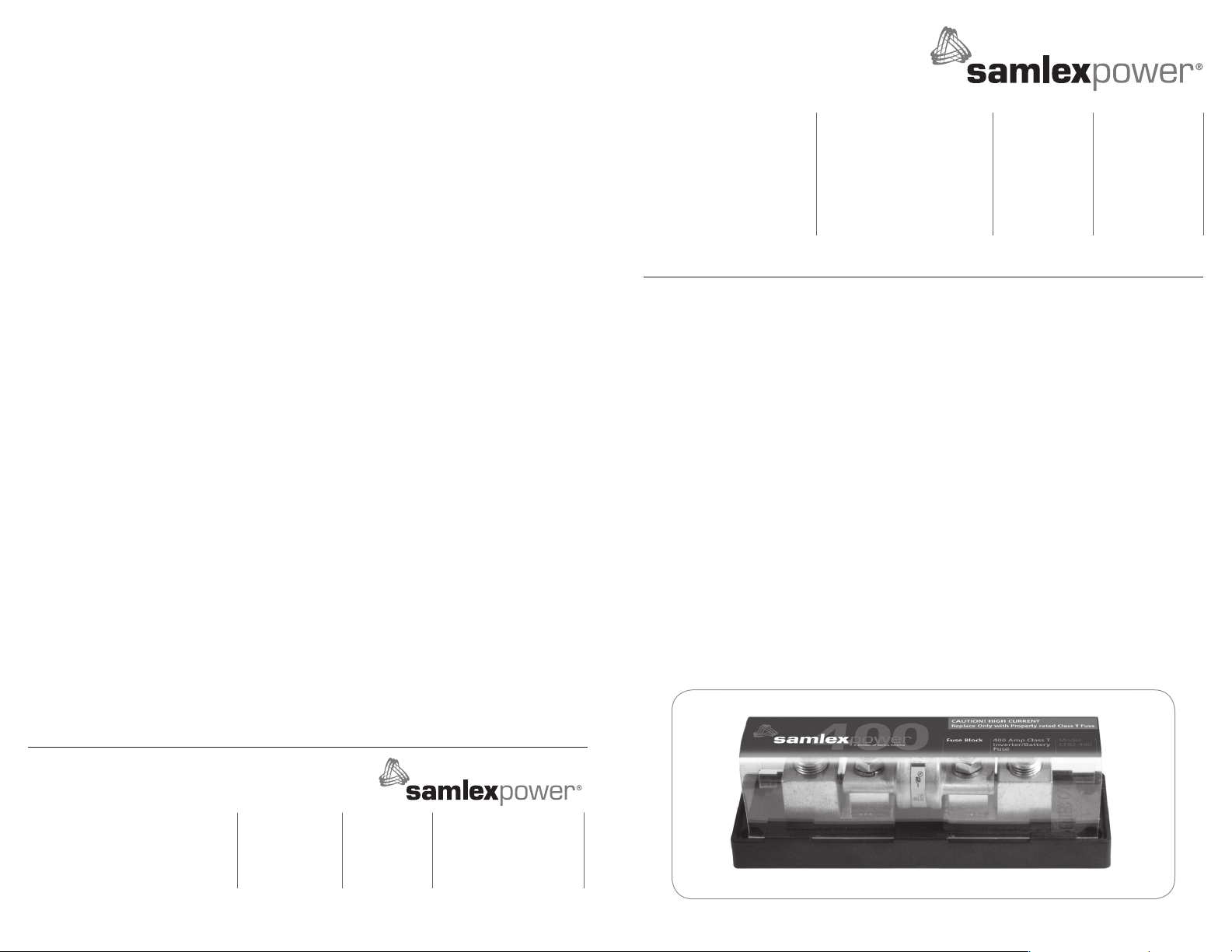

400 Amp, Class T

Fuse Block

Owner's

Manual

Please read this

manual before

installing your

fuse block

CFB2-400

INTRODUCTION

Fuse Protection in the Battery Circuit

A battery is an unlimited source of current. If there is a short circuit along the length of the

cables that connect the battery to the inverter, thousands of Amperes of current can ow

from the battery causing shorting: a section of the cable can overheat, the insulation can melt

and the cable can ultimately break. This interruption of high current can generate hazardous,

high temperature, high energy arc accompanied by a high pressure wave that may cause re,

damage to nearby objects or injury. To prevent the occurrence of such hazards under short

circuit conditions, an appropriate fuse should be used in the battery circuit with the required

current interrupting capacity (Termed AIC – Ampere Interrupting Capacity). For this purpose,

fuses with an AIC rating of 10000 A at 14 V / 5000 A at 32 V, or higher should be used.

CONsTRUCTION

The Class T Fuse Block (Fig. 1) contains the following components:

• Class T Fuse – Fig. 2: This is rated at 125 V, 400 A. It is UL Class “T” rated and UL listed as per UL

Standard 248-15. It has AIC (Ampere Interrupting Capacity) of 20,000 A.

• Fuse Holder – Fig. 3: This consists of a breglass insulated base with studs / bolts (5/16” diameter,

18 Threads Per Inch) and nut (requires ½” size wrench) for holding the fuse. The two terminals for

cable entry are designed for #4/0 cable (Hole size is 0.6” / 15.5 mm). Hexagonal headed socket screws

(requires Allen Key size 5/16”) are used to clamp the cable ends.

• Snap on cover: Is made of clear polycarbonate and provides touch safety.

Samlex America Inc. (the “Warrantor”)

www.samlexamerica.com

4

103 - 4268 Lozells Ave.

Burnaby, BC

Canada V5A 0C6

T: 604 525 3836

F: 604 525 5221

TF: 1 800 561 5885

e-mail: samlex@samlexsolar.com

website: www.samlexsolar.com

11013-CFB2-400-1112

MAN-10006

Fig. 1. Class “T” Fuse Assembly

1

Page 2

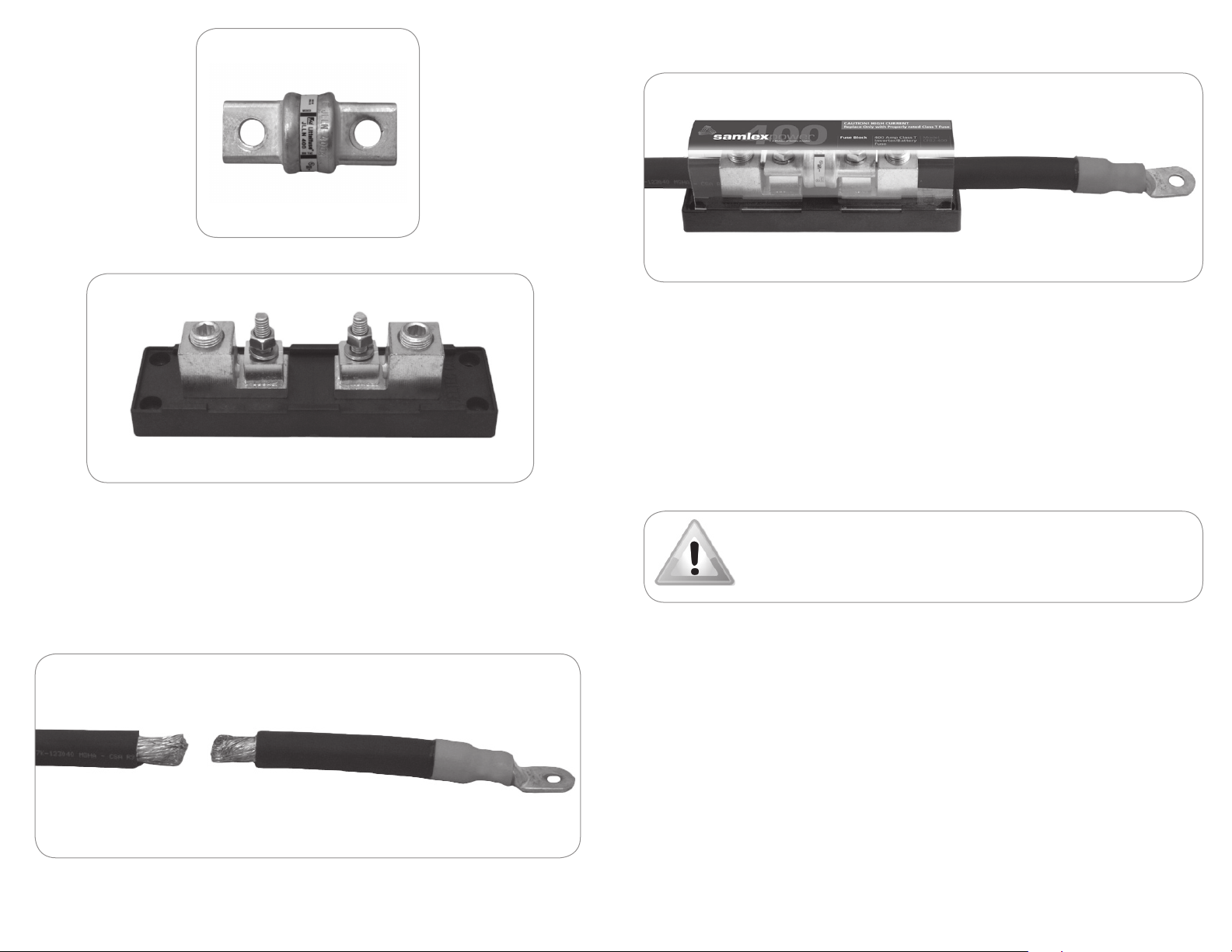

B. Insert the bare ends of the cable into the hole for the cable entry and tighten the screw down

terminals rmly. Attach the clear polycarbonate snap on cover for touch safety. See Fig. 5.

Replacement JLLN 400 Amp fuses are also sold separately. Samlex Model: JLLN-400

Fig. 2. Class “T” 400 Amp Fuse

Fig. 3. Fuse Holder

INsTallaTION

A. The fuse should be installed within 7 inches of the Positive Terminal of the battery. Cut the

Positive cable based on the desired location of the Class “T” Fuse Block using wire cutter. Strip

1.05” of the insulation at the cut ends using a stripper. Please ensure that the innermost layer of

the tape separator is completely removed. See Fig. 4.

Fig. 5. Fitted Class “T” Fuse Assembly

NOTE: The diameter of the hole in the screw down terminal for the cable entry is 0.6” and is

just big enough for the diameter of the bare AWG #4/0 stranded cable. It is likely that the ends

of the strands towards the cut face of the cable get bent / frayed / spread outwards during

cutting and thereby, the diameter of the cable near the cut face may increase slightly. Also, the

strands towards the cut face should be pressed together closely to reduce the diameter near

the cut face to less than 0.6”. To help keep the strands towards pressed together for easier

entry into the terminal, tightly warp insulation tape around 0.2” to 0.3” from the cut face. If

required, straighten and compress the bent / frayed / spread out ends to reduce the diameter to

the minimum. Now insert the leading 0.2” to 0.3” bare portion into the hole. Once this leading

portion has entered the hole, remove the insulating tape and insert the bare end of the cable

fully.

Please ensure that all the strands get inserted into the hole and that no

Caution!

strand(s) is left forced out of the hole.

Fig. 4. Battery end of Positive cable cut and prepared for inserting into the Class “T” Fuse Block

32

Loading...

Loading...