Index revision : A 1 7118

User manual

SAMES KREMLIN SAS - 13, Chemin de Malacher - 38240 MEYLAN - FRANCE

Tel. 33 (0)4 76 41 60 60 - www.sames-kremlin.com

Nanogun Airmix

®

H2O

GNM 6080

Index revision : A 2 7118

This document may not be disclosed or copied, in any form, and its content may not be used

or disclosed, without the explicit written authorisation of SAMES

KREMLIN.

The descriptions and characteristics contained in this document may be modified without prior

notice.

© SAMES KREMLIN 2017

WARNING : SAMES KREMLIN SAS has been declared as a training centre with the

Ministry of employment.

Our company organises training courses providing the indispensable know-how

for the installation and maintenance of our equipment all year long.

A catalogue is available on request. Select the training programme, type of

learning method and skills you need from our range, to meet your production

targets.

These training courses can be organised on the premises of your company or at

the training centre located at our head office in Meylan.

Training service:

Tel.: 33 (0)4 76 41 60 04

E-mail: formation-client@sames-kremlin.com

SAMES KREMLIN SAS has drafted this operating manual in French and mandated English, German, Spanish,

Italian and Portuguese translations.

The company declares reservations on all translations and refuses any liability with respect to these translated

documents.

Index revision : 3

Nanogun Airmix® H2O

GNM 6080

1. Product identification - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

1.1. Version identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.1. On the gun barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1.2. On the lower part of the gun handle . . . . . . . . . . . . . . . . . . . . 5

1.2. GNM 6080 control module . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Health and safety guidelines - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7

2.1. Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2. Installation rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3. Rules of use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.4. Maintenance rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.4.1. Products used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3. Description of spray gun and GNM 6080 control module- - - - - - 11

3.1. Functions available based on this gun . . . . . . . . . . . . . . . . 11

3.2. GNM 6080 control module . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4. Technical characteristics - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 14

4.1. General characteristics of the guns . . . . . . . . . . . . . . . . . . 14

4.2. Flows . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.3. Characteristics of the GNM 6080 . . . . . . . . . . . . . . . . . . . . 16

4.4. Characteristics of the compressed air . . . . . . . . . . . . . . . . 16

5. Operations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 17

6. Specific tooling- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 18

6.1. Use of the multipurpose wrench . . . . . . . . . . . . . . . . . . . . . 20

7. Installation- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 21

8. Use - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 22

8.1. Recommendations regarding the paint to be used . . . . 22

8.1.1. Viscosity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.1.2. Flash point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8.2. Spraying rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

9. Examples of poor equipment use- - - - - - - - - - - - - - - - - - - - - - - - 24

10. Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 25

10.1. Summary table of preventive maintenance . . . . . . . . . . 25

10.2. Electro-pneumatic link . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

10.3. Paint hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.4. Spraying head assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10.5. Replacement of the head electrode. . . . . . . . . . . . . . . . 29

10.6. Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

10.7. Paint nozzle needle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

10.8. Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

10.9. Trigger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Index revision : 4

10.10. Air valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

10.10.1. Repairing of the air valve. . . . . . . . . . . . . . . . . . . . . . . . . . . 36

10.11. Fastening hook . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

10.12. High-voltage cascade . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

10.13. Barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

10.14. Handle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

10.15. Electrical diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.15.1. GNM 6080 / Nanogun Airspray Airmix® H2O connection

cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

10.15.2. GNM 6080 trigger cord. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

11. Cleaning- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 42

11.1. Cleaning of the product circuit . . . . . . . . . . . . . . . . . . . . 42

11.2. Cleaning of the gun . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

11.3. Hollow cone nozzle cleaning . . . . . . . . . . . . . . . . . . . . . . 43

11.4. Elimination of wastes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

11.5. Dismantling and Recycling . . . . . . . . . . . . . . . . . . . . . . . . 45

11.5.1. Nanogun Airmix® H2O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

11.5.2. GNM 6080 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

12. Common malfunctions and repairs - - - - - - - - - - - - - - - - - - - - - 48

13. Spare parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 50

13.1. Nanogun Airmix® H2O guns for water-based paint (LR) 50

13.1.1. The nozzles as an option. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

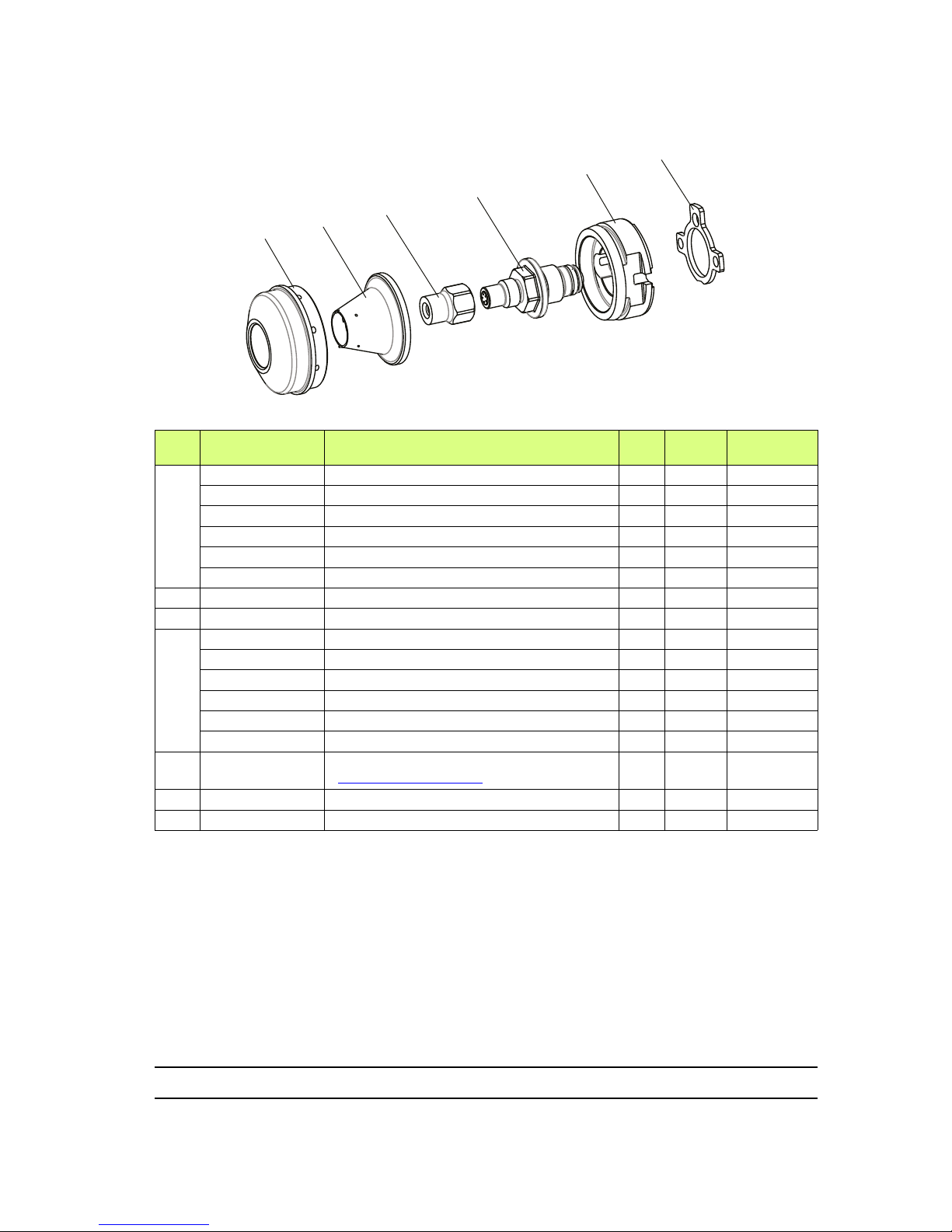

13.1.2. Fitted head ring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13.1.3. Fitted head. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

13.2. Nanogun Airmix® H2O gun . . . . . . . . . . . . . . . . . . . . . . . . . 54

13.3. Equipped seat casing (flat spray only) . . . . . . . . . . . . . . . 57

13.4. Equipped adapter (flat spray only) . . . . . . . . . . . . . . . . . 57

13.5. Equipped barrel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

13.6. Equipped air valve and air valve Nut . . . . . . . . . . . . . . . . 59

13.7. Equipped nozzle needle . . . . . . . . . . . . . . . . . . . . . . . . . . 60

13.8. Electro-pneumatic coupling . . . . . . . . . . . . . . . . . . . . . . . 60

13.9. Paint hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

13.10. Nanogun Airmix® H2O seal kit . . . . . . . . . . . . . . . . . . . . . 62

13.11. Hollow cone kit (not available for North American

market) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

13.11.1. Equipped hollow cone seat casing . . . . . . . . . . . . . . . . . . 64

13.11.2. Procedure for changing from a flat spray

to a round spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

13.12. GNM 6080 control module . . . . . . . . . . . . . . . . . . . . . . . . 66

13.13. Options for the Nanogun Airmix® H2O guns . . . . . . . . . 66

13.14. Appendices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.14.1. Hose protection casing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.14.2. Gun protective cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.14.3. Warning sign. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

13.14.4. Safety relief valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Index revision : A 5 7118

1. Product identification

The Nanogun Airmix® H2O gun markings will allow differentiating between the 120-bar and the

200-bar model configuration.

1.1. Version identification

1.1.1. On the gun barrel

The marking on the barrel is the same across the entire Nanogun Airmix® H2O range.

1.1.2. On the lower part of the gun handle

This marking combines, under a single number, the configurat ions of guns operating at the

same level of pressure generation.

Product pressure Versions of Nanogun Airmix® H2O

120 bar JP (flat spray)

200 bar JP (flat spray)

DES06782

Serial no.

Index revision : A 6 7118

1.2. GNM 6080 control module

The GNM 6080 control module has been installed outside of the “A TEX” zone.

Markings

Example: * 2014: Year of manufacturing

26: Week number

123: nth generator built during week 26.

WARNING : The Nanogun Airmix® H2O equipment are all compliant with the operational safety

standard (i.e. Standard EN13849, level SIL 1); maintaining this level of safety requires periodic

inspections of the equipment, at least once every 5 years or 15,000 hours of operations (which

ever comes first). This control step pertains to each of the electrical and electronic components

as well as to the set of very specific program(s); you should contact your subsidiary, distributor

or regular SAMES KREMLIN representative, who will inform you of the appropriate steps to

take.

DES05878

DES05879

Software version:

S/N:

EC marking

2014 26123 *

CSA marking

Software version:

S/N:

2014 26123 *

Index revision : A 7 7118

2. Health and safety guidelines

WARNING : This equipment may be hazardous if it is not used, disassembled and reassembled

in accordance with the rules indicated in this manual and in any applicable Euro

-

pean Standard or national safety regulations.

The warning sign summarising the safety rules (procedures and precautions) of the

present user’s manual must be placed in a visible location within the zone of the

coating product spraying station.

WARNING : The good working order of this equipment is only under warranty provided use of

original spare parts distributed by ”SAMES KREMLIN” company.

2.1. Regulations

The Nanogun Airmix® H2O gun must always be used under the set of conditions required by cur-

rent standards and rules as regards the application of paints and varnishes (see the Standards

and Directive EN 50.053 Directive, Part 1 ISO 12100, EN 1953 and 99/92/CE).

In Canada, the installation must comply with the Code "C22.1 Canadian Electrical Code, Part

I, Safety Standard for Electrical Installations

".

In the United States, the installation must comply with the Code "NFPA 70: National Electrical

Code

".

The Nanogun Airmix® H2O gun has been designed to operate within a 2nd-degree pollution

environment, as defined according to the Standard IEC-664-1.

2nd-degree pollution: Under normal use conditions, only non-conductive type pollution arises.

On a temporary basis, conduction caused by condensation may arise.

WARNING : Before using the Nanogun Airmix® H2O gun, be sure that all operators

• have received preliminary training by the SAMES KREMLIN, or by the Distributors it has

certified for this purpose.

• have read and understood the user’s manual as well as all installat ion and us e rules li sted

below.

It is incumbent upon the Operators’ Workshop Manager to ensure and verify that all operators

have read and understood the user’s manuals relative to peripheral electrical devices present

within the spraying perimeter.

2.2. Installation rules

• The hand-held electrostatic projection equipment can only be used in designated projection spots in accordance with Standard EN 12215 or under equivalent ventilation conditions.

• Install the equipment away from any explosive zone.

• Servo-control the control module start-up to the “on” position of the booth’s suction fan.

• Correctly connect the control module to the installation’s ground terminal.

• Connect the pump and the paint tank by means of an equipotential connection.

• Connect all metal parts of the installation (paint pumps, containers, stools, spin coaters,

etc.), which positioned within three meters of the gun to the ground.

• Keep the spray zone clean and free of all unnecessary components.

Index revision : A 8 7118

• The floor where the operator works must be antistatic (either unclad concrete flooring or

a metal grating). Never cover the floor with an insulating covering. In potentially explosive

locations, the floor assemblies must be antistatic, in accordance with Standard EN 613404-1.

• The use inside the booth of an uncovered flame, any incandescent object, a device or

object capable of generating sparks other than the gun is strictly prohibited.

It is also prohibited to store in the vicinity of the booth or in front of the doors flammable

products or containers in which such products had been stored.

• The jars and cans containing paint or solvent must be systematically closed after use.

• The paint feed pump used must be rated with a ratio suited to the type of gun, such as

19:1 for the 120 bar version and 30:1 for the200 bar version, and the pump’s air supply

must be equipped with a safety relief valve to limit pressure to a maximum value of 6.5 bar.

• Inside an explosive zone, it is prohibited to use electrical or non-electrical equipment that

has not been certified, like electrical extension cables, surge protector power bars,

switches, etc.

2.3. Rules of use

• Verify the extraction ventilation system efficiency on a daily basis.

• Once a week, verify the adequate operations of the ventilation system servo controls.

• Before starting to spray, be sure the gun contains a nozzle and a head, and moreover verify that the head ring, fitted with its so-called “duckbill” protection device, has been perfectly clamped.

• Correctly ground all metal parts of the booth, along with the parts to be p ainted. The

resistance relative to the ground must be less than or equal to 1M

Ω (for a 500-V voltage

measurement). This resistance must be regularly checked and, in any case, at least once

a week.

• The operator must wear antistatic shoes in accordance with Standard EN 61340-4-3 and

moreover hold the Nanogun Airmix

®

H2O gun either with a bare hand or with antistatic

gloves or gloves modified so as to establish a direct contact between the handle and his/

her hand. The shoes intended to be worn by the operator mu st be compliant with Stand

-

ard ISO 20344. The measured insulation resistance must not exceed 100MΩ

• The protective clothing intended to be worn, including gloves, must be compliant with

Standard EN 1149-5. The measured insulation resistance must not exceed 100M

Ω

• The operator must also wear ear defenders when using the guns Nanogun Airmix® H2O

(

see § 4 page 14).

• Ensure that anyone entering the spray zone is wearing the antistatic shoes or has been

grounded by any other means.

• Never throw or intentionally allow the electrostatic gun to fall. A gun drop could damage

the high-voltage generator. After a fall, it is advised to verify the good working order of

the gun outside of the zone before its subsequent reuse.

• Never point the gun in the direction of another person.

• Verify the gun at least once a week.

• Refrain from using the equipment in the following cases:

1 If an air leak is observed around the gun when the trigger is released;

2 If the gun’s e lectrical connector is not being securely held in pl ace by means of the

two safety screws;

3 If the gun barrel and handle show signs of a shock capable of altering the seal on the

gun’s internal parts.

• The manual electrostatic projection device can only be operated if it is in perfect condition. Any damaged equipment must be immediately removed from active service and

repaired.

Worn parts must be immediately replaced.

• Only use paints whose flash point is at least 15°C higher than room temperature.

• Closely follow use guidelines for the paints and solvents being applied (e.g. wear a mask).

• Close and purge both the air and paint inlet prior to any extended equipment downtime.

Index revision : A 9 7118

• Verify the good working order of the paint hose prior to any equipment start-up.

• The electro-pneumatic coupling connector, secured by means of two screws, MUST NEVER

BE DISCONNECTED WHILE IN AN EXPLOSIVE ATMOSPHERE.

• Use of the equipment must imperatively cease if any of the following elements

barrel, handle, electro-pneumatic coupling, head or head ring is damaged.

2.4. Maintenance rules

• Regularly maintain and repair the electrostatic projection equipment according to the

instructions contained in this user’s manual.

• Only use metal containers to hold the cleaning li quids and conn ect to ground according

to a safe procedure.

• Before any maintenance procedure:

1 Turn off the control module.

2 Verify that the air and paint circuits are no longer pressurised.

3 Dump the paint circuit.

4 All energy sources must be locked out.

• Clean the gun either in their dedicated spots with mechanical ventilation or by using

cleaning liquids with a flash point at least 15°C higher than ambient temperature.

• Opt to use non-flammable cleaning products.

• Do not restore electrical power supply as long as the head and nozzl e have not been correctly remounted onto the gun.

• Never soak or immerse the gun in the solvent. The operator is able, as needed, to use a

cloth soaking in solvent in order to clean the gun and then immediately dry it to avoid sol

-

vent from entering the gun.

WARNING : Never spray solvent when the control module is turned on and/or when the switch

placed at the back of the gun is in the “I” position.

WARNING : Shutting off the compressed air supply line does not prohibit triggering high voltage

should the trigger be activated.

• The operator must have been trained by a SAMES KREMLIN company or else by the

Distributors it has certified for this purpose, in order to carry out the Nanogun Airmix

®

H2O.

gun maintenance operations.

WARNING : It is strictly prohibited to use solvents derived from halogenated hydrocarbons as

well as products containing these solvents in the presence of aluminium or zinc.

Failure to comply with these guidelines exposes the user to the risks of explosion.

Index revision : A 10 7118

2.4.1. Products used

Given the diversity of products used and the impossibility to inventory the characteristics of

these products, SAMES KREMLIN cannot be held liable for:

• for any incompatibility in the materials of products used whenever they come into contact with the materials listed below:

• Stainless steel

• Fluoro-Ethylene-Propylene (FEP)

• Polyamide Imide (PAI)

• Polyoxymethylene (POM)

• Tungsten carbide and tungsten

• PTFE elastomer

• Polypropylene

•IXEF

• Glass fibre

•Ceramic

•Aluminium

•Titanium

• PEEK

•PEHD and PEBD

• prefluorinated rubber

• Risks related to the use of these products on both personnel and the environment.

• Wear, misalignment, equipment or machine malfunction as well as subpar quality of the

application caused by use of these products.

Index revision : A 11 7118

3. Description of spray gun and GNM 6080 control module

The Nanogun Airmix® H2O guns are for spraying water-soluble or water-dilutable water-based

paint.

Sprayed liquids must be non-flammable (defined in the draft standard pr EN 50059:2016 Annex

C) and strongly conductive.

The use of any other type of paint is excluded.

The Nanogun Airmix® H2O guns will be connected to the GNM 6080 control module.

The versions of the Nanogun Airmix® H2O range are differentiated by the permissible product

pressure product and by the calibre of the insert.

3.1. Functions available based on this gun

• The switch (Rep. 1) allows turning on or off the high voltage supply.

When this switch is placed in position " I ", activating the trigger turns on the high voltage.

When this switch is placed in position " 0 ", activating the trigger does not turn on the high

voltage.

WARNING :

• The knob in back of the gun (Rep. 2) must always be held in place (clockwise); it does not

influence the paint flow rate.

• The side detented knob (Rep. 3) serves to adjust the spray dimension. Its action will

become even weaker as product pressure rises.

Characteristics

Nanogun Airmix® H2O 120 7.5

Flat spray - 120 bar hose 7.5 m

Nanogun Airmix® H2O 200 7.5

Flat spray - 200 bar hose 7.5 m

1

2

3

Index revision : A 12 7118

3.2. GNM 6080 control module

The GNM 6080 control module serves to display the use parameters along with their settings.

Temperature default: The temperature default forces the indicator lights (Rep. 11

and 12). Once the temperature drops below the minimum, the temperature indica

tor light (Rep. 11) shuts off, and the operator has the option of deletin g the default

by pressing the “Default Acknowledgement” button (Rep. 3).

Generator default: This default combines all internal generator defaults. If it is impossible to acknowledge this default, the problem would require a service call by the

repairs department, please contact SAMES KREMLIN.

1 Maintenance indicator light

2 High voltage default indicator light

3 Acknowledgement of defaults

4 Display of the voltage set point

5 Increase of the voltage set point

6 Bar graph of current consumption

7 Active, preset memory indicator lights

8 Selection of the active memory

9 Voltage bar graph

10 Decrease in the voltage set point

11 Temperature default indicator light

12 Generator default indicator light

13 Low-voltage cable default indicator light

Front side of the GNM 6080 control module

12

4

3

5

6

7

8

9

10

11

12 13

Index revision : A 13 7118

Low-voltage connection default: The generator fails to detect or no longer detects

the presence of the gun. After shutting off the power supp ly, verify the gun/genera

-

tor connection.

High-voltage default: Defaults specific to gun operations related to the high voltage:

• Generator service start-up with the trigger activated.

• Demand for a abrupt current surge during high-voltage operations.

• Defective operations of the high-voltage cascade.

Maintenance indicator light: This indicator light turns on (orange) once the trigger

has been pulled 800,000 times or after 1,000 hours of gun operations (

see § 10.1 page

25).

This indicator light in the on position notifies that the gun is in need of a maintenance

visit. No specific maintenance on the GNM 6080 module.

The generator is capable of managing up to 20 different guns.

12 Gun cable connector

13 Connector for external cabling

14 On/off switch

15 Power supply

16 Ground connector

17 Pressure balancing membrane

18 Diagnostic outlet (mini USB type)

Side face of the GNM 6080 control module

12

13

15

14

161718

Index revision : A 14 7118

4. Technical characteristics

4.1. General characteristics of the guns

120 200

Type of spray

Flat

Original head assembled

09

Maximum incoming paint pressure

120 bar 200 bar

Incoming compressed air pressure 6 bar ± 1 bar

Min/max ambient temperature 0°C - 40°C

Maximum water flow rate See table below

Spray width at 25 cm See table below

Air flow rate, in Nm3/h

10.3-25.2

Acoustic pressure

90 dB(A)

AFNOR Cup No. 4 suggested paint viscosity

20 s to 120 s

Space requirements 305 x 220 x 52

Mass (without either the hose or the cable) 595 g

Output voltage 60 kV maximum [+0 kV; -1.5 kV] (adjustable on GNM 6080)

Output current 80 μA maximum

Output current in a short-circuit < 20 μA

Input voltage of the high-voltage cascade 45 V AC maximum

Input current of the high-voltage cascade 300 mA maximum

Air coupling 1/4 NPS - F

Paint coupling 1/2 JIC - F

Electrical functions available on the gun

High-voltage On / Off switch

Electrical / pneumatic connector

The electro-pneumatic connector, secured by means of two screws.

MUST NEVER BE DISCONNECTED IN AN EXPLOSIVE

ATMOSPHERE

Maximum operating altitude

2,000 m

Maximum relative humidity of 80% for

temperatures of up to 31°C, then linear

decrease until 50% relative humidity at

40°C

Maximum of 80% without condensation

Surface temperature T6

Protection index IP 20

Transport / Storage

Time spent in storage Max. 2 years

Min/max storage temperature -10°C + 45°C

Humidity 95% without condensation

Min. pressure 750 mbar

Exposure to UV rays Stored out of direct light

Exposure to ionising radiation Not accepted

Index revision : A 15 7118

4.2. Flows

Flat spray

Remarks: The flow rate measurements were conducted with water. The width of the impact is

measured at a distance of 25 cm (10 inches).

Hollow cone round spray

Note: The hollow cone only gives good results at high product pressures; we do not recommend

working below 140 bars. The best results are obtained between 160 and 200 bars.

Gauge

Flow rate (in cc/min) Width, in

cm

at 70 bar at 120 bar at 200 bar

03-05 150 200 260 12

03-07 150 200 260 17

04-05 220 290 380 12

04-07 220 290 380 17

04-09 220 290 380 21

04-11 220 290 380 25

04-13 220 290 380 29

06-09 330 430 570 21

06-11 330 430 570 25

06-13 330 430 570 29

06-15 330 430 570 33

09-09 450 590 770 21

09-11 450 590 770 25

09-13 450 590 770 29

09-15 450 590 770 33

12-11 600 790 1030 25

12-13 600 790 1030 29

12-15 600 790 1030 33

14-09 720 940 1230 21

14-11 720 940 1230 25

14-13 720 940 1230 29

14-15 720 940 1230 33

14-17 720 940 1230 37

Gauge Flow (cc/min)

Impact diameter

at 250 mm in cm

Impact diameter

at 250 mm in cm

Dynamic air

pressure

Nanogun 120 bar

Spraying air

4 bars

Nanogun 200 bar

Spraying air

4 bars

Dynamic

product pressure

120 140 200 140 200

K20 250 260 330 100 110

K30 320 350 420 110 120

K40 400 440 540 110 120

K50 580 600 780 120 130

K60 900 1000 1200 120 130

K70 900 1000 1200 120 130

Index revision : A 16 7118

Note: The spraying air pressure must be set between 2 and 3 bars (4 for the K70 gauges); below

this, the spraying becomes less precise and above the jet becomes more dynamic and the hol

-

low cone's benefits are reduced.

4.3. Characteristics of the GNM 6080

Category II installation (in accordance with Standard EN 61010-1).

WARNING : The GNM 6080 automatically adapts to the power supply voltage.

4.4. Characteristics of the compressed air

Required characteristics of the compressed air supply according to Standard NF ISO 8573-1

(*): The values are given for a temperature of 20°C (68°F) at atmospheric pressure.

General

Mass 1.7 kg

Space requirements

Diameter: 168 mm

Height: 91 mm

Operating temperature 0 - 40°C

GNM 6080 input

Voltage 88 - 264 V AC

Frequency 50 - 60 Hz

Maximum current 0.25 A

Maximum power 25 V.A

GNM 6080 output

Voltage 40 V RMS

Current 200 mA RMS

Characteristics Value

Maximum dew point at 6 bar (87 psi) Category 4, i.e. +3°C (37° F)

Maximum particle size distribution of the

solid pollutants

Category 3 i.e. 5 μm

Maximum oil concentration

Category 1 i.e. 0.01mg / m

0

3

*

Maximum concentration of solid pollutants

5 mg / m

0

3

*

Index revision : A 17 7118

5. Operations

Pressing the trigger serves to delay the order to open the air valv e, then activ ation of the hi gh

voltage, and lastly the paint nozzle needle. The high-voltage order may be inhibited by shifting

the gun switch.

The Nanogun Airmix® H2O gun is equipped with a magnetic sensor that detects the trigger position. This sensor serves to activate the high-voltage power supply once the air valve returns to

a value lying between 1 and 1.8 mm.

WARNING : The button located in back of the gun does not serve to adjust the paint flow rate;

nonetheless, it is possible to adjust it by modifying the nozzle calibre and/or the

incoming product pressure.

• The side button serves to adjust the spray dimension within a range that narrows as the

product pressure increases.

• Clamped screw: large impact.

• Loosened screw: reduced impact.

Note: The higher the pressure of the product, the less the button on the side can vary the size

of the spray.

• In order to modify the spray dimension, it is necessary to change the nozzle.

Index revision : A 18 7118

6. Specific tooling

Part Number Description Qty Sales unit

900012843 Multipurpose wrench 1 1

Part Number Description Qty Sales unit

H1GMIN017 White Vaseline (100 ml) 1 1

H1GSYN037

Dielectric grease for the high-voltage cascade and

nozzle needle channel (100 ml)

1 1

Part Number Description Qty Sales unit

900010160 Cartridge and air valve assembly tool 1 1

Part Number Description Qty Sales unit

240000301 Seal extractor tool 1 1

Part Number Description Qty Sales unit

129400923 Air cap cleaning brush 1 10

DES06505

Index revision : A 19 7118

Other necessary tools and accessories:

It is recommended to possess the tools listed below to install and maintain the product.

• Flat-head screwdriver (2.5 x 75; 4 x 100, 5, 5 x 100)

• Crosspoint screwdriver(0 x 75; 2 x 125)

• Allen wrenches (3 - 6 mm)

• Torque wrench 1 to 5 Nm (R.304DA Facom) (Ref. SAMES KREMLIN: 240000095)

• Flat wrenches (5 - 5.5 - 11 - 15 - 17 - 18 - 21 - 24 - 27)

• Pipe wrench (4 - 13)

• Flat pliers

• Fine cutting pliers.

• Ohmmeter

Part Number Description Qty Sales unit

900016773 Supply pad removal tool (hollow cone) 1 10

Part Number Description Qty Sales unit

900016975 Rapid injector rinsing tool (hollow cone) 1 10

Part Number Description Qty Sales unit

000094000 Unplugging needles for gauges 04 through 09 1 1 box (12)

000094002 Unplugging needles for gauges above 09 1 1 box (12)

DES06974

DES06973

Index revision : A 20 7118

6.1. Use of the multipurpose wrench

1 : Clamping of the head ring.

2 : Extraction of the head nozzle.

DES06769

1

DES06505

2

Index revision : A 21 7118

7. Installation

WARNING : Before proceeding with any operation, please refer to the installation rules (see §

2.2 page 7).

With a piston pump for all versions

The paint intake must be installed within a ventilated zone.

The tank of paint must be a conductor and a capacity ≤ 30 liters (8 US gal).

The dump hose end must be immersed in the paint.

WARNING : The paint supply pump:

• must feature a maximum ratio of 19:1 for the 120-bar version and of 30:1 for the

200-bar version;

• and the pump’s air inflow must be equipped with a safety relief valve to limit

pressure to a maximum value of 6.5 bar.

1

Nanogun Airmix H2O gun

2 GNM 6080 control module

3 Piston pump

4 Insulating cabinet

5 Short circuiter

2

3

4

5

DES06789

1

Cab

Index revision : A 22 7118

8. Use

8.1. Recommendations regarding the paint to be used

In general, all the paints and varnishes used with conventional pneumatic guns are used normally with the Nanogun Airmix® H2O gun. the pigments contained in the paint should be less

than 5

μm.

8.1.1. Viscosity

The best results are obtained with a visc osity th at extends from 25 to 90 seconds, as measured

with the AFNOR Cup no. 4. Nonetheless, some paints with a lowe r or higher viscosity (e.g. 120

seconds or more) may be projected as well.

8.1.2. Flash point

Only use paints whose flash point is at least 15°C higher than room temperature.

Index revision : A 23 7118

8.2. Spraying rules

Regardless of the type of nozzle, the quality of spraying depends on both the supply pressure

and the product viscosity: as viscosity increases, pressure must also rise, yet the final outcome is

also influenced by the product’s dilution.

A few key points:

• Viscosity: 40 sec CA4: minimum product pressure of 70 bar.

• Viscosity: 60 sec CA4: minimum product pressure of 90 bar.

• Viscosity: 90 sec CA4: minimum product pressure of 130 bar.

The addition of more air serves to reduce the impact width by 25% at a 120-bar pressure; moreover, the higher the product pressure, th e smaller the influence being exerted by the additional

air. In order to limit the production of overspray, it is recommended to never exceed an air pres

sure of 4 bar.

Using the nozzles with small impact width (XX-09 or 11), whenever the additional air is open, the

jet is practically round.

Table of impact widths in water at a gun/part distance of 25 cm (closed to any additional air).

Nozzles Impact width

03-05

12 cm

04-05

03-07

17 cm

04-07

04-09

21 cm

06-09

09-09

12-09

14-09

04-11

25 cm

06-11

09-11

12-11

14-11

04-13

29 cm

06-13

09-13

12-13

14-13

06-15

33 cm

09-15

12-15

14-15

14-17 37 cm

Index revision : A 24 7118

9. Examples of poor equipment use

The non-exhaustive list below indicates the primary cases of poor paint spraying equipment

use.

WARNING : SAMES KREMLIN would like to recall therefore that it is essential to comply with

the prescriptions listed below.

It is prohibited to install the control module in an explosive atmosphere.

It is prohibited to perform excessive and repeated traction on the paint and air hose or on

the electrical cable connecting the gun.

It is prohibited to disconnect the gun’s electrical coupling in an explosive atmosphere.

It is prohibited to leave the hoses and electrical cable in a space where vehicles circulate,

preventing the risk of them being crushed or severed.

It is prohibited to spray a liquid other than paint or varnish using the Nanogun Airmix®H2O

It is prohibited to leave the gun or subject it to mechanical shocks.

It is prohibited to leave the gun on the floor.

It is prohibited to use the gun in order to handle or displace the parts to be painted.

It is prohibited to let the gun soak in a solvent or spray it with solvent.

It is prohibited to spray solvent without first having turned off the control module and/or shut

down the high voltage at the level of the gun.

It is essential to connect the control module ground terminal to the paint insulation ground

terminal.

It is essential to clamp both safety screws on the electrical coupling.

Index revision : A 25 7118

10. Maintenance

10.1. Summary table of preventive maintenance

To be carried out when the maintenance indicator light on the GNM 6080 turns on.

WARNING : (*) Once either of these two time periods has elapsed.

Subassembly Description

Part

Number

Qty

Minimum

replacement

period

Seat casing

O-ring - chemically inert J3STKL046 1 3 months

O-ring - chemically inert J3STKL075 1 3 months

Adapter

Flat seal 900014821 1 6 months

O-ring - FEP Viton J2FENV288 1 12 months

Barrel

Seal cartridge 910015881 1

6 months or

500,000 handling

operations(*)

O-ring (Seal cartridge) J3STKL005 1 3 months

O-ring - chemically inert J3STKL014 1 6 months

O-ring - FEP Viton J2FENV435 1 12 months

O-ring - chemically inert J3STKL078 2 12 months

O-ring - chemically inert J3STKL032 1 12 months

O-ring - chemically inert J3STKL019 1 12 months

Handle

O-ring (electrical connector) 160000041 1 12 months

O-ring (handle base) 160000067 1 12 months

O-ring (air nipple)

J2FTCF018 1 12 months

J3STKL018 1 12 months

Air valve

O-ring - chemically inert (exterior

valve)

J3STKL005 1 12 months

O-ring - chemically inert (interior

valve)

J3STKL032 1 12 months

Seal ring 900010256 1 12 months

Nozzle

Sieve or flat seal depending on the

calibre

129609901

or

900012793

1

When

changing the

nozzle or every

month

Head ring O-ring - FEP Viton 160000170 1 12 months

Index revision : A 26 7118

WARNING : Prior to any maintenance operation carried out on the gun, please refer to the

health and safety instructions (

see § 2 page 7):

- Turn off the the control module.

- Verify that the air and paint circuits are no longer pressurised.

- Dump the paint circuit.

10.2. Electro-pneumatic link

• Step 1: Disassemble the low-voltage cable

using a 3 Allen wrench, unscrew the two cap

tive screws of the electro-pneumatic coupling.

• Step 2: Disconnect the electro-pneumatic

coupling by pulling on it.

Step 1

Step 2

Index revision : A 27 7118

10.3. Paint hoses

It is not necessary to remove the electro-pneumatic coupling (see § 10.2 page 26) to complete

these operations.

• Step 1: Unscrew the locknut of the cable

gland using a 27 flat wrench, remove the

cable gland from the bracket.

• Step 2: With a 21 flat wrench, unscrew the

upper nut on the paint hose. Unscrew the nut

while turning the hose.

For the reassembly step, screw the upper nut on the paint hose until re aching its stop point.

Position the locknut of the cable gland below the bracket, with the cable gland above in the

hexagonal imprint. Clamp the locknut of the cable gland onto the bracket.

Step 1

Step 2

Index revision : A 28 7118

10.4. Spraying head assembly

• Step 1: with the multipurpose wrench (Ref.:

900012843), unscrew the head ring.

• Step 2: Extract the head nozzle using the multipurpose wrench.

Do not use your fingers.

If necessary, replace the head seal.

For the reassembly step, proceed in the reverse order.

Step 1

Step 2

Index revision : A 29 7118

10.5. Replacement of the head electrode.

Disassembly:

• Step 1: Extract the conductive PTFE washer.

Insert the blade of the screwdriver under

the washer through one of the two slots at

the rear of the head(do not use the

housing where the centering pin is

located).

Make a slight rotating movement with the

screwdriver and proceed in the same man

ner with the second slot.

Remove the washer by hand.

The rear part of the electrode is visible.

• Step 2: Straighten the electrode vertically

with the flat nose pliers.

• Step 3: Push the electrode toward the rear

of the head.

When the electrode is sufficiently out,

extract it from the rear with the flat nose

pliers.

Index revision : A 30 7118

• Step 4: With the flat nose pliers, remove the

small PTFE tube surrounding the electrode.

Check that there are no residues in the passage of the electrode. If necessary, manually push a drill bit or a metal rod of 1 mm in

the hole.

Reassembly:

The repair kit includes an electrode equipped

with its small PTFE tube.

• Step 1: Manually clean, if necessary with

caution, the passage of the electrode with

a drill bit or a metal rod of 1 mm in diame

-

ter.

• Step 2: Insert the electrode with the PTFE

tube. As soon as it appears on the other

side of the head, pull it out with your fingers.

Then push it up to the bottom of the

housing using the screwdriver, and the

return strand of the electrode must go

back into a small bore, with only the rear

part of the electrode being flush with the

bottom of the counterbore.

Index revision : A 31 7118

• Step 3: Clip the conductive PTFE washer.

Replace it if necessary. It is recommended

not to reuse the washer more than 3 to 4

times, and it must not be able to be

removed without the aid of a tool.

• Step 4: Check the continuity between the

PTFE conductive washer and the metal tip

of the electrode. The value usually meas

ured is of the order of 200 to 300 Ω but a

value up to 1000

Ω is permissible.

• Step 5: Fold the electrode with the flat nose

pliers and fold it over to a length of about 5

mm.

WARNING : The small PTFE tube must not hide the

end of the electrode, so fold it over if necessary.

However, the metal end may be a little

uncovered (less than 1mm).

WARNING : The electrode must not be in contact

with the injector when the head is mounted on

the gun.

Checking

continuity

Index revision : A 32 7118

10.6. Barrel

• Step 1: Unscrew the seat casing using a 13mm pipe wrench.

Then remove it.

Should the O-rings and anti-extrusion rings

located in front and back of the nozzle

require replacement, remove them using a

screwdriver, position the new rings and new

seals in place while double checking their

correct location and after coating them first

with Vaseline.

• Step 2: Seal cartridge: Unscrew the cartridge

using the tool (Ref.: 900010160).

Should the ring and external joint require

replacement, remove them using a screw

driver, position the new ring and new seal in

place while double checking their correct

location and coating them with Vaseline in

advance.

Note: The lip seals located inside the cartridge cannot be changed.

Step 1

Step 2

O-ring

Ring

Anti-extrusion

Rings

Anti-extrusion

O-ring

O-ring

Index revision : A 33 7118

• Step 3: Manually remove the adapter

equipped with its O-ring and high-voltage

resistance by its spring and pulling on it.

WARNING : Be careful not to damage the

resistance during its extraction.

10.7. Paint nozzle needle

• Step 1: Unscrew the knob at the back of the

gun, and recover the spring.

• Step 2: Press on the trigger and pull it manually towards the back of the paint nozzle

needle.

WARNING : After every 4 or 5 reassemblies, add some dielectric grease (Ref.: H1GSYN037)

within the open channel in the barrel.

Step 3

Step 1

Step 2

Index revision : A 34 7118

10.8. Switch

• Step 1: With a 5.5-mm screwdriver, unscrew

the washer head screw. Pull the switch lever

upward.

• Step 2: Replace the O-ring (see § 13.2 page

54). Insert the new switch into its housing.

Coat the retaining screw with LOCTITE low

strength thread lock and then clamp the

screw so that the switch shows slight resist

-

ance.

10.9. Trigger

• Step 1: Using a screwdriver, unscrew the two

washer head screws and remove both sides

of the trigger.

Reassembly of the trigger:

• Insert one of the trigger sides onto its shoulder

and then slide the other side into its housing.

Step 1

Step 2

Step 1

Index revision : A 35 7118

10.10. Air valve

• Step 1: Disassemble the paint nozzle needle

(

see § 10.7 page 33).

• Step 2: Unscrew the air valve stop nut using

an 18 flat wrench.

Point the gun barrel upwards and recover

the spring and air valve. Should the parts not

fall, tap in the palm of your hand

or use the paint nozzle needle to withdraw

the air valve.

Step 2

Index revision : A 36 7118

10.10.1. Repairing of the air valve

Three levels of maintenance are possible:

• Level 1: Standard level of maintenance since the air valve body is not subject to any fric tion or wear.

• Level 2: Corrective level, to be performed in case the valve body has deteriorated.

• Level 3: Exceptional level, to only be performed in case the magnet gets lost or broken.

Level 1: Replacement of the three O-ring (P/N#

J3STKL032 interior O-ring, J3STKL005 exterior O-ring

and 900010256 conic sealant joint.

• For all three O-rings, extract the former one in

taking care not to damage the air valve

body (they may however be destroyed).

• The conic sealant joint must be pushed down

into its locking mechanism on the valve body

in being sure not to alter its conic range.

Level 2: If the air valve body (black part) has deteriorated.

• Manually extract or insert an M4 screw into

the aluminium ring (activating the locking

mechanism), pull along the axis of the part,

remove the magnet in paying attention to

identify its direction (silver-plated / black

sides).

• Raise the magnet in the right direction (see §

10.10.1.1 page 37) and lock the ring into the valve body by pushing firmly with your finger.

Once the gun has been completely reassembled, inspect the high-voltage activation and shutdown. If the high-voltage is permanently activated or does not turn off: verify the magnet direc

-

tion.

Index revision : A 37 7118

Level 3: If the magnet is broken or lost.

• Replace the complete air valve (Ref.: 910015405) (see § 10.10 page 35).

Before using the gun, inspect the high-voltage on and off switches.

If the high-voltage is permanently activated, disassemble the handle and remove one of the

washers that serve to adjust the reed sensor position; proceed step by step without removing

multiple washers at a time.

If the high-voltage does not activate, don’t disassemble the handle and instead add a washer

to adjust the reed sensor position; proceed step-by-step without adding multiple washers at the

same time.

WARNING : Various washer thicknesses may be installed, always begin by adding or removing

the thinnest.

10.10.1.1. Magnet assembly direction

• Case no. 1: For guns of type 1 (see serial no.). Back stop without a marking, the sliverplated side of the magnet must make contact with the shoulder of the back stop.

• Case No. 2: For guns of type 2 (see serial no.). Back stop with markings, the black side of

the magnet must make contact with the shoulder of the back stop.

10.11. Fastening hook

• Place the switch in the “I” position. Using a 5.5mm screwdriver, unscrew the washer head

screw and remove the hook by pulling

upward.

Index revision : A 38 7118

10.12. High-voltage cascade

• Step 1: Remove the trigger see § 10.9 page 34, and remove the paint nozzle needle.

• Step 2: Unscrew the 4 screws using a 2-mm

crosspoint screwdriver while holding the bar

rel on the handle.

Note: Each time a screw is disassembled,

replace the fibre washers as well (Ref.:

J4BRND039).

• Step 3: Manually unscrew or by using a small

flat pliers the three cascade connection

wires, then carefully pull the contacts

towards the back.

• Step 4: Unscrew the high-voltage contact in

front of the barrel with a flat screwdriver.

Extract the cascade.

WARNING : Be mindful of the colours used (termi-

nal 1: black; terminal 2: green; terminal 3:

pink).

For the reassembly step, proceed in the reverse order.

Replace the high-voltage cascade. Coat the cascade with some dielectric grease (Ref.:

H1GSYN037) and then place it in its housing.

Push the cascade until its stop in the barrel. Connect the three wires and clamp all three. Verify

the condition of the O-rings, replace them as needed.

Step 3

Step 4

Step 2

1

2

3

Index revision : A 39 7118

10.13. Barrel

• Step 1: Remove the trigger see § 10.9 page 34, and the paint nozzle needle.

• Step 2: Unscrew the four screws used to fasten the barrel onto the handle.

• Step 3: Manually unscrew or by using a small flat pliers the three cascade connection

wires, then carefully pull the contacts towards the back.

• Step 4: Replacement of the O-rings of both

air channels and the air valve (step 3: not

required): Remove and replace the three O-

rings.

• Step 5: Replacement of the barrel/handle O-

ring (step 3: mandatory): Remove and

replace the O-ring.

This seal is to be replaced every year.

• Step 6: Replacement of an O-ring in back of

the nozzle needle: Remove and replace the

O-ring.

WARNING : Coat the O-rings with a fine layer of Vaseline before setting them into place.

For the reassembly step, proceed in the reverse order.

Step 4

Step 5

Step 6

Index revision : A 40 7118

10.14. Handle

• Step 1: Separate the barrel from the handle.

• Step 2: Gun handle base

Unscrew the air nipple using a 16 Allen

wrench. Replace the seals every 12

months.

• Step 3: Unscrew the two screws (K35 x 14)

with a 2 crosspoint screwdriver. Upon each

screw removal, replace the fibre washers.

• Step 4: Raise the base in order to gain

access to the handle base joint. Replace

this joint every 12 months.

• Step 5: Remove the electrical connector

by pushing it to a point where the base

exits.

Replace the connector joint every 12

months.

• Step 6: Replacement of the base: unscrew

the ground wire screw using a 0 crosspoint

screwdriver, remove it and replace it.

For the reassembly step, proceed in the reverse

order. Replace the pin of the connector in the

base polarising slot and re-screw the ground connection.

Coat the air nipple seals with dielectric grease.

Tighten the air nipple with 1.5 N.m of torque. Tighten the two screws (K35 x 14) with a 1.3 N.m

tightening torque.

Step 2

Step 3

Step 4

Step 6

Index revision : A 41 7118

10.15. Electrical diagrams

10.15.1. GNM 6080 / Nanogun Airspray Airmix® H2O connection cable

10.15.2. GNM 6080 trigger cord

(*)

Switch open: Nanogun Airmix® H2O trigger released

Switch closed: Nanogun Airmix® H2O trigger activated.

Characteristics of the dry contact: 0.5 A max / 24 V AC/DC max.

A Pink Primary transformer UHT 3

B Shield Shield

C White REED sensor (trigger)

D Yellow Dallas chip

E Brown 0 V joint chip / reed

F Third-party shield

G Green Primary transformer UHT 2

H Black Return IHT 1

E

D

C

G

F

B

A

A

H

G

F

E

D

C

B

Outlet on the GNM 6080 side

Outlet for Nanogun Airmix

®

H2O

Pink

Brown

White

Yellow

Black

Green

Pink

Yellow

Brown

White

Green

Black

E

D

C

B

A

F

H

G

DES05943

Outlet on the GNM 6080 side

Index revision : A 42 7118

11. Cleaning

Prior to any maintenance operation carried out on the gun, please refer to the health and safety

instructions (

see § 2 page 7).

11.1. Cleaning of the product circuit

• Unplug the GNM 6080 control module.

• Install a bucket of solvent instead of a barrel of paint.

• Open the recirculation valve in order to clean the pump.

• Close the recirculation valve and press the trigger until clean solvent exits the gun nozzle.

11.2. Cleaning of the gun

The gun must be cleaned immediately after use and at the end of the day.

In order to proceed with the cleaning steps, follow the instructions listed below:

WARNING : It is strictly prohibited to immerse the Nanogun Airmix® H2O gun into the solvent.

WARNING : Use an appropriate solvent: not greasy and non-chlorinated.

• Step 1: Unplug the GNM 6080 control module.

• Step 2: Depressurise the gun’s air circuit.

• Step 3: Dump the gun’s paint circuit and rinse it using an appropriate solvent (see § 2.4

page 9).

• Step 4: Depressurise the gun’s paint circuit.

• Step 5: Dry the gun head using a dry soft cloth that remains intact.

• Step 6: Unscrew the gun’s head ring, remove the gun head (see § 10.4 page 28).

• Step 7: Clean the head with a wet brush of solvent and dry the head.

• Step 8: Raise the head and its ring.

• Step 9: Carefully dry the gun with compressed air (head placed downward) before

turning the GNM 6080 control module back on.

WARNING : Never disassemble the nozzle needle line whenever the paint hose still contains

either paint or solvent.

WARNING : During cleaning of the nozzle, aim the spray gun nozzle towards the floor in order

to prevent solvent or paint from flowing into the barrel ducts.

WARNING : After each cleaning cycle, dry using compressed air the supply hose and ducts in

order to eliminate all traces of solvent.

Index revision : A 43 7118

11.3. Hollow cone nozzle cleaning

It is vital to clean the spraying head fully at the end of each shift or when use is interrupted,

depending on the type of product between 5 and 30 minutes.

Cleaning procedure:

• Step 1: Disconnect t he air and high voltage

supplies. Engage the safety catch on the

trigger.

• Step 2: Loosen the cap nut, retrieve the

cap and the low cone and plunge them

into a solvent bath for a few minutes then

clean them with a clean cloth.

• Step 3: Using an 11 flat wrench, unscrew the

injector, leave to soak in the solvent then

clean with a clean cloth and a soft brush.

• Step 4: Screw the placebo injector ful ly in

place by hand.

Remove the safety catch and bleed the

circuit.

Index revision : A 44 7118

Reassembly:

• Step 5: Remove the placebo injector.

• Step 6: Coat the rear part (threading / seal)

of the dielectric grease injector.

• Step 7: Add more and/or put back the dielectric grease on the HV contact. Coat the

external thread of the barrel with dielectric

grease.

• Step 8: Put the internal cone and the cap back in place. Tighten the cap nut.

11.4. Elimination of wastes

The removal, transport and elimination of wastes generated by use of the equipment (used solvent, unused paint, residue, dirty cloths, booth sludge, water from curtains applied in the booth,

used dry filters, ventilation air, etc.) must take pl ace i n st ric t compli anc e with c urrent loc al reg

-

ulations.

Index revision : A 45 7118

11.5. Dismantling and Recycling

11.5.1. Nanogun Airmix® H2O

WARNING : All parts may be contaminated by paint and/or solvent residue.

Before proceeding to dismantle the equipment, clean the gun and more specifically the inside of the paint hoses with an appropriate cleaning product and dry

them with compressed air.

Rep. Material

1 Polypropylene not containing with glass fibre

2, 6* POM C, PTFE, chemically inert rubber

3 Plastic material containing glass fibre, PTFE, stainless steel

4 PEEK, tungsten carbide, PTFE, stainless steel

5* PEEK, chemically inert rubber, stainless steel

7* PTFE

8* Brass, agglomerated carbon

9* Stainless steel, chemically inert rubber, PTFE

10*,11 Plastic material containing fibre, PEEK

23, 12, 13, 14, 15 Chemically inert rubber

16 Loaded PEEK , chemically inert rubber, PTFE

18*

Plastic material, copper, steel, ceramic, ROH electronic components,

19* Tungsten, PEEK, stainless stee l, aluminium

DES06770

1

2

3

4

5

67 8

9

10

12

11

13 14 15

16 19 20

21

22 23

25

26

27

28

29

30

31

32

33

34

18

24

Index revision : A 46 7118

* These parts (5, 6, 7, 8, 9, 10, 11, 18, 19, 20, 24, 25, 26) may be fouled due to dielectric grease.

20*, 26*, 22, 31, 33 Stainless steel

21 Plastic material containing fibre

24* Plastic material, prefluorinated rubber

25*, 28 Aluminium

27, 29 Rubber

30 Plastic material containing fibre, copper, stainless steel

32 Fibre joint

34 Polyamide not loaded

Not represented Air hose: PU

Not represented

Product hose: PTFE - aramid - PU

Fittings: zinc-plated steel or stainless steel

Cable gland: plastic material containing fibres

Index revision : A 47 7118

11.5.2. GNM 6080

* Reminder: This part may become fouled by paint residue.

Rep.

Description

Material

1 Keyboard / front side* Plastic material

2 Fastening screws front side Steel

3

Primary card support and front side

Aluminium

4 Primary card

Electrical and electronic components,

ROHS printed circuit

5 Bottom sheet metal and fastening

screws

Steel

6 Connector card

Electrical and electronic components,

ROHS printed circuit

7 Electrical power supply

Electrical and electronic components,

ROHS printed circuit

8 Box Aluminium

9 Fastening accessories Steel and brass

10 Electrical switch ROH electrical component

11 Cable gland Plastic material

Not represented

12 Power supply cable Plastic material and copper

2

1

3

4

5

5

7

8

9

9

9

9

10

11

9

9

9

6

Index revision : A 48 7118

12. Common malfunctions and repairs

Defaults Possible Causes Remedies

Uneven paint flow

Presence of air in the paint circuit

Dump the paint circuit

Paint flow rate too slow

Increase pressure at the pump

or pressurised vessel.

Impurities in the circuit

Verify the filters, then dump the

circuit.

Lack of paint in the

paint tank

Replace paint

Paint too viscous Verify the paint viscosity

The paint is not flowing or only barely

flowing upon exiting

the gun.

Nozzle clogged Clean the nozzle

The nozzle needle does not

retract

Verify the nozzle needle line

Clogged filters Clean the filters

No pump pressure Verify the pump

Paint too viscous Verify the paint viscosity

Obstructed paint pipe

Unclog or change the paint

pipe

The paint is constantly flowing.

Foreign body preventing the

nozzle needle from closing.

Disassemble the seat casing,

clean it along with the seat.

Clean the nozzle needle end

Worn nozzle needle

Change the nozzle needle and

ultimately the seat door.

Damaged seat casing Change the seat casing

The paint exits by the

head air holes.

Damaged cartridge Change the cartridge

Damaged paint joint Change the joint

Poor spray

Nozzle partially clogged Clean the nozzle

Insufficient paint pressure Increase the paint flow rate

Excessive viscosity Dilute the paint

Lack of air in the spray Increase the air pressure

Excessive paint flow rate Decrease the paint flow rate

Nozzle damaged or worn Change the nozzle

Orange skin

Evaporation of solvents too fast Use heavier solvents

Paint droplets too thick

Increase the spraying distance

Dilute the paint

Increase the paint pressure

Reduce the nozzle size

Increase the electrostatic effect

Index revision : A 49 7118

Defaults Possible Causes Remedies

Running / dripping

paint

Evaporation of solvents too slow Use more lightweight solvents

Speed of application too slow

Slow the paint flow rate

Decrease the electrostatic

effect

Paint jet poorly distributed

Excessive paint flow rate

Decrease the paint flow rate

Increase the air pressure

Nozzle too thick Use a smaller and thinner nozzle

Viscosity of the paint excessive Dilute the paint

Air orifices partially blocked Clean the spraying head

Little electrostatic

effect

Absence of high voltage

See indication on the control

module

Insufficient high voltage Increase the high voltage

Distance too great between

spraying head and part

Control the Nanogun Air-

mix®H2O output voltage

Spray at a distance lying

between 200 and 300 mm

Part not grounded

Clean the hooks. Verify the

grounding of parts and the con

-

veyor

Excessive ventilation

Reduce the booth’s suction flow

rate, while respecting current

regulations

Spraying pressure too high Reduce the spraying pressure of

the product and/or air

Excessive paint flow rate Reduce the paint flow rate

Generator short-circuit:

- by the exterior

Clean the gun exterior using a

non-conductive solvent

Take a new cover, one that’s

clean and dry

Generator short-circuit:

- by the nozzle needle line

Change both the cartridge and

the nozzle needle

Generator short-circuit:

- by the air channel

Clean the air channels in the

barrel

Generator short-circuit:

- by the product pipe

- and/or the cabinet

- or the insulating table.

Check the product hose

Check the insulation of the

pump and the paint tank.

Clean the insulating enclosure

and dry it carefully

The operator has felt

electrical dis

charges when

touching the part.

Part not grounded or poorly

grounded

Verify the ground connections.

The user must wear gloves and

conductive shoes, in

accordance with Standards EN

61340-4-3 and ISO20344.

Index revision : A 50 7118

13. Spare parts

13.1. Nanogun Airmix® H2O guns for water-based paint (LR)

DES06565

1

3

2

4

Index revision : A 51 7118

For the various options: see § 13.13 page 66.

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

Item

Part Number Description Qty

Sales

unit

Spare

parts level

(*)

910023074-075

Nanogun Airmix® H2O 120 bar JP with

09-091 nozzle and 7.5 m paint hose

1 1 -

910023074-150

Nanogun Airmix® H2O 120 bar JP with

09-091 nozzle and 15 m paint hose

1 1 -

-

Nanogun Airmix® H2O gun

(see § 13.2 page 54)

- - -

1 900013829 Duckbill (included in Item 2) 1 1 3

2 910019358 Head ring (see § 13.1.2 page 53) 1 1 1

3 130001435 Fitted head (see § 13.1.3 page 53) 1 1 3

4 130001420 Nozzle (see § 13.1.1 page 52) 1 1 1

Not shown

050123306 Adapter M1/2 JIC - F3/8NPS paint pipe 1 1 3

Item

Part Number Description Qy

Sales

unit

Spare

parts level

(*)

910023075-075

Nanogun Airmix® H2O 200 barJP

with 09-091 nozzle and 7.5 m paint hose

1 1 -

910023075-150

Nanogun Airmix® H2O 200 barJP

with 09-091 nozzle and 15 m paint hose

1 1 -

-

Nanogun Airmix® H2O gun

(see § 13.2 page 54)

- - -

1 900013829 Duckbill (included in Item2) 1 1 3

2 910019358 Head ring (see § 13.1.2 page 53) 1 1 1

3 130001435 Fitted head (see § 13.1.3 page 53) 1 1 3

4 130001420 Nozzle (see § 13.1.1 page 52) 1 1 1

Not shown

050123306 Adapter M1/2 JIC - F3/8NPS paint hose 1 1 3

Index revision : A 52 7118

13.1.1. The nozzles as an option

Hollow cone nozzle: (not available for North American market)

Part Number Description Quantity

130001597 Nozzle MX03.05 Option

130001563 Nozzle MX03.07 Option

130001564 Nozzle MX04.05 Option

130001565 Nozzle MX04.07 Option

130001566 Nozzle MX04.09 Option

130001414 Nozzle MX04.111 Option

130001415 Nozzle MX04.131 Option

130001416 Nozzle MX06.091 Option

130001417 Nozzle MX06.111 Option

130001418 Nozzle MX06.131 Option

130001419 Nozzle MX06.151 Option

130001420 Nozzle MX09.091 1

130001421 Nozzle MX09.111 Option

130001422 Nozzle MX09.131 Option

130001423 Nozzle MX09.151 Option

130001424 Nozzle MX12.091 Option

130001425 Nozzle MX12.111 Option

130001426 Nozzle MX12.131 Option

130001427 Nozzle MX12.151 Option

130001428 Nozzle MX14.091 Option

130001429 Nozzle MX14.111 Option

130001430 Nozzle MX14.131 Option

130001431 Nozzle MX14.151 Option

130001432 Nozzle MX14.171 Option

130001433 Nozzle MX18.111 Option

129609901 Sieve no. 4 10

129529903 Sealant washer 10

Part Number Description Quantity

910025472 Injector 20 holllow cone nozzle Option

910025473 Injector 30 holllow cone nozzle Option

910025474 Injector 40 holllow cone nozzle Option

910025475 Injector 50 holllow cone nozzle Option

910025476 Injector 60 holllow cone nozzle Option

910025477 Injector 70 holllow cone nozzle Option

Index revision : A 53 7118

13.1.2. Fitted head ring

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

13.1.3. Fitted head

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

Item

Part Number Description Qty

Sales

unit

Spare parts

level (*)

910019358 Fitted head ring 1 1 1

1 900013829 Duckbill 1 1 3

2 900010164 PTFE flat seal 2 1 1

3 160000170 FEP/FKM seal 1 1 1

Item

Part Number Description Qty

Sales

unit

Spare parts

level (*)

130001435 Fitted head 1 1 3

1 132284012 Electrode and PTFE tube 1 5 1

2 132284010 Conductive PTFE washer 1 1 2

DES06511

1

2

3

1

2

3

DES06762

1

2

Index revision : A 54 7118

13.2. Nanogun Airmix® H2O gun

2

3

8

9

10

11

12

14

17

18

23

24

25

26

19

20

27

28

29

30

31

33

8

13

34

16

21

22

13

33

1

4

5

15

20

32

6

7

Index revision : A 55 7118

Item

Part Number Description Qty

Sales

unit

Spare

parts level

(*)

-

Nanogun Airmix® H2O gun

- - -

1 910019359 Fitted seat casing (see § 13.3 page 57) 1 1 1

2 910019360

Fitted adapter Nanogun Airmix® H2O (see

§ 13.4 page 57)

1 1 3

3 910015934

Fitted high-voltage contact (included in

Item 8)

1 1 2

4 J3STKL014

Chemically inert O-ring (included in Item

3)

1 1 2

5 900014787 Spring 1 1 1

6 910019356

High-voltage contact screw (included in

Item 8)

1 1 1

7 J2FTDF014 O-ring (included in Item 6) 1 1 1

8 910025082 Equipped barrel (see § 13.5 page 58) 1 1 3

9 910015508 Equipped high-voltage cascade 1 1 3

10 910019508 Fitted nozzle needle (see § 13.7 page 60) 1 1 1

11

910022672

Equipped handle Nanogun Airmix® H2O

120 bar

1 1 3

910022679

Equipped handle Nanogun Airmix® H2O

200 bar

1 1 3

12 900010239 Fastening hook 1 1 3

13 900010385 C M4 curved washer head screw 4 1 3

14 900013808 PTFE flat washer (include d in Item 15) 1 1 2

15 910018204

On/off button with seal and magnet

(included in Item11)

1 1 3

16 J3STKL005

Chemically inert O-ring (included in Item

15)

1 1 1

17

900010266 Paint spring 120 bar 1 1 1

900010267 Paint spring 200 bar 1 1 1

18 900015784 Knurl back of paint 1 1 3

19 900010882 High-pressure paint stop 1 1 3

20 250000036 Handle / barrel fastening screw 4 1 3

21 J4BRND039 Fibre washer for fastening screw 6 1 3

22 910014166

Fitted additional air settings button

(included in Item 11)

1 1 3

23 J2FTDF121 Black FKM O-ring (included in Item 22) 1 1 1

24 160000041

Grey chemically inert seal (included in

Item 11)

1 1 1

25 160000067 Red FKM seal (included in Item 11) 1 1 1

Index revision : A 56 7118

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

WARNING : It is strictly forbidden to remove the rear paint knurl (Item 18) when the gun is under

pressure.

26 900010009 LR gun base 1 1 3

27 910006118 Fitted air nipple 1 1 2

28 J2FTCF018 Black FKM O-ring (included in Item 27) 2 1 1

29 J3STKL018

White chemically inert O-ring

(included in Item 27)

1 1 1

30 250000037 Base-handle fastening screw 2 1 3

31 910022663 Trigger / pin lock assembly 1 1 3

32 910018203 Fitted air valve (see § 13.6 page 59) 1 1 3

33

900010237 Trigger 1 1 3

900014446 4-finger trigger

1

option

1 3

34 910015869-XXX

Electro-pneumatic coupling

(see § 13.8 page 60)

1 1 3

Index revision : A 57 7118

13.3. Equipped seat casing (flat spray only)

13.4. Equipped adapter (flat spray only)

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

Item

Part Number Description Qty

Sales

unit

Spare

parts

level (*)

910019359 Equipped seat casing 1 1 1

1 J3STKL046 O-ring - chemically inert 1 1 1

2 900013368 Anti-extrusion ring 1 1 1

3 900012300 Anti-extrusion ring 1 1 1

4 J3STKL075 O-ring - chemically inert 1 1 1

Item

Part Number Description Qty

Sales

unit

Spare

parts

level (*)

910019360 Equipped adapter 1 1 3

1 J2FENV288 O-ring - FEP FKM 1 1 1

2 900014821 Flat seal 1 1 1

DES06542

1

4

2

3

DES06543

1

2

Index revision : A 58 7118

13.5. Equipped barrel

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

Item

Part Number Description Qty

Sales

unit

Spare

parts

level (*)

910025082 Equipped barrel 1 1 3

1 910015881 Nozzle needle sealant cartridge 1 1 1

2 900012782 Anti-extrusion ring (included in Item 1) 1 1 1

3 J3STKL005 O-ring - chemically inert (included in Item 1) 1 1 1

4 J2FENV435 O-ring - FEP Viton 1 1 1

5 J3STKL078 O-ring - chemically inert 2 1 1

6 J3STKL019 O-ring - chemically inert 1 1 1

7 J3STKL032 O-ring - chemically inert 1 1 1

1

5

5

6

7

4

2

3

Index revision : A 59 7118

13.6. Equipped air valve and air valve Nut

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

WARNING : Recover the magnet on the former air valve in order to retain the same trigger

values.

If the magnet is lost, contact SAMES KREMLIN.

Item

Part Number Description Qty

Sales

unit

Spare parts

level (*)

910018203 Equipped air valve 1 1 3

1 900010256 Sealant ring 1 1 1

2 J3STKL005 O-ring - chemically inert (exterior valve) 1 1 1

3 J3STKL032 O-ring - chemically inert (interior valve) 1 1 1

910015922 Equipped air valve nut 1 1 3

4 J2FTDF155 Black FKM O-ring 1 1 1

5 J2FTDF160 Black FKM O-ring 1 1 1

6 J2FTDF999 Black FKM O-ring 1 1 1

7 900009024 Air spring 1 1 1

DES05944

7

1

2

3

5

4

A

6

A

Index revision : A 60 7118

13.7. Equipped nozzle needle

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

13.8. Electro-pneumatic coupling

Item

Part Number Description Qty

Sales

unit

Spare parts

level (*)

910019508 Equipped nozzle needle 1 1 1

1 X7CEHU003 H M3 U brass nut 1 1 3

Item

Part Number Description Qty

Sales

unit

Spare

parts

level

910015869-100 10-m electro-pneumatic coupling 1 1 3

910015869-200 20-m electro-pneumatic coupling 1 1 3

1 900015289 Simple male union 1 1 3

2

910021087-100 Equipped air hose outer diameter: 10 10 m 1 1

910021087-200 Equipped air hose outer diameter: 10 20 m 1 1

3 F6RLHG362 NPT female / BSP male adapter

option

1 3

4 130000527 Quick cou pler 1 1 3

DES06512

1

DES05933

1

2

3

Connection

GNM 6080

4

Index revision : A 61 7118

13.9. Paint hose

(*)

Level 1: Standard preventive maintenance.

Level 2: Corrective maintenance.

Level 3: Exceptional maintenance.

Item

Part Number Description Qty

Sales

unit

Spare parts

level (*)

1

910020165-075 Product hose LR PTFE 7.5m ∅ 5 1 1 1

910020165-150 Product hose LR PTFE 15m ∅ 5 1 1 1

1a J3STKL028

Chemically inert O-ring (included in

Item 1)

1 1 1

1b 900013398 Anti-extrusion ring (included in Item1) 1 1 1

1c J2FTDF177 Black FKM O-ring (included in Item 1) 1 1 1

2 E3RPLS018 Cable gland nut 1 1 3

1

2

1a - 1b

1

1c

Index revision : A 62 7118

13.10. Nanogun Airmix® H2O seal kit

Part Number Title Location Quantity

910022694

Nanogun Airmix® H2O seal kit

1

J3STKL005 Chemically inert O-ring

Barrel, air valve, on/off

button

3

J2FENV435 FEP/FKM O-ring Barrel 1

J3STKL078 Chemically inert O-ring Barrel 2

J3STKL019 Chemically inert O-ring Barrel 1

910015881 Nozzle needle sealant cartridge Barrel 1

J3STKL032 Chemically inert O-ring Barrel, air valve 2

900012782 Anti-extrusion ring Barrel 1

160000041 Chemically inert O-ring Handle 1

160000067 Red FKM O-ring Handle 1

J2FTCF018 Black FKM O-ring Air nipple 2

J3STKL018 Chemically inert O-ring Air nipple 1