DOCUMENTATION

ELECTRONIC MIXING SYSTEM

CYCLOMIX

MICRO / MICRO+ / MICRO+ PH / MICRO+ PH+

Manual : 582.079.110-UK - 1902

Date: 07/02/19

Supersede : 23/05/16

Modif.:

TRANSLATION FROM THE ORIGINAL MANUAL

IMPORTANT : Before assembly and start-up, please read and clearly understand all the documents relating to

this equipment (professional use only).

THE PICTURES AND DRAWINGS ARE NON CONTRACTUAL. WE RESERVE THE RIGHT TO MAKE CHANGES WITHOUT PRIOR NOTICE..

SAMES KREMLIN SAS

l

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

www.sames-kremlin.com

578.034.130 1901

SAMES KREMLIN SAS

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

www.sames-kremlin.com

Pour une utilisation sure, Il est de votre responsabilité

de :

Lire attentivement tous les documents contenus

dans le CD joint avant la mise en service de

l’équipement,

D’installer, d’utiliser, d’entretenir et de réparer

l’équipement conformément aux préconisations de

SAMES KREMLIN ainsi qu’aux réglementations

nationales et/ou locales,

Vous assurez que les utilisateurs de cet équipement

ont été formés, ont parfaitement compris les règles de

sécurité et qu’ils les appliquent.

To ensure safe use of the machinery, it is your

responsibilityto:

Carefully read all documents contained on the

enclosed CD before putting the machinery into service,

Install, use, maintain and repair the machinery in

accordance with SAMES KREMLIN's recommendations

and national and/or local regulations,

Make sure that the users of the machinery have

received proper training and that they have perfectly

understood the safety rules and apply them.

Eine sichere Nutzung setzt voraus, dass Sie: :

alle in der CD enthaltenen Dokumente vor der

Inbetriebnahme der Anlage aufmerksam lesen,

die Anlage im Einklang mit den Empfehlungen von

SAMES KREMLIN sowie mit den nationalen und/oder

lokalen Bestimmungen installieren, verwenden,

warten und reparieren,

sich vergewissern, dass die Nutzer dieser Anlage

angemessen geschult wurden, die

Sicherheitsbestimmungen verstanden haben und sie

anwenden.

ES IT PT

FR UK DE

Para una utilización segura, será de su

responsabilidad:

leer atentamente todos los documentos que se

incluyen en el CD adjunto antes de la puesta en servicio

del equipo,

instalar, utilizar, efectuar el mantenimiento y reparar

el equipo con arreglo a las recomendaciones de

SAMES KREMLIN y a la normativa nacional y/o local,

cerciorarse de que los usuarios de este equipo han

recibido la formación necesaria, han entendido

perfectamente las normas de seguridad y las aplican.

Per un uso sicuro, vi invitiamo a:

leggere attentamente tutta la documentazione

contenuta nel CD allegato prima della messa in

funzione dell'apparecchio,

installare, utilizzare, mantenere e riparare

l'apparecchio rispettando le raccomandazioni di SAMES

KREMLIN, nonché le normative nazionali e/o locali,

accertarvi che gli utilizzatori dell'apparecchio

abbiano ricevuto adeguata formazione, abbiano

perfettamente compreso le regole di sicurezza e le

applichino.

Para uma utilização segura, é da sua

responsabilidade:

Ler atentamente todos os documentos incluídos no

CD em anexo antes de pör o equipamento em

funcionamento,

Proceder à instalação, utilização, manutenção e

reparação do equipamento de acordo com as

preconizações de SAMES KREMLIN, bem como com

outros regulamentos nacionais e/ou locais aplicáveis,

Assegurar-se que os utilizadores do equipamento

foram devidamente capacitados, compreenderam

perfeitamente e aplicam as devidas regras de

segurança.

NL SE FI

Voor een veilig gebruik dient u:

alle document op de bijgevoegde cd aandachtig te

lezen alvorens het apparaat in werking te stellen,

het apparaat te installeren, gebruiken, onderhouden

en repareren volgens de door SAMES KREMLIN

gegeven aanbevelingen en overeenkomstig de

nationale en/of plaatselijke reglementeringen,

zeker te stellen dat de gebruikers van dit apparaat

zijn opgeleid, de veiligheidsregels perfect hebben

begrepen en dat zij die ook toepassen.

För en säker användning av utrustningen ansvarar ni

för följande:

Läs noga samtliga dokument som finns på den

medföljande cd-skivaninnan utrustningen tas i drift.

Installera, använd, underhåll och reparera

utrustningen enligt anvisningarna från SAMES

KREMLIN och enligt nationella och/eller lokala

bestämmelser.

Försäkra er om att användare av denna utrustning

erhållit utbildning, till fullo förstått säkerhetsföreskrifterna

och tillämpar dem.

Käytön turvallisuuden varmistamiseksi

velvollisuutesi on:

Lukea huolella kaikki CD:llä olevat asiakirjat ennen

laitteiston käyttöönottoa,

Noudattaa laitteiston asennuksessa, käytössä,

kunnossapidossa ja huollossa SAMES KREMLIN in

suosituksia sekä kansallisia ja/tai paikallisia

määräyksiä,

Varmistaa, että laitteiston käyttäjät ovat koulutettuja

ja ymmärtävät täysin turvallisuusmääräykset ja miten

niitä sovelletaan.

PL CS SL

Dla zapewnienia bezpiecznego użytkowania na

użytkowniku spoczywa obowiązek:

Uważnego zapoznania się ze wszystkimi

dokumentami znajdującymi się na załączonej płycie CD

przed pierwszym uruchomieniem urządzenia,

Instalowania, użytkowania, konserwacji i naprawy

urządzenia zgodnie z zaleceniami firmy SAMES

KREMLIN oraz z przepisami miejscowymi,

Upewnienia, że wszyscy przeszkoleni użytkownicy

urządzenia zrozumieli zasady bezpieczeństwa i stosują

się do nich.

Pro bezpečné používání jste povinni:

Před uvedením zařízení do provozu si pozorně

přečíst veškeré dokumenty obsažené na přiloženém

CD,

Nainstalovat, používat, udržovat a opravovat

zařízení v souladu s pokyny firmy SAMES KREMLIN

a s národními a/nebo místními legislativními předpisy,

Ujistit se, že uživatelé tohoto zařízení byli vyškoleni,

že dokonale pochopili bezpečnostní pravidla a že je

dodržují.

Za varno uporabo ste dolžni:

natančno prebrati vse dokumente na CD pred

zagonom stroja,

inštalirati, uporabljati, vzdrževati in popravljati

opremo po določilih SAMES KREMLIN in v skladu z

veljavnimi nacionalnimi in/ali lokalnimi predpisi,

poskrbeti, da so uporabniki te opreme ustrezno

usposobljeni, poznajo varnostne predpise in da jih

upoštevajo.

SK HU RO

V záujme bezpečného je vašou povinnosťou:

pozorne si prečítať všetky dokumenty obsiahnuté na

priloženom CD predtým, ako zariadenie uvediete do

prevádzky,

nainštalovať, používať, udržiavať a opravovať

zariadenie v súlade s odporúčaniami spoločnosti

SAMES KREMLIN a národnými a/alebo miestnymi

predpismi,

uistiť sa, že používatelia tohto zariadenia boli

zaškolení, riadne porozumeli pravidlám bezpečnosti a

používajú ich.

Déclaration(s) de conformité au verso de ce document / Declaration(s) of conformity at the back of this document / Konformitätserklärung(en) auf der Rückseite dieser Unterlage

/ Declaración (es) de conformidad en el reverso de este documento / Dichiarazione/i di conformità sul retro del presente documento

/ Declaração(ções) de conformidade no verso do documento / Conformiteitsverklaring(en) op de keerzijde van dit document / Försäkran om överensstämmelse på omstående sida

av detta dokument / Vaatimustenmukaisuusvakuutukset tämän asiakirjan kääntöpuolella / Deklaracja(e) zgodności na odwrocie dokumentu

/ Prohlášení o shodě se nachází/nacházejí na zadní straně tohoto dokumentu / Deklaracija(e) o skladnosti na hrbtni strani tega dokumenta / Vyhlásenie/-a o zhode sa nachádzajú na

zadnej strane dokumentu / A dokumentum hátlapján szereplő megfelelőségi nyilatkoz(ok) / Declaraţii de conformitate pe versoul acestui document

A biztonságos használat érdekében az Ön

felelőssége, hogy:

a berendezés üzembe helyezése előtt figyelmesen

elolvassa a mellékelt CD által tartalmazott összes

dokumentumot,

a berendezést a SAMES KREMLIN ajánlasainak

valamint a nemzeti és/vagy helyi szabályozásoknak

megfelelően helyezze üzembe, használja, tartsa karban

és javítsa,

megbizonyosodjon róla, hogy a berendezés

felhasználói képzettek, tökéletesen megértették és

alkalmazzák a biztonsági előírásokat.

Pentru o utilizare sigură, este responsabilitatea dvs.

să:

Citiţi cu atenţie toate documentele de pe CD-ul

anexat, înainte de punerea în funcţiune a

echipamentului,

Instalaţi, utilizaţi, întreţineţi şi reparaţi echipamentul

conform instrucţiunilor SAMES KREMLIN precum şi

reglementărilor naţionale şi/sau locale,

Vă asiguraţi că utilizatorii acestui echipament au

fost instruiţi, au înţeles perfect regulile de securitate şi

le aplică integral.

SAMES KREMLIN N° : 578.034.130-1901

DECLARATION UE DE CONFORMITE

EU DECLARATION OF CONFORMITY

EU- KONFORMITÄTSERKLÄRUNG

DECLARACIÓN UE DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITÀ UE

DECLARAÇÃO UE DE CONFORMIDADE

EU-CONFORMITEITSVERKLARING

EU-FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

EU- VAATIMUKSENMUKAISUUSVAKUUTUS

DEKLARACJA ZGODNOŚCI UE

EU PROHLÁŠENÍ O SHODĚ

IZJAVA EU O SKLADNOSTI

VYHLÁSENIE O ZHODE

EU-MEGFELELŐSÉGI NYILATKOZAT

DECLARAŢIA DE CONFORMITATE UE

Le fabricant / The manufacturer / Der Hersteller

/ El fabricante / Il produttore / O fabricante

/ De fabrikant / Tillverkare / Valmistaja / Producent / Výrobce

/ Proizvajalec / Výrobca / Gyártó / Fabricantul:

Déclare que le matériel désigné ci-après / Herewith declares that the equipment / erklärt hiermit, dass die / Declara que el material designado a

continuación / Dichiara che il materiale sottoindicato / Declara que o material a seguir designado / verklaart dat de hieronder aangeduide apparatuur

/ Kungör att den utrustning som anges här nedan / ilmoittaa, että alla mainitut laitteistot / Oświadcza, że wymienione poniżej urządzenia / Prohlašuje,

že níže uvedené vybavení / Izjavlja, da je opisana oprema spodaj / Vyhlasuje, že zariadenie uvedené nižšie / Kijelenti, hogy a megjelölt anyag a

továbbiakban / Declară că echipamentul precizat mai jos:

SAMES KREMLIN SAS

13, chemin de Malacher

38 240 - MEYLAN - FRANCE

Tél. : 33 (0)4 76 41 60 60

SYSTEME DE DOSAGE ELECTRONIQUE / MIXING & DOSING SYSTEM

ELEKTRONISCHE 2-K- ANLAGE / SISTEMA DE DOSIFICACIÓN ELECTRÓNICA

CYCLOMIXTMMICRO

CYCLOMIXTMMICRO+

CYCLOMIXTMMICRO+ PH

CYCLOMIXTMMICRO+ PH+

Est conforme à la législation d’harmonisation de l’Union applicable suivante / Is in conformity with the relevant Union harmonisation legislation / Erfüllt

die einschlägigen Harmonisierungsrechtsvorschriften der Union / es conforme con la legislación de armonización pertinente de la Unión / è conforme

alla pertinente normativa di armonizzazione dell’Unione / in overeenstemming met de desbetteffende harmonisatiewetgeving van de Unie / med den

relevanta harmoniserade unionslagstiftningen / on asiaa koskevan unionin yhdenmukaistamislainsäädännön vaatimusten mukainen / jest zgodny z

odnośnymi wymaganiami unijnego prawodawstwa harmonizacyjnego / Shoduje se s následující příslušnou evropskou harmonizační legislativou

/ V skladu s harmonizirano zakonodajo Unije / Je v súlade s uplatniteľnými harmonizačnými právnymi predpismi EÚ / Megfelel a következő

alkalmazandó uniós harmonizációs szabályozásnak / Este conform cu legislaţia aplicabilă de armonizare de mai jos

Directive Basse Tension / Low Voltage Directive / Niederspannung-Richtlinie / Directiva Baja Tensión / Direttiva Bassa

Tensione / Directiva de Baixa Tensão / Richtlijn Laagspanning / Lågspänningsdirektivet / Pienjännitedirektiivi / Dyrektywa

Niskonapięciowa / Směrnice Pro Nízké Napĕtí / Direktiva O Nizki Napetosti / Smernica O Nízkom Napätí / Feszültséghatárra

Vonatkozó Irányelv / Directiva Privind Tensiunile Joase

Directive Compatibilité Electromagnétique / Electromagnetic Compatibility Directive / Richtlinie Für Elektromagnetische

Verträglchkeit / Directiva de Compatibilidad Eletromagnética / Direttiva Compatibilita Elettromagnetica / Directiva relativa à

Compatibilidade Eletromagnética / Richtlijn Elektromagnetische Compatibiliteit / Direktivet om Eletktromagnetisk Kompatibilitet

/ EMC-direktivi / Dyrektywa Kompatybilności Elektromagnetycznej / Směrnice Pro Elektromagnetickou Kompatibilitu

/ Direktiva O Elektromagnetni Združljivost / Smernica O Elektromagnetickej Kompatibilite / Az Elektromágneses

Összeférhetőségre vonatkozó Irányelv / Directiva Privind Compatibilitatea Electromagnetică

2014/35/UE

2014/30/UE

SAMES KREMLIN - 2 - N° : 578.034.130-1901

La présente déclaration de conformité est établie sous la seule responsabilité du fabricant / This declaration of conformity is issued under the sole

responsibility of the manufacturer / Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt der Hersteller / La presente

declaración de conformidad se expide bajo la exclusiva responsabilidad del fabricante / La presente dichiarazione di conformità è rilasciata sotto la

responsabilità esclusiva del fabbricante / A presente declaração de conformidade é emitida sob a exclusiva responsabilidade do fabricante / Deze

conformiteitsverklaring wordt verstrekt onder volledige verantwoordelijkheid van de fabrikant / Denna försäkran om överensstämmelse utfärdas på

tillverkarens eget ansvar / Tämä vaatimustenmukaisuusvakuutus on annettu valmistajan yksinomaisella vastuulla / Niniejsza deklaracja zgodności

wydana zostaje na wyłączną odpowiedzianość producenta / Toto prohláŝení o skodě se vydává na výhradní odpovědnost výrobce / Za izdajo te izjave

o skladnosti je odgovoren izključno proizvajalec / Toto vyhlásenie o zhode sa vydáva / na vlastnú zodpovednosť výrobcu / Ezt a megfelelőségi

nylatkozatot a gyártó kizárólagos felelőssége mellett adják ti / Prezenta declaraţie de conformitate este emisă pe răspunderea exclusivă a

producătorului.

Hervé WALTER

Directeur Recherche & Développement / Research & Development Director / Direktor für Forschung & Entwicklung

/ Director de Investigación y Desarrollo / Direttore Ricerca e sviluppo / Diretor de Pesquisa e desenvolvimento/

Manager Onderzoek en Ontwikkeling / Direktör för Forskning och Utveckling / Johtaja tutkimus ja kehitys / Dyrektor

ds. Badań i rozwoju / Ředitel výzkumu a vývoje / Direktor za raziskave in razvoj / Riaditeľ pre výskum a vývoj /

Kutatási és Fejlesztési Igazgató / Director de cercetare și dezvoltare

Fait à Meylan, le / Established in Meylan, on / Geschehen zu Meylan, am / En Meylan, a / Redatto a Meylan, / Vastgesteld te Meylan, / Utformat i

Meylan, den / Meylan, Ranska, / Sporządzono w Meylan, dnia / Meylan, dnia / V Meylanu, / V Meylan dňa / Kelt Meylanban, / Întocmită la Meylan, pe

data de 25/01/2019 - 01/25/2019

SAMES KREMLIN - 3 - N° : 578.034.130-1901

INSTRUCTION MANUAL

CYCLOMIX

TM

MICRO, MICRO+

MICRO+ PH,

MICRO+ PH+

MIXING SYSTEM

# 155.660.9XX

Manual : 1812 573.191.112

Date : 05/12/18 - Cancels : 15/12/14

Modif.: Update

TRANSLATION FROM THE ORIGINAL MANUAL

IMPORTANT : Before assembly and start-up, please read and clearly understand all the documents

relating to this equipment (professional use only).

THE PICTURES AND DRAWINGS ARE NON CONTRACTUAL. WE RESERVE THE RIGHT TO MAKE CHANGES WITHOUT PRIOR

NOTICE.

SAMES KREMLIN SAS

l

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

www.sames-kremlin.com

INSTRUCTION MANUAL

CYCLOMIX

TM

MICRO, MICRO+, MICRO+ PH, MICRO+ PH+

MIXING SYSTEM

TABLE OF CONTENTS

1. GENERAL SAFETY INSTRUCTIONS ......................................................................................................... 3

INSTALLATION REQUIREMENTS ............................................................................................ 3

EQUIPMENT REQUIREMENTS ................................................................................................ 3

MAINTENANCE REQUIREMENTS ............................................................................................ 4

ENVIRONMENT ......................................................................................................................... 4

2. DESCRIPTION ............................................................................................................................................. 5

3. OPERATING PRINCIPLE ............................................................................................................................ 7

4. TECHNICAL FEATURES ............................................................................................................................ 8

5. INSTALLATION ........................................................................................................................................... 9

DESCRIPTION OF THE LABEL MARKINGS ............................................................................ 9

INSTALLATION DIAGRAM ...................................................................................................... 11

IMPLANTATION ....................................................................................................................... 12

CONNECTION OF THE CONTROL UNIT AND OF THE FLUID PA RT .................................. 14

6. OPERATING .............................................................................................................................................. 15

DRIVING FROM THE CYCLOMIXTM MICRO ........................................................................... 15

SWITCHING ON THE CYCLOMIXTM MICRO .......................................................................... 15

7. FIRST SWITCHING ON ............................................................................................................................. 16

8. FIRST PLACING INTO OPERATION ........................................................................................................ 18

FLUSHING OF THE PUMPS AND OF THE CYCLOMIXTM MICRO INTO SOLVENT ............. 18

START-UP OF THE CYCLOMIXTM MICRO ............................................................................. 18

9. APPLICATION PROGRAMMING (F3) ...................................................................................................... 19

PASSWORD ............................................................................................................................. 19

PROCEDURE TO GET THE VERSION NUMBER OF THE ELECTRONIC CARD ................ 19

PARAMETERS FOR CYCLOMIXTM MICRO WITHOUT CATALYST FLUSHING ................... 20

PARAMETERS FOR CYCLOMIXTM MICRO WITH CATALYST FLUSHING ........................... 21

10. PRODUCTION (F1) .................................................................................................................................... 23

PROPORTIONING TEST ......................................................................................................... 24

11. FLUSHING (F2) .......................................................................................................................................... 24

12. CONSUMPTIONS / PRINT (F4) ................................................................................................................. 26

13. DOWNLOADING DATA FROM CYCLOMIX MICRO TO A COMPUTER ................................................. 27

14. INDICATIONS GIVEN BY THE LEDS ........................................................................................................ 31

15. MAINTENANCE ......................................................................................................................................... 31

TROUBLESHOOTING .............................................................................................................. 33

DIAGNOSTICS ......................................................................................................................... 34

16. DISASSEMBLY - REASSEMBLY ............................................................................................................. 36

MIXER ....................................................................................................................................... 36

FLOWMETER ........................................................................................................................... 36

NEW MODULE INSTALLATION (OR MODULE REPLACEMENT) ........................................ 37

PILOTED VALVES (FLUID VALVES AND TEST VALVES) ..................................................... 38

SAMES KREMLIN Page 1 Manual : 573.191.112

ADDITIONAL DOCUMENTATIONS :

Declaration

EU declaration of conformity Doc. 578.034.130

Annexes

Mixing ratio chart Doc. 573.191.120

Pneumatic & electric diagrams 055.660.999

Spare parts

CyclomixTM micro Doc. 573.359.050

Color changer Doc. 573.186.112 + 573.187.050 + 573.188.050

CyclomixTM : Flowmeters and sensors

replacement

Doc. 573.705.070

SAMES KREMLIN Page 2 Manual : 573.191.112

Dear Customer, You are the owner of our new CYCLOMIXTM MICRO mixing system and we would

like to take this opportunity to thank you.

To make sure your investment will provide full satisfaction, special care has been taken by SAMES

KREMLIN during all designing and manufacturing processes. To obtain the best result, safe and

efficient operation of your equipment, we advice you to read and make yourself familiar with this

instruction and service manual.

1. GENERAL SAFETY INSTRUCTIONS

The CYCLOMIXTM MICRO mixing system shall be installed outsid e the exp losive

area. It shall be installed in a safe area (non-explosive area according to the ATEX

directive - refer to § 5).

The display control unit must not be installed above the fluid module.

WARNING : Any misuse of the equipment or accessories can damage them, result in serious body

injury, fire or explosion hazard and reduce the equipment working life. Read carefully the safety

instructions hereafter.

The personnel involved in operating and servicing this equipment must be aware of all safety

requirements stated in this manual. The workshop supervisor must be certain that the personnel has

perfectly understood the safety instructions and complies with them.

Read all instruction manuals as well as the tags of the equipments before operating the equipment.

Read local safety instructions and comply with them.

INSTALLATION REQUIREMENTS

Ground the equipments.

Use the equipment only in a well-ventilated area to prevent from serious body injuries, fire and

explosion hazards. Do not smoke in the spray area.

Never stock paints and solvents in the spray area. Always close the pots and the tins.

Keep the spray area clean and free from debris (solvent, rags,…).

Read paint and solvent manufacturer's technical instructions.

Spraying of some materials may result in hazardous working conditions. To protect the operator,

respirator mask, hand cream and glasses are required (Refer to chapter "Safety equipment" of

SAMES KREMLIN selection guide).

EQUIPMENT REQUIREMENTS

The operating pressure of these equipments is particularly high. Consequently, some precautions

must be taken in order to prevent from accidents and from unsafe working conditions.

Never exceed the components maximum working pressure of the equipment.

HOSES

Do not use hoses with a maximum burst-proof pressure less than four times the maximum service

pressure of the pump (see data sheet).

Be certain hoses are not crimped, leaking and not unrolled.

Be certain hoses are in good conditions and showing no evidence of damage.

Use only air hose with static conductor to connect the pump with the spray gun.

All fittings must be tight and in good condition.

PUMP

Ground the equipment (use the connection on the pump).

Do not use any product or solvent incompatible with the pump components.

Use the appropriate solvent for the material being sprayed to increase the equipment working life.

SAMES KREMLIN Page 3 Manual : 573.191.112

GUN

Never wipe the end of the tip with the fingers.

Always depressurize air and fluid hoses before carrying out any servicing on the gun.

Never point the spray gun at anyone or at any part of the body.

CYCLOMIXTM MICRO

Do not install the CYCLOMIX

TM

MICRO in an explosive area. It shall be in a safe area (non

explosive area).

The display control unit must not be installed above the fluid module.

Connect the display control unit to the mains supply fitted with a ground.

The fluid module is fitted with a ground. Connect the ground cable to earth.

Do not use any product or solvent incompatible with the components of the CYCLOMIX

TM

MICRO.

Use the appropriate solvent for the material being sprayed to increase the equipment

working life.

Wear protective glasses to protect the operator from possible discharges during the

handling of the CYCLOMIX

TM

MICRO test valves.

Do not use electrostatic spraying for water-based paints with a resistivity lower than 5 M

Ω

.

MAINTENANCE REQUIREMENTS

Guards (air motor cover, coupling shields, connectors,…) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards.

Never modify these equipments.

Check them daily, keep them in a good condition and replace the worn parts only with SAMES

KREMLIN parts.

Before cleaning or removing components of the equipment, it is compulsory :

1 - to stop the air supply,

2 - to open the gun fluid circuit to depressurize the hoses,

3 - to shut off the CYCLOMIXTM MICRO electrical supply,

4 - to open the drain valves.

ENVIRONMENT

The equipment consists of a label plate with the name of the manufacturer, the

equipment part number, the interesting informations to use correctly the

equipment (pressure, voltage…) and the above pictogram.

The equipment is designed with and consists of high quality materials and

components which can be re-used.

The 2012/19/UE European Directive covers all equipments with a crossed-out

bin pictogram. Please inform yourself about the collection systems for electric

and electronic equipments.

Please act according to local rules and do not throw the old equipments with

household wastes. A correct disposal of the old equipment will help prevent

negative consequences for the environment and health.

SAMES KREMLIN Page 4 Manual : 573.191.112

2. DESCRIPTION

The CYCLOMIXTM MICRO mixing system is designed for applying two-component paints and varnishes

(water-based or solvanted).

It is available for 2 technologies of application : pneumatic spraying, AIRMIX spraying

(maximum pressure : 172 bar / 2500 psi).

It comes in an independent form. It is only supplied with compressed air (maximum 6 bar / 87 psi) and a

mains supply (115V / 230V).

It consists of :

- a control unit (2) with automaton and electromagnetic control components,

- a fluid module (1) that receives the volumetric meters, the automatic valves for materials and solvents

and electropneumatic control components.

Captions :

1 Fluid module 7 Electrovalves

2 Control unit 8 Air flow switch

3 Display unit 9 Color changer

9a : base CTM

9b : cata CTM

4 Flowmeters 10 Protective housing

5 Automatic valve 11 Three-way valve

6 Mixer 12 Non-return valve

1 8 7 6 2

3

10

5

11

9b

12

9a

4

Material

outlet

Material

inlet

SAMES KREMLIN Page 5 Manual : 573.191.112

CONTROL UNIT FRONT PART

Ind. Description Function

- Red LED Fault

- Orange LED Operating (except producti on)

- Green LED Production

The CYCLOMIXTM MICRO is totally programmable via a man/machine interface. The screen indicates

continuously by a simple identification, the statuses of the CYCLOMIX

TM

MICRO and enables to have

access to the essential functionalities: ON / OFF - FLUSHING -PRODUCTION.

The informations relating to the operating of the CYCLOMIX

TM

MICRO (real-time display of the ratio, of

the consumption…) can be read on the LCD screen.

The CYCLOMIX

TM

MICRO saves continuously the instantaneous consumptions of base, catalyst and

solvent as well as the total consumptions and the emissions of Volatile Organic Compounds (VOC)

during the operating of the equipment.

On the control unit, there is a cord grip. It enables to supply electricity to the CYCLOMIX

TM

MICRO via a

safety isolating switch (115V / 230V).

Do not use electrostatic spraying for water-

based paints or paints with a

resistivity lower than 5 MΩ.

SAMES KREMLIN Page 6 Manual : 573.191.112

3. OPERATING PRINCIPLE

The 2 BASE and CATALYST materials are sent to the mixing system from 2 pumps or pressure tanks.

The base crosses a piloted valve (A1) and a meter (CA), the catalyst is directly sent to the meter (CB).

The cycle begins with the opening of the BASE valve (A1). The 2 meters send their informations to the

computer that shuts off the catalyst valve (VP6) when the computerized mixing ratio is reached.

The mixing process is based on a base constant flow. The catalyst flow is injected low under high

frequency. The injection is made directly into the base flux at the mixer level.

The automaton checks continuously the mixing ratio and if it notices a fault that it cannot correct, an

alarm is activated. The CYCLOMIX

TM

MICRO goes on safety mode.

TA

vp6

A1

SA

CB

CA

AR2

AR1

IN

A SA

MEL

A2

A3

A

A

B1

SB

B SB

A1 Base piloted valve (A) IN Three way-valve to mixer

SA Base solvent piloted valve(SA) TA Sampling outlet for the base

A2 Base piloted valve (depending upon version) CA Base meter

A3 Base piloted valve (depending upon version) CB Cata meter

B Catalyst piloted valve (depending upon

version)

VP6 Injection piloted valve

SB Cata solvent piloted valve (depending upon

version)

MEL Mixer

SAMES KREMLIN Page 7 Manual : 573.191.112

4. TECHNICAL FEATURES

Number of colors : 1 or 3

Number of catalyst : 1

Solvent paints compatibility

Piloting via magnet on the control bay

Print kit (connection to a printer)

Voltage : 230V / 115V - 10W

Air pressure :

minimum 4 bar / 58 psi; maximum 6 bar / 87 psi

Fluid pressure: from 2 to 175 bar / from 29 to 2538 psi

Weight : 25 kg / 55 lb

Dimensions :

- control unit : 370 mm x 172.5 mm x 110 mm

/ 14.6" x 6.8" x 4.3"

- fluid module : 370 mm x 460 mm x 110 mm

/ 14.6" x 18.1" x 4.3"

Fluid circuits (base and cata) made of stainless steel for

the CyclomixTM Micro and Micro+.

CATALYST circuit made of 316 L stainless steel Circuit

for the Cyclomix

TM

Micro+ PH.

Adjustable mixing ratio : 1/0 and from 0,6/1 to 20/1

(BASE volume / CATALYST volume) (0% and from 166%

to 5%)

Measure precision : 1 %

Mixed fluid flow : from 100 to 2000 cm3/mn

Solvent flow : 7000 cm3/mn

Fluid viscosity : from 30 to 5000 cps

Mixing permanent check

Adjustable threshold alarm

Adjustable pot-life indicator

Automatic mixing control cycle

Automatic flushing cycle (time)

VOC display

Total indicator for base, catalyst and solvent

consumption

OPTION :

*Auto-wash (gun support)

You cannot go to production with the auto-

wash, no

connection to the CYCLOMIXTM MICRO.

* Connecting cable (5 m).

* Pickit 2 (Electronic programming kit) : the kit allows you

to update the program on the electronic cards.

Connections :

- Air :

Inlet : F 1/4 BSP / Outlet : F 1/4 BSP

- Material : :

Inlet : M 1/2 JIC / Outlet : M 1/2 JIC

SAMES KREMLIN Page 8 Manual : 573.191.112

NOTA : The version 2.82 is only compatible on electronic boards with version higher than V.2.32. Here

after an overview of major versions :

Kinf of

processor

- Electronic

card

Manufacturing

date first units

Soft

version

Presence of error 6 Soft compatibility

with 2.82 latest

version

PIC 18F4520

-

2.31 - -

PIC 18F4620

09 Y 1001

2.32 - Yes

10 Y 1133

2.6

Yes

Yes

14 Y 1152

2.82

Yes

- Can be setup with P12

Yes

Different versions of the CYCLOMIXTM MICRO :

Configurations

BASE

CATALYST

CYCLOMIXTM MICRO

1 base + 1 solvent

1 cata

3 bases + 1 solvent

1 cata

CYCLOMIXTM MICRO +

1 base + 1 solvent 1 cata + 1 solvent

3 bases + 1 solvent 1 cata + 1 solvent

CYCLOMIXTM MICRO+ PH

1 base + 1 solvent 1 cata + 1 solvent

3 bases + 1 solvent 1 cata + 1 solvent

The control unit is the same for all the versions of the CYCLOMIXTM MICRO.

You can change the configuration displacing the shunt located on the µ card (J7 terminal)

- (refer to"Annexes" - electric diagram).

5. INSTALLATION

DESCRIPTION OF THE LABEL MARKINGS

The CYCLOMIXTM MICRO is fitted with 2 label markings : a label marking on the control unit and the other one

on the fluid module.

Marking label on the control unit

(bay located outside the spray booth in a safe area)

Marking label on the fluid module

(fluid module located outside the spray booth in a

safe area)

SAMES KREMLIN Page 9 Manual : 573.191.112

CONTROL UNIT :

SAMES KREMLIN

STAINS FRANCE

Name and address of the manufacturer

CE

European conformity

Tension

CYCLOMIXTM MICRO voltage

P air

Maximum air pressure

P prod

Maximum fluid pressure

Serie / Serial

Number given by SAMES KREMLIN. The two first numbers indicate the

manufacturing year.

Ref

CYCLOMIXTM MICRO part number

Phase

Single phase

Fréquence

50-60Hz / Mains frequency

Ampérage

Maximum current used

NE PAS DEBRANCHER

SOUS TENSION

DO NOT DISCONNECT

WHILE POWER ON

-

Environmental Indication

(refer to § 2 - Environment)

FLUID MODULE :

SAMES KREMLIN

STAINS FRANCE

Name and address of the manufacturer

CE

European conformity

P air : 6 bar / 87 psi

Maximum air pressure

P prod : 175 bar / 2536 psi

Maximum fluid pressure

NE PAS DEBRANCHER

SOUS TENSION

DO NOT DISCONNECT

WHILE POWER ON

-

Environmental Indication

(refer to § 2 - Environment)

Caution!

The CYCLOMIX

TM

MICRO mixing system must be installed outside the explosive area.

It must be installed in a safe area (non explosive area according to the ATEX directive).

The control unit must not be above the fluid module.

The control unit must be connected to a mains supply fitted with a ground.

The ground of the fluid module must be grounded.

SAMES KREMLIN Page 10 Manual : 573.191.112

INSTALLATION DIAGRAM

A ATEX zone

B Non explosive area (safe area)

C ATEX zone

1A CYCLOMIXTM MICRO control unit

1B CYCLOMIXTM MICRO fluid module

2 Pumps + Accessories

The user is liable for the delimitation of the zones which depends on the materials

used, the material environment and the use conditions (refer to EN 60079 -10

standard).

SAMES KREMLIN Page 11 Manual : 573.191.112

IMPLANTATION

There are different ways to install the CYCLOMIXTM MICRO to answer to the majority of installations.

Nevertheless, some installations are forbidden because dangerous.

The control unit must not be installed the fluid module.

Fixing the control unit on the fluid module is forbidden.

Correct installation :

the control unit is not fixed to the fluid module.

Incorrect installation :

the control unit is fixed to the fluid module.

Correct installation :

The display unit and the fluid module are installed in a safe area.

Incorrect installation :

the display unit and/or the fluid module are installed in the spraybooth.

SAMES KREMLIN Page 12 Manual : 573.191.112

Assembly for piloting outside the booth :

The CYCLOMIXTM MICRO gets two parts to

enable the mismatch of the control part (5 m

/ 196.85 ft cable between the 2 components).

Assembly for piloting in the booth :

There is a control kit in booth (available in

option).

That kit enables to fix the control box on the

spray booth by means of a glass sheet and

to pilot that one inside. The piloting is

carried out thanks to a magnet provided with

the CYCLOMIX

TM

MICRO. The distance

between the control box and the fluid part is

of 5 m / 196.85 ft (cable provided with the

CYCLOMIX

TM

MICRO).

SAMES KREMLIN Page 13 Manual : 573.191.112

CONNECTION OF THE CONTROL UNIT AND OF THE FLUID PART

The CYCLOMIX

TM

MICRO must be

connected to a dry and clean

compressed air (minimum 4 bar / 58 psi)

and to a single phase electric supply

(115 V / 230V) connected to an isolating

switch. The network ground will be

connected in the control bay on a contact

provided.

Before connecting the

CYCLOMIX

TM

MICRO, be certain the

mains voltage is the

same than the

one of the CYCLOMIXTM MICRO

(230

V).

If no, open the electric box removing the

protective housing (10) and shift the

staple (230V 115V).

The air connection of the CYCLOMIX

TM

MICRO

is Female 1/4 G (air inlet = R1

and air outlet = R2).

The connection between the control unit

and the fluid module is carried out via

the

provided cable, length 5 m / 196.85 ft

.

For lengths up to 5 m / 196.85 ft

connect

the cables between them (male-female).

The connection between the two

cables must not be in the explosive area.

A valve fitted with fittings is supplied with

the CYCLOMIXTM MICRO

. It will be

mounted on the gun air inlet : it enables

to shut off quickly the fan air (priming,

flushing stage).

Fuse 160 mA

for CYCLOMIX

TM

MICRO

with serial number < to 09Y1080

Fuse 315 Ma

for CYCLOMIX

TM

MICRO

with serial number >to 09Y1080

Connection of the fluid inlets :

The fluid inlets are M 1/2 JIC.

We advice you to install AIRMIX

filters on the fluid inlets (catalyst and

base).

The base(s) and the base solvent are

connected on the color changer installed

on the CYCLOMIXTM MICRO.

The catalyst is connected :

-

directly on the elbow installed before

the non-return valve,

-

or on the color changer (cata and cata

solvent) installed in the CYCLOMIX

TM

MICRO.

It depends upon the configuration of the

CYCLOMIXTM MICRO.

The air connection is made on the two

G 1/4 connecting parts.

Air inlet /

outlet

Base(s) and solvent base

Catalyst

SAMES KREMLIN Page 14 Manual : 573.191.112

Assemble filters at the outlet of the BASE and CAT A p u mps.

Assemble pressure regulators at the outlet of the BASE and CATA pumps.

Install the fluid and air hoses between the pumps and the CYCLOMIXTM MICRO, and between the

CYCLOMIX

TM

MICRO and the gun. When choosing the fluid hoses, comply with the pressures delivered

by the pumps. For the air hoses, install non-static hoses.

Unscrew the regulators before supplying air to the installation.

Check that the three way-valve is in the IN fluid circuit sense and not in the TA circuit sense.

Nota : To connect the SOLVENT pump (CATA) to the CYCLOMIX MICRO :

- choose a CYCLOMIX

TM

MICRO set up with 1 catalyst and one cata solvent,

- or disconnect the CATA hose at non-return valve level (CATA) of the equipment and replace it

connecting the SOLVENT hose (CATA).

6. OPERATING

DRIVING FROM THE CYCLOMIX

TM

MICRO

SCREEN

The different menus and the informations relating to the CYCLOMIXTM MICRO are displayed on the

alphanumeric screen.

KEYBOARD

ESC

That key enables to quit the menus or the different modes (production, flushing,

parameters).

↵

That key enables to enter in the different menus or to validate a value of parameter.

▲

That key enables to shift from a menu to another and to increase the value of a

parameter during modifications of value.

▼

That key enables to shift from a menu to another and to decrease the value of a

parameter during modifications of value.

The keyboard is used thanks to a magnet provided with the CYCLOMIXTM MICRO. That piloting mode

enables to drive the CYCLOMIX

TM

MICRO inside the booth if the box is installed behind the booth glass.

That technology enables the operator to save time and to carry out his work from the application place.

SWITCHING ON THE CYCLOMIX

TM

MICRO

The placing of the system into operation requires that the BASE, CATALYST and

SOLVENT drums are full enough to ensure the production.

Connect the gun before placing the system into operation.

Supply air to the CYCLOMIXTM MICRO (minimum 4 bar / 58 psi).

Supply air to the air regulators of the pumps (BASE, CATALYST, SOLVENT).

Switch on the control unit (switch located on the side of the unit).

When switching on the control unit, a menu is displayed on the screen.

Nota : Parameters have been programmed in the factory before the delivery of the CYCLOMIX

TM

MICRO.

You must adapt the parameters to the use. They must be modified by an authorized person (refer to list

of parameters).

SAMES KREMLIN Page 15 Manual : 573.191.112

7. FIRST SWITCHING ON

STANDARD MENU

When switching on, the CYCLOMIX

TM

MICRO is waiting. The 'F-1' menu corresponds to the shift to the

production mode. There are 4 different menus : they enable to control the CYCLOMIX

TM

MICRO.

- F-1 : production

- F-2 : flushing

- F-3 : parameters

- F-4 : consumptions

To surf from a menu to another, you must move placing the magnet on the sensors indicated with '▲/▼'.

The menus scroll as follows :

Countdown of the fluid life time.

(countdown from 9 to 0; 9 represents

90% of the remaining time before the

regeneration).

A line is visible when the CYCLOMIX

TM

MICRO is flushed.

Function 1

Color 1

Consumptions

Production

Flushing

Parameters

SAMES KREMLIN Page 16 Manual : 573.191.112

Arborescence of the menus

Menu pending choice of

program

Menu of program change

ESC

ESC/↵

ESC/↵

ESC/↵

ESC/↵

ESC/↵

↵

ESC

3 color's

CYCLOMIXTM MICRO

↵

ESC

↵

ESC

With CATA flushing

Without CATA

flushing

If CATA flushing

↵

ESC

SAMES KREMLIN Page 17 Manual : 573.191.112

8. FIRST PLACING INTO OPERATION

During that first placing into operation, it is compulsory to have all the pumps

into solvent as well as the CYCLOMIX

TM

MICRO to ensure the good quality of

the fluid get by the CYCLOMIX

TM

MICRO.

The fluid pressure must not exceed 20 bar / 290 psi.

We advice you to install the TB fitting (provided with the CYCLOMIX

TM

MICRO)

instead of the mixer.

FLUSHING OF THE PUMPS AND OF THE CYCLOMIX

TM

MICRO INTO SOLVENT

• Carry out the connections indicated at § 5 (INSTALLATION).

• Check that the three way-valve is turned towards 'TA'.

• Remove the static mixer to install, instead of it, the adapter fitting (marked TB, F 3/4 JIC - F 1/4

G).

• Start the pumps with solvent and increase the fluid pressure to 1 bar / 14.5 psi.

• On the page of the display main menu, input "PRODUCTION MODE" ( F-1 then

↵

).

• Do not change the factory parameters for the moment.

• Make the CYCLOMIX

TM

MICRO mix until the solvent flows out clean. During that stage, t he

CYCLOMIX

TM

MICRO must be in fault due to air presence into hoses. In case of alarm, acquit,

then go to production mode.

CAUTION : shut off air turning the valve that has been mounted to the gun air inlet (Cf. § 5)

• Quit the production mode passing to ESC.

• Repeat the 4 stages previously indicated, when using a 3 shades' CYCLOMIX

TM

MICRO, with all

the shades (A2 and A3).

START-UP OF THE CYCLOMIX

TM

MICRO

• Check that the three way-valve is turned towards 'TA'.

• Start the pumps.

• Pass to production and let the fluid flow until it flows clean. In case of alarm, acquit then go to

production.

CAUTION : shut off air turning the valve that has been mounted to the gun air inlet (Cf. §

5).

• Repeat the stages previously indicated, when using a 3 shades' CYCLOMIX

TM

MICRO, with all

the shades (A2 and A3).

• Carry out a flushing before cleaning the 3 way-valve. As soon as the solvent is clean, pass to

ESC.

From now on you can enter your parameters of application.

After that first placing into operation, you must carry out a flushing to clean the 3

way-valve. During the flushing, flush correctly the TA side of the valve, then turn

the 3 way-valve to IN to flush the fitting at the outlet of the injector.

Once the first placing into opeartion and the flushing carried out, install the mixer

and leave the 3 way-valve on IN.

SAMES KREMLIN Page 18 Manual : 573.191.112

9. APPLICATION PROGRAMMING (F3)

To alter the parameters of the CYCLOMIXTM MICRO, go to F3, then validate. To shift from a parameter to

another, use the arrows

or .

Select the parameter to alter. Depress the key

, then the arrows or to increase or decrease the

value. Activate to validate the new value or ESC to cancel.

To quit a parameter, activate ESC.

To quit the PARAMETERS menu, activate ESC.

When using a 3 shades' CYCLOMIX

TM

MICRO, you must select the shade and alter later on the

parameters.

The parameters are pre-programmed in the factory. They must be modified (by an authorized person) to

adapt themselves to the material.

PASSWORD

When you start the CYCLOMIXTM MICRO for the first time the access code of the menu `Parameters'

is deactivated, everyone is able to modify the CYCLOMIX

TM

MICRO parameters.

To activate this access code you have to :

- enter in the parameter 0 of the menu F3 :

« key

»

« key

». The

code

‘

’ appears, it’s the code present by default in the equipment.

- change the code by using the arrows

or and the «key

» for each digit which compose this

code.

Once the access code was validated, the access is protected by the password. Only the people who

know this password and those which know the administrator code

‘

’ will be able to reach the

menu `Parameters'.

Each time a user wants to enter in the menu 'Parameters' the password will be required:

.

The user shall enter the password by using the arrows

or and the «key

» for each digit

which compose this code :

- If the entered code is correct, the following fonts

appear.

- If the entered code is incorrect, the word ‘

appears and the CYCLOMIXTM MICRO allows

you to enter the password again (Press 'Esc' to return to the principal menu).

If you want to desactivate the password, you just have to parameterise the code

‘

’ again as

access code.

PROCEDURE TO GET THE VERSION NUMBER OF THE ELECTRONIC CARD

- Install the magnet on the OK key,

- Start the CYCLOMIX

TM

MICRO.

SAMES KREMLIN Page 19 Manual : 573.191.112

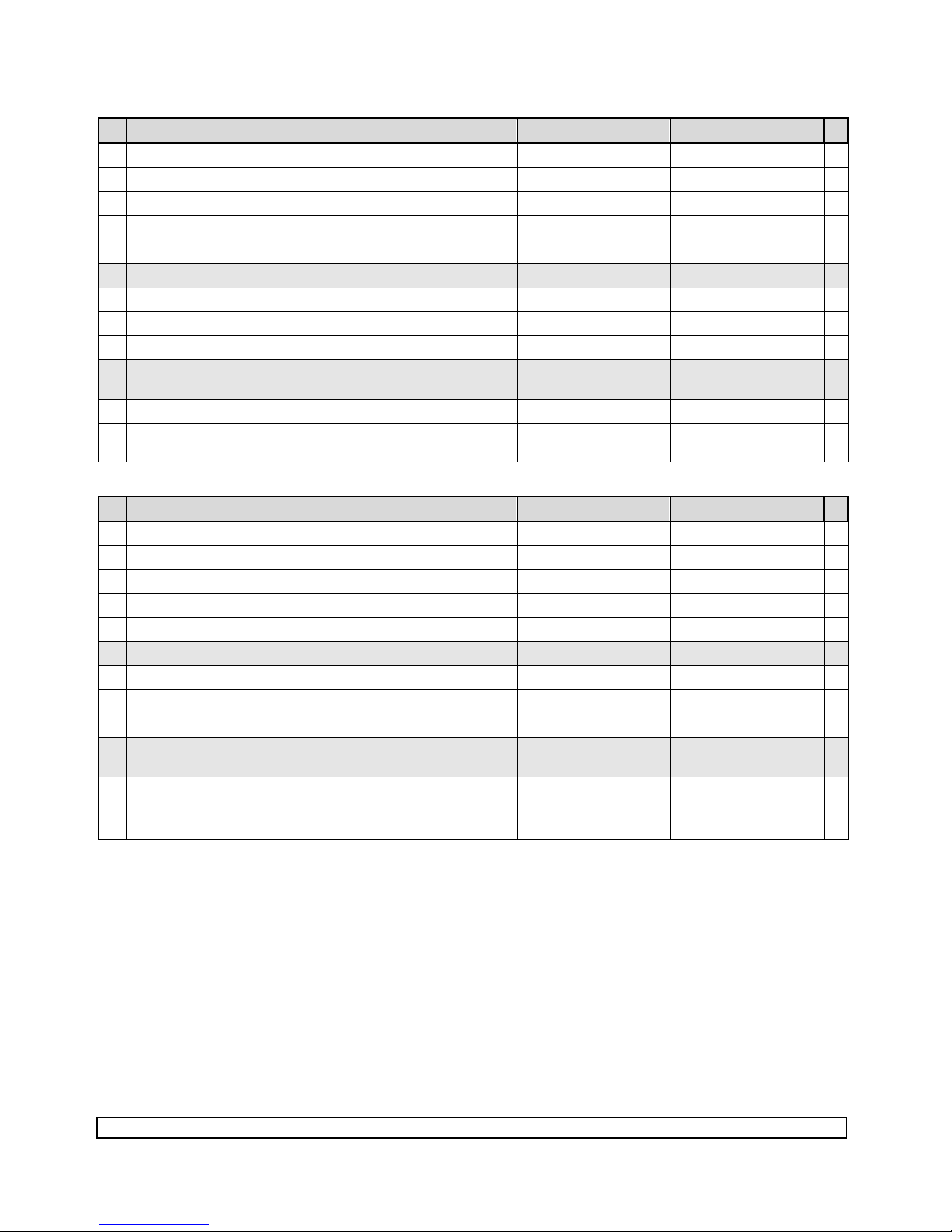

PARAMETERS FOR CYCLOMIX

TM

MICRO WITHOUT CATALYST FLUSHING

Parameters Description

Factory

adjustment

For the 3

programs

Your

adjustment

Program 1

Your

adjustment

Program 2

Your

adjustment

Program 3

Parameter of the password

Mixing ratio parameter. Percentage

of catalyst in the base, from 0% to

160%

50 %

Parameters of the mixed fluid life

time

Minimum value : 1min

Maximum value : 480 min

100 min

Regeneration volume parameter in

cubic centimetre

Minimum value : 100 c.c

Maximum value : 10 000 c.c

5000 c.c

Flushing volume during which the

CYCLOMIXTM MICRO flushes

with solvent

Minimum value : 10 c.c

Maximum value : 10 000 c.c

500 c.c

Mixing tolerance parameter to

enable the CYCLOMIX

TM

MICRO

to make an alarm.

Minimum value : 1%

Maximum value : 100%

5 %

Parameter of the fluid dry extract to

count the VOC

Minimum value : 0%

Maximum value : 100%

55 %

Parameter of volume by tooth of

base flowmeter. You must change

that parameter when changing the

flowmeter.

Minimum value : 0.01 c.c

Maximum value : 2.00 c.c

0.24 c.c

(Value of

origin)

Parameter of volume by tooth of

catalyst flowmeter. You must

change that parameter when

changing the flowmeter.

Minimum value : 0.01 c.c

Maximum value : 2.00 c.c

0.24 c.c

(Value of

origin)

Parameter of time between the air

opening and the fluid opening

before fault

Minmum value : 1 s

Maximum value : 6 s

6 s

(Value of

origin)

Parameter of the proportioning test

: to activate this parameter

-

SAMES KREMLIN Page 20 Manual : 573.191.112

Parameters Description

Factory

adjustment

For the 3

programs

Your

adjustment

Program 1

Your

adjustment

Program 2

Your

adjustment

Program 3

Handling of the error 6 in the

operating of the

CYCLOMIXTM

MICRO

during the production

sequence (parameter available for

CYCLOMIXTM MICRO with serial

number > 14 V 1152).

Minimum value : 0 pulse

Maximum value : 5000 pulses

100 pulses

(Value of

origin)

PARAMETERS FOR CYCLOMIX

TM

MICRO WITH CATALYST FLUSHING

Parameters Description

Factory

adjustment

For the 3

programs

Your

adjustment

Program 1

Your

adjustment

Program 2

Your

adjustment

Program 3

Parameter of the password

Mixing ratio parameter. Percentage

of catalyst in the base, from 0% to

160%

50%

Parameters of the mixed fluid life

time

Minimum value : 1min

Maximum value : 480 min

100 min

Regeneration volume parameter in

cubic centimetre

Minimum value : 100 c.c

Maximum value : 10 000 c.c

5000 c.c

BASE flushing volume during which

the CYCLOMIX

TM

MICRO flushes

with solvent

Minimum value : 10 c.c

Maximum value : 10 000 c.c

500 c.c

CATA flushing vol ume during which

the CYCLOMIX

TM

MICRO flushes

with solvent

Minimum value : 10 c.c

Maximum value : 10 000 c.c

500 c.c

Mixing tolerance parameter to

enable the

CYCLOMIXTM MICRO

to make an alarm.

Minimum value : 1%

Maximum value : 100%

5 %

SAMES KREMLIN Page 21 Manual : 573.191.112

Parameters Description

Factory

adjustment

For the 3

programs

Your

adjustment

Program 1

Your

adjustment

Program 2

Your

adjustment

Program 3

Parameter of the fluid dry extract to

count the VOC

Minimum value : 0%

Maximum value : 100%

55 %

Parameter of volume by tooth of

base flowmeter. You must change

that parameter when changing the

flowmeter.

Minimum value : 0.01 c.c

Maximum value : 2.00 c.c

0.24 c.c

(Value of

origin)

Parameter of volume by tooth of

catalyst flowmeter. You must

change that parameter when

changing the flowmeter.

Minimum value : 0.01 c.c

Maximum value : 2.00 c.c

0.24 c.c

(Value of

origin)

Parameter of time between the air

opening and the fluid opening

before fault

Minimum value : 1 s

Maximum value : 10 s

6 s

(Value of

origin)

Parameter of the proportioning test

: to activate this parameter

-

Handling of the error 6 in the

operating of the

CYCLOMIXTM

MICRO

during the production

sequence (parameter available for

CYCLOMIXTM MICRO with serial

number > 14 V 1152).

Minimum value : 0 pulse

Maximum value : 5000 pulses

100 pulses

(Value of

origin)

SAMES KREMLIN Page 22 Manual : 573.191.112

10. PRODUCTION (F1)

When passing for the first time to production, the CYCLOMIX

TM

MICRO carries out a regeneration :

The control unit consists of a countdown that enables to know, in percentage (9 between 90% and

100% of the volume), the pending volume flow according to the P3 parameter. At the end of that stage, the

CYCLOMIX

TM

MICRO enters in production. You can also activate ESC during the fluid priming; we advice

you not to start painting immediately.

In production, as well as in regeneration, the CYCLOMIX

TM

MICRO injects little volumes of catalyst in a

base constant flow. At the end of each injection, the CYCLOMIX

TM

MICRO checks the mixing and re-

adjusts the volumes of injections considering the mixing difference.

In production, there are 3 main cases :

- the operator is spraying and the CYCLOMIXTM MICRO operates correctly. The real mixing ratio is

displayed on the screen.

- the CYCLOMIXTM MICRO stops because of a dysfunction. The kind of breakdown is displayed on the

screen, the CYCLOMIXTM MICRO emits a sound signal to inform the operator (cf §

"TROUBLESHOOTINGS") .

- The CYCLOMIXTM MICRO has reached the maximum life duration of the material and passes

automatically in regeneration mode. The CYCLOMIXTM MICRO

emits a sound signal to inform the

operator. The following screen is displayed :

Open the gun until the regeneration ends.

To exit from production : activate ESC. The following screen is displayed :

In the 3 shades' version, during the color change, the potlife is updated with the new parameters of the

selected color. If you validate another color, the potlife in progress with the old color will remain until a flushing

or a regeneration is carried out.

If the CYCLOMIXTM MICRO

is not in mixed material, a regeneration is automatically

carried out to bring the mixed material to the gun.

We advice you to shut off air during that stage.

You can stop the regeneration activating ESC.

Then, the regeneration stops, but

careful, the quality of the product can be inferior.

Program

Real mixing ratio

Potlife (9-0)

SAMES KREMLIN Page 23 Manual : 573.191.112

PROPORTIONING TEST

L

K

To carry out a mixing test, decrease a lot the pressure of the fluids

(maximum 18 bar / 261 psi) to provide any projection of dangerous

material. We advice you to wear protective glasses and gloves.

1. Turn the three way-valve to the TA index.

2. Remove the static mixer to install, instead of it, the adapter fitting (marked TB, F 3/4 JIC

- F 1/4 G).

3. Place 2 beakers under the fluid outlets : TA and at the outlet of the TB mixer block.

4. Go in the menu F3 an then access to the parameter 10 (without catalyst flushing) or

parameter 11 (with catalyst flushing) to activate the proportioning test.

5. When you have a sufficient sample volume, activate ESC.

Note : During the proportioning test, the error 6 is desactivated. The other errors are active only if

the flow-switch is activated. We advice you to keep the error 6 active (P11 / P12 >0).

After that operation, you must carry out a flushing to clean the 3 way-valve.

During the flushing, flush correctly the TA side of the valve, then turn the 3 wayvalve to IN to flush the fitting at the outlet of the injector.

Once the test ended and the flushing carried out, install the mixer and leave the 3

way-valve on IN.

11. FLUSHING (F2)

The menu is useful for the flushing. When you want to flush the CYCLOMIX

TM

MICRO, activate

when you are on the F-2 menu.

For the CYCLOMIX

TM

MICRO without CATA flushing :

The CYCLOMIXTM MICRO asks for a confirmation to start flushing :

After confirming via

, the CYCLOMIX

TM

MICRO opens the solvent valve, starts the counting of the

volume and the buzzer sounds continuously. When you begin the flow, the buzzer sounds

intermittently and a breakdown begins on the display unit :

When the breakdown has reached 0, the CYCLOMIX

TM

MICRO closes the solvent valve and the

BASE flushing has ended.

For a long duration shutdown without CATA flushing, flush the catalyst circuit :

You must disconnect the CATA hose and connect, instead of it, the SOLVENT hose (CATA). Pilot

with air the VP6 valve until the solvent flows clean.

SAMES KREMLIN Page 24 Manual : 573.191.112

For the CYCLOMIXTM MICRO with CATA flushing :

That mode is only available for the CYCLOMIXTM MICRO+ and CYCLOMIXTM MICRO+ PH versions. A

J7 shunt inside the electric box is also necessary - (refer to"Annexes" - electric diagram).

The CYCLOMIX

TM

MICRO suggests a BASE

flushing :

Choose :

- to confirm via

:

⇒

the CYCLOMIXTM MICRO opens the solvent valve, starts the counting of the BASE

FLUSHING volume and the buzzer sounds continuously.

- Or to select the CATA FLUSHING (BASE side flushing, then CATA side flushing), via

the

orkeys.

⇒

The CYCLOMIXTM MICRO

suggests the CATA

flushing :

Confirm via

:

⇒

the CYCLOMIXTM MICRO opens the BASE solvent valve, starts the counting of the BASE

FLUSHING volume then opens the CATA solvent valve, starts the counting of the CATA FLUSHING

volume and the buzzer sounds continuously.

- Or to select the CATA FLUSHING (CATA side flushing, then BASE side flushing), via the

or

keys.

⇒

The CYCLOMIXTM MICRO suggests the CATA

flushing :

Confirm via

:

⇒

the CYCLOMIX

TM

MICRO opens the CATA solvent valve, starts the counting of the CATA

FLUSHING volume, then opens the BASE solvent valve, starts the counting of the BASE FLUSHING

volume and the buzzer sounds continuously.

When you begin to flow, the buzzer sounds intermittently and a breakdown begins on the display unit.

The breakdown display evokes the kind of flushing in progress :

BASE : -F-A 9

or

BASE + CATA : -F-Ab9

or

CATA + BASE : -F-bA9

When the breakdown has reached 0, the CYCLOMIXTM MICRO closes the solvent valve and the

flushing has ended.

You can stop flushing activating ESC but if so, the CYCLOMIX

TM

MICRO can be

incorrectly flushed.

The volume of flushing with solvent starts when the flowmeter begins counting. It

means that the time between the validation of the flushing and the opening of the

gun is not taken into account.

SAMES KREMLIN Page 25 Manual : 573.191.112

12. CONSUMPTIONS / PRINT (F4)

The 'F-4' menu enables to view the consumptions of each material (color, catalyst, solvent, VOC in

c.c.). You can also print the ratio of the consumptions as well as the parameters of the applications

but, you must equip yourself with the 'print' option. The option consists of a connection cable with

connectors to connect the printer (RS 232 connection) (printer not provided with the option).

Consumption of the color 1

Consumption of the flushing solvent

Consumption of the color 2

(for a 3 shades' CYCLOMIX

TM

MICRO)

Consumption of the VOC

Consumption of the color 3

(for a 3 shades' CYCLOMIX

TM

MICRO)

Reset of the consumptions activating

the key

Consumption of the catalyst

Enables to print the consumptions

and the parameters activating the key

Consumption of the CATA

solvent (depending upon

version of the CYCLOMIX

TM

MICRO)

SAMES KREMLIN Page 26 Manual : 573.191.112

13. DOWNLOADING DATA FROM CYCLOMIX MICRO TO A COMPUTER

Nota : The following procedure has some screenshots w ith the PU 3000 quote . The procedure is

the same for the Cyclomix

TM

Micro.

Preamble / "Hyper Terminal" issue

This application is necessary. Two cases are to be considered :

.PC under Windows XP/Vista/2000,

.PC under Windows 7.

• With Windows XP/Vista/2000, "HyperTerminal" application is av ailable wit h the f ollowing pat h :

Menu Start

>

All programs > Accessories > Communications > HyperTerminal

• With Windows7, you will need to download freeware "HyperTerminal" from some website.

For example : http://www.01net.com/telecharger/windows/Bureautique/telephonie/fiches/5829.html

Once it is downloaded and installed, carry out a simple test of opening and closing.

It should look like this whenever open :

Switching of the control box

•

Switch the control box.

•

Link a "RS232 male / USB male"

cable to the plug located below the Micro back frame, the other end

to the USB plugs on the computer. Cable not supplied by KR.

•

According to the USB plug used a "port com

" number appears in the "device manager" screen

(Menu

Start > Control panel > Device manager).

SAMES KREMLIN Page 27 Manual : 573.191.112

•

After deployment of the "Ports" line, one of them indicates the cable pilot name ("Prolific USB" for

example or else), followed by the "port com" number (COM5 in that display).

• Open "HyperTerminal" window.

•

At the first connection, create a new connecting session, write a name in (order number or paint

reference)

by choosing the first left icon. Press OK.

• This screen appears. Select the "port com" number previously noted during your connection.

Press OK.

SAMES KREMLIN Page 28 Manual : 573.191.112

• That new screen will appears. Select band rate 9600 bits/s. Press OK.

• A connection stopwatch gets activated. Leave the "Hyper Terminal" window open.

• If a session has already been created, opening the existing file is possible by going directly

through the, of the "HyperTerminal" menu, and by choosing it within the list of the *.ht files.

(ex : PU3000usb).

•

Create a .txt file through "transfer"

(transfer >

capture text), choose some file name as target

(ex : dataPU3000.txt), with a location within the PC disk, and press "START" (the empty file is

created

/

leave the HyperTerminal window always open) :

SAMES KREMLIN Page 29 Manual : 573.191.112

• Launch the data transfer from the control box (menu "F4. Prn" + OK), the data do appear

(partially) in the display zone.

• Get back in the "transfer" menu (transfer

> capture text) and press "Stop" :

• Data then become available when opening the previous created .txt file.

SAMES KREMLIN Page 30 Manual : 573.191.112

• From these displayed elements .txt (difficult to read up), make a simple "copy/paste" i n an E xcel

file and data will appear as per that screen :

14. INDICATIONS GIVEN BY THE LEDS

Description Function Action

Red LED Fault The CYCLOMIXTM MICRO stops.

Orange LED Working Function other than production (flushing, pot-

life alarm …)

Green LED Production

Green + orange LED Waiting

LED switched off Programming

15. MAINTENANCE

Guards (air motor cover, coupling shields, connectors,…) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards.

SAMES KREMLIN Page 31 Manual : 573.191.112

L

K

Never leave the mixed material in the CYCLOMIX

TM

MICRO

. Properly adjust the

pot life parameter to avoid hardening. Carry out a flushing when the work is

over.

Flush when ending the work.

The life duration of the different elements depends on the features of the material used. The following maintenance plan is for

information only and could not be taken into account when making a complaint.

option

SAMES KREMLIN Page 32 Manual : 573.191.112

TROUBLESHOOTING

For any intervention on the CYCLOMIX

TM

MICRO :

- Flush the circuits,

- Shut off the compressed air,

- Depressurize the hoses by triggering the gun,

- Shut off the electric supply.

If a problem occurs during the operating of the CYCLOMIXTM MICRO, some alarm will be displayed on

the screen of the CYCLOMIX

TM

MICRO.

Enter

to acquit each alarm (we advice you to keep active the error 6 even if you can can desactivate

it).

TROUBLES CAUSES SOLUTIONS

BASE flowmeter blocked. Check the fluid circuit (pump, valve).

Clean or change.

Check o

r install a filter upstream the

flowmeter.

CATA flowmeter blocked. Check the fluid circuit (pump, valve).

Clean or change.

Check or install a filter upstream the

flowmeter.

Incorrect mixing ratio

Flow improperly adjusted

Check the pressure differe

ntial : the

CATA pressure must be higher than the

BASE pressure of 15%

Time between air opening and fluid

opening upper than 6 s

Flow switch blocked

Air leak

Trigger the gun quickler.

Change the flow switch.

VP6 valve leaking Remove VP6 and

check the correct

operating.

Change the valve if necessary.

(Caution: this error

appears

only in F1 mode

(production) and except

the priming

/regeneration stage)

There is no signal from the flowswitch whereas there are impulses on

the base flowmeter or on the catalyst

flowmeter.

Check the good operation of the flowswitch. Change it if necessary.

Control the good operation of the

electronic card.

Increase the value of P12.

SAMES KREMLIN Page 33 Manual : 573.191.112

DIAGNOSTICS

ELECTRIC

FAULTS CHECKING

The CYCLOMIXTM MICRO does not switch on

Check that the isolating switch is on 'I'.

Check that the mains supply is connected.

No : connect it.

Check that the fuse on the electric card inside the

box is in working order.

No : change the fuse (ind. 3).

Check the electric wirin

g of the supply cable (bad

contact or other).

You can choose the color (when using a 3 colors'

CYCLOMIXTM MICRO)

Check the connection of the J7 shunt inside of the

electric box (refer to Annexes).

FLUID

FAULTS CHECKING

No fluid flows when passing into p

roduction or

flushing mode.

Check if the valves are open :

No : - Check air supply (minimum 4 bar / 58 psi),

- Check the connection of the 25 pts cable

- Check the correct operating of

theelectrovalves.

Yes : - Check the fluid pressure

- Check the static mixer.

In production :

there is only catalyst and the

injection valve opens but

does not close.

Moreover, the CYCLOMIXTM MICRO

does not

indicate faults.

Check the flow switch and the CATALYST flowmeter.

In production :

the base only flows and the

injection valve does not open.

Check the flow switch & the BASE flowmeter.

The CYCLOMIXTM MICRO

displays the correct

mixing but the consumption of catalyst is too

important.

Check the non-return valve of the BASE .

Check the grounds of the CYCLOMIX

TM

MICRO

(230V intake and ground cable of the fluid module)

The CYCLOMIXTM MICRO

displays the correct

mixing but the consumption of catalyst is not

enough.

Check the grounds of the CYCLOMIXTM MICRO.

When the main menu page is displayed, fluid

flows out when the gun is open

Check the valves

Checking of the valve : look at what is flowing :

if it is solvent, change the valve (Vp 1),

if it is base, change the valve (Vp 2),

if it is catalyst, change the valve (Vp 6).

In production : the fluid flows from the TA test

outlet

Change the 3 way-valve.

SAMES KREMLIN Page 34 Manual : 573.191.112

FAULTS CHECKING

One of the meters does not count

If the CYCLOMIX

TM

MICRO

indicates that the BASE

flowmeter is blocked and that the fault is recurrent :

-

Clean the mobile parts of the flowmeter (gearing

and bearings),

- Check the sensor assembly,

- Check the electric wiring of the sensor.

If the CYCLOMIXTM MICRO

indicates that the

CATALYST flowmeter is blocked and that the fault is

recurrent :

-

Clean the mobile parts of the flowmeter (gearing

and bearings),

- Check the sensor assembly,

- Check the electric wiring of the sensor,

- Check the VP6 valve,

- Check the piloting electrovalve of the VP6 valve,

- Check if there is a clogging of the injector.

AUTO-WASH

You cannot switch to production with the auto-wash : it only can be used as a support.

SAMES KREMLIN Page 35 Manual : 573.191.112

16. DISASSEMBLY - REASSEMBLY

Stop the CYCLOMIXTM MICRO after its flushing.

Depressurize the systems.

Guards (air motor cover, coupling shields, connectors,…) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards.

MIXER

Unscrew the mixer assembly and replace it with a new one.

FLOWMETER

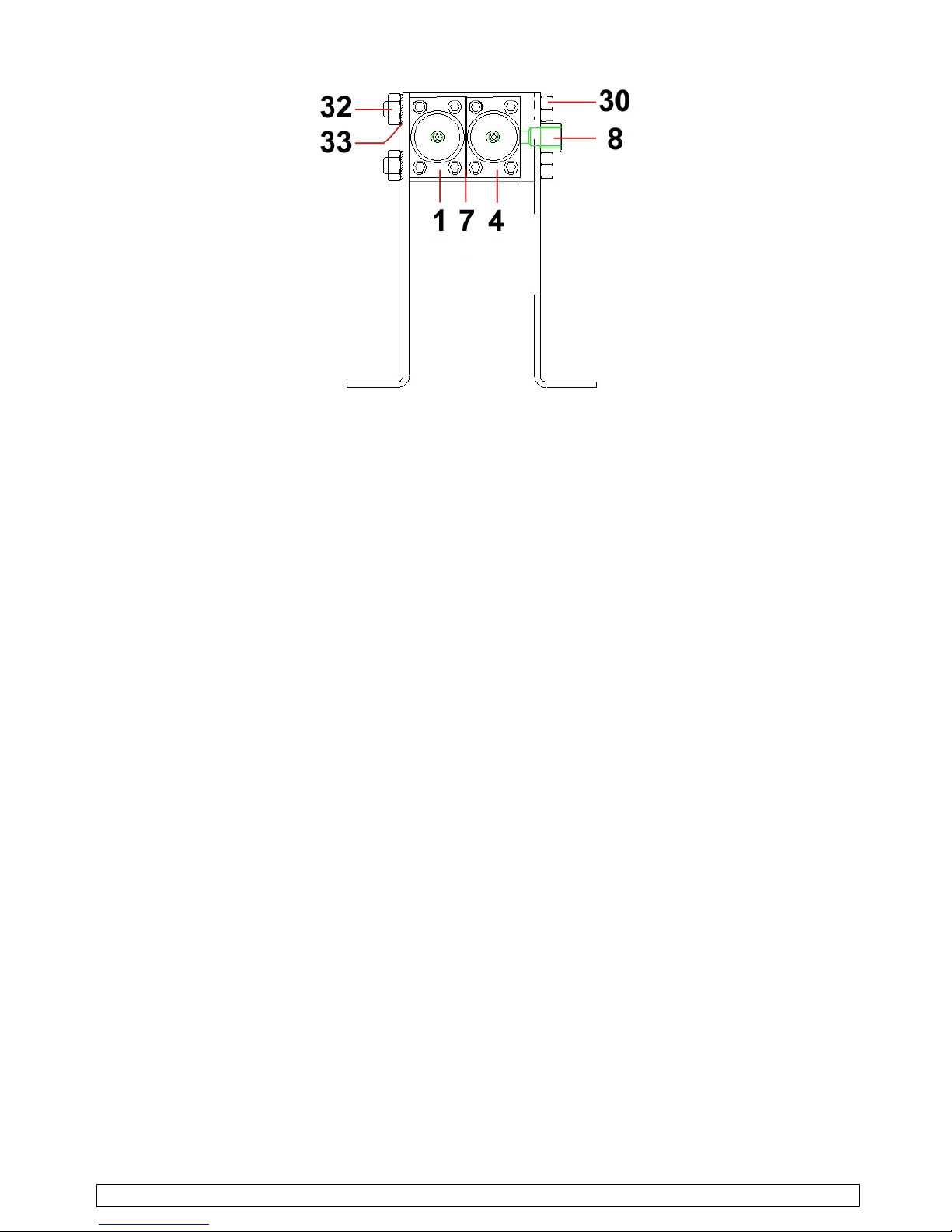

The flowmeters consist of an electronic sensor

(1) and of a mechanical part that is composed

of bearings and gearings.

To remove the flowmeter : disconnect the

connector (2) and unscrew the sensor (1).

Then loosen the screws (3) of the mechanic

part. Once the screws removed, open the

flowmeter paying attention to the seal (4) and

to the gearings (5).

Clean the different

elements then reinstall.

SAMES KREMLIN Page 36 Manual : 573.191.112

NEW MODULE INSTALLATION (OR MODULE REPLACEMENT) (REFER TO DOC. 573.187.050)

Unscrew nuts (32).

Remove washers (33).

Carry out the same operation for the second tie-rod.

Remove both tie-rods (30).

Mount the new module (be certain seal (7) is installed between two modules).

Slide the appropriate tie-rods through the modules, from fluid outlet flange to the end

module.

Be careful when positioning tie-rods (30), tie-rods head against fluid outlet flange

(8).

Install washers (33) and then screw nuts (32).

SAMES KREMLIN Page 37 Manual : 573.191.112

PILOTED VALVES (FLUID VALVES AND TEST VALVES)

CARTRIDGE OF A FLUID VALVE (IND. 9A / 9B / 9C / 9D) (REFER TO DOC. 573.188.050)

Unscrew the 3 screws (7).

Extract the valve from the module body.

Unscrew the needle (1a / 1b / 1c).

Unscrew the cylinder (4a / 4b).

Hold rod carrier (6), unscrew the needle rod and remove cartridge with rod assembly (9a /

9b / 9c / 9d). Remove the seals.

When reassembling :

Change the seals (11a / 11b), lubricate them then install new cartridge (9a / 9b / 9c / 9d) in

cylinder support (2) by pushing it until the cartridge shoulder comes to lean against the

cylinder support shoulder. Then reinstall all the components in the reverse order of

disassembly.

Install the valve in front of the module body.

Centre the cartridge (9a / 9b / 9c / 9d) on the module body and reinstall screws (7).

A 1

C 2

C 2

A 1

A 1

SAMES KREMLIN Page 38 Manual : 573.191.112

PISTON PACKING (Ind. 14)

131415164

8

5

Unscrew the cylinder (4).

Remove the spring (5).

Unscrew the opening signal light (8).

Unscrew the nut (16).

Remove the support washer (15) and the packing (14).

Clean the parts and change them if necessary.

Before reassembling :

Before assembling on the piston (13), take care of shaping the cartridge lip (14) by hand as

shown in the above drawing (cartridge turned up on the piston).

The nut (16) must be glued on the piston (13) with loctite adhesive

(eg : Loctite 222).

Index Instructions Description Part number

A 1

PTFE grease

PTFE grease (10 ml / 0.0026 US gal)

560.440.101

C 2

Low strength

- Anaerobic Adhesive

Loctite 222 (50 ml / 0.013 US gal)

554.180.010

SAMES KREMLIN Page 39 Manual : 573.191.112

INSTRUCTION MANUAL

COLOR CHANGER

Manual : 1812 573.186.112

Date : 20/12/18 - Supersede : 31/05/16

Modif. : Update

TRANSLATION FROM THE ORIGINAL MANUAL

IMPORTANT : Before assembly and start-up, please read and clearly understand all the doc-

uments relating to this equipment (professional use only).

THE PICTURES AND DRAWINGS ARE NON CONTRACTUAL. WE RESERVE THE RIGHT TO MAKE CHANGES WITHOUT PRIOR

NOTICE.

SAMES KREMLIN SAS

l

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

www.sames-kremlin.com

SAMES KREMLIN Page 1 Manual : 573.186.112

INSTRUCTION MANUAL

COLOR CHANGER

TABLE OF CONTENTS

1. GENERAL SAFETY INSTRUCTIONS ........................................................ .... .... .... ... ........ .... .... ... .... .... .. 2

2. DESCRIPTION ................................................................................. .................................. ..................... 2

3. ASSEMBLING ......................................................................................................................................... 3

4. TECHNICAL FEATURES............ ........ .... .... ... .... .... .... ....... .... .... ... .... .... .... ... ........ .... .... ... .... .... .... ............. 3

5. DISASSEMBLY - ASSEMBLY................................................................................................................ 5

ADDITIONAL

DOCUMENTATIONS :

EU declaration of conformity 578.050.130

Spare parts

Color changer 573.187.050

CTM valve 573.188.050

SAMES KREMLIN Page 2 Manual : 573.186.112

Dear Customer,

You are the owner of our new color c hanger and we would like to take this opportunity to thank

you.

To make sure your investment will provide full satisfaction, special care has been taken by