DOCUMENTATION

PUMP 06R440

Manual : 582.053.110-UK - 1908

Date: 12/08/19

Supersede : 27/05/16

Modif.: Update

TRANSLATION FROM THE ORIGINAL MANUAL

IMPORTANT : Before assembly and start-up, please read and clearly understand all the documents relating to

this equipment (professional use only).

THE PICTURES AND DRAWINGS ARE NON CONTRACTUAL. WE RESERVE THE RIGHT TO MAKE CHANGES WITHOUT PRIOR NOTICE..

SAMES KREMLIN SAS

l

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

www.sames-kremlin.com

SAMES KREMLIN SAS

13, chemin de Malacher

38 240 - MEYLAN - France

578.116.130 1908

: 33 (0)4 76 41 60 60

www.sames-kremlin.com

Pour une utilisation sure, Il est de votre

responsabilité de :

Lire attentivement tous les documents contenus

dans le CD joint avant la mise en service de

l’équipement,

D’installer, d’utiliser, d’entretenir et de réparer

l’équipement conformément aux préconisations de

SAMES KREMLIN ainsi qu’aux réglementations

nationales et/ou locales,

Vous assurez que les utilisateurs de cet

équipement ont été formés, ont parfaitement compris

les règles de sécurité et qu’ils les appliquent.

ES IT PT

FR UK DE

Para una utilización segura, será de su

responsabilidad:

leer atentamente todos los documentos que se

incluyen en el CD adjunto antes de la puesta en

servicio del equipo,

instalar, utilizar, efectuar el mantenimiento y

reparar el equipo con arreglo a las recomendaciones

de SAMES KREMLIN y a la normativa nacional y/o

local,

cerciorarse de que los usuarios de este equipo han

recibido la formación necesaria, han entendido

perfectamente las normas de seguridad y las aplican.

NL SE FI

Voor een veilig gebruik dient u:

alle document op de bijgevoegde cd aandachtig te

lezen alvorens het apparaat in werking te stellen,

het apparaat te installeren, gebruiken,

onderhouden en repareren volgens de door SAMES

KREMLIN gegeven aanbevelingen en overeenkomstig

de nationale en/of plaatselijke reglementeringen,

zeker te stellen dat de gebruikers van dit apparaat

zijn opgeleid, de veiligheidsregels perfect hebben

begrepen en dat zij die ook toepassen.

PL CS SL

Dla zapewnienia bezpiecznego użytkowania na

użytkowniku spoczywa obowiązek:

Uważnego zapoznania się ze wszystkimi

dokumentami znajdującymi się na załączonej płycie CD

przed pierwszym uruchomieniem urządzenia,

Instalowania, użytkowania, konserwacji i naprawy

urządzenia zgodnie z zaleceniami firmy SAMES

KREMLIN oraz z przepisami miejscowymi,

Upewnienia, że wszyscy przeszkoleni użytkownicy

urządzenia zrozumieli zasady bezpieczeństwa i stosują

się do nich.

SK HU RO

V záujme bezpečného je vašou povinnosťou:

pozorne si prečítať všetky dokumenty obsiahnuté

na priloženom CD predtým, ako zariadenie uvediete do

prevádzky,

nainštalovať, používať, udržiavať a opravovať

zariadenie v súlade s odporúčaniami spoločnosti

SAMES KREMLIN a národnými a/alebo miestnymi

predpismi,

uistiť sa, že používatelia tohto zariadenia boli

zaškolení, riadne porozumeli pravidlám bezpečnosti a

používajú ich.

Déclaration(s) de conformité au verso de ce document / Declaration(s) of conformity at the back of this document / Konformitätserklärung(en) auf der Rückseite dieser Unterlage

/ Declaración (es) de conformidad en el reverso de este documento / Dichiarazione/i di conformità sul retro del presente documento

/ Declaração(ções) de conformidade no verso do documento / Conformiteitsverklaring(en) op de keerzijde van dit document / Försäkran om överensstämmelse på omstående

sida av detta dokument / Vaatimustenmukaisuusvakuutukset tämän asiakirjan kääntöpuolella / Deklaracja(e) zgodności na odwrocie dokumentu

/ Prohlášení o shodě se nachází/nacházejí na zadní straně tohoto dokumentu / Deklaracija(e) o skladnosti na hrbtni strani tega dokumenta / Vyhlásenie/-a o zhode sa nachádzajú

na zadnej strane dokumentu / A dokumentum hátlapján szereplő megfelelőségi nyilatkoz(ok) / Declaraţii de conformitate pe versoul acestui document

SAMES KREMLIN N° : 578.116.130-1908

To ensure safe use of the machinery, it is your

responsibility to:

Carefully read all documents contained on the

enclosed CD before putting the machinery into service,

Install, use, maintain and repair the machinery in

accordance with SAMES KREMLIN's

recommendations and national and/or local

regulations,

Make sure that the users of the machinery have

received proper training and that they have perfectly

understood the safety rules and apply them.

Per un uso sicuro, vi invitiamo a:

leggere attentamente tutta la documentazione

contenuta nel CD allegato prima della messa in

funzione dell'apparecchio,

installare, utilizzare, mantenere e riparare

l'apparecchio rispettando le raccomandazioni di

SAMES KREMLIN, nonché le normative nazionali e/o

locali,

accertarvi che gli utilizzatori dell'apparecchio

abbiano ricevuto adeguata formazione, abbiano

perfettamente compreso le regole di sicurezza e le

applichino.

För en säker användning av utrustningen ansvarar ni

för följande:

Läs noga samtliga dokument som finns på den

medföljande cd-skivan innan utrustningen tas i drift.

Installera, använd, underhåll och reparera

utrustningen enligt anvisningarna från SAMES

KREMLIN och enligt nationella och/eller lokala

bestämmelser.

Försäkra er om att användare av denna utrustning

erhållit utbildning, till fullo förstått

säkerhetsföreskrifterna och tillämpar dem.

Pro bezpečné používání jste povinni:

Před uvedením zařízení do provozu si pozorně

přečíst veškeré dokumenty obsažené na přiloženém

CD,

Nainstalovat, používat, udržovat a opravovat

zařízení v souladu s pokyny firmy SAMES KREMLIN

a s národními a/nebo místními legislativními předpisy,

Ujistit se, že uživatelé tohoto zařízení byli

vyškoleni, že dokonale pochopili bezpečnostní pravidla

a že je dodržují.

A biztonságos használat érdekében az Ön

felelőssége, hogy:

a berendezés üzembe helyezése előtt figyelmesen

elolvassa a mellékelt CD által tartalmazott összes

dokumentumot,

a berendezést a SAMES KREMLIN ajánlasainak

valamint a nemzeti és/vagy helyi szabályozásoknak

megfelelően helyezze üzembe, használja, tartsa

karban és javítsa,

megbizonyosodjon róla, hogy a berendezés

felhasználói képzettek, tökéletesen megértették és

alkalmazzák a biztonsági előírásokat.

Eine sichere Nutzung setzt voraus, dass Sie: :

alle in der CD enthaltenen Dokumente vor der

Inbetriebnahme der Anlage aufmerksam lesen,

die Anlage im Einklang mit den Empfehlungen von

SAMES KREMLIN sowie mit den nationalen und/oder

lokalen Bestimmungen installieren, verwenden,

warten und reparieren,

sich vergewissern, dass die Nutzer dieser Anlage

angemessen geschult wurden, die

Sicherheitsbestimmungen verstanden haben und sie

anwenden.

Para uma utilização segura, é da sua

responsabilidade:

Ler atentamente todos os documentos incluídos

no CD em anexo antes de pör o equipamento em

funcionamento,

Proceder à instalação, utilização, manutenção e

reparação do equipamento de acordo com as

preconizações de SAMES KREMLIN, bem como com

outros regulamentos nacionais e/ou locais aplicáveis,

Assegurar-se que os utilizadores do equipamento

foram devidamente capacitados, compreenderam

perfeitamente e aplicam as devidas regras de

segurança.

Käytön turvallisuuden varmistamiseksi

velvollisuutesi on:

Lukea huolella kaikki CD:llä olevat asiakirjat ennen

laitteiston käyttöönottoa,

Noudattaa laitteiston asennuksessa, käytössä,

kunnossapidossa ja huollossa SAMES KREMLIN in

suosituksia sekä kansallisia ja/tai paikallisia

määräyksiä,

Varmistaa, että laitteiston käyttäjät ovat

koulutettuja ja ymmärtävät täysin

turvallisuusmääräykset ja miten niitä sovelletaan.

Za varno uporabo ste dolžni:

natančno prebrati vse dokumente na CD pred

zagonom stroja,

inštalirati, uporabljati, vzdrževati in popravljati

opremo po določilih SAMES KREMLIN in v skladu z

veljavnimi nacionalnimi in/ali lokalnimi predpisi,

poskrbeti, da so uporabniki te opreme ustrezno

usposobljeni, poznajo varnostne predpise in da jih

upoštevajo.

Pentru o utilizare sigură, este responsabilitatea dvs.

să:

Citiţi cu atenţie toate documentele de pe CD-ul

anexat, înainte de punerea în funcţiune a

echipamentului,

Instalaţi, utilizaţi, întreţineţi şi reparaţi

echipamentul conform instrucţiunilor SAMES

KREMLIN precum şi reglementărilor naţionale şi/sau

locale,

Vă asiguraţi că utilizatorii acestui echipament au

fost instruiţi, au înţeles perfect regulile de securitate şi

le aplică integral.

DECLARATION UE DE CONFORMITE

EU DECLARATION OF CONFORMITY

EU- KONFORMITÄTSERKLÄRUNG

DECLARACIÓN UE DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITÀ UE

DECLARAÇÃO UE DE CONFORMIDADE

EU-CONFORMITEITSVERKLARING

EU-FÖRSÄKRAN OM ÖVERENSSTÄMMELSE

EU- VAATIMUKSENMUKAISUUSVAKUUTUS

DEKLARACJA ZGODNOŚCI UE

EU PROHLÁŠENÍ O SHODĚ

IZJAVA EU O SKLADNOSTI

VYHLÁSENIE O ZHODE

EU-MEGFELELŐSÉGI NYILATKOZAT

DECLARAŢIA DE CONFORMITATE UE

Le fabricant / The manufacturer / Der Hersteller

/ El fabricante / Il produttore / O fabricante

/ De fabrikant / Tillverkare / Valmistaja / Producent / Výrobce

/ Proizvajalec / Výrobca / Gyártó / Fabricantul:

Déclare que le matériel désigné ci-après / Herewith declares that the equipment / erklärt hiermit, dass die / Declara que el material designado a

continuación / Dichiara che il materiale sottoindicato / Declara que o material a seguir designado / verklaart dat de hieronder aangeduide apparatuur

/ Kungör att den utrustning som anges här nedan / ilmoittaa, että alla mainitut laitteistot / Oświadcza, że wymienione poniżej urządzenia / Prohlašuje,

že níže uvedené vybavení / Izjavlja, da je opisana oprema spodaj / Vyhlasuje, že zariadenie uvedené nižšie / Kijelenti, hogy a megjelölt anyag a

továbbiakban / Declară că echipamentul precizat mai jos:

SAMES KREMLIN SAS

13, chemin de Malacher

38 240 - MEYLAN - FRANCE

Tél. : 33 (0)4 76 41 60 60

POMPE A BILLE / BALL PUMP / KUGELPUMPEN / BOMBA CON BOLA

Est conforme à la législation d’harmonisation de l’Union applicable suivante / Is in conformity with the relevant Union harmonisation legislation / Erfüllt die

einschlägigen Harmonisierungsrechtsvorschriften der Union / es conforme con la legislación de armonización pertinente de la Unión / è conforme alla

pertinente normativa di armonizzazione dell’Unione / in overeenstemming met de desbetteffende harmonisatiewetgeving van de Unie / med den relevanta

harmoniserade unionslagstiftningen / on asiaa koskevan unionin yhdenmukaistamislainsäädännön vaatimusten mukainen / jest zgodny z odnośnymi

wymaganiami unijnego prawodawstwa harmonizacyjnego / Shoduje se s následující příslušnou evropskou harmonizační legislativou

/ V skladu s harmonizirano zakonodajo Unije / Je v súlade s uplatniteľnými harmonizačnými právnymi predpismi EÚ / Megfelel a következő alkalmazandó

uniós harmonizációs szabályozásnak / Este conform cu legislaţia aplicabilă de armonizare de mai jos

Directive ATEX / ATEX Directive / ATEX Richtlinie / Directiva ATEX / Direttiva ATEX / Diretiva ATEX

/ ATEX-Richtijn / ATEX-direktivet / ATEX-direktivi / Dyrektywa ATEX / Směrnice ATEX / Директива ATEX

03R440

06R440

II 2G IIA T3

Attestation d’examen CE de type / EC type examination certificate CE0029

Notifiée par / Notified by : ISSeP - Transférée chez / Transferred to : APRAGAZ A.S.B.L. - Chaussée de Vilvorde, 156,

B-1120 Bruxelles/Brussel - Belgigue/Belgium

Notification Assurance Qualité de Production / Production Quality Assurance Notification INERIS 03 ATEX Q721

Notifiée par / Notified by : INERIS 0080 - 60550 Verneuil-en-Halatte - France

2014/34/UE

SAMES KREMLIN - 2 - N° : 578.116.130-1908

La présente déclaration de conformité est établie sous la seule responsabilité du fabricant / This declaration of conformity is issued under the sole

responsibility of the manufacturer / Die alleinige Verantwortung für die Ausstellung dieser Konformitätserklärung trägt der Hersteller / La presente

declaración de conformidad se expide bajo la exclusiva responsabilidad del fabricante / La presente dichiarazione di conformità è rilasciata sotto la

responsabilità esclusiva del fabbricante / A presente declaração de conformidade é emitida sob a exclusiva responsabilidade do fabricante / Deze

conformiteitsverklaring wordt verstrekt onder volledige verantwoordelijkheid van de fabrikant / Denna försäkran om överensstämmelse utfärdas på

tillverkarens eget ansvar / Tämä vaatimustenmukaisuusvakuutus on annettu valmistajan yksinomaisella vastuulla / Niniejsza deklaracja zgodności

wydana zostaje na wyłączną odpowiedzianość producenta / Toto prohláŝení o skodě se vydává na výhradní odpovědnost výrobce / Za izdajo te izjave

o skladnosti je odgovoren izključno proizvajalec / Toto vyhlásenie o zhode sa vydáva / na vlastnú zodpovednosť výrobcu / Ezt a megfelelőségi

nylatkozatot a gyártó kizárólagos felelőssége mellett adják ti / Prezenta declaraţie de conformitate este emisă pe răspunderea exclusivă a

producătorului.

Hervé WALTER

Directeur Innovation & Développement / Innovation & Development

Director / Direktor für Innovation & Entwicklung / Director de

Inovación y Desarrollo / Direttore Innovazione e sviluppo

/ Diretor de Inovação / Manager Innovatie en Ontwikkeling / Direktör

för Forskning och Utveckling / Innovaatio- ja kehitysjohtaja

/ Dyrektor ds. Innowacji I Rozwoju / Ředitel pro inovace a vývoj

/ Direktor za inovacije in razvoj / Riaditeľ pre inováciu a rozvoj

/ Innovációs és fejlesztési igazgató / Director Inovaţie şi Dezvoltare

Fait à Meylan, le / Established in Meylan, on / Geschehen zu Meylan, am / En Meylan, a / Redatto a Meylan, / Vastgesteld te Meylan, / Utformat i

Meylan, den / Meylan, Ranska, / Sporządzono w Meylan, dnia / Meylan, dnia / V Meylanu, / V Meylan dňa / Kelt Meylanban, / Întocmită la Meylan,

pe data de 09/08/2019 - 08/09/2019

SAMES KREMLIN - 3 - N° : 578.116.130-1908

INSTALLATION AND SAFETY

INSTRUCTIONS

TRANSLATION FROM THE ORIGINAL MANUAL

IMPORTANT : Before assembly and start-up, please read and clearly understand all the

documents relating to this equipment (professional use only).

THE PICTURES AND DRAWINGS ARE NON CONTRACTUAL. WE RESERVE THE RIGHT TO MAKE CHANGES WITHOUT

PRIOR NOTICE.

SAMES KREMLIN SAS

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

l

www.sames-kremlin.com

SAMES KREMLIN N° : 578.001.130-UK-1804

1. SAFETY INSTRUCTIONS

GENERAL SAFETY INSTRUCTIONS

CAUTION : The equipment can be dangerous if you do not follow our

instructions concerning installation and servicing described in this manual

and in accordance with applicable European standards and local national safety

regulations.

Please carefully read all the instruction literature before operating your

equipment.

Only trained operators can use the equipment.

The foreman must ensure that the operator has understood the safety instructions for this equipment as

well as the instructions in the manuals for the different parts and accessories.

Read carefully all instruction manuals, label markings before operating the equipment.

Incorrect use may result in injury. This equipment is for professional use only. It must be used only for

what it has been designed for. Never modify the equipment. The parts and accessories supplied must be

regularly inspected. Defective or worn parts must be replaced.

Guards (motor cover, coupling shields, connectors,…) have been designed for a

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

property damage due to destruction, the overshadowing or the partial or total

removal of the guards.

Never exceed the equipment components' maximum working pressure.

Comply with regulations concerning safety, fire risks, electrical regulations in force in the country of final

destination of the material. Use only products or solvent compatible with the parts in contact with the

material (refer to data sheet of the material manufacturer).

PICTOGRAMS

A

NIP HAZARD WARNING

MOVING

ELEVATOR

H

RELIEF OR

DRAIN VALVE

WARNING

HOSE UNDER

PRESSURE

D

MOVING PARTS

J

WEAR GLASSES

WARNING

L

OBLIGATORY

F

MOVING SHOVEL

OBLIGATORY

WARNING

WEAR OF

GLOVES IS

E

DO NOT

EXCEED THIS

PRESSURE

K

PRODUCT

VAPOR

HAZARDS

C G

HIGH

PRESSURE

HAZARD

M

WARNING

HOT PARTS OR

AREAS

Q

R

GROUNDING WARNING

(USER)

WARNING

SERIOUS

ELECTRICAL

HAZARD

N

WARNING

FIRE HAZARDS

P

EXPLOSION

HAZARDS

INJURIES

SAMES KREMLIN - 1 - N° : 578.001.130-UK-1804

PRESSURE HAZARDS

circuit. Once depressurised and drained, work /servicing may then commence on the equipment

Current legislation requires that an air relief valve be fitted in the air supply circuit to the air

motor to prevent over pressurisation. This safety feature,ensures that it is not possible to supply

the air motor with excessive air pressure that may cause injury.

Please ensure that a material drain valve is fitted in the fluid circuit to drain and depressurise the

Please remember to close these valves when restarting the system.

HIGH PRESSURE INJECTION HAZARDS

When working with high pressure equipment, special care is required. Fluid leaks can occur.

There is a risk of material being injected to any exposed parts of body, this could cause severe

injury :

medical care must be sought immediately if paint is injected under the skin or in other

parts of the body (eyes, fingers).

never point the spray gun at any one. Never try to stop the spray with your hands or fingers

nor with rags or similars.

follow the shut down procedure and always depressurize air and fluid circuits before

carrying out any servicing on the gun (cleaning, checking, maintenance of the material or

cleaning of the gun nozzles).

for the guns equipped with a safety device, always lock the trigger when not in use.

FIRE - EXPLOSION - SPARKS - STATIC ELECTRICITY HAZARDS

A poor earth connection, inadequate ventilation, sparks or static electricity can cause an

explosion or fire. to avoid these risks when using or servicing SAMES KREMLIN equipment, the

following safety procedures must be followed :

ensure a good earth connection and ground the parts to be handled i.e. solvents, materials,

components and equipment,

ensure adequate ventilation,

keep working area clean and free from waste solvents, chemicals, or solid waste i.e. rags,

paper and empty chemicals drums,

never use electrical switches / power if in an atmosphere of volatile solvent vapour,

stop working immediately in case of electrical arcs,

never store chemicals and solvents in the working area.

use paint whose flash point is the highest possible to prevent from any formation of gas

and inflammable vapours (refer to materials' safety instructions),

install a cover on the drums to reduce the diffusion of gas and vapours in the spraybooth.

TOXIC PRODUCT HAZARDS

Toxic products or vapours can cause severe injury not only though contact with the body, but also

if the products are ingested or inhaled. It is imperative :

to know the material products and their risks,

notified or hazardous materials must be stored in accordance with the regulations,

the material must be stored in an appropriate container, never place materials in a

container where there is a risk of spillage or leakage,

a procedure must be applied for the safe disposal of waste material. It must comply with all

prevailing regulations and legislations of the country where the equipment is to be used,

protective clothing should always be worn in compliance with the material manufacturers'

recommendations,

depending on the application and chemical safety instructions, safety glasses, hearing

protective earplug, gloves, foot wear, protective masks and possible breathing equipment

should be worn to comply with the regulations (Refer to chapter "Safety equipment of

SAMES KREMLIN selection guide).

SAMES KREMLIN - 2 - N° : 578.001.130-UK-1804

CAUTION!

It is forbidden to use material containing high concentrations of halogenated hydrocarbon

solvents with aluminium or zinc fillers .Non-compliance with the instructions may cause

explosion risk causing serious or fatal injury.

EQUIPMENT REQUIREMENTS

Guards (motor cover, coupling shields, connectors,…) have been designed for

The manufacturer will not be held responsible for bodily injury or failure

and / or property damage due to destruction, the overshadowing or the

PUMP

Before carrying out any work, it is imperative to read and clearly understand the disassembly and

reassembly instructions before servicing. The operator must understand the equipment and the

safety instructions. These instructions are available in the equipment manuals.

The air motor is designed to be mounted with a pump. Never modify any components or

couplings. When operating, please keep hands away from moving parts. Before starting up the

equipment, please read the PRESSURE RELIEF instructions. Please ensure that any relief or

drain valves fitted are in good working order.

HOSES

Keep hoses out of circulation areas, moving parts or hot surfaces,

Never expose product hoses to temperature higher than + 60°C / 140° F or lower than 0°C

/ 32° F,

Never pull or use the hoses to move the equipment,

Tighten all fittings as well as the hoses before operating the equipment,

Check the hoses regularly;change them if they are damaged,

Never exceed the maximum working pressure (MWP) indicated on the hose.

a safe use of the equipment.

partial or total removal of the guards.

USED PRODUCTS

Considering the wide variety of products that are available and can be used in our equipment it is

impossible to check and make recommendations for all chemical data,regarding the risks of

possible chemical attack and their long term chemical reaction

SAMES KREMLIN can not be held liable for :

compatibilityof wetted parts,

risks to staff and the surroundings,

for worn or defective parts, for faulty equipment or units, or the qualitiy of final product.

It is the responsibility of the user to know and prevent any possible risks such as toxic vapours,

fires or explosions. He shall determine the risks of immediate reactions or pursuant to repeated

exposures of the staff,

SAMES KREMLIN shall not be liable for physical injuries, direct or indirect material damages

caused by the use of chemicals.

SAMES KREMLIN - 3 - N° : 578.001.130-UK-1804

2. HANDLING

Check the weight and the dimensions of the equipment

(refer to 'Technical features' section of the instruction manual

If weight and dimensions are too important, the unloading must be carried out by means of a forklift or

any other appropriate means with a qualified personnal and in a clear horizontal area to prevent from

risks of damage injury or an accident.

The centre of gravity is not in the centre of the machine : carry out by hand a stability-test after having

lifted the whole at 10 cm / 3.937" maximum.

After the unloading, the handling of the whole (eg: elevator pump) is carried out by means of a pallet

truck taking the bottom part of the frame.

Remark : Each pump motor is fitted with a ring. The ring is designed for the hoisting of one

pump and can not be used for the handling of the complete assembly.

3. STORING

Storing before installation :

- Storing ambient temperature : 0 / +50 °C / 0 / +122°F

- Protect the whole against dust, water trickling, dampness and shocks.

Storing after installation :

- Operating temperature : +15 / +35 °C / +59 / +138.2° F

- Protect the whole against dust, water tricling, dampness and shocks.

4. INSTALLATION OF THE EQUIPMENT

The machine is installed on a stable horizontal floor (for eg a concrete flag).

The machine shall be made stable by the use of holding down bolts or by the use of other anchoring

methods, strong enough to prevent unintended bodily movement of the equipment.

To avoid risks caused by static electricity, the equipment as well as its components must

be grounded.

For the pumping equipments (pumps, pneumatic rams, frame…), a section wire of 2.5

mm² is fixed on the material. Use this wire to connect the material to “the general ground”.

In case of severe environments (mechanical protection of the wire of earthing insufficient,

vibrations, mobile material…) where function damages at the ground are probable, the user

have to replace the provided wire of 2.5 mm² by a device more adapted to its environment

(wire with a more important section, bonding strip, fixing by thimble with eyelet…).

The continuity of the ground must be controlled by a qualified electrician. If the continuity of

the ground is not ensured, check the terminal, the wire and the earthing point. Never use the

material without have solved this problem.

In the severe cases of environments (mechanical protection of the wire of earthing

insufficient, vibrations, mobile material…) where damages of the function put at the ground

are probable, the user will have to replace the wire of 2.5 mm² provided, by a device more

adapted to its environment (wire of more important section, bonding strip, fixing by thimble

with eyelet…),

The gun must be 'grounded' via a material hose or an air hose. In case of spraying by

means of a gun with cup, the air hose must be conductive,

The materials to be painted must also be grounded.

All the materials situated in the working area shall be grounded.

SAMES KREMLIN - 4 - N° : 578.001.130-UK-1804

Never store more than necessary inflammable materials inside the working area,

The materials must be stored into approved drums and grounded,

Use onlygrounded metals containers for the use of cleaning solvents,

Cardboard and paper are prohibited.

5. MARKING OF THE EQUIPMENT

Each equipment has a label plate with the name of the manufacturer, the equipment part number,

the interesting informations to use correctly the equipment (pressure, voltage,…) and sometimes

the above pictogram.

The equipment is designed with and consists of high quality materials and components which can

be re-used.

The 2012/19/UE European Directive covers all equipments with a crossed-out bin pictogram.

Please inform yourself about the collection systems for electric and electronic equipments.

Please act in accordance with local rules and do not dispose of old equipment with household

wastes. A correct disposal of old equipment will help prevent negative consequences for the

environment and health.

SAMES KREMLIN - 5 - N° : 578.001.130-UK-1804

PUMP 06-R440

Disassembly / Reassembly

TRANSLATION FROM THE ORIGINAL MANUAL

IMPORTANT : Before assembly and start-up, please read and clearly understand all the

documents relating to this equipment (professional use only).

THE PICTURES AND DRAWINGS ARE NON CONTRACTUAL. WE RESERVE THE RIGHT TO MAKE CHANGES WITHOUT PRIOR

SAMES KREMLIN SAS

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

NOTICE.

l

www.sames-kremlin.com

SAMES KREMLIN N° 578.209.110-UK-1907

CAUTION :

Before any action on the pump, the T lubricant should be removed, shut off the

compressed air supply and depressurize the system.

The pump is manufactured under the ATEX agreement and can not be modified.

SAMES KREMLIN will not be held responsible for any failure to comply with that instruction.

FLUID MOTOR OR AIR MOTOR REPLACEMENT (REFER TO DOC. 573.462.050 & 573.463.050)

Guards (air motor cover, coupling shields, housings …) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards

To work on the pump, it requires to :

- Disassemble all the accessories of the pump (rod, filter), if necessary.

- The T lubricant should be removed from the upper part (A).

- Put aside the pump, if necessary (the pump is fitted with an hoisting ring).

The pump fluid section is made up of 2 subassemblies :

- the upper part (bellows suction

sub-assembly : A)

- the lower part

(fluid sub-assembly: B)

The most frequently maintenance

concerns this part.

SAMES KREMLIN - 1 - N° 578.209.110-UK-1907

PUMP DRAINING

Guards (air motor cover, coupling shields, housings …) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards

Place a container (2L / 0.53 US gal minimum) under the drain plug.

Unscrew the drain plug with a hexagon key size 12mm.

A procedure must be applied for the safe disposal of waste material. It must comply with all

prevailing regulations and legislations of the country where the equipment is to be used

REPLACING THE PLUG

Clean the drain plug.

Apply a light coating of glue to the drain plug threading (Loctite 577)

Screw the drain plug with a hexagon key size 12mm.

SAMES KREMLIN - 2 - N° 578.209.110-UK-1907

PUMP SEPARATION / COUPLING PROCEDURE

Guards (air motor cover, coupling shields, housings …) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards

SEPARATE THE PUMP

Stop the pump.

Lift the axis-lock (37).

Lift the closing ring (19).

Take off the bush (38) and the

closing ring(19).

Unscrew the nuts (5) from the

coupling tie-rods.

COUPLING THE PUMP

Unscrew the nuts (5) from the coupling tie-rods.

After sliding the axis-lock (37) and the closing ring (19), take off the motor piston rod to bring in

contact with the pump piston.

Put the bush (38) on motor and pump piston rod ends.

Go down the closing ring (19).

Put the axis-lock (37).

SAMES KREMLIN - 3 - N° 578.209.110-UK-1907

FILLING THE SUCTION SUB-ASSEMBLY (A) WITH T LUBRICANT

Nota : Use only lubricant compatible with the parts in contact with the product (See data

sheet of the product manufacturer).

Use only SAMES KREMLIN T lubricant.

- Unscrew the lid from the cup (3).

- Run the pump to load the product.

- When the pump is loaded fill the T lubricant

into the cup (1) until it reaches the maximum

level.

- Refill with the T lubricant until the backflow

into the cup (≃1.2L / 0.32 US gal).

- Screw the lid on the cup (3).

SAMES KREMLIN - 4 - N° 578.209.110-UK-1907

DISASSEMBLY / REASSEMBLY OF THE FLUID SECTION

Guards (air motor cover, coupling shields, housings …) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards

DISASSEMBLY / REASSEMBLY OF THE FLUID SUB-ASSEMBLY (B)

Nota : The suction valve, the cylinder, the exhaust valve can be removed or change without

needing to separate the product sub-assembly (B) from the suction sub-assembly (A).

SUCTION VALVE (34)

Disassembly

Unscrew the suction valve (34) with a 50mm wrench.

Nota : If the cylinder (32) remains attached to the

suction valve, unscrew both parts, then hold cylinder

(32) by inserting a rod into the cylinder holes

designed for this purpose.

The ball (37) is secured on the valve (35) by means of

a stop ring (36).

Clean the parts with an appropriate cleaning product.

Assembly

Reinstall the ball (37) and the stop ring (36) on the

suction valve body (35).

Change the seal (28). Grease it.

Apply grease to the the suction valve body thread

.

Remount the valve assembly (34) on the cylinder

(32).

CYLINDER (32)

In order to make easier the disassembly, a hole is

drilled in the cylinder (32) at each end.

Depending on the part that it is unscrewed first, insert

a rod into one of these holes to unscrew the other

part.

When reassemblying, make sure the two seals (28)

are installed. Grease them.

Lubricate inside the cylinder (grease, type A1)

and the threads to prevent damaging the mobile

packing (grease, type A2) - (refer to greases in §

Assembly instructions).

SAMES KREMLIN - 5 - N° 578.209.110-UK-1907

EXHAUST VALVE (33) AND CUP SEAL (31)

Disassembly

Unscrew the cylinder (32) and pull it

downwards..

Unscrew the exhaust valve (33) with a 58mm

wrench by holding the piston (29).

Remove the ball (30),

Remove the cup seal (31).

Clean the parts.

Assembly

Remount a new cup seal (31),

Reinstall the ball (30) on the exhaust valve (33).

Apply a light coating of grease to the threading of exhaust valve (33) (grease, type A2).

Screw the part in the piston lower part (29) (refer to greases in § Assembly instructions).

SAMES KREMLIN - 6 - N° 578.209.110-UK-1907

DISASSEMBLY / REASSEMBLY OF THE SUCTION SECTION SUB-ASSEMBLY (A)

Nota : The disassembling of the upper tightness seal and of the bellows requires to separ ate

the fluid sub-assembly (B) from the suction sub-assembly (A).

SEPARATION PROCEDURE

Disassemble the cylinder (32). You can see the fluid

section (29).

You must place the piston downwards.

Install an air pressure (from 0.2 to 0.5 bar / from

2.9 to 7.2 psi) on the air motor. When the piston is at

its lower point, close the air inlet valve to prevent the

piston from getting up.

Remove the 3 nuts (22), the washers (21).

Pull the suction flange (20) downwards, you can see

the skirt (10).

Nota: The cylinder (17) must keep assemble with the

suction bearing (11).

Unscrew slightly 3 screws (15).

Unscrew the skirt (10) (tools : with a 36mm wrench).

Nota : To make easier the disassembly of the skirt,

you can remove one of the 3 pump tie-rods (19).

Slide up the skirt-bellows set to clear the access to

the flat on the coupling rod (8).

Caution : the skirt must be visible.

By means of 2 wrenches, to separate the piston (29)

from the coupling rod (8) by using the flats on the

coupling rod and those on the base of the piston.

SAMES KREMLIN - 7 - N° 578.209.110-UK-1907

COUPLING PROCEDURE

Change all the seals (16 and 28) and lubricate them.

Clean the threading of the coupling rod (8) and the tapping of the pump piston (29).

Slide down the motor rod (see previous §) .

Apply a light coating of glue to the threading of the motor rod (Loctite 222).

Present piston-fluid section-discharge flange assembly

Screw the motor rod into the fluid section piston. Lock the assembly.

Apply a light coating of glue to the fluid section piston threading (Loctite 577).

Pull the skirt (10) downwards, and screw it onto the fluid section piston (29).

(tool : with a 36mm wrench).

Detail of the skirt (10)

assembly (29) on the piston

Remount the coupling rod (19) if it has been removed.

Replace the suction flange (20).

Screw the 3 screws (15).

Reinstall the 3 washers (21) and screw the nuts (22).

Remount the pump lower part as explained previously (cylinder, suction,…).

SAMES KREMLIN - 8 - N° 578.209.110-UK-1907

UPPER TIGHTNESS SEAL (25)

Disassembly

Unscrew the 8 screws (27).

Separate the fluid section (A) from the suction part

(B).

Remove the GT seal (25) by pulling the exhaust

flange (26) downwards.

Remove the O-ring seals (16 and 28).

Assembly

Place a new GT seal (25) into the discharge

flange (26) after having lubricated it.

Comply with the GT seal (25) installation order.

DETAIL VIEW

25

BELLOWS

This operation must be done after the separation of the lower part from the upper part of the fluid

section and after the dismounting of the upper thightness seal.

In the work table, prepare assembly, which consists of fluid section piston-exhaust flange while

following the procedure of the upper thightness seal (25).

Disassembly

- Remove the cylinder (17) from the suction bearing (11).

- Separate the suction bearing (11) from the motor by remowing the screws (15).

- Slide, then put aside the bellows-skirt-flange assembly.

- Remove the bellows flange (7) to take off the upper part of the bellows.

- Dismount the skirt (10).

Assembly

On the work table, prepare a bellows-skirt-flange set. You must :

- Install a new bellows (9) into the bellows flange (7).

- When installing the bellows, push it into skirt (10).

- Install the upper bellows flange (7).

- Slide the bellows-skirt-flange assembly along the motor rod.

Orientate and tighten it on air motor base by means of the 3 screws (15).

Nota : To make easier the reassembly, you can remove one of the three tie rods (19).

Couple product section (B) with the suction part (A).

SAMES KREMLIN - 9 - N° 578.209.110-UK-1907

SAMES KREMLIN - 10 - N° 578.209.110-UK-1907

CUP

Disassembly

- Unscrew the lid (3) from the cup (1).

- Unscrew the cup (18) from the elbow tube (24) with a

17mm wrench.

- Move the lid (3) on the elbow tube (24).

- Separate by hand the end cup (9) and remove the

assembly (5, 9, 7 and 2) from the cup.

- Remove the screen (2).

- Unscrew the nut (7) with a 8mm wrench from the valve

(5).

- Unscrew the valve body (4) with a 18mm wrench from

the upper elbow tube (14).

- Unscrew the nut (7) with a 8mm wrench and the washer

(12) from the valve body (4) and remove the spring (6)

with its washer (8).

Assembly

- Slide the lid of the cup onto the upper elbow tube (14)

and hold it in the up position.

- Screw the upper valve assembly with the valve (5), the

spring (6), the washer (8), the nut (7) with a 8mm wrench

and the washer (12) onto the valve body (4).

- Screw the upper valve onto the elbow tube (14) with a

18mm wrench.

- Screw the lower valve with the valve (5) and the nut (7)

with a 8mm wrench onto the end cup (9).

- Place the screen (2).

- Clip manually as far as it will go the lower valve

assembly into the cup.

Apply a light coating of glue to the cup threading

(Loctite 577).

- Screw the reassembled cup (1) onto the lower

elbow tube (24).

- Screw the lid (3) onto the cup (1).

SAMES KREMLIN - 11 - N° 578.209.110-UK-1907

MOTOR

REVERSING BLOCK

Guards (air motor cover, coupling shields, housings …) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards

The maintenance consists in changing the wetted or worn parts and to clean the parts with compatible

materials without using abrasive materials that can damage them. The O-Rings are installed with "Kluber

petamo" grease. Make sure the seals are not damaged, one damaged seal can lead to a motor

malfunction.

MUFFLER

Disassembly

- Unscrew the muffler (15)

Assembly

- Screw the muffler (15).

DETAIL VIEW

SAMES KREMLIN - 12 - N° 578.209.110-UK-1907

DISCHARGE VALVE

Disassembly

- Unscrew the discharge-valve (14).

Assembly

Apply a light coating of glue to the

discharge valve threading (Loctite 222).

- Screw the discharge valve (14).

DISTRIBUTOR, MODEL 4/2

Disassembly

- Unscrew the hoisting ring (1) and remove the washer (2).

- Remove the cover (3).

- Unscrew the 4 screws (19) with a hexagon key size 4mm.

- Remove the distributor (10).

DETAIL VIEW

DETAIL VIEW

Assembly

- Replace the distributor (10) on its location.

- Screw the 4 screws (19) with a hexagon key size 4mm.

- Replace the cover (3).

- Put the washer (2).

- Screw the hoisting ring (1).

SAMES KREMLIN - 13 - N° 578.209.110-UK-1907

DISTRIBUTOR, MODEL 5/2 1/8"

Disassembly

- Unscrew the hoisting ring (1) and remove the

washer (2).

- Remove the cover (3).

- Disconnect the hoses (42).

- Unscrew the 2 screws (56) with a hexagon key

size 2,5mm.

- Unscrew the 5 elbows (45) with a 10mm

wrench.

Assembly

Apply a light coating of glue to the elbow

threading (Loctite 222).

- Screw the 5 elbows (45) with a 10mm wrench.

- Screw the 2 screws (56) with a hexagon key

size 2,5mm.

- Connect the hoses (42).

- Replace the cover (3).

- Put the washer (2).

- Screw the hoisting ring (1).

DETAIL VIEWS

SWITCH

Disassembly

- Unscrew the hoisting ring (1) and remove

the washer (2).

- Remove the cover (3).

- Identify and disconnect the hoses (42).

- Unscrew the 4 screws (53) with a hexagon

key size 3mm.

Assembly

- Screw the 4 screws (53) with a hexagon key

size 3mm.

- Connect the hoses (42).

- Replace the cover (3).

- Put the washer (2).

- Screw the hoisting ring (1).

DETAIL VIEW

SAMES KREMLIN - 14 - N° 578.209.110-UK-1907

SEALS

First remove, the axis-lock, the closing ring, the bush used for the pump separation.

Disassembly

- Unscrew the hoisting ring (1) and

remove the washer (2).

- Remove the cover (3).

- Identify and disconnect the hoses (42).

- Remove the elbows (41).

- Unscrew the 2 screws (5) with a

hexagon key size 5mm and remove the ubolt (4).

- Unscrew the 4 screws (53) with a

hexagon key size 3mm.

- Unscrew the screw (7) with a hexagon

key size 4mm and remove the cam (8).

- Unscrew the 4 screws (23) with a

hexagon key size 6mm and remove the

cover (22).

- Remove the seal (26) with a flat

screwdriver.

- Remove the piston (29) and piston rod

(17).

- Remove the seal (34) with a flat

screwdriver.

- Remove the ring (33) with a half round

tongs.

- Remove the seal (27).

- Remove the seal (24).

- Remove the ring (30) with a half round

tongs.

- Remove the scraper seal (32) with a flat

screwdriver.

- Remove the seal (31) with a flat

screwdriver.

Assembly

Grease slightly the seals.

- Install the seal (31) into the cylinder.

- Install the scraper seal (32) into the

cylinder.

- Install the ring (30) with a half round

tongs.

- Install the seal (24) on the cylinder.

- Install the seal (27) into the cover.

- Install the seal (26) into the cover.

- Install the ring (33) with a half round

tongs on the piston (29) and piston rod

(17) assembly.

- Install the seal (34) in the piston grooves

(29).

- Lubricate the cylinder (16).

SAMES KREMLIN - 15 - N° 578.209.110-UK-1907

- Install the piston (29) and piston rod (17)

assembly into the cylinder (16).

- Replace the cover (22) on the cylinder

(16).

- Screw the 4 screws (23) with a hexagon

key size 6mm.

- Install the cam (8) on the piston rod (17).

- Screw the screw (7) with a hexagon key

size 4mm.

- Install the u-bolt (4) on the cover (22).

- Screw the screw (5) with a hexagon key

size 5mm

- Install the elbows (41) on the switches

(52).

- Connect the hoses (42) on the elbows

(45).

- Replace the cover (3).

- Put the washer (2).

- Screw the hoisting ring (1).

DEGREES OF WEAR

The wetted parts in contact with the material are subject to wear with time. It depends, of course, on the

rates and duration of pump operating; also on the material handled.

Under normal operating and servicing conditions, with standard filled material not including foreign

matters or chemically aggressive, the average working life can be estimated as :

- 1 million strokes for the tightness seals.

- 10 millions strokes for the bellows.

SAMES KREMLIN - 16 - N° 578.209.110-UK-1907

FLUID SECTION ASSEMBLY INSTRUCTIONS

C 3

A 2

A 1

C 3

A 1

C 2

A 2

A 1

A 1

A 2

A 1

C 1

C 1

A 1

SAMES KREMLIN - 17 - N° 578.209.110-UK-1907

MOTOR ASSEMBLY INSTRUCTIONS

C 1

C 1

C 2

A 5

A 5

A 5

A 5

A 5

A 5

SAMES KREMLIN - 18 - N° 578.209.110-UK-1907

Index Instruction Description Part number

A 1

A 2

A 5

C 1

C 2

C 3

PTFE grease

Anti-seize grease

High-performance lubricating

grease

Medium strength

Aneorobic Pipe sealant

Low strength - Aneorobic

Adhesive

High strength - Aneorobic

Adhesive

'TECHNILUB' grease

(10 ml / 0.0026 US gal)

Grease box (450 g / 0.99 lb)

Grease box Kluber petamo

GHY 133N (1 kg / 2.204 lb)

Loctite 577 (250 ml / 0.066 US gal)

Loctite 222 (50 ml / 0.013 US gal)

Loctite 270 (50 ml / 0.013 US gal)

560.440.101

560.420.005

560.440.005

554.180.015

554.180.010

554.180.004

SAMES KREMLIN - 19 - N° 578.209.110-UK-1907

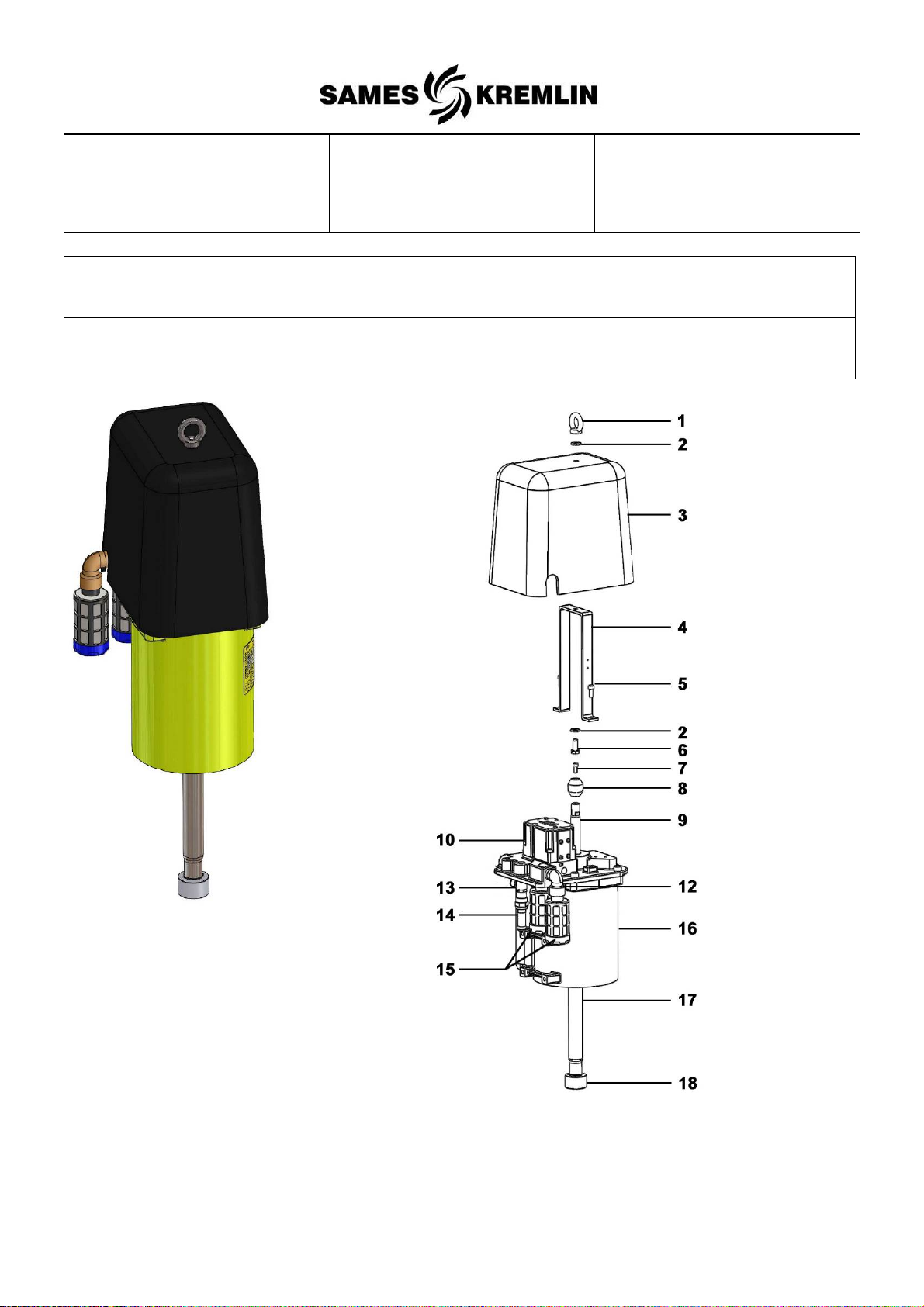

Doc. 573.464.050

Date/Datum/Fecha : 09/07/19

Annule/Cancels/

Ersetzt/Anula : 16/08/16

POMPE,

modèle 06R440

PUMPE,

Modell 06R440

Modif. / Änderung :

Mise à jour / Update / Aktualisierung

/ Actualización

PUMP,

model 06R440

BOMBA,

tipo 06R440

Pièces de rechange

Spare parts list

Ersatzteilliste

Piezas de repuesto

POMPE MURALE,

modèle 06R440

(Pour produit solventé)

WANDANLAGE,

Modell 06R440

(Für Lösemittel Materialien)

POMPE MURALE,

modèle 06R440

(Pour produit hydro)

WANDANLAGE,

Modell 06R440

(Für Wasser Materialien)

Pièces communes - Common parts - Gleiche Teile - Partes comunes

Ind # Désignation Description Bezeichnung Denominación Qté

- NC / NS Pompe 06R440 nue Bare pump,

*1 146 310 200 Moteur 3000-100

(voir

Doc. 573.463.050)

*3 144 990 530 Godet équipé (voir

Doc. 573.465.050)

5 016 480 000 Détendeur d'air 3/4

0 - 10 bar - volant rouge

6 9 015 Support de pompe Pump bracket Wandhalterung Soporte de bomba 1

WALL MOUNTED PUMP,

model 06R440

(For solvent material)

BOMBA MURAL,

tipo 06R440

(Para producto disolventado)

WALL MOUNTED PUMP,

model 06R440

(For hydro material)

BOMBA MURAL,

tipo 06R440

(Para producto hidro)

Pumpe Modell,

model 06R440

Motor, model 3000-100

(refer to

Doc. 573.463.050)

Cup assembly (refer to

Doc. 573.465.050)

Air regulator, model 3/4

0 - 10 bar / 0 - 145.1 psi

- red knob

06R440

Motor, 3000-100

(siehe

Dok. 573.463.050)

Kompletter Behälter

(siehe

Dok. 573.465.050)

Druckminderer, 3/4

0 - 10 bar

(Rote Stellglocke)

#

151.864.100

#

151.864.300

Bomba sola,

tipo 06R440

Motor, tipo 3000-100

(consultar

Doc. 573.463.050)

Bote equipado

(consultar

Doc. 573.465.050)

Manorreductor de aire,

tipo 3/4 0 - 10 bar - pomo

rojo

1

1

1

1

Pièces spécifiques - Specific parts - Spezifische Teile - Partes específicas

pour produit solventé / for solvent material / für Lösemittel Materialien / para producto disolventado

Ind # Désignation Description Bezeichnung Denominación Qté

*2 144 990 500 Hydraulique R 440

(voir Doc. 573.462.050)

SAMES KREMLIN 2 Doc. / Dok. : 573.464.050

Fluid section,

model R 440 (refer to

Doc. 573.462.050)

Hydraulikteil R 440

(siehe Dok. 573.462.050)

Hidráulica, tipo R 440

(consultar

Doc. 573.462.050)

1

Pièces spécifiques - Specific parts - Spezifische Teile - Partes específicas

pour produit hydro / for hydro material / für Wasser Materialien / para producto hidro

Ind # Désignation Description Bezeichnung Denominación Qté

*2 144 990 600 Hydraulique R 440 (voir

Doc. 573.462.050)

Fluid section,

model R 440 (refer to

Doc. 573.462.050)

Hydraulikteil R 440

(siehe Dok. 573.462.050)

Hidráulica, tipo R 440

(consultar

Doc. 573.462.050)

1

* Pièces de maintenance préconisées

* Preceding the index number denotes a suggested spare part.

* Bezeichnete Teile sind empfohlene Ersatzteile.

* Piezas de mantenimiento preventivas.

N C : Non commercialisé.

N S : Denotes parts are not serviceable.

N S : Bezeichnete Teile gibt es nicht einzeln, sondern nur

komplett.

N S : no suministrado.

SAMES KREMLIN 3 Doc. / Dok. : 573.464.050

Doc. 573.463.050

Date/Datum/Fecha : 10/07/19

Annule/Cancels/

Ersetzt/Anula 26/02/15

Modif. / Änderung :

Mise à jour / Update / Aktualisierung

/ Actualización

Pièces de rechange

Spare parts list

Ersatzteilliste

Piezas de repuesto

MOTEUR,

modèle 3000-100

MOTOR,

Modell 3000-100

MOTOR,

model 3000-100

MOTOR,

tipo 3000-100

MOTEUR,

modèle 3000-100

MOTOR

Modell 3000-100

MOTOR

model 3000-100

MOTOR,

tipo 3000-100

Détails - Details - Einzelheiten - Detalles

#

146.310.200

Ind # Désignation Description Bezeichnung Denominación Qté

1 91 421 Anneau de levage Hoisting ring Ringsschraube Anillo de sujeción 1

2 963 040 019 Rondelle MU 8 Washer, model MU 8 Scheibe, MU 8 Arandela, tipo MU 8 2

3 NC / NS Capot Cover Haube Capó 1

4 210 286 Etrier U-bolt Halterung Tirante 1

5 933 151 196 Vis CHc M 6 x 16 Screw,

model CHc M 6 x 16

6 933 011 279 Vis HM 8 x 20 Screw, model HM 8 x 20 Schraube, HM 8 x 20 Tornillo, tipo HM 8 x 20 1

7 88 121 Vis CHc M 5 x 12 Screw,

model CHc M 5 x 12

8 210 444 Came Cam Nocken Brida de ajuste 1

9 146 310 203 Tige d’inversion

*10 146 310 092 Distributeur 4/2

11 NC / NS Joint d'embase Base seal Grundplattendichtung Junta de base 1

12 NC / NS Coude MF 1/2" Elbow, model MF 1/2" Winkelnippel, AG/IG 1/2" Codo, tipo MH 1/2" 2

Reversing rod Umsteuerstange Eje de inversión

Distributor, model 4/2 4/2 Wege Pneum. Ventil Distribuidor, tipo 4/2

Schraube, CHc M 6 x 16 Tornillo,

tipo CHc M 6 x 16

Schraube, CHc M 5 x 12 Tornillo,

tipo CHc M 5 x 12

2

1

1

1

SAMES KREMLIN 2 Doc. / Dok. 573.463.050

Ind # Désignation Description Bezeichnung Denominación Qté

13 552 542 Raccord 1/4" G Fitting, 1/4" G Anschluss 1/4" G Racor, tipo 1/4" G 1

*14 903 080 401 Soupape de décharge Discharge-valve Sicherheitsventil Válvula de seguridad 1

*15 146 310 091 Silencieux Muffler Schalldämpfer Silenciador 2

16 209 405 Cylindre Cylinder Zylinder Cilindro 1

17 210 441 Tige de piston Piston rod Kolbenstange Eje de pistón 1

18 205 094 Bague de fermeture Closing ring Hülse Anillo de cierre 1

19 NC / NS Vis CHc M 5 x 30 Screw,

model CHc M 5 x 30

20 NC / NS Rondelle WZ 5 Washer, model WZ 5 Scheibe, M5 Arandela, tipo WZ 5 4

21 NC / NS Goupille Pin Splint Pasador 1

22 NC / NS Couvercle Cover Deckel Tapa 1

23 88 152 Vis CHc M 8 x 25 Screw,

model CHc M 8 x 25

24 NC / NS Joint plat Flat seal Flachdichtung Junta plana 1

25 055 680 006 Borne de mise à la terre

équipée

26 NC / NS Joint torique O-Ring O-Ring Dichtung Junta tórica 1

27 NC / NS Joint Seal Dichtung Junta 1

28 210 442 Ecrou Nut Mutter Tuerca 1

*29 209 407 Piston Piston Kolben Pistón 1

30 NC / NS Circlips Ring Sicherungsring Anillo truarc 1

31 NC / NS Joint NBR NBR seal NBR Dichtung Junta NBR 1

32 NC / NS Joint racleur Scraper seal Abstreifring Junta rascadora 1

33 NC / NS Circlips Ring Sicherungsring Anillo truarc 1

34 NC / NS Joint torique (piston) O-Ring (piston) O-Ring Dichtung (Kolben) Junta tórica (pistón) 1

35 90 040 Frein d'axe Axis-lock Sicherungsring Freno de eje 1

36 209 394 Coquille Bush Kupplung Coquilla 1

Earth terminal assembly Erdungsanschluss

Schraube, CHc M 5 x 30 Tornillo,

tipo CHc M 5 x 30

Schraube, CHc M 8 x 25 Tornillo,

tipo CHc M 8 x 25

Toma de tierra equipada 1

montiert

4

4

SAMES KREMLIN 3 Doc. / Dok. 573.463.050

Détails - Details - Einzelheiten - Detalles

Ind # Désignation Description Bezeichnung Denominación Qté

37 905 120 902 Coude M 1/8" G Elbow, M 1/8" G Winkelnippel AG 1/8" G Codo, tipo M 1/8" G 1

38 NC / NS Tuyau PU 4x6

(lg. 0,20 m)

39 552 226 Raccord Y T 4x6 Fitting, Y T 4x6 Y-Anschluss für 4x6 Racor, tipo Y T 4x6 1

40 905 120 937 Bouchon pour tube Tube plug Verschlussstopfen für

41 905 120 983 Coude MF T 2x4 Elbow, MF T 2x4 Winkelnippel A/I für 2x4 Codo, tipo MH T 2x4 4

42 NC / NS Tuyau PU 2,5x4

(lg. 25 m)

43 NC / NS Tuyau PU 6x8

(lg.100m)

Hose PU 4x6

(lg. 0.20 m / 7.87")

Hose PU 2,5x4

(lg. 25 m / 82.02 ft)

Hose PU 6x8

(lg. 100 m / 328.1 ft)

Schlauch PU 4x6

(Länge: 0,20 m)

Steckanschluss

Schlauch PU 2,5x4

(Länge: 25 m)

Schlauch PU 6x8

(Länge: 100 m)

Tubería PU 4x6

(0,20 m de largo)

Tapón de tubo 2

Tubería PU 2,5x4

(25 m de largo)

Tubería PU 6x8

(100 m de largo)

1

1

1

SAMES KREMLIN 4 Doc. / Dok. 573.463.050

Ind # Désignation Description Bezeichnung Denominación Qté

44 905 120 904 Raccord droit 1/4" Straight fitting, model 1/4" Gerader Nippel 1/4" Racor recto, tipo 1/4" 1

45 905 120 926 Coude M 1/8" G Elbow, model M 1/8" G Winkelnippel AG 1/8" G Codo, tipo M 1/8" G 5

46 552 260 Coude M 5 G Elbow, model M 5 G Winkelnippel M 5 AG Codo, tipo M 5 1

47 905 120 912 Coude M 1/4" G Elbow, model M 1/4" G Winkelnippel AG 1/4" G Codo, tipo M 1/4" G 1

48 905 124 901 Raccord droit 1/8" Straight fitting, model 1/8" Gerader Nippel 1/8" Racor recto, tipo 1/8" 1

49 91 723 Clip Ø 6 Clip, model Ø 6 Clip Ø 6 Clip, tipo Ø 6 2

50 146 310 202 Equerre Bracket Haltewinkel Escuadra 1

51 933 011 143 Vis HM 5x10 Screw, model HM 5x10 Schraube HM 5x10 Tornillo, tipo HM 5x10 2

*52 151 800 002 Interrupteur (x 2) Switch (x 2) Endschalter (2x) Interruptor (x 2) 1

53 933 151 273 Vis CHc M 4x20 Screw,

model CHc M 4x20

Schraube CHc M 4x20 Tornillo,

tipo CHc M 4x20

54 963 040 012 Rondelle MU 4 Washer, model MU 4 Scheibe MU 4 Arandela, tipo MU 4 4

*55 91 424 Distributeur 5/2 1/8" Distributor,

5/2 Wege Ventil 1/8" Distribuidor, tipo 5/2 1/8" 1

model 5/2 1/8"

56 932 151 326 Vis CHc M 3x25 Screw,

Schraube CHc M 3x25 Tornillo, tipo CHc M 3x25 2

model CHc M 3x25

Ind # Désignation Description Bezeichnung Denominación Qté

* 146 310 090 Pochette de joints

moteur (Ind. 24, 26, 27,

30, 31, 32, 33, 34)

* 146 320 094 Kit pneumatique

(Ind. 52, 55)

Seal kit air motor

(Ind. 24, 26, 27, 30, 31,

32, 33, 34)

Pneumatic kit

(Ind. 52, 55)

Dichtungssatz für

Luftmotor (Pos. 24, 26,

27, 30, 31, 32, 33, 34)

Pneumatik Kit

(Pos. 52, 55)

Bolsa de juntas motor

(Índ. 24, 26, 27, 30, 31,

32, 33, 34)

Kit neumático

(Índ. 52, 55)

* Pièces de maintenance préconisées.

* Preceding the index number denotes a suggested spare part.

* Bezeichnete Teile sind empfohlene Ersatzteile.

* Piezas de mantenimiento preventivas.

N C : Non commercialisé.

N S : Denotes parts are not serviceable.

N S : Bezeichnete Teile gibt es nicht einzeln, sondern nur

komplett.

N S : no suministrado.

4

1

1

SAMES KREMLIN 5 Doc. / Dok. 573.463.050

Doc. 573.462.050

Date/Datum/Fecha : 09/07/19

Annule/Cancels/

Ersetzt/Anula : 16/08/16

HYDRAULIQUE,

modèle R 440

HYDRAULIKTEIL,

Modell R 440

Modif. / Änderung :

Mise à jour / Update / Aktualisierung

/ Actualización

FLUID SECTION,

model R 440

HIDRÁULICA,

tipo R 440

Pièces de rechange

Spare parts list

Ersatzteilliste

Piezas de repuesto

HYDRAULIQUE, modèle R 440

(Pour produit solventé)

HYDRAULIKTEIL Modell R 440

(Für Lösemittel Materialien)

HYDRAULIQUE, modèle R 440

(Pour produit hydro)

HYDRAULIKTEIL Modell R 440

(Für Wasser Materialien)

FLUID SECTION model R 440

(For solvent material)

HIDRÁULICA, tipo R 440

(Para producto disolventado)

FLUID SECTION model R 440

(For hydro material)

HYDRAULIKTEIL Modell R 440

(Para producto hidro)

#

144.990.500

#

144.990.600

SAMES KREMLIN 2 Doc. / Dok. : 573.462.050

Pièces communes - Common parts - Gleiche Teile - Partes comunes

Ind # Désignation Description Bezeichnung Denominación Qté

1 144 990 504 Bride d'accouplement Coupling flange Pumpenflansch Brida de acoplamiento 1

2 209 601 Tirant d'accouplement Coupling rod Kupplungsstange Tirante de acoplamiento 3

3 144 990 505 Flasque Flange Flansch Brida 1

4 963 040 023 Rondelle M 12 Washer, model M 12 Scheibe M 12 Arandela, tipo M 12 3

5 953 010 023 Ecrou M 12 Nut, model M 12 Mutter M 12 Tuerca, tipo M 12 3

6 931 151 168 Vis CHc M 5 x 12 Screw,

model CHc M 5 x 12

7 044 970 046 Bride soufflet Flange, bellows Faltenbalg-Flansch Brida fuelle 1

8 144 990 501 Tige d’accouplement Coupling rod Verbindungsstange Eje de acoplamiento 1

*9 044 970 055 Soufflet Bellows Faltenbalg Fuelle 1

10 044 990 211 Jupe Skirt Klemmstück Faldón 1

11 044 990 013 Palier d’aspiration Suction bearing Oberer Flansch Palier de aspiración 1

*12 150 040 321 Joint PTFE (les 10) Seal, PTFE (pack of 10) Dichtung PTFE (10 St.) Junta PTFE (bolsa de 10) 1

13 88 512 Vis CHc M 6 x 16 Screw,

model CHc M 6 x 16

14 144 990 502 Tube coudé Elbow tube Oberer Rohrbogen Tubo acodado 1

15 933 151 671 Vis CHc M 8 x 75 Screw,

model CHc M 8 x 75

*16 050 040 325 Joint PTFE Seal, PTFE Dichtung PTFE Junta PTFE 3

*17 044 990 012 Cylindre Cylinder Materialzylinder Cilindro 1

*18 144 990 530 Godet équipé

(voir Doc. 573.465.050)

19 044 990 016 Tirant d'accouplement Coupling rod Kupplungsstange Tirante de acoplamiento 3

20 044 990 011 Bride d’aspiration Suction flange Unterer Flansch Brida de aspiración 1

21 963 020 025 Rondelle Z 16 Washer, model Z 16 Scheibe Z 16 Arandela, tipo Z 16 3

22 953 010 025 Ecrou HM 16 Nut, model HM 16 Mutter M 16 Tuerca, tipo HM 16 3

*23 129 489 902 Joint PTFE (les 10) Seal, PTFE (pack of 10) Dichtung PTFE (10 St.) Junta PTFE (bolsa de 10) 1

24 144 990 503 Tube coudé Elbow tube Unterer Rohrbogen Tubo acodado 1

26 044 990 021 Bride de refoulement Discharge flange Druckflansch Brida de expulsión 1

27 932 151 551 Vis CHc M 8 x 50 Screw,

*28 050 040 326 Joint PTFE Seal PTFE Dichtung PTFE Junta PTFE 2

*29 044 990 221 Piston Piston Kolben Pistón 1

*30 907 414 269

*32 044 990 022 Cylindre Cylinder Materialzylinder Cilindro 1

33 044 990 025 Clapet de refoulement Exhaust valve Druckventil Válvula de expulsión 1

- 906 314 219 Bouchon 1" Plug, model 1" Stopfen, 1" Tapón, tipo 1" 1

38 905 210 404 Coude MF 1" Elbow, model MF 1" Winkelnippel, AG/IG 1" Codo, tipo MH 1" 1

39 903 090 208 Vanne Valve Ventil Válvula

Bille 27, inox 440C Ball 27,

Cup assembly (refer to

Doc. 573.465.050)

model CHc M 8 x 50

stainless steel 440C

Schraube M 5 x 12 Tornillo,

tipo CHc M 5 x 12

Schraube M 6 x 16 Tornillo,

tipo CHc M 6 x 16

Schraube M 8x75 Tornillo,

tipo CHc M 8 x 75

Kompletter Behälter

(siehe

Dok. 573.465.050)

Schraube M 8 x 50 Tornillo,

Kugel 27,

Edelstahl 440C

Bote equipado

(consultar

Doc. 573.465.050)

tipo CHc M 8 x 50

Bola 27, inox 440C

4

4

3

1

8

1

SAMES KREMLIN 3 Doc. / Dok. : 573.462.050

Ind # Désignation Description Bezeichnung Denominación Qté

*34 144 990 540 Clapet d'aspiration

équipé

(ind. 28, 35, 36, 37)

*28 050 040 326 Joint PTFE Seal PTFE Dichtung PTFE Junta PTFE 1

*35 144 990 550 Corps de clapet avec

siège carbure

36 044 990 032 Jonc Stop ring Sicherungsring Anillo de retención bola 1

37 907 414 297

Bille 40, inox 440C Ball 40,

Suction valve assembly

(ind. 28, 35, 36, 37)

Suction valve body with

carbide seat

stainless steel 440C

Komplettes

Ansaugventil

(Pos. 28, 35, 36, 37)

Ansaugventilkörper mit

Hartmetall-Sitz

Kugel 40,

Edelstahl 440C

Válvula de aspiración

équipada

(índ. 28, 35, 36, 37)

Cuerpo de válvula con

asiento de carburo

Bola 40, inox 440C

1

1

1

Pièces spécifiques - Specific parts - Spezifische Teile - Partes específicas

pour produit solventé / for solvent material / für Lösemittel Materialien / para producto solventado

Ind # Désignation Description Bezeichnung Denominación Qté

*25 909 150 223 Joint GT GT seal GT Dichtung Junta GT 1

*31 044 990 024 Joint coupelle (PEHD) Cup seal (UHMW) Kolbenmanschette

(PEHD)

Junta copa (PEHD) 1

Ind # Désignation Description Bezeichnung Denominación Qté

* 144 990 090 Pochette de joints

(ind. 12, 16x3, 23, 25,

28x2, 30, 31, 36, 37)

* 144 990 595 Pochette de

maintenance (ind. 33, 34

+ pochette de joints)

Package of seals

(ind. 12, 16x3, 23, 25,

28x2, 30, 31, 36, 37)

Servicing kit

(ind. 33, 34 + package of

seals)

Dichtungssatz

(Pos. 12, 16 (3x), 23, 25,

28 (2x), 30, 31, 36, 37)

Reparatursatz

(beinhaltet Pos. 33, 34

+ den Dichtungssatz)

Bolsa de juntas

(ind. 12, 16x3, 23, 25,

28x2, 30, 31, 36, 37)

Bolsa de

mantenimiento (índ. 33,

34 + bolsa de juntas)

* Pièces de maintenance préconisées

* Preceding the index number denotes a suggested spare part.

* Bezeichnete Teile sind empfohlene Ersatzteile.

* Piezas de mantenimiento preventivas.

N C : Non commercialisé.

N S : Denotes parts are not serviceable.

N S : Bezeichnete Teile gibt es nicht einzeln, sondern nur

komplett.

N S : no suministrado.

1

1

SAMES KREMLIN 4 Doc. / Dok. : 573.462.050

Pièces spécifiques - Specific parts - Spezifische Teile - Partes específicas

f

pour produit hydro / for hydro material / für Wasser Materialien / para producto hidro

Ind # Désignation Description Bezeichnung Denominación Qté

*-

144 990 120 Ensemble d'adaptation

pour joints PU

25 NC / NS Joint PU Polyurethane seal PU-Dichtung Junta Poliuretano 1

60 NC / NS Joint de piston (PU) Seal, piston

61 NC / NS Porte-joint Seal holder Dichtungshalterung Porta junta 1

62 NC / NS Joint PTFE Seal PTFE Dichtung PTFE Junta PTFE 1

63 NC / NS Bague anti-extrusion Anti-extrusion ring Stützring Manschette Anillo anti-extrusión 1

Adaptation assembly

for Polyurethane seals

(Polyurethane)

Adaptereinheit für PUDichtungen

Kolbenmanschette (PU) Junta de pistón

Conjunto de adaptación

para juntas de

poliuretano

(Poliuretano)

1

1

Ind # Désignation Description Bezeichnung Denominación Qté

* 144 990 130 Pochette de joints PU

(ind. 12, 16x3, 23, 28x2,

25, 30, 35, 36, 60, 62, 63)

* 144 990 695 Pochette de

maintenance (ind. 33, 34

+ pochette de joints PU)

* Pièces de maintenance préconisées

* Preceding the index number denotes a suggested spare part.

* Bezeichnete Teile sind empfohlene Ersatzteile.

* Piezas de mantenimiento preventivas.

Package of seals

(Polyurethane)

(ind. 12, 16x3, 23, 28x2,

25, 30, 35, 36, 60, 62, 63)

Servicing kit

(ind. 33, 34 + package o

seals (Polyurethane))

PU-Dichtungssatz

(Pos. 12, 16 (3x), 23, 28

(2x), 25, 30, 35, 36, 60,

62, 63)

Reparatursatz

(beinhaltet Pos. 33, 34

+ PU-Dichtungssatz)

N C : Non commercialisé.

N S : Denotes parts are not serviceable.

N S : Bezeichnete Teile gibt es nicht einzeln, sondern nur

komplett.

N S : no suministrado.

Bolsa de juntas

(Poliuretano)

(índ. 12, 16x3, 23, 28x2,

25, 30, 35, 36, 60, 62, 63)

Bolsa de

mantenimiento (índ. 33,

34 + bolsa de juntas

(Poliuretano))

SAMES KREMLIN 5 Doc. / Dok. : 573.462.050

1

1

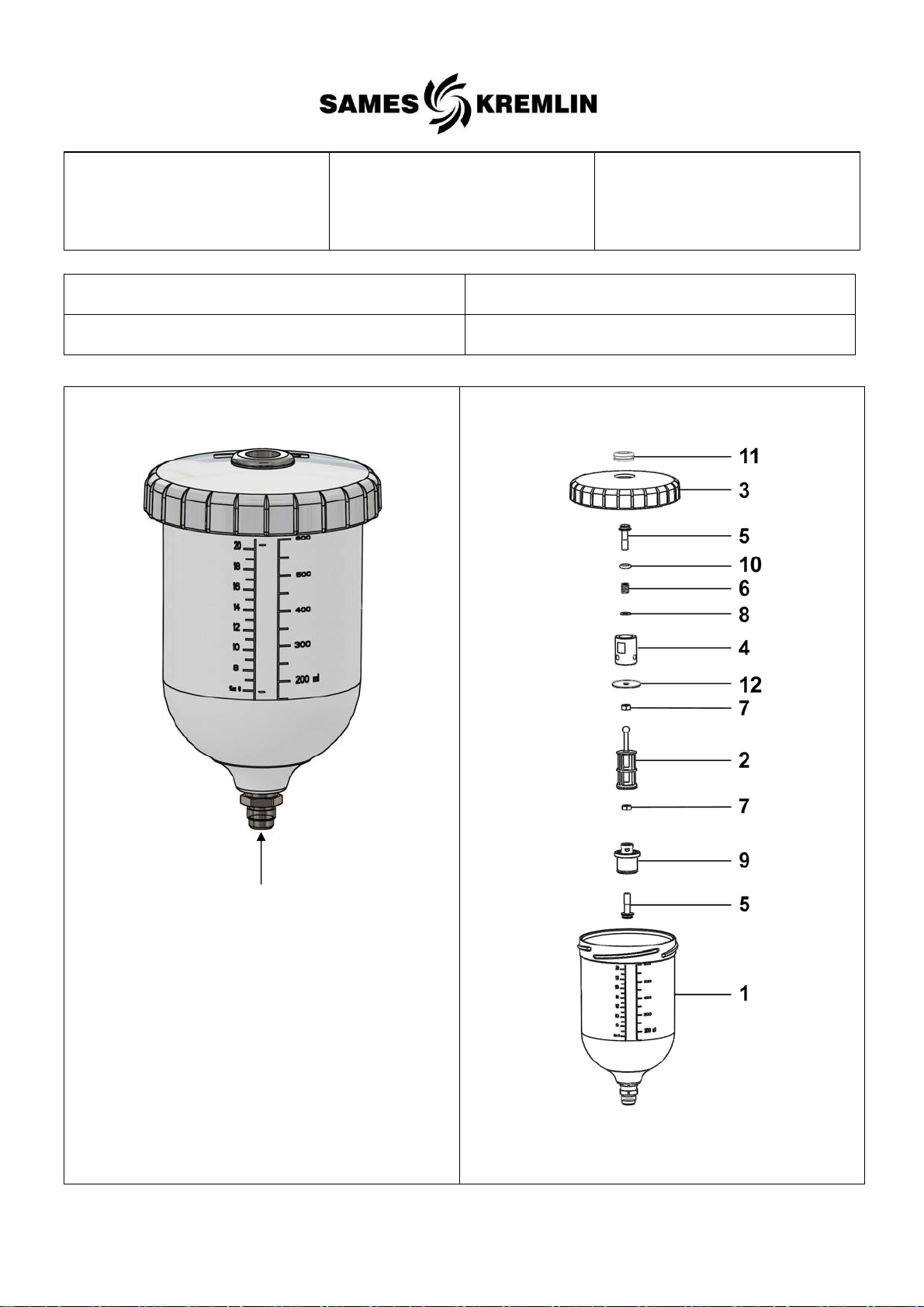

Doc. 573.465.050

Date/Datum/Fecha : 10/07/19

Annule/Cancels/

Ersetzt/Anula : 11/10/16

Modif. / Änderung :

Mise à jour / Update / Aktualisierung

/ Actualización

Pièces de rechange

Spare parts list

Ersatzteilliste

Piezas de repuesto

GODET EQUIPE (600 ml) CUP ASSEMBLY (600 ml / 20.29 oz)

KOMPLETTER BEHÄLTER (600 ml) BOTE EQUIPADO (600 ml)

A

A : raccordement produit (M 1/4" G)

A : fluid fitting (M 1/4" G)

A : Material Anschluss (AG 1/4" G)

A : racor producto (M 1/4" G)

GODET EQUIPE (600 ml) CUP ASSEMBLY (600 ml / 20.29 oz) #

KOMPLETTER BEHÄLTER (600 ml) BOTE EQUIPADO (600 ml) 144.990.530

Ind # Désignation Description Bezeichnung Denominación Qté

*1 NC / NS Godet seul (600 ml) Cup (600 ml / 20.29 oz) Behälter(600 ml) Bote solo (600 ml) 1

*2 139 270 220 Tamis (les 5) Screen (pack of 5) Sieb (5er Satz) Tamiz (bolsa de 5) 1

3 NC / NS Couvercle Lid Deckel Tapa 1

4 NC / NS Corps de clapet Valve body Ventilkörper Cuerpo de válvula 1

5 NC / NS Soupape Valve Ventil Válvula 2

6 NC / NS Ressort Spring Feder Muelle 1

7 NC / NS Ecrou M 5 Nut, model M 5 Mutter M 5 Tuerca, tipo M 5 2

8 NC / NS Rondelle MU 5 Washer, model MU 5 Scheibe MU 5 Arandela, tipo MU 5 1

9 NC / NS Butée de godet End cup Endanschlag Behälter Tope de bote 1

*10 129 479 910 Joint (les 10) Seal (pack of 10) Dichtung (10 St.) Junta (bolsa de 10) 1

11 NC / NS Joint Seal Dichtung Junta 1

12 NC / NS Rondelle Washer Scheibe Arandela 1

* Pièces de maintenance préconisées

* Preceding the index number denotes a suggested spare part.

* Bezeichnete Teile sind empfohlene Ersatzteile.

* Piezas de mantenimiento preventivas.

N C : Non commercialisé.

N S : Denotes parts are not serviceable.

N S : Bezeichnete Teile gibt es nicht einzeln, sondern nur

komplett.

N S : no suministrado.

SAMES KREMLIN 2 Doc. / Dok. 573.465.050

BALL PUMPS

MODEL "R"

PREVENTIVE MAINTENANCE

TRANSLATION FROM THE ORIGINAL MANUAL

IMPORTANT : Before assembly and start-up, please read and clearly understand all the

documents relating to this equipment (professional use only).

THE PICTURES AND DRAWINGS ARE NON CONTRACTUAL. WE RESERVE THE RIGHT TO MAKE CHANGES WITHOUT PRIOR

SAMES KREMLIN SAS

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

NOTICE.

l

www.sames-kremlin.com

SAMES KREMLIN N° : 578.211.110-UK-1907

FREQUENCY

OPERATION TO CARRY OUT

D W M Q H Y

GENERAL

Check earthings

Check leakage from the fittings

Check hoses

Operate the valves

X

X

X

X

PUMP

Check piston rod tightness

X

Caution : flush the pump for a long duration shutdown of the installation (more than two weeks)

MOTOR

Check the tightness of the piston rod

Check if the control system is clean

Check if the muffler(s) is clogged

Check that there is no air leakage

Check that air hoses are not damaged

Check that the connections between fittings and

hoses are correct

Check the correct condition of the supply hoses

(rubber, setting,…), regulators and gauges

X

X

X

X

X

X

X

Check the tightening of the components

Check the fixing of the cover

Check the correct operating of the safety valve(s)

D : daily

W : weekly

M : monthly

Q : quarterly

H : half-yearly

Y : yearly

X

X

X

SAMES KREMLIN - 1 - N° : 578.211.110-UK-1907

OPERATION TO CARRY OUT

FREQUENCY

D W M Q H Y

CUP - FLUID SECTION

Check that the filter is not damaged

Check that the valves and the seal are not damaged

X

X

Disassemble the fluid section, clean the parts with

the appropriate cleaning solvent, change the seals

and the parts if necessary

Drain the lubricant if the coloration is too important

Clean regularly the cup

Check the presence of lubricant in the cup

D : daily

W : weekly

M : monthly

Q : quarterly

X

X

X

H : half-yearly

Y : yearly

Note : Frequencies are given as a clue. They must be adapted by the maintenance

service of the user for every installation according to the product, the working cadence

and the working pressure.

X

SAMES KREMLIN - 2 - N° : 578.211.110-UK-1907

BALL PUMPS

MODEL "R"

TROUBLESHOOTING GUIDE

TRANSLATION FROM THE ORIGINAL MANUAL

IMPORTANT : Before assembly and start-up, please read and clearly understand all the

documents relating to the equipment (professional use only).

THE PICTURES AND DRAWINGS ARE NOT CONTRACTUAL. WE RESERVE THE RIGHT TO MAKE CHANGES WITHOUT PRIOR

SAMES KREMLIN SAS

13, chemin de Malacher

38 240 - MEYLAN - France

: 33 (0)4 76 41 60 60

NOTICE.

l

www.sames-kremlin.com

SAMES KREMLIN N° : 578.210.110-UK-1907

The pump is manufactured under the ATEX agreement and can not be modified.

SAMES KREMLIN will not be held responsible for any failure to comply with that

instruction.

Guards (air motor cover, coupling shields, housings …) have been designed for

safe use of the equipment.

The manufacturer will not be held responsible for bodily injury or failure and / or

damage to property due to removal or partial removal of the guards

CAUTION :

Before any intervention on the equipment, shut off the air supply and follow the

general safety instructions. Open the drain or the gun to depressurize the gun.

The ram must be in the low position.

TROUBLE CAUSE SOLUTION

Pump does not start or stops

The pump cycles continuously

(drain valve closed)

The pump at stop, the piston

carries on going down

The fluid is polymerized,

hardened, dried in the pump.

Broken part(s) in the pump Remove, check and replace.

Incorrect air supply Check air pressure.

Packings of fluid section are

stuck

Frosting (motor) Defrost and lubricate using oil.

Outlet fluid hose is blocked Change hose.

Gun nozzle is clogged Clean it.

No starting up Check feeding pressure.

Lack of material Add material.

Valves are blocked Clean or replace.

Suction valve worn or incorrectly

mounted

Plug or drain valve not tightened

Clean the pump; change parts if

necessary.

Clean or replace the packings.

Check and replace parts.

Head piston seals or upper valve

The pump at stop, the piston

carries on going up

SAMES KREMLIN - 1 - N° : 578.210.110-UK-1907

worn or incorrectly mounted

Plug or drain valve not tightened

Check and replace parts.

TROUBLE CAUSE SOLUTION

Insufficient air pressure to the

motor (valve insufficiently open,

Check; adjust.

air leak,…)

The pump does not deliver

enough pressure

The pump operates but irregular

flow

Important pressure drop at down

stroke

Insufficient air inlet on the motor

or outlet clogged

Check filter and mounting.

Hose not adapted Replace hose.

Head piston seals worn

Check mounting and replace

seals.

Check mounting, state of the

Air inlet in the suction circuit

parts, tightening of parts and

seals.

Valves not tightened or clogged

on the seats

Worn valves

Valves incorrectly mounted

Clean.

Check the valves and replace

them.

Check the valves and mount

them.

Check the seals of the power

Leakage during the exhaust

distributor(s); change them if

necessary.

Muffler(s) clogged up Clean or change.

Too important getting up of the

ball

Displace the ball cage to reduce

the getting up.

Fluid leakage through pump body

The piston is going down quickly

(simple effect working)

The piston goes up quickly

Wrong tightening of the cylinder

Seals missing or damaged

Check cylinder and seals ;

replace if necessary.

Check the use parameters of the

accessories (pressure on

Wrong feeding of the pump

follower plate or suction rod,…) ;

they can be clogged or not

adapted.

Suction valve worn Check and replace parts.

A foreign product obstructs the

suction valve

Piston seals incorrectly mounted

or damaged

Clean and check.

Check the mounting; change if

necessary.

Drain valve worn or damaged Check and replace parts.

A foreign product obstructs the

drain valve

Piston seals incorrectly mounted

or damaged

Clean and check.

Check the mounting; change if

necessary.

SAMES KREMLIN - 2 - N° : 578.210.110-UK-1907

TROUBLE CAUSE SOLUTION

The piston goes down very

quickly untill it reaches half stroke

and restarts operating slowly

Abnormal operating after racing

or too important temperature

Material flow rate drop

Important leakage during the

exhaust

Wrong draining of the pump

Leakage at the suction valve

Head piston seals too tightened,

damaged

Product drum empty

Open the drain valve and close it

after the outlet of the air bubles.

Check the suction valve; replace

it if necessary.

Check mounting ; reduce

pumping rate; replace parts if

necessary.

Fill the drum; check the suction

circuit and possible air leakage.

Check the piston seal(s); replace

if necessary.

Leakage during the exhaust

Check the seals of the power

distributor(s); replace them if

necessary.

Muffler(s) clogged up Clean or change.

Power distributor(s) seals

incorrectly mounted

Defective Power distributor(s)

Mount the seals correctly ;

replace them if necessary.