SAMES SA2005PPA, SA2005PSA Datasheet

Programmable Three Phase Power / Energy Metering

IC for Stepper Motor / Impulse Counter Applications

SA2005P

FEATURES

+ Direct drive for electro-mechanical counters or stepper

motors

+ Calibration and setup stored on external EEPROM - no

trim-pots required

+ Flexible programmable features providing ease of

implementation for meter manufacturers

+ Per phase energy direction and voltage fail indication

+ Precision oscillator on chip

DESCRIPTION

The SAMES SA2005P provides a single chip active energy

metering solution for three phase mechanical counter-based

meter designs.

Th SA2005P does not require any external trim-pots or resistor

ladders for meter calibration. Calibration and meter

configuration information is stored on a small external

EEPROM.

Meter setup stored on the EEPROM includes various metering

direction modes (total sum, absolute sum, positive or negative

energy) phase calibration data, rated metering conditions,

LED pulse rate, counter pulse width, counter resolution and

creep current.

samessames

+ Meets the IEC 521/1036 Specification requirements for

Class 1 AC Watt hour meters

+ Operates over a wide temperature range

+ Easily adaptable to different signal levels

+ Adaptable to different types of sensors

+ Precision voltage reference on-chip

+ Protected against ESD

A programmable rate pulse output is available for meter

calibration purposes. Per phase voltage fail and voltage

sequence faults as well as energy direction indication are

available as LED outputs. Programmable dividers enable

various mechanical counter or stepper motor counter

resolutions.

A precision oscillator, that replaces an external crystal, is

integrated on chip. A voltage reference is integrated on chip.

The SA2005P integrated circuit is available in 24-pin dual in

line plastic (DIP-24) and small outline (SOIC-24) package

options.

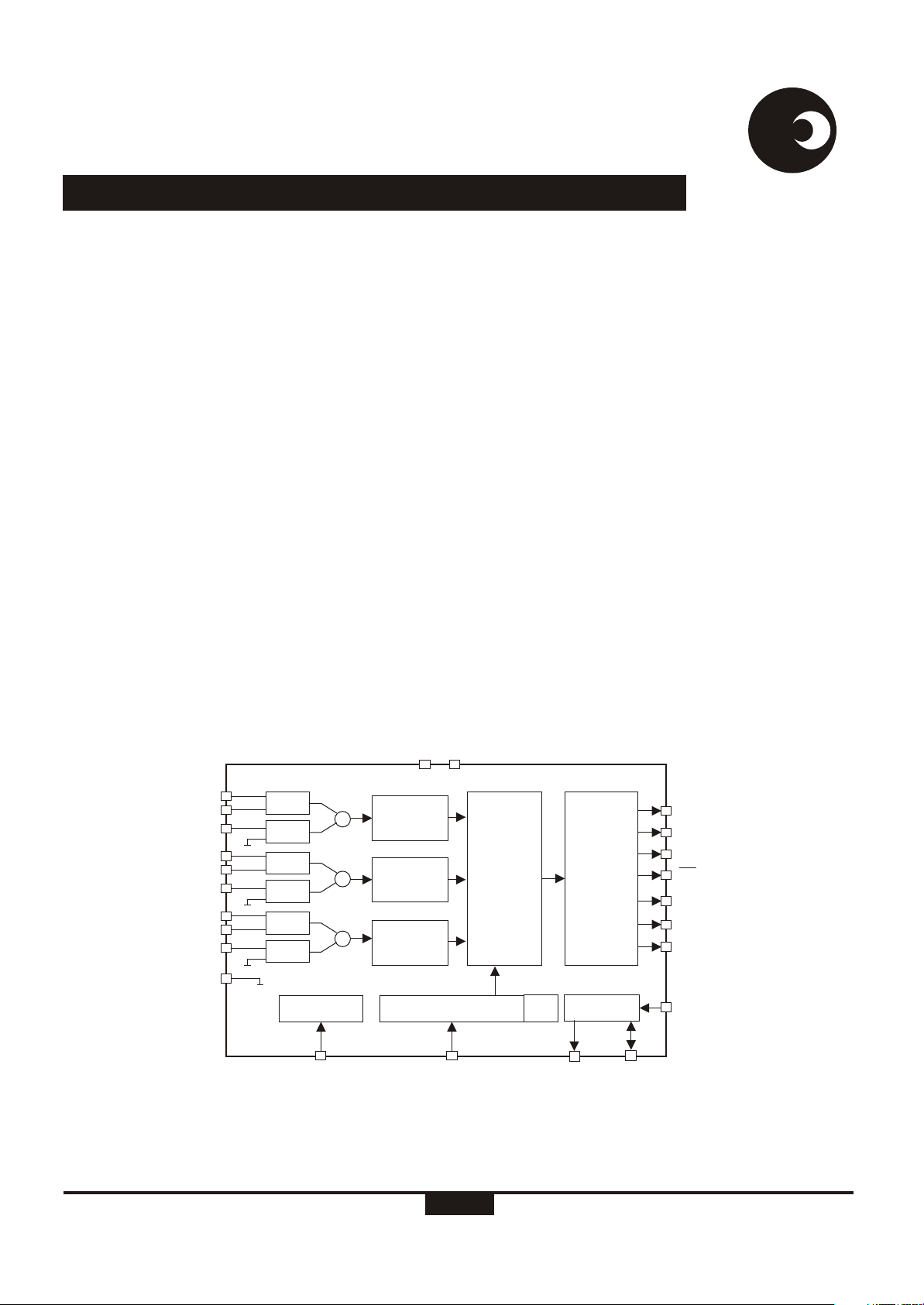

IIN1

IIP1

IVN1

IIN2

IIP2

IVN2

IIN3

IIP3

IVN3

GND

dr-01605

I1

V1

I2

V2

I3

V3

REF

VREF

X

X

X

VDD VSS

CHANNEL

BALANCE

PROG.

CHANNEL

ADDER

BALANCE

CHANNEL

BALANCE

TIMING & CONTROL

Figure 1: Block diagram

PROGRAM-

MABLE

ADDER

TEST

OSC

POWER

TO

PULSE

RATE

INTERFACE

SCL

LED

MON

MOP

PH / DIR

PH1

PH2

PH3

RLOAD

SDA

SPEC-0086 (REV. 2)

1/16

07-02-01

SA2005P

samessames

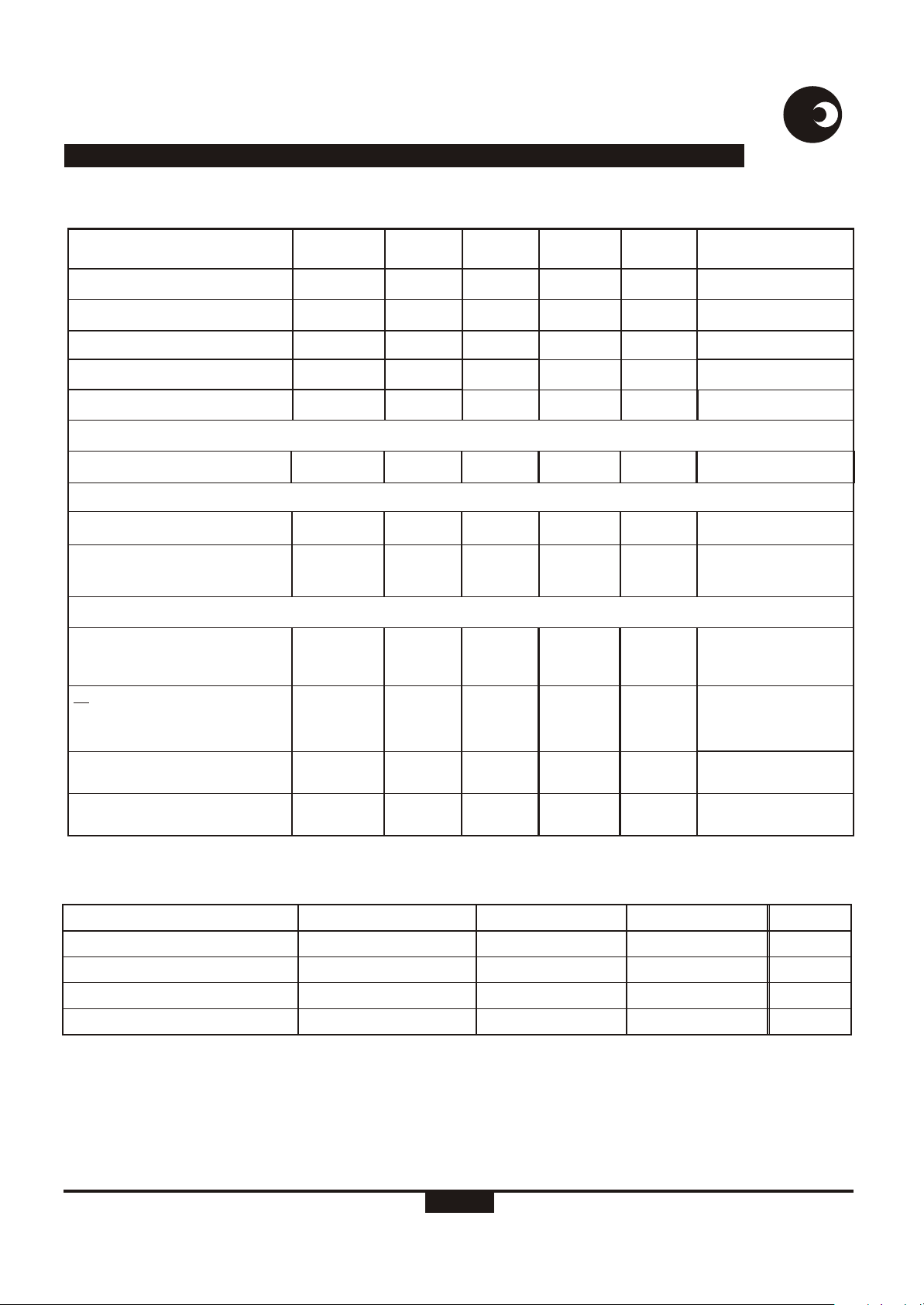

ELECTRICAL CHARACTERISTICS

(V = 2.5V, V = -2.5V, over the temperature range -10°C to +70°C , unless otherwise specified.)

DD SS

Parameter

Operating temp. Range

Supply Voltage: Positive

Supply Voltage: Negative

Supply Current: Positive

Supply Current: Negative

Symbol

T

O

V

DD

V

SS

I

DD

I

SS

Min

-25

2.25

-2.75 -2.25

#

Typ

Max

+85

2.75

15

15

16

16

Current Sensor Inputs (Differential)

Input Current Range

I

II

-25

+25

Voltage Sensor Input (Asymmetrical)

Input Current Range

Pin VREF

Ref. Current

Ref. Voltage

I

IV

-I

R

V

R

-25

45

1.1

50

+25

55

1.3

Digital I/O

Pins RLOAD, TEST, SDA

Input High Voltage

Input Low Voltage

V

IH

V

IL

V-1

DD

V+1

SS

Pins MOP, MON, LED, SCL,

PH/DIR, PH1, PH2, PH3

Output High Voltage

Output Low Voltage

V

OH

V

OL

V-1

DD

V+1

SS

Pin SDA

Pull up current

-I

IL

24

54 µA

Unit

°C

V

V

mA

mA

µA

µA

µA

V

V

V

V

V

Condition

Peak value

Peak value

With R = 24kW

connected to V

Reference to V

I = -2mA

OH

I = 5mA

OL

V = V

ISS

SS

SS

Pins TEST, RLOAD

Pull down current

I

IH

48 110 µA

V = V

IDD

#Extended Operating Temperature Range available on request.

ABSOLUTE MAXIMUM RATINGS*

Parameter Symbol Min Max Unit

Supply Voltage V -V -0.3 6.0 V

Current on any pin I -150 +150 mA

Storage Temperature T -40 +125 °C

Operating Temperature T -40 +85 °C

*Stresses above those listed under “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress

rating only. Functional operation of the device at these or any other condition above those indicated in the operational sections of

this specification, is not implied. Exposure to Absolute Maximum Ratings for extended periods may affect device reliability.

http://www.sames.co.za

DD SS

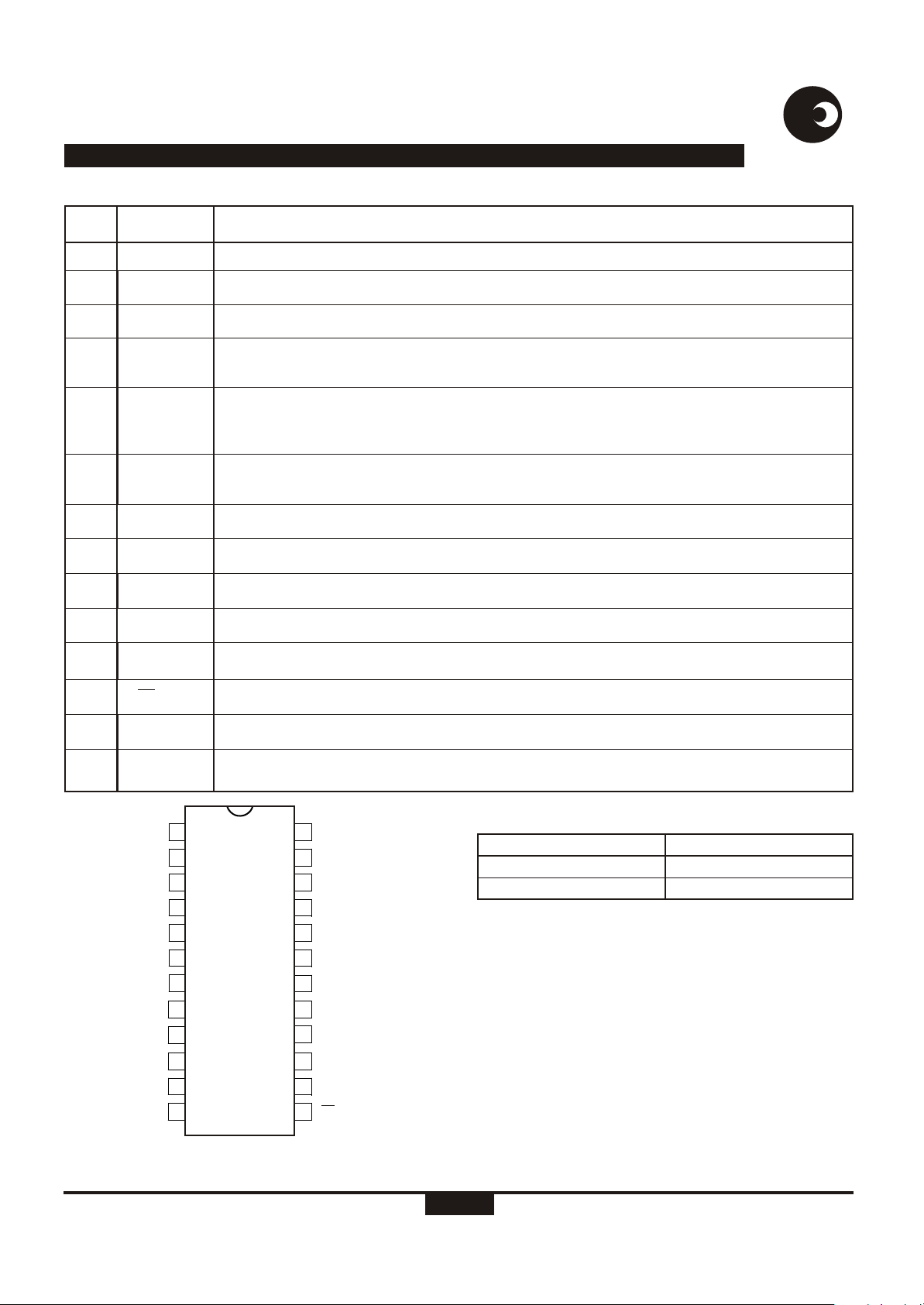

PIN

STG

O

2/16

SA2005P

PIN DESCRIPTION

Designation Description

PIN

samessames

20

6

18

21, 24,

3

23, 22,

2, 1,

5, 4

19

8

9

17

10

11, 12

13

GND

V

DD

V

SS

IVN1, IVN2,

IVN3

IIN1, IIP1,

IIN2, IIP2,

IIN3, IIP3

VREF

SCL

SDA

TEST

LED

MON, MOP

PH / DIR

Analog Ground. The voltage to this pin should be mid-way between V and V .

DD SS

Positive supply voltage. Typically +5V if a current transformer is used for current sensing.

Negative supply voltage. Typically 0V if a current transformer is used for current sensing.

Voltage sense inputs. The current into the A/D converter should be set at 14µA at nominal mains

RMS

voltage. The voltage sense input saturates at an input current of ±25µA peak.

Inputs for current sensors. The termination resistor voltage from each current transformer is

converted to a current of 16µA at rated conditions. The current sense input saturates at an input

RMS

current of ±25µA peak.

This pin provides the connection for the reference current setting resistor. A 24kW resistor

connected to V sets the optimum operating condition.

SS

Serial clock output. This output is used to strobe data from the external EEPROM.

Serial data. Send and receive data from an external EEPROM.

Test input. For normal operation connect this pin to V .

SS

Calibration LED output. Refer to section Led Output (LED) for the pulse rate output options.

Motor pulse outputs. These outputs can be used to drive an impulse counter or stepper motor directly.

Multiplexed phase or direction driver output.

7

14, 15,

16

RLOAD

PH1, PH2,

PH3

1IIP2 IVN2

IIN2 IIN1

2

3

IVN3 IIP1

IIP3

4

IIN3

5

VDD

6 19

RLOAD

SCL

SDA

LED

MON

MOP

7

8

9

10

11

12

Triggers a data reload from the external EEPROM.

Multiplexed LED drivers for direction and mains fail indication.

24

23

22

IVN1

21

GND

20

VREF

VSS

18

TEST

17

PH3

16

PH2

15

PH1

14

PH / DIR

13

dr-01602

Figure 2: Pin connections: Package: DIP-24, SOIC-24

ORDERING INFORMATION

Part Number

SA2005PPA

SA2005PSA

Package

DIP-24

SOIC-24

http://www.sames.co.za

3/16

SA2005P

FUNCTIONAL DESCRIPTION

The SAMES SA2005P is a CMOS mixed signal analog/digital

integrated circuit that performs three phase power/energy

calculations across a power range of 1000:1 to an overall

accuracy of better than Class 1.

The integrated circuit includes all the required functions for 3phase power and energy measurement such as oversampling

A/D converters for the voltage and current sense inputs, power

calculation and energy integration. Internal offsets are

eliminated through the use of cancellation procedures.

samessames

operation of the meter. Every data byte stored in the EEPROM

is protected with a checksum byte to ensure data integrity.

ELECTROSTATIC DISCHARGE (ESD) PROTECTION

The SA2005P integrated circuit's inputs/outputs are protected

against ESD.

POWER CONSUMPTION

The overall power consumption rating of the SA2005P

integrated circuit is less than 80mW with a 5V supply.

The integrated circuit includes all the required functions for a

three phase mechanical counter-based meter design. A

precision oscillator, that replaces an external crystal, is

integrated on chip providing a temperature stable time base for

the digital circuitry. A temperature stable voltage reference

integrated on chip generates the reference current used by the

analog circuitry.

Voltage and currents are sampled simultaneously by means of

a sigma delta modulator type ADC and power is calculated for

each individual phase. A programmable channel balance on

each channel is used for individual channel calibration.

The scaled power is fed to a programmable adder that allows

the representation of the measured energy to be either total

sum or absolute sum.

The summed power is integrated and divided down to

represent integrated energy. Pulses on the LED output and on

the mechanical counter outputs represent measured amounts

of energy. The programmable dividers provide flexible counter

and calibration LED resolutions.

Outputs for phase voltage fail and voltage sequence faults and

energy direction are available.

The SA2005P does not require any external trim-pots or

resistor ladders as meter calibration and configuration data is

stored on a small external EEPROM. The SA2005P configures

itself from the EEPROM during power up. These features

enables meter manufacturers flexible meter designs from a

single integrated circuit.

AUTOMATIC DEVICE CONFIGURATION (BOOT UP)

During power up, registers containing configuration and

calibration information is updated from an external EEPROM.

The device itself never writes tot he EEPROM so any write

protect features offered by manufacturer of EEPROM’s may

be used to protect the configuration and calibration constant of

the meter. The device reloads its configuration every 1193

seconds from the external EEPROM in order to ensure correct

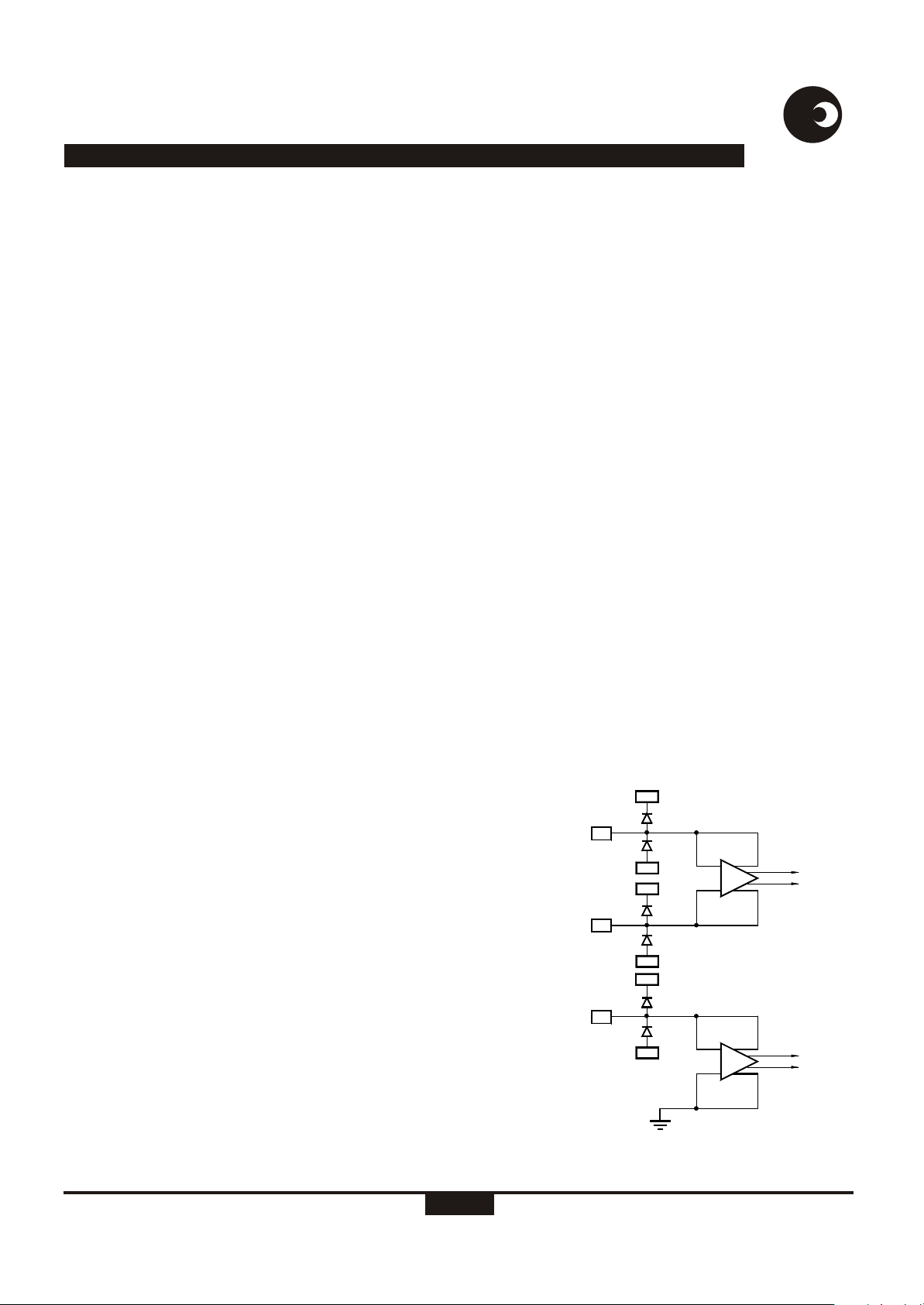

INPUT SIGNALS

ANALOG INPUT CONFIGURATION

The current and voltage sensor inputs are illustrated in figure 3.

These inputs are protected against electrostatic discharge

through clamping diodes, in conjunction with the amplifiers

input configuration. The feedback loops from the outputs of the

amplifiers A and A generate virtual shorts on the signal inputs.

Exact duplications of the input currents are generated for the

analog processing circuitry. The current and voltage sense

inputs are identical. Both inputs are differential current driven

up to ±25µA peak. One of the voltage sense amplifiers input

terminals is internally connected to GND. This configuration is

possible because the voltage sense input is much less

sensitive to externally induced parasitic signals compared to

the current sense inputs.

Current Sense Inputs (IIN1, IIP1, IIN2, IIP2, IIN3, IIP3)

The current sense inputs connects to a termination resistor

connected across the terminals of a current transformer. At

I V

V

DD

IIP

V

CURRENT

SENSOR

INPUTS

IIN

IVP

VOLTAGE

SENSOR

INPUT

DR-01288

SS

V

DD

V

SS

V

DD

V

SS

GND

A

I

A

V

Figure 3: Analog input internal configuration

http://www.sames.co.za

4/16

SA2005P

samessames

rated current the resistor values should be selected for input

currents of 16µA . Referring to figure 8, the resistors R1 and

RMS

R2 on current channel 1, resistors R3 and R4 on current

channel 2 and resistors R5 and R6 on current channel 3, define

the current level into the current sense inputs of the SA2005P.

The current sense inputs saturates at an input current of

±25µA peak. Resistors R29, R30 and R31 are used as current

transformer termination resistors. The voltage drop across the

termination resistors should be at least 20mV at rated

conditions. Values for the current sense inputs are calculated

as follows:

R1 = R2 = ( IL / 16µARMS ) x R29 / 2

R3 = R4 = ( IL / 16µARMS ) x R30 / 2

R5 = R6 = ( IL / 16µARMS ) x R31 / 2

Where:

I = Line current/CT-ratio

L

In case a current transformer is used for current sensing the

value of the termination resistors should be less than the

resistance of the CT's secondary winding.

Voltage Sense Inputs (IVN1, IVN2, IVN3)

The mains voltage are measured by means of a resistor divider

and the divided voltage are converted to a current. The current

into the voltage sense inputs (virtual ground) should be set to

14µARMS at rated voltage conditions. The individual mains

voltages are divided down to 14V per phase. The resistors

RMS

R12, R13 and R14 (figure 8) set the current for the voltage

sense inputs. The voltage sense inputs saturate at an input

current of ±25uA peak.

Voltage Reference Connection (VREF)

A bias resistor of 24k provides an optimum bias conditions on

chip. Calibration of the SA2005P is done by means of divider

ratios stored on an external EEPROM. This is described in the

Device Configuration section.

Serial Data (SDA)

The SDA pin connects directly to the SDA pin of an external

EEPROM. The pin is used to transfer data between the

EEPROM and the SA2005P. An external pull-up resistor in not

needed.

Serial Clock (SCL)

The SCL pin connects directly to the SCL of an external

EEPROM. The SCL output is used to strobe data at a rate of

50kHz out of the EEPROM. An external pull up resistor is not

needed. The SCL output uses a soft driver and may be

overdriven by the calibration equipment.

Reload (RLOAD)

A falling edge on the RLOAD pin will trigger a register update

from the external EEPROM. This feature may be used during

calibration to load updated register data in the SA2005P. For

normal operation of the SA2005P the RLOAD pin may be left

floating.

Test Inputs (TEST)

The TEST input is the manufacturers test pin and must be

connected to VSS in a metering application.

OUTPUT SIGNALS

LED Output (LED)

Four options for the LED output pulse rate are available, 6400,

3200, 1600 pulses per kWh, and a pulse rate of 1252 pulses

per second at rated conditions. At 1252 pulses per second t LED

is 71µs, for the other options tLED is 10ms. The LED output is

active low as shown in figure 4.

VDD

LED

VSS

DR-01332

Figure 4: LED pulse output

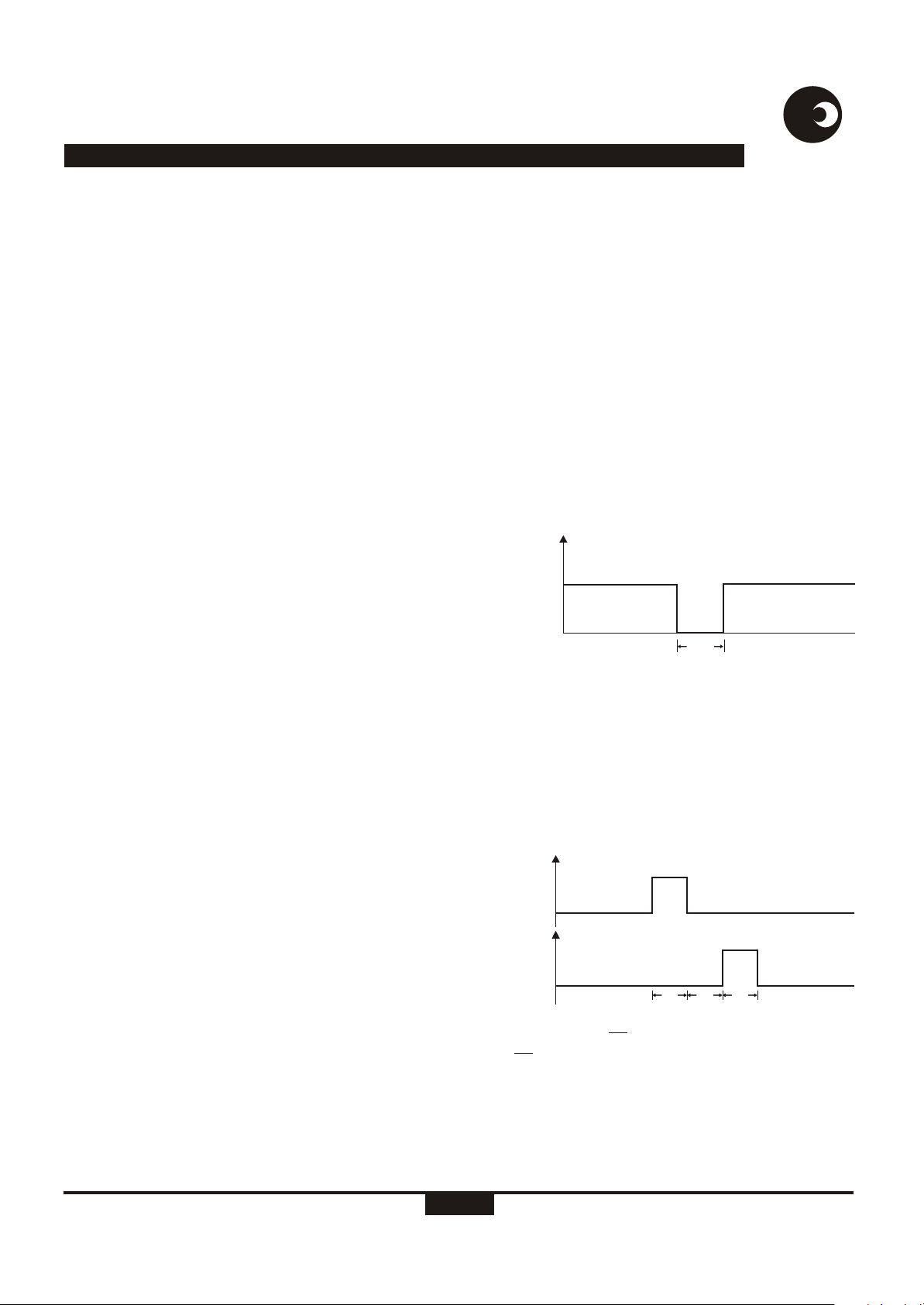

Motor Output (MOP, MON)

The motor pulse width is programmable for 71ms, 142ms and

284ms. The MON pulse will follow the MOP pulse within the

selected pulse width time. This prevents the motor armature

being in the wrong position after a power failure. Both MOP

and MON outputs are active high. A MOP pulse followed by a

MON pulse represents one energy pulse. The motor drive

waveforms are shown in figure 5.

VDD

MOP

VSS

VDD

MON

VSS

DR-01559

Figure 5: Motor drive on MON and MOP pins of device

Multiplex Output (PH/ DIR)

The PH/DIR output enables either direction or voltage

information on the phase LED driver outputs (PH1, PH2 and

PH3). This multiplex output switches between logic 1 and 0 at

a frequency of approximately 280Hz. A logic 1 enables energy

direction information on the LED driver outputs and a logic 0

enables voltage information.

t

LED

t

m

t

t

m

m

http://www.sames.co.za

5/16

Loading...

Loading...